Experimental Investigation of EU-DEMO Breeding Blanket First Wall Mock-Ups in Support of the Manufacturing and Material Development Programmes

Abstract

:1. Introduction

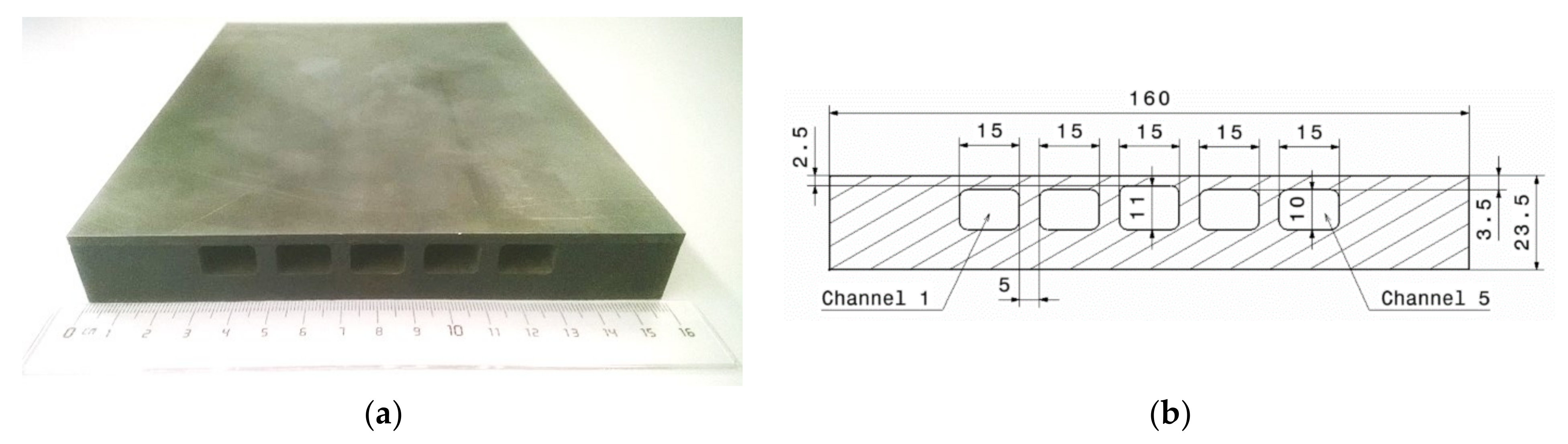

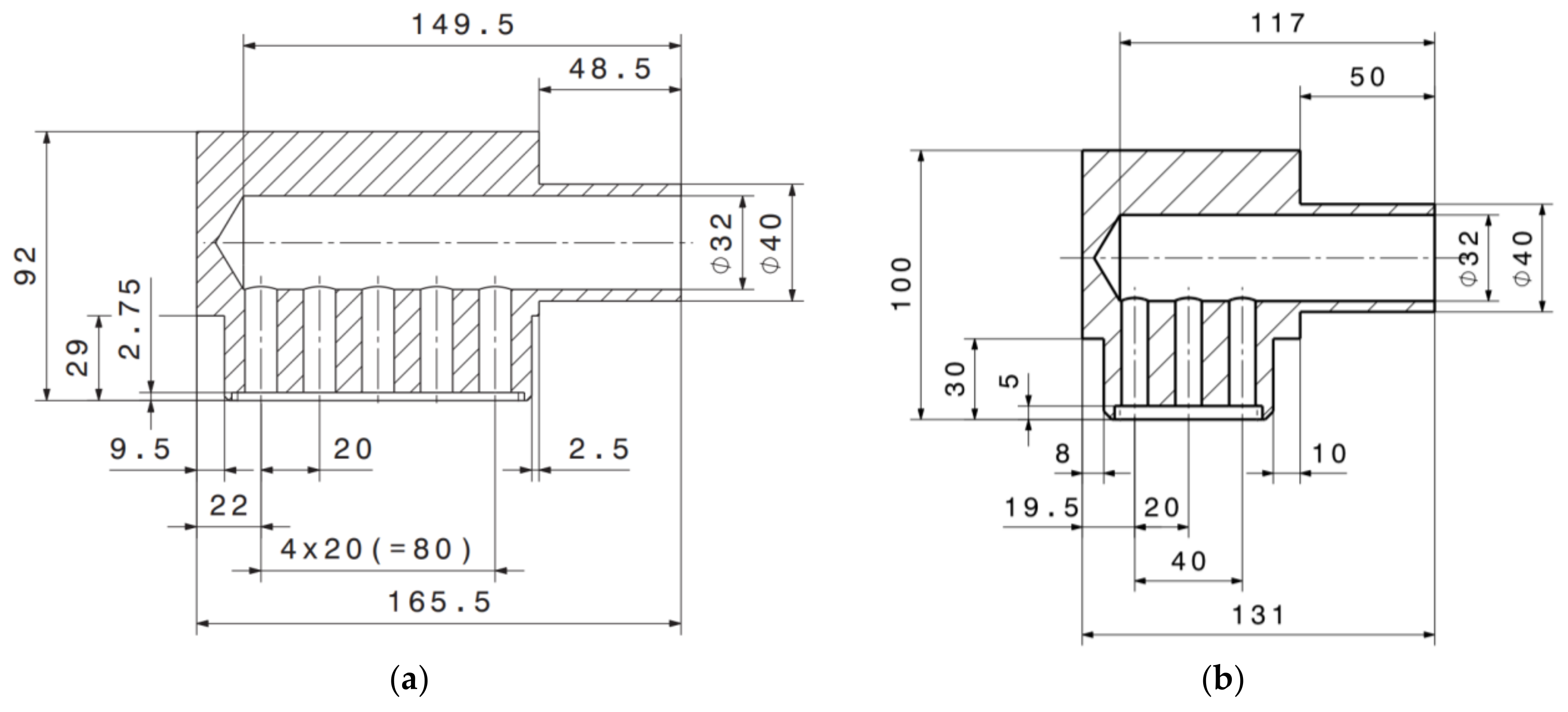

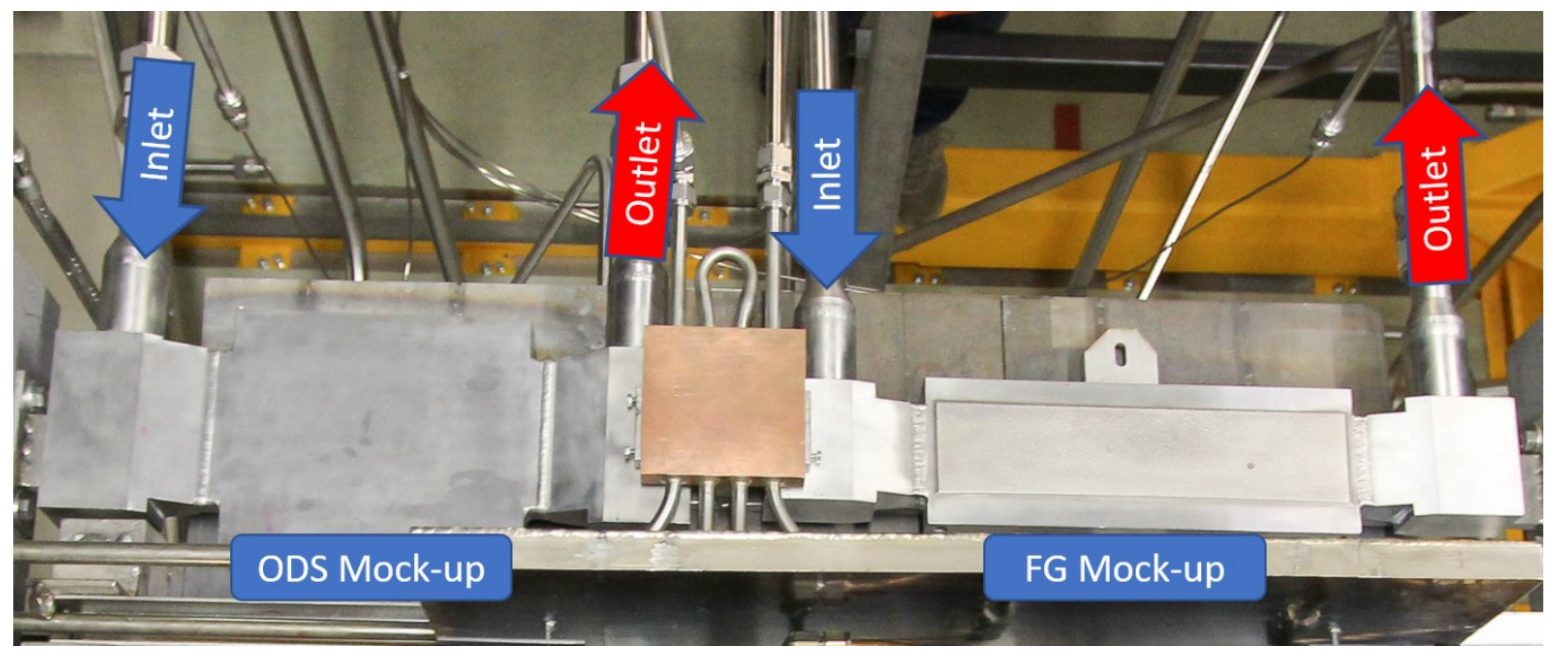

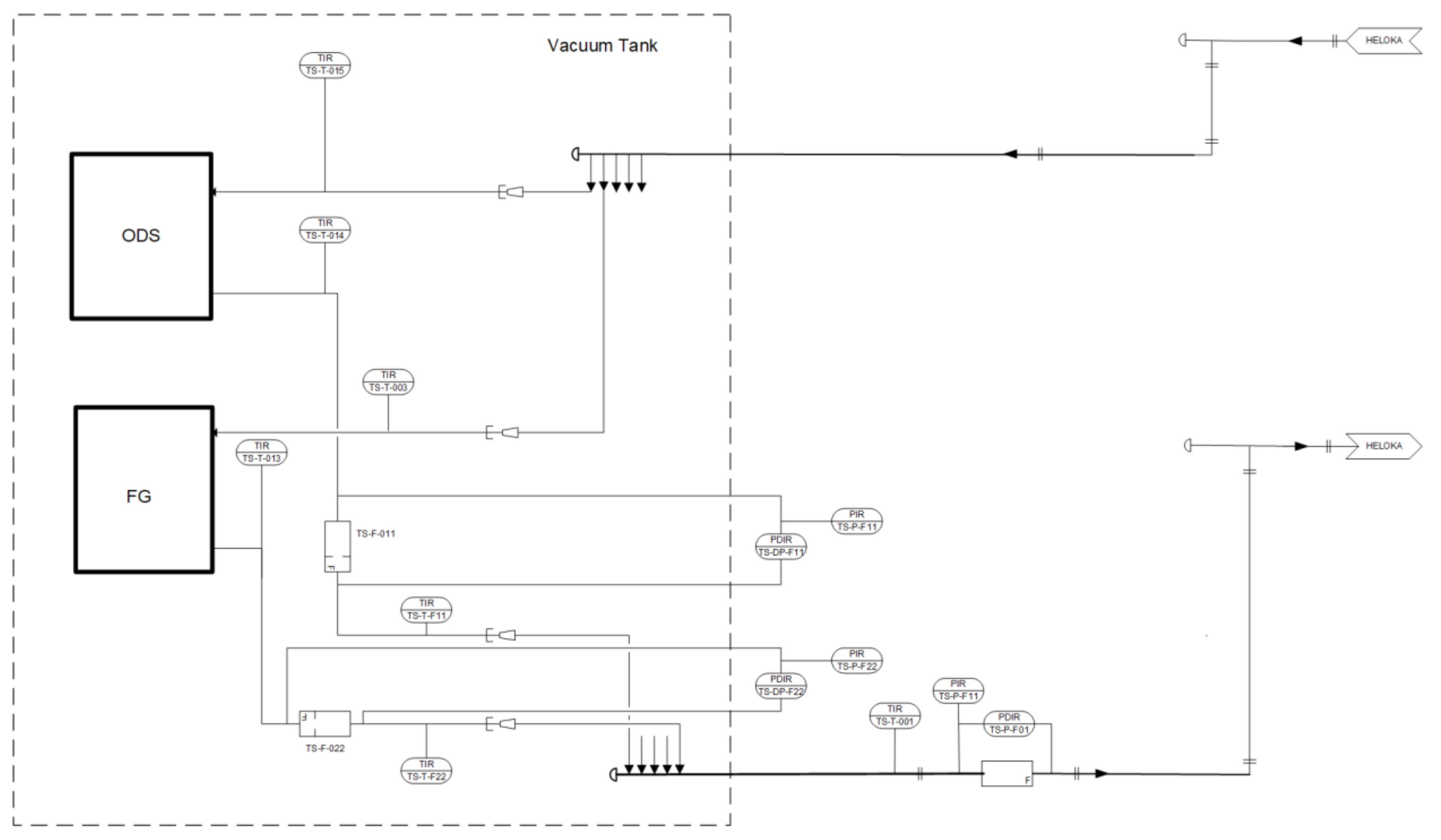

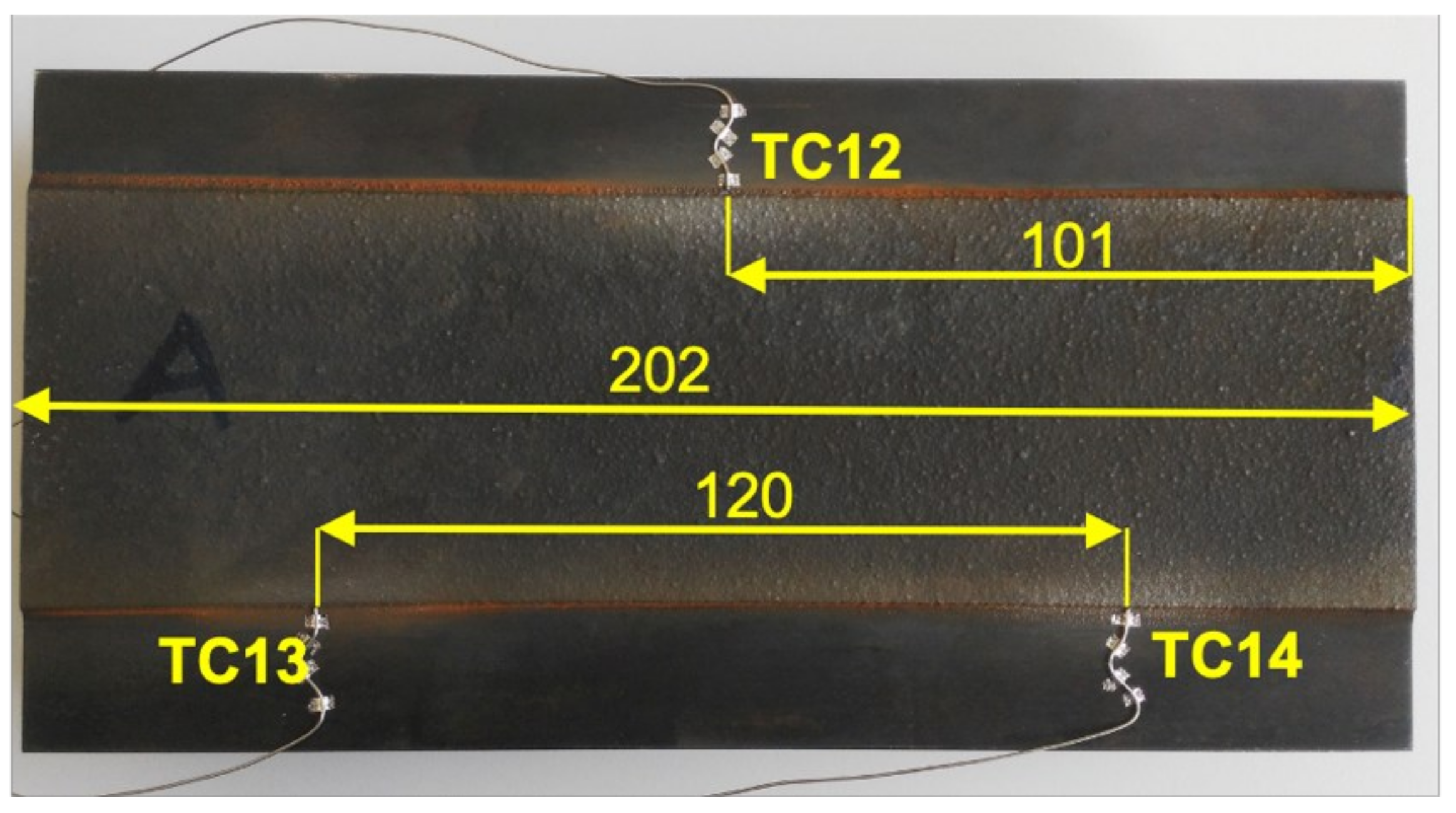

