Research on Economic and Operating Characteristics of Hydrogen Fuel Cell Cars Based on Real Vehicle Tests

Abstract

:1. Introduction

2. Subjects of Study

2.1. Subsection

2.2. Introduction to Test Vehicles A and B’s Onboard Hydrogen Storage Systems

2.3. Onboard Hydrogen Storage Systems of the Test Vehicles

2.3.1. Hydrogen Supply System in Test Vehicle A

2.3.2. Hydrogen Supply System in Test Vehicle B

3. Test Method

3.1. Test Setup

- (1)

- Mount the vehicle on the drum stand;

- (2)

- Pull up the vehicle speed to 60 km/h, warm up the engine for half an hour, and observe the stable water temperature at the outlet of the electric stack (fluctuation ±0.5 °C);

- (3)

- Stop the vehicle, switch the chassis dynamometer to constant speed mode within 3 s, and set the cooling fan airflow to the maximum;

- (4)

- Pull the vehicle speed up to 80 km/h via chassis dynamometer;

- (5)

- Depress the pedal and observe the FCS output power. After stabilizing at the set power ±0.5 kW range, start the timer for 5 min. After the timer is finished, switch to the following working condition and continue the test until the test is complete;

- (6)

- Observe the FCS outlet water temperature during the test. When the FCS outlet temperature exceeds 80 °C, the FCS power should be immediately reduced to 10 kW for cooling until the FCS outlet water temperature drops to 60 °C, and then continue to complete the test.

- (1)

- Fix the vehicle to the chassis dynamometer, and immerse the car for 30 min;

- (2)

- Warm up the vehicle and drive the car on the chassis dynamometer for one completed CLTC-P cycle, after which switch off the car and preset the car for 15 min;

- (3)

- Start recording the CAN signals of the whole vehicle in a frequency of 10 Hz;

- (4)

- Carry out a continuous cycle work test according to the CLTC-P work table, during which parameters such as hydrogen consumption and chassis dynamometer mileage are recorded for each cycle;

- (5)

- Stop after the completion of 13 cycles of testing;

- (6)

- Stop data logging and analyze the data.

3.2. The Steady-State Test

3.2.1. GB/T24554-2009

3.2.2. GB/T35178-2017

- (1)

- The measurement method is as follows:

- (2)

- The test procedure for flow method measurements is as follows:

- (3)

- The test procedure for the pressure-temperature measurement method is as follows:

