Construction Planning and Operation of Battery Swapping Stations for Electric Vehicles: A Literature Review

Abstract

:1. Introduction

- Less air pollution.

- Less noise pollution.

- Low fuel and operating cost.

- High price. Electric car production is not yet fully commercialized. Hence, these vehicles are more expensive than conventional cars that run on petrol or diesel.

- Low-range EVs can travel less than half the distance of gas-powered vehicles before they require a “fill-up”.

1.1. Current Bottleneck in Charging Mode

1.2. Advantages and Problems of Battery Swapping Stations

- Reducing the initial purchase cost for consumers. Since batteries account for 40% of the total cost of vehicles, consumers do not need to pay high battery costs under the concept of vehicle battery separation.

- Quickly replenishing energy. It only takes approximately 3–5 min.

- Reducing the load on the power grid. It is easier to manage the battery in a unified way and play an active role in controlling the charging load.

- High construction investment cost. Battery cost is very expensive—too many batteries increase costs, and too few batteries cannot meet customer demand.

- Heavy power grid pressure caused by disordered charging of batteries. Both fast charging and slow charging will cause load pressure on the power grid with the popularity of electric vehicles.

- Unbalanced utilization of battery swapping stations. Some electrical changing stations are congested due to excessive demand, and some are idle.

2. General Overview

3. Construction and Planning of Battery Swapping Infrastructure

3.1. Deployment of Battery Swapping Stations

3.2. Location-Routing Problem

3.3. Inventory Problem of Battery

4. Battery Charging Strategy

4.1. Reduce Grid Load

4.2. Queuing Theory

4.3. Economic Perspective

5. Assignment Problem of BSS

6. Other Relevant Research

7. Feasibility Analysis of Battery Swapping Station

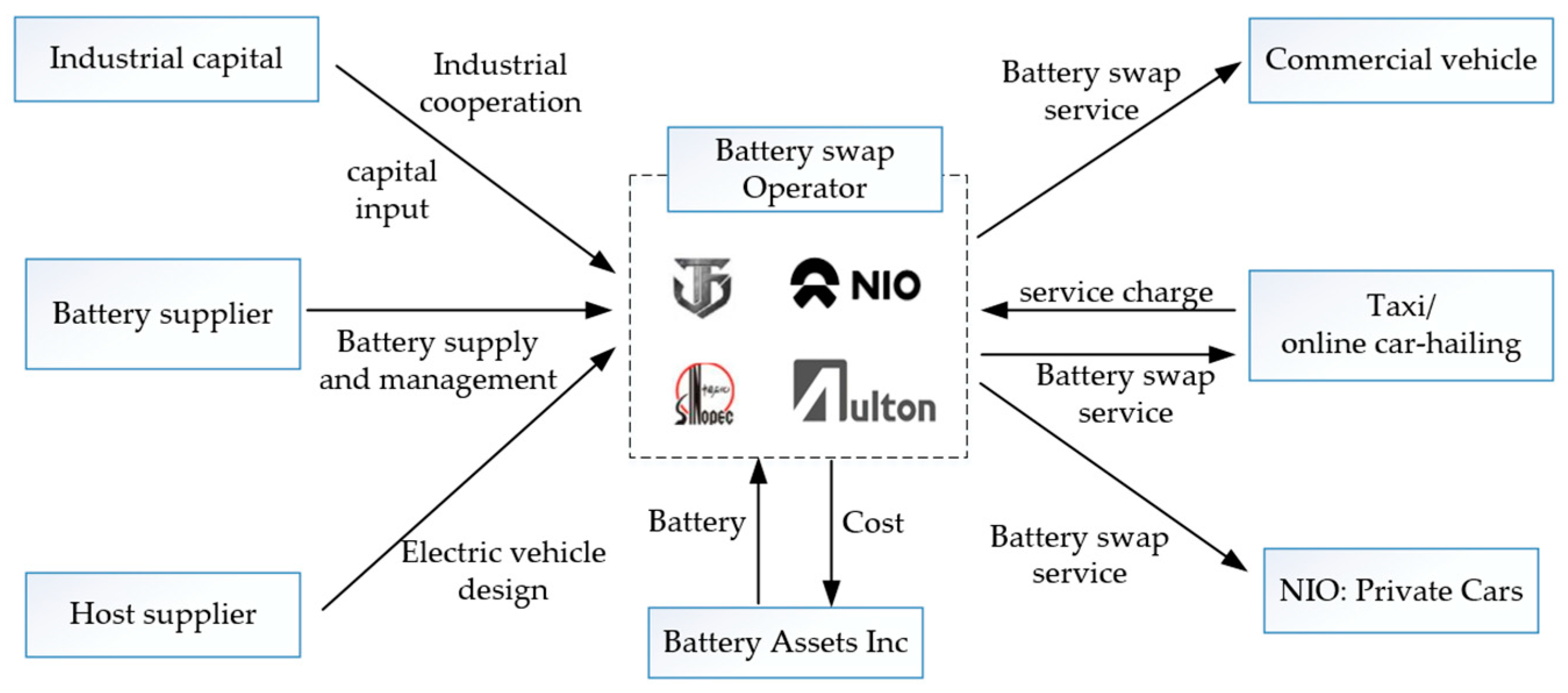

7.1. Business Model of BSS

7.1.1. Case 1: Better Place

- The market space of the new energy industry was small initially, so it was difficult to cover the huge investment in the early stage.

- Better Place did not have the capacity to produce a car and sold too few battery-switched vehicles.

- Better Place was cash strapped and could not continue to operate.

7.1.2. Case 2: Tesla

- Customers had to pay a service fee although a large number of charging stations were installed.

- Batteries could not be shared across vehicle models.

- The cost of construction the battery swapping stations was too high.

7.1.3. Case 3: Business Model of Chinese Enterprises

- Business models are maturing.

- National policies support battery swapping, make provisions on battery standards and there are battery swapping safety requirements.

- Technology is constantly upgrading. The fastest change time has been reduced to 90 s.

- More enterprises are joining the battery swapping industry.

7.2. Profitability Analysis

8. Conclusions

- (1)

