Experimental Validation of a Dynamic Photovoltaic/Thermal Collector Model in Combination with a Thermal Energy Storage Tank

Abstract

:1. Introduction

1.1. Literature Review of Existing Studies

1.2. Aims and Specifics of the Current Research

2. Materials and Methods

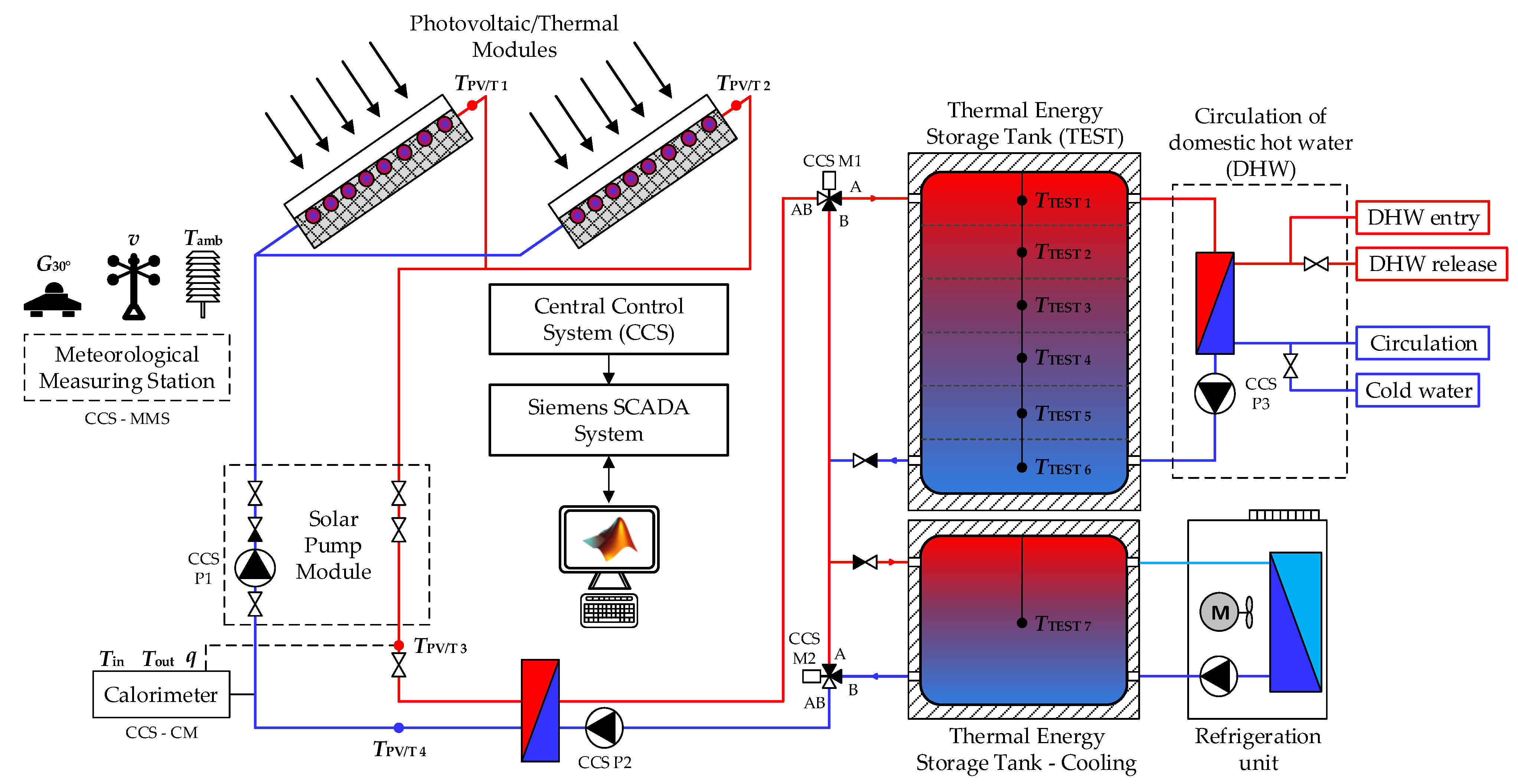

2.1. Experimental Set-Up

- TPV/T 1 or TPV/T 2 > TTEST 1 = M1-A & M2-A + P1 & P2 (ON)

