Numerical Study on the Flow and Heat Transfer Characteristics of a Second Throat Exhaust Diffuser According to Variations in Operating Pressure and Geometric Shape

Abstract

1. Introduction

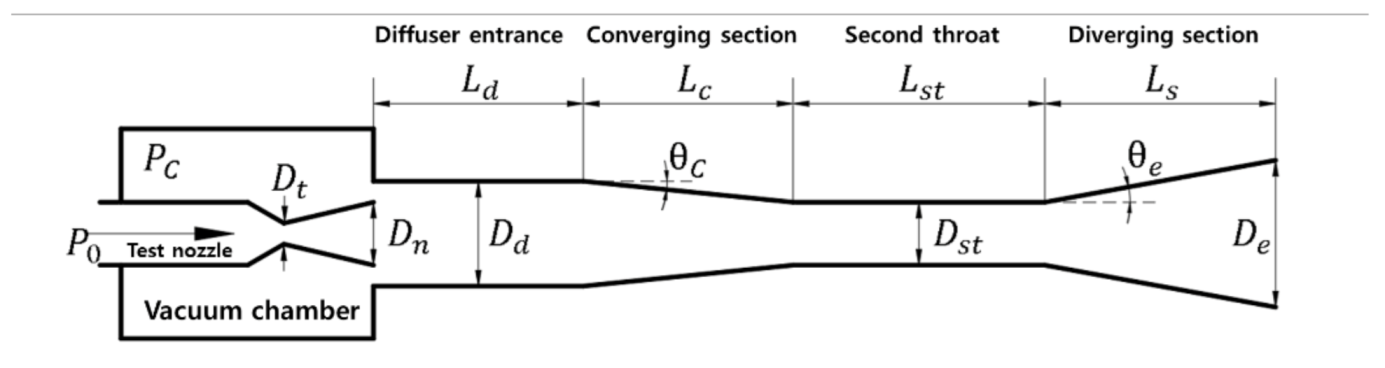

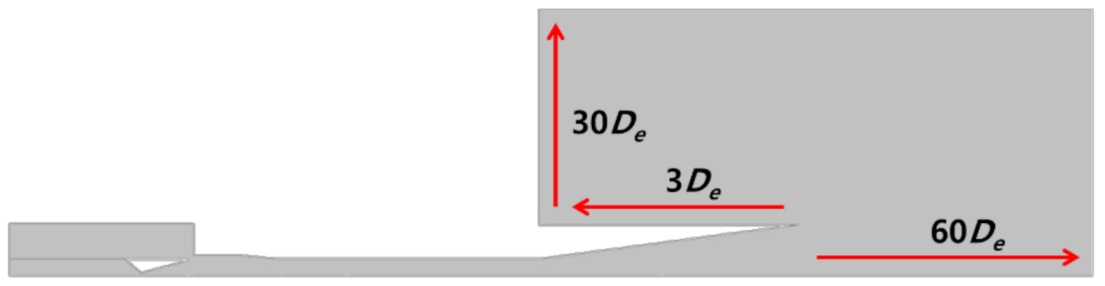

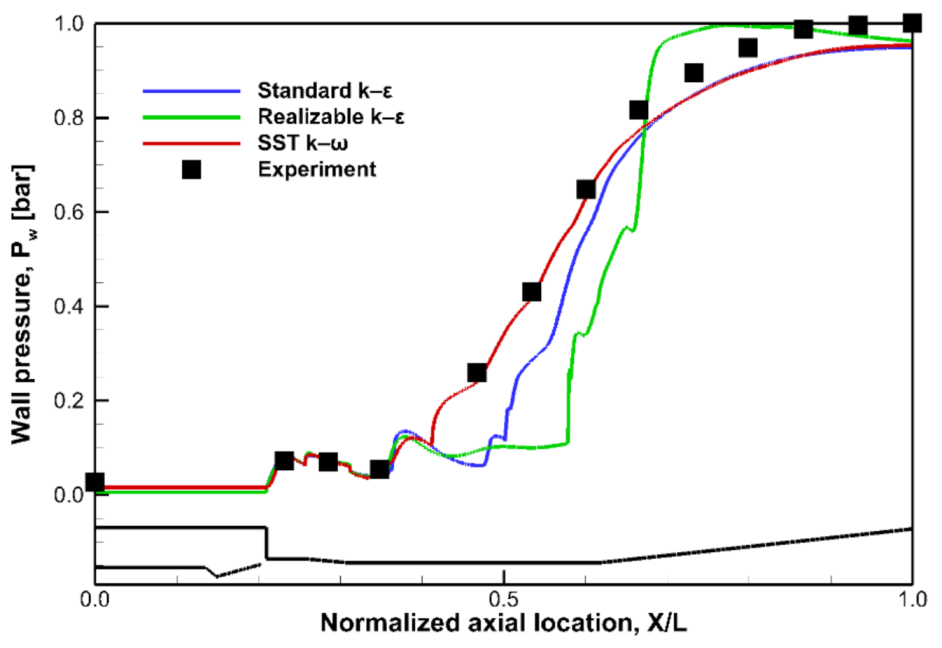

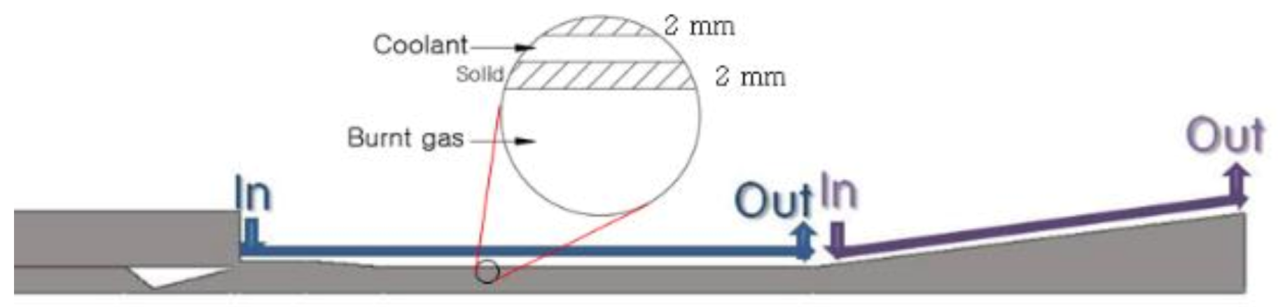

2. Numerical Analysis

3. Results and Discussions

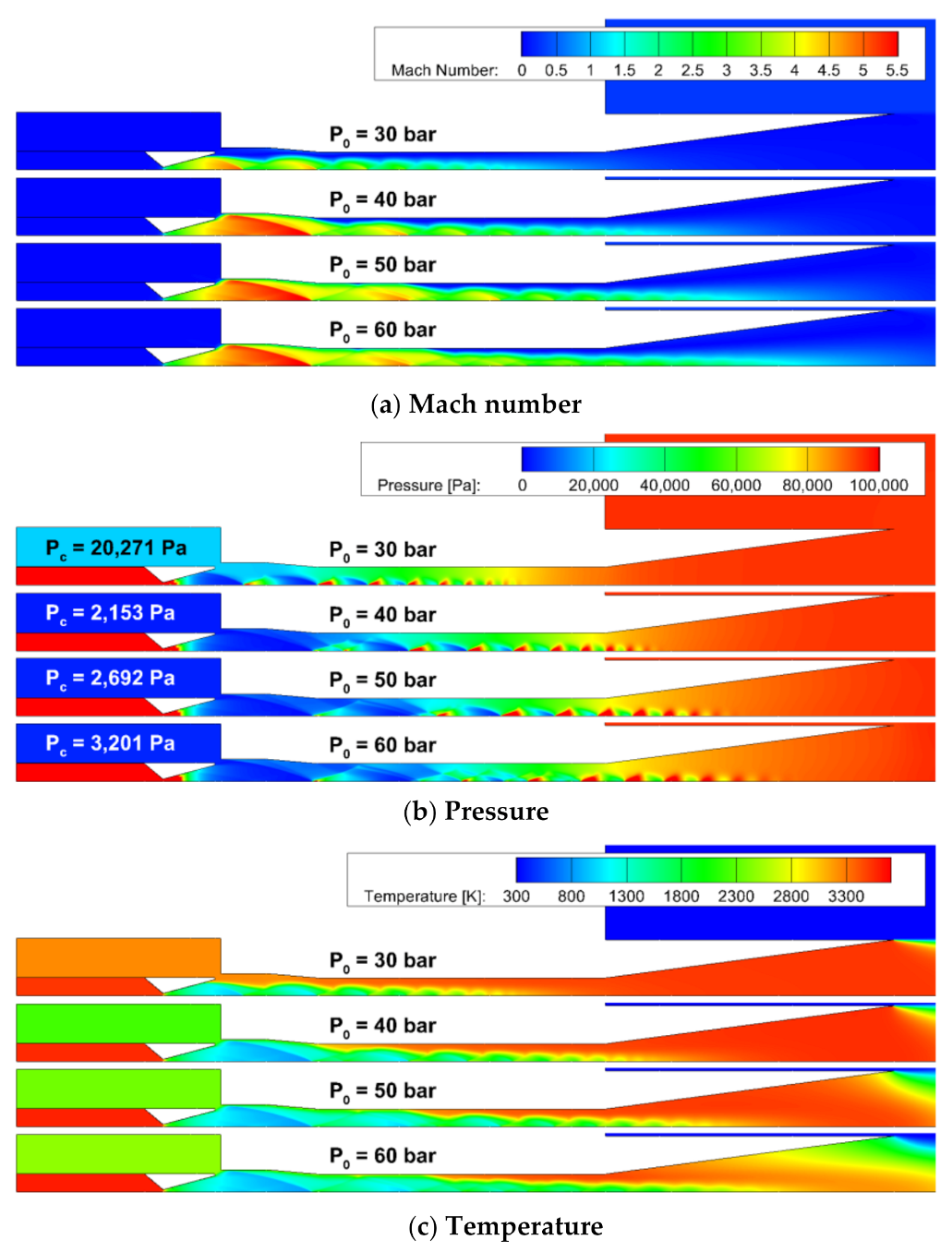

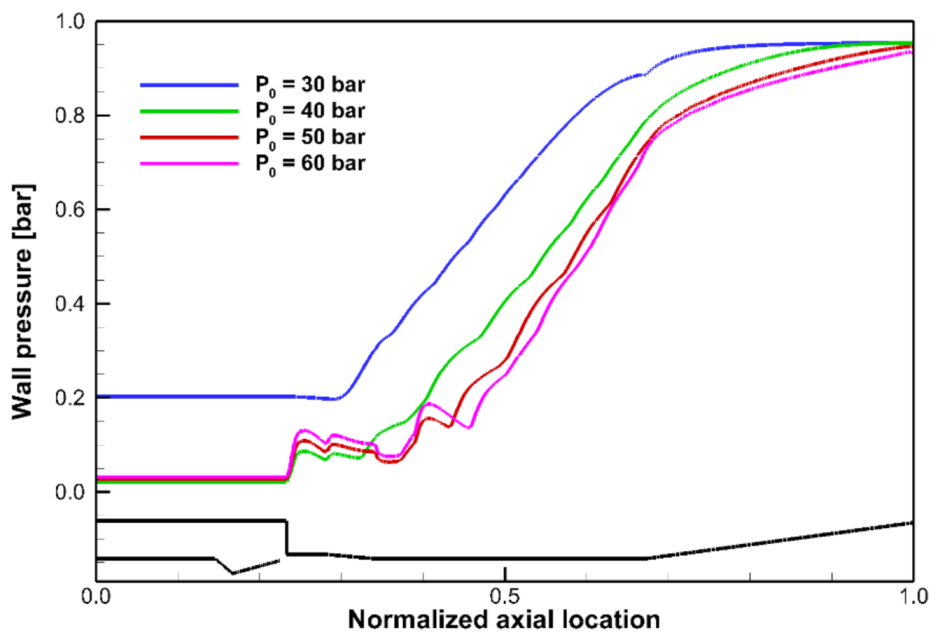

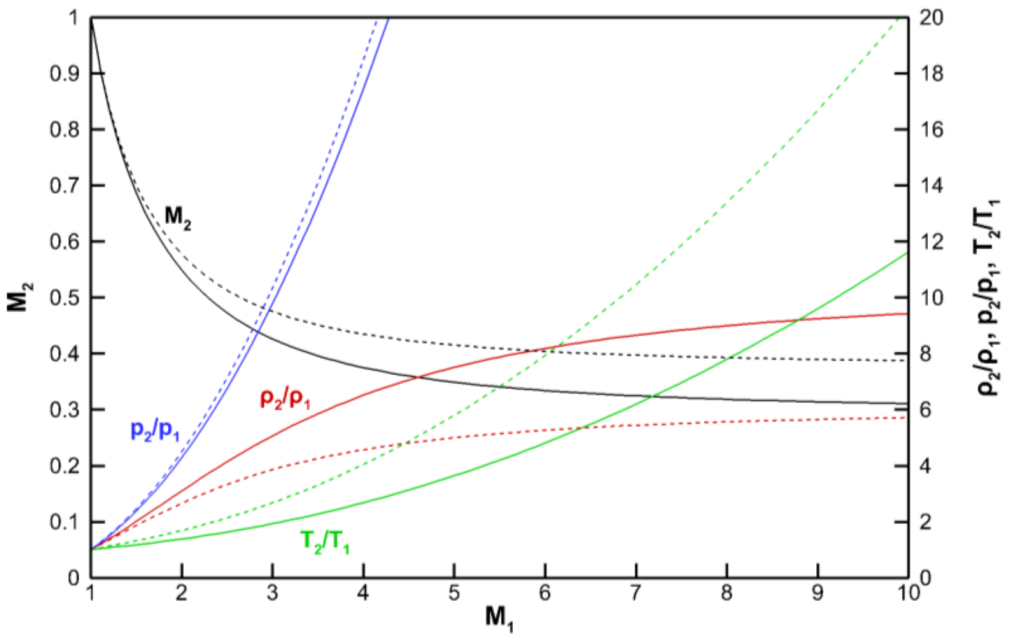

3.1. Flow Characteristics According to Operating Pressure Variations

