1. Introduction

Increasing the efficiency of turbomachinery, such as a gas turbine, by decreasing the leakage flow rate has become an important topic in the engineering community. Although contact seals can constrict the leakage flow rate efficiently, they cannot be used in turbomachinery with many parts moving at a high speed because of the possibility of causing damage through friction or heat expansion. Therefore, non-contact seals are used to reduce the leakage flow rate and increase the efficiency of turbomachinery by increasing the flow resistance under a specific pressure difference and reducing the leakage flow rate [

1]. One of the most used non-contact seals is the labyrinth seal, because of its high sealing capacity and ease of manufacturing [

2]. It is an annular type divided into three categories—stepped, straight, and staggered [

3]. Of these, the straight-through seal is a simple and basic type that is the most frequently manufactured. The labyrinth seal consists of a rotor, stator, and a series of teeth and cavities to increase the flow resistance.

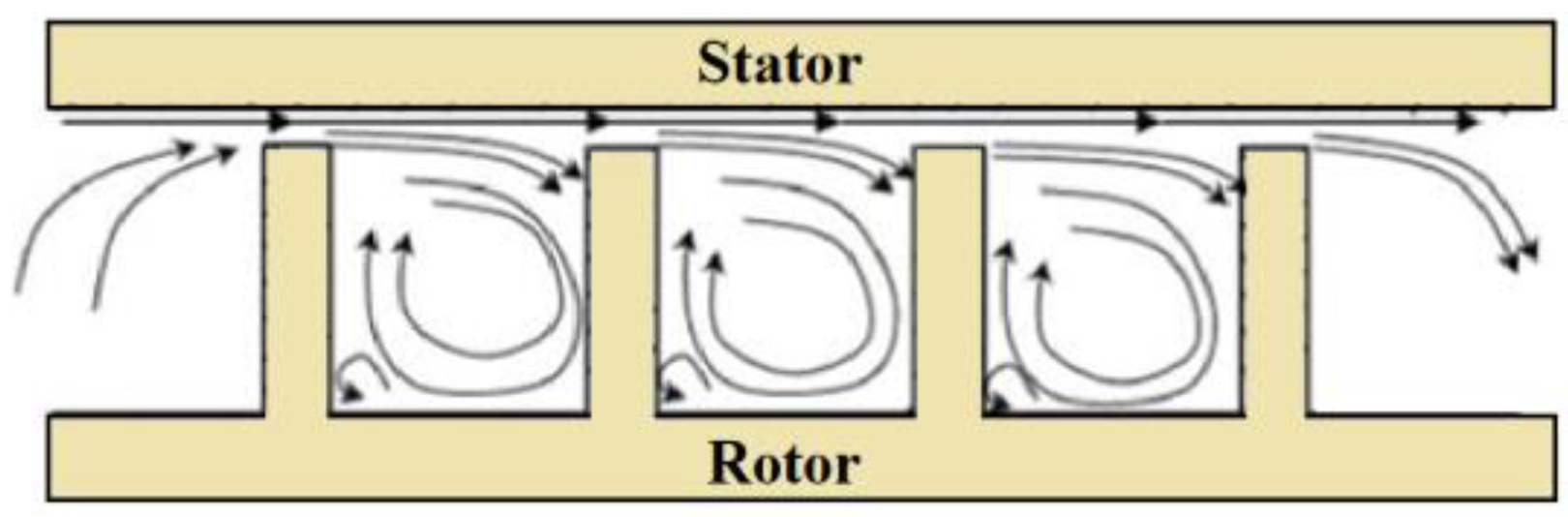

Figure 1 illustrates the typical flow pattern in a straight-through labyrinth seal.

As the fluid flow goes through the clearance above a tooth, the high-pressure head is converted into kinetic energy in the flow, and a jet is generated because of the narrow clearance. A portion of the jet that passes above the tooth goes on to the next tooth, while the remainder interacts with the vortex within the cavity [

4]. Meanwhile, part of the kinetic energy is dissipated by the vortex generated in the cavities [

5], and as the flow continues on through constrictions made by the series of teeth and cavities, the kinetic energy of the flow is dissipated continuously, leading to a reduction in the leakage flow rate and the discharge coefficient.

Becker [

6] explained the fluid flow in labyrinth seals and modeled the flow as a Poiseuille flow and tried to find the friction coefficient, while Martin [

7] derived an equation to calculate the leakage flow rate in a labyrinth seal for the first time; he thought that the fluid flow through a labyrinth seal is similar to that in a series of orifices when assuming that the kinetic energy of the flow in the cavity is totally dissipated. Stodola [

8] also formulated a leakage flow rate equation using Bernoulli’s principle and the continuity equations; although his equation was similar to Martin’s, he neglected the movement of the kinetic energy in the cavities. Egli [

9] investigated the effect of changing the number of teeth on the leakage flow rate and stated that Martin’s equation could be used when the labyrinth seal has four or more teeth; he modified Martin’s equation by applying flow coefficients determined empirically. Dollin and Brown [

10] adapted Martin’s equation using a polytropic thermodynamic path function; they reported that Martin’s equation underestimated the leakage flow rate, as he assumed that the flow in the seal is isothermal. Hodkinson [

11] analyzed the kinetic energy carryover coefficient in the labyrinth seal by assuming that a portion of the jet is carried over to the next cavity. He also produced an equation to estimate the leakage flow rate through the seal using the kinetic energy carryover coefficient and predicted its value experimentally. Jeri [

12] carried out experiments on a labyrinth seal and reported that the optimum ratio of the tooth height to the pitch was slightly less than 1; when the ratio is too high and the teeth are too concentrated, the sealing performance is reduced, and the leakage flow rate is increased.

