Impact of Simulated Biogas Compositions (CH4 and CO2) on Vibration, Sound Pressure and Performance of a Spark Ignition Engine

Abstract

:1. Introduction

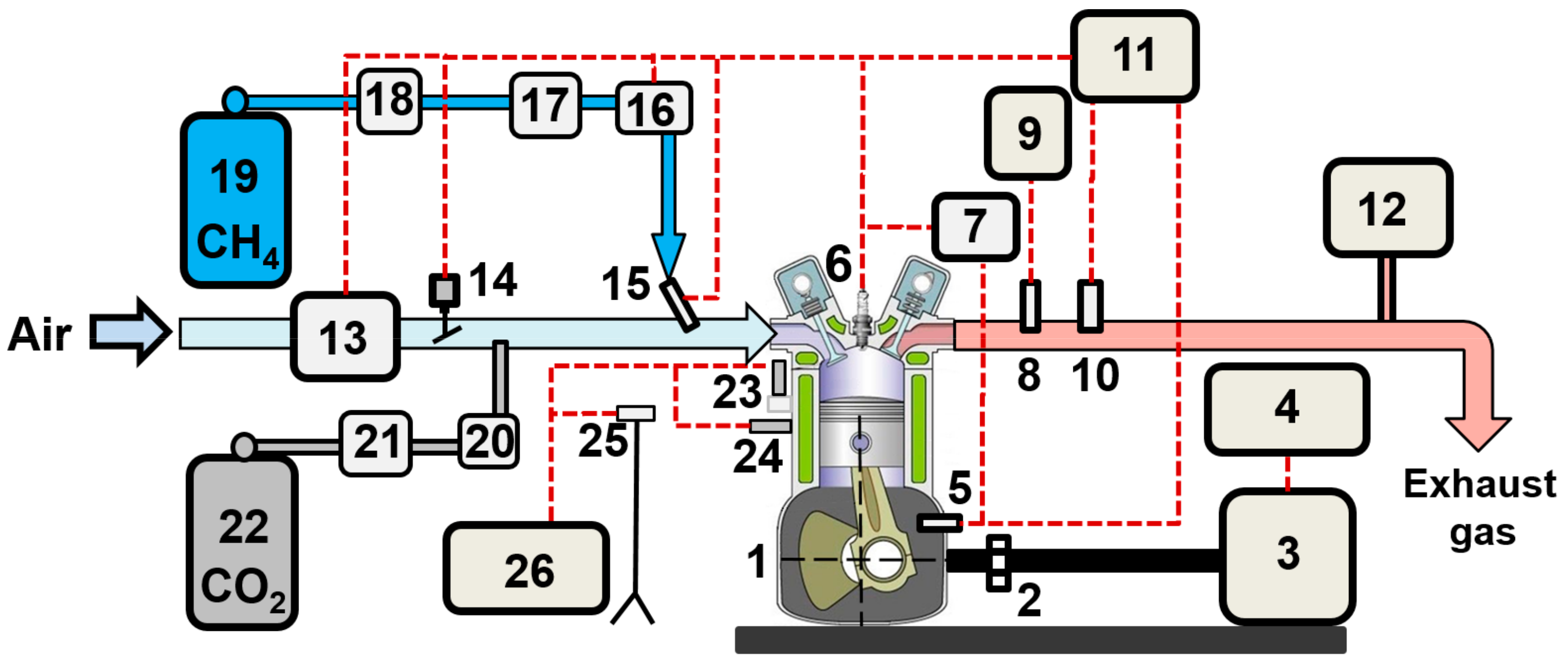

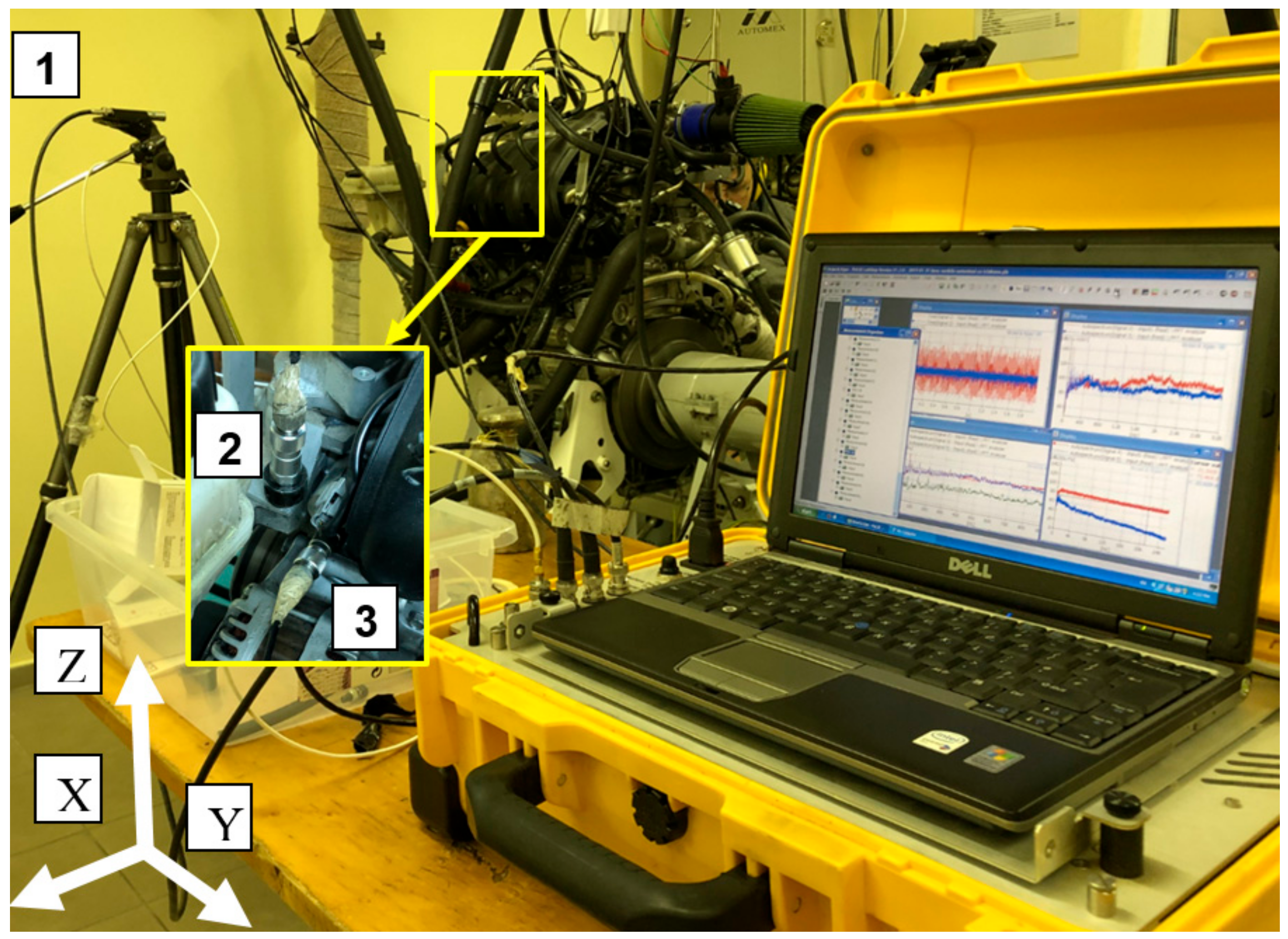

2. Materials and Methods

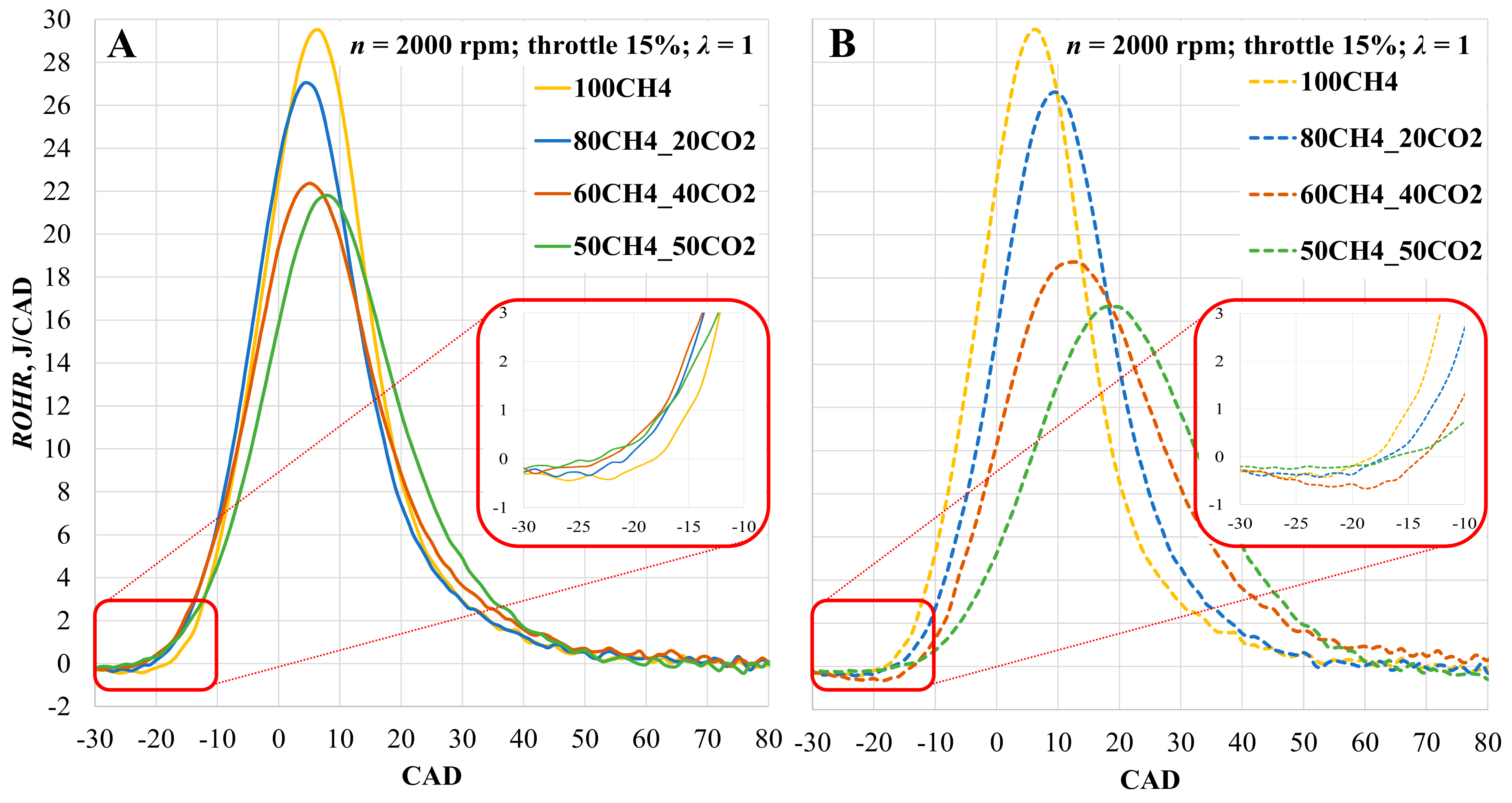

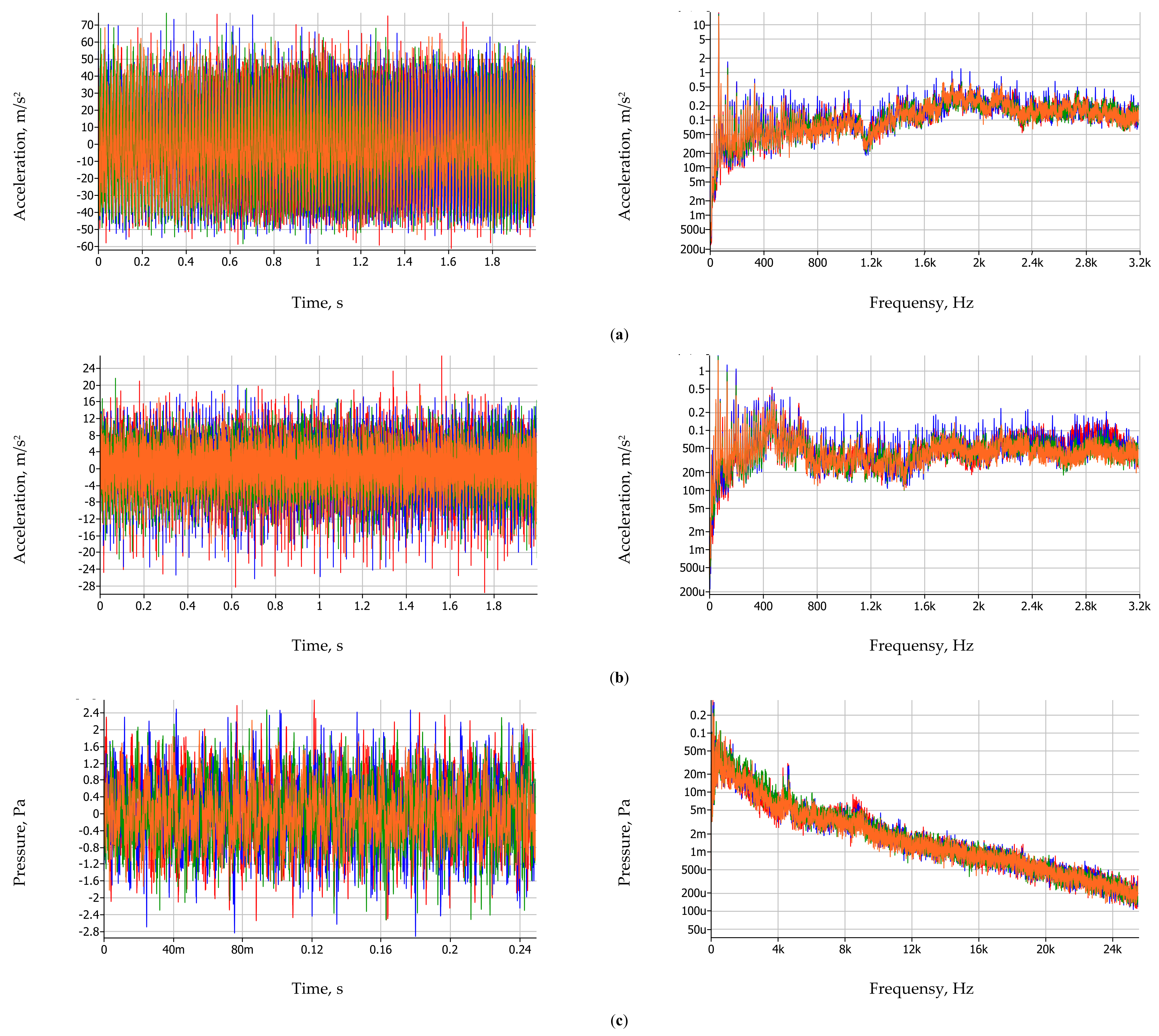

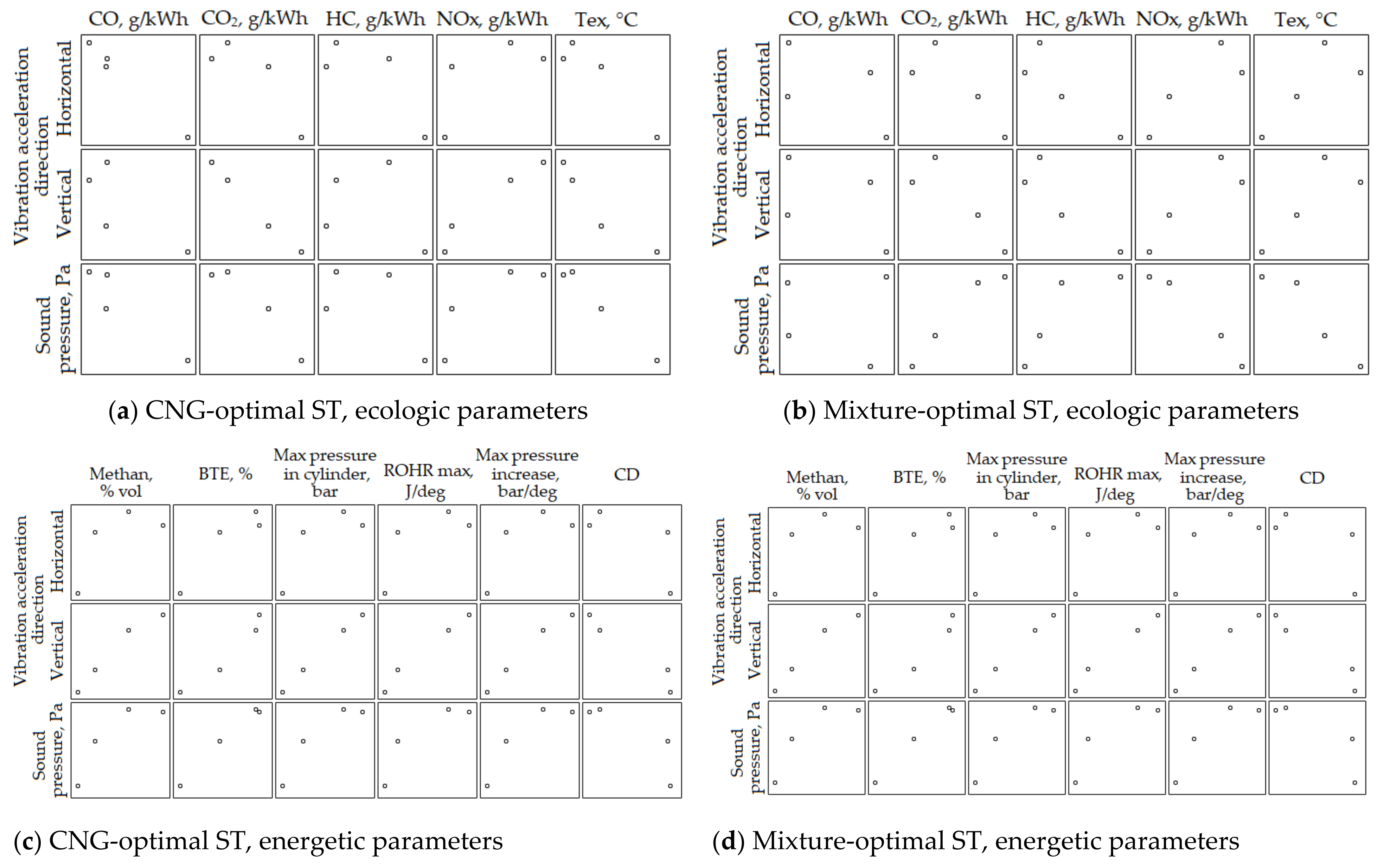

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kallas, S. White Paper on Transport: Roadmap to a Single European Transport Area—Towards a Competitive and Resource-Efficient Transport System; European Commission, Ed.; Publications Office of the European Union: Luxembourg, 2011; ISBN 978-92-79-18270-9. [Google Scholar]

- Fuc, P.; Lijewski, P.; Ziolkowski, A.; Dobrzynski, M. Dynamic Test Bed Analysis of Gas Energy Balance for a Diesel Exhaust System Fit with a Thermoelectric Generator. J. Electron. Mater. 2017, 46, 3145–3155. [Google Scholar] [CrossRef]

- Kończak, M.; Kukla, M.; Warguła, Ł.; Talaśka, K. Determination of the Vibration Emission Level for a Chipper with Combustion Engine. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 776, p. 012007. [Google Scholar] [CrossRef] [Green Version]