- TPV/T 4 ≥ 75 °C = M1-B & M2-A+B

- TPV/T 4 ≥ 90 °C = P1 (OFF)

- TPV/T 1 or TPV/T 2 ≥ 80 °C = refrigeration unit (ON)

- TTEST 1 ≥ 75 °C = refrigeration unit (ON)

- or TTEST 1 ≥ 75 °C = DHW release (ON)

- TPV/T 1 or TPV/T 2 < TTEST 1 = M1-A & M2-A + P1 & P2 (ON)

2.2. Model Setup

2.3. Dynamic Model of the Photovoltaic/Thermal Collector

2.3.1. Electric Model of the Photovoltaic/Thermal Collector

2.3.2. Thermal Model of the Photovoltaic/Thermal Collector

2.4. Dynamic Model of the Thermal Energy Storage Tank

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Con sent Statement:

Acknowledgments

Conflicts of Interest

Nomenclature

| ANN | artificial neural network |

| CCS | central control system |

| DHW | domestic hot water |

| EVA | ethylene-vinyl acetate |

| MAPE | mean absolute percentage error |

| MPP | maximum power point |

| MPPT | maximum power point tracking |

| NOCT | nominal operating cell temperature |

| nRMSE | normalized root mean square error |

| PCM | phase change material |

| PV | photovoltaic |

| PV/T | photovoltaic/thermal |

| PVF | polyvinyl fluoride |

| STC | standard test condition |

| TEST | thermal energy storage tank |

| TR-BDF2 | trapezoidal rule with second order backward difference formula |

| Quantities used in equations: | |

| Ac,i | cross-sectional area of the i-th layer of the TEST (m2) |

| As,i | inner surface of the i-th layer of the TEST (m2) |

| C | specific heat (J/kgK) |

| d | thickness (m) |

| D | heat exchanger pipe diameter (m) |

| Eg0 | bandwidth of cell material (eV) |

| F | view factor |

| G | solar radiation (W/m2) |

| GSTC | solar radiation at STC (W/m2) |

| h | conductive heat transfer coefficient (W/m2K) |

| I01 | reverse saturation current of the first diode (A) |

| I02 | reverse saturation current of the second diode (A) |

| IMPP,STC | current at maximum power point under STC conditions (A) |

| Iph | photo-generated current (A) |

| ISC | short-circuit current (A) |

| ISC,STC | short-circuit current under STC conditions (A) |

| K | Boltzmann constant (1.38065 × 1023 J/K) |

| k | thermal conductivity (W/mK) |

| n | number of observations |

| n1 | the diode ideality factor of the first diode |

| n2 | the diode ideality factor of the second diode |

| NS | number of series-connected PV cells |

| m | mass flow (kg/s) |

| M | mass of the working medium inside TEST (kg) |

| P | output power (W) |

| q | electron charge (1.602 × 1019 C) |

| qf | thermal conduction of the working medium (W/mK) |

| qtotal | total thermal conduction (W/mK) |

| qwall | thermal conduction of the TEST wall (W/mK) |

| Pr | Prandtl number |

| Rs | series resistance (Ω) |

| Rsh | shunt resistance (Ω) |

| T | temperature (°C) |

| Ta | ambient temperature (°C) |

| TPV/T | temperature of the PV/T module (°C) |

| TTEST | temperature of the TEST (°C) |

| v | wind speed (m/s) |

| VMPP,STC | voltage at maximum power point under STC conditions (V) |

| VOC | open-circuit voltage (V) |

| VOC,STC | open-circuit voltage under STC conditions (V) |

| VT1 | thermal voltage of the first diode (V) |

| VT2 | thermal voltage of the second diode (V) |

