Pine Wood and Sewage Sludge Torrefaction Process for Production Renewable Solid Biofuels and Biochar as Carbon Carrier for Fertilizers

Abstract

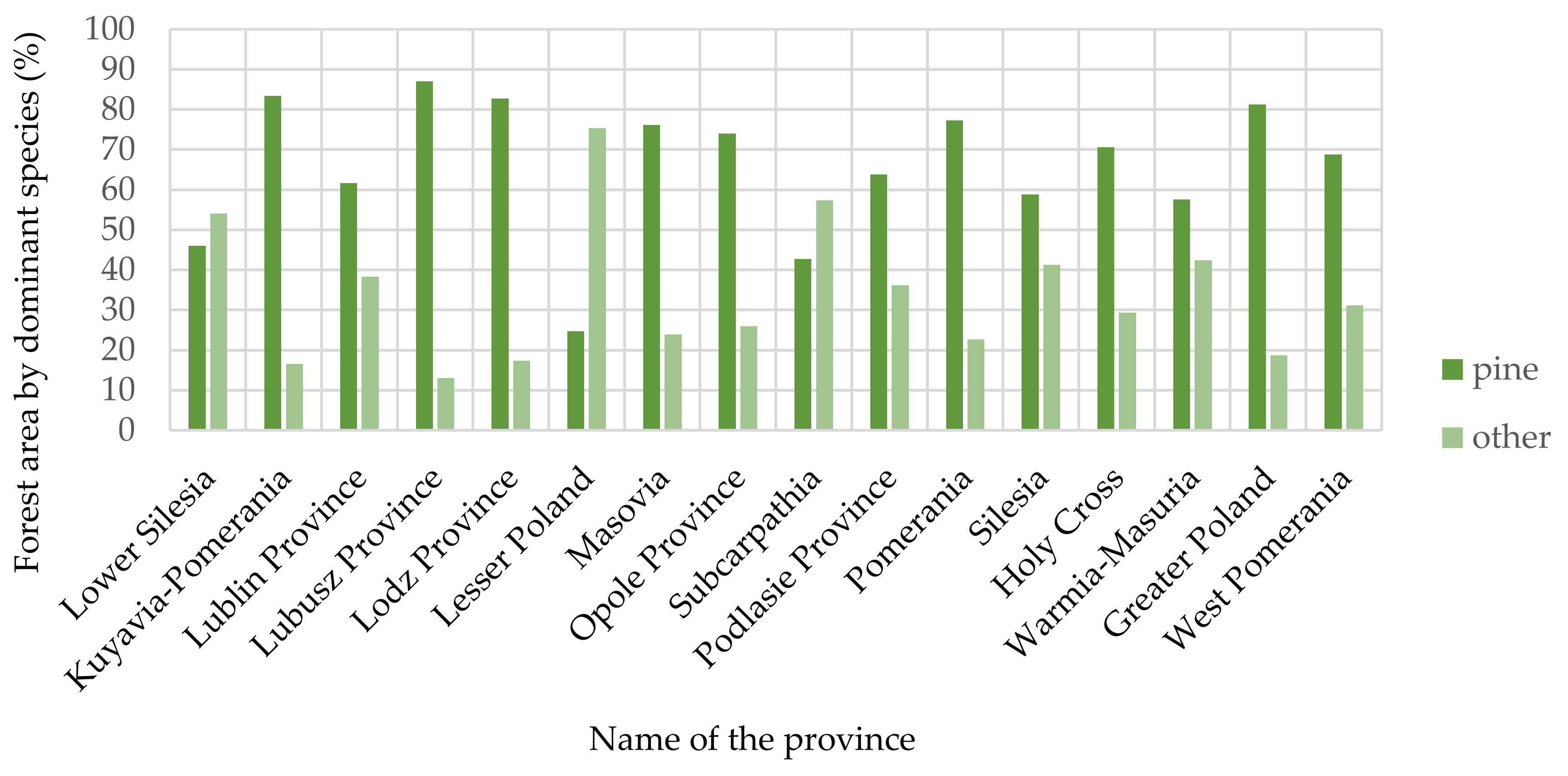

1. Introduction

2. Materials and Methods

2.1. Thermogravimetric Analysis

2.2. Kinetic Analysis

2.3. Study of the Emission of the Total Volatile Organic Compounds

2.4. Determination of the Heat of Combustion Value of the Obtained Torrefaction

3. Results

3.1. Thermogravimetric Analysis

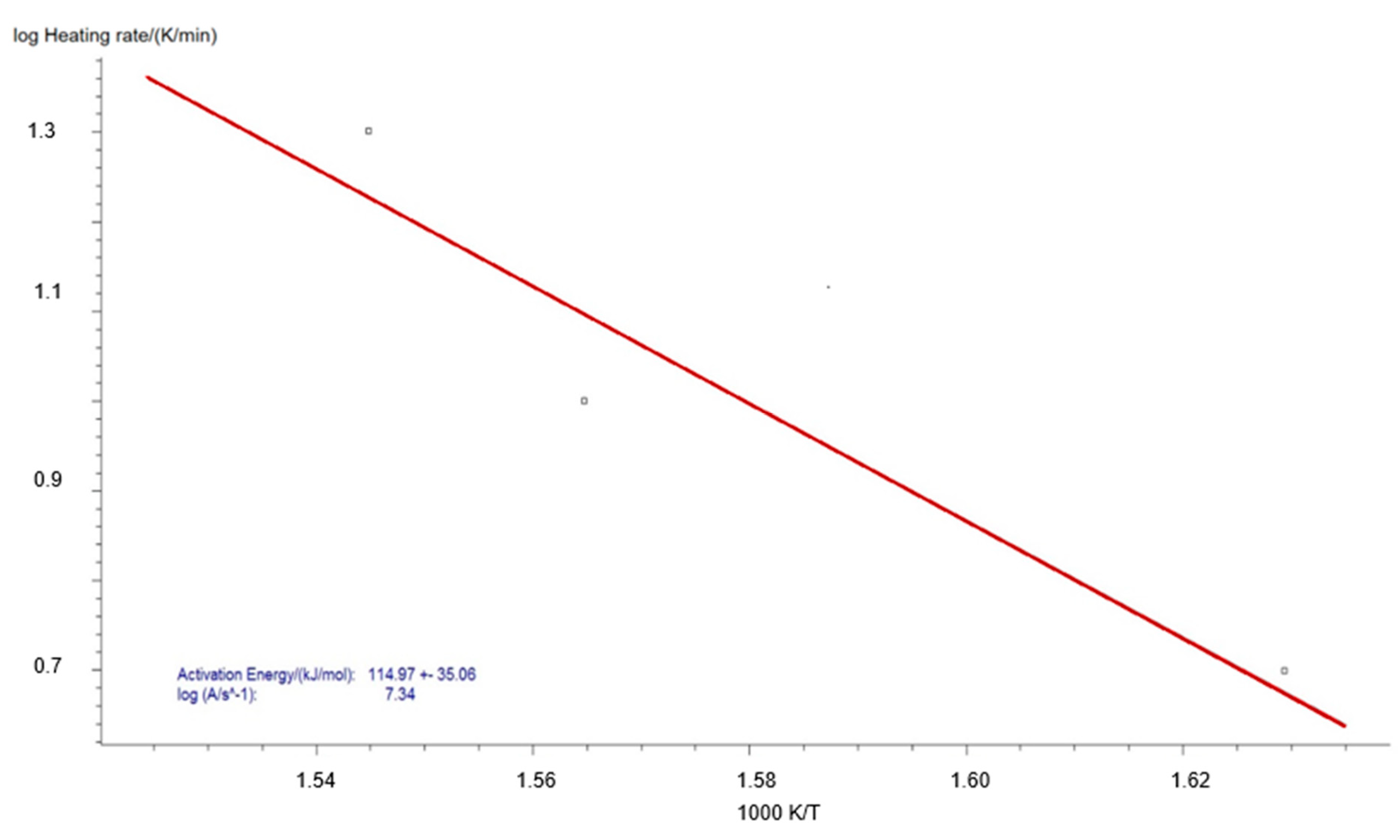

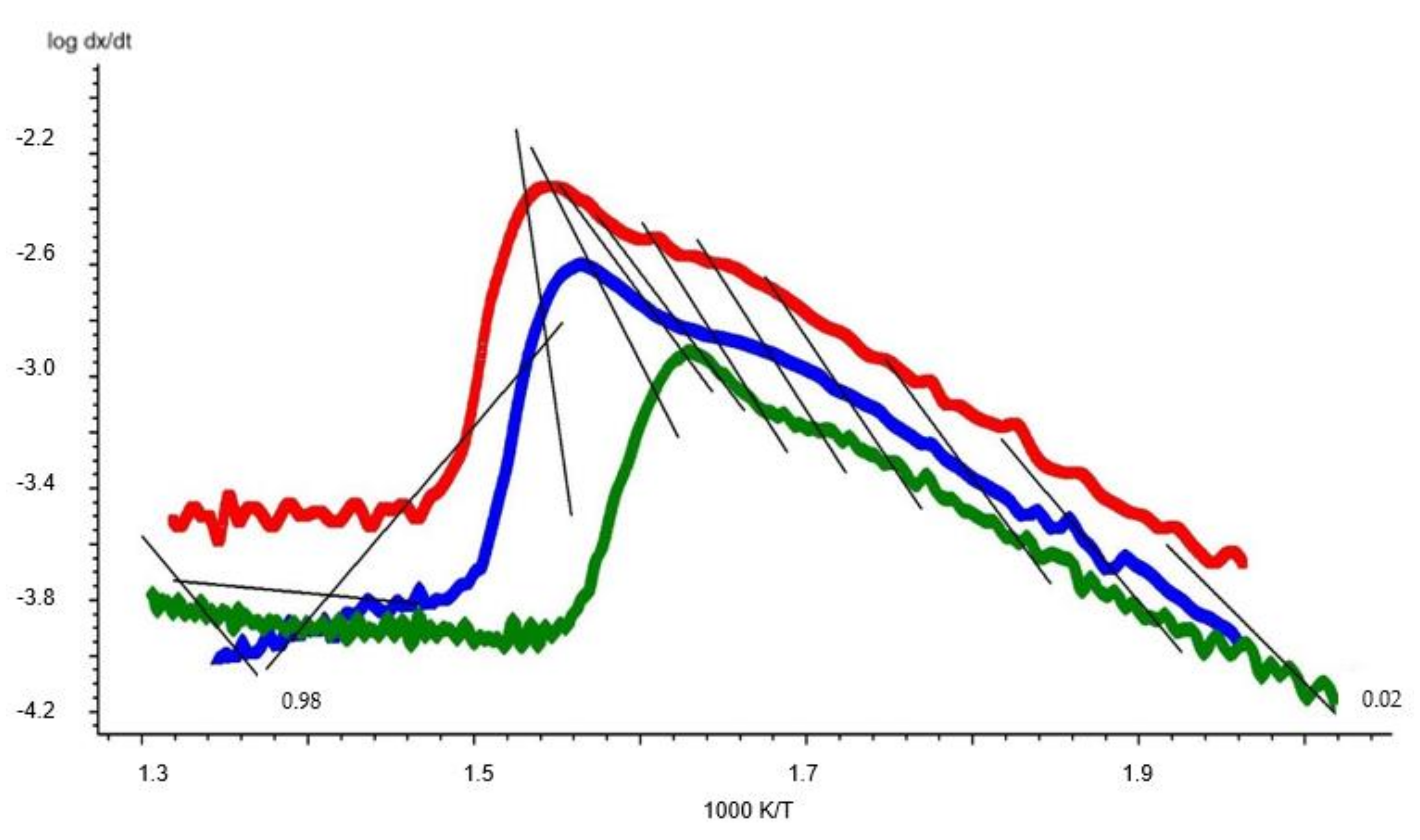

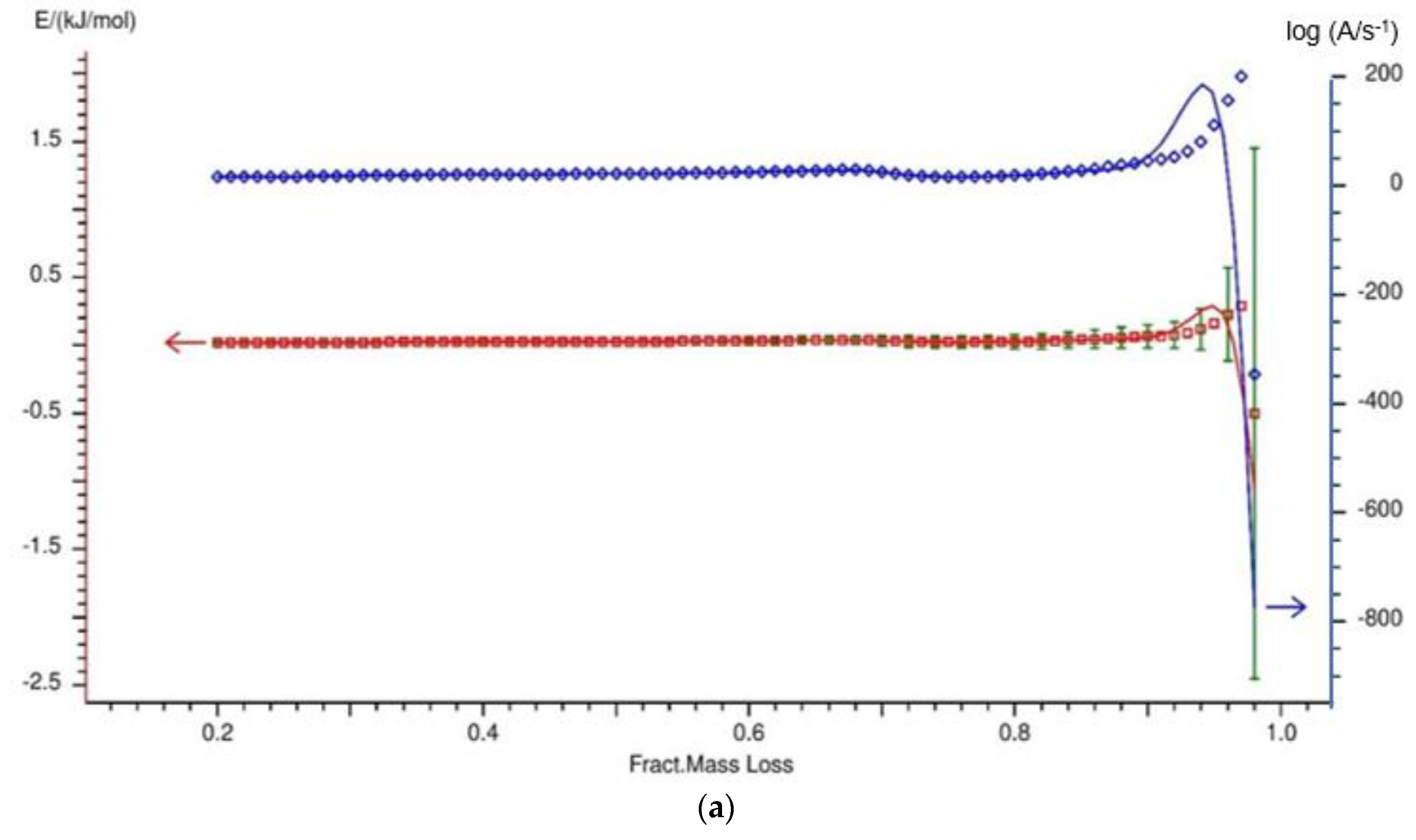

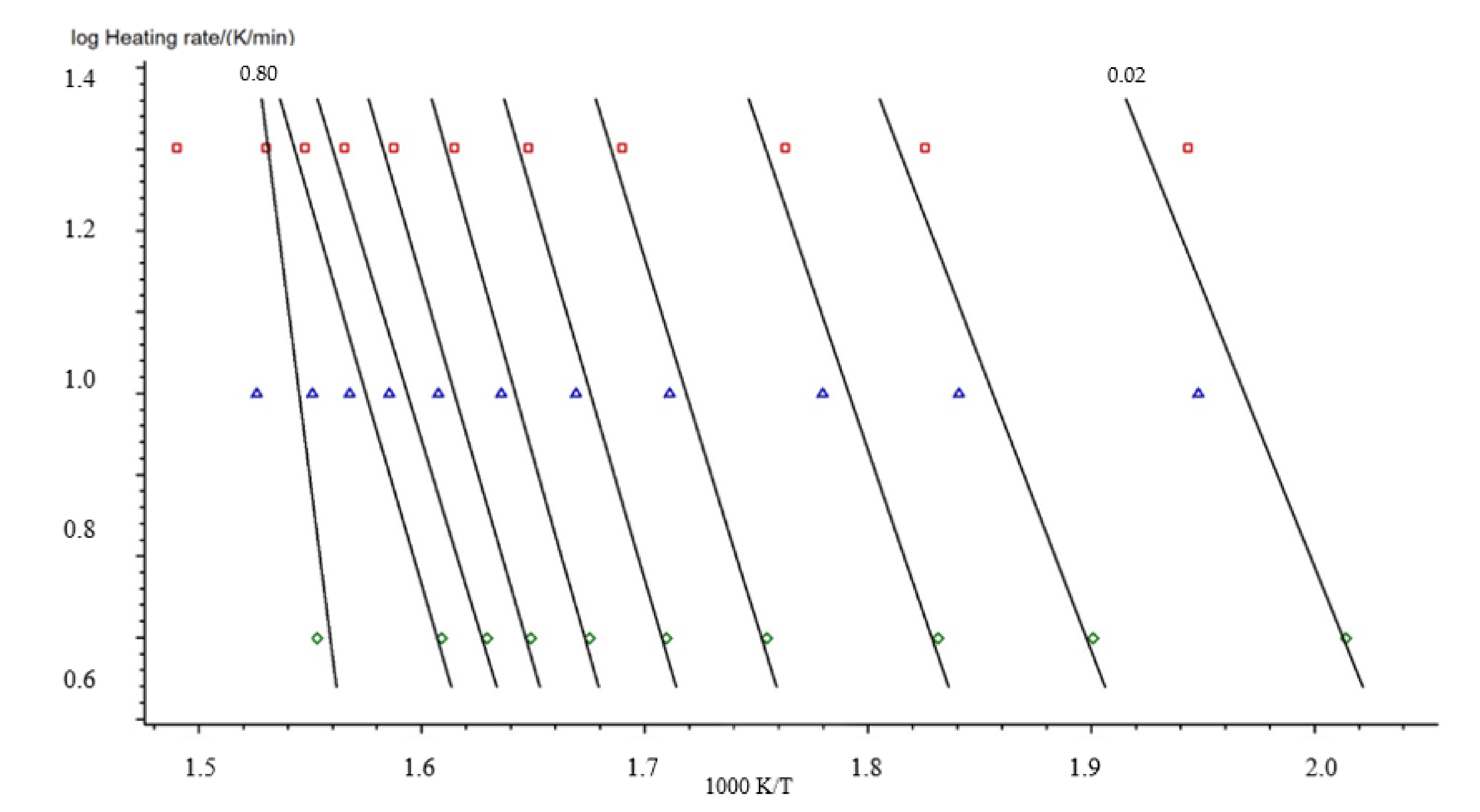

3.2. Kinetic Analysis

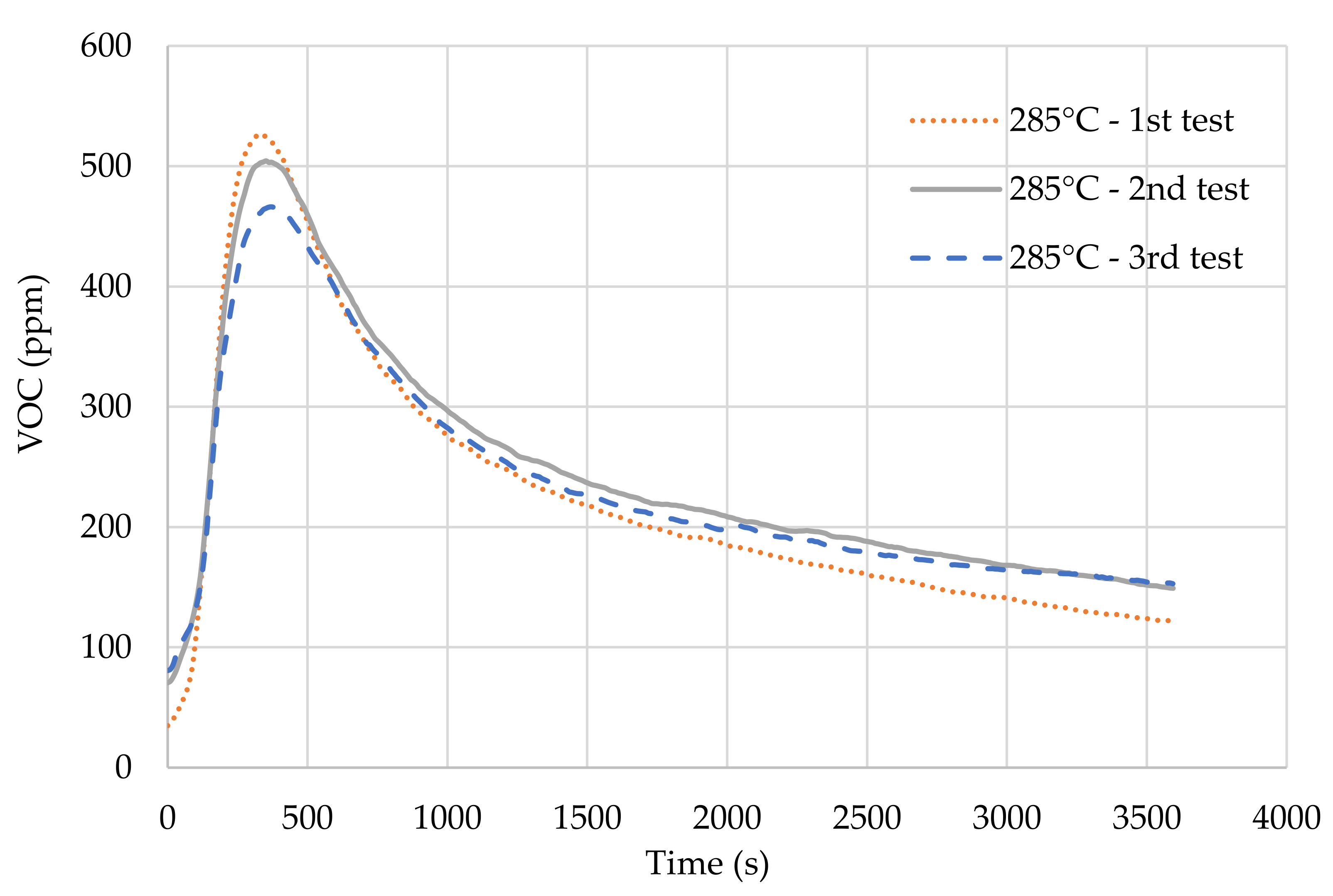

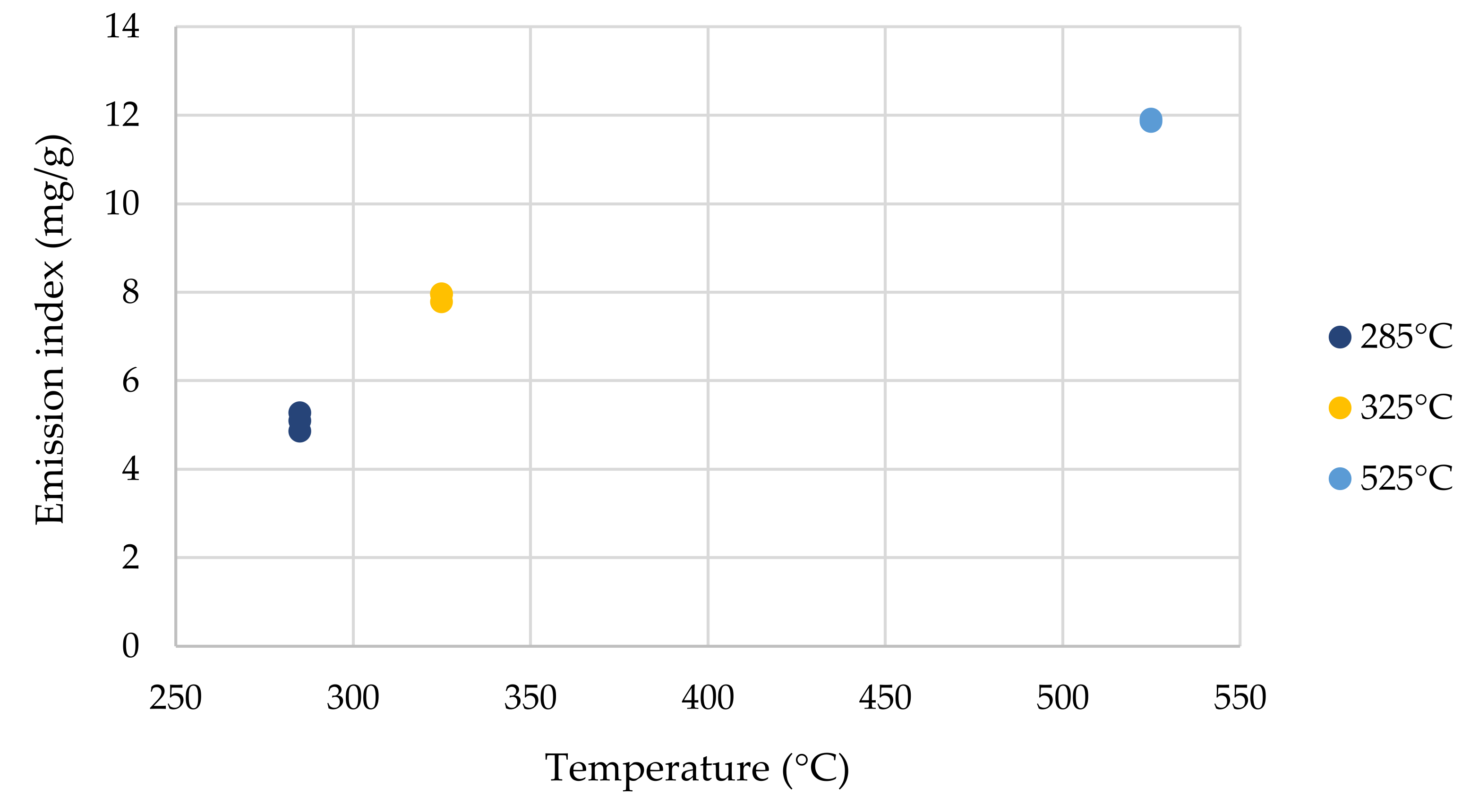

3.3. Study of the Emission of the Sum of Volatile Organic Compounds

3.4. Determination of the Heat of Combustion Value of the Obtained Torrefaction Products

4. Discussion

The Effect of the Torrefaction Residence Time

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

Appendix A

| Fract. Mass Loss | Activation Energy (kJ/mol) | Log (A/s−1) |

|---|---|---|

| 0.020 | 113.71 ± 57.16 | 7.79 |

| 0.050 | 134.47 ± 43.26 | 9.56 |

| 0.100 | 154.97 ± 36.97 | 11.25 |

| 0.200 | 169.96 ± 27.86 | 12.33 |

| 0.300 | 178.59 ± 31.70 | 12.89 |

| 0.400 | 179.87 ± 39.00 | 12.82 |

