Procedure for Detection of Stator Inter-Turn Short Circuit in AC Machines Measuring the External Magnetic Field †

Abstract

:1. Introduction

- methods for the identification and estimation of physical parameters of the machine [4];

- methods based on modeling of signals that analyze the time variation and the spectral content of different physical quantities. The work presented in this paper concerns that kind of analysis.

2. Analytical Approach for Healthy Machine

2.1. Air-Gap Permeance

2.2. Healthy Machine m.m.f

2.3. Air-Gap Flux Density

2.4. Transverse Field

2.5. Measurement of the Transverse Field

3. Analytical Approach for Faulty Machine

3.1. Structure of the Faulty Machine

3.2. Faulty Turns m.m.f

3.3. Searching for Sensitive Components

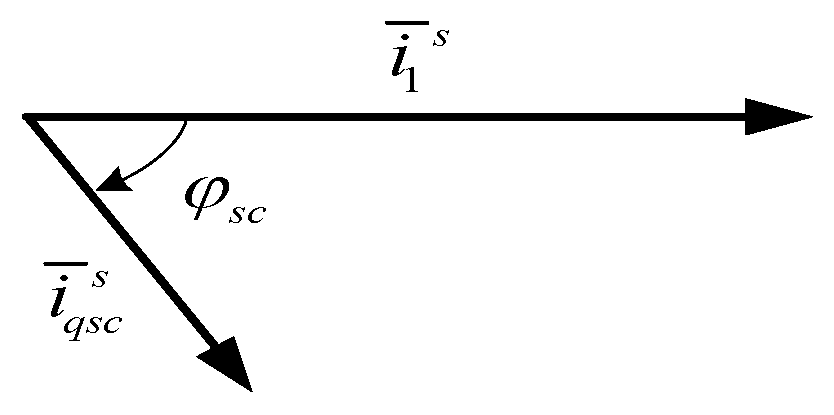

3.4. Influence of the Load

- In the healthy case:

- In the faulty case:

3.5. Application to a Salient Pole Synchronous Machine

4. Experimental Results

4.1. Presentation of the IM Test Bench

4.2. Induction Machine in Motor Case

- in healthy conditions, the lines at 850 Hz evolve in the same direction with the change of the load,

- in faulty conditions, the lines at 850 Hz in position 1, compared with those in position 2 vary in opposite directions.

- the value of the short circuit current Isc can influence the evolution of the lines

4.3. Induction Machine in Generator Case

4.4. Synchronous Machine

4.5. Self-Excited Induction Generator

4.6. Practical Precautions

- the kind of sensor: the sensor has to be small enough so that one can consider that the measured value of the flux density is the same as the flux density at the center of the sensor. In order to get an acceptable value of the output voltage, the small size has to be compensated by the number of turns. But as the increase of the number of turns decreases the resonance frequency of the sensor, this latter has to be checked with an impedance analyzer to get sure that the frequency resonance is far from the analyzed frequency. The used sensors are 3.2 cm diameter and 1200 turns, which leads to a resonance frequency at 93 KHz.

- the location of the sensors: both sensors have to be placed symmetrically from the machine axis, approximately in the middle of the stator, between the end bells. Concerning the accuracy of the symmetry of the sensors, it increases when the pole pair number p of the machine is high. Actually, an error in the sensor alignment will be multiplied by p and it could not be possible to consider that the first terms of (22) and (23) are the same, leading to a disturbance in the diagnosis method.

- the number of measurements: practical tests have shown that when the sensors are far from the axis of the damaged coil, the results give the impression that the machine is healthy because the magnitudes at sensitive spectral lines always vary in the same direction with the load variation. Theoretically, this can be taken into account considering all the elementary components of Table 2 and Table 4 instead of the predominant components grey highlighted. To avoid this confusion, it is necessary to perform several measurements such as at least one is closer to the faulty winding than the healthy winding, among the p windings that constitute a whole phase. Consequently, the minimal number of measurements should be 2p, but to increase the probability of fault detection, we recommend 3p measurement. Of course, in a practical point of view, the locations of the sensors have to take into account the non-accessible areas, e.g., the areas of the mounting base or the terminal box (Figure 20).