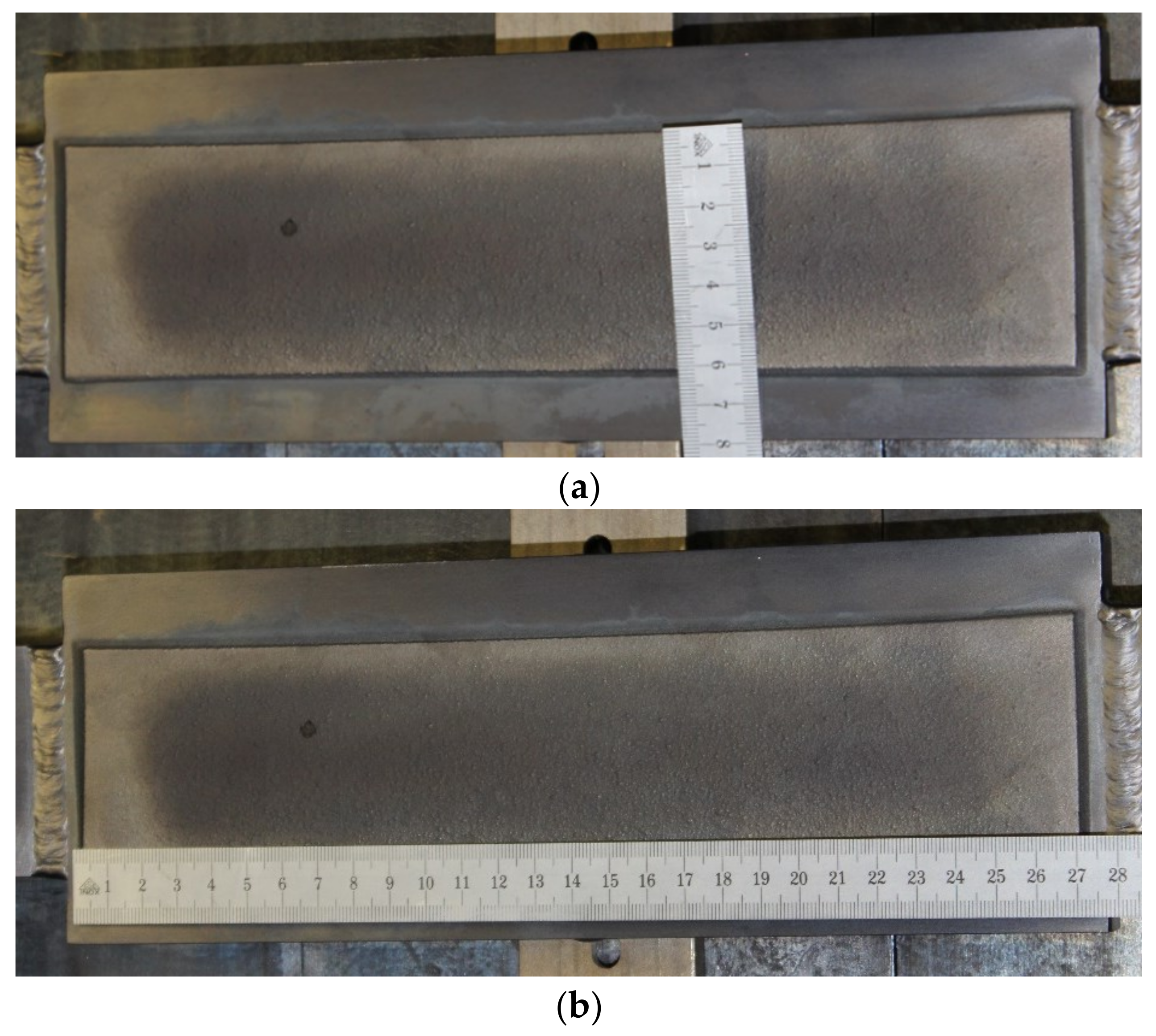

2. Mock-Ups and Experimental Set-Up Description

3. Measurements & Diagnostics

3.1. Mass Flow and Pressure Measurements

3.2. Coolant Temperature Measurements

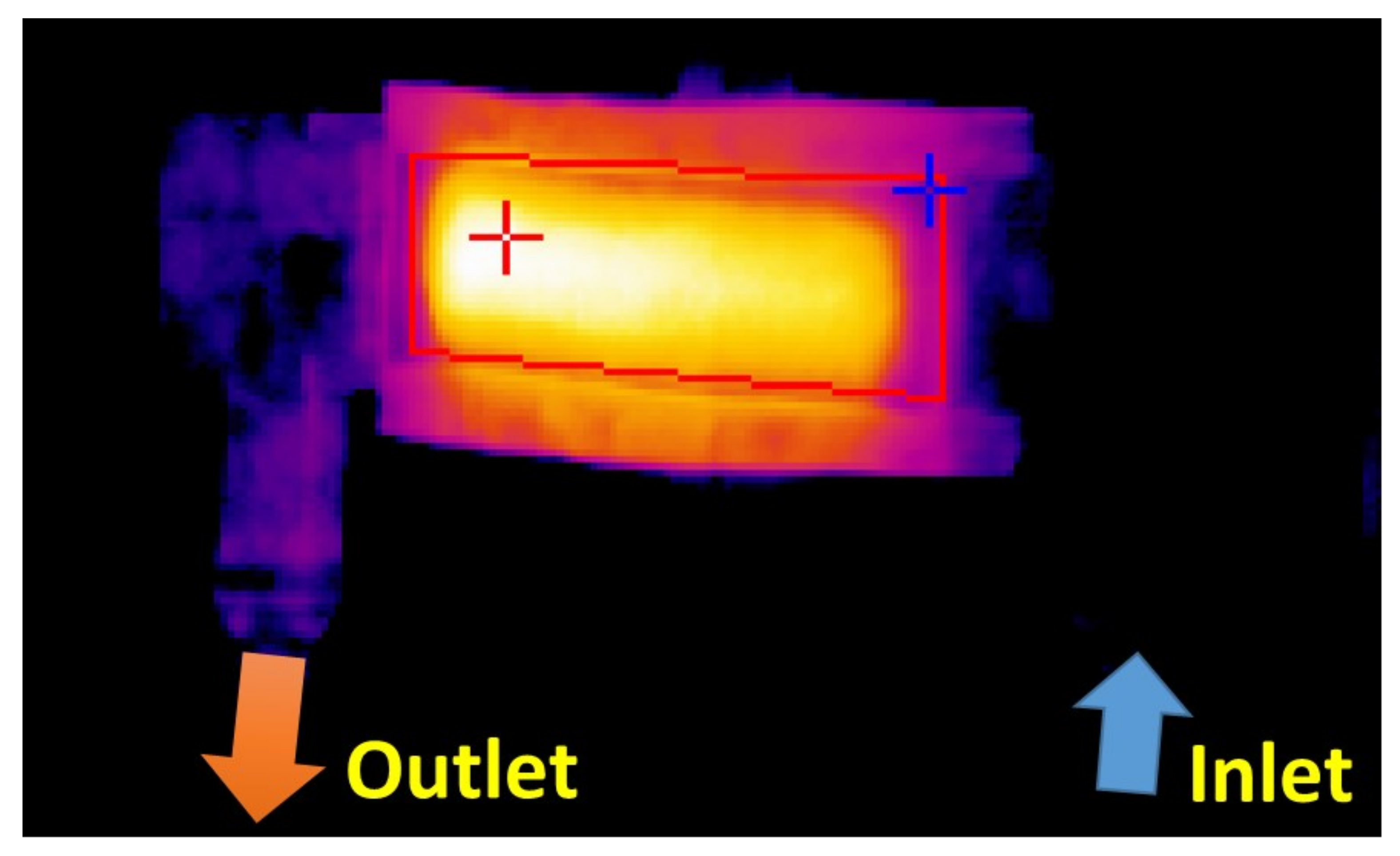

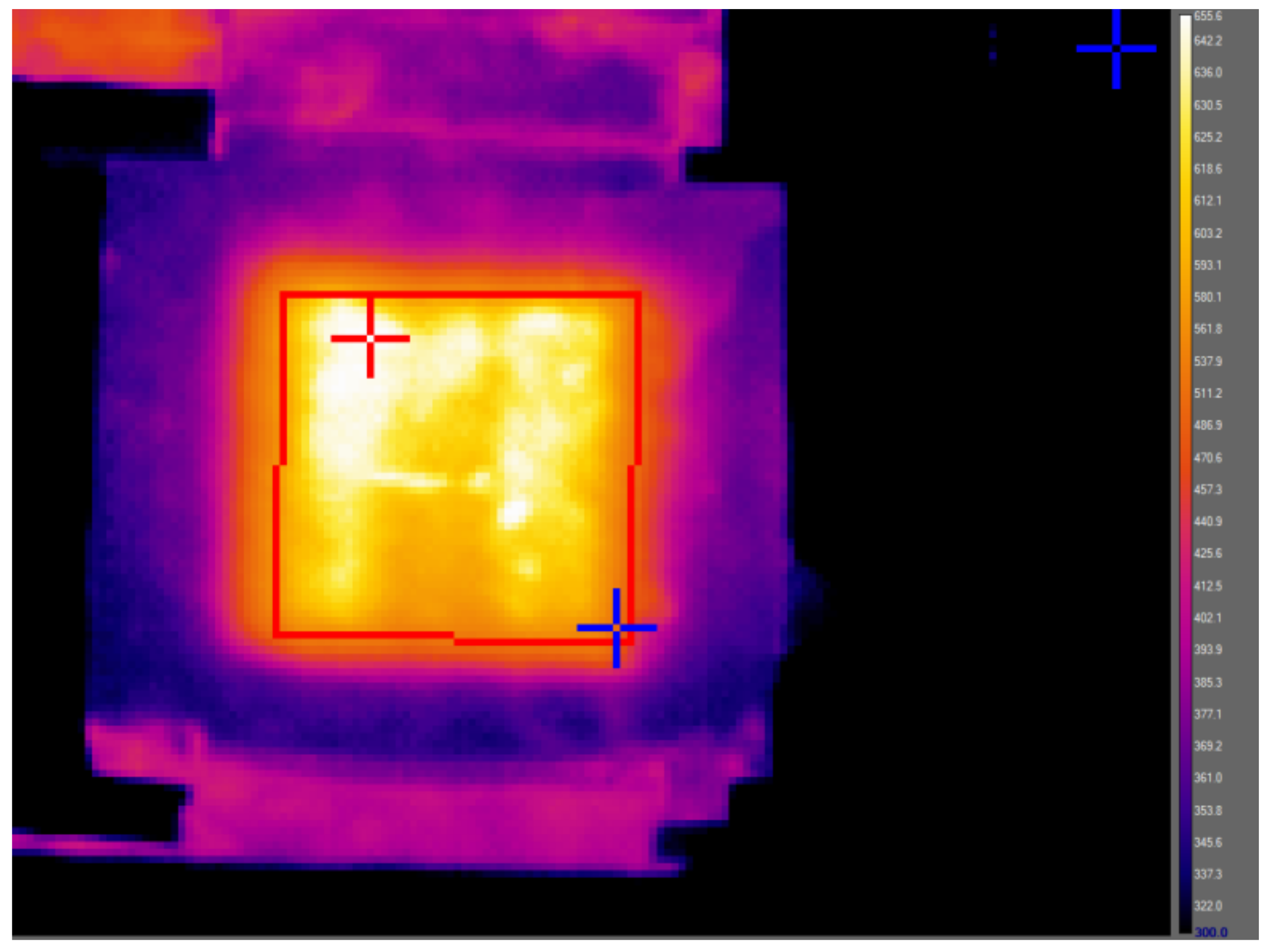

3.3. Mock-Up Temperature Measurement

4. Testing Parameters and Loading Conditions

