Design and Parametric Investigation of an Efficient Heating System, an Effort to Obtain a Higher Seasonal Performance Factor

Abstract

:1. Introduction

2. Methodology

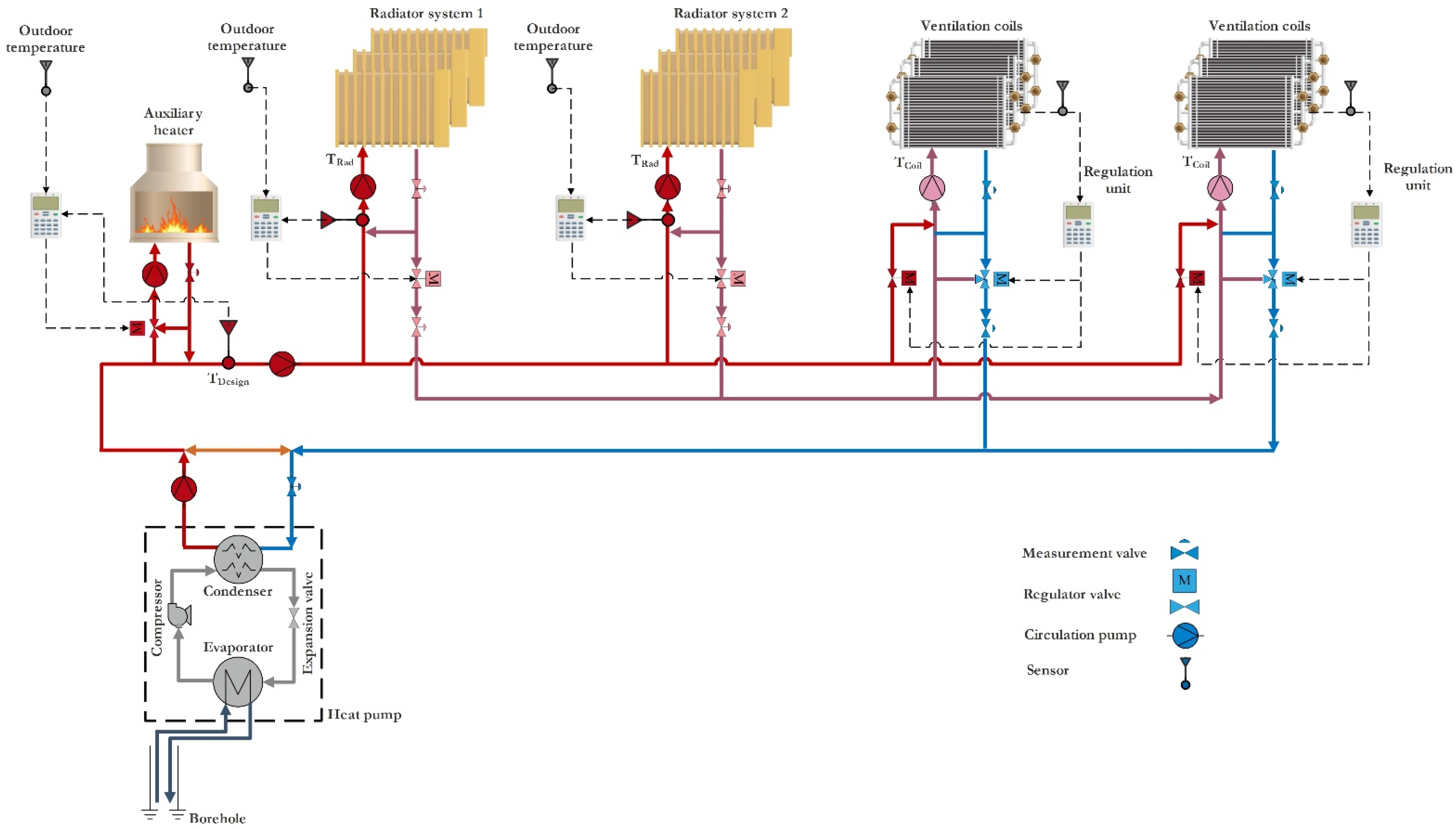

