Preparation of Boron Nitride and Silicone Rubber Composite Material for Application in Lithium Batteries

Abstract

:1. Introduction

2. Materials and Experiments

2.1. Materials

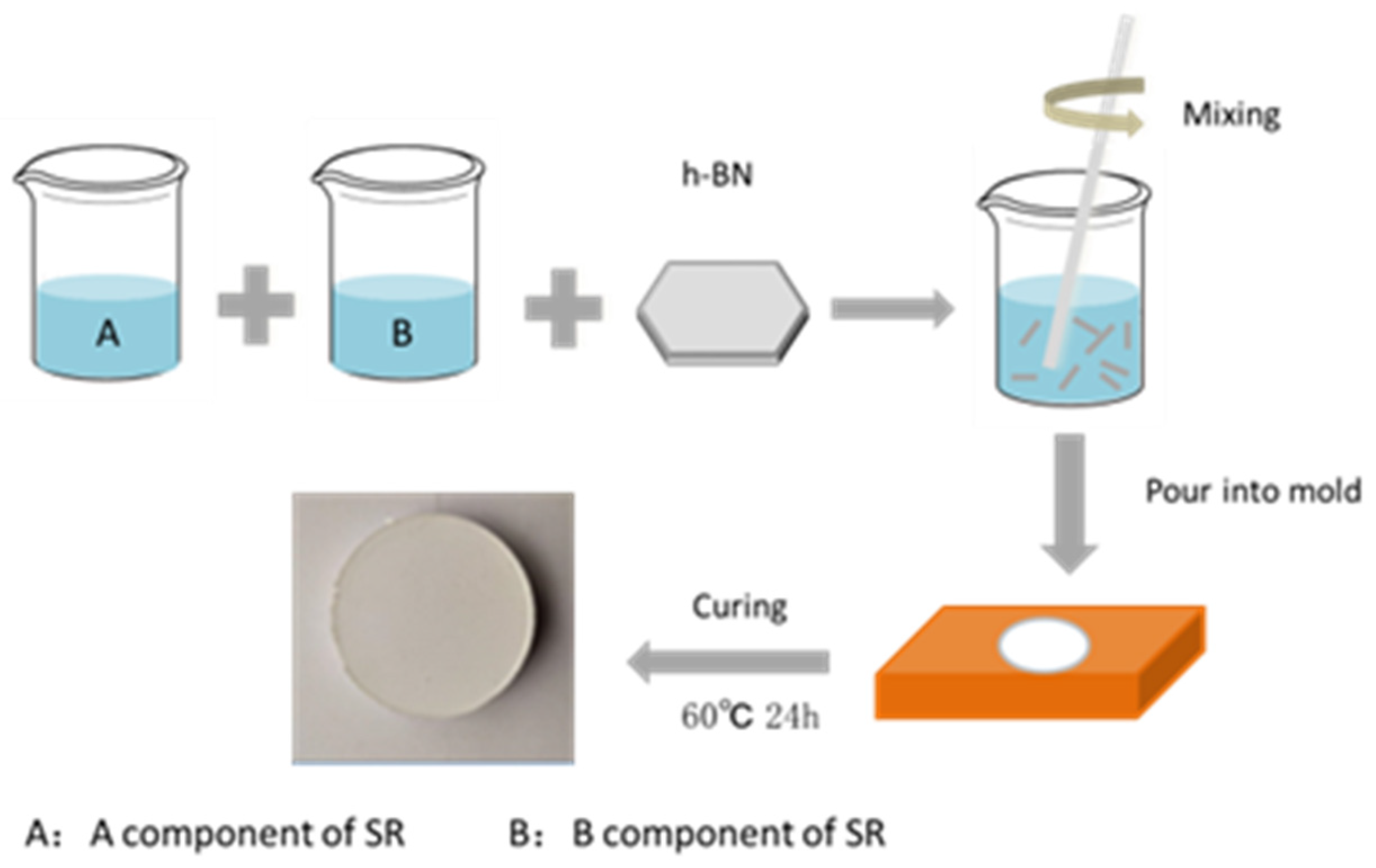

2.2. Preparation of h-BN/SR Composite

2.3. Characterization

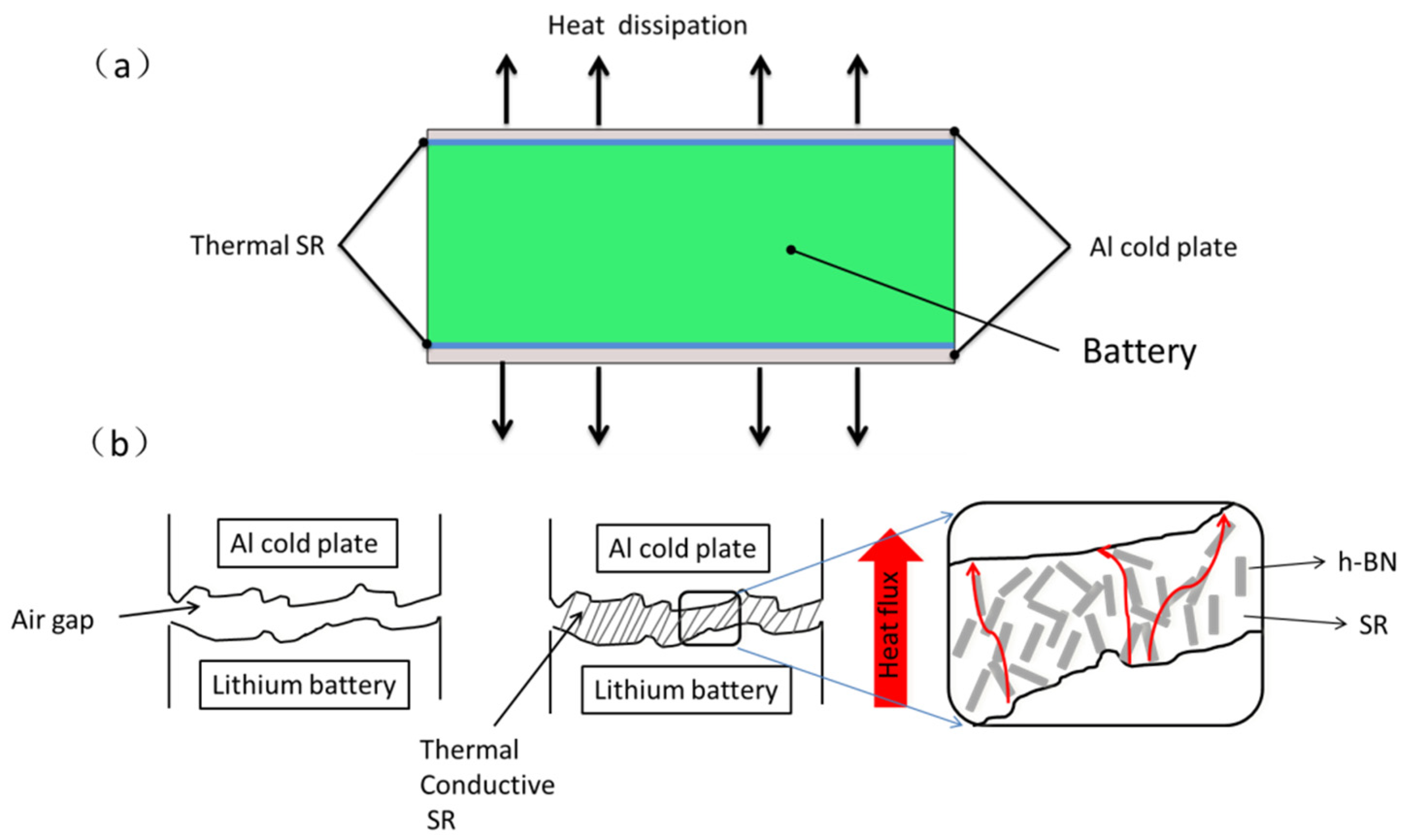

2.4. Battery Thermal Management Simulation

3. SR, h-BN, and h-BN/SR Composite Characteristics

3.1. Crystal Morphology

3.2. Chemical Structure Analysis