3.3. The CLTC-P Cycle Test

4. Results and Discussion

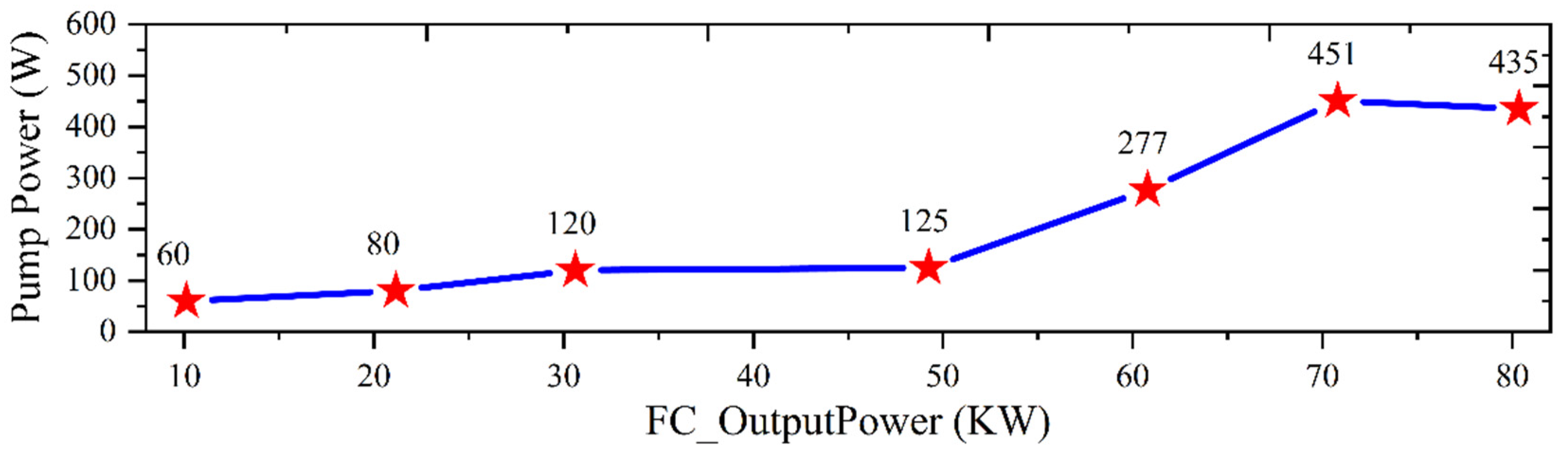

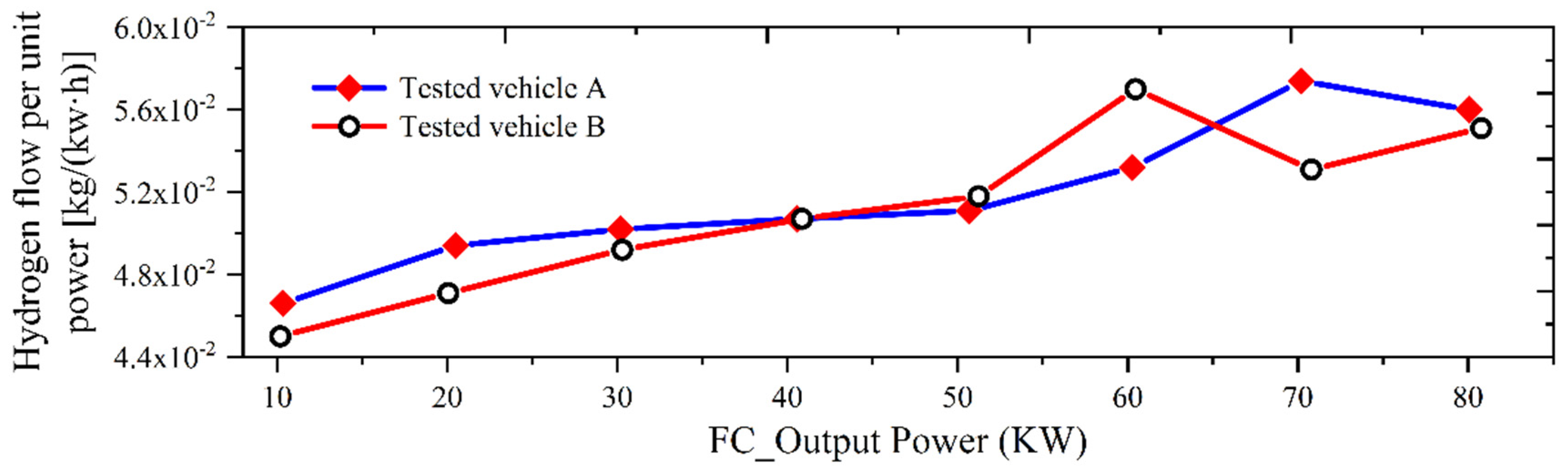

4.1. Comparations of Hydrogen Consumption and Utilization under Steady-State Conditions

4.1.1. Comparative Analysis of Hydrogen Consumption

4.1.2. Comparison of Hydrogen Emission Rates at Steady-State Power

4.1.3. Subsubsection

4.2. Comparisons of Operating Characteristics under CLTC-P Cycle Conditions

4.2.1. Analysis of the Operating Characteristics of Test Vehicle A under Cyclic Conditions

4.2.2. Analysis of Test Vehicle B Operating Characteristics under Cyclic Conditions

4.2.3. Comparative Analysis of the Operating Characteristics of the Two Tested Vehicles

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| CATC | China Automotive Test Cycle |

| CLTC-P | Chinese Vehicle Driving Conditions-Passenger Car |

| FCEV | Fuel cell electric vehicle |

| FCS | Fuel cell stacks |

| NEDC | New European Driving Cycle |

| PEMFC | Proton exchange membrane fuel cell |

| SOC | State of charge |

| WLTP | World Light Vehicle Test Procedure |

References

- Yang, P. Research on key technologies of electric vehicles. Automot. Pract. Technol. 2018, 276, 30–31, 49. [Google Scholar]

