Experimental Determination of CO2 Diffusion Coefficient in a Brine-Saturated Core Simulating Reservoir Condition

Abstract

1. Introduction

2. Calculation Model

2.1. Physical Model of the Diffusion Experiment

2.2. Assumptions

- The Berea core is homogeneous, and the solution is uniformly distributed in it.

- The swelling effect of NaCl solution is not considered in the experiments.

- The diffusion coefficient in the core is constant.

- Water evaporated in the experiment is negligible.

2.3. Mathematical Model

3. Experiment

3.1. Materials

3.2. Apparatus

3.3. Experimental Process

- Different aqueous concentrations of NaCl (0.5 mol/L, 1 mol/L, 1.5 mol/L and 2 mol/L) were prepared with sodium chloride and preserved.

- The core was completely immersed in a beaker filled with NaCl solution, vacuumed with a vacuum pump, and then allowed to stand for 24 h.

- The pipe was purged with N2 to ensure that there was no impurity gas in the pipe.

- High pressure N2 was injected into the system to ensure that there is no leakage.

- After putting the core into the reactor, the reactor was vacuumed by a vacuum pump to guarantee that the reactor is in a vacuum state.

- The reactor was heated to the predetermined temperature using the oil bath.

- The CO2 in the intermediate container was pressurized to higher than 50% of the experimental value to guarantee that the pressure in reactor could quickly reach the expected value.

- After the intermediate container reached the expected pressure, open the valve to allow CO2 to enter the diffusion cell. The pressure in the reactor was measured by the pressure sensor during the diffusion process and recorded in real time.

- The diffusion process was over when the pressure in the reactor reached a steady state, and data recording was terminated. The CO2 was released from the exhaust port, and then the Berea core and the reactor were rinsed and dried carefully.