| ymeas | measured values |

| ymodel | modeled values |

| αo | absorptivity |

| αPV | temperature coefficient of ISC (%/°C) |

| βPV | temperature coefficient of VOC (%/°C) |

| γPV | temperature coefficient of PMPP (%/°C) |

| ε | emissivity |

| ρ | density (kg/m3) |

| ρo | reflectivity |

| τo | transmissivity |

| ν | kinematic viscosity (mm2/s) |

References

- Libra, M.; Petrík, T.; Poulek, V.; Tyukhov, I.I.; Kouřím, P. Changes in the Efficiency of Photovoltaic Energy Conversion in Temperature Range with Extreme Limits. IEEE J. Photovolt. 2021, 11, 1479–1484. [Google Scholar] [CrossRef]

- Buonomano, A.; de Luca, G.; Figaj, R.D.; Vanoli, L. Dynamic simulation and thermo-economic analysis of a PhotoVoltaic/Thermal collector heating system for an indoor-outdoor swimming pool. Energy Convers. Manag. 2015, 99, 176–192. [Google Scholar] [CrossRef]

- Arkar, C.; Žižak, T.; Domjan, S.; Medved, S. Dynamic parametric models for the holistic evaluation of semi-transparent photovoltaic/thermal façade with latent storage inserts. Appl. Energy 2020, 280, 115994. [Google Scholar] [CrossRef]

- Barbu, M.; Darie, G.; Siroux, M. Analysis of a residential photovoltaic-thermal (PVT) system in two similar climate conditions. Energies 2019, 12, 3595. [Google Scholar] [CrossRef] [Green Version]

- Chow, T.T. Performance analysis of photovoltaic-thermal collector by explicit dynamic model. Sol. Energy 2003, 75, 143–152. [Google Scholar] [CrossRef]

- Hu, H.; Wang, R.; Fang, G. Dynamic characteristics modeling of a hybrid photovoltaic-thermal heat pump system. Int. J. Green Energy 2010, 7, 537–551. [Google Scholar] [CrossRef]

- Salameh, T.; Tawalbeh, M.; Juaidi, A.; Abdallah, R.; Hamid, A.K. A novel three-dimensional numerical model for PV/T water system in hot climate region. Renew. Energy 2021, 164, 1320–1333. [Google Scholar] [CrossRef]

- Sakellariou, E.; Axaopoulos, P. Simulation and experimental performance analysis of a modified PV panel to a PVT collector. Sol. Energy 2017, 155, 715–726. [Google Scholar] [CrossRef]

- Shahsavar, A.; Ameri, M. Experimental investigation and modeling of a direct-coupled PV/T air collector. Sol. Energy 2010, 84, 1938–1958. [Google Scholar] [CrossRef]

- Dubey, S.; Tiwari, G.N. Analysis of PV/T flat plate water collectors connected in series. Sol. Energy 2009, 83, 1485–1498. [Google Scholar] [CrossRef]

- Tonui, J.K.; Tripanagnostopoulos, Y. Performance improvement of PV/T solar collectors with natural air flow operation. Solar Energy 2008, 82, 1–12. [Google Scholar] [CrossRef]

- Tonui, J.K.; Tripanagnostopoulos, Y. Air-cooled PV/T solar collectors with low-cost performance improvements. Sol. Energy 2007, 81, 498–511. [Google Scholar] [CrossRef]

- Misha, S.; Abdullah, A.L.; Tamaldin, N.; Rosli, M.A.M.; Sachit, F.A. Simulation CFD and experimental investigation of PVT water system under natural Malaysian weather conditions. Energy Rep. 2020, 6, 28–44. [Google Scholar] [CrossRef]

- Sami, S. Modeling and Simulation of a Novel Combined Solar Photovoltaic-Thermal Panel and Heat Pump Hybrid System. Clean Technol. 2018, 1, 7. [Google Scholar] [CrossRef] [Green Version]