| 0.500 | 150.14 ± 42.32 | 10.22 |

| 0.600 | 154.05 ± 40.74 | 10.57 |

| 0.700 | 224.25 ± 15.23 | 16.32 |

| 0.800 | 799.80 ± 798.45 | 62.31 |

| Fract. Mass Loss | Activation Energy (kJ/mol) | Log (A/s−1) |

|---|---|---|

| 0.020 | 378.99 ± 216.09 | 37.70 |

| 0.050 | 208.04 ± 83.17 | 18.76 |

| 0.100 | 188.15 ± 60.14 | 16.18 |

| 0.200 | 195.43 ± 53.66 | 16.23 |

| 0.300 | 221.23 ± 53.10 | 18.07 |

| 0.400 | 254.79 ± 42.46 | 20.40 |

| 0.500 | 277.71 ± 4.05 | 21.62 |

| 0.600 | 325.90 ± 97.57 | 24.87 |

| 0.700 | 349.52 ± 407.02 | 25.55 |

| 0.800 | 272.76 ± 507.67 | 18.33 |

References

- Statistics Poland. Statistical Yearbook of Forestry; Statistics Poland: Warsaw, Poland, 2019; ISSN 2657-3199. [Google Scholar]

- Matyjaszczyk, E.; Skrzecz, I. Hou European Union accession and implementation of obligatory integrated pest management influenced forest protection against diseases and weeds: A case study from Poland. Crop Prot. 2020, 127, 104986. [Google Scholar] [CrossRef]

- Laurin, G.V.; Puletti, N.; Grotti, M.; Stereńczak, K.; Modzelewska, A.; Lisiewicz, M.; Sadkowski, R.; Kuberski, Ł.; Chirici, G.; Papale, D. Species dominance and above grouns biomass in the Białowieża Forest, Poland, describes by airborne hyperspectral and lider data. Int. J. Appl. Earth Obs. 2020, 92, 102178. [Google Scholar] [CrossRef]