- The existing research on the battery swapping station focuses on the location problem and charging strategy optimization, while the research on the number of batteries in the early stage of the BSS is scant. Some articles regard the initial battery reserve quantity as a fixed value that must be met while other articles utilize sensitivity analysis in determining the the battery reserve, without related research modelling the battery reserve.

- (2)

- Optimization of the electric vehicle charging strategy has become a hot topic in recent years, and has also achieved rich research results. However, under the current development mode of BSS, there are some limitations for practical engineering applications. First, most studies directly control the load on the power grid from the perspective of operators, power grids and electric vehicle users, without considering the operational difficulties caused by actual user needs and user experience. Second, the current research results fully consider the peak shaving and valley filling effect brought by orderly charging under the time-of-use power price, while ignoring the restriction of the number of chargers in the BSS and the constraints of user service ability. Moreover, the research results are suitable for centralized scheduling of electric vehicles, and are not suitable for the orderly scheduling of a single vehicle or a small number of vehicles in the battery swapping mode. Third, most studies model the probability distribution of power price and battery demand by fitting statistical laws to historical data. The difference between artificial assumptions and actual uncertainties will affect the reliability of the results.

- (3)

- At present, there are few studies on the assignment of BSS, and the existing research focuses on how to provide the best scheme for users and reduce the waiting time for power exchange in the future; how to provide users with the shortest waiting time for power exchange; how to effectively improve the utilization rate of power station. Although cooperative scheduling between moving electric vehicles and the power exchange station is considered, the following problems are not considered: when the power exchange demand increases to a certain threshold, the waiting time for power exchange is too long due to an insufficient battery reserve and the single battery swapping stations accepting excessive demand. There is usually only one optimization index, which does not have the ability for self-learning and self-improvement of decision accuracy and reliability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sobol, L.; Dyjakon, A. The Influence of Power Sources for Charging the Batteries of Electric Cars on CO2 Emissions During Daily Driving: A Case Study from Poland. Energies 2020, 13, 4267. [Google Scholar] [CrossRef]

- Mehar, S.; Zeadally, S.; Remy, G.; Senouci, S.M. Sustainable Transportation Management System for a Fleet of Electric Vehicles. IEEE Trans. Intell. Transp. Syst. 2015, 16, 1401–1414. [Google Scholar] [CrossRef]

- Agaton, C.B.; Collera, A.A.; Guno, C. Socio-Economic and Environmental Analyses of Sustainable Public Transport in the Philippines. Sustainability 2020, 12, 4720. [Google Scholar] [CrossRef]