- Shan, F.; Tang, F.; Cao, L.; Fang, G. Comparative simulation analyses on dynamic performances of photovoltaic-thermal solar collectors with different configurations. Energy Convers. Manag. 2014, 87, 778–786. [Google Scholar] [CrossRef]

- Touafek, K.; Haddadi, M.; Malek, A. Modeling and experimental validation of a new hybrid photovoltaic thermal collector. IEEE Trans. Energy Convers. 2011, 26, 176–183. [Google Scholar] [CrossRef]

- Amrizal, N.; Chemisana, D.; Rosell, J.I. Hybrid photovoltaic-thermal solar collectors dynamic modeling. Appl. Energy 2013, 101, 797–807. [Google Scholar] [CrossRef]

- Amrizal, N.; Chemisana, D.; Rosell, J.I.; Barrau, J. A dynamic model based on the piston flow concept for the thermal characterization of solar collectors. Appl. Energy 2012, 94, 244–250. [Google Scholar] [CrossRef]

- Ciabattoni, L.; Ippoliti, G.; Longhi, S. Experimental validation of a dynamic linear model of photovoltaic-thermal collector. In Proceedings of the 2013 IEEE 39th Photovoltaic Specialists Conference (PVSC), Tampa, FL, USA, 16–21 June 2013; pp. 1495–1499. [Google Scholar] [CrossRef]

- Jarimi, H.; Abu Bakar, M.N.; Othman, M.; Din, M.H. Bi-fluid photovoltaic/thermal (PV/T) solar collector: Experimental validation of a 2-D theoretical model. Renew. Energy 2016, 85, 1052–1067. [Google Scholar] [CrossRef]

- Zhou, J.; Ma, X.; Zhao, X.; Yuan, Y.; Yu, M.; Li, J. Numerical simulation and experimental validation of a micro-channel PV/T modules based direct-expansion solar heat pump system. Renew. Energy 2020, 145, 1992–2004. [Google Scholar] [CrossRef]

- Zhang, H.; Liang, K.; Chen, H.; Gao, D.; Guo, X. Thermal and electrical performance of low-concentrating PV/T and flat-plate PV/T systems: A comparative study. Energy 2019, 177, 66–76. [Google Scholar] [CrossRef]

- Zhang, P.; Rong, X.; Yang, X.; Zhang, D. Design and performance simulation of a novel hybrid PV/T-air dual source heat pump system based on a three-fluid heat exchanger. Sol. Energy 2019, 191, 505–517. [Google Scholar] [CrossRef]

- De Rosa, M.; Romano, G.; Rossi, C.; Scarpa, F.; Tagliafico, L.A. Dynamic thermal model for hybrid photovoltaic panels. Energy Procedia 2015, 81, 345–353. [Google Scholar] [CrossRef] [Green Version]

- Su, D.; Jia, Y.; Huang, X.; Alva, G.; Tang, Y.; Fang, G. Dynamic performance analysis of photovoltaic-thermal solar collector with dual channels for different fluids. Energy Convers. Manag. 2016, 120, 13–24. [Google Scholar] [CrossRef]

- Jeffrey Kuo, C.F.; Lee, Y.W.; Lazuardi Umar, M.; Yang, P.C. Dynamic modeling, practical verification and energy benefit analysis of a photovoltaic and thermal composite module system. Energy Convers. Manag. 2017, 154, 470–481. [Google Scholar] [CrossRef]

- Cai, J.; Ji, J.; Wang, Y.; Zhou, F.; Yu, B. A novel PV/T-air dual source heat pump water heater system: Dynamic simulation and performance characterization. Energy Convers. Manag. 2017, 148, 635–645. [Google Scholar] [CrossRef]

- Simonetti, R.; Molinaroli, L.; Manzolini, G. Development and validation of a comprehensive dynamic mathematical model for hybrid PV/T solar collectors. Appl. Therm. Eng. 2017, 133, 543–554. [Google Scholar] [CrossRef]

- Yu, Q.; Hu, M.; Li, J.; Wang, Y.; Pei, G. Development of a 2D temperature-irradiance coupling model for performance characterizations of the flat-plate photovoltaic/thermal (PV/T) collector. Renew. Energy 2020, 153, 404–419. [Google Scholar] [CrossRef]

