Designing Virtual Reality Environments through an Authoring System Based on CAD Floor Plans: A Methodology and Case Study Applied to Electric Power Substations for Supervision

Abstract

:1. Introduction

- Propose and design a software architecture of the Authoring System composed of an input management system, CAD floor-plan editor, Virtual Reality software and communication with asset supervision servers;

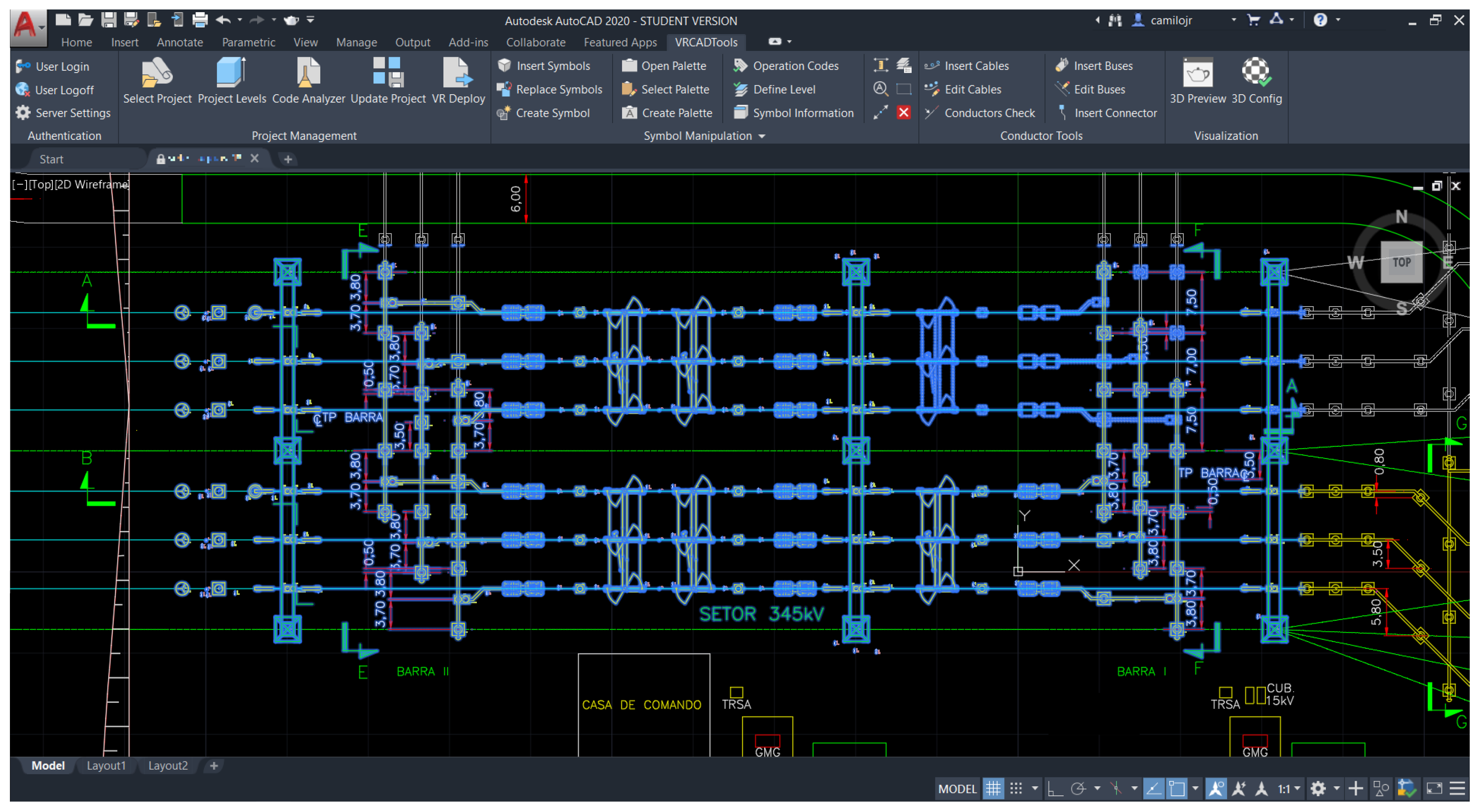

- Present the development of a CAD editing system to create and customize floor-plan drawings through the manipulation of symbols and elements stored in a web management system;

- Propose geometric and symbol modeling conventions to meet the demands of the VR and Authoring systems;

- Propose a design integration strategy between CAD editing and the Virtual Reality software appropriate data structure and suitable for sharing VE construction information over the Internet;

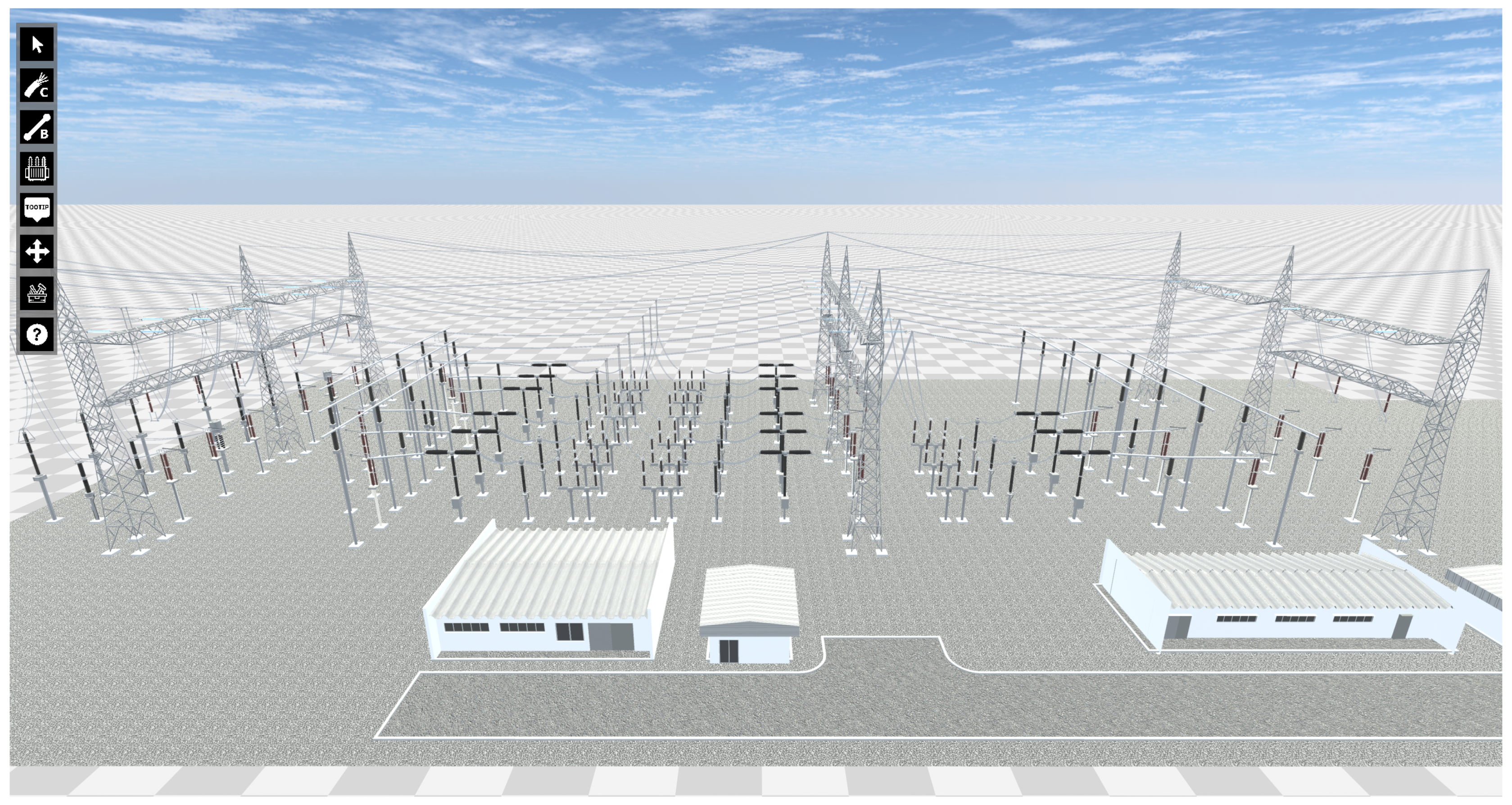

- Assess the work through a Case Study using a real EPS, with the aim of analyzing the software architecture, VE design methodology with the CAD Editor, as well as the capability to reuse 3D geometric objects, integration strategy and its reliability regarding the real environment;

- Show the differences and demonstrate the accuracy of the scenario generated by the Authoring system, regarding the positioning of the assets against the manual design methodology.