- case of inverter fed: it should be checked that the chopping frequency is higher than the sensitive one.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| p | number of pole pair |

| f | supply frequency |

| ns | number of turns in series for a whole phase |

| n’s | number of turns in an elementary section |

| y | number of shorted turns |

| Ns, Nr | number of stator and rotor slots per pole pair |

| rms value of the no load stator current | |

| rms value of the short circuit current | |

| ε | air gap resultant m.m.f—healthy machine |

| λ | air gap permeance |

| b | air gap flux density- healthy machine |

| bx | external radial flux density—healthy machine |

| h, hs | m.m.f rank |

| ks,kr | permeance rank |

| elementary component of air-gap flux density | |

| component of air gap flux density | |

| K | frequency rank of a flux density component |

| H | pole pair number of a flux density component |

| rank K harmonic of bx | |

| CH | attenuation coefficient |

| , | inner and outer radius of the stator |

| All the parameters and variables with “sc” lower index are related to the short circuit turns. | |

References

- Sadeghi, I.; Ehya, H.; Faiz, J.; Akmal, A.A.S. Online condition monitoring of large synchronous generator under short circuit fault—A review. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 19–22 February 2018; pp. 1843–1848. [Google Scholar]

- Ondel, O.; Boutleux, B.E.; Clerc, G. Coupling Pattern Recognition with State Estimation Using Kalman Filter for Fault Diagnosis. IEEE Trans. Ind. Electron. 2012, 59, 4293–4300. [Google Scholar] [CrossRef]

- Skowron, M.; Wolkiewicz, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Effectiveness of selected neutral network structures based on axial flux analysis in stator and rotor winding incipient fault detection of inverter-fed induction motors. Energies 2019, 12, 2392. [Google Scholar] [CrossRef] [Green Version]

- Bachir, S.; Tnani, S.; Trigeassou, J.C.; Champenois, G. Diagnosis by parameter estimation of stator and rotor faults occurring in induction machines. IEEE Trans. Ind. Electron. 2006, 53, 963–973. [Google Scholar] [CrossRef]

- Tsypkin, M. Induction motor condition monitoring: Vibration analysis technique—Diagnosis of electromagnetic anomalies. IEEE Autotescon. 2017, 1–7. [Google Scholar] [CrossRef]

- Artigao, E.; Honrubia-Escribano, A.; Gomez-Lazaro, E. In service wind turbine DFIG diagnosis using current signature analysis. IEEE Trans. Ind. Electron. 2020, 67, 2262–2271. [Google Scholar] [CrossRef]

- Thomson, W.T.; Fenger, M. Current signature analysis to detect induction motor faults. IEEE Ind. Appl. Mag. 2001, 7, 26–34. [Google Scholar] [CrossRef]

- Benbouzid, M.E.H. A review of induction motors signature analysis as a medium for faults detection. IEEE Trans. Ind. Electron. 2000, 47, 984–993. [Google Scholar] [CrossRef] [Green Version]

- Henao, H.; Razik, H.; Capolino, G.A. Analytical approach of the stator current frequency harmonics computation for detection of induction machine rotor faults. IEEE Trans. Ind. Appl. 2005, 41, 801–807. [Google Scholar] [CrossRef]

- Khezzar, A.; Kaikaa, M.Y.; Oumaamar, M.E.K.; Boucherma, M.; Razik, H. On the use of slot harmonics as a potential indicator of rotor bar breakage in the induction machine. IEEE Trans. Ind. Electron. 2009, 56, 4592–4605. [Google Scholar] [CrossRef]

- Bossio, G.R.; De Angelo, C.H.; Bossio, J.M.; Pezzani, C.M.; Garcia, G.O. Separating broken rotor bars and load oscillations on IM Fault Diagnosis Through the Instantaneous Active and Reactive Currents. IEEE Trans. Ind. Electron. 2009, 56, 4571–4580. [Google Scholar] [CrossRef]

- Athulya, K. Inter Turn Fault Diagnosis in Wound Rotor Induction Machine Using Wavelet Transform. In Proceedings of the 2018 International CET Conference on Control, Communication, and Computing (IC4), Thiruvananthapuram, India, 5–7 July 2018; pp. 22–27. [Google Scholar]

- Radecki, A. Stator winding inter-turn short circuit modelling of a squirrel cage induction motor. Power Electron. Drives 2016, 1, 140–148. [Google Scholar] [CrossRef]

- Bouzida, A.; Touhami, O.; Ibtiouen, R.; Belouchrani, A.; Fadel, M.; Rezzoug, A. Fault diagnosis in industrial induction machines through discrete wavelet transform. IEEE Trans. Ind. Electron. 2011, 59, 4385–4395. [Google Scholar] [CrossRef]