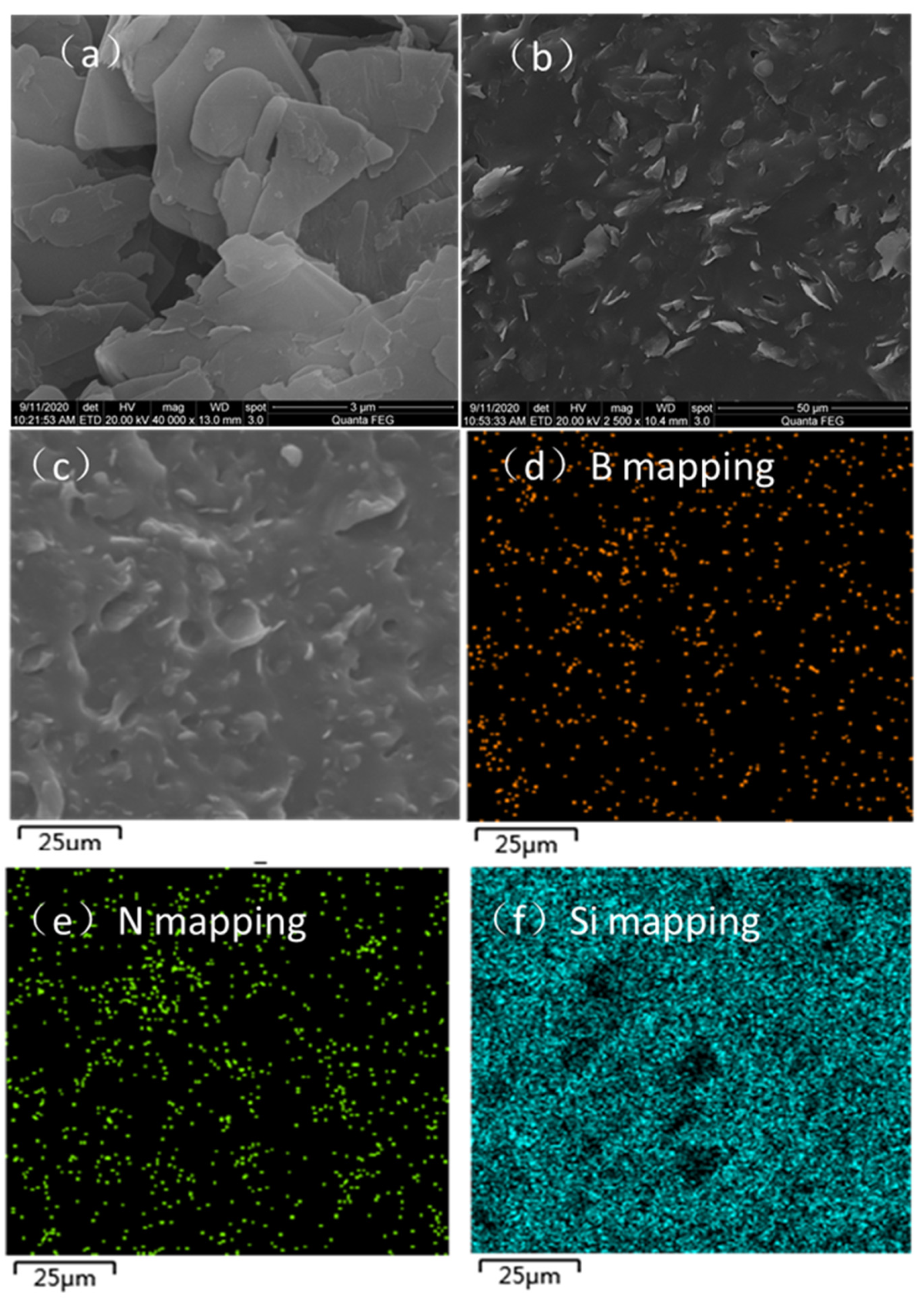

3.3. Microscopic Analysis

3.4. Thermal Conductivity

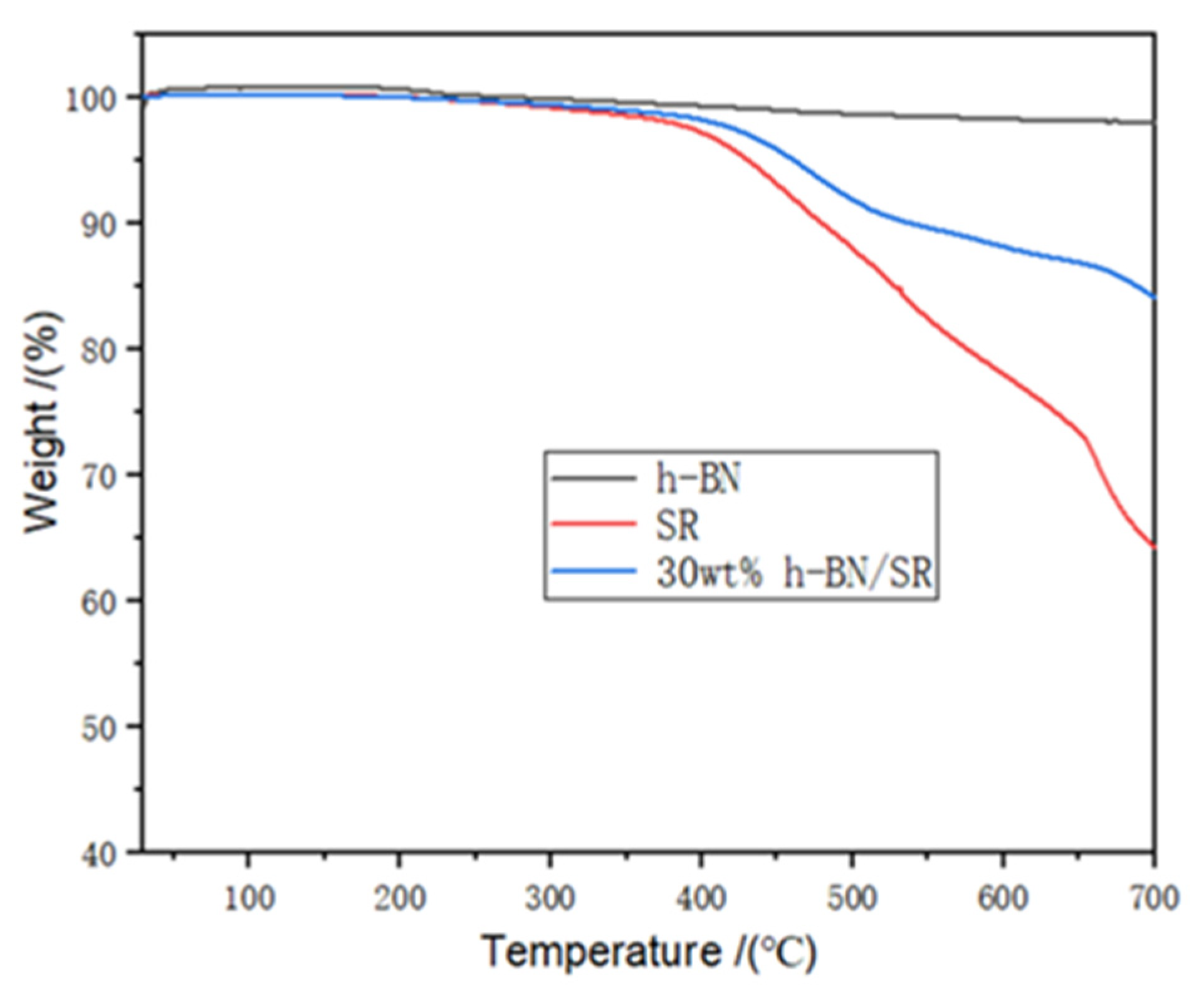

3.5. Thermal Stability Analysis

3.6. Compression Performance Test

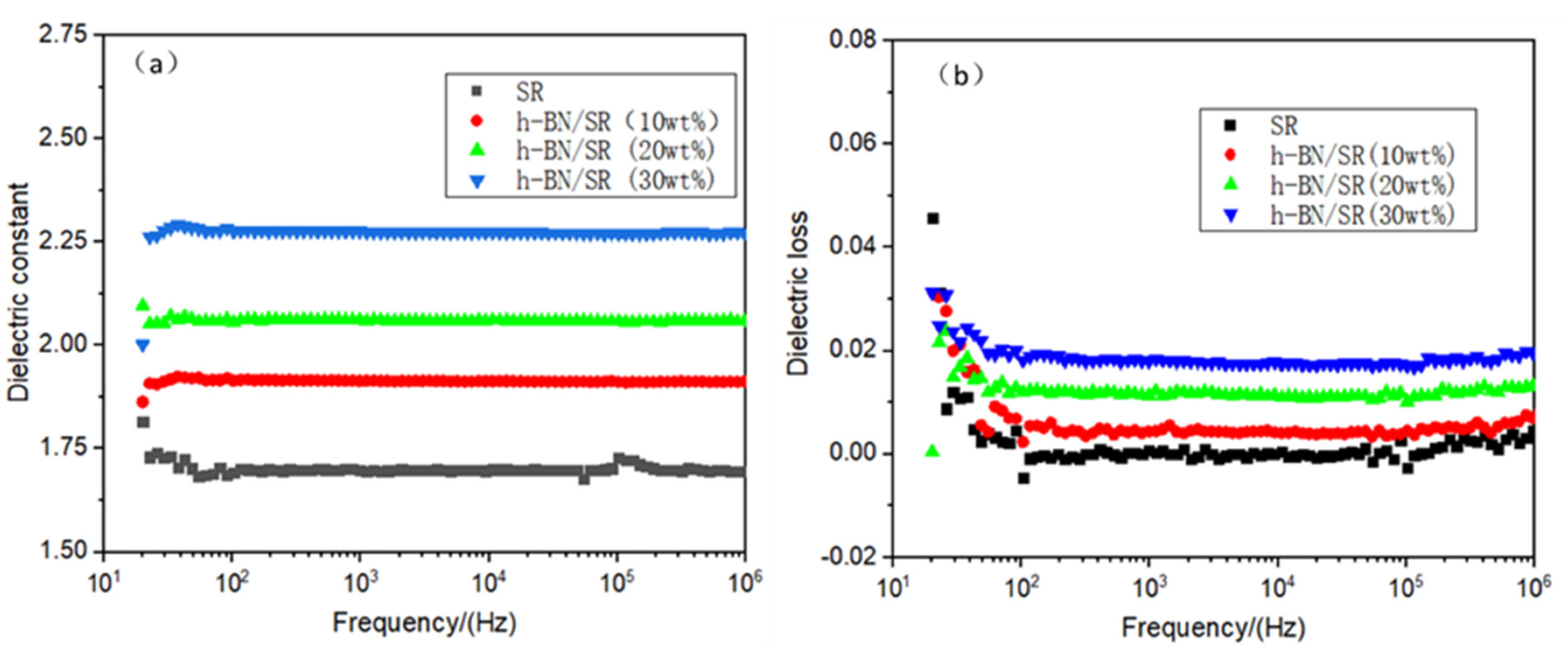

3.7. Dielectric Performance Test

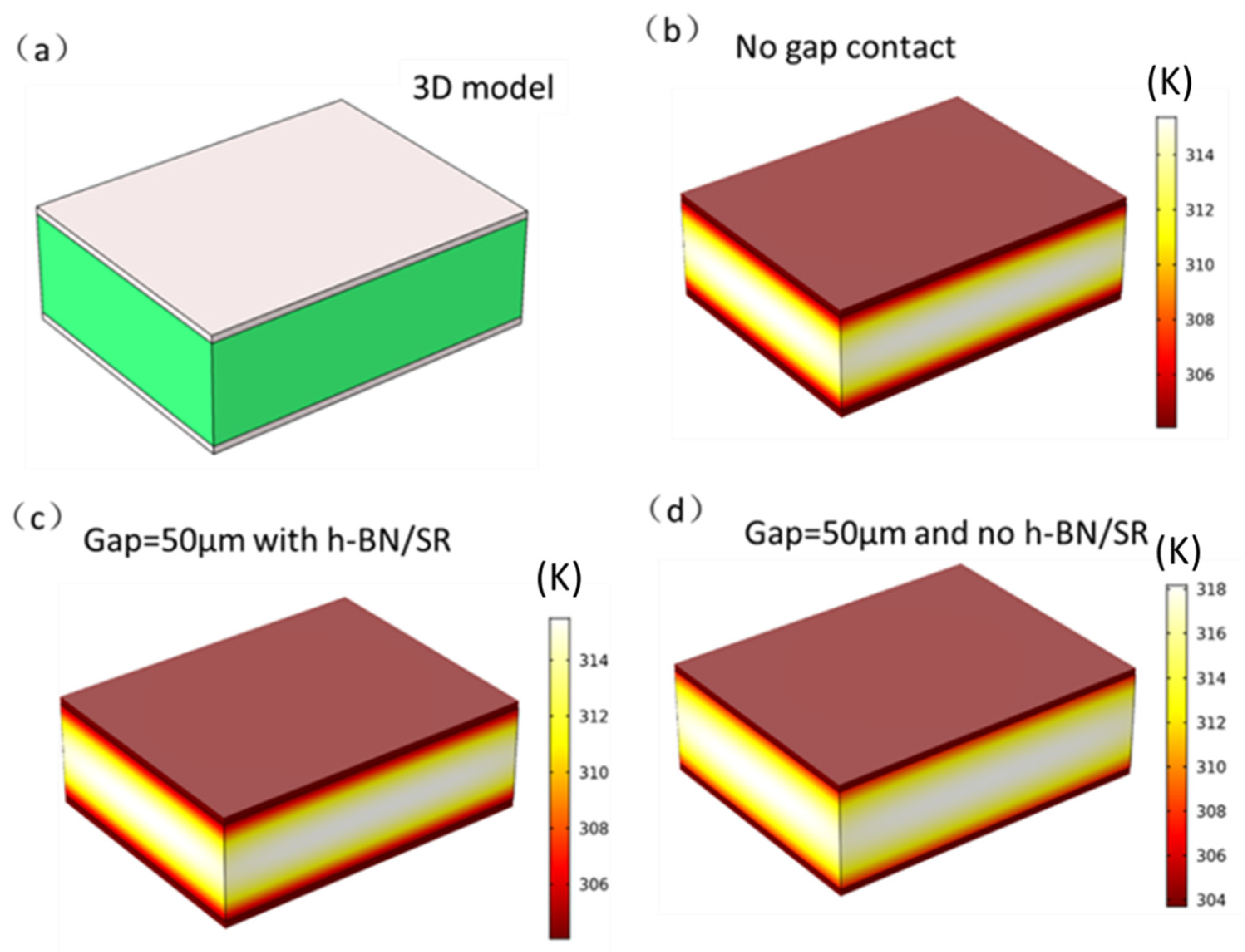

4. Battery Thermal Management Simulation

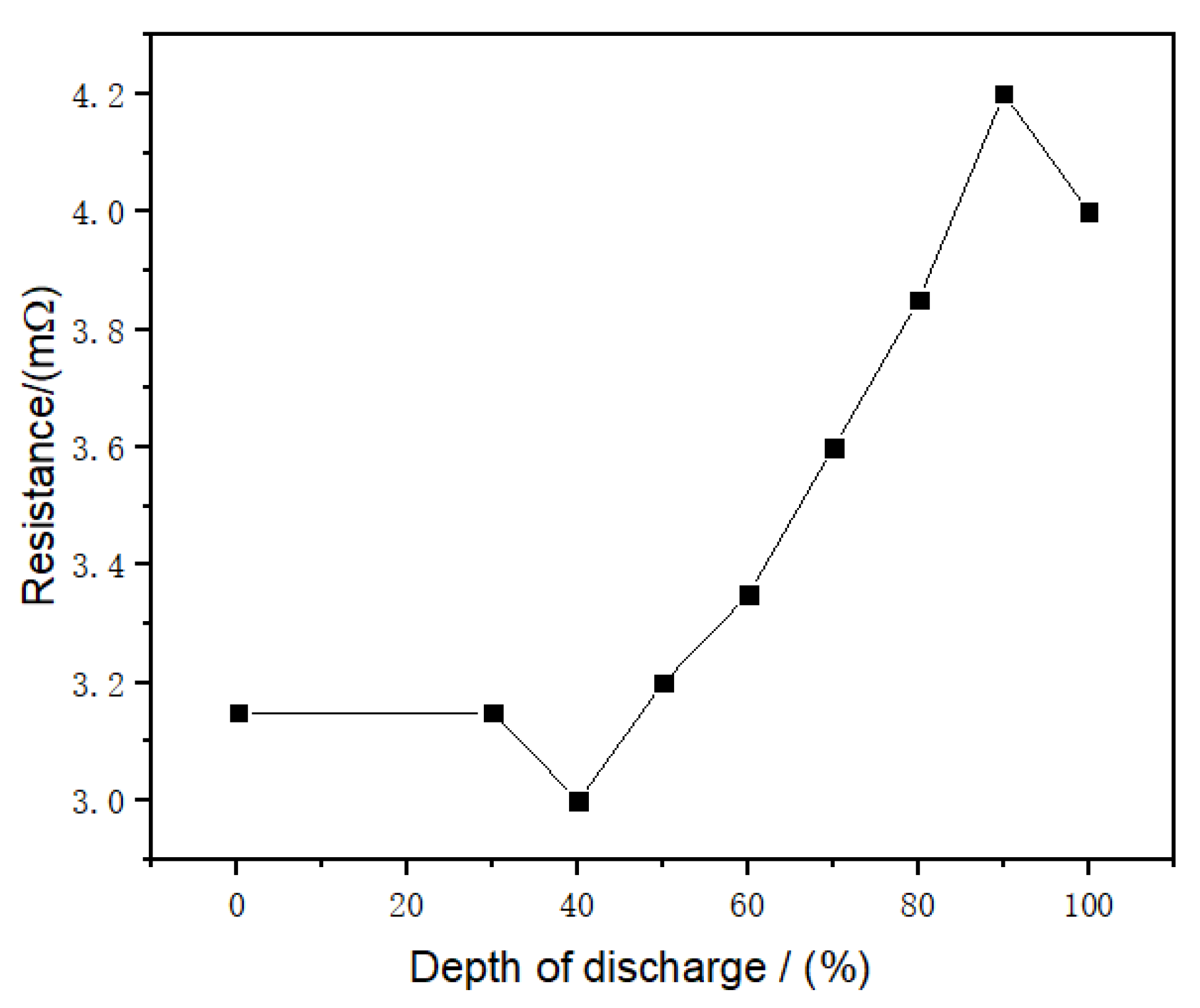

4.1. Heating Model of Lithium Battery

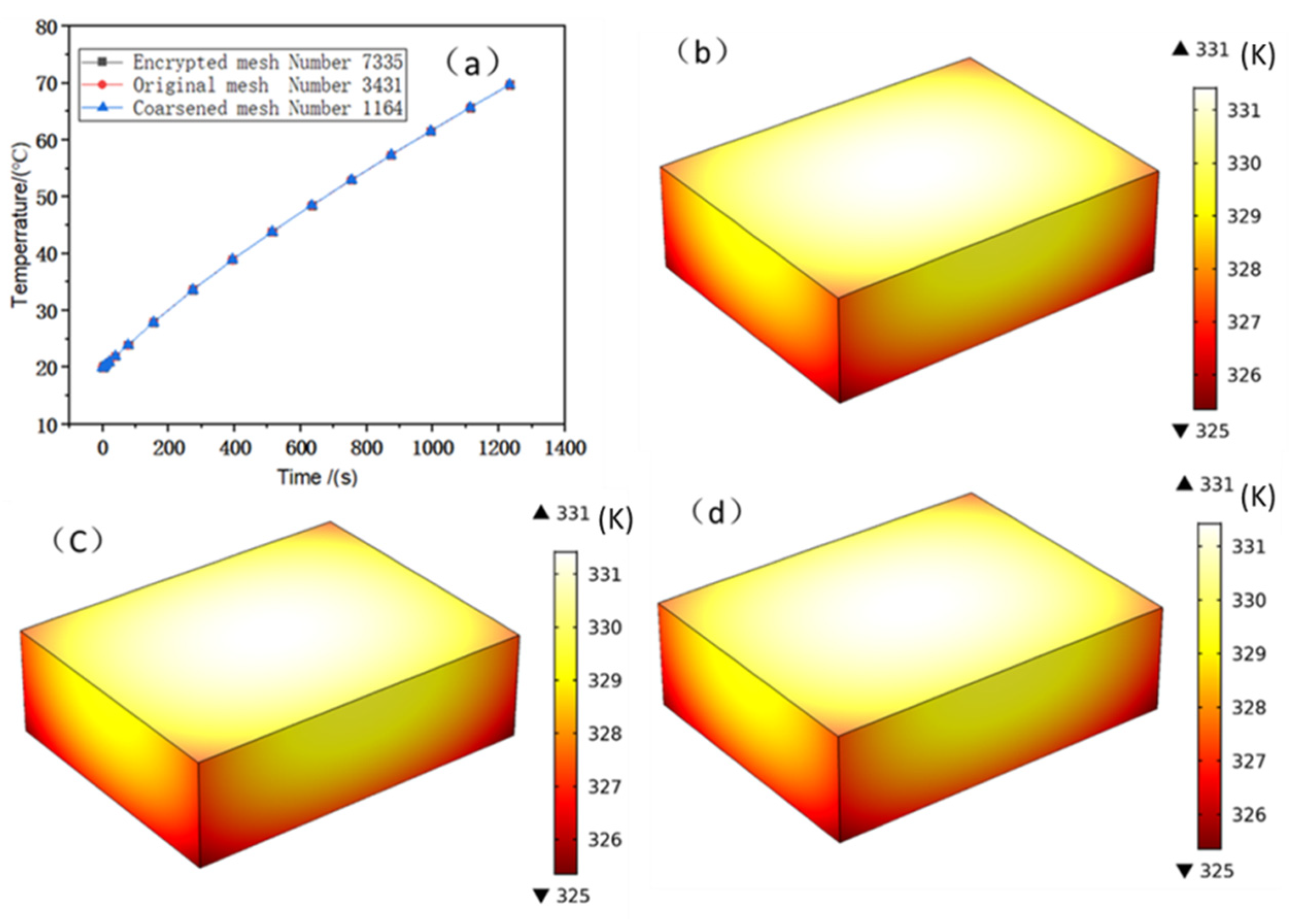