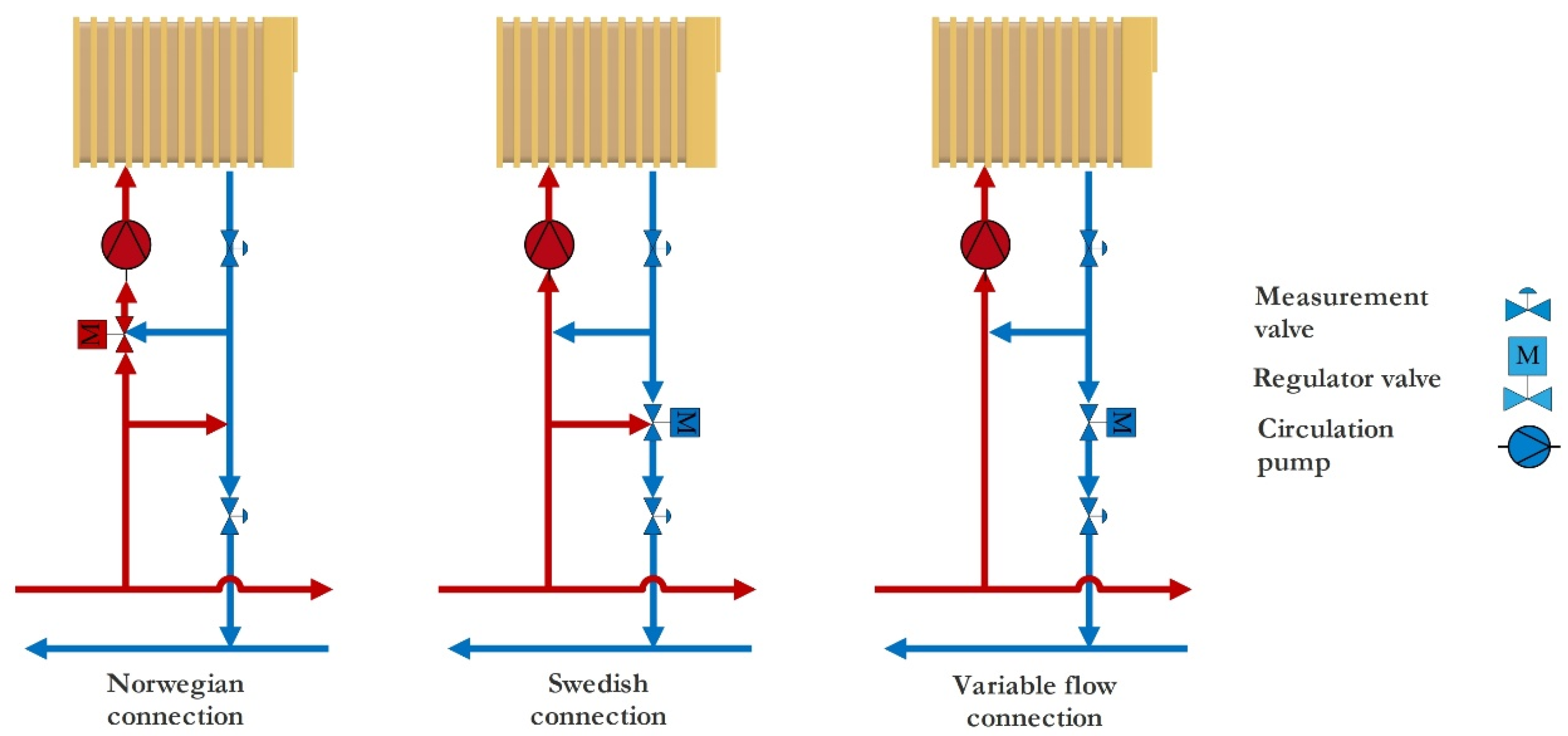

2.1. The Studied System

2.2. Mathematical Modeling

2.3. Validation of Simulation Tool

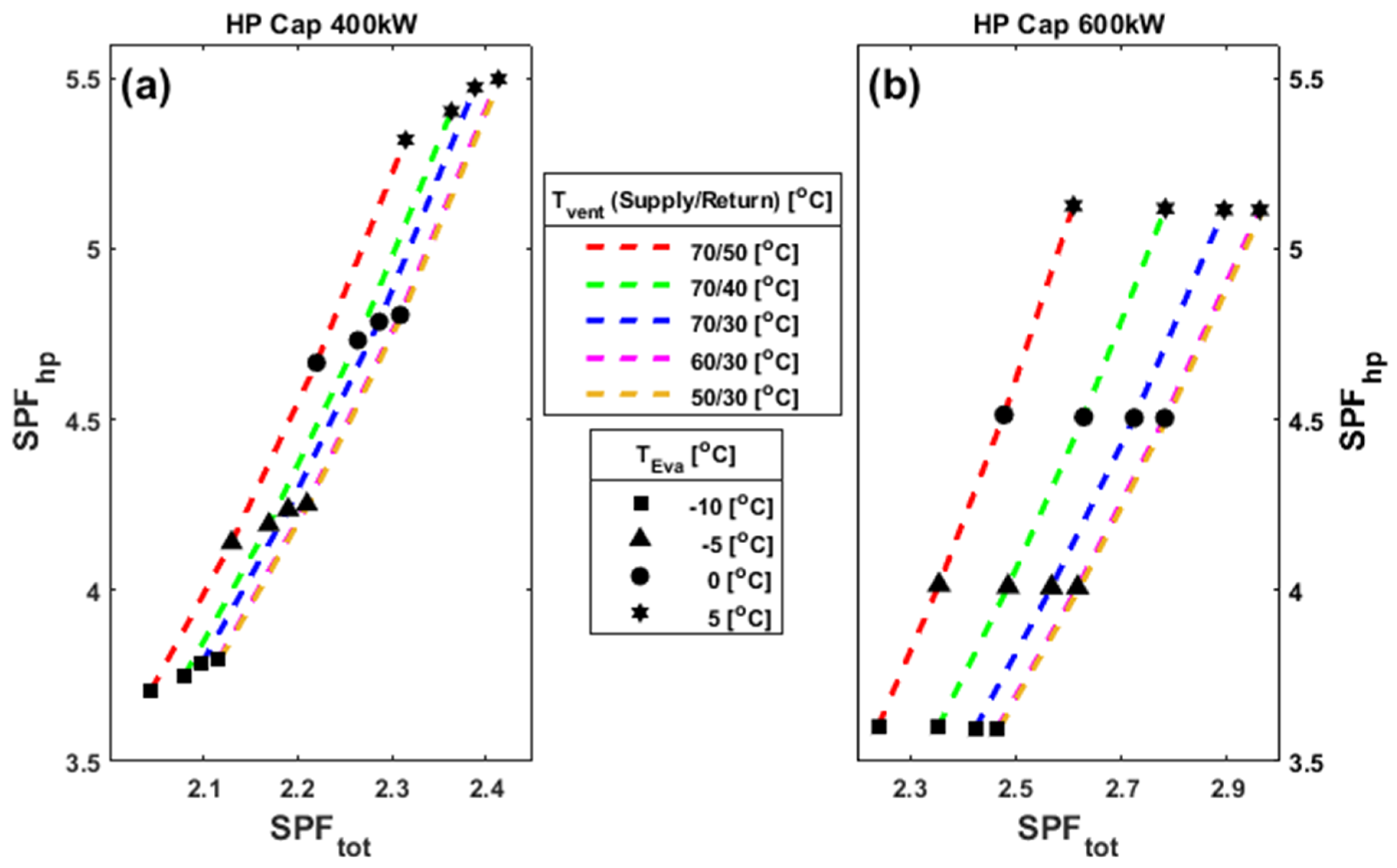