- Li, D.; Sha, W.; Wang, F.; Liu, L. Design of a high voltage safety system for electric vehicle based on electric shock and heat control model. J. Automot. Saf. Energy 2018, 9, 215. [Google Scholar]

- Bai, Y.; Zhu, Q.; Zhang, J.; Guo, J.; Dong, H. Research on Key Technologies of New Energy Fuel Cell Electric Vehicle. IOP Conf. Series Earth Environ. Sci. 2021, 804, 042030. [Google Scholar] [CrossRef]

- Toyota Motor Corporation. Car Lineup. Available online: https://toyota.jp/carlineup/?padid¼from_tjptop_menu_carlineup/ (accessed on 15 April 2021). (In Japanese).

- Demirdven, N.; Deutch, J. Hybrid Cars Now, Fuel Cell Cars Later. Science 2004, 305, 974–976. [Google Scholar] [CrossRef] [Green Version]

- Edwards, R.; Mahieu, V.; Griesemann, J.C.; Larivé, J.F.; Rickeard, D.J. Well-to-wheels analysis of future automotive fuels and powertrains in the European context. SAE Trans. 2004, 1, vii. [Google Scholar]

- Wu, G.; More, K.L.; Johnston, C.M.; Zelenay, P. High-performance electrocatalysts for oxygen reduction derived from polyaniline, iron, and cobalt. Science 2011, 332, 443–447. [Google Scholar] [CrossRef] [Green Version]

- Pehnt, M.; Henkel, J. Life cycle assessment of carbon dioxide capture and storage from lignite power plants. Int. J. Greenh. Gas Control. 2009, 3, 49–66. [Google Scholar] [CrossRef]

- Hussain, S.P.; Hofseth, L.J.; Harris, C.C. Radical causes of cancer. Nat. Rev. Cancer 2003, 3, 276–285. [Google Scholar] [CrossRef] [PubMed]

- Evangelisti, S.; Tagliaferri, C.; Brett, D.J.; Lettieri, P. Life cycle assessment of a polymer electrolyte membrane fuel cell system for passenger vehicles. J. Clean. Prod. 2017, 142, 4339–4355. [Google Scholar] [CrossRef]

- Zhu, H.; Yu, Z. Life cycle assessment of hydrogen pathways for fuel cell vehicle. J. Tongji Univ. 2017, 45, 138–143, 151. [Google Scholar]

- Chen, Y.; Ding, Z.; Liu, J.; Ma, J. Life cycle assessment and prediction of proton exchange membrane fuel cell vehicles for 2020. China Mech. Eng. 2018, 29, 2546–2552, 2564. [Google Scholar]

- James, B.D.; Huya-Kouadio, J.M.; Houchins, C.; Desantis, D.A. Mass Production Cost Estimation of Direct H2 PEM Fuel Cell Systems for Transportation Applications: 2017 Update. Strateg. Anal. 2017. [Google Scholar] [CrossRef]

- Brack, P.; Dann, S.E.; Wijayantha, K.G.U.; Adcock, P.; Foster, S.E. A Simple, Low-cost, and Robust System to Measure the Volume of Hydrogen Evolved by Chemical Reactions with Aqueous Solutions. J. Vis. Exp. 2016, e54383. [Google Scholar] [CrossRef] [Green Version]

- Franks, A.; Nevin, K. Microbial Fuel Cells, a Current Review. Energies 2010, 3, 899–919. [Google Scholar] [CrossRef]

- Shafiei, E.; Leaver, J.; Davidsdottir, B. Cost-effectiveness analysis of inducing green vehicles to achieve deep reductions in greenhouse gas emissions in New Zealand. J. Clean. Prod. 2017, 150, 339–351. [Google Scholar] [CrossRef]

- Saygin, D.; Kempener, R.; Wagner, N.; Ayuso, M.; Gielen, D. The Implications for Renewable Energy Innovation of Doubling the Share of Renewables in the Global Energy Mix between 2010 and 2030. Energies 2015, 8, 5828–5865. [Google Scholar] [CrossRef]