- Węgrzyn, M.H.; Kołodziejczak, J.; Fałkowska, P.; Wężyk, P.; Zięba-Kulawik, K.; Szostak, M.; Turowska, A.; Grzesiak, B.; Wietrzyk-Pełka, P. Influence of the enviromental factors on the species composition of lichen Scots pine forests as a guide to maintain the community (Bory Tucholskie National Park, Poland). Glob. Ecol. Conserv. 2020, 22, e017017. [Google Scholar] [CrossRef]

- Zribi, M.; Lajili, M.; Escudero-Sanz, F.J. Hydrogen enriched syngas production via gasification of biofuels pellets/powders blended from olive mill solid wastes and pine sawdust under different water steam/nitrogen atmospheres. Int. J. Hydrogen Energy 2019, 44, 11280–11288. [Google Scholar] [CrossRef]

- Dębowski, M.; Bukowski, P.; Kobel, P.; Bieniek, J.; Romański, L.; Knutel, B. Comparison of Energy Consumption of Cereal Grain Dryer Powered by LPG and Hard Coal in Polish Conditions. Energies 2021, 14, 4340. [Google Scholar] [CrossRef]

- Barskov, S.; Zappi, M.; Buchireddy, P.; Dufreche, S.; Guillory, J.; Gang, D.; Hernandez, R.; Bajpai, R.; Baudier, J.; Cooper, R.; et al. Torrefaction of biomass: A review of production methods for biocoal from cultured and waste lignocellulosic feedstocks. Renev. Energy 2019, 142, 624–642. [Google Scholar] [CrossRef]