2. Related Works

2.1. Description of Related Works

2.2. Considerations about Related Works

3. Materials and Methods

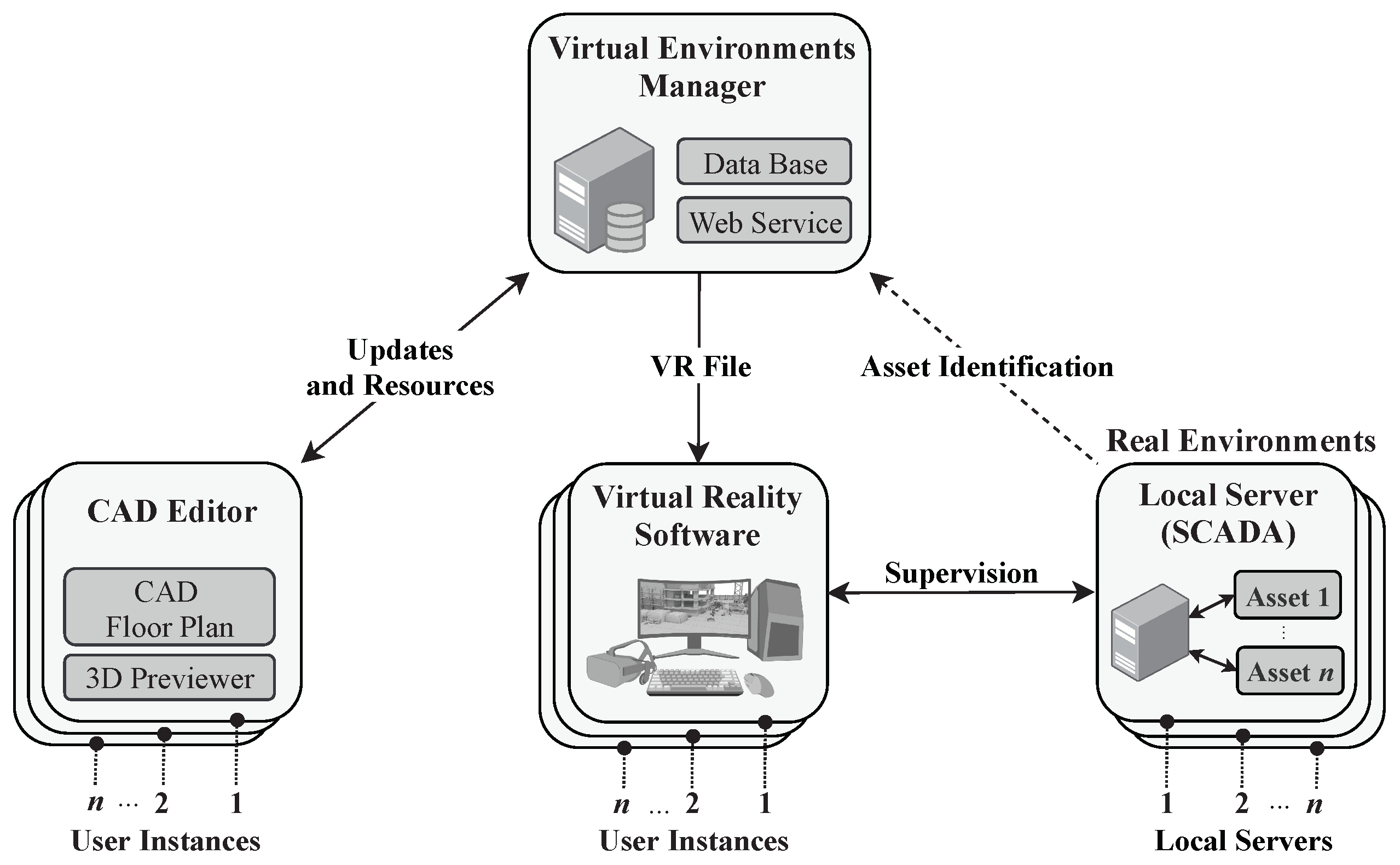

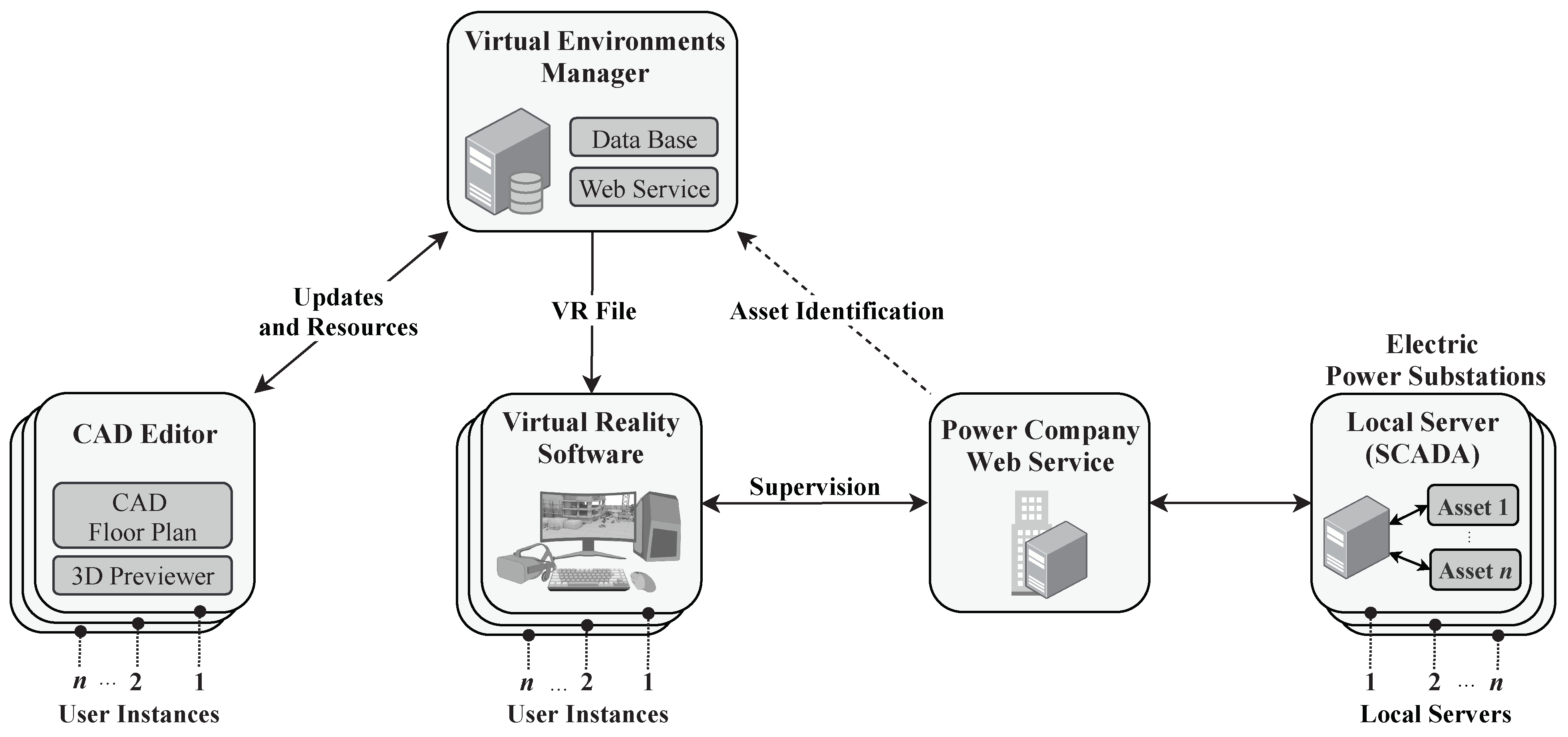

3.1. Architecture of the Authoring System

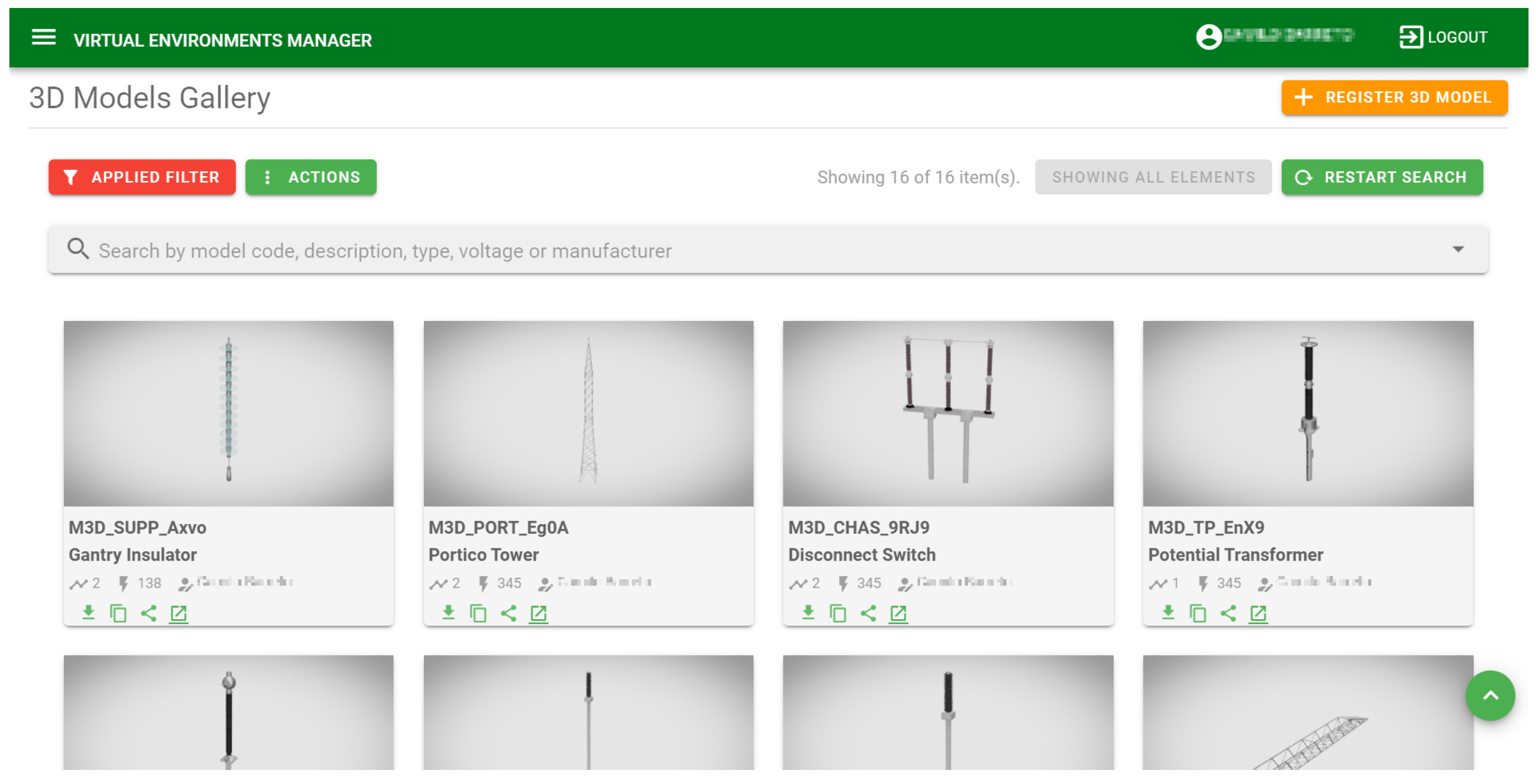

- Virtual Environment Manager (VEM): server responsible for storing the necessary virtual assets (3D models, CAD symbols, etc.) and manage the information between the CAD Editor and the Virtual Reality software;

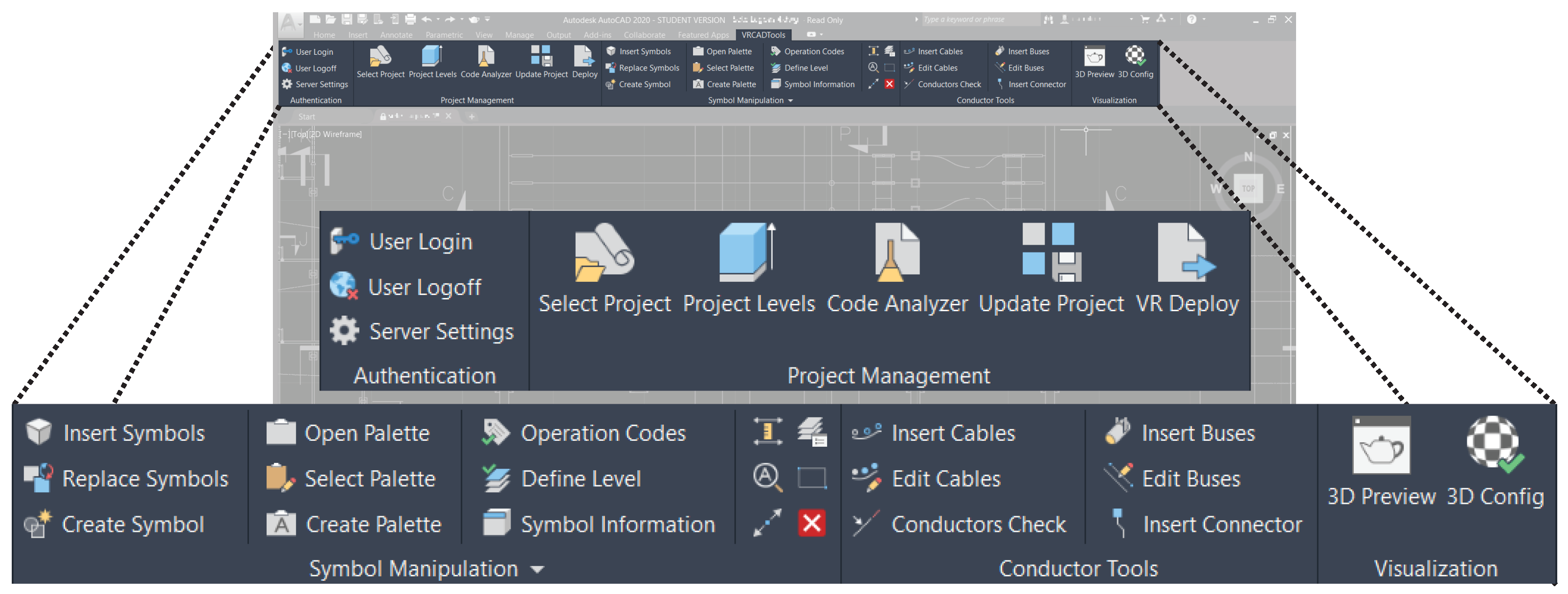

- CAD Editor (CADE): is the software used for the design and customization of floor plans. It is composed of groups of tools with specific purposes, such as the authentication of the user, project management, symbol manipulation, floor-plan review and VR implementation;