- Bereczky, A. The Past, Present and Future of the Training of Internal Combustion Engines at the Department of Energy Engineering of BME. In Vehicle and Automotive Engineering; Jarmai, K., Bollo, B., Eds.; Springer: Cham, Switzerland, 2017; pp. 225–234. [Google Scholar]

- Hunicz, J.; Mikulski, M.; Koszałka, G.; Ignaciuk, P. Detailed Analysis of Combustion Stability in a Spark-Assisted Compression Ignition Engine under Nearly Stoichiometric and Heavy EGR Conditions. Appl. Energy 2020, 280, 115955. [Google Scholar] [CrossRef]

- Sarkan, B.; Stopka, O.; Gnap, J.; Caban, J. Investigation of Exhaust Emissions of Vehicles with the Spark Ignition Engine within Emission Control. Procedia Eng. 2017, 187, 775–782. [Google Scholar] [CrossRef]

- Bazooyar, B.; Gohari Darabkhani, H. The Design Strategy and Testing of an Efficient Microgas Turbine Combustor for Biogas Fuel. Fuel 2021, 294, 120535. [Google Scholar] [CrossRef]

- Ivanchenko, A.; Yelatontsev, D.; Savenkov, A. Anaerobic Co-Digestion of Agro-Industrial Waste with Cheese Whey: Impact of Centrifuge Comminution on Biogas Release and Digestate Agrochemical Properties. Biomass Bioenergy 2021, 147, 106010. [Google Scholar] [CrossRef]

- Rasapoor, M.; Young, B.; Brar, R.; Baroutian, S. Improving Biogas Generation from Aged Landfill Waste Using Moisture Adjustment and Neutral Red Additive—Case Study: Hampton Downs’s Landfill Site. Energy Convers. Manag. 2020, 216, 112947. [Google Scholar] [CrossRef]

- Zeng, W.; Wang, D.; Wu, Z.; He, L.; Luo, Z.; Yang, J. Recovery of Nitrogen and Phosphorus Fertilizer from Pig Farm Biogas Slurry and Incinerated Chicken Manure Fly Ash. Sci. Total Environ. 2021, 782, 146856. [Google Scholar] [CrossRef]

- Feroskhan, M.; Ismail, S.; Panchal, S.H. Study of Methane Enrichment in a Biogas Fuelled HCCI Engine. Int. J. Hydrogen Energy 2021. [Google Scholar] [CrossRef]

- Park, J.; Choi, J. A Numerical Investigation of Lean Operation Characteristics of Spark Ignition Gas Engine Fueled with Biogas and Added Hydrogen under Various Boost Pressures. Appl. Therm. Eng. 2017, 117, 225–234. [Google Scholar] [CrossRef]