- Scataglini, R.; Wei, M.; Mayyas, A.; Chan, S.H.; Lipman, T.; Santarelli, M. A Direct Manufacturing Cost Model for Solid-Oxide Fuel Cell Stacks. Fuel Cells 2017, 17, 825–842. [Google Scholar] [CrossRef]

- Agbossou, K.; Kolhe, M.; Hamelin, J.; Bose, T.K. Performance of a stand-alone renewable energy system based on energy storage as hydrogen. IEEE Trans. Energy Convers. 2004, 19, 633–640. [Google Scholar] [CrossRef]

- Kong, D.; Jun, M.A.; Wang, N. Cost of Ownership Model Based on the Entire Life-cycle For FCVs Consumers. Ind. Eng. Manag. 2009, 14, 81–84. [Google Scholar]

- Yang, Z.; Du, Q.; Jia, Z.; Yang, C.; Xuan, J.; Jiao, K. A comprehensive proton exchange membrane fuel cell system model integrating various auxiliary subsystems. Appl. Energy 2019, 256, 113959. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Z.; Ma, F.; Yang, J.; Xu, X.; Qu, C.; Zhou, Y. Thermal Runaway Prognosis of Battery Systems Using the Modified Multi-Scale Entropy in Real-World Electric Vehicles. IEEE Trans. Transp. Electrif. 2021, 31, 2269–2278. [Google Scholar] [CrossRef]

- Kelouwani, S.; Agbossou, K.; Dubé, Y.; Boulon, L. Fuel cell Plug-in Hybrid Electric Vehicle anticipatory and real-time blended-mode energy management for battery life preservation. J. Power Sources 2013, 221, 406–418. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Z.; Chen, W.; Wang, L.; Lin, P.; Qu, C. Online accurate state of health estimation for battery systems on real-world electric vehicles with variable driving conditions considered. J. Clean. Prod. 2021, 294, 125814. [Google Scholar] [CrossRef]

- Das, H.S.; Tan, C.W.; Yatim, A. Fuel cell hybrid electric vehicles: A review on power conditioning units and topologies. Renew. Sustain. Energy Rev. 2017, 76, 268–291. [Google Scholar] [CrossRef]

- Azidin, F.; Hannan, M.; Mohamed, A. Renewable Energy Technologies and Hybrid Electric Vehicle Challenges. Prz. Elektrotechniczny 2013, 89, 150–156. [Google Scholar]

- Kraa, O.; Ghodbane, H.; Saadi, R.; Ayad, M.; Becherif, M.; Aboubou, A.; Bahri, M. Energy Management of Fuel Cell/Supercapacitor Hybrid Source Based on Linear and Sliding Mode Control. Energy Procedia 2015, 74, 1258–1264. [Google Scholar] [CrossRef] [Green Version]

- Ettihir, K.; Cano, M.H.; Boulon, L.; Agbossou, K. Design of an adaptive EMS for fuel cell vehicles. Int. J. Hydrogen Energy 2017, 42, 1481–1489. [Google Scholar] [CrossRef]

- Robinius, M.; Otto, A.; Syranidis, K.; Ryberg, D.S.; Heuser, P.; Welder, L.; Grube, T.; Markewitz, P.; Tietze, V.; Stolten, D. Linking the Power and Transport Sectors—Part 2: Modelling a Sector Coupling Scenario for Germany. Energies 2017, 10, 957. [Google Scholar] [CrossRef] [Green Version]

- Sorrentino, M.; Adamo, A.; Nappi, G. Optimal Sizing of an rSOC-Based Renewable Microgrid. Energy Procedia 2019, 159, 237–242. [Google Scholar] [CrossRef]

- Aliberti, M.; Arsie, I.; Cricchio, A.; Pianese, C.; Polverino, P.; Sorrentino, M. A Model-based Scenario Analysis for Assessing the Benefits of Fuel Cell Vehicle Hybridization. IFAC-PapersOnLine 2019, 52, 309–315. [Google Scholar] [CrossRef]

- Yu, H.; Yin, J.; Wang, C.; Shen, S.; Yan, X.; Zhang, J. Energy consumption, carbon emission and economy analysis of fuel cell vehicle in China. IOP Conf. Ser. Earth Environ. Sci. 2021, 687, 012191. [Google Scholar] [CrossRef]