- Azzoug, Y.; Pusca, R.; Sahraoui, M.; Ammar, A.; Romary, R.; Cardoso Marques, A.J. A Single Observer for Currents Estimation in Sensor’s Fault-Tolerant Control of Induction Motor Drives. In Proceedings of the ICAAID2019, International Conference on Applied Automation and Industrial Diagnostics, Elazig, Turkey, 25–27 September 2019; pp. 1–6. [Google Scholar]

- Panagiotou, P.A.; Arvanitakis, I.; Lophitis, N.; Antonino-Daviu, J.A.; Gyftakis, K.N. Analysis of Stray Flux Spectral Components in Induction Machines under Rotor Bar Breakages at Various Locations. In Proceedings of the ICEM’18, XIII International Conference on Electrical Machines, Alexandroupoli, Greece, 3–6 September 2018; pp. 2345–2351. [Google Scholar]

- Tavner, P.J.; Hammond, P.; Penman, J. Contribution to the study of leakage fields at the ends of rotating electrical machines. IEE 1978, 125, 1339–1349. [Google Scholar] [CrossRef]

- Kameari, A. Three dimensional eddy current calculation using finite element method with A-V in conductor and in vacuum. IEEE Trans. Magn. 1988, 24, 118–121. [Google Scholar] [CrossRef]

- Ceban, A.; Fireteanu, V.; Romary, R.; Pusca, R.; Taras, P. Finite Element Diagnosis of Rotor Faults in Induction Motors based on Low Frequency Harmonics of the Near-Magnetic Field. In Proceedings of the SDEMPED 2011, IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Bologna, Italy, 5–8 September 2011; pp. 192–198. [Google Scholar]

- Canova, A.; Manzin, A.; Tartaglia, M. Evaluation of different analytical and semi-analytical methods for the design of ELF magnetic field shields. IEEE Trans. Ind. Appl. 2002, 38, 788–796. [Google Scholar] [CrossRef]

- Romary, R.; Roger, D.; Brudny, J.F. Analytical computation of an AC machine external magnetic field. Eur. Phys. J. Appl. Phys. 2009, 47, 31102. [Google Scholar] [CrossRef]

- Frosini, L.; Borin, A.; Girometta, L.; Venchi, G. A novel approach to detect short circuits in low voltage induction motor by stray flux measurement. In Proceedings of the ICEM’12, 20th International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 1536–1542. [Google Scholar]

- Henao, H.; Demian, C.; Capolino, G.A. A frequency-domain detection of stator winding faults in induction machines using an external flux sensor. IEEE Trans. Ind. Appl. 2003, 39, 1272–1279. [Google Scholar] [CrossRef]

- Romary, R.; Corton, R.; Thailly, D.; Brudny, J.F. Induction machine fault diagnosis using an external radial flux sensor. Eur. Phys. J. Appl. Phys. 2005, 32, 125–132. [Google Scholar] [CrossRef]

- Vitek, O.; Jada, M.; Hajek, V.; Bauer, P. Detection of eccentricity and bearing faults using stray flux monitoring. In Proceedings of the SDEMPED 2011, IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Bologna, Italy, 5–8 September 2011; pp. 456–461. [Google Scholar]

- Ceban, A.; Pusca, R.; Romary, R. Study of rotor faults in induction motors using external magnetic field analysis. IEEE Trans. Ind. Electron. 2012, 59, 2082–2093. [Google Scholar] [CrossRef]

- Cabanas, M.F.; Melero, M.G.; Orcajo, G.A.; Rodriguez, F.F.; Sariego, J.S. Experimental application of axial leakage flux to the detection of rotor asymmetries, mechanical anomalies and interturn short circuits in working induction motors. In Proceedings of the ICEM98, International Conference on Electrical Machines, Istanbul, Turkey, 2–4 September 1998; pp. 420–425. [Google Scholar]

- Assaf, T.; Henao, H.; Capolino, G.A. Simplified axial flux spectrum method to detect incipient stator inter-turn short-circuits in induction machine. In Proceedings of the ISIE 2004, IEEE International Symposium on Industrial Electronics, Ajaccio, France, 4–7 May 2004; pp. 815–819. [Google Scholar]

- Kia, S.H.; Henao, H.; Capolino, G.A.; Martis, C. Induction machine broken bars faults detection using stray flux after supply disconection. In Proceedings of the IECON 2006, 32th Annual Conference of the IEEE Industrial Electronics Society, Paris, France, 7–10 November 2006; pp. 1498–1503. [Google Scholar]