- Luo, H.; Niedźwiecki, Ł.; Arora, A.; Mościcki, K.; Pawlak-Kruczek, H.; Krochmalny, K.; Baranowski, M.; Tiwari, M.; Sharma, A.; Sharma, T.; et al. Influence of Torrefaction and Pelletizing of Sawdust on the Design Parameters of a Fixed Bed Gasifier. Energies 2020, 13, 3018. [Google Scholar] [CrossRef]

- Kryszak, D.; Bartoszewicz, A.; Szufa, S.; Piersa, P.; Obraniak, A.; Olejnik, T.P. Modeling of Transport of Loose Products with the Use of the Non-Grid Method of Discrete Elements (DEM). Processes 2020, 8, 1489. [Google Scholar] [CrossRef]

- Soponpongpipat, N.; Nanetoe, S.; Comsawang, P. Thermal Degradation of Cassavaf Rhizome in Thermosyphon-Fixed Bed Torrefaction Reactor. Processes 2020, 8, 267. [Google Scholar] [CrossRef]

- Krochmalny, K.; Niedźwiecki, Ł.; Pelińska-Olko, E.; Wnukowski, M.; Czajka, K.; Tkaczuk-Serafin, M.; Pawlak-Kruczek, H. Determination of the marker for automation of torrefaction and slow pyrolysis processes—A case study of spherical wood particles. Renew. Energy 2020, 161, 350–360. [Google Scholar] [CrossRef]

- Dzikuć, M.; Kuryło, P.; Dudziak, R.; Szufa, S.; Dzikuć, M.; Godzisz, K. Selected Aspects of Combustion Optimization of Coal in Power Plants. Energies 2020, 13, 2208. [Google Scholar] [CrossRef]