- Han, Y.; Chen, W.; Li, Q. Energy Management Strategy Based on Multiple Operating States for a Photovoltaic/Fuel Cell/Energy Storage DC Microgrid. Energies 2017, 10, 136. [Google Scholar] [CrossRef] [Green Version]

- Hong, J.; Wang, Z.; Yao, Y. Fault prognosis of battery system based on accurate voltage abnormity prognosis using long short-term memory neural networks. Appl. Energy 2019, 251, 113381. [Google Scholar] [CrossRef]

- Li, H.-W.; Yan, Y.; Orimo, S.-I.; Züttel, A.; Jensen, C.M. Recent Progress in Metal Borohydrides for Hydrogen Storage. Energies 2011, 4, 185–214. [Google Scholar] [CrossRef]

- Li, Y.; Pei, P.; Wu, Z.; Ren, P.; Jia, X.; Chen, D.; Huang, S. Approaches to avoid flooding in association with pressure drop in proton exchange membrane fuel cells. Appl. Energy 2018, 224, 42–51. [Google Scholar] [CrossRef]

- Chen, D.; Pan, L.; Pei, P.; Huang, S.; Ren, P.; Song, X. Carbon-coated oxygen vacancies-rich Co3O4 nanoarrays grow on nickel foam as efficient bifunctional electrocatalysts for rechargeable zinc-air batteries. Energy 2021, 224, 120142. [Google Scholar] [CrossRef]

| Technical Parameters | Toyota | Honda | Hyundai | |||

|---|---|---|---|---|---|---|

| Product type | TL Power 700 | First- generation fuel cells | Mirai fuel cell | Clarity fuel cell | NEXO fuel cell | ix35 fuel cell |

| Voltage range (V) | / | / | / | / | 250–440 | 255–440 |

| Number of cells | / | 400 | 370 | / | 440 | / |

| Cold start temperature (°C) | 270.15 K | −30 | −30 | −30 | −30 | / |

| Peak power (kW) | / | 114 | 128 | 100 | 135 | / |

| Rated power (kW) | 101 | / | / | / | / | / |

| Power density (kW/L) | 4.9 | 3500 | 5.4 | 3.1 | 3.1 | / |

| Protection class | IP67 | / | / | / | / | / |

| Maximum efficiency | 56% | / | / | / | 60% | / |

| Battery weight (kg) | 142 | 108 | 56 | / | 142 | / |

| Subitem | Percentage (%) |

|---|---|

| Membrane and catalyst | 45 |

| Bipolar plate | 20 |

| Accessory | 19 |

| Proton exchange membrane | 10 |

| Gas diffuse layer | 6 |

| Hydrogen Production Process | Hydrogen Production Cost (RMB/kg) | Carbon Emission Intensity (kg/kg) |