- Schmerber, L.; Rouve, L.L.; Foggia, A. Original 2D cylindrical harmonics method of the near magnetic stray field of an electrical motor. In Proceedings of the IEMDC 2005, IEEE International Electric Machines and Drives Conference, San Antonio, TX, USA, 15–18 May 2005; pp. 92–98. [Google Scholar]

- Penman, J.; Sedding, H.G.; Fink, W.T. Detection and location of interturn short circuits in the stator windings of operating motors. IEEE Trans. Energy Convers. 1994, 9, 652–658. [Google Scholar] [CrossRef] [Green Version]

- Pusca, R.; Romary, R.; Ceban, A.; Brudny, J.F. An online universal diagnosis procedure using two external flux sensors applied to the AC electrical rotating machines. Sensors 2010, 10, 7874–7895. [Google Scholar] [CrossRef] [PubMed]

- Brudny, J.F. Modélisation de la denture des machines asynchrones. Phénomène Résonance J. Phys. III 1997, 7, 1009–1023. [Google Scholar] [CrossRef]

- Pusca, R.; Romary, R.; Ceban, A. Detection of inter-turn short circuit in induction machines without knowledge of the healthy state. In Proceedings of the ICEM ’12, 20th International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 1637–1642. [Google Scholar]

- Thailly, J.D.; Romary, R.; Roger, D.; Brudny, J.F. Attenuation of magnetic field components through an AC machine stator. COMPEL 2008, 27, 744–753. [Google Scholar] [CrossRef]

- Pusca, R.; Demian, C.; Mercier, D.; Lefevre, E.; Romary, R. Improvement of a diagnosis procedure for AC machines using two external flux sensors based on a fusion process with belief functions. In Proceedings of the IECON 2012, 38th Annual Conference of the IEEE Industrial Electronics Society, Montreal, QC, Canada, 25–28 October 2012; pp. 5078–5083. [Google Scholar]