- Ahmed, M.; Zheng, Y.; Amine, A.; Fathiannasab, H.; Chen, Z. The role of artificial intelligence in the mass adoption of electric vehicles. Joule 2021, 5, 2296–2322. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Chi, Y.-Y.; Xu, J.-H.; Li, J.-L. Consumer Preferences for Electric Vehicle Charging Infrastructure Based on the Text Mining Method. Energies 2021, 14, 4598. [Google Scholar] [CrossRef]

- Mak, H.-Y.; Rong, Y.; Shen, Z.-J.M. Infrastructure Planning for Electric Vehicles with Battery Swapping. Manag. Sci. 2013, 59, 1557–1575. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Deng, J.; Zhu, K.; Tao, Y.; Liu, X.; Cui, L. Location and Expansion of Electric Bus Charging Stations Based on Gridded Affinity Propagation Clustering and a Sequential Expansion Rule. Sustainability 2021, 13, 8957. [Google Scholar] [CrossRef]

- Wu, X.; Feng, Q.; Bai, C.; Lai, C.S.; Jia, Y.; Lai, L.L. A novel fast-charging stations locational planning model for electric bus transit system. Energy 2021, 224, 120106. [Google Scholar] [CrossRef]

- Uslu, T.; Kaya, O. Location and capacity decisions for electric bus charging stations considering waiting times. Transp. Res. Part D Transp. Environ. 2021, 90, 102645. [Google Scholar] [CrossRef]

- Arias-Londoño, A.; Montoya, O.D.; Grisales-Noreña, L.F. A Chronological Literature Review of Electric Vehicle Interactions with Power Distribution Systems. Energies 2020, 13, 3016. [Google Scholar] [CrossRef]

- Wang, X.; He, Z.; Yang, J. Electric Vehicle Fast-Charging Station Unified Modeling and Stability Analysis in the dq Frame. Energies 2018, 11, 1195. [Google Scholar] [CrossRef] [Green Version]

- Liu, X. Research on Flexibility Evaluation Method of Distribution System Based on Renewable Energy and Electric Vehicles. IEEE Access 2020, 8, 109249–109265. [Google Scholar] [CrossRef]

- Lee, K.-B.; Ahmed, M.A.; Kang, D.-K.; Kim, Y.-C. Deep Reinforcement Learning Based Optimal Route and Charging Station Selection. Energies 2020, 13, 6255. [Google Scholar] [CrossRef]

- Sierpiński, G.; Staniek, M.; Kłos, M.J. Decision Making Support for Local Authorities Choosing the Method for Siting of In-City EV Charging Stations. Energies 2020, 13, 4682. [Google Scholar] [CrossRef]

- Wang, Y.; Bi, J.; Lu, C.; Ding, C. Route Guidance Strategies for Electric Vehicles by Considering Stochastic Charging Demands in a Time-Varying Road Network. Energies 2020, 13, 2287. [Google Scholar] [CrossRef]

- Ferro, G.; Paolucci, M.; Robba, M. Optimal Charging and Routing of Electric Vehicles with Power Constraints and Time-of-Use Energy Prices. IEEE Trans. Veh. Technol. 2020, 69, 14436–14447. [Google Scholar] [CrossRef]

- Arias-Londoño, A.; Gil-González, W.; Montoya, O. A Linearized Approach for the Electric Light Commercial Vehicle Routing Problem Combined with Charging Station Siting and Power Distribution Network Assessment. Appl. Sci. 2021, 11, 4870. [Google Scholar] [CrossRef]

- Deng, J.; Li, J.; Li, C.; Han, Y.; Liu, Q.; Niu, B.; Liu, L.; Zhang, B. A hybrid algorithm for electric vehicle routing problem with nonlinear charging. J. Intell. Fuzzy Syst. 2021, 40, 5383–5402. [Google Scholar] [CrossRef]

- Schneider, F.; Thonemann, U.W.; Klabjan, D. Optimization of Battery Charging and Purchasing at Electric Vehicle Battery Swap Stations. Transp. Sci. 2018, 52, 1211–1234. [Google Scholar] [CrossRef]