4. Results and Discussion

4.1. Experimental Repeatability and Reliability

4.2. Experimental Data Summary

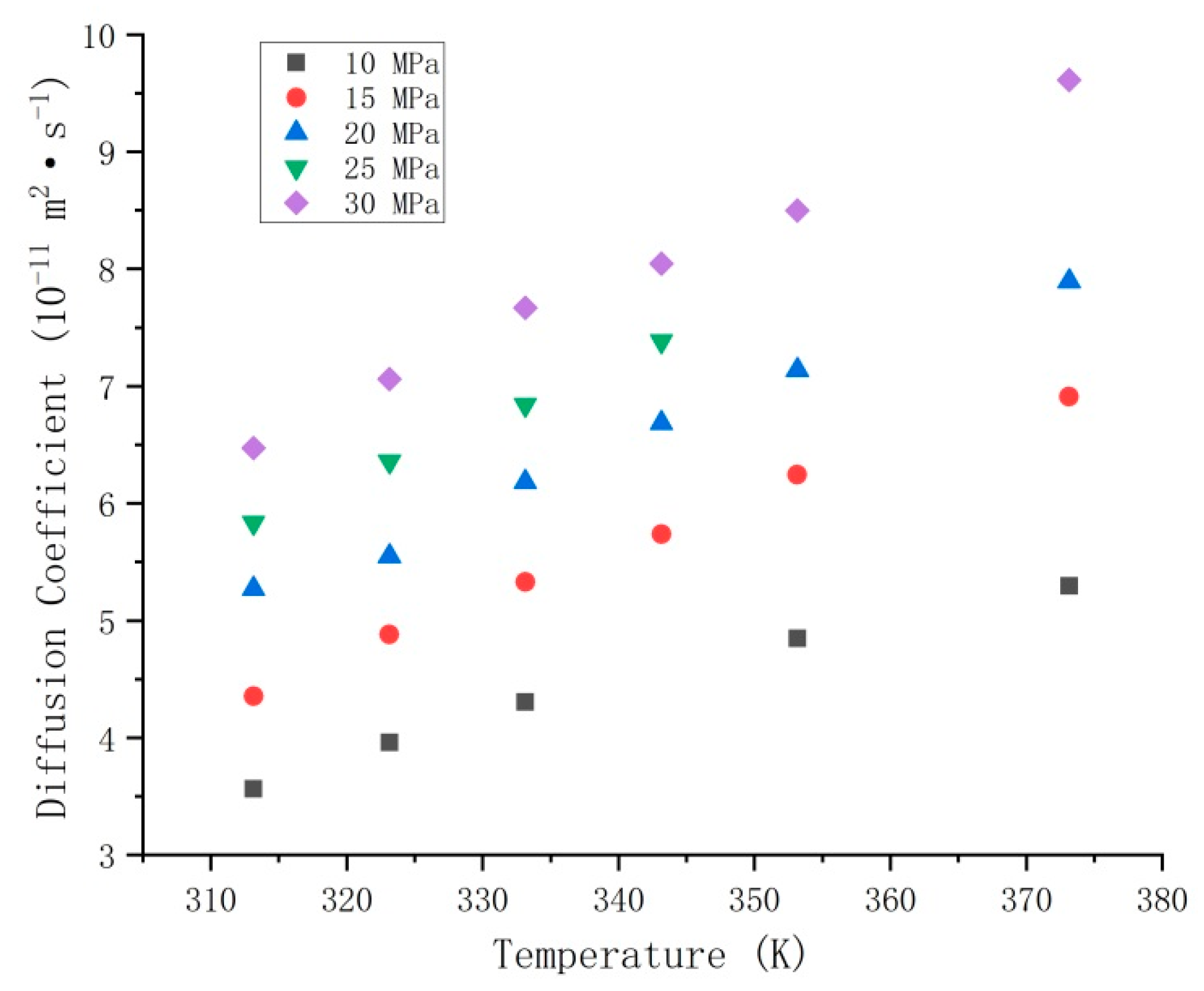

4.3. Effect of Temperature and Pressure on the Diffusion Coefficient of CO2

4.4. Effect of NaCl Concentration on the CO2 Diffusion Coefficient

4.5. Effect of Permeability on Diffusion Coefficient

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, M.; Mu, H.; Ning, Y.; Song, Y. Decomposition of energy-related CO2 emission over 1991–2006 in China. Ecol. Econ. 2009, 68, 2122–2128. [Google Scholar] [CrossRef]

- Liu, Y.; Teng, Y.; Lu, G.; Jiang, L.; Zhao, J.; Zhang, Y.; Song, Y. Experimental study on CO2 diffusion in bulk n-decane and n-decane saturated porous media using micro-CT. Fluid Phase Equilib. 2016, 417, 212–219. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Song, Y.; Zhao, Y.; Zhao, J.; Wang, D. Fractal analysis and its impact factors on pore structure of artificial cores based on the images obtained using magnetic resonance imaging. J. Appl. Geophys. 2012, 86, 70–81. [Google Scholar] [CrossRef]

- Yongan, Y.C.G. Accelerated mass transfer of CO2 in reservoir brine due to density-driven natural convection at high pressures and elevated temperatures. Ind. Eng. Chem. Res. 2006, 45, 2430–2436. [Google Scholar]

- Zheng, S.; Li, H.A.; Sun, H.; Yang, D. Determination of diffusion coefficient for alkane solvent–CO2 Mixtures in heavy oil with consideration of swelling effect. Ind. Eng. Chem. Res. 2016, 55, 1533–1549. [Google Scholar] [CrossRef]

- Teng, Y.; Liu, Y.; Song, Y.; Jiang, L.; Zhao, Y.; Zhou, X.; Zheng, H.; Chen, J. A study on CO2 diffusion coefficient in n-decane saturated porous media by MRI. Energy Procedia 2014, 61, 603–606. [Google Scholar] [CrossRef][Green Version]

- Liu, S.; Zhang, Y.; Xing, W.; Jian, W.; Liu, Z.; Li, T.; Song, Y. Laboratory experiment of CO2—CH4 displace-ment and dispersion in sandpacks in enhanced gas recovery. J. Nat. Gas Sci. Eng. 2015, 26, 1585–1594. [Google Scholar] [CrossRef]

- Li, Z.; Dong, M.; Li, S.; Dai, L. A new method for gas effective diffusion coefficient measurement in water-saturated porous rocks under high pressures. J. Porous Med. 2006, 9, 445–461. [Google Scholar] [CrossRef]

