Activities in Divertor Reflector and Linear Plates Using WCLL and HCPB Breeding Blanket Concepts

Abstract

:1. Introduction

- Safe. Safety problems in a nuclear fission reactor, such as transient power, supercritical, or other accidental uncontrolled radioactive fission, will not occur in this type of reactor. For fusion reactors to operate stably, plasma must meet stringent conditions. If those conditions are not maintained, the fusion reaction will stop spontaneously, ensuring safety. The residual heat in the fusion reactor is mainly due to the fission of activated materials during the shutdown. Thus, the residual heat in the fusion reactor is much lower and more accessible to remove than in the fission reactor, where the heat is dissipated using spent fuel, leading to significant accidents [4];

- No long-lasting or high-level waste. During the decommissioning of a fusion reactor, the radioactive waste consists mainly of tritium and activation products such as structural materials, breeding blankets, and cooling materials irradiated with neutrons. In addition, the half-life of tritium is short (about 12.3 years), and the energy of the electrons emitted by beta decay is low (average 5.68 keV). Thus, the tritium does not cause external radiation exposure. Even if there is a leak, there will be no long-term radioactivity at that site [5].

- Near-term: Construction, research and development of ITER, IFMIF-DONES, and DEMO conceptual design, and research to determine whether stellarator is a cheaper, easier way to reach fusion;

- Medium-term: Utilize ITER to its full potential to construct the best version of DEMO and possible further development of the stellarator concept;

- Long-term: Using results from ITER performance, finalized design of DEMO and its construction. At this point, there will be qualified long-life materials for DEMO and power plants [8].