- Sun, B.; Sun, X.; Tsang, D.H.; Whitt, W. Optimal battery purchasing and charging strategy at electric vehicle battery swap stations. Eur. J. Oper. Res. 2019, 279, 524–539. [Google Scholar] [CrossRef]

- Zhong, L.; Pei, M. Optimal Design for a Shared Swap Charging System Considering the Electric Vehicle Battery Charging Rate. Energies 2020, 13, 1213. [Google Scholar] [CrossRef] [Green Version]

- Upchurch, C.; Kuby, M. Comparing the p-median and flow-refueling models for locating alternative-fuel stations. J. Transp. Geogr. 2010, 18, 750–758. [Google Scholar] [CrossRef]

- Shen, Z.-J.M.; Feng, B.; Mao, C.; Ran, L. Optimization models for electric vehicle service operations: A literature review. Transp. Res. Part B Methodol. 2019, 128, 462–477. [Google Scholar] [CrossRef]

- Yang, J.; Sun, H. A hybrid genetic algorithm for battery swap stations location and inventory problem. Int. J. Shipp. Transp. Logist. 2015, 7, 246. [Google Scholar] [CrossRef]

- An, K.; Jing, W.; Kim, I. Battery-swapping facility planning for electric buses with local charging systems. Int. J. Sustain. Transp. 2019, 14, 489–502. [Google Scholar] [CrossRef]

- He, F.; Yin, Y.; Zhou, J. Deploying public charging stations for electric vehicles on urban road networks. Transp. Res. Part C Emerg. Technol. 2015, 60, 227–240. [Google Scholar] [CrossRef]

- Zeng, M.; Pan, Y.; Zhang, D.; Lu, Z.; Li, Y. Data-Driven Location Selection for Battery Swapping Stations. IEEE Access 2019, 7, 133760–133771. [Google Scholar] [CrossRef]

- Yang, X.; Shao, C.; Zhuge, C.; Sun, M.; Wang, P.; Wang, S. Deploying battery swap stations for shared electric vehicles using trajectory data. Transp. Res. Part D Transp. Environ. 2021, 97, 102943. [Google Scholar] [CrossRef]

- Wang, R.; Li, X.; Xu, C.; Li, F. Study on location decision framework of electric vehicle battery swapping station: Using a hybrid MCDM method. Sustain. Cities Soc. 2020, 61, 102149. [Google Scholar] [CrossRef]

- Yang, J.; Sun, H. Battery swap station location-routing problem with capacitated electric vehicles. Comput. Oper. Res. 2015, 55, 217–232. [Google Scholar] [CrossRef]

- Hof, J.; Schneider, M.; Goeke, D. Solving the battery swap station location-routing problem with capacitated electric vehicles using an AVNS algorithm for vehicle-routing problems with intermediate stops. Transp. Res. Part B Methodol. 2017, 97, 102–112. [Google Scholar] [CrossRef]

- Arango, J.D.S.; Londono, A.A.; Echeverri, M.G. Electric Vehicles for merchandise transportation: Integrated planning taking into acount the electrical distribution system. IEEE Lat. Am. Trans. 2018, 16, 2192–2198. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, H.; Feng, R. A two-echelon vehicle routing problem involving electric vehicles with time windows. J. Phys. Conf. Ser. 2019, 1324, 012071. [Google Scholar] [CrossRef] [Green Version]

- Jie, W.; Yang, J.; Zhang, M.; Huang, Y. The two-echelon capacitated electric vehicle routing problem with battery swapping stations: Formulation and efficient methodology. Eur. J. Oper. Res. 2019, 272, 879–904. [Google Scholar] [CrossRef]

- Ban, M.F.; Yu, J.L.; Yao, Y.Y. Joint Optimal Scheduling for Electric Vehicle Battery Swapping-charging Systems Based on Wind Farms. CSEE J. Power Energy Syst. 2021, 7, 555–566. [Google Scholar]

- Zhou, B.-H.; Tan, F. Electric vehicle handling routing and battery swap station location optimisation for automotive assembly lines. Int. J. Comput. Integr. Manuf. 2018, 31, 978–991. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, M.Z.; Zhang, W.Y. A novel location-routing problem in electric vehicle transportation with stochastic de-mands. J. Clean. Prod. 2019, 221, 567–581. [Google Scholar] [CrossRef]