- Nadaleti, W.C.; Przybyla, G. Emissions and Performance of a Spark-Ignition Gas Engine Generator Operating with Hydrogen-Rich Syngas, Methane and Biogas Blends for Application in Southern Brazilian Rice Industries. Energy 2018, 154, 38–51. [Google Scholar] [CrossRef]

- Piechota, G. Biogas/Biomethane Quality and Requirements for Combined Heat and Power (CHP) Units/Gas Grids with a Special Focus on Siloxanes—A Short Review. Sustain. Chem. Eng. 2021, 3, 1–10. [Google Scholar] [CrossRef]

- Kougias, P.G.; Treu, L.; Benavente, D.P.; Boe, K.; Campanaro, S.; Angelidaki, I. Ex-Situ Biogas Upgrading and Enhancement in Different Reactor Systems. Bioresour. Technol. 2017, 225, 429–437. [Google Scholar] [CrossRef]

- Makaruk, A.; Miltner, M.; Harasek, M. Membrane Biogas Upgrading Processes for the Production of Natural Gas Substitute. Sep. Purif. Technol. 2010, 74, 83–92. [Google Scholar] [CrossRef]

- Hotta, S.K.; Sahoo, N.; Mohanty, K. Comparative Assessment of a Spark Ignition Engine Fueled with Gasoline and Raw Biogas. Renew. Energy 2019, 134, 1307–1319. [Google Scholar] [CrossRef]