4.2. Grid Independence Verification

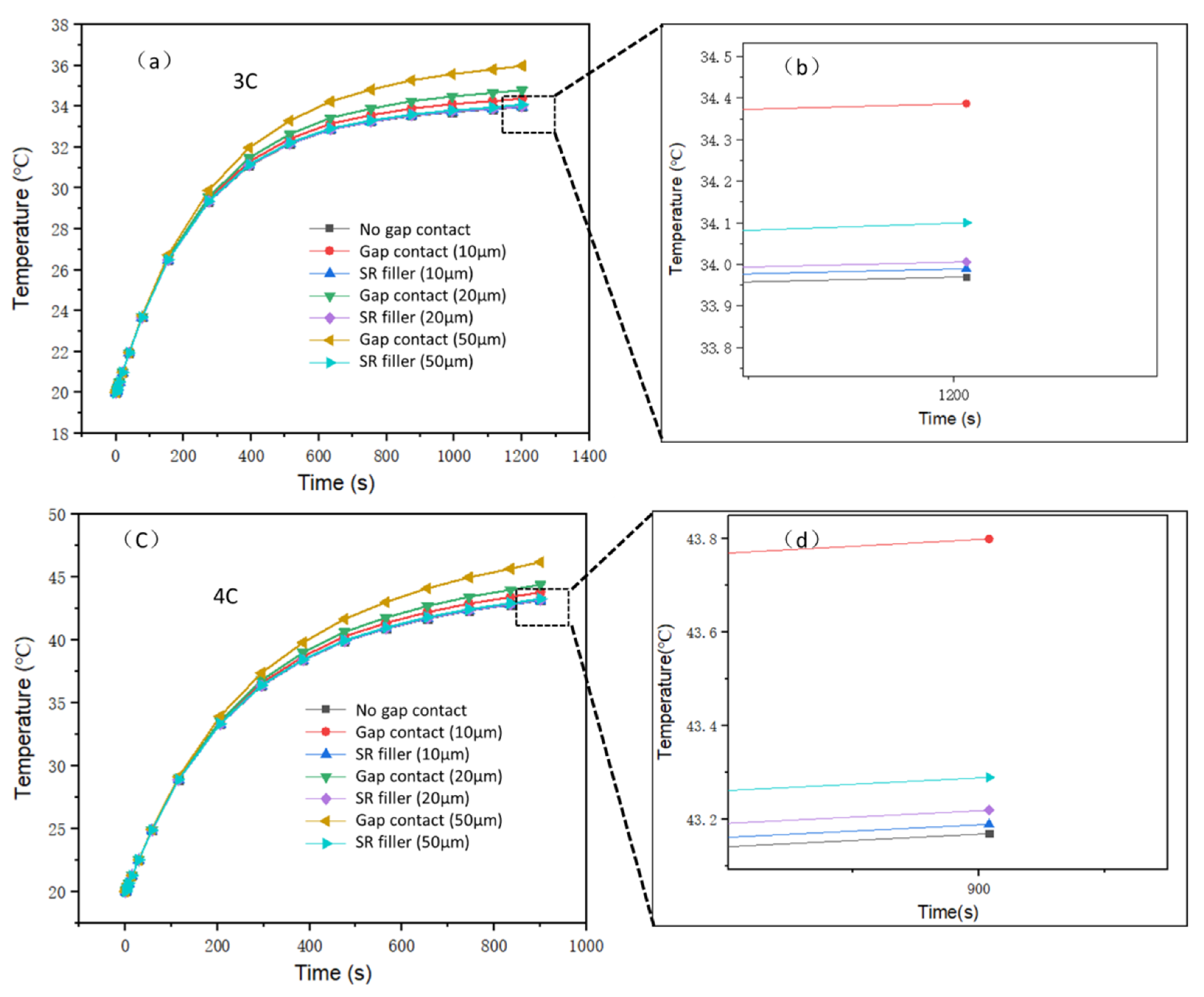

4.3. Battery Thermal Management System with h-BN/SR Composite

5. Conclusions

- (1)

- FTIR and XRD analyses showed that the h-BN and SR were physically mixed and that no chemical reactions occurred. The SEM analysis showed that the h-BN had good dispersion in SR without agglomeration, which is beneficial for improving the thermal conductivity of the composite.

- (2)