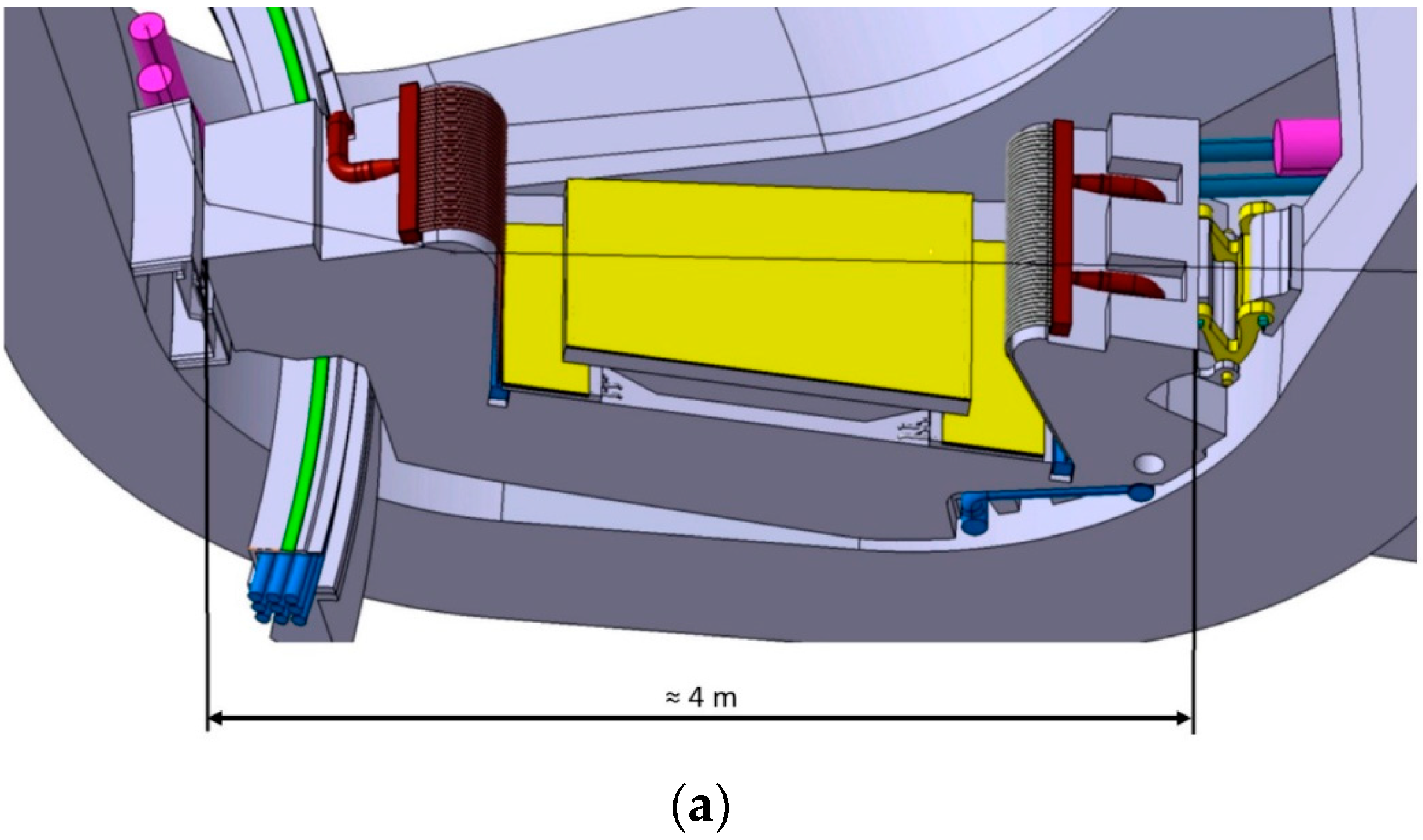

2. EU DEMO Divertor

- Convert fusion heat energy to electricity, approximately 500 MWe;

- Achieve tritium self-sufficiency;

- Operate for at least several years at full power;

- Produce no long-term radioactive waste; and

- Lead the development of fusion power plants [10].

- Vertical target or plasma-facing components (PFC): In one cassette, there are inner and outer parts. The height of the inner part is 0.76 m, and the height of the outer part is 0.65 m. The width of the targets is 1.07 and 0.82 for the outer and inner parts accordingly. One cassette has 78 plasma-facing units (PFU), 45 in the outer part and 33 PFUs in the inner part. The plasma facing unit is made out of tungsten monoblock. Tungsten is cooled by water flowing through CuCrZr pipes. The internal diameter of the pipe is 12 mm, and its width is 1.5 mm; 1 mm is reserved for the interlayer between the monoblock and the pipes [16].

- Shielding liner plate: The primary shielding liner plate function is to provide shielding for the VV and magnet coils from neutrons. The shielding liner plate is made of Eurofer and is cooled by the cassette cooling circuit. The plate is coated with 3 mm tungsten (see Figure 2). The purpose of the coating is to protect the stainless steel, in this work Eurofer, from erosion due to interaction with high energy neutrons. It is estimated that the shielding liner will be produced by using the vacuum plasma spraying technique to deposit a W (tungsten) layer on a small Eurofer surface.

- Reflector plates: The primary function of the reflector plates is to provide thermal shielding for the components underneath, PFC manifolds and distributor cooling. It also protects those components from alpha particles and other impurities. Like the shielding liner plates, reflector plates are made of Eurofer with a 3 mm tungsten coating.

- Locking on vacuum vessel: “Nose” is the locking part of the divertor which attaches to the inboard vacuum vessel, while “whisbone” attaches to the outboard part. The NOSE concept was created to reduce the gap between the blanket and the cassette body in the final installation. The wishbone is a flexible component that fixes the cassette body via pin connections to the VV. It is made from Ti alloy, and the pins are made from Inconel alloy [20].

3. Materials and Calculational Methods

3.1. Geometrical DEMO Model and Materials

3.2. Irradiation Scenario

3.3. Modelling Tools

- Primary information is taken from the nuclear data library. TENDL-2017 [35] was used in the present calculations. TENDL libraries contain cross-section data when neutron, proton, photon, alpha, and more particle-induced reaction energy is up to 200 MeV [35]. Now it is known as one of the most extensive data libraries, and it is updated every year or two [36];

- Deterministic methods provide the activation results by solving a set of differential rate equations. Equations are constructed in response to different irradiation scenarios. Results for different nuclide contents in materials after irradiation steps are obtained by solving Bateman differential equations [37];

- Calculation and production of radiological quantities extracted;

- Additional calculations provide information about: pathway analysis, Monte Carlo sensitivity, and uncertainties [33].