- Hotta, S.K.; Sahoo, N.; Mohanty, K.; Kulkarni, V. Ignition Timing and Compression Ratio as Effective Means for the Improvement in the Operating Characteristics of a Biogas Fueled Spark Ignition Engine. Renew. Energy 2020, 150, 854–867. [Google Scholar] [CrossRef]

- Gómez Montoya, J.P.; Amell, A.A.; Olsen, D.B.; Amador Diaz, G.J. Strategies to Improve the Performance of a Spark Ignition Engine Using Fuel Blends of Biogas with Natural Gas, Propane and Hydrogen. Int. J. Hydrogen Energy 2018, 43, 21592–21602. [Google Scholar] [CrossRef]

- Da Costa, R.B.R.; Valle, R.M.; Hernández, J.J.; Malaquias, A.C.T.; Coronado, C.J.R.; Pujatti, F.J.P. Experimental Investigation on the Potential of Biogas/Ethanol Dual-Fuel Spark-Ignition Engine for Power Generation: Combustion, Performance and Pollutant Emission Analysis. Appl. Energy 2020, 261, 114438. [Google Scholar] [CrossRef]

- Porpatham, E.; Ramesh, A.; Nagalingam, B. Experimental Studies on the Effects of Enhancing the Concentration of Oxygen in the Inducted Charge of a Biogas Fuelled Spark Ignition Engine. Energy 2018, 142, 303–312. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, M.; Zhang, Z.; Chan, Y.L.; Zhang, D. Combustion and Emission Characteristics of Simulated Biogas from Two-Phase Anaerobic Digestion (T-PAD) in a Spark Ignition Engine. Appl. Therm. Eng. 2018, 129, 927–933. [Google Scholar] [CrossRef]

- Karagöz, M.; Sarıdemir, S.; Deniz, E.; Çiftçi, B. The Effect of the CO2 Ratio in Biogas on the Vibration and Performance of a Spark Ignited Engine. Fuel 2018, 214, 634–639. [Google Scholar] [CrossRef]

- Kilikevičius, A.; Kilikevičienė, K.; Fursenko, A.; Matijošius, J. The Analysis of Vibration Signals of Critical Points of the Bus Body Frame. Period. Polytech. Transp. Eng. 2020, 48, 296–304. [Google Scholar] [CrossRef] [Green Version]

- Kilikevičienė, K.; Kačianauskas, R.; Kilikevičius, A.; Maknickas, A.; Matijošius, J.; Rimkus, A.; Vainorius, D. Experimental Investigation of Acoustic Agglomeration of Diesel Engine Exhaust Particles Using New Created Acoustic Chamber. Powder Technol. 2020, 360, 421–429. [Google Scholar] [CrossRef]

- Kilikevičius, A.; Skeivalas, J.; Kilikevičienė, K.; Matijošius, J. Analysis of Dynamic Parameters of a Railway Bridge. Appl. Sci. 2019, 9, 2545. [Google Scholar] [CrossRef] [Green Version]

- Feroskhan, M.; Thangavel, V.; Subramanian, B.; Sankaralingam, R.K.; Ismail, S.; Chaudhary, A. Effects of Operating Parameters on the Performance, Emission and Combustion Indices of a Biogas Fuelled HCCI Engine. Fuel 2021, 298, 120799. [Google Scholar] [CrossRef]

- Mahla, S.K.; Safieddin Ardebili, S.M.; Sharma, H.; Dhir, A.; Goga, G.; Solmaz, H. Determination and Utilization of Optimal Diesel/n-Butanol/Biogas Derivation for Small Utility Dual Fuel Diesel Engine. Fuel 2021, 289, 119913. [Google Scholar] [CrossRef]

- De Faria, M.M.N.; Vargas Machuca Bueno, J.P.; Ayad, S.M.M.E.; Belchior, C.R.P. Thermodynamic Simulation Model for Predicting the Performance of Spark Ignition Engines Using Biogas as Fuel. Energy Convers. Manag. 2017, 149, 1096–1108. [Google Scholar] [CrossRef]

- Balki, M.K.; Erdoğan, S.; Aydın, S.; Sayin, C. The Optimization of Engine Operating Parameters via SWARA and ARAS Hybrid Method in a Small SI Engine Using Alternative Fuels. J. Clean. Prod. 2020, 258, 120685. [Google Scholar] [CrossRef]

- Erdoğan, S.; Aydın, S.; Balki, M.K.; Sayin, C. Operational Evaluation of Thermal Barrier Coated Diesel Engine Fueled with Biodiesel/Diesel Blend by Using MCDM Method Base on Engine Performance, Emission and Combustion Characteristics. Renew. Energy 2020, 151, 698–706. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Čereška, A.; Matijošius, J.; Rimkus, A.; Bausys, R. Internal Combustion Engine Analysis of Energy Ecological Parameters by Neutrosophic MULTIMOORA and SWARA Methods. Energies 2019, 12, 1415. [Google Scholar] [CrossRef] [Green Version]

- Yousef, S.; Šereika, J.; Tonkonogovas, A.; Hashem, T.; Mohamed, A. CO2/CH4, CO2/N2 and CO2/H2 Selectivity Performance of PES Membranes under High Pressure and Temperature for Biogas Upgrading Systems. Environ. Technol. Innov. 2021, 21, 101339. [Google Scholar] [CrossRef]

- Andriani, D.; Wresta, A.; Atmaja, T.D.; Saepudin, A. A Review on Optimization Production and Upgrading Biogas through CO2 Removal Using Various Techniques. Appl. Biochem. Biotechnol. 2014, 172, 1909–1928. [Google Scholar] [CrossRef] [PubMed]

- Fuksa, P.; Hakl, J.; Míchal, P.; Hrevušová, Z.; Šantrůček, J.; Tlustoš, P. Effect of Silage Maize Plant Density and Plant Parts on Biogas Production and Composition. Biomass Bioenergy 2020, 142, 105770. [Google Scholar] [CrossRef]