- Guarracino, I.; Mellor, A.; Ekins-Daukes, N.J.; Markides, C.N. Dynamic coupled thermal-and-electrical modelling of sheet-and-tube hybrid photovoltaic/thermal (PVT) collectors. Appl. Therm. Eng. 2016, 101, 778–795. [Google Scholar] [CrossRef] [Green Version]

- Guarracino, I.; Freeman, J.; Ramos, A.; Kalogirou, S.A.; Ekins-Daukes, N.J.; Markides, C.N. Systematic testing of hybrid PV-thermal (PVT) solar collectors in steady-state and dynamic outdoor conditions. Appl. Energy 2019, 240, 1014–1030. [Google Scholar] [CrossRef]

- Pierrick, H.; Christophe, M.; Leon, G.; Patrick, D. Dynamic numerical model of a high efficiency PV-T collector integrated into a domestic hot water system. Sol. Energy 2015, 111, 68–81. [Google Scholar] [CrossRef]

- Das, D.; Kalita, P.; Dewan, A.; Tanweer, S. Development of a novel thermal model for a PV/T collector and its experimental analysis. Sol. Energy 2019, 188, 631–643. [Google Scholar] [CrossRef]

- Da Silva, R.M.; Fernandes, J.L.M. Hybrid photovoltaic/thermal (PV/T) solar systems simulation with Simulink/Matlab. Sol. Energy 2010, 84, 1985–1996. [Google Scholar] [CrossRef]

- Ji, J.; He, H.; Chow, T.; Pei, G.; He, W.; Liu, K. Distributed dynamic modeling and experimental study of PV evaporator in a PV/T solar-assisted heat pump. Int. J. Heat Mass Transf. 2009, 52, 1365–1373. [Google Scholar] [CrossRef]

- Fan, W.; Kokogiannakis, G.; Ma, Z.; Cooper, P. Development of a dynamic model for a hybrid photovoltaic thermal collector-Solar air heater with fins Publication Details Development of a dynamic model for a hybrid photovoltaic thermal collector-Solar air heater with fins. Renew. Energy 2017, 101, 816–834. [Google Scholar] [CrossRef] [Green Version]

- Hussain, M.I.; Kim, J.T. Performance optimization of unglazed nanofluid photovoltaic/thermal system: Energy and exergy analyses. Int. J. Photoenergy 2018, 2018, 3895013. [Google Scholar] [CrossRef] [Green Version]

- Sakellariou, E.; Axaopoulos, P. An experimentally validated, transient model for sheet and tube PVT collector. Sol. Energy 2018, 174, 709–718. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Chaichan, M.T.; Sopian, K.; Kazem, H.A.; Mahood, H.B.; Khadom, A.A. Modeling and experimental validation of a PVT system using nanofluid coolant and nano-PCM. Sol. Energy 2019, 177, 178–191. [Google Scholar] [CrossRef]

- Maadi, S.R.; Khatibi, M.; Ebrahimnia-Bajestan, E.; Wood, D. Coupled thermal-optical numerical modeling of PV/T module—Combining CFD approach and two-band radiation DO model. Energy Convers. Manag. 2019, 198, 111781. [Google Scholar] [CrossRef]

- D’Angola, A.; Enescu, D.; Mecca, M.; Ciocia, A.; di Leo, P.; Fracastoro, G.V.; Spertino, F. Theoretical and numerical study of a photovoltaic system with active fluid cooling by a fully-coupled 3D thermal and electric model. Energies 2020, 13, 852. [Google Scholar] [CrossRef] [Green Version]

- Ghani, F.; Duke, M.; Carson, J.K. Effect of flow distribution on the photovoltaic performance of a building integrated photovoltaic/thermal (BIPV/T) collector. Sol. Energy 2012, 86, 1518–1530. [Google Scholar] [CrossRef]