3.2. Flow Characteristics According to Geometric Shape Variations

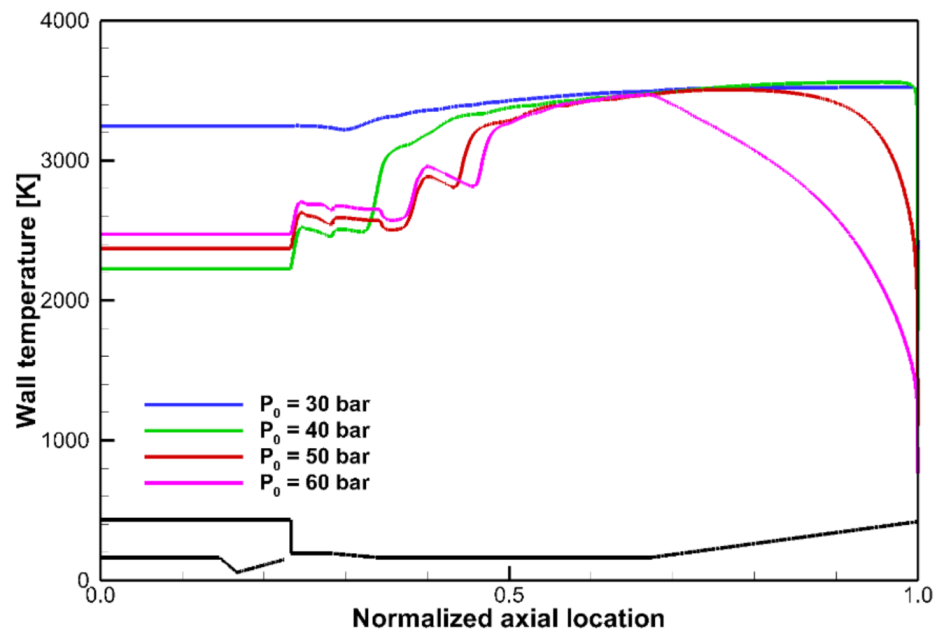

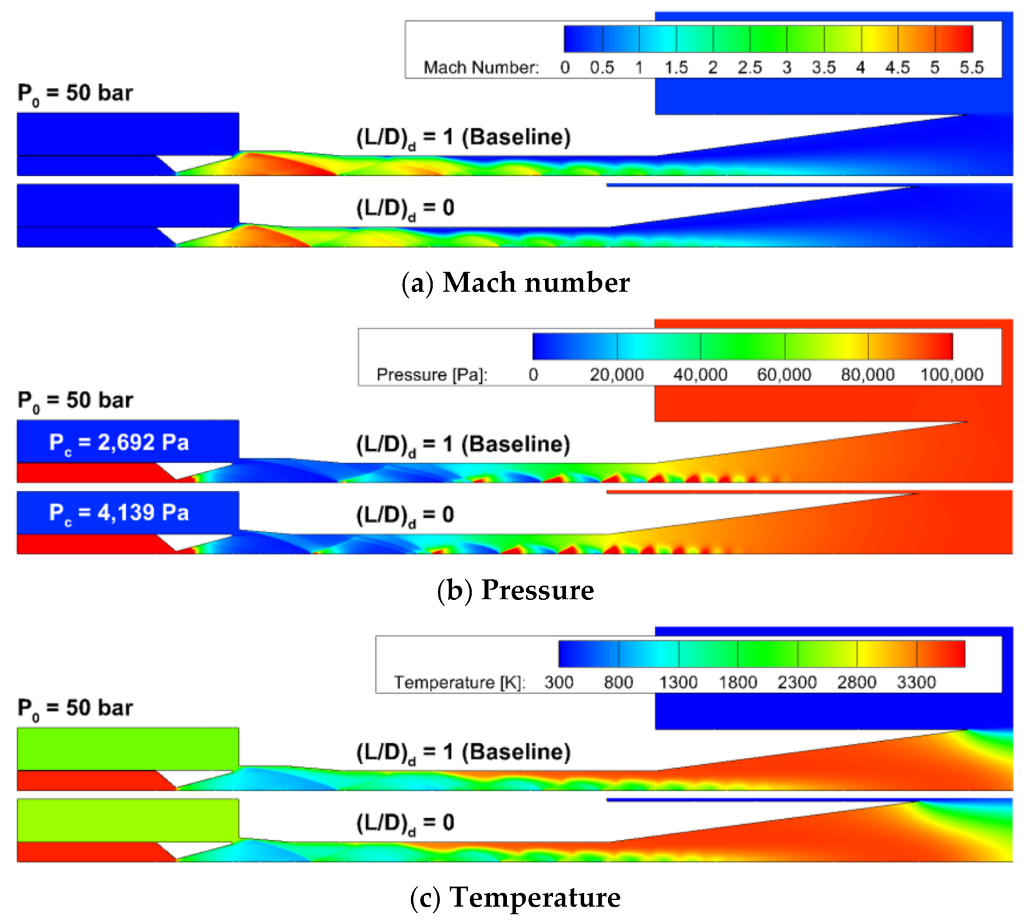

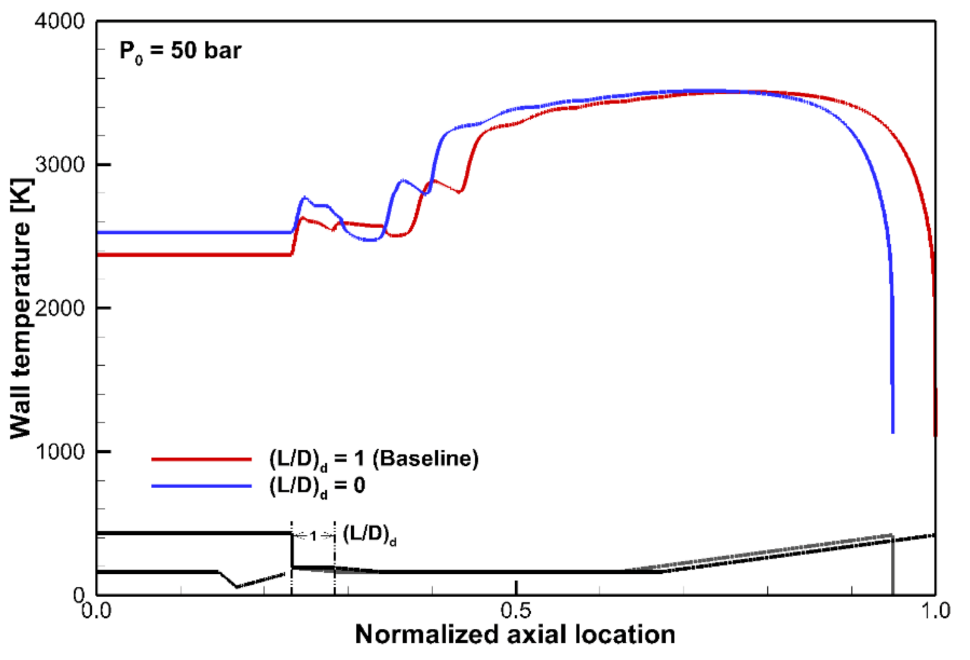

3.2.1. Effects of Diffuser Entrance Length

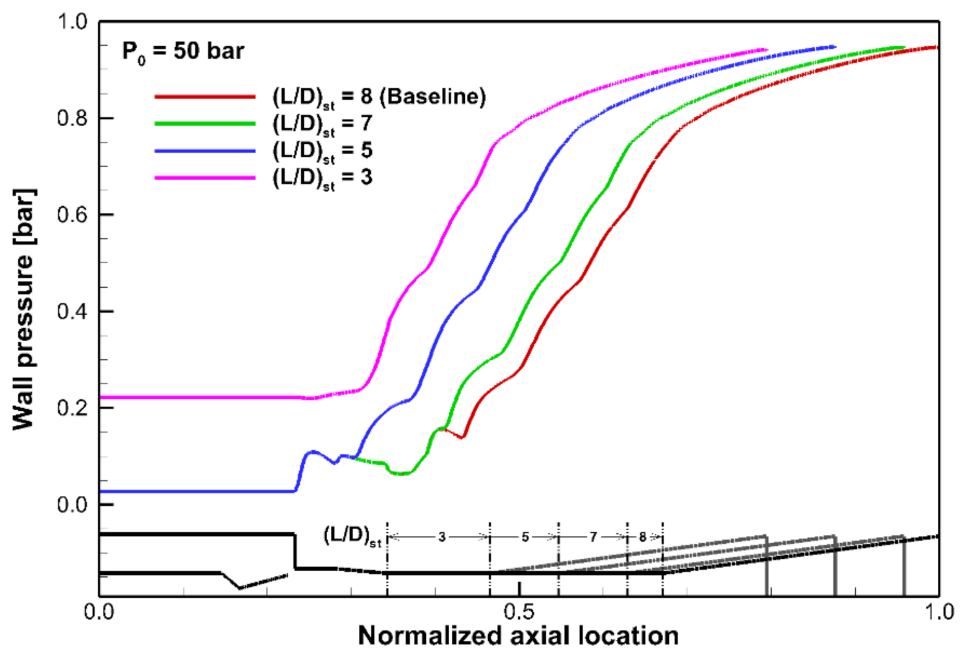

3.2.2. Effects of Second Throat Length

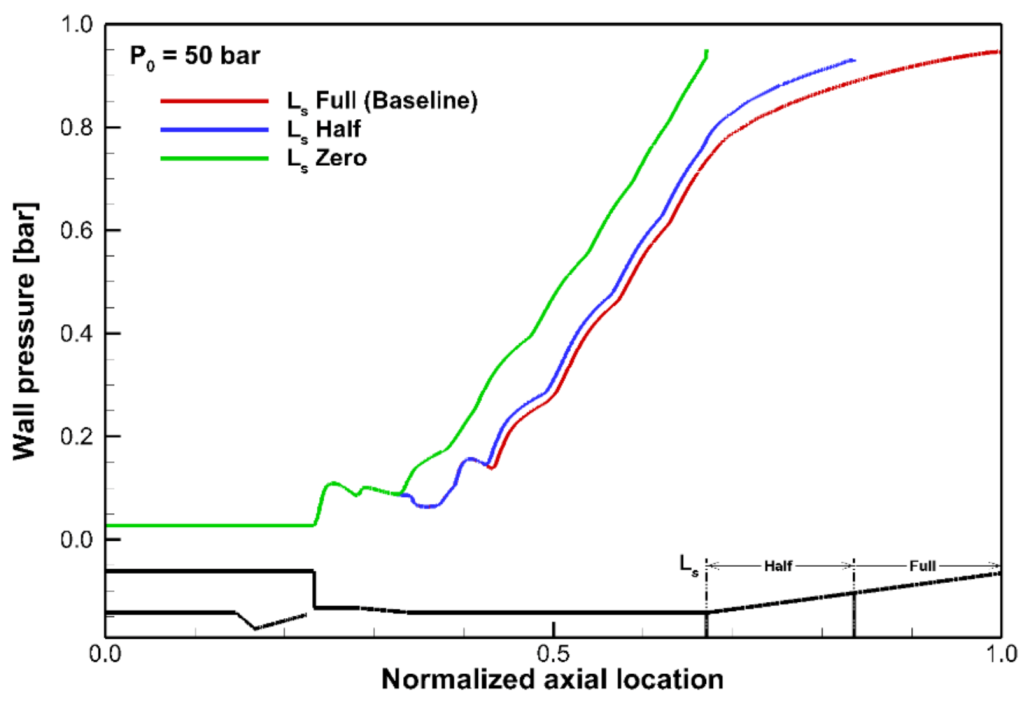

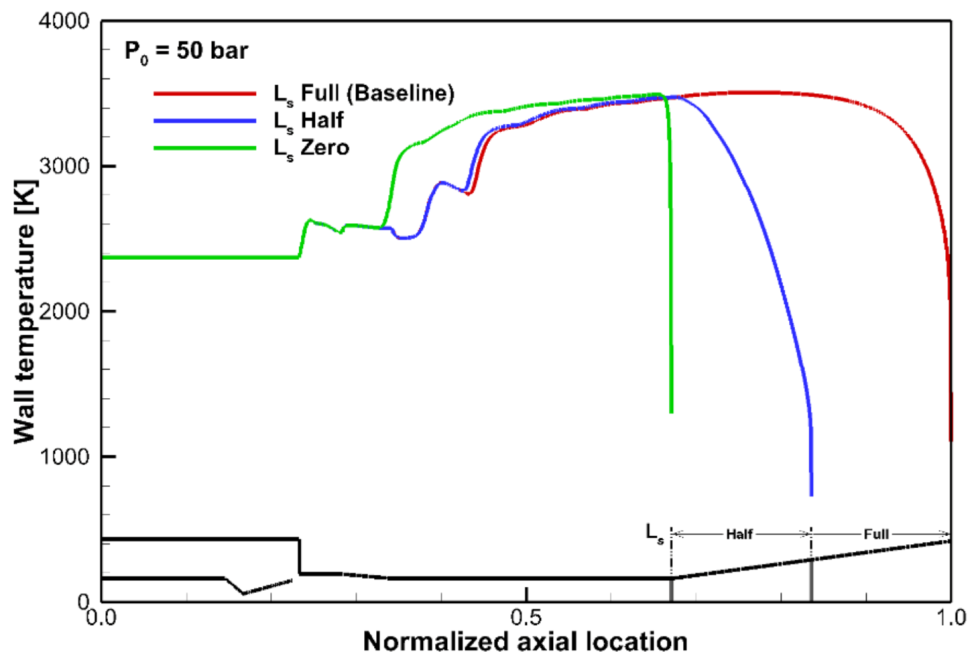

3.2.3. Effects of Diverging Section Length

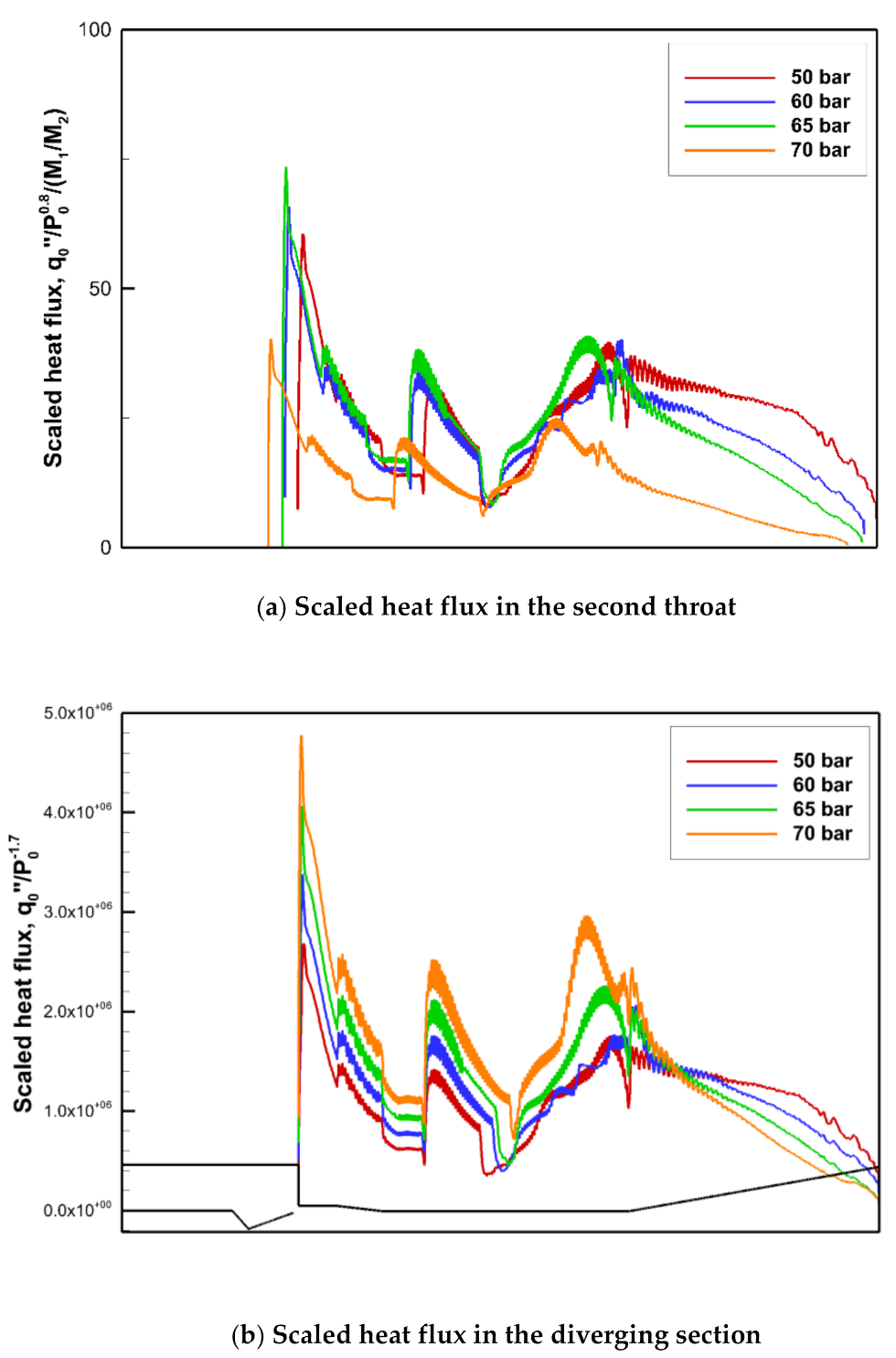