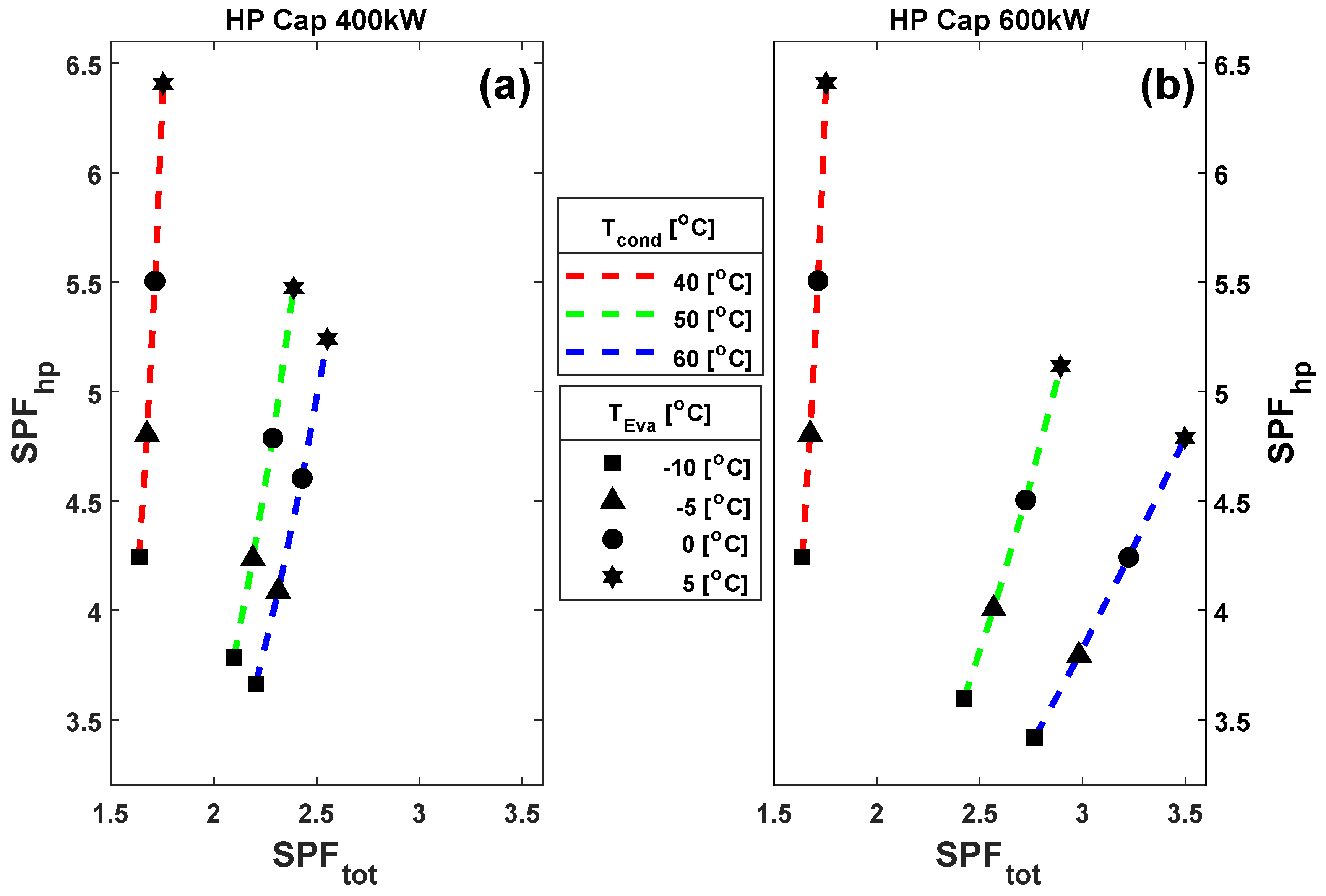

3. Results and Discussion

4. Conclusions

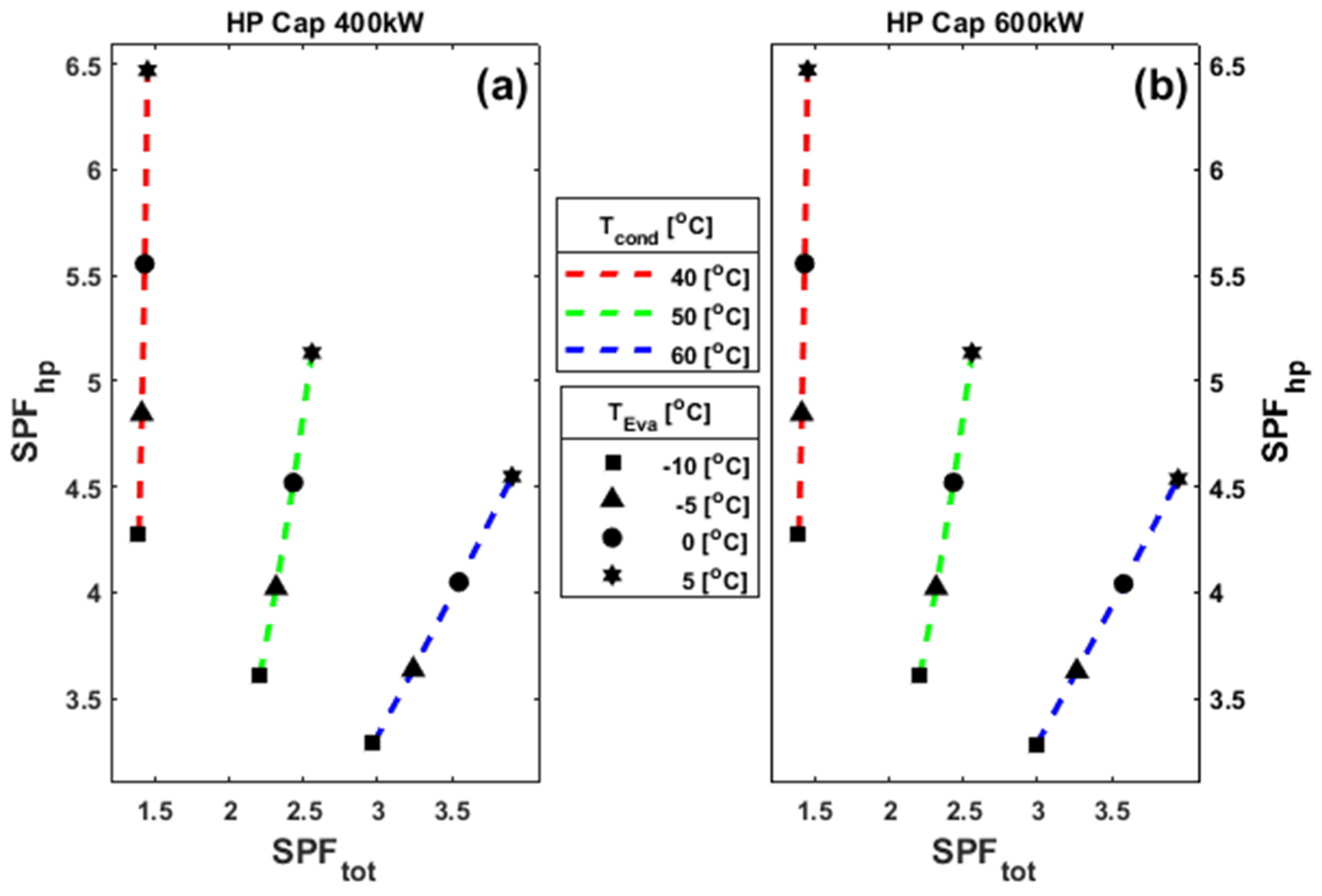

- According to the parametric study outcomes, the evaporator and condenser temperatures are key parameters that highly affect the heat pump and the total system performance;

- Because of a longer running time with full capacity, 400 kW is the best option from the heat pump performance viewpoint. However, the highest total seasonal performance factor is achieved by using a heat pump of 600 kW due to delivering more heat for charging the system;