| kr | ks | hs | K | H | f(Hz) | K × f (Hz) | CH | |

|---|---|---|---|---|---|---|---|---|

| −1 | 1 | −5 | −15 | 6 | 50 | −750 | 5.08 × 10−5 | 1.48 × 10−5 |

| −1 | 1 | −11 | −15 | −6 | 50 | −750 | 5.08 × 10−5 | 4.04 × 10−6 |

| 1 | −1 | 7 | 17 | −2 | 50 | 850 | 4.71 × 10−4 | 1.41 × 10−4 |

| 1 | −1 | 13 | 17 | 10 | 50 | 850 | 2.66 × 10−6 | 2.81 × 10−7 |

| −2 | 1 | 7 | −31 | −2 | 50 | −1550 | 4.7 × 10−4 | −1.28 × 10−4 |

| −2 | 2 | −17 | −31 | −2 | 50 | −1550 | 4.71 × 10−4 | 2.82 × 10−5 |

| k’r | k’s | hs | KSC | Hsc | Ksc × f(Hz) | CH | |

|---|---|---|---|---|---|---|---|

| −1 | 1 | −10 | −15 | 6 | −750 | 5.08 × 10−5 | 9.2 × 10−6 |

| −1 | 1 | −13 | −15 | 3 | −750 | 2.56 × 10−4 | −3.52 × 10−5 |

| −1 | 1 | −14 | −15 | 2 | −750 | 4.71 × 10−4 | −1.02 × 10−4 |

| −1 | 1 | −15 | −15 | 1 | −750 | 0.00107 | −1.84 × 10−4 |

| −1 | 1 | −18 | −15 | −2 | −750 | 4.71 × 10−4 | 9.1 × 10−5 |

| −1 | 1 | −19 | −15 | −3 | −750 | 2.56 × 10−4 | 2.61 × 10−5 |

| −1 | 1 | −21 | −15 | −5 | −750 | 8.62 × 10−5 | −5.8 × 10−6 |

| −1 | 1 | −22 | −15 | −6 | −750 | 5.08 × 10−5 | −4.07 × 10−6 |

| 1 | −1 | 10 | 17 | −6 | 850 | 5.08 × 10−5 | 9.32 × 10−6 |

| 1 | −1 | 11 | 17 | −5 | 850 | 8.62 × 10−5 | 1.12 × 10−5 |

| 1 | −1 | 14 | 17 | −2 | 850 | 4.71 × 10−4 | −1.02 × 10−4 |

| 1 | −1 | 15 | 17 | −1 | 850 | 0.00107 | −1.9 × 10−4 |

| 1 | −1 | 17 | 17 | 1 | 850 | 0.00107 | 1.82 × 10−4 |

| 1 | −1 | 18 | 17 | 2 | 850 | 4.71 × 10−4 | 9.1 × 10−5 |

| 1 | −1 | 21 | 17 | 5 | 850 | 8.62 × 10−5 | −5.8 × 10−6 |

| 1 | −1 | 22 | 17 | 6 | 850 | 5.08 × 10−5 | −4.07 × 10−6 |

| −2 | 1 | 17 | −31 | 1 | −1550 | 0.00107 | −1.52 × 10−4 |

| −2 | 1 | 21 | −31 | 5 | −1550 | 8.62 × 10−5 | 5.04 × 10−6 |

| −2 | 1 | 22 | −31 | 6 | −1550 | 5.08 × 10−5 | 3.26 × 10−6 |

| −2 | 2 | −26 | −31 | 6 | −1550 | 5.08 × 10−5 | 1.92 × 10−6 |

| kr | ks | hs | K | H | K × f (Hz) | CH | |

|---|---|---|---|---|---|---|---|

| 6 | 0 | −5 | 13 | 14 | 650 | 7.2 × 10−6 | 6.04 × 10−3 |

| 6 | 0 | 1 | 13 | 26 | 650 | 8.19 × 10−8 | 3.43 × 10−3 |

| 7 | 0 | −5 | 15 | 18 | 750 | 1.63 × 10−6 | 13.5 × 10−3 |

| 7 | 0 | 1 | 15 | 30 | 750 | 1.83 × 10−8 | 10.8 × 10−3 |

| −7 | 0 | −5 | −13 | −38 | −650 | 9.19 × 10−10 | 2.21 × 10−3 |

| −7 | 0 | 1 | −13 | −26 | −650 | 8.19 × 10−8 | 2.29 × 10−3 |

| 8 | 0 | −5 | 17 | 22 | 850 | 3.65 × 10−7 | 11.8 × 10−3 |

| 8 | 0 | 1 | 17 | 34 | 850 | 4.01 × 10−9 | 8.8 × 10−3 |

| −8 | 0 | −5 | −15 | −42 | −750 | 2.05 × 10−10 | 4.91 × 10−3 |

| −8 | 0 | 1 | −15 | −30 | −750 | 1.83 × 10−8 | 10.3 × 10−3 |

| kr | ks | hs | K | H | K × f (Hz) | CH | |

|---|---|---|---|---|---|---|---|

| 6 | 0 | −5 | 13 | 19 | 650 | 1.12 × 10−6 | 5.13 × 10−4 |

| 6 | 0 | 1 | 13 | 25 | 650 | 1.19 × 10−7 | 3.64 × 10−4 |

| 7 | 0 | −5 | 15 | 23 | 750 | 2.51 × 10−7 | 2.13 × 10−3 |

| 7 | 0 | 1 | 15 | 29 | 750 | 2.66 × 10−8 | 1.82 × 10−3 |

| −7 | 0 | −5 | −13 | −33 | −650 | 5.90 × 10−9 | 7.9 × 10−4 |

| −7 | 0 | 1 | −13 | −27 | −650 | 5.60 × 10−8 | 9.8 × 10−4 |

| 8 | 0 | −5 | 17 | 27 | 850 | 5.60 × 10−8 | 1.2 × 10−3 |

| 8 | 0 | 1 | 17 | 33 | 850 | 5.90 × 10−9 | 4.8 × 10−4 |

| −8 | 0 | −5 | −15 | −37 | −750 | 1.33 × 10−9 | 1.46 × 10−4 |

| −8 | 0 | 1 | −15 | −31 | −750 | 1.26 × 10−8 | 1.52 × 10−4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pusca, R.; Romary, R.; Touti, E.; Livinti, P.; Nuca, I.; Ceban, A. Procedure for Detection of Stator Inter-Turn Short Circuit in AC Machines Measuring the External Magnetic Field. Energies 2021, 14, 1132. https://doi.org/10.3390/en14041132

Pusca R, Romary R, Touti E, Livinti P, Nuca I, Ceban A. Procedure for Detection of Stator Inter-Turn Short Circuit in AC Machines Measuring the External Magnetic Field. Energies. 2021; 14(4):1132. https://doi.org/10.3390/en14041132

Chicago/Turabian StylePusca, Remus, Raphael Romary, Ezzeddine Touti, Petru Livinti, Ilie Nuca, and Adrian Ceban. 2021. "Procedure for Detection of Stator Inter-Turn Short Circuit in AC Machines Measuring the External Magnetic Field" Energies 14, no. 4: 1132. https://doi.org/10.3390/en14041132