Numerical Analysis of the Combustion Dynamics of Passively Controlled Jets Issuing from Polygonal Nozzles

Abstract

:1. Introduction

2. Computational Approach

3. Computational Configuration

4. Results

4.1. Model Validation

4.2. Impact of the Nozzle Geometry

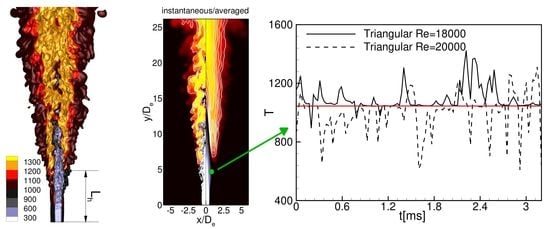

4.3. Reacting cases

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Quinn, W.R. Turbulent free jet flows issuing from sharp-edged rectangular slots: The influence of slot aspect ratio. Exp. Therm. Fluid Sci. 1992, 5, 203–215. [Google Scholar] [CrossRef]

- Xu, M.; Zhang, J.; Li, P.; Mi, J. On two distinct Reynolds number regimes of a turbulent square jet. Theor. Appl. Mech. Lett. 2015, 5, 117–120. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.; Luo, L.S.; Girimaji, S.S. LES of turbulent square jet flow using an MRT lattice Boltzmann model. Comput. Fluids 2006, 35, 957–965. [Google Scholar] [CrossRef]

- Tyliszczak, A.; Geurts, B.J. Controlling spatio-temporal evolution of natural and excited square jets via inlet conditions. Int. J. Heat Fluid Flow 2019, 80, 108488. [Google Scholar] [CrossRef]

- Rembold, B.; Adams, N.A.; Kleiser, L. Direct numerical simulation of a transitional rectangular jet. Int. J. Heat Fluid Flow 2002, 23, 547–553. [Google Scholar] [CrossRef]

- Gohil, T.B.; Saha, A.K.; Muralidhar, K. Control of flow in forced jets: A comparison of round and square cross sections. J. Vis. 2010, 13, 141–149. [Google Scholar] [CrossRef]

- Gutmark, E.J.; Grinstein, F.F. Flow control with noncircular jets. Annu. Rev. Fluid Mech. 1999, 31, 239–272. [Google Scholar] [CrossRef]

- Gutmark, E.; Schadow, K.; Parr, T.; Parr, D.; Wilson, K. Noncircular jets in combustion systems. In Proceedings of the 19th AIAA, Fluid Dynamics, Plasma Dynamics, and Lasers Conference, Honolulu, HI, USA, 8–10 June 1987. [Google Scholar]

- Gutmark, E.; Schadow, K.C.; Wilson, K.J. Subsonic and supersonic combustion using noncircular injectors. J. Propul. Power 1991, 7, 240–249. [Google Scholar] [CrossRef]

- Gutmark, E.; Grinstein, F. Passive combustion enhancement using non-circular jets—A review. In Proceedings of the 35th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 June 1997. [Google Scholar]

- Iyogun, C.O.; Birouk, M. Effect of fuel nozzle geometry on the stability of a turbulent jet methane flame. Combust. Sci. Technol. 2008, 180, 2186–2209. [Google Scholar] [CrossRef]

- Akbarzadeh, M.; Birouk, M. Liftoff of a co-flowing non-premixed turbulent methane flame: Effect of the fuel nozzle orifice geometry. Flow Turbul. Combust. 2014, 92, 903–929. [Google Scholar] [CrossRef]

- Huang, R.F.; Kivindu, R.M.; Hsu, C.M. Combusting jets issued from rectangular nozzles of high and low aspect ratios with co-flowing air. J. Therm. Sci. Eng. Appl. 2018, 10, 041009. [Google Scholar] [CrossRef]

- Iyogun, C.O.; Birouk, M.; Kozinski, J.A. Experimental investigation of the effect of fuel nozzle geometry on the stability of a swirling non-premixed methane flame. Fuel 2011, 90, 1416–1423. [Google Scholar] [CrossRef]

- Zhou, Z.; Chen, G.; Zhou, C.; Hu, K.; Zhang, Q. Experimental study on determination of flame height and lift-off distance of rectangular source fuel jet fires. Appl. Therm. Eng. 2019, 152, 430–436. [Google Scholar] [CrossRef]

- Liu, C.; Huang, L.; Deng, T.; Zhou, S.; Liu, X.; Deng, J.; Luo, Z. On the influence of nozzle geometry on jet diffusion flames under cross-wind. Fuel 2020, 263, 116549. [Google Scholar] [CrossRef]

- Miller, R.; Madnia, C.; Givi, P. Numerical simulation of non-circular jets. Comput. Fluids 1995, 24, 1–25. [Google Scholar] [CrossRef]