- Virtual Reality Software: used by the end user to navigate and interact with the VE.

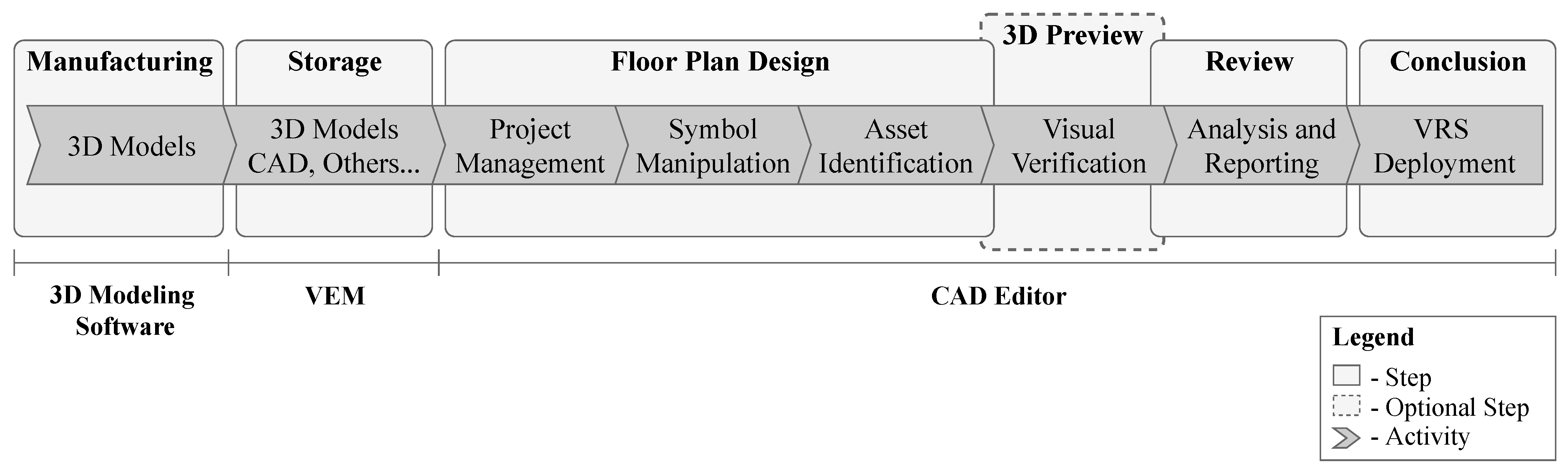

3.2. Authoring System Methodology

- Project Management: routine activities such as user authentication to VEM, selection of user floor-plan design, configurations of element levels (height in relation to ground) and store version history of actual floor plan;

- Symbol Manipulation: search, insert, edit, substitute, erase, move, rotate and scale the symbols that represent 3D models of assets;

- Asset Identification: attribute the code to the symbol when the VRS is destined to supervision of field assets. This stage can be performed at the moment of symbol insertion into the floor-plan design.

3.2.1. Symbol Manipulation on the Floor Plan

- Block: CAD symbol in the base 64 format for sharing via internet;

- Thumbnail: rasterized thumbnail of the symbol;

- Description: description of the element;

- Objects3D: identification code of the 3D model to which the 3D symbol was attributed.

- Fingerprint: global symbol identification in the VEM database;

- Thumbnail: rasterized thumbnail of the symbol;

- Block: CAD symbol in base 64 format for data serialization via the Internet;

- Description: element description;

- Object3D: identification code of the 3D model that the symbol represents.

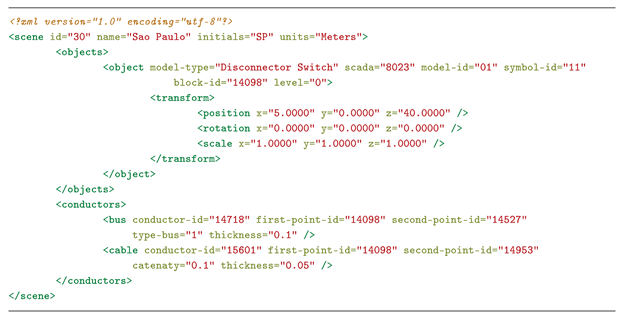

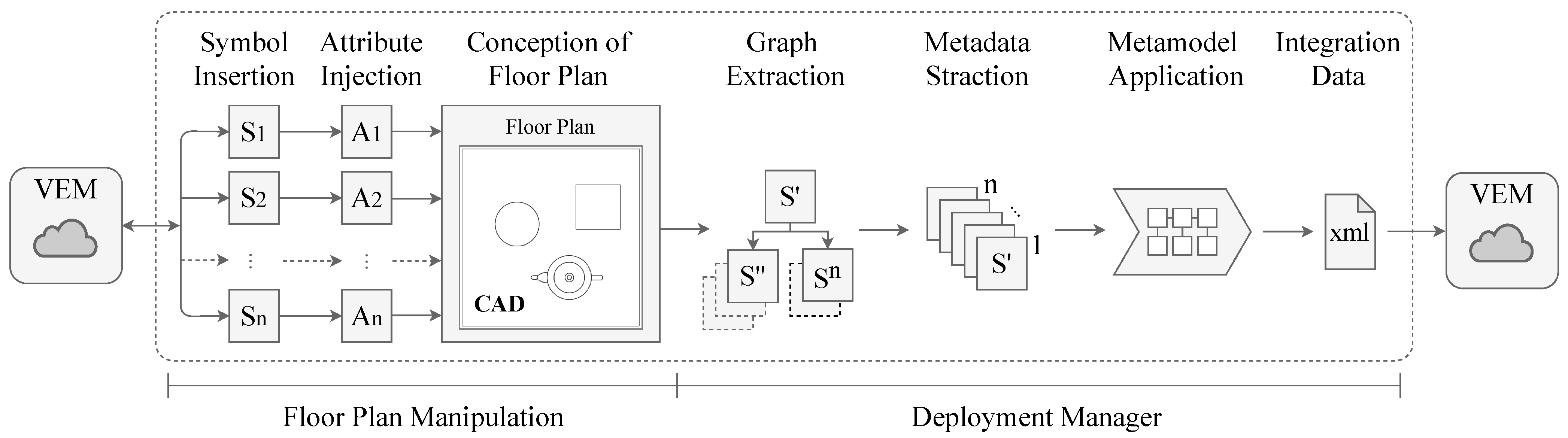

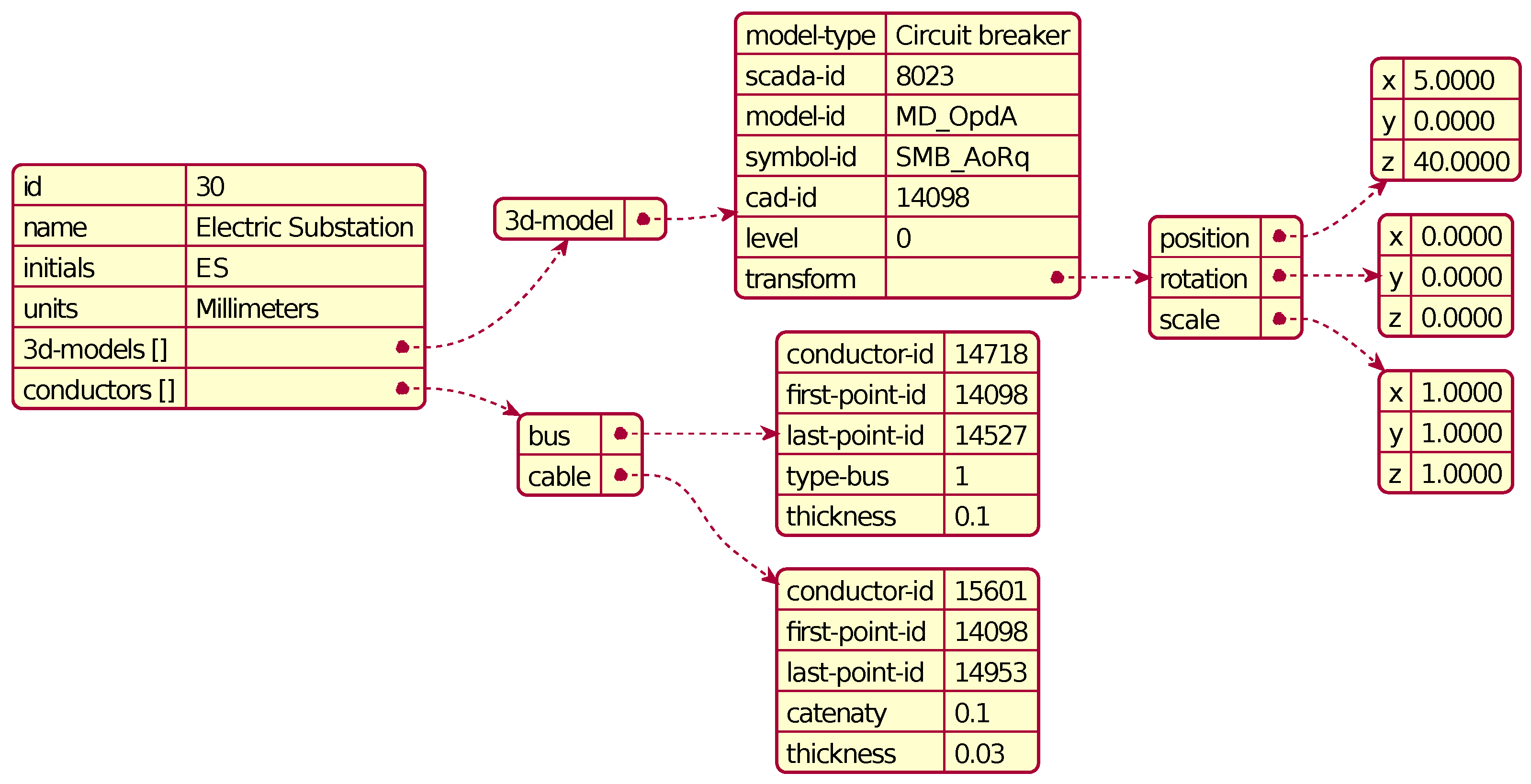

3.2.2. Integration between the CAD Editor and Virtual Reality Software

- Extraction of graph structure: this process obtains all the relationships between symbols in hierarchical form and stores these temporarily in a data in memory structure;

- Extraction of metadata: this process extracts the attributes of the symbols inserted during design manipulation. Furthermore, additional information is extracted, such as the transformation matrix (position, rotation and scale);

- Application of the Metamodel: this process organizes the graphs and the metadata into one unified data structure. In this stage, the data are organized into referenced blocks, maintaining the hierarchy of the elements. All the information is stored in an XML file and used to send data over the internet.