- When the weight proportion of boron nitride is 30 wt%, the thermal conductivity is 0.58 W/m∙K, which is 3.4 times that of pure SR, and the strength is 4.27 MPa, which is 6.7 times that of pure SR. The composite material also has low dielectric constant and dielectric loss, and it is suitable for electronic packaging applications.

- (3)

- The BTM simulation shows that when the interface is filled with the h-BN/SR composite, the maximum temperature of the battery decreased for different discharge rates. When the battery was discharged at a constant current rate of 4C, the use of the thermally conductive h-BN/SR composite material decreased the maximum temperature of the battery by 0.6 °C, 1.27 °C, and 2.9 °C for interface gaps of 10 μm, 20 μm, and 50 μm, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Razeeb, K.M.; Dalton, E.; Cross, G.L.W.; Robinson, A.J. Present and future thermal interface materials for electronic devices. Int. Mater. Rev 2018, 63, 1–21. [Google Scholar] [CrossRef]

- Hansson, J.; Nilsson, T.M.J.; Ye, L.; Liu, J. Novel nanostructured thermal interface materials: A review. Int. Mater. Rev. 2017, 63, 22–45. [Google Scholar] [CrossRef]

- Ji, T.; Zhang, L.-Q.; Wang, W.-C.; Liu, Y.; Zhang, X.-F.; Lu, Y.-L. Cold plasma modification of boron nitride fillers and its effect on the thermal conductivity of silicone rubber/boron nitride composites. Polym. Compos. 2012, 33, 1473–1481. [Google Scholar] [CrossRef]

- Yang, D.; Huang, S.; Ruan, M.; Li, S.; Yang, J.; Wu, Y.; Guo, W.; Zhang, L. Mussel Inspired Modification for Aluminum Oxide/Silicone Elastomer Composites with Largely Improved Thermal Conductivity and Low Dielectric Constant. Ind. Eng. Chem. Res. 2018, 57, 3255–3262. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Chen, Z. A novel phase-change composites based on silicone rubber containing energy-storage microcapsules. J. Therm. Anal. Calorim. 2018, 133, 1365–1370. [Google Scholar] [CrossRef]