- Grinstein, F.F.; Kailasanath, K. Exothermicity and three-dimensional effects in unsteady propane square jets. Symp. Int. Combust. 1996, 26, 91–96. [Google Scholar] [CrossRef]

- Luo, K.H. Axis switching in turbulent buoyant diffusion flames. Proc. Combust. Inst. 2005, 30, 603–610. [Google Scholar] [CrossRef]

- ANSYS, Inc. ANSYS Fluent User’s Guide, Release 19.5; ANSYS, Inc.: Canonsburg, PA, USA, 2019. [Google Scholar]

- Nicoud, F.; Ducros, F. Subgrid-scale stress modelling based on the square of the velocity gradient tensor. Flow Turbul. Combust. 1999, 62, 183–200. [Google Scholar] [CrossRef]

- Vreman, A.W. An eddy-viscosity subgrid-scale model for turbulent shear flow: Algebraic theory and applications. Phys. Fluids 2004, 16, 3670–3681. [Google Scholar] [CrossRef]

- Wawrzak, K.; Boguslawski, A.; Tyliszczak, A. LES predictions of self-sustained oscillations in homogeneous density round free jet. Flow Turbul. Combust. 2015, 95, 437–459. [Google Scholar] [CrossRef] [Green Version]

- Duwig, C.; Nogenmyr, K.J.; Chan, C.; Dunn, M.J. Large eddy simulations of a piloted lean premix jet flame using finite-rate chemistry. Combust. Theor. Model. 2011, 15, 537–568. [Google Scholar] [CrossRef]

- Stempka, J.; Tyliszczak, A. Impact of Evaporation Models and Droplet Size on Auto-ignition and Lift-off Height in a Spray Jet Flame. Combust. Sci. Technol. 2019, 1–20. [Google Scholar] [CrossRef]

- Wawrzak, A.; Tyliszczak, A. Study of a flame kernel evolution in a turbulent mixing layer using LES with a laminar chemistry model. Flow Turbul. Combust. 2020, 105, 807–835. [Google Scholar] [CrossRef]

- Mueller, M.A.; Kim, T.J.; Yetter, R.A.; Dryer, F.L. Flow reactor studies and kinetic modeling of the H2/O2 reaction. Int. J. Chem. Kinet. 1999, 31, 113–125. [Google Scholar] [CrossRef]

- Tyliszczak, A. A high-order compact difference algorithm for half-staggered grids for laminar and turbulent incompressible flows. J. Comput. Phys. 2014, 276, 438–467. [Google Scholar] [CrossRef]

- Tyliszczak, A. High-order compact difference algorithm on half-staggered meshes for low Mach number flows. Comput. Fluids 2016, 127, 131–145. [Google Scholar] [CrossRef]

- Tyliszczak, A.; Geurts, B.J. Parametric analysis of excited round jets—Numerical study. Flow Turbul. Combust. 2014, 93, 221–247. [Google Scholar] [CrossRef] [Green Version]

- Tyliszczak, A.; Geurts, B.J. Controlled mixing enhancement in turbulent rectangular jets responding to periodically forced inflow conditions. J. Turbul. 2015, 16, 742–771. [Google Scholar] [CrossRef]

- Boguslawski, A.; Wawrzak, K.; Tyliszczak, A. A new insight into understanding the Crow and Champagne preferred mode: A numerical study. J. Fluid Mech. 2019, 869, 385–416. [Google Scholar] [CrossRef]

- Tyliszczak, A. LES-CMC of excited hydrogen jet. Combust. Flame 2015, 162, 3864–3883. [Google Scholar] [CrossRef]

- Rosiak, A.; Tyliszczak, A. LES-CMC simulations of a turbulent hydrogen jet in oxy-combustion regimes. Int. J. Hydrogen Energy 2016, 41, 9705–9717. [Google Scholar] [CrossRef]

- Wawrzak, A.; Tyliszczak, A. A spark ignition scenario in a temporally evolving mixing layer. Combust. Flame 2019, 209, 353–356. [Google Scholar] [CrossRef]

- Cabra, R.; Chen, J.Y.; Dibble, R.W.; Karpetis, A.N.; Barlow, R.S. Lifted methane-air jet flames in a vitiated coflow. Combust. Flame 2005, 143, 491–506. [Google Scholar] [CrossRef]

- Da Silva, C.B.; Métais, O. Vortex control of bifurcating jets: A numerical study. Phys. Fluids 2002, 14, 3798–3819. [Google Scholar] [CrossRef]

- Crow, S.C.; Champagne, F.H. Orderly structure in jet turbulence. J. Fluid Mech. 1971, 48, 547–591. [Google Scholar] [CrossRef]