3.3. Heat Transfer Characteristics with Respect to Operating Pressure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Goethert, B.H. High altitude and space simulation testing. ARS J. 1962, 32, 872–882. [Google Scholar] [CrossRef]

- Lijo, V.; Kim, H.D.; Rajesh, G.; Setoguchi, T. Numerical simulation of transient flows in a vacuum ejector-diffuser system. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2010, 224, 777–786. [Google Scholar] [CrossRef]

- Sung, H.G.; Yeom, H.W.; Yoon, S.; Kim, S.J.; Kim, J. Investigation of rocket exhaust diffusers for altitude simulation. J. Propuls. Power 2010, 26, 240–247. [Google Scholar] [CrossRef]

- Park, B.H.; Lim, J.; Park, S.; Lee, J.H.; Yoon, W.S. Design and analysis of a second-throat exhaust diffuser for altitude simulation. J. Propuls. Power 2012, 28, 1091–1104. [Google Scholar] [CrossRef]

- Annamalai, K.; Satyanarayana, T.N.V.; Sriramulu, V.; Bhaskaran, K.A. Development of design methods for short cylindrical supersonic exhaust diffuser. Exp. Fluids 2000, 29, 305–308. [Google Scholar] [CrossRef]

- Chen, F.; Liu, C.F.; Yang, J.Y. Supersonic flow in the second-throat ejector-diffuser system. J. Spacecr. Rocket. 1994, 31, 123–129. [Google Scholar] [CrossRef]