|---|---|---|

| Hydrogen from coal | 10.67 | 22.00 |

| Hydrogen from natural gas | 13.44 | 4.80 |

| Hydrogen from methanol | 19.45 | 8.25 |

| Hydrogen production from electrolytic water (thermal power) | 22.9 | 51.50 |

| Hydrogen production from renewable energy electrolysis | 13.07 | 0.00 |

| Name | Specified Accuracy | Note |

|---|---|---|

| Voltage Sensor | ≤0.5% FS | / |

| Current sensor | ≤0.5% FS | / |

| Thermometer | ±1 C | / |

| Humidity meter | ±3% | / |

| Hydrogen flow meter | ≤1% | According to the relative error |

| Coolant flow meter | ≤1% FS | / |

| Weighing scales | ≤0.5% FS | / |

| Parameters | Unit | Accuracy |

|---|---|---|

| Temperature | K | ±1 |

| Gas pressure | Mpa | ±1% |

| Mass | g | ±0.5 |

| Volumetric flow rate | L/s | ±1% |

| Mass flow rate | g/s | ±1% |

| Features | Overall | Part 1 | Part 2 | Part 3 |

|---|---|---|---|---|

| Running time/s | 1800 | 674 | 693 | 433 |

| Mileage/km | 14.48 | 2.45 | 5.91 | 6.12 |

| Maximum speed/(km/h) | 114.00 | 48.10 | 71.20 | 144.00 |

| Maximum acceleration/(m/s2) | 1.47 | 1.47 | 1.44 | 1.06 |

| Maximum deceleration/(m/s2) | −1.47 | −1.42 | −1.47 | −1.46 |

| Average speed/(km/h) | 28.96 | 13.09 | 30.68 | 50.90 |

| Average running speed/(km/h) | 37.18 | 20.20 | 38.24 | 53.89 |

| Average acceleration/(m/s2) | 0.45 | 0.42 | 0.46 | 0.46 |

| Average deceleration/(m/s2) | −0.49 | −0.45 | −0.50 | −0.54 |

| Relative positive acceleration/(m/s2) | 0.17 | 0.14 | 0.16 | 0.18 |

| Acceleration ratio/% | 28.78 | 22.55 | 30.45 | 35.80 |

| Deceleration ratio/% | 26.44 | 21.51 | 28.43 | 30.95 |

| Uniformity ratio/% | 22.67 | 20.77 | 21.36 | 27.71 |

| Idle speed ratio/% | 22.11 | 35.16 | 19.77 | 5.54 |

| Set Power (kW) | Test Vehicle A | Test Vehicle B | ||||

|---|---|---|---|---|---|---|

| Actual Power (kW) | Actual Hydrogen Mass Flow Rate (kg/h) | Actual Hydrogen Flow Rate per Unit Power [kg/(kW·h)] | Actual Power (kW) | Actual Hydrogen Flow Rate (kg/h) | Actual Hydrogen Flow Rate per Unit Power [kg/(kW·h)] | |

| 10 | 10.3472 | 0.4821 | 0.0466 | 10.1839 | 0.4579 | 0.0450 |

| 20 | 20.4949 | 1.0127 | 0.0494 | 20.0545 | 0.9444 | 0.0471 |

| 30 | 30.1725 | 1.5160 | 0.0502 | 30.2895 | 1.4900 | 0.0492 |

| 40 | 40.5500 | 2.0549 | 0.0507 | 40.8430 | 2.0707 | 0.0507 |

| 50 | 50.6707 | 2.5871 | 0.0511 | 51.2121 | 2.6524 | 0.0518 |

| 60 | 60.2494 | 3.2075 | 0.0532 | 60.4346 | 3.4451 | 0.0570 |

| 70 | 70.1754 | 4.0295 | 0.0574 | 70.7718 | 3.7589 | 0.0531 |

| 80 | 80.0496 | 4.4795 | 0.0560 | 80.7534 | 4.4532 | 0.0551 |

| Set Power (kW) | Actual Power (kW) | Actual Hydrogen Flow Rate (kg/h) | Theoretical Hydrogen Flow Rate (kg/h) | Hydrogen Emissions (kg/h) | Hydrogen Emission Rate [g/(kW·h)] | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vehicle A | Vehicle B | Vehicle A | Vehicle B | Vehicle A | Vehicle B | Vehicle A | Vehicle B | Vehicle A | Vehicle B | |

| 10 | 10.3472 | 10.1839 | 0.4821 | 0.4579 | 0.4742 | 0.4575 | 0.0079 | 0.00036 | 0.7606 | 0.0003 |

| 20 | 20.4949 | 20.0545 | 1.0127 | 0.9444 | 0.9935 | 0.9425 | 0.0192 | 0.00192 | 0.9449 | 0.0016 |

| 30 | 30.1725 | 30.2895 | 1.5160 | 1.4900 | 1.5100 | 1.4828 | 0.0060 | 0.00712 | 0.1843 | 0.0057 |

| 40 | 40.5500 | 40.8430 | 2.0549 | 2.0707 | 2.0517 | 2.0536 | 0.0032 | 0.01709 | 0.1401 | 0.0182 |

| 50 | 50.6707 | 51.2121 | 2.5871 | 2.6524 | 2.5795 | 2.6307 | 0.0076 | 0.02167 | 0.1325 | 0.0226 |

| 60 | 60.2494 | 60.4346 | 3.2075 | 3.4451 | 3.2001 | 3.1572 | 0.0074 | 0.28790 | 0.1231 | 0.3944 |