- The results further show that by varying ventilation ratio from 70/50 °C/°C to 70/30 °C/°C—that is, the reduction of return temperature—the values of heat pump and total seasonal performance factors will increase, indicating the importance of the proposed configuration;

- What stands out from the results is that for the condensation temperature of 40 °C and the heat recovery of 50%, the increment of heat pump capacity does not change the heat pump and total system performance;

- At heat recovery of 75% (or greater), choosing a heat pump with a smaller capacity is economically beneficial because the seasonal performance values are independent of heat pump capacity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Nomenclature

| Abbreviations | |

| AHU | Air handling unit |

| COP | Coefficient of performance |

| GSHP | Ground source heat pump |

| MVHR | Mechanical ventilation with heat recovery |

| SPF | Seasonal performance factor |

| TES | Thermal energy storage |

| Latin letters | |

| Mass flowrate, [kg s−1] | |

| Thermal energy, [kW] | |

| Power, [kW] | |

| Enthalpy, [kJ kg−1] | |

| Specific heat capacity, [kJ kg−1 K−1] | |

| Temperature, [°C] (or [K]) | |

| Greek letters | |

| Density, [kgm−3] | |

| Efficiency, [-] | |

| Subscripts | |

| amb | Infiltration gains ( |

| cap | Capacity |

| cond | Condensor |

| equipments | Internal convective gains ( |

| eva | Evaporator |

| hp | Heat pump |

| in | Input |

| lm | Logarithmic mean temperature |

| out | Output |

| rad | Radiator |

| surfaces | Transmission heat gains ( |

| T | Temperature |

| tot | Total (system) |

| vent | Ventilation |

| z | Zone |

| zones | Heat transfer among zones ( |

References

- IEA. Tracking Buildings 2021. Available online: https://www.iea.org/reports/tracking-buildings-2021 (accessed on 5 November 2021).

- Behzadi, A.; Arabkoohsar, A.; Yang, Y. Optimization and dynamic techno-economic analysis of a novel PVT-based smart building energy system. Appl. Therm. Eng. 2020, 181, 115926. [Google Scholar] [CrossRef]

- Sharma, S.; Agarwal, S.; Jain, A. Significance of Hydrogen as Economic and Environmentally Friendly Fuel. Energies 2021, 14, 7389. [Google Scholar] [CrossRef]

- Sadrizadeh, S.; Aganovic, A.; Bogdan, A.; Wang, C.; Afshari, A.; Hartmann, A.; Croitoru, C.; Khan, A.; Kriegel, M.; Lind, M.; et al. A systematic review of operating room ventilation. J. Build. Eng. 2021, 40, 102693. [Google Scholar] [CrossRef]

- Yuan, F.; Yao, R.; Sadrizadeh, S.; Li, B.; Cao, G.; Zhang, S.; Zhou, S.; Liu, H.; Bogdan, A.; Croitoru, C. Thermal comfort in hospital buildings–A literature review. J. Build. Eng. 2021, 45, 103463. [Google Scholar] [CrossRef]

- Lee, C.-G.; Cho, L.-H.; Kim, S.-J.; Park, S.-Y.; Kim, D.-H. Comparative Analysis of Combined Heating Systems Involving the Use of Renewable Energy for Greenhouse Heating. Energies 2021, 14, 6630. [Google Scholar] [CrossRef]

- Stamatakis, M.E.; Ioannides, M.G. State Transitions Logical Design for Hybrid Energy Generation with Renewable Energy Sources in LNG Ship. Energies 2021, 14, 7803. [Google Scholar] [CrossRef]

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Solarin, S.A.; Gil-Alana, L.A.; Lafuente, C. Persistence and non-stationarity in the built-up land footprint across 89 countries. Ecol. Indic. 2021, 123, 107372. [Google Scholar] [CrossRef]