Bell and Bergelin [

13] investigated the effect of the fluid flow’s Reynolds number on the flow coefficients. When the Reynolds number is low, the flow coefficients are dependent on it, whereas when it is high, the flow coefficients are almost constant; they reported that the geometry of the seal affects the flow coefficients considerably. Vermes [

14] modified Martin’s equation by assuming a non-isothermal flow; the flow coefficients from Bell and Bergelin [

13] and a correction factor for the carried over kinetic energy were used. Wittig et al. [

15] predicted the discharge coefficients in the labyrinth seals both experimentally and numerically; he used computational fluid dynamic (CFD) codes and compared the results with the experimental data and reported that the discharge coefficient strongly depends on the size of the clearance, and that increasing the clearance makes the discharge coefficient higher. Saikishan [

16] investigated the effects of tooth geometry on leakage flow characteristics using the Reynolds-Averaged Navier–Stokes (RANS) turbulence model; he calculated the discharge and kinetic carryover coefficients by varying geometric parameters and compared his results with the experimental data. Zhao [

17] carried out RANS simulations to investigate the effects of changing the cavity depth and length, the number of cavities, and the cavity locations on the leakage loss; he concluded that when the depth and length, or the number of cavities, is increased, the leakage loss is increased. However, he did not compare the CFD results with the experimental data, and the number of cases was insufficient to make generalizations in the conclusions.

There have been several studies on the effect of changing some of the geometrical parameters on the leakage flow rate and the discharge coefficient. However, when the labyrinth seals in turbomachinery are designed by engineers, the space to install the seal is limited, and so it is important to optimize the geometry of the labyrinth seal for a fixed axial length so as to minimize the leakage flow rate and the discharge coefficient. The objective of this study is to understand the effects of changing several geometric parameters of a straight-through seal on the discharge coefficient, and to optimize the geometry for a fixed axial length. The effects of changing the clearance, tooth inclination angle, tooth height, cavity width, and tooth width on the discharge coefficient were investigated using RANS simulations, after which the optimal geometric parameter values to decrease the discharge coefficient were decided upon. Based on this knowledge, an example of the optimized geometry of a labyrinth seal for a fixed axial length was suggested. Actually, RANS could not accurately predict the complex flow structures induced in the labyrinth seal, as all of the turbulent fluctuations were ensemble-averaged, while LES resolves directly large-scale eddies in the turbulent flow, leading to more accurate predictions of the complex flow. However, LES requires much higher computational costs than RANS; therefore, in this study, RANS was used.

2. Geometry and Boundary Conditions

Figure 2 shows the geometrical parameters of a straight-through labyrinth seal in the computational domain. The baseline geometry of the labyrinth seal in the current study was taken from Wittig et al. [

15], whose experimental apparatus consisted of five teeth on a flat plate. In their apparatus, the tooth height, width, and inclination angle; the cavity width; the pitch; and the clearance were set to 10.5 mm, 2.5 mm, 0, 9.5 mm, 12 mm, and 0.5 mm, respectively. Air was supplied by a compressor and the maximum flow rate was 0.5 kg/s. The mass flow rate was measured by the orifice meter and it was controlled by the valves located in the orifice meter section. The maximum pressure ratio was 4. The settling chamber was located in front of the labyrinth seal to make the entrance condition similar to that of real turbomachinery. The boundary conditions in the computational domain are specified in

Table 1. The turbulence intensity of the mainstream flow at the inlet was 0.2% and the pressure ratios at the inlet were 1.1, 1.5, and 2. The temperature of the main flow was set as 300 K.

The divergence angle (β) introduced by Hodkinson [

11] was measured by the streamline separating the vortex in the cavity and the fluid flow passing to the next cavity, as can be seen in

Figure 3. This angle was decided by the line between the lip of the former tooth and the point of the impingement of the jet on the sidewall of the next tooth. If β is increased, a smaller portion of the upstream jet is passed to the next cavity, resulting in a decrease in the leakage flow rate and the discharge coefficient.