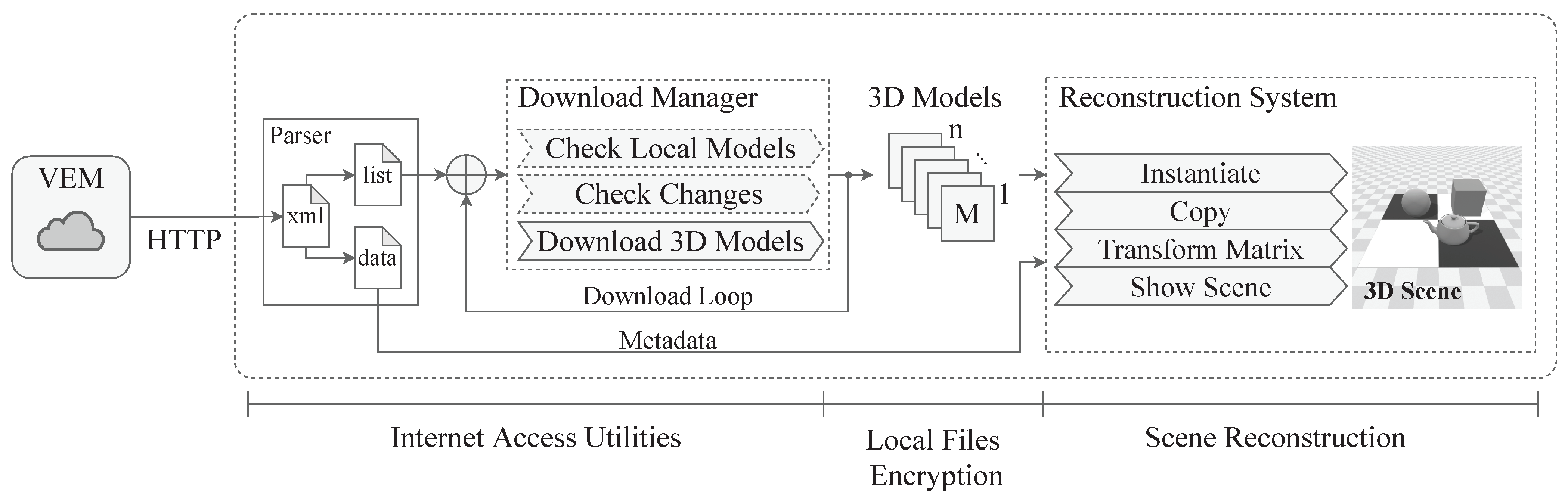

|

- Instantiate: a model of each type is instantiated in memory and remains until the end of the reconstruction of the scene. This process is performed by the Trilib library [39], which is costly in terms of processing;

- Copy: after the 3D models are instantiated in memory, the reconstruction system makes copies of each model, using the metadata as reference from the integration file. This process is less costly and reduces scenario reconstruction time;

- Transform Matrix: after copying the 3D models, the transformation matrix is applied to each 3D model for its spatial positioning (position, rotation and scale of each element);

- Show Scene: when the reconstruction process is completed, the VE containing the positioned assets is then presented to the user.