- Li, J.; Wang, F.; He, Y. Electric Vehicle Routing Problem with Battery Swapping Considering Energy Consumption and Carbon Emissions. Sustainability 2020, 12, 10537. [Google Scholar] [CrossRef]

- Mao, H.; Shi, J.; Zhou, Y.; Zhang, G. The Electric Vehicle Routing Problem With Time Windows and Multiple Recharging Options. IEEE Access 2020, 8, 114864–114875. [Google Scholar] [CrossRef]

- Sun, B.; Tan, X.Q.; Tsang, D.H.K. Optimal Charging Operation of Battery Swapping Stations with QoS Guarantee. In Proceedings of the IEEE International Conference on Smart Grid Communications, Venice, Italy, 3–6 November 2014; pp. 13–18. [Google Scholar]

- Tan, X.Q.; Sun, B.; Tsang, D.H.K. Queueing Network Models for Electric Vehicle Charging Station with Battery Swapping. In Proceedings of the IEEE International Conference on Smart Grid Communications, Venice, Italy, 3–6 November 2014; pp. 1–6. [Google Scholar]

- Jing, W.T.; Kim, I.; An, K. The Uncapacitated Battery Swapping Facility Location Problem with Localized Charging System Serving Electric Bus Fleet. In Proceedings of the International Symposium of Transport Simulation, Matsuyama, Japan, 6–8 August 2018; pp. 227–234. [Google Scholar]

- Lu, X.; Liu, N.; Huang, Y.; Zhang, J.; Zhou, N. Optimal Configuration of EV Battery Swapping Station Considering Service Availability. In Proceedings of the 1st International Conference on Intelligent Green Building and Smart Grid (IGBSG), Taipei, Taiwan, 23–25 April 2014; National Taiwan University of Science and Technology: Taipei, Taiwan, 2014. [Google Scholar]

- Wu, T.H.; Pang, G.K.H.; Choy, K.; Lam, H. An optimization model for a battery swapping station in Hong Kong. In Proceedings of the IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 14–17 June 2015. [Google Scholar] [CrossRef] [Green Version]

- Liu, N.; Lin, X.; Chen, Q.; Zou, F.; Chen, P.Z. Optimal Configuration for Batteries and Chargers in Battery Switch Station Considering Extra Waiting Time of Electric Vehicles. J. Energy Eng. 2017, 143, 04016035. [Google Scholar] [CrossRef]

- Tan, X.; Sun, B.; Wu, Y.; Tsang, D.H. Asymptotic performance evaluation of battery swapping and charging station for electric vehicles. Perform. Eval. 2018, 119, 43–57. [Google Scholar] [CrossRef] [Green Version]

- Nie, Y.; Chung, C.Y.; Chen, L.; Wang, X.; Yu, R.; Qin, M. In Inventory Management of DSCC System via Improved (s, S) Model. In Proceedings of the IEEE PES General Meeting, National Harbor, MD, USA, 27–31 July 2014. [Google Scholar]

- Dai, Q.; Cai, T.; Duan, S.; Zhang, W.; Zhao, J. A smart energy management system for electric city bus battery swap station. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Dearborn, MI, USA, 15–18 June 2014. [Google Scholar] [CrossRef]

- Wu, H.; Pang, G.K.H.; Choy, K.; Lam, H. A charging-scheme decision model for electric vehicle battery swapping station using varied population evolutionary algorithms. Appl. Soft Comput. 2017, 61, 905–920. [Google Scholar] [CrossRef]

- Amiri, S.S.; Jadid, S.; Saboori, H. Multi-objective optimum charging management of electric vehicles through battery swapping stations. Energy 2018, 165, 549–562. [Google Scholar] [CrossRef]

- Huang, X.; Qiang, H.; Zhang, Q.; Li, H. Research on ISFLA-Based Optimal Control Strategy for the Coordinated Charging of EV Battery Swap Station. Math. Probl. Eng. 2013, 2013, 1–7. [Google Scholar] [CrossRef]

- Zhao, G.; Guo, J.; Qiang, H. Research on SFLA-Based Bidirectional Coordinated Control Strategy for EV Battery Swapping Station. CMC Comput. Mater. Continua 2017, 53, 343–356. [Google Scholar]