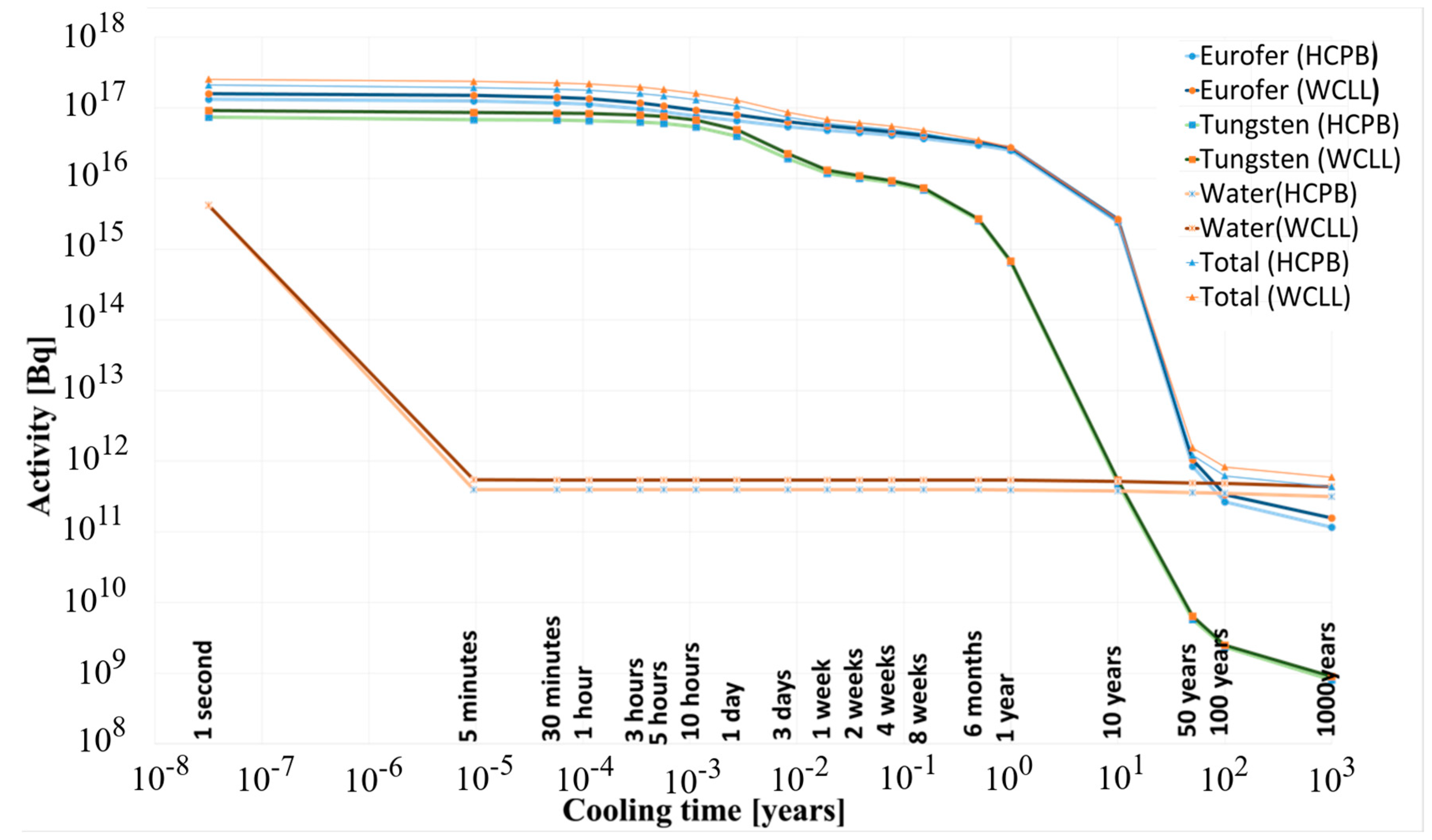

4. Results

- Water: 4.20 × 1015 Bq to 3.16 × 1011 Bq;

- Tungsten 7.42 × 1016 Bq to 0.802 × 109 Bq;

- Eurofer 1.32 × 1017 Bq to1.17 × 1011 Bq.

- Water: 4.19 × 1015 Bq to 4.34 × 1011 Bq;

- Tungsten 9.202 × 1016 Bq to 0.90 × 109 Bq;

- Eurofer 1.58 × 1017 Bq to 1.57 × 1011 Bq (see Figure 9 for more information).