- Zaman, K.B.M.Q.; Hussain, A.K.M.F. Vortex pairing in a circular jet under controlled excitation. Part 1. General jet response. J. Fluid Mech. 1980, 101, 449–491. [Google Scholar] [CrossRef]

- Aleyasin, S.S.; Fathi, N.; Tachie, M.F.; Vorobieff, P.; Koupriyanov, M. On the development of incompressible round and equilateral triangular jets due to Reynolds number variation. J. Fluids Eng. 2018, 140, 1–12. [Google Scholar] [CrossRef]

- Ball, C.G.; Fellouah, H.; Pollard, A. The flow field in turbulent round free jets. Prog. Aerosp. Sci 2012, 50, 1–26. [Google Scholar] [CrossRef]

- Geurts, B.J. Interacting errors in large-eddy simulation: A review of recent developments. J. Turbul. 2006, 7, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Quinn, W.R.; Militzer, J. Experimental and numerical study of a turbulent free square jet. Phys. Fluids 1988, 31, 1017–1025. [Google Scholar] [CrossRef]

- Xu, M.; Pollard, A.; Mi, J.; Secretain, F.; Sadeghi, H. Effects of Reynolds number on some properties of a turbulent jet from a long square pipe. Phys. Fluids 2013, 25, 035102. [Google Scholar] [CrossRef]

- Cocks, P.A.T.; Soteriou, M.C.; Sankaran, V. Impact of numerics on the predictive capabilities of reacting flow LES. Combust. Flame 2015, 162, 3394–3411. [Google Scholar] [CrossRef] [Green Version]

- Wygnanski, I.; Fiedler, H. Some measurements in the self-preserving jet. J. Fluid Mech. 1969, 38, 577–612. [Google Scholar] [CrossRef] [Green Version]

- Stankovic, I.; Triantafyllidis, A.; Mastorakos, E.; Lacor, C.; Merci, B. Simulation of hydrogen auto-ignition in a turbulent co-flow of heated air with LES and CMC approach. Flow Turbul. Combust. 2011, 86, 689–710. [Google Scholar] [CrossRef] [Green Version]

| Case Name | Nozzle | Re | () | |

|---|---|---|---|---|

| Ci-23C | Circular | 23,600 | (0.034, 0.067, 0.034) | |

| Ci-23CF | Circular | 23,600 | (0.027, 0.056, 0.027) | |

| Ci-18H | Circular | 18,000 | (0.034, 0.067, 0.034) | |

| Ci-20H | Circular | 20,000 | (0.034, 0.067, 0.034) | |

| Ci-23H | Circular | 23,600 | (0.034, 0.067, 0.034) | |

| He-23C | Hexagonal | 23,600 | (0.034, 0.067, 0.034) | |

| He-23H | Hexagonal | 23,600 | (0.034, 0.067, 0.034) | |

| Sq-23C | Square | 23,600 | (0.034, 0.067, 0.034) | |

| Sq-23CF | Square | 23,600 | (0.027, 0.056, 0.027) | |

| Sq-18H | Square | 18,000 | (0.034, 0.067, 0.034) | |

| Sq-20H | Square | 20,000 | (0.034, 0.067, 0.034) | |

| Sq-23H | Square | 23,600 | (0.034, 0.067, 0.034) | |

| Hg-23C | Hexagram | 23,600 | (0.034, 0.067, 0.034) | |

| Hg-23H | Hexagram | 23,600 | (0.034, 0.067, 0.034) | |

| Tr-23C | Triangular | 23,600 | (0.034, 0.067, 0.034) | |

| Tr-23CF | Triangular | 23,600 | (0.027, 0.056, 0.027) | |

| Tr-18H | Triangular | 18,000 | (0.034, 0.067, 0.034) | |

| Tr-20H | Triangular | 20,000 | (0.034, 0.067, 0.034) | |

| Tr-23H | Triangular | 23,600 | (0.034, 0.067, 0.034) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuban, Ł.; Stempka, J.; Tyliszczak, A. Numerical Analysis of the Combustion Dynamics of Passively Controlled Jets Issuing from Polygonal Nozzles. Energies 2021, 14, 554. https://doi.org/10.3390/en14030554

Kuban Ł, Stempka J, Tyliszczak A. Numerical Analysis of the Combustion Dynamics of Passively Controlled Jets Issuing from Polygonal Nozzles. Energies. 2021; 14(3):554. https://doi.org/10.3390/en14030554

Chicago/Turabian StyleKuban, Łukasz, Jakub Stempka, and Artur Tyliszczak. 2021. "Numerical Analysis of the Combustion Dynamics of Passively Controlled Jets Issuing from Polygonal Nozzles" Energies 14, no. 3: 554. https://doi.org/10.3390/en14030554