- Zabala, D.; Nieto-Draghi, C.; de Hemptinne, J.C.; Lopez de Ramos, A.L. Diffusion coefficients in CO2/n-alkane binary liquid mixtures by molecular simulation. J. Phys. Chem. B 2008, 112, 16610–16618. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Li, Z.; Dong, Q. Diffusion coefficients of supercritical CO2 in oil-saturated cores under low permeability reservoir conditions. J. CO2 Util. 2016, 14, 47–60. [Google Scholar] [CrossRef]

- Hangyu, W.L.S. Diffusion of carbon dioxide in tetradecane. J. Chem. Eng. Data 1997, 42, 1181–1186. [Google Scholar]

- Wang, D.; Qiao, J.; Zhou, H.; Li, W.; Song, Y. Numerical analysis of CO2 and water displacement in natural rock cores based on a fully heterogeneous model. J. Hydrol. Eng. 2016, 21, 04015070. [Google Scholar] [CrossRef]

- Hu, H.; Li, X.; Fang, Z.; Wei, N.; Li, Q. Small-molecule gas sorption and diffusion in coal: Molecular simulation. Energy 2010, 35, 2939–2944. [Google Scholar] [CrossRef]

- Li, Q.; Liu, G.; Zhang, J.; Jia, L.; Liu, H. Status and suggestion of environmental monitoring for CO2 geological storage. Adv. Earth Sci. 2013, 28, 718–727. [Google Scholar]

- Li, Z.; Dong, M. Experimental study of diffusive tortuosity of liquid-saturated consolidated porous media. Ind. Eng. Chem. Res. 2010, 49, 6431–6437. [Google Scholar] [CrossRef]

- Li, Z.; Dong, M.; Shirif, E. Transient natural convection induced by gas diffusion in liquid-saturated vertical porous columns. Ind. Eng. Chem. Res. 2006, 45, 3311–3319. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, Y.; Liu, Y.; Jiang, L.; Zhu, N. Visualization of CO2 and oil immiscible and miscible flow processes in porous media using NMR micro-imaging. Pet. Sci. 2011, 8, 183–193. [Google Scholar] [CrossRef]

- Loulou, T.; Adhikari, B.; Lecomte, D. Estimation of concentration-dependent diffusion coefficient in drying process from the space-averaged concentration versus time with experimental data. Chem. Eng. Sci. 2006, 61, 7185–7198. [Google Scholar] [CrossRef]

- Xu, T.; Apps, J.A.; Pruess, K. Mineral sequestration of carbon dioxide in a sandstone–shale system. Chem. Geol. 2005, 217, 295–318. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Bai, B.; Fang, Z. Ranking and screening of CO2 saline aquifer storage zones in China. Chin. J. Rock Mech. Eng. 2006, 25, 963–968. [Google Scholar]

- Chen, C.; Zhang, N.; Li, W.; Song, Y. Water contact angle dependence with hydroxyl functional groups on silica surfaces under CO2 sequestration conditions. Environ. Sci. Technol. 2015, 49, 14680–14687. [Google Scholar] [CrossRef] [PubMed]

- Upreti, S.R.; Mehrotra, A.K. Experimental measurement of gas diffusivity in bitumen: Results for carbon dioxide. Ind. Eng. Chem. Res. 2000, 39, 1080–1087. [Google Scholar] [CrossRef]

- Krooss, B.M.; Leythaeuser, D. Experimental measurements of the diffusion parameters of light hydrocarbons in water-saturated sedimentary rocks—II. Results and geochemical significance. Org. Geochem. 1988, 12, 91–108. [Google Scholar] [CrossRef]

- Zhang, Y.; Hyndman, C.; Maini, B. Measurement of gas diffusivity in heavy oils. J. Pet. Sci. Eng. 2000, 25, 37–47. [Google Scholar] [CrossRef]

- Riazi, M.R. A new method for experimental measurement of diffusion coefficients in reservoir fluids. J. Pet. Sci. Eng. 1996, 14, 235–250. [Google Scholar] [CrossRef]