- Banja, M.; Jégard, M.; Motola, V.; Sikkema, R. Support for Biogas in the EU Electricity Sector–A Comparative Analysis. Biomass Bioenergy 2019, 128, 105313. [Google Scholar] [CrossRef]

- Dahman, Y.; Dignan, C.; Fiayaz, A.; Chaudhry, A. 13-An introduction to biofuels, foods, livestock, and the environment. In Biomass, Biopolymer-Based Materials, and Bioenergy, Woodhead Publishing Series in Composites Science and Engineering; Verma, D., Fortunati, E., Jain, S., Zhang, X., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 241–276. ISBN 978-0-08-102426-3. [Google Scholar]

- Dębowski, M.; Zieliński, M.; Grala, A.; Dudek, M. Algae Biomass as an Alternative Substrate in Biogas Production Technologies—Review. Renew. Sustain. Energy Rev. 2013, 27, 596–604. [Google Scholar] [CrossRef]

- Dutta, K.; Daverey, A.; Lin, J.-G. Evolution Retrospective for Alternative Fuels: First to Fourth Generation. Renew. Energy 2014, 69, 114–122. [Google Scholar] [CrossRef]

- Khatri, N.; Khatri, K.K. Hydrogen Enrichment on Diesel Engine with Biogas in Dual Fuel Mode. Int. J. Hydrogen Energy 2020, 45, 7128–7140. [Google Scholar] [CrossRef]

- Rimkus, A.; Stravinskas, S.; Matijošius, J. Comparative Study on the Energetic and Ecologic Parameters of Dual Fuels (Diesel–NG and HVO–Biogas) and Conventional Diesel Fuel in a CI Engine. Appl. Sci. 2020, 10, 359. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Zhang, Y.; Gong, J.; Su, S.; Wei, Z. Combustion Behaviours and Emission Characteristics of a Retrofitted NG/Gasoline Duel-Fuel SI Engine with Various Proportions of NG-Gasoline Blends. Fuel 2020, 266, 116957. [Google Scholar] [CrossRef]

- Chiong, M.-C.; Valera-Medina, A.; Chong, W.W.F.; Chong, C.T.; Mong, G.R.; Mohd Jaafar, M.N. Effects of Swirler Vane Angle on Palm Biodiesel/Natural Gas Combustion in Swirl-Stabilised Gas Turbine Combustor. Fuel 2020, 277, 118213. [Google Scholar] [CrossRef]

- Fischer, M.; Jiang, X. An Investigation of the Chemical Kinetics of Biogas Combustion. Fuel 2015, 150, 711–720. [Google Scholar] [CrossRef]

- Spearman, C. The Proof and Measurement of Association between Two Things. Am. J. Psychol. 1904, 15, 72. [Google Scholar] [CrossRef]

- Mann, H.B.; Whitney, D.R. On a Test of Whether One of Two Random Variables Is Stochastically Larger than the Other. Ann. Math. Stat. 1947, 18, 50–60. [Google Scholar] [CrossRef]

- Kukharonak, H.; Ivashko, V.; Pukalskas, S.; Rimkus, A.; Matijošius, J. Operation of a Spark-Ignition Engine on Mixtures of Petrol and N-Butanol. Procedia Eng. 2017, 187, 588–598. [Google Scholar] [CrossRef]

- Gutarevych, Y.; Shuba, Y.; Matijošius, J.; Karev, S.; Sokolovskij, E.; Rimkus, A. Intensification of the Combustion Process in a Gasoline Engine by Adding a Hydrogen-Containing Gas. Int. J. Hydrogen Energy 2018, 43, 16334–16343. [Google Scholar] [CrossRef]

- Gutarevych, Y.; Mateichyk, V.; Matijošius, J.; Rimkus, A.; Gritsuk, I.; Syrota, O.; Shuba, Y. Improving Fuel Economy of Spark Ignition Engines Applying the Combined Method of Power Regulation. Energies 2020, 13, 1076. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Value |

|---|---|

| Number of cylinders | 4 |

| Displacement, dm 3 | 1.598 |

| Cylinder bore, mm | 78.0 |

| Piston stroke, mm | 86.6 |

| Engine power, kW (at rpm) | 84 (6000) |

| Engine torque, Nm (at rpm) | 156 (4400) |

| Compression ratio | 10.7 |

| Intake valves open (CAD BTDC 1) | 24 |

| Intake valves close (CAD ABDC 2) | 72 |

| Exhaust valves open CAD BBDC 3) | 24 |

| Exhaust valves close (CAD ATDC 4) | 10 |

| Parameter | Measuring Range | Accuracy |

|---|---|---|

| NOx | 0~5000 ppm, by vol. | ±1 ppm |

| CO | 0~10%, by vol. | ±0.01% |

| CO2 | 0~20%, by vol. | ±0.1% |

| HC | 0~20,000 ppm, by vol. | ±1 ppm |

| O2 | 0~25%, by vol. | ±0.01% |

| CH4, vol.% | CO2, vol.% | LHV, MJ/kg | Stoichiometric A/F Ratio | Marking | ST, CAD BTDC | |