- Corradi, E.; Rossi, M.; Mugnini, A.; Nadeem, A.; Comodi, G.; Arteconi, A.; Salvi, D. Energy, Environmental, and Economic Analyses of a District Heating (DH) Network from Both Thermal Plant and End-Users’ Prospective: An Italian Case Study. Energies 2021, 14, 7783. [Google Scholar] [CrossRef]

- Spitler, J.D.; Javed, S.; Ramstad, R.K. Natural convection in groundwater-filled boreholes used as ground heat exchangers. Appl. Energy 2016, 164, 352–365. [Google Scholar] [CrossRef]

- Maddah, S.; Goodarzi, M.; Safaei, M.R. Comparative study of the performance of air and geothermal sources of heat pumps cycle operating with various refrigerants and vapor injection. Alexandria Eng. J. 2020, 59, 4037–4047. [Google Scholar] [CrossRef]

- Chang, Y.; Gu, Y.; Zhang, L.; Wu, C.; Liang, L. Energy and environmental implications of using geothermal heat pumps in buildings: An example from north China. J. Clean. Prod. 2017, 167, 484–492. [Google Scholar] [CrossRef]

- Fadejev, J.; Simson, R.; Kurnitski, J.; Kesti, J.; Mononen, T.; Lautso, P. Geothermal Heat Pump Plant Performance in a Nearly Zero-energy Building. Energy Procedia 2016, 96, 489–502. [Google Scholar] [CrossRef]

- Fadejev, J.; Kurnitski, J. Geothermal energy piles and boreholes design with heat pump in a whole building simulation software. Energy Build. 2015, 106, 23–34. [Google Scholar] [CrossRef]

- Hepbasli, A.; Tolga Balta, M. A study on modeling and performance assessment of a heat pump system for utilizing low temperature geothermal resources in buildings. Build. Environ. 2007, 42, 3747–3756. [Google Scholar] [CrossRef]

- Massarotti, N.; Mauro, A.; Normino, G.; Vanoli, L.; Verde, C.; Allocca, V.; Calcaterra, D.; Coda, S.; de Vita, P.; Forzano, C.; et al. Innovative solutions to use ground-coupled heat pumps in historical buildings: A test case in the city of Napoli, Southern Italy. Energies 2020, 14, 296. [Google Scholar] [CrossRef]

- Villarino, J.I.; Villarino, A.; de Arteaga, I.; Quinteros, R.; Alañón, A. A comparative energy and economic analysis between a low enthalpy geothermal design and gas, diesel and biomass technologies for a HVAC system installed in an office building. Energies 2019, 12, 870. [Google Scholar] [CrossRef] [Green Version]

- Blázquez, C.S.; Borge-Diez, D.; Nieto, I.M.; Martín, A.F.; González-Aguilera, D. Multi-parametric evaluation of electrical, biogas and natural gas geothermal source heat pumps. Renew. Energy 2021, 163, 1682–1691. [Google Scholar] [CrossRef]

- Liang, L.; Wang, X.; Zhang, X.; Sun, H. Multi-Building Systems Thermal and Energy Management via Geothermal Heat Pump. IFAC PapersOnLine 2020, 53, 17125–17131. [Google Scholar] [CrossRef]

- Farzanehkhameneh, P.; Soltani, M.; Moradi Kashkooli, F.; Ziabasharhagh, M. Optimization and energy-economic assessment of a geothermal heat pump system. Renew. Sustain. Energy Rev. 2020, 133, 110282. [Google Scholar] [CrossRef]

- Sun, F.; Hao, B.; Fu, L.; Wu, H.; Xie, Y.; Wu, H. New medium-low temperature hydrothermal geothermal district heating system based on distributed electric compression heat pumps and a centralized absorption heat transformer. Energy 2021, 232, 120974. [Google Scholar] [CrossRef]

- Bottarelli, M.; Gallero, F.J.G. Energy analysis of a dual-source heat pump coupled with phase change materials. Energies 2020, 13, 2933. [Google Scholar] [CrossRef]

- Shin, J.S.; Park, J.W.; Kim, S.H. Measurement and Verification of Integrated Ground Source Heat Pumps on a Shared Ground Loop. Energies 2020, 13, 1752. [Google Scholar] [CrossRef] [Green Version]