3. Validation of Numerical Methods

The CFD calculations were performed using ANSYS Fluent v.19.1 [

18], and the meshes were generated in Pointwise v.18.1 [

19]. The fluid was assumed to be Newtonian and compressible. The governing equations of the CFD simulations were continuity and momentum equations, while the Navier–Stokes equations are the conservation of momentum and the continuity equations in a differential form. In the RANS approach, all of the turbulent fluctuations in the flow were temporally averaged. The ensemble averages of the conservation of mass (Equation (1)), momentum (Equations (2)–(4)), and energy (Equation (5)) equations for turbulent flows are expressed as follows [

20,

21,

22]:

Conservation of mass (the continuity equation):

Conservation of momentum:

Conservation of energy:

The six Reynolds stresses, namely,

,

,

,

,

, and

in Equations (1)–(3), and

,

and

in Equation (4), needed to be modeled [

20]. The overbar represents the mean components; while

are the fluctuating velocity components; and

is the temperature. Closure for the equations was obtained through Boussinesq′s hypothesis, which is expressed as [

22]:

where

is the turbulence viscosity and needs to be modeled as [

22]

μt is assumed to be the same in all directions, and the assumption shows good results for a lot of simple turbulent flows, even though the assumption is not true [

22]. Equations (1)–(7) could not be solved analytically, thus CFD simulations were the only way to obtain solutions for the equations, which required a turbulence model to close the equations mathematically.

The numerical simulations were executed in RANS using the various turbulence models; the RANS runtime using 16 cores of an Intel Xeon Gold 6148 processor was around 6 h for each case. The levels of 10

−6 were used as the solution convergence criteria.

Figure 4 shows the 3D baseline mesh of the straight-through labyrinth seal composed of around 8 million hexahedron cells; the clearance was 0.5 mm, the tooth inclination angle was 0°, the tooth height was 10.5 mm, the cavity width was 9.5 mm, the tooth width was 2.5 mm, and the number of cavities was 5, as described in Wittig et al. [

15]. Y

+ values around the walls were set to less than 3 so as to capture the normal velocity gradient of the wall in the viscous sublayer accurately.

Figure 5 displays the results of the grid sensitivity tests, with the grid description shown in

Table 2. The results were obtained using the standard

k−ε model in RANS, and the sensitivity test was performed on the five different grids. The discharge coefficient on the third grid with 7.97 million cells matched those of the finer fourth and fifth grids. Thus, the discharge coefficient in the baseline mesh of the labyrinth seal was evaluated on the 7.97 million cells grid. The uncertainty bar (5%) was added in the plot, and the discharge coefficients on the third, fourth, and fifth grid were within the uncertainty error of the experimental data.

For the CFD verification, RANS simulations were carried out using several turbulence models, and the results were compared with the experimental data.

Figure 6 shows the effect of the pressure ratio on the discharge coefficient by using three RANS turbulence models for the clearance of 0.5 mm in the baseline seal. The differences between the RANS and the experimental discharge coefficient results were around 4%, 6%, and 13% for the standard

k−ε,

k−ω shear stress transport (Menter’s SST), and standard

k−ω models, respectively, indicating that the result from the standard

k−ε model showed the least difference with the experimental data. As the standard

k−ε model under-predicts the discharge coefficient while the

k−ω model overestimates it, all numerical simulations in this study from this point forward were executed using the standard

k−ε model. In the setting of the fluent, the two-layer model was employed and the one-equation model of Wolfstein was used in the near-wall region, whereas in the fully turbulent region, the standard k-epsilon model was employed [

18].

Figure 6 indicates the discharge coefficient according to the ratio of the actual leakage flow rate to the ideal leakage flow rate.

Figure 7 shows the pressure distribution based on the pressure measured in each cavity of the baseline labyrinth seal for a pressure ratio of 1.38. It was found that the pressure distribution predicted by the standard

k−ε model was a good match with the experimental data.

5. Conclusions

A straight-through labyrinth seal is one of the most popular non-contacting annular seals. Kinetic energy dissipation through the turbulence viscosity interaction is achieved by the labyrinth seal consisting of a series of teeth and cavities. The effects of changing several geometric parameters of the labyrinth seal on the discharge coefficient were investigated using CFD simulation and RANS models. As the space to install labyrinth seals in a gas turbine is limited, it is important to determine the optimal geometry of the seal per unit length so as to minimize the leakage flow rate and the discharge coefficient. First, the clearance should be kept as small as possible within the range to avoid any possible damage and for a good sealing performance. Decreasing the tooth inclination angle decreased the discharge coefficient slightly, but an angle exceeding 16° negatively affected the reduction in the discharge coefficient. Increasing the tooth height was not beneficial, but when it was small, there was a positive effect on decreasing the discharge coefficient. When the whole length was fixed, increasing the number of cavities was more useful for increasing the sealing capacity, as its effect on the discharge coefficient was stronger than when increasing the cavity width. In addition, when the whole axial length was fixed, increasing the number of cavities was more helpful to increase the sealing capacity than increasing the tooth width. The most effective parameter for decreasing the discharge coefficient was the clearance, whereas the second most effective parameter for improving the sealing performance was the cavity width. The third most effective parameter for decreasing the leakage flow rate was the tooth width. Changing the tooth inclination angle and the tooth height was not as effective decreasing the discharge coefficient and increasing the sealing performance. Based on our investigations, an example using the optimized geometry of the labyrinth seal with a fixed axial length is suggested. The discharge coefficient for the labyrinth seal with the suggested optimal design was lower by around 23%, 14%, and 12% under the pressure ratios of 1.1, 1.5, and 2, respectively.