- Layer 1 was made of tungsten.

- Layer 2 was made of tungsten, CuCrZr, Cu alloy, and water.

- Layer 3 was made of tungsten.

- Layer 4 was made of EUROFER steel and water [43].

5. Summary

- At the beginning of cooling time: 55Fe, 56Mn, 187W, 16N, 52V;

- After one year: 55Fe, 185W; and

- 14C dominates in water for 100 years and beyond.

- In water, activity is higher using the HCPB breeding blanket, but activity is higher in WCLL, approximately 1.37 times later.

- In tungsten material, values differ 1.24 times at the first second after shutdown, and 1.07 times after 100 years.

- In Eurofer material, activity differs 1.20 times at the first second, and around 1.10 times after ten years.

Author Contributions

Funding

Conflicts of Interest

References

- Kemfert, C. Green Deal for Europe: More Climate Protection and Fewer Fossil Fuel Wars. Intereconomics 2019, 54, 353–358. [Google Scholar] [CrossRef] [Green Version]

- Chen, F.F. Plasma Applications Introduction to Plasma Physics and Controlled Fusion; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Hughes, J. Making isotopes matter: Francis Aston and the mass-spectrograph. Dynamis 2009, 29, 131–165. [Google Scholar] [CrossRef]

- Wu, Y.C.; Chen, Z.B.; Hu, L.Q. Identification of safety gaps for fusion demonstration reactors. Nat. Energy 2016, 1, 1–11. [Google Scholar] [CrossRef]

- Wu, Y.C.; Stevens, E.; Kim, K. Summary of the 1st international workshop on environmental, safety and economic aspects of fusion power. Nucl. Fusion 2016, 54, 127001. [Google Scholar] [CrossRef]

- Donné, A.J.H. The European roadmap towards fusion electricity. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2019, 377, 20170432. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Turcanu, C.; Prades, A.; Sala, R.; Perko, T.; Oltra, C. Fusion energy: A deeper look into attitudes among the general public. Fusion Eng. Des. 2020, 161, 111891. [Google Scholar] [CrossRef]

- Realising Fusion Electricity. Available online: https://www.euro-fusion.org/eurofusion/roadmap/ (accessed on 3 September 2021).

- Sawan, M.E.; Abdou, M.A. Physics and technology conditions for attaining tritium self-sufficiency for the DT fuel cycle. Fusion Eng. Des. 2006, 81, 1131–1144. [Google Scholar] [CrossRef]

- Federici, G.; Bachmann, C.; Barucca, L.; Biel, W.; Boccaccini, L.; Brown, R.; Bustreo, C.; Ciattaglia, S.; Cismondi, F.; Coleman, M.; et al. DEMO design activity in Europe: Progress and updates. Fusion Eng. Des. 2018, 136, 729–741. [Google Scholar] [CrossRef]

- Ciattaglia, S.; Federici, G.; Barucca, L.; Lampasi, A.; Minucci, S.; Moscato, I. The European DEMO fusion reactor: Design status and challenges from balance of plant point of view. In Proceedings of the 2017 IEEE International Conference on Environment and Electrical Engineering and 2017 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Milan, Italy, 6–9 June 2017; pp. 1–6. [Google Scholar]

- Gliss, C.; Ciattaglia, S.; Korn, W.; Moscato, I. Initial layout of DEMO buildings and configuration of the main plant systems. Fusion Eng. Des. 2018, 136, 534–539. [Google Scholar] [CrossRef]

- You, J.; Mazzone, G.; Visca, E.; Bachmann, C.; Autissier, E.; Barrett, T.; Cocilovo, V.; Crescenzi, F.; Domalapally, P.; Dongiovanni, D.; et al. Conceptual design studies for the European DEMO divertor: Rationale and first results. Fusion Eng. Des. 2015, 109, 1598–1603. [Google Scholar] [CrossRef] [Green Version]

- Bachmann, C.; Ciattaglia, S.; Cismondi, F.; Eade, T.; Federici, G.; Fischer, U.; Franke, T.; Gliss, C.; Hernandez, F.; Keep, J.; et al. Overview over DEMO design integration challenges and their impact on component design concepts. Fusion Eng. Des. 2018, 136, 87–95. [Google Scholar] [CrossRef]