- Renner, T.A. Measurement and correlation of diffusion coefficients for CO2 and rich-gas applications. SPE Reserv. Eng. 1988, 3, 517–523. [Google Scholar] [CrossRef]

- Tang, Y.P.; Himmelblau, D.M. Effect of solute concentration on the diffusivity of carbon dioxide in water. Chem. Eng. Sci. 1965, 20, 7–14. [Google Scholar] [CrossRef]

- Tamimi, A.; Rinker, E.B.; Sandall, O.C. Diffusion coefficients for hydrogen sulfide, carbon dioxide, and nitrous oxide in water over the temperature range 293–368 K. J. Chem. Eng. Data 1994, 39, 330–332. [Google Scholar] [CrossRef]

- Hirai, S.; Okazaki, K.; Yazawa, H.; Ito, H.; Tabe, Y.; Hijikata, K. Measurement of CO2 diffusion coefficient and application of lifin pressurized water. Energy 1997, 22, 363–367. [Google Scholar] [CrossRef]

- Wang, L.S.; Lang, Z.X.; Guo, T.M. Measurement and correlation of the diffusion cofficients of carbon dioxide in liquid hydrocarbons under elevated pressures. Fluid Phase Equilib. 1996, 117, 364–372. [Google Scholar] [CrossRef]

- Azin, R.; Mahmoudy, M.; Raad, S.M.J.; Osfouri, S. Measurement and modeling of CO2 diffusion coefficient in Saline Aquifer at reservoir conditions. Open Eng. 2013, 3, 585–594. [Google Scholar] [CrossRef]

- Zarghami, S.; Boukadi, F.; Al-Wahaibi, Y. Diffusion of carbon dioxide in formation water as a result of CO2 enhanced oil recovery and CO2 sequestration. J. Pet. Explor. Prod. Technol. 2016, 7, 161–168. [Google Scholar] [CrossRef]

- Shi, Z.; Wen, B.; Hesse, M.; Tsotsis, T.; Jessen, K. Measurement and modeling of CO2 mass transfer in brine at reservoir conditions. Adv. Water Resour. 2018, 113, 100–111. [Google Scholar] [CrossRef]

- Raad, S.M.J.; Azin, R.; Osfouri, S. Measurement of CO2 diffusivity in synthetic and saline aquifer solutions at reservoir conditions: The role of ion interactions. Heat Mass Transf. 2015, 51, 1587–1595. [Google Scholar] [CrossRef]

- Wang, S.; Hou, J.; Liu, B.; Zhao, F.; Yuan, G.; Liu, G. The pressure-decay method for nature convection accelerated diffusion of CO2 in Oil and water under elevated pressures. Energy Sources Part A Recovery Util. Environ. Eff. 2013, 35, 538–545. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, S.; Ren, S.; Zhang, L.; Li, J. The modeling and experimental studies on the diffusion coefficient of CO2 in saline water. J. CO2 Util. 2015, 11, 49–53. [Google Scholar] [CrossRef]

- Moghaddam, R.N.; Rostami, B.; Pourafshary, P. A method for dissolution rate quantification of convection-diffusion mechanism during CO2 storage in saline aquifers. Spéc. Top. Rev. Porous Media Int. J. 2013, 4, 13–21. [Google Scholar] [CrossRef]

- Belgodere, C.; Dubessy, J.; Vautrin, D.; Caumon, M.-C.; Sterpenich, J.; Pironon, J.; Robert, P.; Randi, A.; Birat, J.-P. Experimental determination of CO2 diffusion coefficient in aqueous solutions under pressure at room temperature via Raman spectroscopy: Impact of salinity (NaCl). J. Raman Spectrosc. 2015, 46, 1025–1032. [Google Scholar] [CrossRef]

- Cadogan, S.P.; Maitland, G.C.; Trusler, J.P.M. Diffusion coefficients of CO2 and N2 in water at temperatures between 298.15 K and 423.15 K at pressures up to 45 MPa. J. Chem. Eng. Data 2014, 59, 519–525. [Google Scholar] [CrossRef]

- Farajzadeh, R.; Zitha, P.L.; Bruining, J. Enhanced mass transfer of CO2 into water: Experiment and modeling. Ind. Eng. Chem. Res. 2009, 48, 6423–6431. [Google Scholar] [CrossRef]