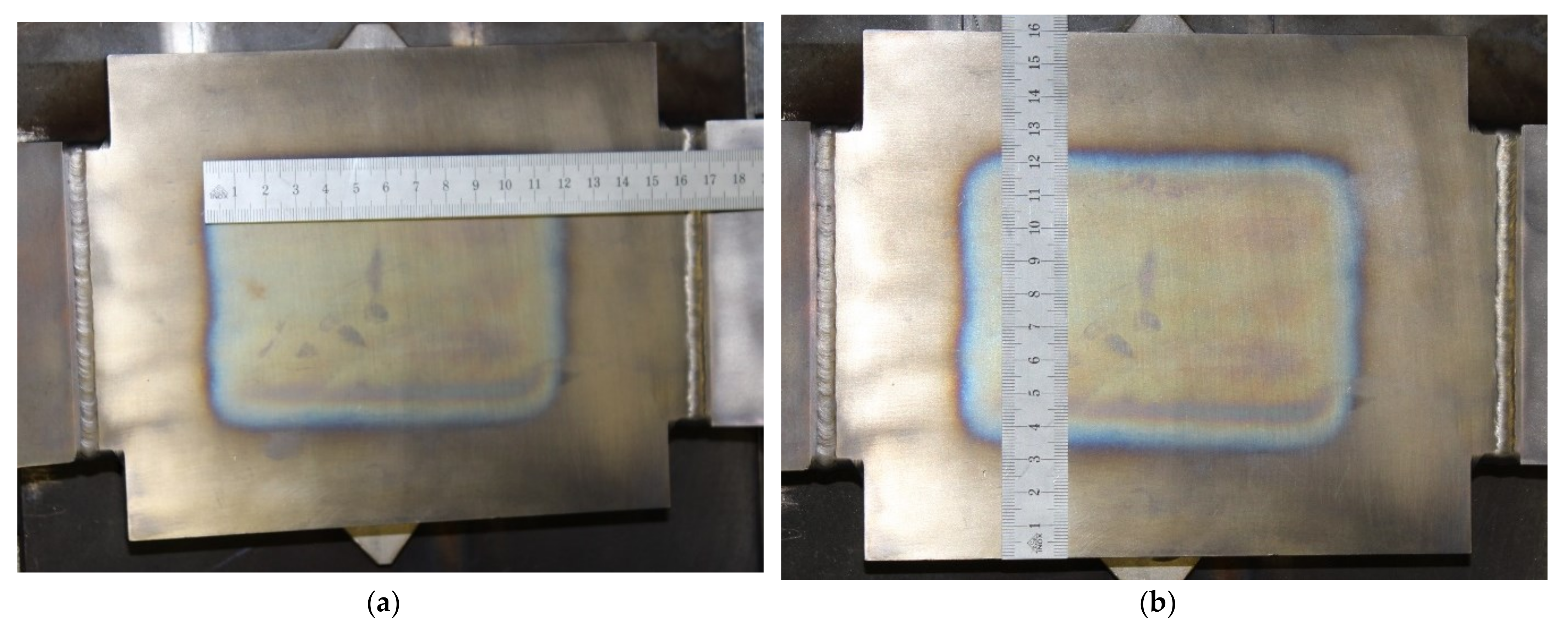

5. Results and Discussion

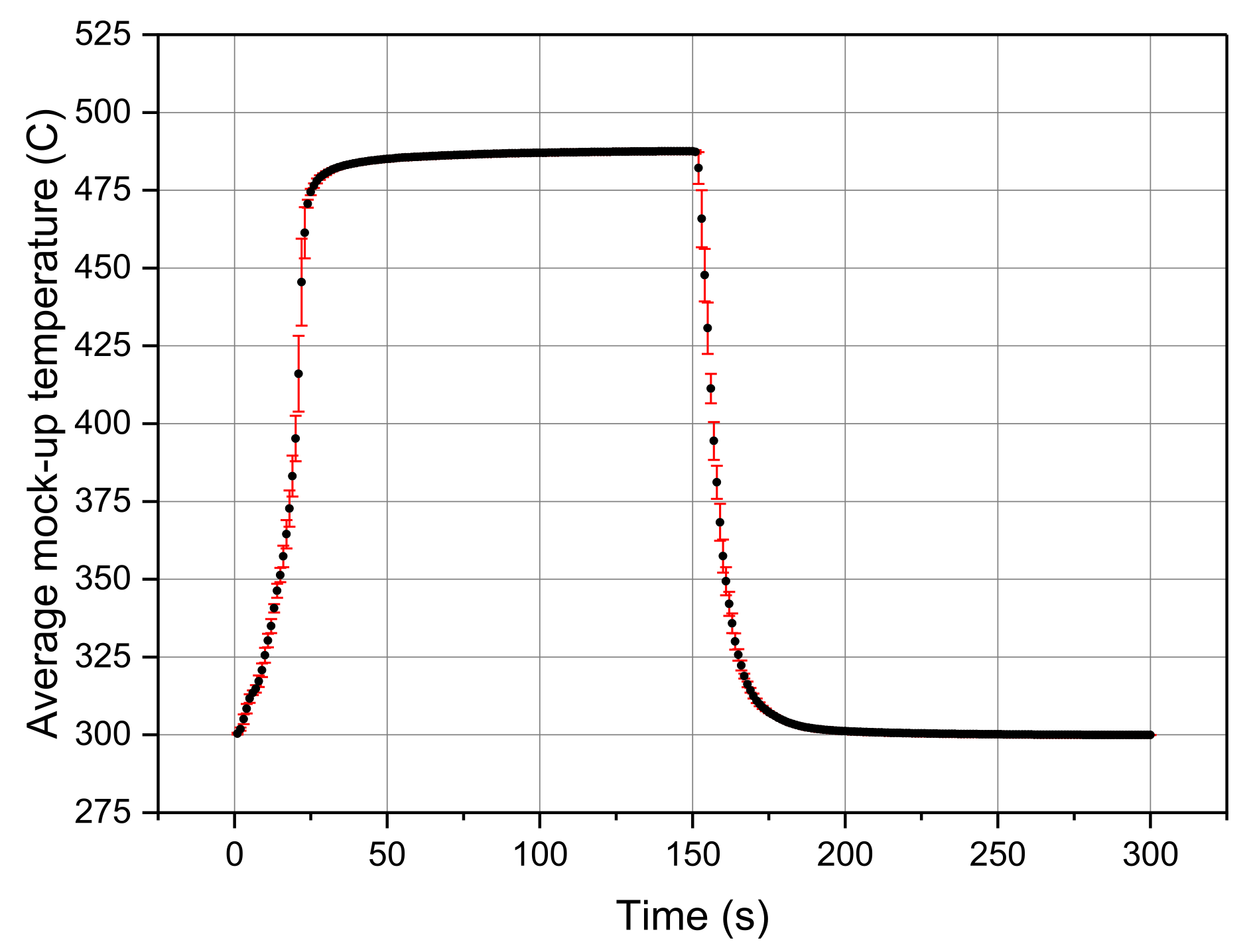

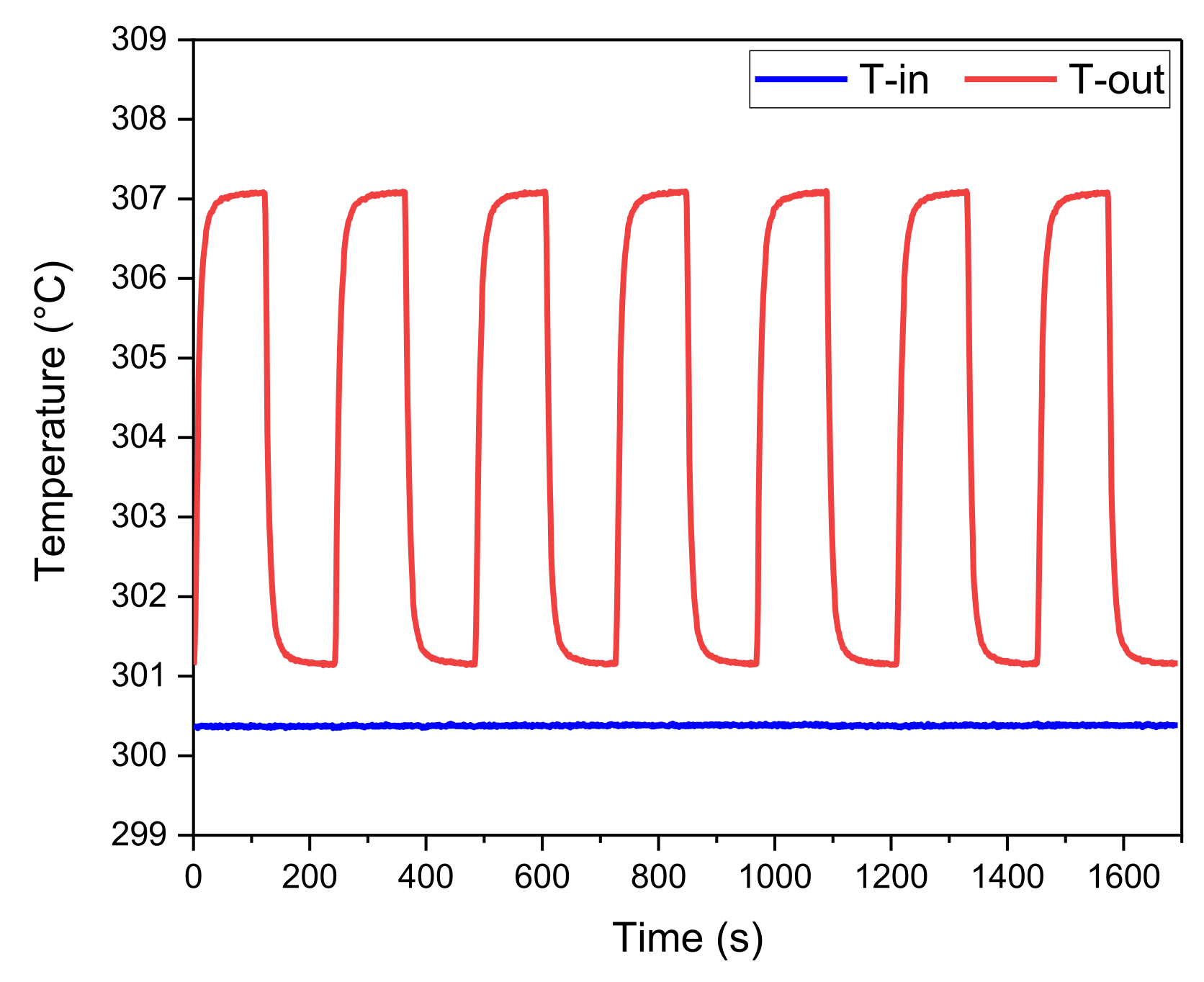

5.1. Results for the FG Mock-Up

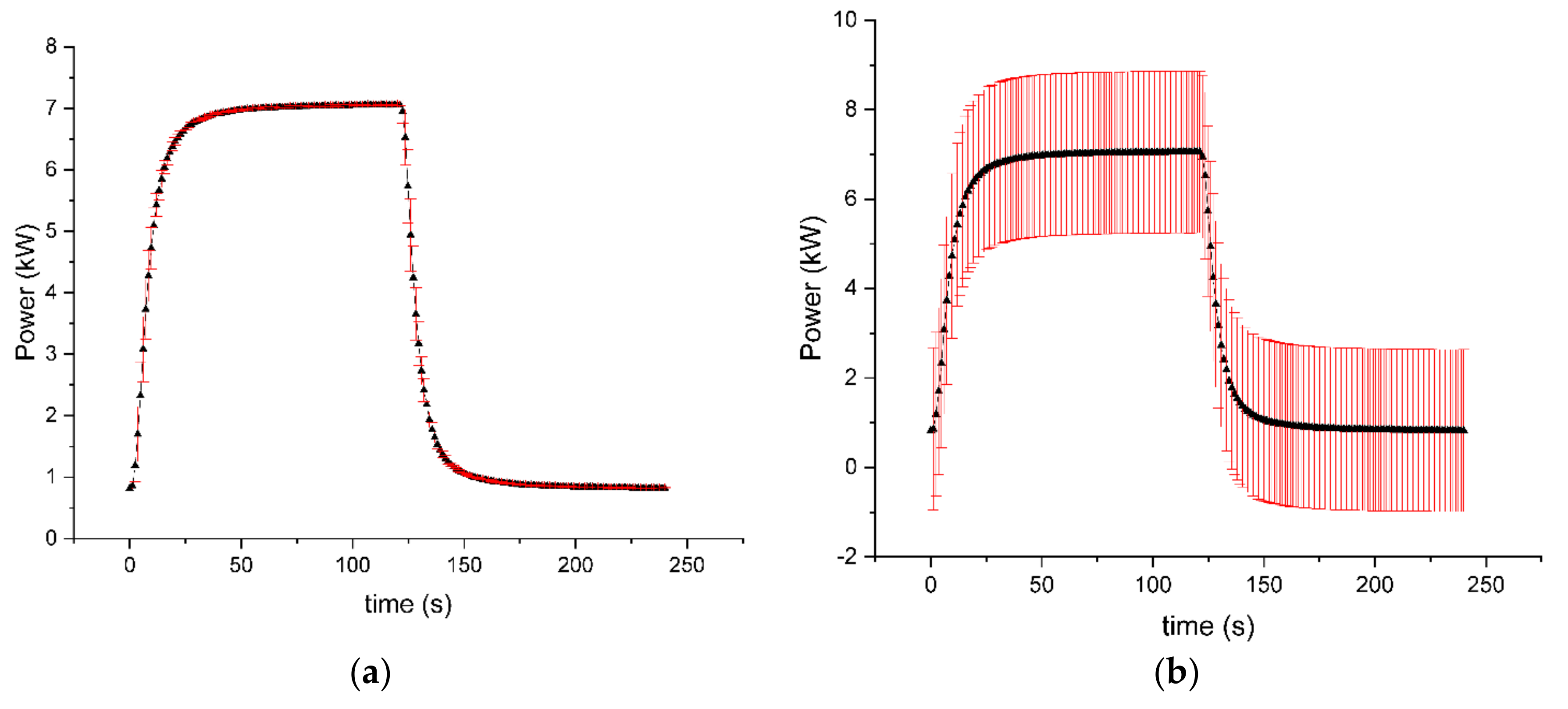

- From the measured data, we compile first typical evolution profiles for the helium mass flow rate , and the mock-up inlet and outlet temperatures, and in a similar way it