- Lim, J.; Park, B.H.; Yoon, W.; Lee, Y. Parametric Investigation on the essential flow factors commanding steady operations of the second throat exhaust diffuser. In Proceedings of the 44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Hartford, CT, USA, 21–23 July 2008. [Google Scholar]

- Prabakar, S.M.; Panchabudhe, L.M.; Muruganandam, T.M.; Sundararajan, T. A study on the performance characteristics of two-stream supersonic diffusers. Aerosp. Sci. Technol. 2019, 95, 105470. [Google Scholar] [CrossRef]

- Fouladi, N.; Farahani, M.; Mirbabaei, A.R. Performance evaluation of a second throat exhaust diffuser with a thrust optimized parabolic nozzle. Aerosp. Sci. Technol. 2019, 94, 105406. [Google Scholar] [CrossRef]

- Jia, Y.; Li, Z.; Ye, W.; Xu, W. Numerical and experimental investigation of an adjustable dual-channel supersonic diffuser. Acta Astronaut. 2019, 157, 102–110. [Google Scholar] [CrossRef]

- Teh, E.J.; Johansen, C.T. Effect of particle momentum transfer on an oblique-shock-wave/laminar-boundary-layer interaction. Acta Astronaut. 2016, 128, 431–439. [Google Scholar] [CrossRef]

- Wei, X.; Xue, R.; Qin, F.; Hu, C.; He, G. Research on shock wave characteristics in the isolator of central strut rocket-based combined cycle engine under Ma5.5. Acta Astronaut. 2017, 140, 284–292. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Roohi, E. Three dimensional investigation of the shock train structure in a convergent–divergent nozzle. Acta Astronaut. 2014, 105, 117–127. [Google Scholar] [CrossRef]

- Gnani, F.; Zare-Behtash, H.; Kontis, K. Pseudo-shock waves and their interactions in high-speed intakes. Prog. Aerosp. Sci. 2016, 82, 36–56. [Google Scholar] [CrossRef]