- Klein, A.S. TRNSYS: A Transient System Simulation Program; Engineering Experiment Station Report; University Wisconsin-Madison: Madison, WI, USA, 1988; pp. 12–38. [Google Scholar]

- Shin, J.S.; Kim, S.H.; Park, J.W. Economic analysis of integrated ground source heat pumps on a shared ground loop. Energies 2020, 13, 2928. [Google Scholar] [CrossRef]

- Lee, D.C.; Lee, M.; Cho, W.; Kim, Y. Performance improvement of heat pumps by optimizing refrigerant charge using novel variable liquid-line length system. Appl. Therm. Eng. 2021, 196, 117287. [Google Scholar] [CrossRef]

- Trüschel, A. Hydronic Heating Systems—The Effect of Design on System Sensitivity. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, January 2002. [Google Scholar]

- Behrouz, N.; Wang, Q.; Ploskić, A. Maximizing thermal performance of building ventilation using geothermal and wastewater heat. Resour. Conserv. Recycl. 2019, 143, 90–98. [Google Scholar]

- Fakhari, I.; Behzadi, A.; Gholamian, E.; Ahmadi, P.; Arabkoohsar, A. Comparative double and integer optimization of low-grade heat recovery from PEM fuel cells employing an organic Rankine cycle with zeotropic mixtures. Energy Convers. Manag. 2021, 228, 113695. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A.; Ahmadi, P. Optimization of Energy Systems; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

| Description | Value | Unit |

|---|---|---|

| Maximum delivered heat by radiators | 614 | kW |

| Heat pump maximum delivery | 400–600 | kW |

| Heat pump condensing temperature | 50 (40–60) | °C |

| Heat pump evaporating temperature | −10–+5 | °C |

| Auxiliary heater maximum delivery | 800 | kW |

| Maximum design supply/return temperature | 70/50–70/30 | °C |

| Design outdoor temperature | −20 | °C |

| Maximum ventilation rate | 194,000 | m³h−1 |

| Ventilation heat recovery | 50–82 | % |

| System Configuration | SPFhp | SPFtot | Total Delivered Energy (MWh) | Building Heating Demand (MWh) | |

|---|---|---|---|---|---|

| Heat Pump Capacity (kW) | Ventilation Heat Recovery % | ||||

| 400 | 50% | 4236 | 2190 | 1182 | 2589 |

| 75% | 4020 | 2315 | 539 | 1248 | |

| 82% | 4058 | 2194 | 436 | 957 | |

| 600 | 50% | 4008 | 2568 | 1009 | 2590 |

| 75% | 4021 | 2316 | 539 | 1248 | |

| 82% | 4059 | 2196 | 436 | 957 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Harsem, T.T.; Nourozi, B.; Behzadi, A.; Sadrizadeh, S. Design and Parametric Investigation of an Efficient Heating System, an Effort to Obtain a Higher Seasonal Performance Factor. Energies 2021, 14, 8475. https://doi.org/10.3390/en14248475

Harsem TT, Nourozi B, Behzadi A, Sadrizadeh S. Design and Parametric Investigation of an Efficient Heating System, an Effort to Obtain a Higher Seasonal Performance Factor. Energies. 2021; 14(24):8475. https://doi.org/10.3390/en14248475

Chicago/Turabian StyleHarsem, Trond Thorgeir, Behrouz Nourozi, Amirmohammad Behzadi, and Sasan Sadrizadeh. 2021. "Design and Parametric Investigation of an Efficient Heating System, an Effort to Obtain a Higher Seasonal Performance Factor" Energies 14, no. 24: 8475. https://doi.org/10.3390/en14248475

APA StyleHarsem, T. T., Nourozi, B., Behzadi, A., & Sadrizadeh, S. (2021). Design and Parametric Investigation of an Efficient Heating System, an Effort to Obtain a Higher Seasonal Performance Factor. Energies, 14(24), 8475. https://doi.org/10.3390/en14248475