- Gao, T.; Liu, R.Y.; Hua, K. Dispatching Strategy Optimization for Orderly Charging and Discharging of Flectric Vehicle Battery Charging and Swapping Station. In Proceedings of the 5th International Conference on Electric Utility Deregulation and Restructuring and Power Technologies (DRPT), Changsha, China, 26–29 November 2015; pp. 2640–2645. [Google Scholar]

- Rao, R.; Zhang, X.; Xie, J.; Ju, L. Optimizing electric vehicle users’ charging behavior in battery swapping mode. Appl. Energy 2015, 155, 547–559. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, J.J.; Yang, M.; Li, Z. Deep Reinforcement Learning Based Optimal Schedule for a Battery Swapping Station Considering Uncertainties. IEEE Trans. Ind. Appl. 2020, 56, 5775–5784. [Google Scholar] [CrossRef]

- Sun, B.; Tan, X.Q.; Tsang, D.H.K. Optimal Charging Operation of Battery Swapping and Charging Stations with QoS Guarantee. IEEE Trans. Smart Grid 2018, 9, 4689–4701. [Google Scholar] [CrossRef]

- Widrick, R.S.; Nurre, S.G.; Robbins, M. Optimal Policies for the Management of an Electric Vehicle Battery Swap Station. Transp. Sci. 2018, 52, 59–79. [Google Scholar] [CrossRef]

- Asadi, A.; Pinkley, S.N. A stochastic scheduling, allocation, and inventory replenishment problem for battery swap stations. Transp. Res. Part E Logist. Transp. Rev. 2021, 146, 1366–5545. [Google Scholar] [CrossRef]

- Zhang, M.; Wen, K.; Zhou, C.; Li, W.; Zou, N. Capacity Optimization Configuration for Second Use of Electric Vehicle Batteries in Battery Swapping Stations. In Proceedings of the 2nd IEEE International Conference on Civil Aviation Safety and Information Technology (ICCASIT), Wuhan, China, 14–16 October 2020; pp. 282–288. [Google Scholar]

- Zhang, M.; Chen, J. The Energy Management and Optimized Operation of Electric Vehicles Based on Microgrid. IEEE Trans. Power Deliv. 2014, 29, 1427–1435. [Google Scholar] [CrossRef]

- Rehman, U.; Feng, D.; Su, H.; Numan, M.; Abbas, F. Network overloading management by exploiting the in-system batteries of electric vehicles. Int. J. Energy Res. 2021, 45, 5866–5880. [Google Scholar] [CrossRef]

- Sepetanc, K.; Pandzic, H. A Cluster-based Operation Model of Aggregated Battery Swapping Stations. IEEE Trans. Power Syst. 2020, 35, 249–260. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, X.; Xie, J.; Liu, W. An Optimal Operation Model and Ordered Charging/Discharging Strategy for Battery Swapping Stations. Sustainability 2017, 9, 700. [Google Scholar] [CrossRef] [Green Version]

- Schiffer, M.; Schneider, M.; Walther, G.; Laporte, G. Vehicle Routing and Location Routing with Intermediate Stops: A Review. Transp. Sci. 2019, 53, 319–343. [Google Scholar] [CrossRef]

- Kucukoglu, I.; Dewil, R.; Cattrysse, D. The electric vehicle routing problem and its variations: A literature review. Comput. Ind. Eng. 2021, 161, 107650. [Google Scholar] [CrossRef]

- You, P.; Low, S.H.; Yang, Z.; Zhang, Y.; Fu, L. Real-time recommendation algorithm of battery swapping stations for electric taxis. In Proceedings of the 2016 IEEE Power and Energy Society General Meeting (PESGM), Boston, MA, USA, 17–21 July 2016; pp. 1–5. [Google Scholar] [CrossRef]

- You, P.; Pang, J.Z.F.; Chen, M.; Low, S.H.; Sun, Y. Battery swapping assignment for electric vehicles: A bipartite matching approach. In Proceedings of the 2017 IEEE 56th Annual Conference on Decision and Control (CDC), Melbourne, Australia, 12–15 December 2017; pp. 1421–1426. [Google Scholar] [CrossRef] [Green Version]

- You, P.; Cheng, P.; Pang, J.Z.; Low, S.H. Efficient Online Station Assignment for EV Battery Swapping. In Proceedings of the Ninth International Conference on Future Energy Systems, Karlsruhe, Germany, 12–15 June 2018; pp. 383–385. [Google Scholar] [CrossRef]