- Frank, M.J.W.; Kuipers, J.A.M.; van Swaaij, W.P.M. Diffusion coefficients and viscosities of CO2+ H2O, CO2+ CH3OH, NH3+ H2O, and NH3+ CH3OH liquid mixtures. J. Chem. Eng. Data 1996, 41, 297–302. [Google Scholar] [CrossRef]

- Lu, W.; Guo, H.; Chou, I.M.; Burruss, R.C.; Li, L. Determination of diffusion coefficients of carbon dioxide in water between 268 and 473K in a high-pressure capillary optical cell with in situ Raman spectroscopic measurements. Geochim. Cosmochim. Acta 2013, 115, 183–204. [Google Scholar] [CrossRef]

- Sell, A.; Fadaei, H.; Kim, M.; Sinton, D. Measurement of CO2 diffusivity for carbon sequestration: A micro-fluidic approach for reservoir-specific analysis. Environ. Sci. Technol. 2013, 47, 71–78. [Google Scholar] [CrossRef] [PubMed]

- Lv, J.; Chi, Y.; Zhao, C.; Zhang, Y.; Mu, H. Experimental study of the supercritical CO2 diffusion coefficient in porous media under reservoir conditions. R. Soc. Open Sci. 2019, 6, 181902. [Google Scholar] [CrossRef]

| Source | Solution | Method | Porous Media | Temperature, K | Pressure, MPa | Diffusivity, 10−9 m2/s |

|---|---|---|---|---|---|---|

| Azin [31] | Brine | Pressure decay method | / | 305.15–323.15 | 5.90–6.90 | 3.52–6.16 |

| Raad [34] | Brine | Pressure decay method | / | 303.15–313.15 | 5.88–6.27 | 0.6–23 |

| Renner [26] | Brine | Pressure decay method | / | 311.15 | 1.54–5.83 | 3.07–6.86 |

| Chaodong Yang [4] | Brine | Pressure decay method | / | 300.15–331.15 | 2.60–7.50 | 170.7–269.8 |

| Wang [35] | Brine | Pressure decay method | / | 311.15 | 1.52–5.18 | 2.925–4.827 |

| Zarghami [32] | Brine | Pressure decay method | / | 323.15–348.15 | 17.45 | 6.5–8.2 |

| Zhang [36] | Brine | Pressure decay method | / | 298.15 | 1.17 | 1.5–1.91 |

| Z. Shi [33] | Brine | Pressure decay method | Beads, quartz | 323.15 | 6.00 | 1.25–82 |

| Rasoul Nazari Moghaddam [37] | Brine | Pressure decay method | Sand | 310.15 | 3.44 | 0.825–94.6 |

| Belgodere [38] | Pure water | situ Raman spectroscopic measurement | Porous media | 294.15 | 4.00 | 1.71 |

| Cadogan [39] | Pure water | Taylor dispersion method | / | 298.15–423.15 | 15.00–45.00 | 2.233–12.21 |

| Farajzadeh [40] | Pure water | Pressure decay method | / | 298.15–303.15 | 0.80–5.00 | 2.75–245 |

| Frank [41] | Pure water | Taylor−Aris dispersion method | / | 298.15–328.15 | 0.10 | 1.97–3.67 |

| Hirai [29] | Pure water | laser-induced fluorescence | / | 286.15 | 9.40–39.20 | 1–1.5 |

| Lu [42] | Pure water | situ Raman spectroscopic measurement | / | 268.15–473.15 | 20.00 | 0.7–1.6 |

| Sell [43] | Pure water | Microfluidic method | / | 299.15 | 0.50–5.00 | 1.86 |

| Tamimi [27] | Pure water | liquid-jet method | / | 293.15–368.15 | 0.10 | 2.11 |

| Wang [35] | Pure water | Pressure decay method | / | 318.15 | 3.43–8.02 | 233.6–251.34 |