- Szufa, S.; Adrian, Ł.; Piersa, P.; Romanowska-Duda, Z.; Grzesik, M.; Cebula, A.; Kowalczyk, S. Experimental studies on energy crops torrefaction process using batch reactor to estimate torrefaction temperature and residence time. In Renewable Energy Sources: Engineering, Technology, Innovation, ICORES 2017; Mudryk, K., Werle, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 365–373. [Google Scholar] [CrossRef]

- Szufa, S.; Adrian, Ł.; Piersa, P.; Romanowska-Duda, Z.; Ratajczyk-Szufa, J. Torrefaction process of millet and cane using batch reactor, In Renewable Energy Sources: Engineering, Technology, Innovation; Springer Proceedings in Energy; Wróbel, M., Jewiarz, M., Szlęk, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 371–379. ISBN 978-3-030-13887-5. [Google Scholar] [CrossRef]

- Jewiarz, M.; Wróbel, M.; Mudryk, K.; Szufa, S. Impact of the Drying Temperature and Grinding Technique on Biomass Grindability. Energies 2020, 13, 3392. [Google Scholar] [CrossRef]

- Friedl, A.; Padouvas, E.; Rotter, H.; Varmuza, K. Prediction of heating values of biomass fuel from elemental composition. Anal. Chim. Acta 2005, 544, 191–198. [Google Scholar] [CrossRef]

- Wang, L.; Barta-Rajnai, E.; Skreiberg, Ø.; Khalil, R.; Czégény, Z.; Jakab, E.; Barta, Z.; Grønli, M. Effect of torrefaction on physiochemical characteristics and grindability of stem wood, stump and bark. Appl. Energy 2018, 227, 137–148. [Google Scholar] [CrossRef]