- You, P.; Low, S.H.; Tushar, W.; Geng, G.; Yuen, C.; Yang, Z.; Sun, Y. Scheduling of EV Battery Swapping—Part I: Centralized Solution. IEEE Trans. Control Netw. Syst. 2018, 5, 1887–1897. [Google Scholar] [CrossRef] [Green Version]

- You, P.; Low, S.H.; Zhang, L.; Deng, R.; Giannakis, G.B.; Sun, Y.; Yang, Z. Scheduling of EV Battery Swapping—Part II: Distributed Solutions. IEEE Trans. Control Netw. Syst. 2018, 5, 1920–1930. [Google Scholar] [CrossRef] [Green Version]

- Choi, D.I.; Lim, D.-E. Analysis of the State-Dependent Queueing Model and Its Application to Battery Swapping and Charging Stations. Sustainability 2020, 12, 2343. [Google Scholar] [CrossRef] [Green Version]

- Shu, X.; Li, G.; Zhang, Y.; Shen, S.; Chen, Z.; Liu, Y. Stage of Charge Estimation of Lithium-Ion Battery Packs Based on Improved Cubature Kalman Filter With Long Short-Term Memory Model. IEEE Trans. Transp. Electrif. 2021, 7, 1271–1284. [Google Scholar] [CrossRef]

- Roselyn, J.P.; Ravi, A.; Devaraj, D.; Venkatesan, R. Optimal SoC Estimation Considering Hysteresis Effect for Effective Battery Management in Shipboard Batteries. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 5533–5541. [Google Scholar] [CrossRef]

- Zhou, W.; Zheng, Y.; Pan, Z.; Lu, Q. Review on the Battery Model and SOC Estimation Method. Processes 2021, 9, 1685. [Google Scholar] [CrossRef]

- Naguib, M.; Kollmeyer, P.; Emadi, A. Lithium-Ion Battery Pack Robust State of Charge Estimation, Cell Inconsistency, and Balancing: Review. IEEE Access 2021, 9, 50570–50582. [Google Scholar] [CrossRef]

- Espedal, I.B.; Jinasena, A.; Burheim, O.S.; Lamb, J.J. Current Trends for State-of-Charge (SoC) Estimation in Lithium-Ion Battery Electric Vehicles. Energies 2021, 14, 3284. [Google Scholar] [CrossRef]

- Deleebeeck, L.; Veltze, S. Electrochemical impedance spectroscopy study of commercial Li-ion phosphate batteries: A me-trology perspective. Int. J. Energy Res. 2020, 44, 7158–7182. [Google Scholar] [CrossRef]

- Ban, M.; Zhang, Z.; Li, C.; Li, Z.; Liu, Y. Optimal scheduling for electric vehicle battery swapping-charging system based on nanogrids. Int. J. Electr. Power Energy Syst. 2021, 130, 106967. [Google Scholar] [CrossRef]

- Wang, R.; Li, X.; Li, C. Optimal selection of sustainable battery supplier for battery swapping station based on Triangular fuzzy entropy—MULTIMOORA method. J. Energy Storage 2021, 34, 102013. [Google Scholar] [CrossRef]

- Zhang, M.; Li, W.; Yu, S.S.; Wen, K.; Zhou, C.; Shi, P. A unified configurational optimization framework for battery swapping and charging stations considering electric vehicle uncertainty. Energy 2021, 218, 119536. [Google Scholar] [CrossRef]

| Charging Mode | Slow Charging | Fast Charging |

|---|---|---|

| Charging equipment | AC charging pile+ on-board charger | DC charging pile+ DC charger |

| Charging duration | 6–10 h | 30 min–2 h |

| Infrastructure cost | low | high |

| Impact on battery life | less | comparatively large |

| Battery Swapping | Charging | |

|---|---|---|

| Charging efficiency | 3–5 min | ≥30 min |

| Battery recycling | easy battery recovery | difficult battery recovery |

| Battery maintenance | managed by professionals, extending the battery life by 30–60% | managed by consumer, short battery life |

| Operability | Manual charging | Intelligent, fully automated |

| (1) Deployment of Battery Swapping Stations | |||

| References | Target | Model | Solution Method |

| Mak et al. (2013) | Minimize the cost in the worst case; maximize the probability of the worst case | Distributed robust optimization | CPLEX |