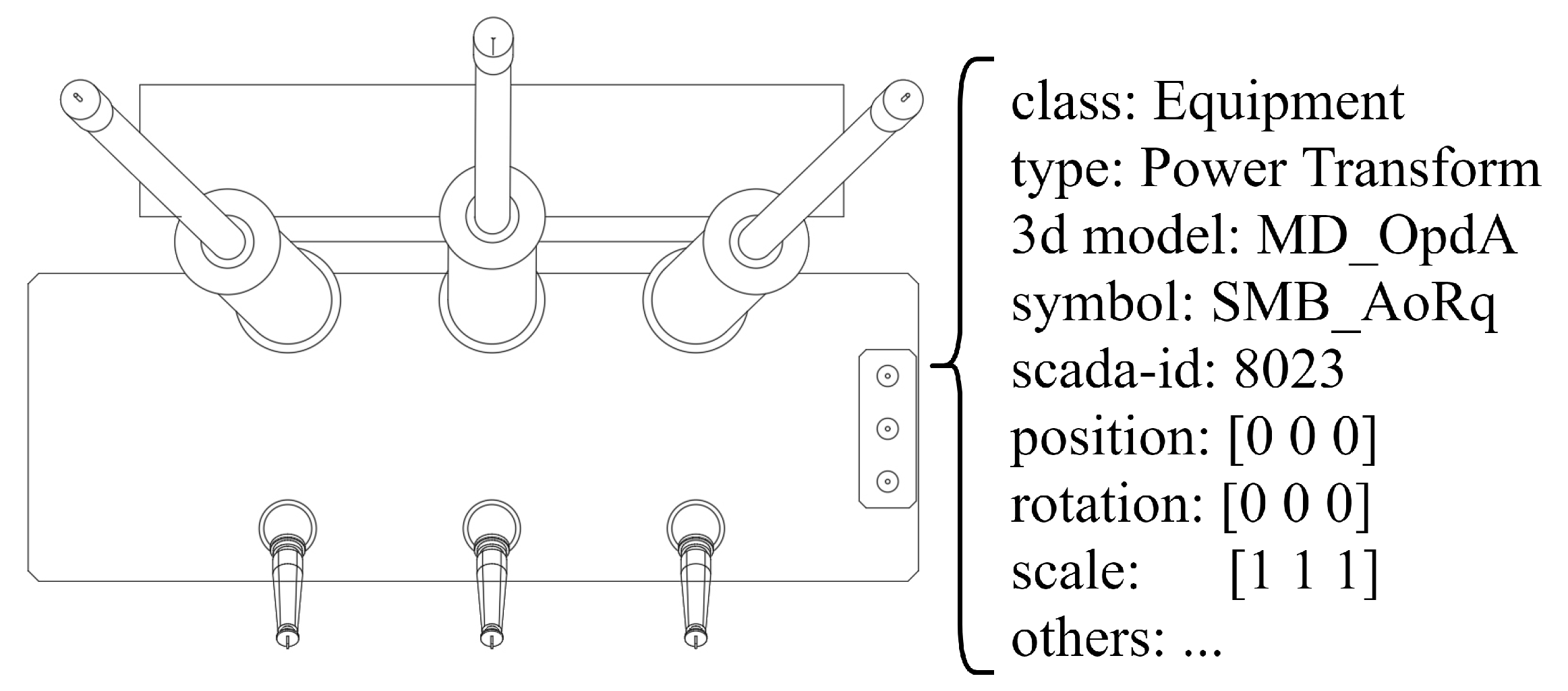

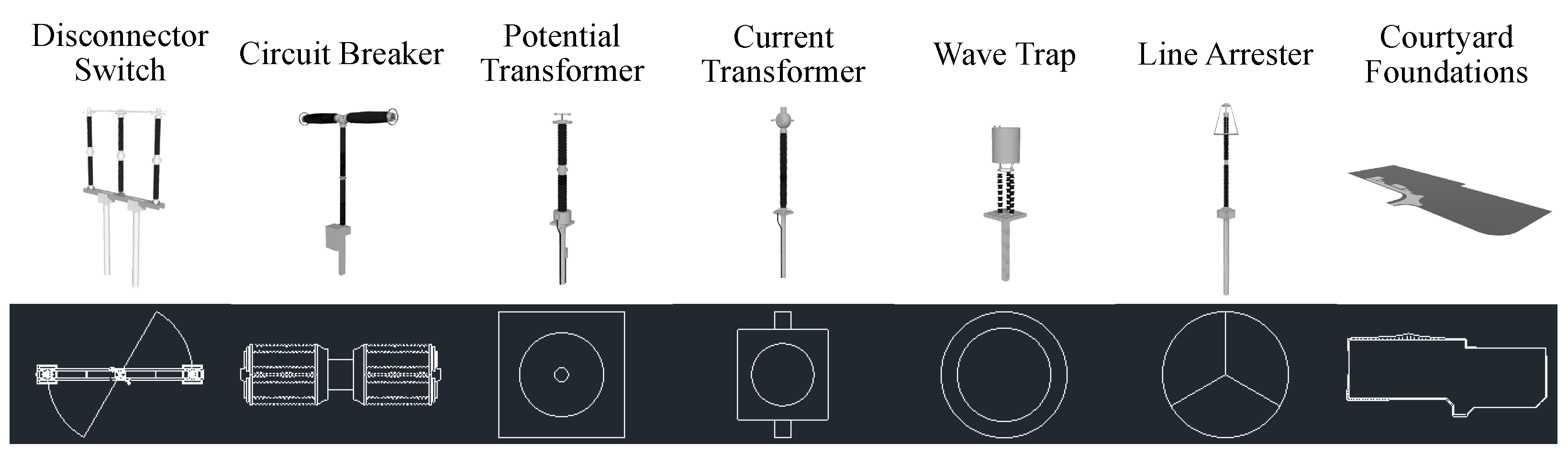

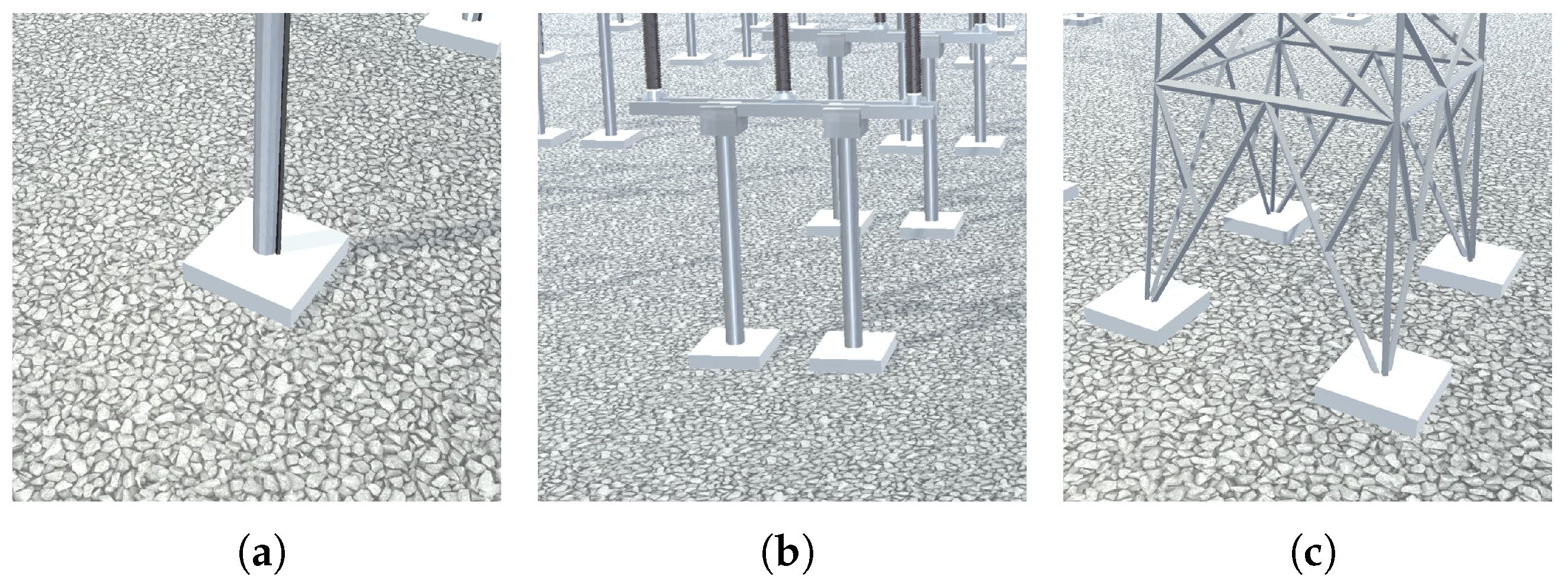

3.2.3. Geometric and Symbol Modeling

- Object dimensions: the dimensions should be identical to real object, maintaining the physical and constructive aspects;

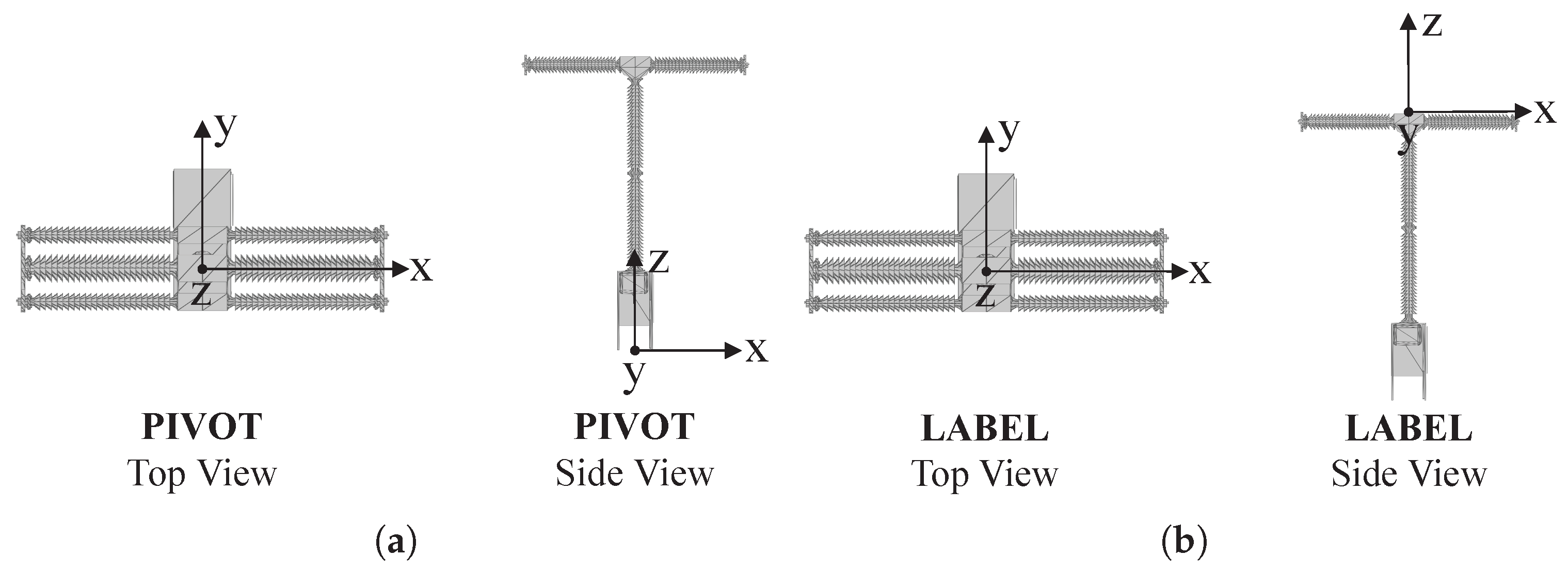

- Object center (pivot): the object should have its pivot point in the mass center of the model, centralized on the XY plane and with the Z axis corresponding to the lowest level (Z = 0 in relation to the object), as demonstrated in Figure 7a;

- Object label: the label is used to aid the positioning of graphic elements or texts above the object. Its usage is optional. An empty element or dummy known as “label” should be inserted and positioned in the mass center of the object with displacement on the Z axis until the highest point (Figure 7b);

- Object scale: the scale of the model should be analyzed whenever possible, thus ensuring that it has values on the X, Y and Z axes (without changes to the geometric aspects).

- Symbolic representation: the symbol should be designed representing the 3D model in top view;

- Similarity with the 3D model: the designed symbol should represent the 3D model with a high similarity;

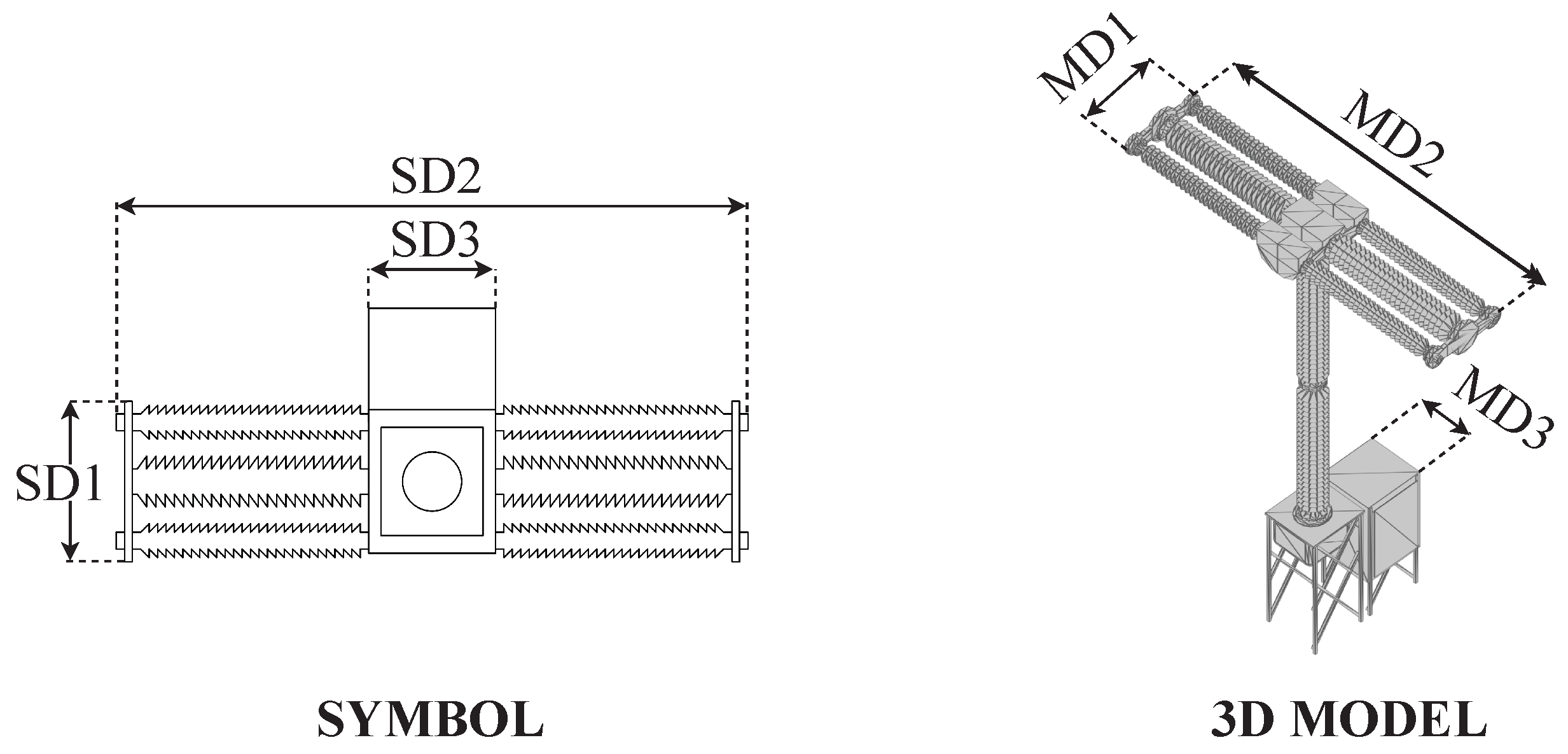

- Dimensions: the dimensions of the symbols should be equal to those of the model. Figure 8 presents the equality between dimensions of a symbol and its 3D model, where , and .

- Center of symbol (pivot): the symbol should have the pivot point on the XY plane positioned on the same pivot point as the 3D model on the XY plane;

- Measurement unit: the symbol should be created without a unit of measure (dimensionless), so that when used on a floor plan it will be attributed automatically with that value already in use.