- Chen, W.H.; Wang, C.W.; Ong, H.C.; Show, P.L.; Hsieh, T.H. Torrefaction, pyrolysis and two stage thermodegradation of hemicellulose, cellulose and lignin. Fuel 2019, 258, 116168. [Google Scholar] [CrossRef]

- Szufa, S.; Dzikuć, M.; Adrian, Ł.; Piersa, P.; Romanowska-Duda, Z.; Marczak, M.; Błaszczuk, A.; Piwowar, A.; Lewandowska, W. Torrefaction of oat straw to use as solid biofuel, an additive to organic fertilizers for agriculture purposes and activated carbon—TGA analysis, kinetics. E3S Web Conf. 2020, 154, 02004. [Google Scholar] [CrossRef]

- Peng, J.H.; Bi, X.T.; Sokhansanj, S.; Lim, C.J. Torrefaction and densification of different species of softwood residues. Fuel 2013, 111, 411–421. [Google Scholar] [CrossRef]

- Adamski, R.; Siuta, D.; Kukfisz, B.; Frydrysiak, M.; Prochoń, M. Integration of Safety Aspects in Modeling of Superheated Steam Flash Drying of Tobacco. Energies 2021, 14, 5927. [Google Scholar] [CrossRef]

- Junga, R.; Pospolita, J.; Niemiec, P. Combustion and grindability characteristics of palm kernel shells torrefied in a pilot-scale installation. Renew. Energy 2020, 147 Pt 1, 1239–1250. [Google Scholar] [CrossRef]

- Wen, J.-L.; Sun, S.-L.; Yuan, T.-Q.; Xu, F.; Sun, R.-C. Understanding the chemical and structural transformations of lignin macromolecule during torrefaction. Appl. Energy 2014, 121, 1–9. [Google Scholar] [CrossRef]

- Chen, W.-H.; Lu, K.-M.; Tsai, C.-M. An experimental analysis on property and structure variations of agricultural wastes undergoing torrefaction. Appl. Energy 2012, 100, 318–325. [Google Scholar] [CrossRef]

- Dacres, O.D.; Tong, S.; Li, X.; Zhu, X.; Edries, E.M.A.; Liu, H.; Luo, G.; Worasuwannarak, N.; Kerdsuwan, S.; Fungtammasan, B.; et al. Pyrolysis kinetics of biomasses pretreated by gas-pressurized torrefaction. Energy Convers. Manag. 2019, 182, 117–125. [Google Scholar] [CrossRef]

- Peng, J.; Wang, J.; Bi, X.T.; Lin, C.J.; Sokhansanj, S.; Peng, H.; Jia, D. Effects of thermal treatment on energy density and hardness of torrefied wood pellets. Fuel Process. Technol. 2015, 129, 168–173. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Adrian, Ł.; Sielski, J.; Grzesik, M.; Romanowska-Duda, Z.; Piotrowski, K.; Lewandowska, W. Acquisition of Torrefied Biomass from Jerusalem Artichoke Grown in a Closed Circular System Using Biogas Plant Waste. Molecules 2020, 25, 3862. [Google Scholar] [CrossRef] [PubMed]

- Tong, S.; Xiao, L.; Li, X.; Zhu, X.; Liu, H.; Luo, G.; Worasuwannarak, N.; Kerdsuwan, S.; Fungtammasan, B.; Yao, H. A gas-pressurized torrefaction method for biomass wastes. Energy Convers. Manag. 2018, 173, 29–36. [Google Scholar] [CrossRef]

- Bourgonje, K.; Veringa, H.J.; Smeulders, D.M.J.; van Oijen, J.A. Oxygen ad a Torrefaction Control Parameter. Energy Environ. Res. 2018, 8, 18–31. [Google Scholar] [CrossRef][Green Version]

- Romanowska-Duda, Z.; Piotrowski, K.; Wolska, B.; Dębowski, M.; Zieliński, M.; Dziugan, P.; Szufa, S. Stimulating effect of ash from Sorghum on the growth of Lemnaceae—A new source of energy biomass. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer Proceedings in Energy; Wróbel, M., Jewiarz, M., Szlęk, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 341–349. ISBN 978-3-030-13887-5. [Google Scholar] [CrossRef]

- Szufa, S.; Wielgosiński, G.; Piersa, P.; Czerwińska, J.; Dzikuć, M.; Adrian, Ł.; Lewandowska, W.; Marczak, M. Torrefaction of Straw from Oats and Maize for Use as a Fuel and Additive to Organic Fertilizers—TGA Analysis, Kinetics as Products for Agricultural Purposes. Energies 2020, 13, 2064. [Google Scholar] [CrossRef]

- Singh, S.; Chakraborty, J.P.; Mondal, M.K. Torrefaction od woody biomass (Acacia nilotica): Investigation of fuel and flow properties to study its suitability as a good quality solid fuel. Renew. Energy 2020, 153, 711–724. [Google Scholar] [CrossRef]

- Wilk, M.; Magdziarz, A.; Gajek, M.; Zajemska, M.; Jayawaman, K.; Gokalp, I. Combustion and kinetic parameters estimation of torrefied pine, acacia and Miscanthus giganteus using experimental and modelling techniques. Bioresour. Technol. 2017, 243, 304–314. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Li, Y.; Deng, M.; Wang, J.; Chen, M.; Yan, B.; Yuan, Q. Effect of torrefaction pretreatment and catalytic pyrolysis on the pyrolysis poly-generation of pine wood. Bioresour. Technol. 2016, 214, 615–622. [Google Scholar] [CrossRef]

- Leontiev, A.; Kichatow, B.; Korhunov, A.; Kiverin, A.; Zaichenko, V.; Sytchev, S.; Melnikova, K. Oxidative torrefaction of pine pellets in the quiescent layer of mineral filler. Fuel Process. Technol. 2018, 182, 113–122. [Google Scholar] [CrossRef]

- Liang, J.; Xu, X.; Yu, Z.; Chen, L.; Liao, Y.; Ma, X. Effects of microwave pretreatment on catalytic fast pyrolysis of pine sawdust. Bioresour. Technol. 2019, 293, 122080. [Google Scholar] [CrossRef]

- Cahuanti, M.N.; Doddapaneni, T.R.K.C.; Kikas, T. Biomass torrefaction: An overview on process parameters, economic and environmental aspects and recent advancements. Bioresour. Technol. 2020, 301, 122737. [Google Scholar] [CrossRef] [PubMed]

- Mamvura, T.A.; Danha, G. Biomass torrefaction as an emerging technology to aid in energy production. Heliyon 2020, 6, e03531. [Google Scholar] [CrossRef] [PubMed]

- Rago, Y.P.; Collard, F.X.; Görgens, J.F.; Surroop, D.; Mohee, R. Torrefaction of biomass and plastic from municipal solid waste streams and their blends: Evaluation of interactive effects. Fuel 2020, 277, 118089. [Google Scholar] [CrossRef]