| Yang and Sun (2015) | Minimize construction cost and inventory cost | Mixed-integer linear programming | Genetic algorithm |

| An et al. (2020) | Minimize construction cost | Two-stage stochastic programming model | Gradient descent algorithm |

| He et al. (2015) | Minimize the total social cost | Mixed-integer non-linear programming | Genetic algorithm |

| Zeng et al. (2019) | Reduce the average distance error between power demand point and BSS | Hidden Markov Model | Map matching algorithm based on hidden Markov: trajectory reduction algorithm (TTR); K-means clustering; hierarchical clustering |

| Wang et al. (2019) | Minimize cost | System dynamics model; space-time distribution model of electricity demand | Improve the difference algorithm; Monte Carlo search |

| (2) Location-Routing Problem | |||

| Yang and Sun (2015) | Minimize construction and transportation costs | Mixed-integer linear programming | Taboo search; improve mileage saving; four-stage heuristic algorithm: scanning algorithm, iterative greed, adaptive large neighborhood, CPLEX |

| Hof et al. (2017) | Minimize construction and transportation costs | Mixed-integer linear programming | Adaptive large neighborhood search algorithm |

| Jie et al. (2019) | Minimize transportation costs, distribution center handling costs, and battery exchange costs | Bilevel integer programming | Gurobi; column generation algorithm; adaptive large neighborhood search algorithm |

| Li et al. (2020) | Minimize the total cost associated with energy consumption and travel time of electric vehicles | Mixed-integer programming | Adaptive genetic algorithm based on climbing optimization and neighborhood search |

| References | Target | Model | Solution Method |

|---|---|---|---|

| Wu et al. (2017) | Improve BSS battery inventory level and minimize battery charging damage | Multi-objective optimization model | Genetic algorithm; differential evolution algorithm; particle swarm optimization algorithm |

| Huang et al. (2013) Zhao et al. (2017) | Improve BSS battery inventory level and minimize battery charging damage | Multi-objective optimization model | Genetic algorithm; differential evolution algorithm; particle swarm optimization algorithm |

| Gao et al. (2015) | Restrain load fluctuation | Charge scheduling model with charge and discharge power in different periods as constraints | Multi-population particle swarm optimization algorithm |

| Gao et al. (2020) | Optimal real-time charging and discharging strategy | Reinforcement learning model | DRL algorithm |

| Sun et al. (2019) | Minimize battery investment cost and operating cost | Periodic fluid model; queuing theory | Polynomial optimization |

| Widrick et al. (2018) | profit maximization | Markov decision processes | Polynomial optimization |

| Asadi et al. (2021) | Reduce the charging cost; Optimize number of batteries | Markov decision processes | Backward induction; heuristic algorithm; intensified study |

| Liang et al. (2017) | Maximize the operating profit of the power station | Linear programming constrained by electricity exchange demand and battery charge and discharge balance | Simulation analysis |

| References | Target | Model | Solution Method |

|---|---|---|---|

| You et al. (2016) | Relieve the congestion of changing stations | Game theory | Game theory |

| You et al. (2017) | Relieve the congestion of changing stations | Mixed-integer linear programming | Hungary algorithm; second-order cone programming |

| Choi et al. (2020) | Relieve the congestion of changing stations | Markov decision processes | Markov decision processes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Lu, X. Construction Planning and Operation of Battery Swapping Stations for Electric Vehicles: A Literature Review. Energies 2021, 14, 8202. https://doi.org/10.3390/en14248202

Feng Y, Lu X. Construction Planning and Operation of Battery Swapping Stations for Electric Vehicles: A Literature Review. Energies. 2021; 14(24):8202. https://doi.org/10.3390/en14248202

Chicago/Turabian StyleFeng, Yu, and Xiaochun Lu. 2021. "Construction Planning and Operation of Battery Swapping Stations for Electric Vehicles: A Literature Review" Energies 14, no. 24: 8202. https://doi.org/10.3390/en14248202

APA StyleFeng, Y., & Lu, X. (2021). Construction Planning and Operation of Battery Swapping Stations for Electric Vehicles: A Literature Review. Energies, 14(24), 8202. https://doi.org/10.3390/en14248202