- Gnani, F.; Zare-Behtash, H.; White, C.; Kontis, K. Effect of back-pressure forcing on shock train structures in rectangular channels. Acta Astronaut. 2018, 145, 471–481. [Google Scholar] [CrossRef]

- He, M.; Qin, L.; Liu, Y. Numerical investigation of flow separation behavior in an over-expanded annular conical aerospike nozzle. Chin. J. Aeronaut. 2015, 28, 983–1002. [Google Scholar] [CrossRef]

- Wang, C.; Xue, L.; Tian, X. Experimental characteristics of oblique shock train upstream propagation. Chin. J. Aeronaut. 2017, 30, 663–676. [Google Scholar] [CrossRef]

- Jeon, J.S.; Kim, W.C.; Yeoun, H.I.; Kim, M.S.; Ko, Y.S.; Han, Y.M. An experimental study on performance of second throat exhaust diffusers of different configuration. Trans. Korean Soc. Mech. Eng. B 2014, 38, 279–288. [Google Scholar] [CrossRef][Green Version]

- Ansys Fluent 14.0: Users Guide. Available online: https://www.scribd.com/doc/140163383/Ansys-Fluent-14-0-Users-Guide (accessed on 10 December 2020).

- Ansys Fluent 14.0: Theory Guide. Available online: https://www.scribd.com/doc/140163341/Ansys-Fluent-14-0-Theory-Guide (accessed on 10 December 2020).

- Kim, T.W.; Jeon, J.S.; Kim, W.C.; Ko, Y.S.; Kim, S.J.; Han, Y.M. Construction of high altitude test facility for liquid rocket engine. In Proceedings of the Korean Society of Propulsion Engineers Spring Conference, Seoul, Korea, 29–30 May 2014. [Google Scholar]

- Huang, D.H.; Huzel, D.K. Modern Engineering for Design of Liquid-Propellant Rocket Engines; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 1992. [Google Scholar]

| Symbol Parameter | Value | |

|---|---|---|

| Diffuser entrance diameter (mm) | 1001 | |

| Second throat diameter (mm) | 80 | |

| Diffuser exit diameter (mm) | 250 | |

| Converging section length (mm) | 115.217 | |

| Converging angle (°) | 4.95 | |

| Diverging angle (°) | 7.5 | |

| Diffuser entrance length ratio | 0, 1 | |

| Second throat length ratio | 3, 5, 7, 8 | |

| Diverging section length (mm) | 0, 322, 644 | |

(bar) | (K) | (kJ/kg·K) | (g/mol) | (kg/m·s) | (W/m·K) |

|---|---|---|---|---|---|

| 30 | 3523 | 2044 | 22.82 | 1.08E-4 | 1.5143 |

| 40 | 3562 | 2047 | 22.90 | 1.09E-4 | 1.4445 |

| 50 | 3592 | 2049 | 22.96 | 1.10E-4 | 1.3919 |

| 60 | 3616 | 2051 | 23.02 | 1.11E-4 | 1.3499 |

| Property | Value | |

|---|---|---|

| Density (kg/m3) | 8030 | |

| Specific heat (J/kg·K) | 502.48 | |

| Melting point (K) | 1673.15 | |

| Conductivity (W/m·K) | Temp. (K) | |

| 293.15 | 15.09 | |

| 373.15 | 15.22 | |

| 473.15 | 17.20 | |

| 573.15 | 18.20 | |

| 673.15 | 21.04 | |

| 773.15 | 25.59 | |

| 873.15 | 30.93 | |

| Pressure (bar) | (°) | |||

|---|---|---|---|---|

| 50 | 3.541 | 1.755 | 2.018 | 18.7 |

| 60 | 3.756 | 2.042 | 1.840 | 17.9 |

| 65 | 3.840 | 2.364 | 1.624 | 16.8 |

| 70 | 3.971 | 1.373 | 2.900 | 18.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jo, S.; Han, S.; Kim, H.J.; Yim, K.J. Numerical Study on the Flow and Heat Transfer Characteristics of a Second Throat Exhaust Diffuser According to Variations in Operating Pressure and Geometric Shape. Energies 2021, 14, 532. https://doi.org/10.3390/en14030532

Jo S, Han S, Kim HJ, Yim KJ. Numerical Study on the Flow and Heat Transfer Characteristics of a Second Throat Exhaust Diffuser According to Variations in Operating Pressure and Geometric Shape. Energies. 2021; 14(3):532. https://doi.org/10.3390/en14030532

Chicago/Turabian StyleJo, Seonghwi, Sanghyeon Han, Hong Jip Kim, and Kyung Jin Yim. 2021. "Numerical Study on the Flow and Heat Transfer Characteristics of a Second Throat Exhaust Diffuser According to Variations in Operating Pressure and Geometric Shape" Energies 14, no. 3: 532. https://doi.org/10.3390/en14030532

APA StyleJo, S., Han, S., Kim, H. J., & Yim, K. J. (2021). Numerical Study on the Flow and Heat Transfer Characteristics of a Second Throat Exhaust Diffuser According to Variations in Operating Pressure and Geometric Shape. Energies, 14(3), 532. https://doi.org/10.3390/en14030532