- Świechowski, K.; Hnat, M.; Stępień, P.; Stegenta-Dąbrowska, S.; Kugler, S.; Koziel, J.A.; Białowiec, A. Waste to Energy: Solid Fuel Production from Biodas Plant Digestate and Sewage Sludge by Torrefaction-Process Kinetics, Fuel Properties, and Energy Balance. Energies 2020, 12, 3161. [Google Scholar] [CrossRef]

- Ong, H.C.; Chen, W.H.; Singh, Y.; Gan, Y.Y.; Chen, C.Y.; Show, P.L. A state-of-the-art review on thermochemical conversion of biomass for biofuel production: A TG-FTIR approach. Energy Convers. Manag. 2020, 209, 112634. [Google Scholar] [CrossRef]

- Ławińska, K.; Serweta, W.; Gendaszewska, D. Applications of Bamboo Textiles in Individualised Children’s Footwear. Fibres Text. East. Eur. 2018, 5, 87–92. [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Wnukowski, M.; Krochmalny, K.; Kowal, M.; Baranowski, M.; Zgóra, J.; Czerep, M.; Ostrycharczyk, M.; Niedźwiecki, Ł. The Staged Thermal conversion of Sewage Sludge in the Presence of Oxygen. J. Energy Resour. ASME 2019, 141, 070701. [Google Scholar] [CrossRef]

- Tic, W.J.; Guziałowska-Tic, J.; Pawlak-Kruczek, H.; Woźnikowski, E.; Zadorożny, A.; Niedźwiecki, Ł.; Wnukowski, M.; Krochmalny, K.; Czerep, M.; Ostrycharczyk, M.; et al. Novel Concept of an Installation for Sustainable Thermal Utilization of Sewage Sludge. Energies 2018, 11, 748. [Google Scholar] [CrossRef]

- Obraniak, A.; Gluba, T.; Lawińska, K.; Derbiszewski, B. Minimisation of environmental effects related with storing fly ash from combustion of hard coal. Environ. Protect. Eng. 2015, 44, 177–189. [Google Scholar] [CrossRef]

- Ławińska, K.; Szufa, S.; Obraniak, A.; Olejnik, T.; Siuda, R.; Kwiatek, J.; Ogrodowczyk, D. Disc Granulation Process of Carbonation Lime Mud as a Method of Post-Production Waste Management. Energies 2020, 13, 3419. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Adrian, Ł.; Czerwińska, J.; Lewandowski, A.; Lewandowska, W.; Sielski, J.; Dzikuć, M.; Wróbel, M.; Jewiarz, M.; et al. Sustainable Drying and Torrefaction Processes of Miscanthus for Use as a Pelletized Solid Biofuel and Biocarbon-Carrier for Fertilizers. Molecules 2021, 26, 1014. [Google Scholar] [CrossRef] [PubMed]

- Havrylianchyk, R.; Bilyk, T.; Hutsol, T.; Osadchuk, O.; Mudryk, K.; Jewiarz, M.; Wrobel, M.; Dziedzic, K. Straw of Buckwheat as an Alternative Source of Biofuels. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Cham, Switzerland, 2020; pp. 323–329. ISBN 978-3-030-13887-5. [Google Scholar] [CrossRef]

- Saxena, J.; Rawat, J.; Kumar, R. Conversion of Biomass Waste into Biochar and the Effect on Mung Bean Crop Production. Clean Soil Air Water 2017, 45, 15010201501020. [Google Scholar] [CrossRef]

- Ünyay, H.; Yılmaz, F.; Başar, I.A.; Perendeci, N.A.; Çoban, I.; Şahinkaya, E. Effects of organic loading rate on methane production from switchgrass in batch and semi-continuous stirred tank reactor system. Biomass Bioenergy 2022, 156, 106306. [Google Scholar] [CrossRef]

- Karhunov, A.; Kichatov, B.; Sudakov, V.; Kolobov, A.; Gubernov, V.; Golubkov, A.; Libet, P.A.; Kireynov, A.; Yurchenko, S.O. Hydroscopic property of biofuel obtained by torrefaction of wood in a quiescent layer of bentonite. Fuel 2020, 282, 118766. [Google Scholar] [CrossRef]

- Abelha, P.; Kiel, J. Techno-economic assessment of biomass upgrading by washing and torrefaction. Biomass Bioenergy 2020, 142, 105751. [Google Scholar] [CrossRef]

- Biopaliwa Stałe—Oznaczenie Zawartości Wilgoci—Metoda Suszarkową—Część 1: Wilgoć Całkowita—Metoda Referencyjna; PN-EN ISO 18134-1:2015-11; Sklep PKN: Warszawa, Poland, 2020.

- Haseli, Y. Process Modeling of a Biomass Torrefaction Plant. Energy Fuel 2018, 32, 5611–5622. [Google Scholar] [CrossRef]

- Peduzzi, E.; Boissonnet, G.; Haarlemmer, G.; Dupont, C.; Maréchal, F. Torrefaction modelling for lignocellulosic biomass conversion processes. Energy 2014, 70, 58–67. [Google Scholar] [CrossRef]

- Wojtko, P.; Gaze, B.; Knutel, B.; Wacławek, A.; Bukowski, P.; Romański, L. The use of catalytic additives for the combustion of sunflower husk pellets in a low-power boiler. Przemysł Chem. 2021, 5, 1000–1004. [Google Scholar]

- Ngyuen, Q.; Nguyen, D.D.; Vothi, H.; He, C.; Goodarzi, M.; Bach, Q.V. Isothermal torrefaction kinetics for sewage sludge pretreatment. Fuel 2020, 277, 118103. [Google Scholar] [CrossRef]

- Haseli, Y. Simplified model of torrefaction-grinding process integrated with a power plant. Fuel Process. Technol. 2019, 188, 118–128. [Google Scholar] [CrossRef]

- Bates, R.B.; Ghoniem, A.F. Biomass torrefaction: Modeling of reaction thermochemistry. Bioresour. Technol. 2013, 134, 331–340. [Google Scholar] [CrossRef] [PubMed]

- He, Q.; Ding, L.; Gong, Y.; Li, W.; Wei, J.; Yu, G. Effects of torrefaction on pinewood pyrolysis kinetics and thermal behavior using thermogravimetric analysis. Bioresour. Technol. 2019, 280, 104–111. [Google Scholar] [CrossRef] [PubMed]

- Szufa, S. Use of superheated steam in the process of biomass torrefaction. Przemysł Chem. 2020, 99, 1797–1801. (In Polish) [Google Scholar] [CrossRef]

- Nwabunwanne, N.; Vuyokazi, T.; Olagoke, A.; Patrick, M.; Anthony, O. Improving the solid fuel properties of non-lignocellulose and lignocellulose materials through torrefaction. Materials 2021, 14, 2072. [Google Scholar] [CrossRef] [PubMed]

- Atienza-Martínez, M.; Fonts, I.; Ábrego, J.; Ceamanos, J.; Gea, G. Sewage sludge torrefaction in a fluidized bed reactor. Chem. Eng. 2013, 222, 534–545. [Google Scholar] [CrossRef]