was carried out for the mock-up thermocouple measurement. Together with the averaged values we also obtain the associated standard deviation, which will give us the measure of the random uncertainty. The associated systematic uncertainties are calculated using the averaged values of the parameters.

- From these averaged profiles, the evolution of the power rise over the mock-up is calculated using the formulawhere Cp is the helium specific heat capacity. Here, for the specific heat capacity (Cp) of helium, we consider a value of 5.195 kJ/kg∙K with an uncertainty of 0.3% according to reference [10]. The associated systematic uncertainty is calculated aswhere , and are the systematic uncertainties calculated in the first step, while . The random uncertainties are obtained using the same formula and taking the corresponding random uncertainties for the mass flow and temperatures, the random uncertainty for the specific heat capacity being taken as zero.

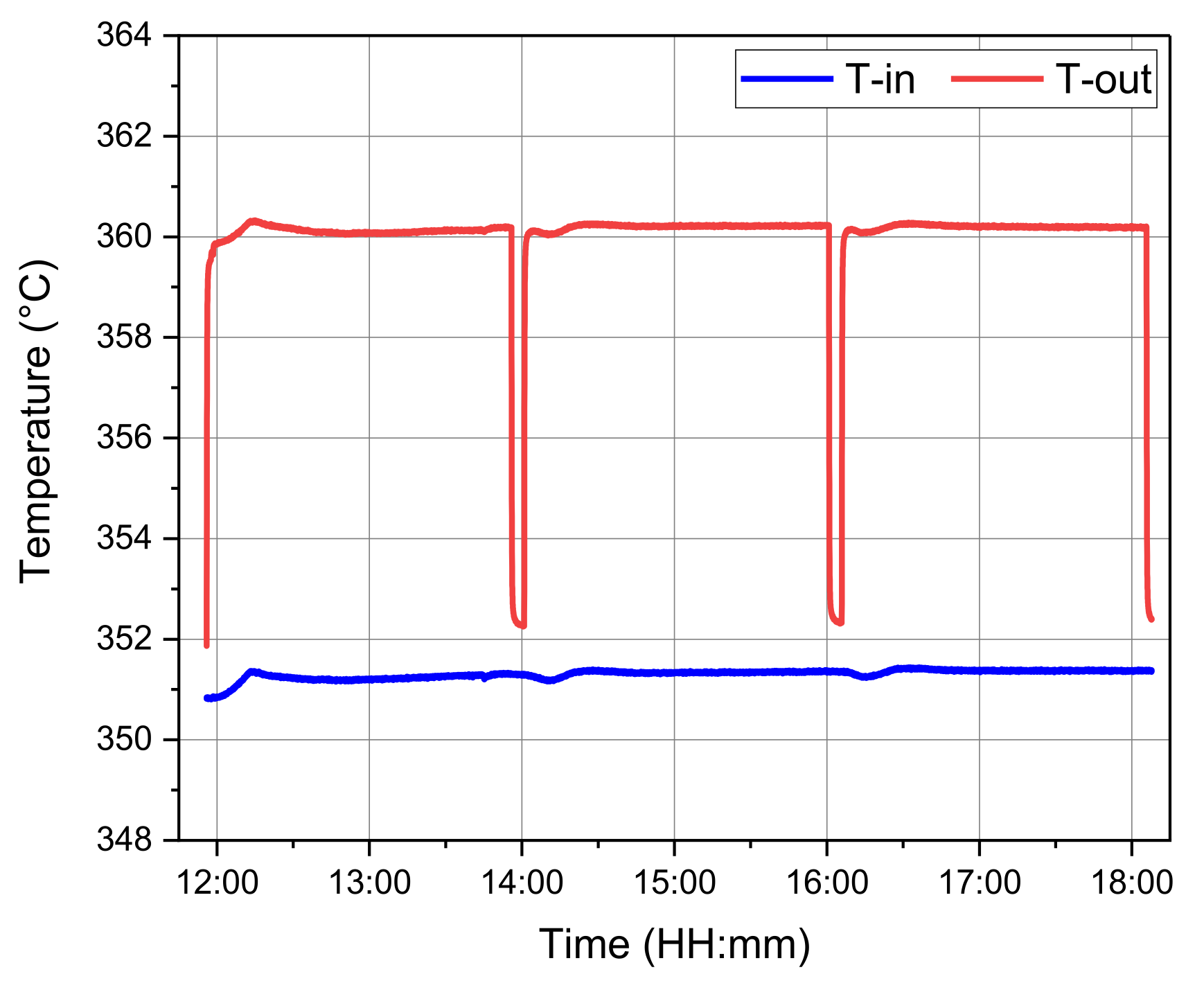

5.2. Results for the ODS Mock-Up

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gräning, T.; Rieth, M.; Hoffmann, J.; Möslang, A. Production, microstructure and mechanical properties of two different austenitic ODS steels. J. Nucl. Mater. 2017, 487, 348–361. [Google Scholar] [CrossRef]

- Emmerich, T.; Qu, D.D.; Vaßen, R.; Aktaa, J. Development of W-coating with functionally graded W/EUROFER-layers for protection of First-Wall materials. Fusion Eng. Des. 2018, 128, 58–67. [Google Scholar] [CrossRef] [Green Version]