4. Experimental Evaluation

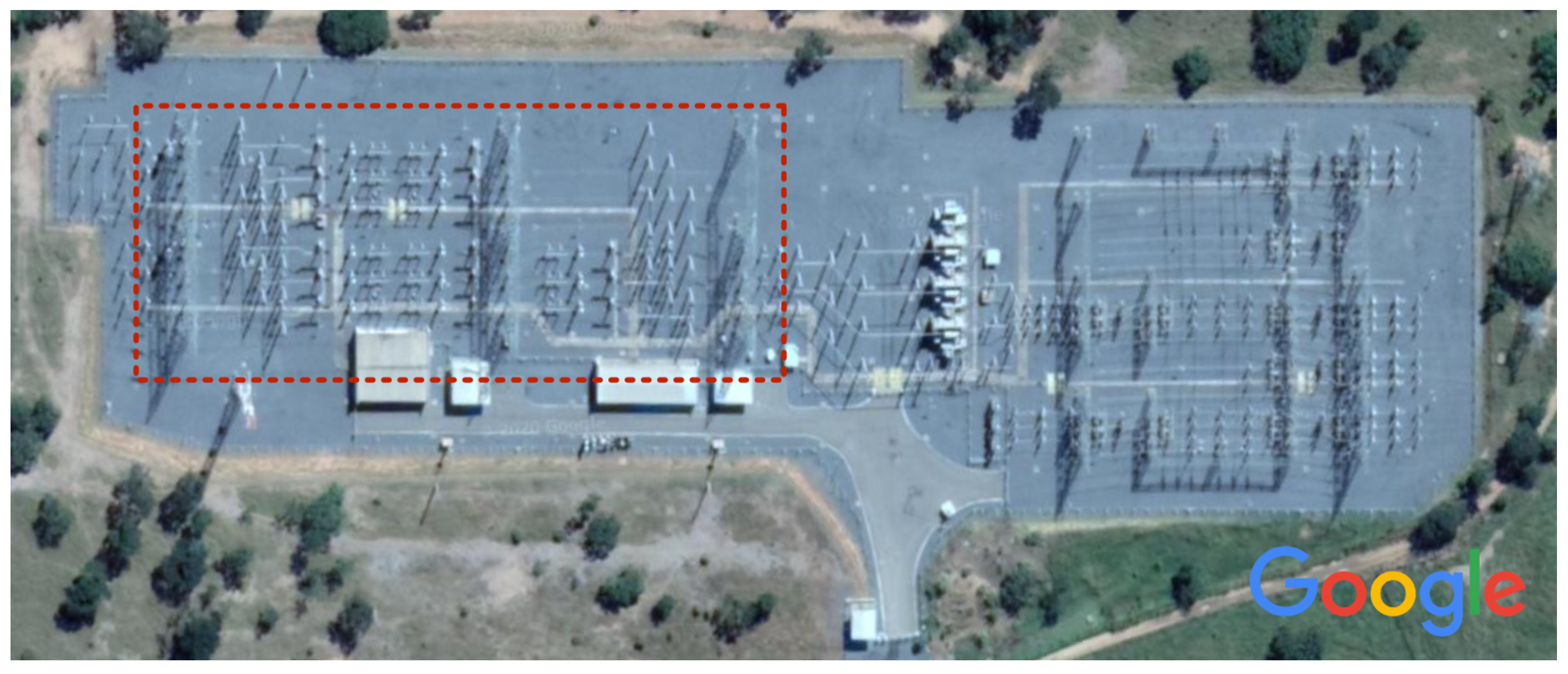

4.1. Case Study Applied to Electric Power Substations

4.2. Adaptation of the Methodology to the Context of Electric Power Substations

4.2.1. Web Service Layer for Asset Supervision

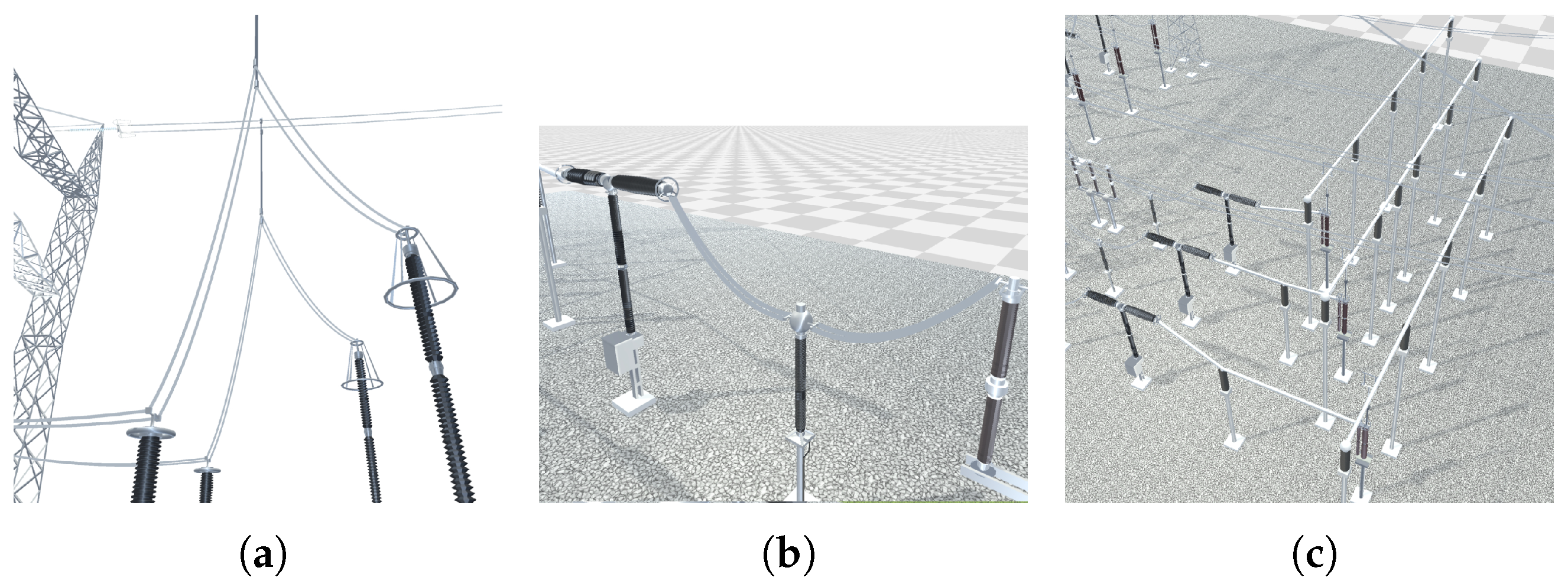

4.2.2. 3D Model Conventions

- Connectors: elements responsible for anchoring the connection points of electrical conductors between two or more pieces of equipment, as presented in Figure 11a. Simple objects such as a box, cylinder or capsule should be created in cable connection regions and should be named “connector”, regardless of quantity;

- Base references: elements that have two or more areas of contact with the ground should be referenced as dummy objects positioned in the contact areas. Figure 11b demonstrates the six references for bases in a part of equipment of the disconnect switch type.