|---|---|---|---|---|---|---|

| CNG Optimal | Optimal for Mixture | |||||

| 100 | 0 | 50.04 | 17.2 | 100CH4 | 26 | 26 |

| 80 | 20 | 29.69 | 10.2 | 80CH4_20CO2 | 26 | 30 |

| 60 | 40 | 17.69 | 6.1 | 60CH4_40CO2 | 26 | 35 |

| 50 | 50 | 13.37 | 4.6 | 50CH4_50CO2 | 26 | 40 |

| Parameter | Biogas [23,40,41] | Petrol [42] | Natural Gas [43] |

|---|---|---|---|

| Composition | CH4—57 vol.% | C5H12—C12H26 | C14H30—C18H38 |

| CO2—41 vol.% | |||

| N2—1 vol.% | |||

| O2—0.6 vol.% | |||

| CO—0.18 vol.% | |||

| H2—0.18 vol.% | |||

| H2S—0~130 ppm | |||

| Flammability limit, vol.% in air | 7.5—14.0 | 1.4–7.6 | 5.0–14.3 |

| Density, kg/m3 | 1.2 | 687 | 0.79 |

| Calorific value, MJ/kg | 17.0 | 44.4 | 50.0 |

| Laminar burning velocity, m/s | 0.25 | 0.39–0.47 | 0.34 |

| Methane number | 142 | - | 100 |

| Autoignition temperature, °C | 650 | 228–471 | 537 |

| Stoichiometric air fuel ratio, kg/kg | 5.8 | 14.7 | 17.3 |

| Parameter | 100CH4 | 80CH4_20CO2 | 60CH4_40CO2 | 50CH4_50CO2 | ||||

|---|---|---|---|---|---|---|---|---|

| CNG Optimal | Optimal for Mixture | CNG Optimal | Optimal for Mixture | CNG Optimal | Optimal for Mixture | CNG Optimal | Optimal for Mixture | |

| NOx 1, g/kWh | 1.41 | 1.41 | 0.97 | 1.16 | 0.19 | 0.56 | 0.09 | 0.32 |

| CO 2, g/kWh | 19.9 | 19.9 | 17.4 | 17.9 | 19.8 | 17.9 | 30.81 | 20.2 |

| CO2 3, g/kWh | 641.7 | 641.7 | 801.2 | 808.1 | 1215.5 | 1113.7 | 1548.7 | 1310.7 |

| HC 4, g/kWh | 0.00968 | 0.00968 | 0.00888 | 0.01033 | 0.00874 | 0.01130 | 0.01020 | 0.01387 |

| Tex 5, °C | 655 | 655 | 657 | 650 | 664 | 645 | 679 | 640 |

| CH4 6, vol.% | 100 | 100 | 80 | 80 | 60 | 60 | 50 | 50 |

| BTE7, % | 35.54 | 35.54 | 35.26 | 35.33 | 32.38 | 34.38 | 29.18 | 33.77 |

| Pmax8, MPa | 3.89 | 3.89 | 3.52 | 3.91 | 2.72 | 3.53 | 2.31 | 3.38 |

| ROHRmax9, J/deg | 29.51 | 29.51 | 26.58 | 27.07 | 18.74 | 22.36 | 16.69 | 21.81 |

| Prisemax10, bar/deg | 1.51 | 1.51 | 1.10 | 1.50 | 0.60 | 1.20 | 0.34 | 1.10 |

| CD11, deg | 53.0 | 53.0 | 55.9 | 56.5 | 77.8 | 65.4 | 78.5 | 64.7 |

| Biogas | ST | Acceleration, m/s2 | Sound Pressure, Pa | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Transverse Direction | Longitudinal Direction | |||||||||

| SD | Min | Max | SD | Min | Max | SD | Min | Max | ||

| 100CH4 | 26 | 22.963 | −62.054 | 79.552 | 5.375 | −27.713 | 26.976 | 0.784 | −2.557 | 2.694 |

| 80CH4_20CO2 | 30 | 23.542 | −67.195 | 82.413 | 5.525 | −30.054 | 22.456 | 0.790 | −2.527 | 2.990 |

| 60CH4_40CO2 | 35 | 22.855 | −57.723 | 72.957 | 5.173 | −22.975 | 19.953 | 0.832 | −3.336 | 2.684 |

| 50CH4_50CO2 | 40 | 22.332 | −62.322 | 76.929 | 4.953 | −23.993 | 21.850 | 0.836 | −2.610 | 3.163 |

| Biogas | ST | Acceleration, m/s2 | Sound Pressure, Pa | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Transverse Direction | Longitudinal Direction | |||||||||

| SD | Min | Max | SD | Min | Max | SD | Min | Max | ||

| 100CH4 | 26 | 22.963 | −62.054 | 79.552 | 5.375 | −27.713 | 26.976 | 0.784 | −2.557 | 2.694 |

| 80CH4_20CO2 | 26 | 23.137 | −58.578 | 75.815 | 5.197 | −26.380 | 19.878 | 0.800 | −2.956 | 2.482 |

| 60CH4_40CO2 | 26 | 22.625 | −58.623 | 77.056 | 4.592 | −21.801 | 21.535 | 0.722 | −2.536 | 2.462 |

| 50CH4_50CO2 | 26 | 21.404 | −53.261 | 68.325 | 4.247 | −21.187 | 17.963 | 0.613 | −1.969 | 2.216 |

| Parameters | CNG Optimal ST Mean (SD) | Optimal ST for Mixture Mean (SD) | p-Value |

|---|---|---|---|

| Methane, vol.% | 66.7 (8.37) | 69.8 (4.52) | 0.665 |

| BTE, % | 33 (0.03) | 35 (0.008) | 0.561 |

| Max pressure in cilinder, bar | 3.1 (0.72) | 3.7 (0.26) | 0.245 |

| ROHR max, J/deg | 23 (6.28) | 25.2 (3.72) | 0.665 |

| Max pressure gain, bar/deg | 0.9 (0.52) | 1.3 (0.19) | 0.384 |

| CD | 66.2 (13.9) | 59.9 (6.12) | 0.885 |

| CO, g/kWh | 21.95 (6.009) | 18.97 (1.268) | 1.000 |

| CO2, g/kWh | 1052 (410.2) | 969 (300.4) | 1.000 |

| HC, g/kWh | 0.009 (0.0007) | 0.011 (0.0018) | 0.081 |

| NOx, g/kWh | 0.67 (0.635) | 0.86 (0.511) | 0.561 |

| Tex, °C | 663.7 (10.75) | 647.5 (6.54) | 0.061 |

| Vertical direction | 22.46 (0.723) | 22.97 (0.512) | 0.312 |

| Horizontal direction | 4.87 (0.547) | 5.26 (0.248) | 0.470 |

| Sound pressure, Pa | 0.73 (0.087) | 0.81 (0.034) | 0.312 |

| Parameters | Vertical Direction (, p-Value) | Horizontal Direction (, p-Value) | Sound Pressure, Pa (, p-Value) |