- Rieth, M.; Pintsuk, G.; Aiello, G.; Henry, J.; de Carlan, Y.; Ghidersa, B.E.; Neuberger, H.; Rey, J.; Dürrschnabel, M.; Bolich, D.; et al. Impact of materials technology on the Breeding Blanket design—Recent progress and case studies in materials technology. Fusion Eng. Des. 2021, 166, 112275. [Google Scholar] [CrossRef]

- Emmerich, T.; Qu, D.; Ghidersa, B.E.; Lux, M.; Rey, J.; Vaßen, R.; Aktaa, J. Development progress of coating First Wall components with functionally graded W/Eurofer layers on laboratory scale. Nucl. Fusion 2020, 60, 126004. [Google Scholar] [CrossRef]

- Ghidersa, B.E.; Ionescu-Bujor, M.; Janeschitz, G. Helium Loop Karlsruhe (HELOKA): A valuable tool for testing and qualifying ITER components and their He cooling circuits. Fusion Eng. Des. 2006, 81, 1471–1476. [Google Scholar] [CrossRef]

- Jianu, A.; Marchese, V.; Ghidersa, B.E.; Messemer, G.; Ihli, T. HELOKA data acquisition and control system: Current development status. Fusion Eng. Des. 2009, 84, 974–978. [Google Scholar] [CrossRef]

- Ranjithkumar, S.; Yadav, B.K.; Saraswat, A.; Paritosh Chaudhuri, E.; Kumar, R.; Kunze, A.; Ghidersa, B.E. Performance assessment of the Helium cooled First Wall mock-up in HELOKA facility. Fusion Eng. Des. 2020, 150, 111319. [Google Scholar] [CrossRef]

- Fasano, G.; Vio, R. Fitting a straight line with errors on both coordinates. Bull. D’inf. Cent. Donnees Stellaires 1988, 35, 191. [Google Scholar]

- Association Française pour les Règles de Conception, de Construction et Surveillance en Exploitation des Matériels des Chaudières Électro-Nucléaires. RCC-MRx, Design and Construction Rules for Mechanical Components of Nuclear Installations: High Temperature, Research and Fusion Reactors; AFCEN: Courbevoie, France, 2015. [Google Scholar]

- Peterson, H. The Properties of Helium: Density, Specific Heats, Viscosity, and Thermal Conductivity at Pressures from 1 to 100 Bar and from Room Temperature to About 1800k; Risö Report no. 224; Forskningscenter Risoe: Roskilde, Denmark, 1970. [Google Scholar]

| Flow Channel mn1 | Flow Calculated at the Channel Inlet (g/s) | Deviation from Nominal Flow (%) |

|---|---|---|

| Flow CH1 | 38.4 | 4 |

| Flow CH2 | 39.5 | 1.25 |

| Flow CH3 | 41.4 | −3.5 |

| Flow CH4 | 40.2 | −0.5 |

| Flow CH5 | 40.4 | −1 |

| Total | 200.2 | −0.1 |

| Parameter | Sensor/Signal Label | Sensor Type | Range Accuracy |

|---|---|---|---|

| Flow rate | TS-F-011 | Orifice (d = 14.365 mm, β = 0.53921) | - |

| Differential pressure over the flowmeter | TS-DP-F11 | Membrane differential pressure sensor (type SIEMENS Sitrans P DSIII,) | 0 to 5 bar 0.065% from range |

| Pressure before the flowmeter (+tap) | TS-P-F11 | Membrane pressure sensor (type DMP 320 from BD Sensors GmbH) | 0 to 100 bar 0.1% from range |

| Temperature after flowmeter | TS-T-F11 | Thermocouple (type K, class 1) | <1000 °C 0.4% × temperature (in °C) |

| Inlet temperature | TS-T-015 | Thermocouple (type K, class 1) | <1000 °C 0.4% × temperature (in °C) |

| Outlet temperature | TS-T-014 | Thermocouple (type K, class 1) | <1000 °C 0.4% × temperature (in °C) |

| Parameter | Sensor/Sig Sensor/Signal Label | Sensor Type | Range Accuracy |

|---|---|---|---|

| Flow rate | TS-F-022 | Orifice (d = 14.365 mm, β = 0.53921) | - |

| Differential pressure over the flowmeter | TS-DP-F22 | Membrane differential pressure sensor (type Sitrans P DSIII from SIEMENS) | 0 to 5 bar 0.065% from range |

| Pressure before the flowmeter (+tap) | TS-P-F22 | Membrane pressure sensor (type DMP 320 from BD Sensors GmbH) | 0 to 100 bar 0.1% from range |

| Temperature after flowmeter | TS-T-F22 | Thermocouple (type K, class 1) | <1000 °C 0.4% × temperature (in °C) |

| Inlet temperature | TS-T-003 | Thermocouple (type K, class 1) | <1000 °C 0.4% × temperature (in °C) |

| Outlet temperature | TS-T-013 | Thermocouple (type K, class 1) | <1000 °C 0.4% × temperature (in °C) |

| Helium Mass Flow Rate | 170 g/s |

|---|---|

| Helium inlet temperature | 300 °C |

| Helium pressure | 8 MPa |

| Maximum heat flux | 700 kW/m2 |

| Substrate temperature limit | <520 °C |

| Heating on/off time | 150 s/150 s |

| Number of cycles | 1000 |

| Cycles | He Inlet T | Surface T | Heat on/off Time | Est. Heat Flux |

|---|---|---|---|---|

| 100 | 300 °C | 550 °C | 120 s/120 s | 700 kW/m2 |

| 100 | 300 °C | 600 °C | 120 s/120 s | 800 kW/m2 |

| 100 | 350 °C | 650 °C | 120 s/120 s | 900 kW/m2 |

| 7 | 350 °C | 650 °C | 2 h/5 min | 900 kW/m2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghidersa, B.-E.; Abou Sena, A.; Rieth, M.; Emmerich, T.; Lux, M.; Aktaa, J. Experimental Investigation of EU-DEMO Breeding Blanket First Wall Mock-Ups in Support of the Manufacturing and Material Development Programmes. Energies 2021, 14, 7580. https://doi.org/10.3390/en14227580

Ghidersa B-E, Abou Sena A, Rieth M, Emmerich T, Lux M, Aktaa J. Experimental Investigation of EU-DEMO Breeding Blanket First Wall Mock-Ups in Support of the Manufacturing and Material Development Programmes. Energies. 2021; 14(22):7580. https://doi.org/10.3390/en14227580

Chicago/Turabian StyleGhidersa, Bradut-Eugen, Ali Abou Sena, Michael Rieth, Thomas Emmerich, Martin Lux, and Jarir Aktaa. 2021. "Experimental Investigation of EU-DEMO Breeding Blanket First Wall Mock-Ups in Support of the Manufacturing and Material Development Programmes" Energies 14, no. 22: 7580. https://doi.org/10.3390/en14227580

APA StyleGhidersa, B.-E., Abou Sena, A., Rieth, M., Emmerich, T., Lux, M., & Aktaa, J. (2021). Experimental Investigation of EU-DEMO Breeding Blanket First Wall Mock-Ups in Support of the Manufacturing and Material Development Programmes. Energies, 14(22), 7580. https://doi.org/10.3390/en14227580