| 70 | 70.1754 | 70.7718 | 4.0295 | 3.7589 | 4.0165 | 3.7448 | 0.0130 | 0.01409 | 0.1845 | 0.0235 |

| 80 | 80.0496 | 80.7534 | 4.4795 | 4.4532 | 4.4585 | 4.3253 | 0.0210 | 0.12784 | 0.5413 | 0.2465 |

| Set Power (kW) | Test Vehicle A | Test Vehicle B | ||

|---|---|---|---|---|

| Actual Power (kW) | The Ratio of the Opening Time of the Hydrogen Discharge Valve | Actual Power (kW) | The Ratio of the Opening Time of the Hydrogen Discharge Valve | |

| 10 | 10.3472 | 0.0215 | 10.1839 | 0.0054 |

| 20 | 20.4949 | 0.0116 | 20.0545 | 0.0067 |

| 30 | 30.1725 | 0.0583 | 30.2895 | 0.0073 |

| 40 | 40.5500 | 0.1381 | 40.8430 | 0.0080 |

| 50 | 50.6707 | 0.2515 | 51.2121 | 0.0084 |

| 60 | 60.2494 | 0.3632 | 60.4346 | 0.0088 |

| 70 | 70.1754 | 0.5773 | 70.7718 | 0.0097 |

| 80 | 80.0496 | 0.6218 | 80.7534 | 0.0150 |

| Cycle Number | Cycle Mileage (kM) | Actual Hydrogen Consumption (g) | Actual Hydrogen Consumption per Unit Mileage (g/kM) | Theoretical Hydrogen Consumption (g) | Theoretical Hydrogen Consumption per Unit Mileage (g/kM) | Hydrogen Emission Rate (g/(kW·h)) | Percentage of Time Hydrogen Discharge Valve Is Open |

|---|---|---|---|---|---|---|---|

| Average value | 14.4 | 141.1147 | 9.7723 | 136.7344 | 9.4700 | 1.556 | 2.79% |

| 1 | 14.6 | 141.6526 | 9.7022 | 138.5345 | 9.4887 | 1.106 | 2.88% |

| 2 | 14.4 | 140.7565 | 9.7748 | 135.1728 | 9.387 | 1.988 | 2.67% |

| 3 | 14.5 | 142.3718 | 9.8187 | 138.5345 | 9.5541 | 1.381 | 2.81% |

| 4 | 14.5 | 142.9743 | 9.8603 | 138.3585 | 9.542 | 1.628 | 2.76% |

| 5 | 14.4 | 146.4122 | 10.1667 | 142.3807 | 9.8876 | 1.376 | 2.89% |

| 6 | 14.6 | 144.7451 | 9.911 | 140.7070 | 9.6375 | 1.382 | 2.53% |

| 7 | 14.3 | 143.6235 | 10.042 | 139.7469 | 9.7725 | 1.351 | 2.68% |

| 8 | 14.4 | 134.8275 | 9.3611 | 130.6854 | 9.0754 | 1.525 | 2.63% |

| 9 | 14.4 | 138.3347 | 9.6042 | 133.9542 | 9.3024 | 1.578 | 2.77% |

| 10 | 14.4 | 137.3234 | 9.5347 | 132.5717 | 9.2064 | 1.735 | 2.77% |

| 11 | 14.4 | 146.1787 | 10.1458 | 141.3862 | 9.8185 | 1.621 | 3.11% |

| 12 | 14.4 | 137.8389 | 9.5694 | 132.6882 | 9.2145 | 1.868 | 2.82% |

| 13 | 14.4 | 137.4522 | 9.5451 | 132.8261 | 9.2240 | 1.694 | 2.92% |

| Cycle Number | Cycle Mileage (kM) | Actual Hydrogen Consumption (g) | Actual Hydrogen Consumption per Unit Mileage (g/kM) | Theoretical Hydrogen Consumption (g) | Theoretical Hydrogen Consumption per Unit Mileage (g/kM) | Hydrogen Emission Rate (g/(kW·h)) | Percentage of Time Hydrogen Discharge Valve Is Open |