- Jonas, D.; Lämmle, M.; Theis, D.; Schneider, S.; Frey, G. Performance modeling of PVT collectors: Implementation, validation and parameter identification approach using TRNSYS. Sol. Energy 2019, 193, 51–64. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Vicidomini, M. Design, simulation and experimental investigation of a solar system based on PV panels and PVT collectors. Energies 2016, 9, 497. [Google Scholar] [CrossRef]

- Evola, G.; Marletta, L. Exergy and thermoeconomic optimization of a water-cooled glazed hybrid photovoltaic/thermal (PVT) collector. Sol. Energy 2014, 107, 12–25. [Google Scholar] [CrossRef]

- Behzadi, A.; Arabkoohsar, A.; Yang, Y. Optimization and dynamic techno-economic analysis of a novel PVT-based smart building energy system. Appl. Therm. Eng. 2020, 181, 115926. [Google Scholar] [CrossRef]

- Chen, J.F.; Zhang, L.; Dai, Y.J. Performance analysis and multi-objective optimization of a hybrid photovoltaic/thermal collector for domestic hot water application. Energy 2018, 143, 500–516. [Google Scholar] [CrossRef]

- Herrando, M.; Ramos, A.; Freeman, J.; Zabalza, I.; Markides, C.N. Technoeconomic modelling and optimisation of solar combined heat and power systems based on flat-box PVT collectors for domestic applications. Energy Convers. Manag. 2018, 175, 67–85. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Sopian, K.; Yousif, J.H.; Kazem, H.A.; Boland, J.; Chaichan, M.T. Artificial neural network modeling and analysis of photovoltaic/thermal system based on the experimental study. Energy Convers. Manag. 2019, 186, 368–379. [Google Scholar] [CrossRef]

- Ammar, M.b.; Chaabene, M.; Chtourou, Z. Artificial Neural Network based control for PV/T panel to track optimum thermal and electrical power. Energy Convers. Manag. 2013, 65, 372–380. [Google Scholar] [CrossRef]

- Liang, R.; Zhang, J.; Zhou, C. Dynamic Simulation of a Novel Solar Heating System Based on Hybrid Photovoltaic/Thermal Collectors (PVT). Procedia Eng. 2015, 121, 675–683. [Google Scholar] [CrossRef] [Green Version]

- Nash, A.L.; Badithela, A.; Jain, N. Dynamic modeling of a sensible thermal energy storage tank with an immersed coil heat exchanger under three operation modes. Appl. Energy 2017, 195, 877–889. [Google Scholar] [CrossRef]

- Maveety, J.G.; Razani, A. A two-dimensional numerical investigation of the optimal removal time and entropy production rate for a sensible thermal storage system. Energy 1996, 21, 1265–1276. [Google Scholar] [CrossRef]

- Nelson, J.E.B.; Balakrishnan, A.R.; Murthy, S.S. Parametric studies on thermally stratified chilled water storage systems. Appl. Therm. Eng. 1999, 19, 89–115. [Google Scholar] [CrossRef]

- Kong, L.; Yuan, W.; Zhu, N. CFD Simulations of Thermal Stratification Heat Storage Water Tank with an Inside Cylinder with Openings. Procedia Eng. 2016, 146, 394–399. [Google Scholar] [CrossRef] [Green Version]

- Abdulla, A.; Reddy, K.S. Effect of operating parameters on thermal performance of molten salt packed-bed thermocline thermal energy storage system for concentrating solar power plants. Int. J. Therm. Sci. 2017, 121, 30–44. [Google Scholar] [CrossRef]

- Yin, H.; Ding, J.; Jiang, R.; Yang, X. Thermocline characteristics of molten-salt thermal energy storage in porous packed-bed tank. Appl. Therm. Eng. 2017, 110, 855–863. [Google Scholar] [CrossRef]

- Raccanello, J.; Rech, S.; Lazzaretto, A. Simplified dynamic modeling of single-tank thermal energy storage systems. Energy 2019, 182, 1154–1172. [Google Scholar] [CrossRef]