- Viana, H.F.S.; Rodrigues, A.M.; Godina, R.; Matias, J.C.O.; Nunes, L.J.R. Evaluation of the physical, chemical and thermal properties of Portuguese maritime pine biomass. Sustainable 2018, 10, 2877. [Google Scholar] [CrossRef]

- Huang, Y.F.; Te Sung, H.; Te Chiueh, P.; Lo, S.L. Co-torrefaction of sewage sludge and leucaena by using microwave heating. Energy 2016, 116, 1–7. [Google Scholar] [CrossRef]

- Poudel, J.; Ohm, T.I.; Lee, S.H.; Oh, S.C. A study on torrefaction of sewage sludge to enhance solid fuel qualities. Waste Manag. 2015, 40, 112–118. [Google Scholar] [CrossRef]

- Sobek, S.; Tran, Q.-K.; Junga, R.; Werle, S. Hydrothermal carbonization of the waste straw: A study of the biomass transient heating behavior and solid products combustion kinetics. Fuel 2021, 2021, 122725. [Google Scholar] [CrossRef]

- Romanowska-Duda, Z.; Szufa, S.; Grzesik, M.; Piotrowski, K.; Janas, R. The Promotive Effect of Cyanobacteria and Chlorella sp. Foliar Biofertilization on Growth and Metabolic Activities of Willow (Salix viminalis L.) Plants as Feedstock Production, Solid Biofuel and Biochar as C Carrier for Fertilizers via Torrefaction Process. Energies 2021, 14, 5262. [Google Scholar] [CrossRef]

- Marczak-Grzesik, M.; Budzyń, S.; Tora, B.; Szufa, S.; Kogut, K.; Burmistrz, P. Low-Cost Organic Adsorbents for Elemental Mercury Removal from Lignite Flue Gas. Energies 2021, 14, 2174. [Google Scholar] [CrossRef]

| Fract. Mass Loss | Activation Energy (kJ/mol) | Log (A/s−1) |

|---|---|---|

| 0.020 | 121.96 ± 61.15 | 8.85 |

| 0.050 | 128.18 ± 44.82 | 9.11 |

| 0.100 | 145.76 ± 42.65 | 10.66 |

| 0.200 | 161.46 ± 32.56 | 11.85 |

| 0.300 | 170.33 ± 31.30 | 12.46 |

| 0.400 | 174.80 ± 31.49 | 12.70 |

| 0.500 | 170.09 ± 34.58 | 12.16 |

| 0.600 | 162.39 ± 35.23 | 11.42 |

| 0.700 | 170.42 ± 34.12 | 12.05 |

| 0.800 | 402.87 ± 186.36 | 31.02 |

| Fract. Mass Loss | Activation Energy (kJ/mol) | Log (A/s−1) |

|---|---|---|

| 0.020 | 542.50 ± 172.09 | 56.16 |

| 0.050 | 270.33 ± 88.04 | 25.58 |

| 0.100 | 203.17 ± 64.57 | 18.12 |

| 0.200 | 195.84 ± 53.70 | 16.77 |

| 0.300 | 205.04 ± 53.72 | 17.15 |

| 0.400 | 240.66 ± 50.48 | 19.89 |

| 0.500 | 269.49 ± 19.16 | 21.76 |

| 0.600 | 300.83 ± 48.94 | 23.68 |

| 0.700 | 312.47 ± 297.92 | 23.59 |

| 0.800 | 237.36 ± 492.84 | 16.48 |

| Biomass Type | Moisture, [%] | Cad, [%] | Nad, [%] | Had, [%] | Sad, [%] | Cl, [%] | Volatilead [%] | Ash [%] | Heat of Combustion, [MJ/kg] |

|---|---|---|---|---|---|---|---|---|---|

| Pine wood | 7.7 | 42.3 | 0.63 | 5.61 | 0.07 | 0.115 | 82.4 | 4.2 | 18.19 |

| Torrefied Pine Wood | |||||||||

| (285 °C, 10 min) | 6.42 | 51.15 | 0.67 | 6.14 | 0.03 | 0.014 | 72.36 | 4.64 | 21.72 |

| (325 °C, 7 min) | 2.83 | 53.24 | 0.23 | 5.62 | 0.03 | 0.013 | 70.13 | 6.97 | 27.48 |

| (525 °C, 5 min) | 1.39 | 57.29 | 0.15 | 3.47 | 0.04 | 0.012 | 37.23 | 10.12 | 31.48 |

| Sewage Sludge | 7.8 | 31.10 | 4.46 | 5.87 | 0.09 | 0.01 | 59.8 | 40.5 | 13.24 |

| Torrefied Sewage Sludge: | |||||||||

| (280 °C, 9 min) | 3.8 | 31.4 | 4.47 | 5.23 | 0.01 | 0.009 | 27.4 | 72.5 | 3.68 |

| (320 °C, 6 min) | 2.2 | 32.60 | 4.29 | 4.61 | 0.01 | 0.01 | 25.25 | 74.32 | 3.44 |

| (520 °C, 5 min) | 2.0 | 26.35 | 3.25 | 2.42 | 0.01 | 0.01 | 23.43 | 77.65 | 3.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piersa, P.; Szufa, S.; Czerwińska, J.; Ünyay, H.; Adrian, Ł.; Wielgosinski, G.; Obraniak, A.; Lewandowska, W.; Marczak-Grzesik, M.; Dzikuć, M.; et al. Pine Wood and Sewage Sludge Torrefaction Process for Production Renewable Solid Biofuels and Biochar as Carbon Carrier for Fertilizers. Energies 2021, 14, 8176. https://doi.org/10.3390/en14238176

Piersa P, Szufa S, Czerwińska J, Ünyay H, Adrian Ł, Wielgosinski G, Obraniak A, Lewandowska W, Marczak-Grzesik M, Dzikuć M, et al. Pine Wood and Sewage Sludge Torrefaction Process for Production Renewable Solid Biofuels and Biochar as Carbon Carrier for Fertilizers. Energies. 2021; 14(23):8176. https://doi.org/10.3390/en14238176

Chicago/Turabian StylePiersa, Piotr, Szymon Szufa, Justyna Czerwińska, Hilal Ünyay, Łukasz Adrian, Grzegorz Wielgosinski, Andrzej Obraniak, Wiktoria Lewandowska, Marta Marczak-Grzesik, Maria Dzikuć, and et al. 2021. "Pine Wood and Sewage Sludge Torrefaction Process for Production Renewable Solid Biofuels and Biochar as Carbon Carrier for Fertilizers" Energies 14, no. 23: 8176. https://doi.org/10.3390/en14238176

APA StylePiersa, P., Szufa, S., Czerwińska, J., Ünyay, H., Adrian, Ł., Wielgosinski, G., Obraniak, A., Lewandowska, W., Marczak-Grzesik, M., Dzikuć, M., Romanowska-Duda, Z., & Olejnik, T. P. (2021). Pine Wood and Sewage Sludge Torrefaction Process for Production Renewable Solid Biofuels and Biochar as Carbon Carrier for Fertilizers. Energies, 14(23), 8176. https://doi.org/10.3390/en14238176