- Mazzone, G.; You, J.-H.; Bachmann, C.; Bonavolontà, U.; Cerri, V.; Coccorese, D.; Dongiovanni, D.; Flammini, D.; Frosi, P.; Forest, L.; et al. Eurofusion-DEMO Divertor-Cassette Design and Integration. Fusion Eng. Des. 2020, 157, 111656. [Google Scholar] [CrossRef]

- Noce, S.; Flammini, D.; Mariano, G.; Mazzone, G.; Moro, F.; Romanelli, F.; Villari, R.; You, J.-H. Neutronics analysis and activation calculation for tungsten used in the DEMO divertor targets: A comparative study between the effects of WCLL and HCPB blanket, different W compositions and chromium. Fusion Eng. Des. 2021, 169, 112428. [Google Scholar] [CrossRef]

- Marzullo, D.; Bachmann, C.; Coccorese, D.; Di Gironimo, G.; Frosi, P.; Mazzone, G.; You, J.-H. Progress in the pre-conceptual CAD engineering of European DEMO divertor cassette. Fusion Eng. Des. 2019, 146, 942–945. [Google Scholar] [CrossRef] [Green Version]

- Mazzone, G.; You, J.-H.; Bachmann, C.; Bonavolontà, U.; Cerri, V.; Coccorese, D.; Dongiovanni, D.; Flammini, D.; Frosi, P.; Forest, L.; et al. WPDIV-1-T005 Loads Specification (LS) for Divertor Cassette 2018 (Incl. Neutronics, EM Analysis), IDM Ref. EFDA_D_2NLWLE v1.0. Available online: https://idm.euro-fusion.org/default.aspx?uid=2NLWLE (accessed on 27 November 2021).

- di Maio, P.A.; Burlon, R.; Giardina, M.; You, J.H.; Mazzone, G. On the numerical assessment of the thermal-hydraulic operating map of the DEMO Divertor Plasma Facing Components cooling circuit. Fusion Eng. Des. 2020, 161, 111919. [Google Scholar] [CrossRef]

- Federici, G.; Kemp, R.; Ward, D.; Bachmann, C.; Franke, T.; Gonzalez, S.; Lowry, C.; Gadomska, M.; Harman, J.; Meszaros, B.; et al. Overview of EU DEMO design and R&D activities. Fusion Eng. Des. 2014, 89, 882–889. [Google Scholar] [CrossRef]

- Klein, F.; Litnovsky, A.; Tan, X.; Gonzalez-Julian, J.; Rasinski, M.; Linsmeier, C.; Bram, M.; Coenen, J.W. Smart alloys as armor material for DEMO: Overview of properties and joining to structural materials. Fusion Eng. Des. 2021, 166, 112272. [Google Scholar] [CrossRef]

- Richardson, M.; Gorley, M.; Wang, Y.; Aiello, G.; Pintsuk, G.; Gaganidze, E.; Richou, M.; Henry, J.; Vila, R.; Rieth, M. Technology readiness assessment of materials for DEMO in-vessel applications. J. Nucl. Mater. 2021, 550, 152906. [Google Scholar] [CrossRef]

- Pereslavtsev, P.; Cismondi, F.; Hernández, F.A. Analyses of the shielding options for HCPB DEMO blanket. Fusion Eng. Des. 2020, 156, 111605. [Google Scholar] [CrossRef]

- Moscato, I.; Barucca, L.; Ciattaglia, S.; D’Aleo, F.; Di Maio, P.; Federici, G.; Tarallo, A. Progress in the design development of EU DEMO helium-cooled pebble bed primary heat transfer system. Fusion Eng. Des. 2019, 146, 2416–2420. [Google Scholar] [CrossRef]

- Zhou, G.; Hernández, F.A.; Zeile, C.; Maione, I.A. Transient thermal analysis and structural assessment of an ex-vessel LOCA event on the EU DEMO HCPB breeding blanket and the attachment system. Fusion Eng. Des. 2018, 136, 34–41. [Google Scholar] [CrossRef] [Green Version]

- Hernández, F.; Pereslavtsev, P.; Kang, Q.; Norajitra, P.; Kiss, B.; Nádasi, G.; Bitz, O. A new HCPB breeding blanket for the EU DEMO: Evolution, rationale and preliminary performances. Fusion Eng. Des. 2017, 124, 882–886. [Google Scholar] [CrossRef]