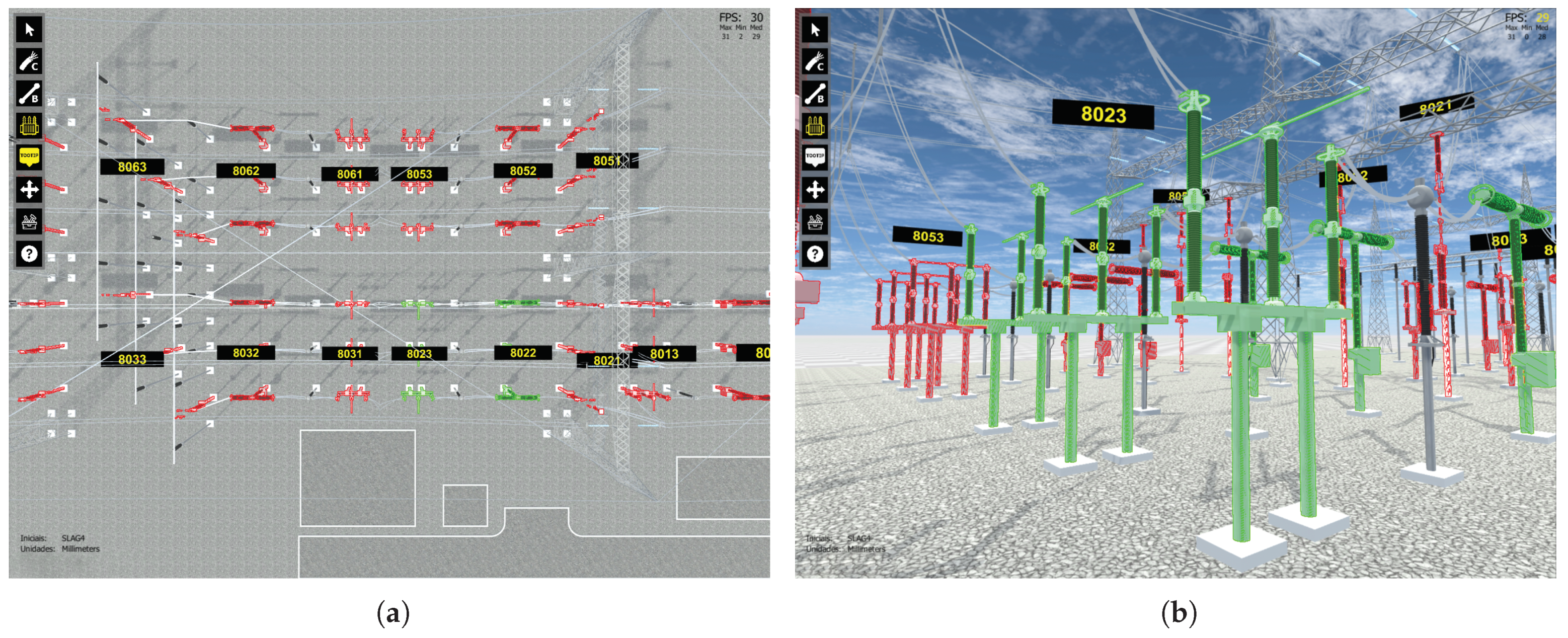

4.3. Graphic Interface of the CAD Editor

4.4. Integration of Design into Virtual Reality

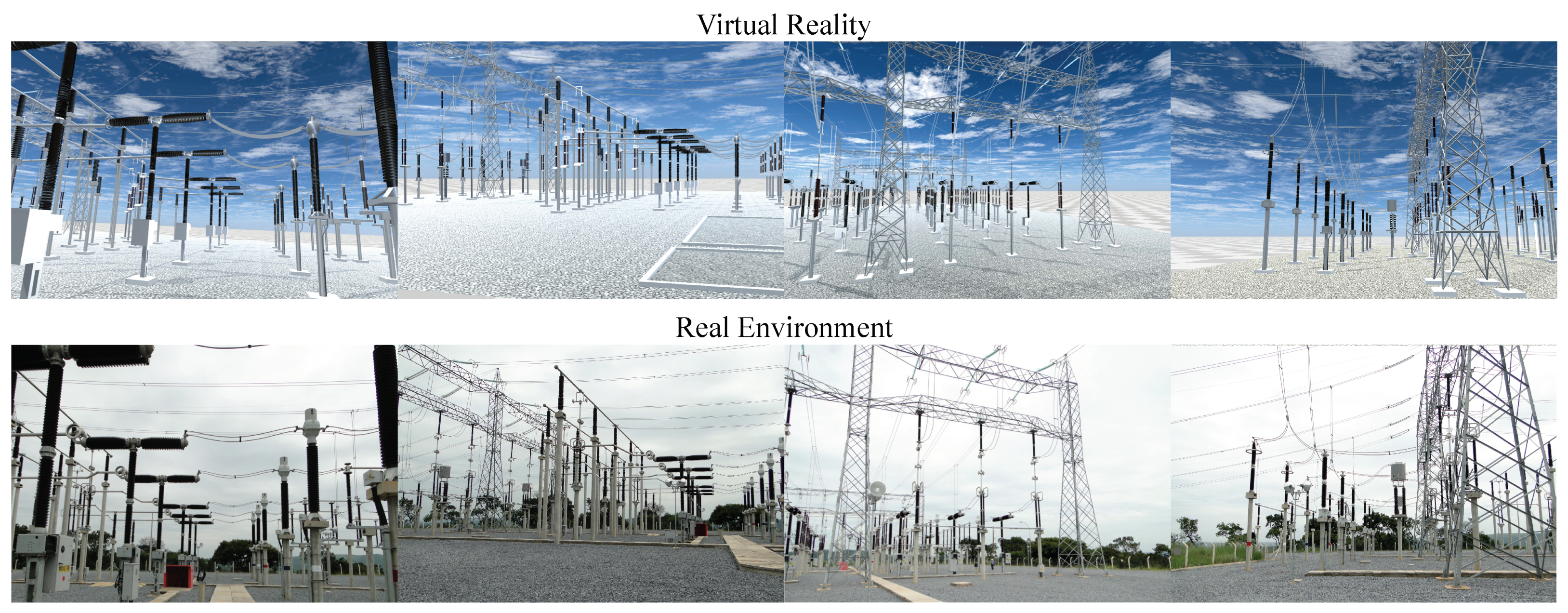

4.5. Development of the Electric Power Substation

4.5.1. Geometric and Symbol Modeling

4.5.2. Preparation of the Electrical Substation Floor Plan

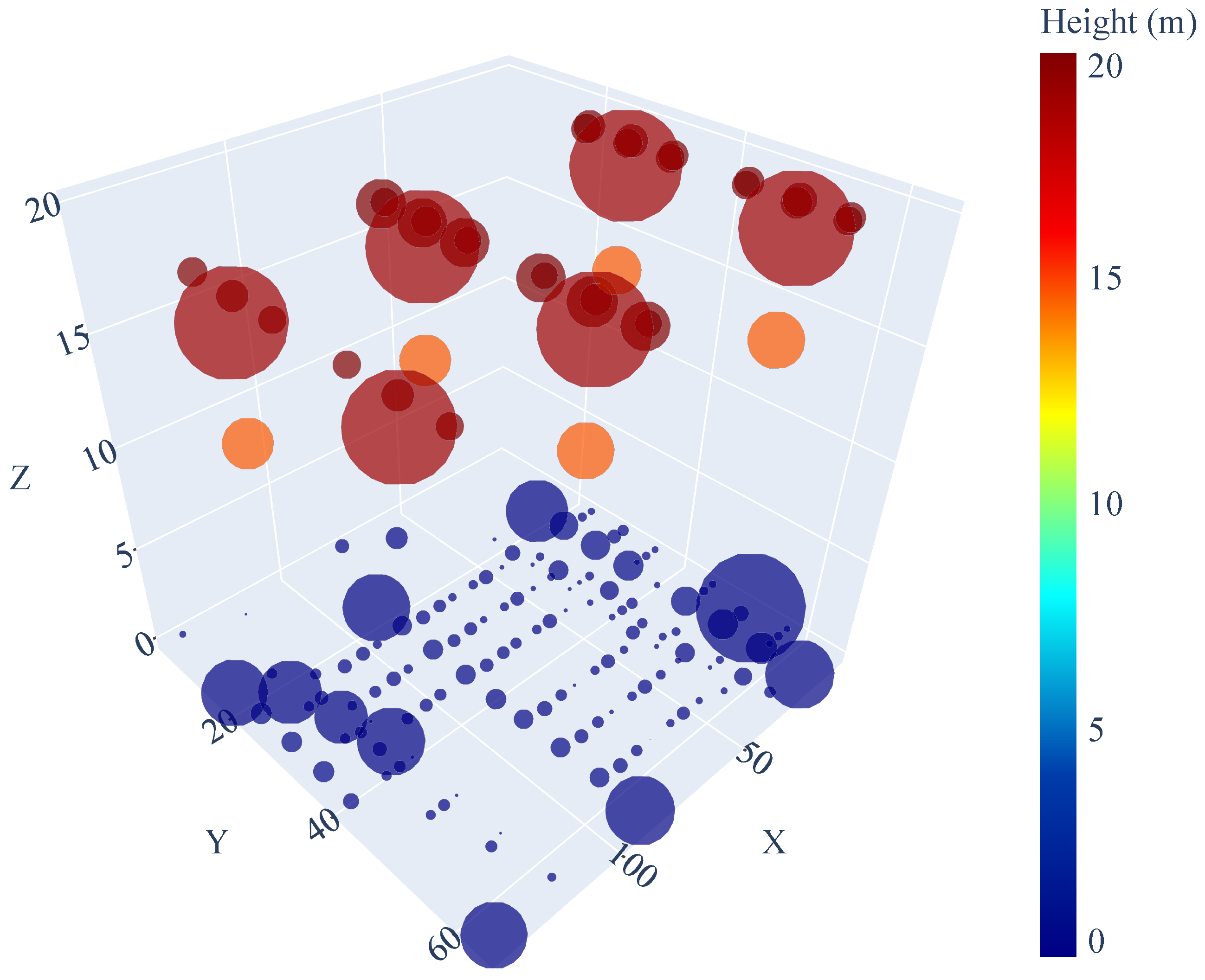

4.6. Results

5. Discussion and Conclusions

Comparative Analysis

- CAD drawing category: two-dimensional or three-dimensional space used by the authors;

- Virtual environment manager (VEM): asset management system used in Virtual Environments such as 3D models assets data (class, type, manufacturer, etc.), VE data (development status, 3D models used, designers, historical versions, etc.), CAD project, users and access control;

- Integration method: manual, semi-automated (involves manual tasks) and automated;

- Metamodel: system abstraction that describes the structural and/or behavioral aspects of the software, it is a definition of data structure of the integration file between CAD and RV software;

- Graphs: data structure that defines the hierarchical elements of the model/scene. Used in elements with moving parts to animate actions and physical states;

- Topology: definition of the logical relationships between design elements. Used to track the flow of electric current in EPS arrangements in order to represent, through simulations or supervision, the electrical state and functioning of the EPS;

- Rebuild at runtime (RR): VRS performs VE rebuild during its startup is more likely to update quickly. This ensures that when accessing VEM and obtaining the latest substation update, the system rebuilds it and presents the most current version of the project.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Wolfartsberger, J. Analyzing the Potential of Virtual Reality for Engineering Design Review. Autom. Constr. 2019, 104, 27–37. [Google Scholar] [CrossRef]

- Silva, A.C.; Cardoso, A.; Lamounier Junior, E.A.; Barreto Junior, C.L. Virtual Reality for Monitor and Control of Electrical Substations. An. Acad. Bras. Ciênc. 2021, 93, e20200267. [Google Scholar] [CrossRef] [PubMed]

- Meiguins, B.S.; Gonçalves, A.S.; Garcia, M.B.; Godinho, P.I.A.; Souza, R.S., Jr. Realidade Virtual e Aumentada em Visualização de Informação. In Fundamentos e Tecnologia de Realidade Virtual e Aumentada; Tori, R., Siscoutto, R., Kirner, C., Eds.; SBC—Sociedade Brasileira de Computação: Belém, Brazil, 2006; pp. 319–326. ISBN 85-7669-068-3. [Google Scholar]

- ISO. Information Technology for Learning, Education and Training—Human Factor Guidelines for Virtual Reality Content—Part 1: Considerations when Using VR Content; Standard ISO/IEC TR 23842-1:2020; International Organization for Standardization: Geneva, Switzerland, 2020. [Google Scholar]

- Roldán, J.J.; Crespo, E.; Martín-Barrio, A.; Peña-Tapia, E.; Barrientos, A. A Training System for Industry 4.0 Operators in Complex Assemblies Based on Virtual Reality and Process Mining. Robot. Comput. Integr. Manuf. 2019, 59, 305–316. [Google Scholar] [CrossRef]

- Kovar, J.; Mouralova, K.; Ksica, F.; Kroupa, J.; Andrs, O.; Hadas, Z. Virtual Reality in Context of Industry 4.0 Proposed Projects at Brno University of Technology. In Proceedings of the 17th International Conference on Mechatronics—Mechatronika (ME), Prague, Czech Republic, 7–9 December 2016. [Google Scholar]

- Kuts, V.; Otto, T.; Caldarola, E.G.; Modoni, G.E.; Sacco, M. Enabling the Teaching Factory Leveraging a Virtual Reality System Base on the Digital Twin. In Proceedings of the 15th Annual EuroVR Conference, London, UK, 22–23 October 2018; VTT Technical Research Centre of Finland, Ltd.: Espoo, Finland, 2018; pp. 26–31. [Google Scholar]

- Pessoa, A.; Gomes, D., Jr.; Reis, P.; Paiva, A.; Silva, A.; Braz, G.; Araújo, A. Uma Ferramenta de Autoria para Construção de Ambientes de Realidade Virtual para Subestações de Energia Baseada em Panoramas Aumentados. In Conference on Graphics, Patterns and Images, 30. (SIBGRAPI), Niterói, RJ. Proceedings; Sociedade Brasileira de Computação: Porto Alegre, Brazil, 2017. [Google Scholar]

- Ciprian Firu, A.; Ion Tapîrdea, A.; Ioana Feier, A.; Drăghici, G. Virtual Reality in the Automotive Field in Industry 4.0. Mater. Today Proc. 2021, 45, 4177–4182. [Google Scholar] [CrossRef]

- Cardoso, A.; Lamounier, E.; de Lima, G.F.M.; do Prado, P.R.; Ferreira, J.N. VRCEMIG: A Novel Approach to Power Substation Control. In Proceedings of the ACM SIGGRAPH 2016 Posters; ACM: Anaheim, CA, USA, 24 July 2016; pp. 1–2. [Google Scholar] [CrossRef]

- Liao, X.; Niu, J.; Wang, H.; Du, B. Research on Virtual Reality Simulation Training System of Substation. In Proceedings of the 2017 International Conference on Virtual Reality and Visualization (ICVRV); IEEE: Zhengzhou, China, 2017; pp. 413–414. [Google Scholar] [CrossRef]

- Nasyrov, R.R.; Excell, P.S. New Approaches to Training of Power Substation Operators Based on Interactive Virtual Reality. In Lifelong Technology-Enhanced Learning; Pammer-Schindler, V., Pérez-Sanagustín, M., Drachsler, H., Elferink, R., Scheffel, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; Volume 11082, pp. 551–555. [Google Scholar] [CrossRef]

- Nasyrov, R.R.; Excell, P.S. Creation of Interactive Virtual Reality Scenarios as a Training and Education Tool. In Technology, Design and the Arts—Opportunities and Challenges; Earnshaw, R., Liggett, S., Excell, P., Thalmann, D., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 353–369. [Google Scholar] [CrossRef]