|---|---|---|---|

| CN-optimal ST and mixture-optimal ST | |||

| Methane, vol.% | 0.732, p = 0.039 | 0.830, p = 0.011 | −0.049, p = 0.909 |

| BTE, % | 0.755, p = 0.031 | 0.922, p = 0.001 | 0.216, p = 0.608 |

| Max pressure in cylinder, bar | 0.850, p = 0.007 | 0.970, p < 0.001 | 0.240, p = 0.568 |

| ROHR max, J/deg | 0.714, p = 0.047 | 0.929, p = 0.001 | 0.238, p = 0.570 |

| Max pressure increase, bar/deg | 0.671, p = 0.069 | 0.934, p = 0.001 | 0.311, p = 0.453 |

| CD | −0.595, p = 0.120 | −0.833, p = 0.010 | −0.310, p = 0.456 |

| CO, g/kWh | −0.659, p = 0.076 | −0.395, p = 0.333 | −0.335, p = 0.417 |

| CO2, g/kWh | −0.731, p = 0.040 | −0.826, p = 0.011 | −0.120, p = 0.778 |

| HC, g/kWh | −0.108, p = 0.799 | 0.012, p = 0.978 | 0.527, p = 0.180 |

| NOx, g/kWh | 0.755, p = 0.031 | 0.922, p = 0.001 | 0.216, p = 0.608 |

| Tex, °C | −0.238, p = 0.570 | −0.405, p = 0.320 | −0.833, p = 0.010 |

| CNG-optimal ST | |||

| Methane, vol.% | 0.800, p = 0.200 | 1.000, p < 0.001 | 0.800, p = 0.200 |

| BTE, % | 0.800, p = 0.200 | 1.000, p < 0.001 | 0.800, p = 0.200 |

| Max pressure in cylinder, bar | 0.800, p = 0.200 | 1.000, p < 0.001 | 0.800, p = 0.200 |

| ROHR max, J/deg | 0.800, p = 0.200 | 1.000, p < 0.001 | 0.800, p = 0.200 |

| Max pressure increase, bar/deg | 0.800, p = 0.200 | 1.000, p < 0.001 | 0.800, p = 0.200 |

| CD | −0.800, p = 0.200 | −1.000, p < 0.001 | −0.800, p = 0.200 |

| CO, g/kWh | −0.800, p = 0.200 | −0.400, p = 0.600 | −0.800, p = 0.200 |

| CO2, g/kWh | −0.800, p = 0.200 | −1.000, p < 0.001 | −0.800, p = 0.200 |

| HC, g/kWh | −0.400, p = 0.600 | −0.200, p = 0.800 | −0.400, p = 0.600 |

| NOx, g/kWh | 0.800, p = 0.200 | 1.000, p < 0.001 | 0.800, p = 0.200 |

| Tex, °C | −0.800, p = 0.200 | −1.000, p < 0.001 | −0.800, p = 0.200 |

| Mixture-optimal ST | |||

| Methane, vol.% | 0.800, p = 0.200 | 0.800, p = 0.200 | −1.000, p < 0.001 |

| BTE, % | 0.800, p = 0.200 | 0.800, p = 0.200 | −1.000, p < 0.001 |

| Max pressure in cylinder, bar | 1.000, p < 0.001 | 1.000, p < 0.001 | −0.800, p = 0.200 |

| ROHR max, J/deg | 0.800, p = 0.200 | 0.800, p = 0.200 | −1.000, p < 0.001 |

| Max pressure increase, bar/deg | 1.000, p < 0.001 | 1.000, p < 0.001 | −0.800, p = 0.200 |

| CD | −0.600, p = 0.400 | −0.600, p = 0.400 | 0.800, p = 0.200 |

| CO, g/kWh | −0.400, p = 0.600 | −0.400, p = 0.600 | 0.200, p = 0.800 |

| CO2, g/kWh | −0.800, p = 0.200 | −0.800, p = 0.200 | 1.000, p < 0.001 |

| HC, g/kWh | −0.800, p = 0.200 | −0.800, p = 0.200 | 1.000, p < 0.001 |

| NOx, g/kWh | 0.800, p = 0.200 | 0.800, p = 0.200 | −1.000, p < 0.001 |

| Tex, °C | 0.800, p = 0.200 | 0.800, p = 0.200 | −1.000, p < 0.001 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kriaučiūnas, D.; Žvirblis, T.; Kilikevičienė, K.; Kilikevičius, A.; Matijošius, J.; Rimkus, A.; Vainorius, D. Impact of Simulated Biogas Compositions (CH4 and CO2) on Vibration, Sound Pressure and Performance of a Spark Ignition Engine. Energies 2021, 14, 7037. https://doi.org/10.3390/en14217037

Kriaučiūnas D, Žvirblis T, Kilikevičienė K, Kilikevičius A, Matijošius J, Rimkus A, Vainorius D. Impact of Simulated Biogas Compositions (CH4 and CO2) on Vibration, Sound Pressure and Performance of a Spark Ignition Engine. Energies. 2021; 14(21):7037. https://doi.org/10.3390/en14217037

Chicago/Turabian StyleKriaučiūnas, Donatas, Tadas Žvirblis, Kristina Kilikevičienė, Artūras Kilikevičius, Jonas Matijošius, Alfredas Rimkus, and Darius Vainorius. 2021. "Impact of Simulated Biogas Compositions (CH4 and CO2) on Vibration, Sound Pressure and Performance of a Spark Ignition Engine" Energies 14, no. 21: 7037. https://doi.org/10.3390/en14217037

APA StyleKriaučiūnas, D., Žvirblis, T., Kilikevičienė, K., Kilikevičius, A., Matijošius, J., Rimkus, A., & Vainorius, D. (2021). Impact of Simulated Biogas Compositions (CH4 and CO2) on Vibration, Sound Pressure and Performance of a Spark Ignition Engine. Energies, 14(21), 7037. https://doi.org/10.3390/en14217037