- Brown, F.B.; Kiedrowski, B.C.; Bull, J.S. Verification of MCNP6.1 and MCNP6.1.1 for Criticality Safety Applications; United States, Los Alamos National Laboratory: Los Alamos, NM, USA, 2014. [Google Scholar] [CrossRef] [Green Version]

- Hasegawa, A.; Fukuda, M.; Tanno, T.; Nogami, S. Neutron Irradiation Behavior of Tungsten. Mater. Trans. 2013, 54, 466–471. [Google Scholar] [CrossRef] [Green Version]

- Tavassoli, F. Eurofer Steel, Development to Full Code Qualification. Procedia Eng. 2013, 55, 300–308. [Google Scholar] [CrossRef] [Green Version]

- Kroese, D.P.; Bretenon, T.; Taimre, T.; Botev, Z.I. Why the Monte Carlo method is so important today. WIREs Comput. Stat. 2014, 6, 386–392, [retrieved on 2020-03-23]. [Google Scholar] [CrossRef]

- Dunn, W.L.; Shultis, J.K. Exploring Monte Carlo Methods; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 978-0-444-51575-9. [Google Scholar]

- X-5 Monte Carlo Team, MCNP- a General Monte Carlo N-Particle Transport Code, Version 5, 2003, LA-UR-03-1987. Available online: https://mcnp.lanl.gov/pdf_files/la-ur-03-1987.pdf (accessed on 28 November 2021).

- Sublet, J.-C.; Eastwood, J.; Morgan, J.; Gilbert, M.; Fleming, M.; Arter, W. FISPACT-II: An Advanced Simulation System for Activation, Transmutation and Material Modelling. Nucl. Data Sheets 2017, 139, 77–137. [Google Scholar] [CrossRef]

- Koning, J.; Rochman, D. Modern Nuclear Data Evaluation with The TALYS Code System. Nucl. Data Sheets 2012, 113, 2841–2934. [Google Scholar] [CrossRef]

- Koning, A.J.; Rochman, D.; Sublet, J.-C.; Dzysiuk, N.; Fleming, M.; van der Marck, S. TENDL: Complete Nuclear Data Library for Innovative Nuclear Science and Technology. Nucl. Data Sheets 2019, 155, 1–55. [Google Scholar] [CrossRef]

- Kwon, S.; Konno, C.; Ohta, M.; Ochiai, K.; Sato, S.; Kasugai, A. TENDL-2017 benchmark test with iron shielding experiment at QST/TIARA. Fusion Eng. Des. 2019, 144, 209–214. [Google Scholar] [CrossRef]

- Forrest, R.A. FISPACT-2007: User Manual. Technical Report Ukaea FUS 534; Euratom/Ukaea Fusion Association, Culham Science centre: Abingdon, UK, 2007. [Google Scholar]

- Ďuran, I.; Entler, S.; Grover, O.; Bolshakova, I.; Výborný, K.; Kočan, M.; Jirman, T.; Vayakis, G.; Vasyliev, O.; Radishevskyi, M.; et al. Status of steady-state magnetic diagnostic for ITER and outlook for possible materials of Hall sensors for DEMO. Fusion Eng. Des. 2019, 146, 2397–2400. [Google Scholar] [CrossRef]

- Batistoni, P.; Angelone, M.; Petrizzi, L.; Pillon, M. Experimental validation of shut down dose rates calculations inside ITER cryostat. Fusion Eng. Des. 2001, 58, 613–616. [Google Scholar] [CrossRef]

- Fisher, U. PMI-5.3-035 Guidelines for Neutronic Analyses, IDM Ref. EFDA_D_2L8TR9. Available online: https://idm.euro-fusion.org/default.aspx?uid=2L8TR9 (accessed on 28 November 2021).

- IAEA Safety Standards: Classification of Radioactive Waste, Tech. Rep. General Safety Guide: GSG-1. 2009. Available online: https://www-pub.iaea.org/MTCD/publications/PDF/Pub1419_web.pdf (accessed on 27 November 2021).