- Barata, P.N.A.; Filho, M.R.; Nunes, M.V.A. Consolidating Learning in Power Systems: Virtual Reality Applied to the Study of the Operation of Electric Power Transformers. IEEE Trans. Educ. 2015, 58, 255–261. [Google Scholar] [CrossRef]

- Ribeiro, T.R.; dos Reis, P.R.J.; Júnior, G.B.; de Paiva, A.C.; Silva, A.C.; Maia, I.M.O.; Araújo, A.S. AGITO: Virtual Reality Environment for Power Systems Substations Operators Training. In Augmented and Virtual Reality; De Paolis, L.T., Mongelli, A., Eds.; Springer International Publishing: Cham, Switzerland, 2014; Volume 8853, pp. 113–123. [Google Scholar] [CrossRef]

- Gonzalez Lopez, J.M.; Jimenez Betancourt, R.O.; Ramirez Arredondo, J.M.; Villalvazo Laureano, E.; Rodriguez Haro, F. Incorporating Virtual Reality into the Teaching and Training of Grid-Tie Photovoltaic Power Plants Design. Appl. Sci. 2019, 9, 4480. [Google Scholar] [CrossRef] [Green Version]

- Romo, J.E.; Tipantasi, G.R.; Andaluz, V.H.; Sanchez, J.S. Virtual Training on Pumping Stations for Drinking Water Supply Systems. In Augmented Reality, Virtual Reality, and Computer Graphics; De Paolis, L.T., Bourdot, P., Eds.; Springer International Publishing: Cham, Switzerland, 2019; Volume 11614, pp. 410–429. [Google Scholar] [CrossRef]

- Kersten, T.P.; Tschirschwitz, F.; Deggim, S. Development of a Virtual Museum Including a 4D Presentation of Building History in Virtual Reality. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, XLII-2/W3, 361–367. [Google Scholar] [CrossRef] [Green Version]

- Chiluisa, M.G.; Mullo, R.D.; Andaluz, V.H. Training in Virtual Environments for Hybrid Power Plant. In Advances in Visual Computing; Bebis, G., Boyle, R., Parvin, B., Koracin, D., Turek, M., Ramalingam, S., Xu, K., Lin, S., Alsallakh, B., Yang, J., et al., Eds.; Springer International Publishing: Cham, Switzerland, 2018; Volume 11241, pp. 193–204. [Google Scholar] [CrossRef]

- Pereira, J.G.; Ellman, A. From CAD to Physics-based Digital Twin: Framework for Real-Time Simulation of Virtual Prototypes. Proc. Des. Soc. Des. Conf. 2020, 1, 335–344. [Google Scholar] [CrossRef]

- ISO. Information Technology—Computer Graphics, Image Processing and Environmental Data Representation—Mixed and Augmented Reality (MAR) Reference Model; Standard ISO/IEC 18039:2019; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- Technologies, U. Unity Real-Time Development Platform|3D, 2D VR & AR Engine. Available online: https://unity.com/ (accessed on 21 June 2021).

- Unreal Engine. Available online: https://www.unrealengine.com/en-US/ (accessed on 31 October 2021).

- Amazon Lumberyard. Available online: https://aws.amazon.com/lumberyard (accessed on 31 October 2021).

- Moreno, E.F.; Pacheco, E.E.; Andaluz, V.H.; Mullo, Á.S. Multi-user Expert System for Operation and Maintenance in Energized Lines. In Advances in Information and Communication; Arai, K., Kapoor, S., Bhatia, R., Eds.; Springer International Publishing: Cham, Switzerland, 2020; Volume 1130, pp. 454–472. [Google Scholar] [CrossRef]

- Mattioli, L.; Cardoso, A.; Lamounier, E.A.; do Prado, P. Semi-automatic Generation of Virtual Reality Environments for Electric Power Substations. In New Contributions in Information Systems and Technologies; Rocha, A., Correia, A.M., Costanzo, S., Reis, L.P., Eds.; Springer International Publishing: Cham, Switzerland, 2015; Volume 353, pp. 833–842. [Google Scholar] [CrossRef]

- Gebert, M.; Sterger, W.; Stelzer, R.; Bertelmann, K. Meta-model for VR-based Design Reviews. In Proceedings of the 21st International Conference on Engineering Design, Vancouver, BC, Canada, 21–25 August 2017; Maier, A., Skec, S., Kim, H., Kokkolaras, M., Oehmen, J., Fadel, F., Salustri, F., Loos, M., Eds.; ICED: Vancouver, BC, Canada, 2017. [Google Scholar]

- Freeman, I.; Salmon, J.; Coburn, J. A Bi-Directional Interface for Improved Interaction with Engineering Models in Virtual Reality Design Reviews. Int. J. Interact. Des. Manuf. 2018, 12, 549–560. [Google Scholar] [CrossRef]

- NX|Software. Available online: https://www.plm.automation.siemens.com/global/en/products/nx/ (accessed on 21 September 2021).

- Han, Y.S.; Lee, J.; Lee, J.; Lee, W.; Lee, K. 3D CAD Data Extraction and Conversion for Application of Augmented/Virtual Reality to the Construction of Ships and Offshore Structures. Int. J. Comput. Integr. Manuf. 2019, 32, 658–668. [Google Scholar] [CrossRef]

- Lorenz, M.; Spranger, M.; Riedel, T.; Pürzel, F.; Wittstock, V.; Klimant, P. CAD to VR—A Methodology for the Automated Conversion of Kinematic CAD Models to Virtual Reality. Procedia CIRP 2016, 41, 358–363. [Google Scholar] [CrossRef] [Green Version]

- Zawadzki, P.; Gorski, F.; Bun, P.; Wichniarek, R.; Szalanska, K. Virtual reality and cad systems integration for quick product variant design. In Advances in Manufacturing; Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 599–608. [Google Scholar] [CrossRef]

- Boyer, S.A. SCADA: Supervisory Control and Data Acquisition, 3rd ed.; ISA-The Instrumentation, Systems, and Automation Society: Research Triangle Park, NC, USA, 2004; ISBN 9781556178771. [Google Scholar]

- Daneels, A.; Salter, W. What Is SCADA? In Proceedings of the International Conference on Accelerator and Large Experimental Physics Control Systems, Trieste, Italy, 4–8 October 1999. [Google Scholar]

- The Web Framework for Perfectionists with Deadlines|Django. Available online: https://www.djangoproject.com/ (accessed on 21 September 2021).

- Blender. Available online: https://blender.org (accessed on 14 August 2021).

- Massé, M.H. REST API Design Rulebook: Designing Consistent RESTful Web Service Interfaces; O’Reilly: Beijing Köln, 2012; ISBN 9781449310509. [Google Scholar]

- AutoCAD Software 2022. Available online: https://www.autodesk.com/products/autocad/overview (accessed on 21 September 2021).

- Trilib 2. Available online: https://ricardoreis.net/trilib-2 (accessed on 14 August 2021).

- Nielson, G.M.; Olsen, D.R. Direct Manipulation Techniques for 3D Objects Using 2D Locator Devices. In Proceedings of the Proceedings of the 1986 workshop on Interactive 3D graphics—SI3D’ 86; ACM Press: Chapel Hill, CA, USA, 1987; pp. 175–182. [Google Scholar] [CrossRef]

- 3ds Max Software 2022. Available online: https://www.autodesk.com/products/3ds-max/overview (accessed on 21 September 2021).

- Inventor Software 2022. Available online: https://www.autodesk.com/products/inventor/overview (accessed on 21 September 2021).

- Vogt, A.; Babel, F.; Hock, P.; Baumann, M.; Seufert, T. Prompting In-Depth Learning in Immersive Virtual Reality: Impact of an Elaboration Prompt on Developing a Mental Model. Comput. Educ. 2021, 171, 104235. [Google Scholar] [CrossRef]

- Casenave, L.; Lugo, J.E. Design Review Using Virtual Reality Enabled CAD. In Proceedings of the ASME 2017 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Cleveland, OH, USA, 6–9 August 2017. [Google Scholar] [CrossRef]

- Baca, M. Introduction to Metadata. The Getty Research Institute Publications Program, 3rd ed.; Getty Research Institute, Ed.; The Getty Research Institute: Los Angeles, CA, USA, 2016; ISBN 9781606064801. [Google Scholar]

- Sui, Z.; Ji, X.; Wu, L.; Weng, J.; Lin, X. Constructing rules and scheduling technology for 3D building models. In Proceedings of the 18th International Conference on Geoinformatics 2010, Beijing, China, 18–20 June 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Sheridan, T.B. Interaction, Imagination and Immersion Some Research Needs. In Proceedings of the ACM Symposium on Virtual Reality Software and Technology—VRST ’00; ACM Press: Seoul, Korea, 2000. [Google Scholar] [CrossRef]

- Google Earth—Coordinates 19°31′04 S 44°19′28 W. Available online: https://www.google.com.br/earth/ (accessed on 21 September 2021).

| Work | CAD | VEM | Integration | Metamodel | Graphs | Topology | RR |

|---|---|---|---|---|---|---|---|

| Mattioli et al. [26] | 2D | No | Semi-automated | No | No | No | No |

| Gebert et al. [27] | 3D | * | Automated | Yes | No | No | No |

| Freeman et al. [28] | 3D | No | Automated | No | No | No | Yes |

| Han et al. [30] | 3D | No | Automated | No | No | No | Yes |

| Lorens et al. [31] | 3D | No | Automated | No | No | No | Yes |

| Zawadzki et al. [32] | 3D | No | Semi-automated | No | No | No | No |

| This work | 2D | Yes | Automated | Yes | Yes | Yes | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barreto Junior, C.d.L.; Cardoso, A.; Lamounier Júnior, E.A.; Silva, P.C.; Silva, A.C. Designing Virtual Reality Environments through an Authoring System Based on CAD Floor Plans: A Methodology and Case Study Applied to Electric Power Substations for Supervision. Energies 2021, 14, 7435. https://doi.org/10.3390/en14217435

Barreto Junior CdL, Cardoso A, Lamounier Júnior EA, Silva PC, Silva AC. Designing Virtual Reality Environments through an Authoring System Based on CAD Floor Plans: A Methodology and Case Study Applied to Electric Power Substations for Supervision. Energies. 2021; 14(21):7435. https://doi.org/10.3390/en14217435

Chicago/Turabian StyleBarreto Junior, Camilo de Lellis, Alexandre Cardoso, Edgard Afonso Lamounier Júnior, Paulo Camargos Silva, and Alexandre Carvalho Silva. 2021. "Designing Virtual Reality Environments through an Authoring System Based on CAD Floor Plans: A Methodology and Case Study Applied to Electric Power Substations for Supervision" Energies 14, no. 21: 7435. https://doi.org/10.3390/en14217435

APA StyleBarreto Junior, C. d. L., Cardoso, A., Lamounier Júnior, E. A., Silva, P. C., & Silva, A. C. (2021). Designing Virtual Reality Environments through an Authoring System Based on CAD Floor Plans: A Methodology and Case Study Applied to Electric Power Substations for Supervision. Energies, 14(21), 7435. https://doi.org/10.3390/en14217435