- Karim, A.; Burnett, A.; Fawzia, S. Investigation of stratified thermal storage tank performance for heating and cooling applications. Energies 2018, 11, 49. [Google Scholar] [CrossRef] [Green Version]

- Rahman, A.; Smith, A.D.; Fumo, N. Performance modeling and parametric study of a stratified water thermal storage tank. Appl. Therm. Eng. 2016, 100, 668–679. [Google Scholar] [CrossRef]

- Hansen, C.; King, B. Determining series resistance for equivalent circuit models of a PV module. IEEE J. Photovolt. 2019, 9, 538–543. [Google Scholar] [CrossRef]

- Photovoltaic/Thermal Collector—SOLIMPEKS VOLTHER POWERVOLT. Available online: https://www.archiexpo.com/prod/solimpeks-solar/product-74376-2098999.html (accessed on 8 November 2021).

- Newton, B.J. Modelling of Solar Storage Tanks. Master’s Thesis, University of Wisconsin-Madison, Madison, WI, USA, 1995. [Google Scholar]

- Thermal Properties of Glycole Mixture. Available online: https://tyfo.de/downloads/TYFOCOR-L_en_TI.pdf (accessed on 30 November 2021).

| SOLIMPEKS Volther | |

|---|---|

| Dimensions (l × w × h) (mm) | 995 × 1670 × 60 |

| PV cell size (mm2) | 156 × 156 |

| PMPP (W) | 330 |

| UMPP (V) | 37.77 |

| IMPP (A) | 9.15 |

| UOC (V) | 39.86 |

| ISC (A) | 9.77 |

| αPV (%/°C) | 0.048 |

| βPV (%/°C) | −0.255 |

| γPV (%/°C) | −0.331 |

| Number of PV cells connected in series | 60 |

| Material | αo (/) | ε (/) | ρo (/) | τo (/) | ρ (kg/m3) | C (J/kgK) | k (W/mK) | d (mm) |

|---|---|---|---|---|---|---|---|---|

| Glass | 0.023 | 0.9 | 0.9 | 0.079 | 3000 | 500 | 1.8 | 4 |

| EVA | - | - | - | - | 960 | 2090 | 0.35 | 0.4 |

| PV cell | 0.9 | 0.95 | 0 | 0.1 | 2330 | 677 | 148 | 0.3 |

| EVA foil | - | - | - | - | 960 | 2090 | 0.35 | 0.4 |

| PVF foil | - | - | - | - | 1450 | 1300 | 0.15 | 0.2 |

| Adhesive | - | - | - | - | 1060 | 980 | 1.40 | 0.1 |

| Copper absorber | - | - | - | - | 2700 | 880 | 237 | 4 |

| Heat exchanger | - | - | - | - | 2700 | 880 | 237 | / |

| Styrofoam | - | - | - | - | 1050 | 1200 | 0.13 | 20 |

| Protective layer | 0 | 0.82 | 0 | 0.18 | 1200 | 1250 | 0.2 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sredenšek, K.; Seme, S.; Štumberger, B.; Hadžiselimović, M.; Chowdhury, A.; Praunseis, Z. Experimental Validation of a Dynamic Photovoltaic/Thermal Collector Model in Combination with a Thermal Energy Storage Tank. Energies 2021, 14, 8162. https://doi.org/10.3390/en14238162

Sredenšek K, Seme S, Štumberger B, Hadžiselimović M, Chowdhury A, Praunseis Z. Experimental Validation of a Dynamic Photovoltaic/Thermal Collector Model in Combination with a Thermal Energy Storage Tank. Energies. 2021; 14(23):8162. https://doi.org/10.3390/en14238162

Chicago/Turabian StyleSredenšek, Klemen, Sebastijan Seme, Bojan Štumberger, Miralem Hadžiselimović, Amor Chowdhury, and Zdravko Praunseis. 2021. "Experimental Validation of a Dynamic Photovoltaic/Thermal Collector Model in Combination with a Thermal Energy Storage Tank" Energies 14, no. 23: 8162. https://doi.org/10.3390/en14238162