- Gilbert, M.; Eade, T.; Bachmann, C.; Fischer, U.; Taylor, N. Activation, decay heat, and waste classification studies of the European DEMO concept. Nucl. Fusion 2017, 57, 046015. [Google Scholar] [CrossRef] [Green Version]

- Tidikas, A.; Stankunas, G. Activation analysis of the European DEMO divertor with respect to the different breeding blanket segmentation. Fusion Eng. Des. 2020, 161, 112012. [Google Scholar] [CrossRef]

| N of toroidal field coils | 16 |

| Major radius (m) | 8.938 |

| Minor radius (m) | 2.883 |

| Aspect ratio | 3.1 |

| Plasma elongation | 1.65 |

| Plasma triangularity | 0.33 |

| Fusion power (MW) | 1998 |

| Eurofer | Tungsten | Water | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M5 | M15 | m100 | |||||||||

| 7.798 g/cm3 | 19.25 g/cm3 | 0.926 g/cm3 | |||||||||

| Element | wt % | Element | wt % | Element | wt % | Element | wt % | Element | wt % | Element | wt % |

| Fe | 88.698 | Mn | 0.4 | Al | 0.0015 | N | 0.0005 | As | 0.0005 | H | 11.2 |

| B | 0.002 | Co | 0.01 | C | 0.003 | Na | 0.001 | Ba | 0.0005 | O | 88.8 |

| C | 0.11 | Ni | 0.01 | Ca | 0.0005 | Nb | 0.001 | Cd | 0.0005 | ||

| N | 0.03 | Cu | 0.01 | Co | 0.001 | Ni | 0.0005 | Zn | 0.0005 | ||

| O | 0.01 | Nb | 0.005 | Cr | 0.002 | O | 0.002 | W | 99.9595 | ||

| Al | 0.01 | Mo | 0.005 | Cu | 0.001 | P | 0.002 | Ag | 0.001 | ||

| Si | 0.05 | Ta | 0.12 | Fe | 0.003 | Pb | 0.0005 | As | 0.0005 | ||

| P | 0.005 | W | 1.1 | H | 0.0005 | S | 0.0005 | Ba | 0.0005 | ||

| S | 0.005 | As | 0.05 | K | 0.001 | Si | 0.002 | Cd | 0.0005 | ||

| Ti | 0.02 | Sn | 0.05 | Mg | 0.0005 | Ta | 0.002 | Zn | 0.0005 | ||

| V | 0.2 | Sb | 0.05 | Mn | 0.0005 | Ti | 0.0005 | ||||

| Cr | 9 | Zr | 0.05 | Mo | 0.01 | Zr | 0.0005 | ||||

| WCLL | HCPB | |||||||

|---|---|---|---|---|---|---|---|---|

| Ref. [16] | Present Work | Ref. [16] | Present Work | |||||

| Inboard | Outboard | Inboard Reflector | Outboard Reflector | Inboard | Outboard | Inboard Reflector | Outboard Reflector | |

| 1 s | 5.17 × 1014 | 5.16 × 1014 | 5.83 × 1014 | 4.54 × 1014 | 4.37 × 1014 | 4.39 × 1014 | 4.52 × 1014 | 3.61 × 1014 |

| 1 year | 5.76 × 1012 | 5.37 × 1012 | 3.97 × 1012 | 3.52 × 1012 | 5.59 × 1012 | 5.17 × 1012 | 3.67 × 1012 | 3.29 × 1012 |

| 50 years | 3.61 × 107 | 3.44 × 107 | 3.87 × 107 | 3.29 × 107 | 3.38 × 107 | 3.24 × 107 | 3.42 × 1012 | 2.92 × 107 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Breidokaite, S.; Stankunas, G. Activities in Divertor Reflector and Linear Plates Using WCLL and HCPB Breeding Blanket Concepts. Energies 2021, 14, 8305. https://doi.org/10.3390/en14248305

Breidokaite S, Stankunas G. Activities in Divertor Reflector and Linear Plates Using WCLL and HCPB Breeding Blanket Concepts. Energies. 2021; 14(24):8305. https://doi.org/10.3390/en14248305

Chicago/Turabian StyleBreidokaite, Simona, and Gediminas Stankunas. 2021. "Activities in Divertor Reflector and Linear Plates Using WCLL and HCPB Breeding Blanket Concepts" Energies 14, no. 24: 8305. https://doi.org/10.3390/en14248305