|---|---|---|---|---|---|---|---|

| Average value | 14.4 | 119.0038 | 8.2772 | 106.7597 | 7.4270 | 5.3967 | 0.68% |

| 1 | 14.5 | 118.7670 | 8.1908 | 118.0480 | 8.1412 | 0.2762 | 0.81% |

| 2 | 14.4 | 135.7284 | 9.4256 | 112.2915 | 7.798 | 9.4737 | 0.66% |

| 3 | 14.3 | 137.3309 | 9.6036 | 104.4185 | 7.302 | 14.2604 | 0.60% |

| 4 | 14.3 | 91.6100 | 6.4063 | 107.5723 | 7.5225 | −6.7434 | 0.64% |

| 5 | 14.4 | 122.9383 | 8.5374 | 112.5401 | 7.8153 | 4.198 | 0.66% |

| 6 | 14.3 | 115.3396 | 8.0657 | 109.5605 | 7.6616 | 2.4043 | 0.68% |

| 7 | 14.5 | 121.1332 | 8.354 | 98.4284 | 6.7882 | 10.4742 | 1.20% |

| 8 | 14.4 | 118.0258 | 8.1962 | 103.2147 | 7.1677 | 6.5477 | 0.59% |

| 9 | 14.4 | 95.7630 | 6.6502 | 107.7721 | 7.4842 | −5.0496 | 0.58% |

| 10 | 14.2 | 124.8953 | 8.7954 | 109.5134 | 7.7122 | 6.378 | 0.58% |

| 11 | 14.5 | 113.0234 | 7.79472 | 99.2022 | 6.8415 | 6.3453 | 0.56% |

| 12 | 14.5 | 135.6756 | 9.3569 | 97.2594 | 6.7075 | 17.906 | 0.58% |

| 13 | 14.2 | 116.8191 | 8.2267 | 108.0544 | 7.6095 | 3.6866 | 0.70% |

| 14 | 186.9 | 1476.6712 | 7.9009 | 1387.8756 | 7.4257 | 2.9063 | 0.68% |

| Honda CLARITY | Toyota Mirai I | Toyota Mirai II | Hyundai NEXO | BYD HAN | GAC AION S | |

|---|---|---|---|---|---|---|

| Fuel cell power (kW) | 103 | 114 | 128 | 95 | / | / |

| Total power (kW) | 130 | 114 | 134 | 135 | 363 | 162 |

| Torque (NM) | 300 | 335 | 300 | 395 | 680 | 350 |

| Acceleration (s) (0–100 km/h) | 8.8 | 10 | / | 9.7 | 3.9 | 6.8 |

| Range | 589 (EPA) | 502 (EPA) | 850 (WLTC) | 754 (NEDC) | 505 (NEDC) | 602 (NEDC) |

| Hydrogen storage | 141 L | 4.6 kg | 5.6 kg | 6.33 kg | / | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Z.; Zhang, L.; Feng, L.; Yu, S.; Jiang, Z.; Xu, X.; Hong, J. Research on Economic and Operating Characteristics of Hydrogen Fuel Cell Cars Based on Real Vehicle Tests. Energies 2021, 14, 7856. https://doi.org/10.3390/en14237856

Duan Z, Zhang L, Feng L, Yu S, Jiang Z, Xu X, Hong J. Research on Economic and Operating Characteristics of Hydrogen Fuel Cell Cars Based on Real Vehicle Tests. Energies. 2021; 14(23):7856. https://doi.org/10.3390/en14237856

Chicago/Turabian StyleDuan, Zhijie, Luo Zhang, Lili Feng, Shuguang Yu, Zengyou Jiang, Xiaoming Xu, and Jichao Hong. 2021. "Research on Economic and Operating Characteristics of Hydrogen Fuel Cell Cars Based on Real Vehicle Tests" Energies 14, no. 23: 7856. https://doi.org/10.3390/en14237856

APA StyleDuan, Z., Zhang, L., Feng, L., Yu, S., Jiang, Z., Xu, X., & Hong, J. (2021). Research on Economic and Operating Characteristics of Hydrogen Fuel Cell Cars Based on Real Vehicle Tests. Energies, 14(23), 7856. https://doi.org/10.3390/en14237856