| Number | Diameter, m | Length, m | Permeability, mD | Porosity, % |

|---|---|---|---|---|

| 1 | 0.025 | 0.060 | 10 | 10.3 |

| 2 | 50 | 16.5 | ||

| 3 | 100 | 17.7 |

| Feeds | Pressure, MPa | Temperature, K | Permeability, mD | NaCl Concentration, mol/L | Diffusion Coefficients, 10−11 m2/s |

|---|---|---|---|---|---|

| 1 | 8.28 | 313.15 | 50 | 1 | 2.97 |

| 2 | 10.05 | 313.15 | 50 | 1 | 3.56 |

| 3 | 15.26 | 313.15 | 50 | 1 | 4.36 |

| 4 | 20.25 | 313.15 | 50 | 1 | 5.27 |

| 5 | 25.83 | 313.15 | 50 | 1 | 5.83 |

| 6 | 30.23 | 313.15 | 50 | 1 | 6.47 |

| 7 | 10.22 | 323.15 | 50 | 1 | 3.96 |

| 8 | 15.15 | 323.15 | 50 | 1 | 4.88 |

| 9 | 20.78 | 323.15 | 50 | 1 | 5.55 |

| 10 | 25.06 | 323.15 | 50 | 1 | 6.36 |

| 11 | 29.68 | 323.15 | 50 | 1 | 7.06 |

| 12 | 10.07 | 333.15 | 50 | 1 | 4.30 |

| 13 | 15.36 | 333.15 | 50 | 1 | 5.33 |

| 14 | 20.14 | 333.15 | 50 | 1 | 6.18 |

| 15 | 25.27 | 333.15 | 50 | 1 | 6.84 |

| 16 | 30.57 | 333.15 | 50 | 1 | 7.67 |

| 17 | 15 | 343.15 | 50 | 1 | 5.74 |

| 18 | 20.07 | 343.15 | 50 | 1 | 6.69 |

| 19 | 25.1 | 343.15 | 50 | 1 | 7.39 |

| 20 | 30.27 | 343.15 | 50 | 1 | 8.05 |

| 21 | 10.88 | 353.15 | 50 | 1 | 4.85 |

| 22 | 15.09 | 353.15 | 50 | 1 | 6.25 |

| 23 | 20.09 | 353.15 | 50 | 1 | 7.14 |

| 24 | 30.91 | 353.15 | 50 | 1 | 8.50 |

| 25 | 11.55 | 373.15 | 50 | 1 | 5.30 |

| 26 | 15.28 | 373.15 | 50 | 1 | 7.71 |

| 27 | 19.7 | 373.15 | 50 | 1 | 7.89 |

| 28 | 30.94 | 373.15 | 50 | 1 | 9.61 |

| 29 | 15.06 | 323.15 | 100 | 1 | 9.50 |

| 30 | 15 | 323.15 | 10 | 1 | 1.66 |

| 31 | 15.03 | 323.15 | 50 | 0.5 | 5.21 |

| 32 | 15.07 | 323.15 | 50 | 1.5 | 4.24 |

| 33 | 15.06 | 323.15 | 50 | 2 | 3.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Yuan, L.; Sun, G.; Lv, J.; Zhang, Y. Experimental Determination of CO2 Diffusion Coefficient in a Brine-Saturated Core Simulating Reservoir Condition. Energies 2021, 14, 540. https://doi.org/10.3390/en14030540

Li Z, Yuan L, Sun G, Lv J, Zhang Y. Experimental Determination of CO2 Diffusion Coefficient in a Brine-Saturated Core Simulating Reservoir Condition. Energies. 2021; 14(3):540. https://doi.org/10.3390/en14030540

Chicago/Turabian StyleLi, Zerong, Lei Yuan, Guodong Sun, Junchen Lv, and Yi Zhang. 2021. "Experimental Determination of CO2 Diffusion Coefficient in a Brine-Saturated Core Simulating Reservoir Condition" Energies 14, no. 3: 540. https://doi.org/10.3390/en14030540

APA StyleLi, Z., Yuan, L., Sun, G., Lv, J., & Zhang, Y. (2021). Experimental Determination of CO2 Diffusion Coefficient in a Brine-Saturated Core Simulating Reservoir Condition. Energies, 14(3), 540. https://doi.org/10.3390/en14030540