- Chiu, H.T.; Sukachonmakul, T.; Kuo, M.T.; Wang, Y.H.; Wattanakul, K. Surface modification of aluminum nitride by polysilazane and its polymer-derived amorphous silicon oxycarbide ceramic for the enhancement of thermal conductivity in silicone rubber composite. Appl. Surf. Sci. 2014, 292, 928–936. [Google Scholar] [CrossRef]

- Cui, W.; Zhu, Y.; Yuan, X.; Chen, K.; Kang, F. Gel-cast-foam-assisted combustion synthesis of elongated β-Si3N4 crystals and their effects on improving the thermal conductivity of silicone composites. J. Alloys Compd. 2012, 540, 165–169. [Google Scholar] [CrossRef]

- Kong, K.T.S.; Mariatti, M.; Rashid, A.A.; Busfield, J.J.C. Effect of processing methods and functional groups on the properties of multi-walled carbon nanotube filled poly(dimethyl siloxane) composites. Polym. Bull. 2012, 69, 937–953. [Google Scholar] [CrossRef]

- Hong, J.; Lee, J.; Hong, C.K.; Shim, S.E. Effect of dispersion state of carbon nanotube on the thermal conductivity of poly(dimethyl siloxane) composites. Curr. Appl. Phys. 2010, 10, 359–363. [Google Scholar] [CrossRef]

- Shahil, K.M.; Balandin, A.A. Graphene-multilayer graphene nanocomposites as highly efficient thermal interface materials. Nano Lett. 2012, 12, 861–867. [Google Scholar] [CrossRef] [Green Version]

- Song, Y.; Yu, J.; Yu, L.; Alam, F.E.; Dai, W.; Li, C.; Jiang, N. Enhancing the thermal, electrical, and mechanical properties of silicone rubber by addition of graphene nanoplatelets. Mater. Des. 2015, 88, 950–957. [Google Scholar] [CrossRef]

- Shen, H.; Guo, J.; Wang, H.; Zhao, N.; Xu, J. Bioinspired Modification of h-BN for High Thermal Conductive Composite Films with Aligned Structure. ACS Appl. Mater. Interfaces 2015, 7, 5701–5708. [Google Scholar] [CrossRef]

- Li, D.; Zeng, D.; Chen, Q.; Wei, M.; Song, L.; Xiao, C.; Pan, D. Effect of different size complex fillers on thermal conductivity of PA6 thermal composites. Plast. Rubber Compos. 2019, 48, 347–355. [Google Scholar] [CrossRef]

- Wang, L.; Han, D.; Luo, J.; Li, T.; Lin, Z.; Yao, Y. Highly Efficient Growth of Boron Nitride Nanotubes and the Thermal Conductivity of Their Polymer Composites. J. Phys. Chem. C 2018, 122, 1867–1873. [Google Scholar] [CrossRef]

- Liu, Z.; Song, L.; Zhao, S.; Huang, J.; Ma, L.; Zhang, J.; Lou, J.; Ajayan, P.M. Direct growth of graphene/hexagonal boron nitride stacked layers. Nano Lett. 2011, 11, 2032–2037. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, S.; Liu, Z.; Cheng, J. Numerical analysis of temperature uniformity of a liquid cooling battery module composed of heat-conducting blocks with gradient contact surface angles. Appl. Therm. Eng. 2020, 178, 115509. [Google Scholar] [CrossRef]

- Varma Siruvuri, S.D.V.S.S.; Budarapu, P.R. Studies on thermal management of Lithium-ion battery pack using water as the cooling fluid. J. Energy Storage 2020, 29, 101377. [Google Scholar] [CrossRef]

- He, J.; Yang, X.; Zhang, G. A phase change material with enhanced thermal conductivity and secondary heat dissipation capability by introducing a binary thermal conductive skeleton for battery thermal management. Appl. Therm. Eng. 2019, 148, 984–991. [Google Scholar] [CrossRef]

- Patil, M.S.; Seo, J.-H.; Panchal, S.; Jee, S.-W.; Lee, M.-Y. Investigation on thermal performance of water-cooled Li-ion pouch cell and pack at high discharge rate with U-turn type microchannel cold plate. Int. J. Heat Mass Transf. 2020, 155, 119728. [Google Scholar] [CrossRef]

- Lv, Y.; Zhou, D.; Yang, X.; Liu, X.; Li, X.; Zhang, G. Experimental investigation on a novel liquid-cooling strategy by coupling with graphene-modified silica gel for the thermal management of cylindrical battery. Appl. Therm. Eng. 2019, 159, 113885. [Google Scholar] [CrossRef]

- Tran, T.-H.; Harmand, S.; Desmet, B.; Filangi, S. Experimental investigation on the feasibility of heat pipe cooling for HEV/EV lithium-ion battery. Appl. Therm. Eng. 2014, 63, 551–558. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, G.; Meng, L.; Li, X.; Situ, W.; Lv, Y.; Rao, M. Liquid cooling based on thermal silica plate for battery thermal management system. Int. J. Energy Res. 2017, 41, 2468–2479. [Google Scholar] [CrossRef]

- Matović, B.; Luković, J.; Nikolić, M.; Babić, B.; Stanković, N.; Jokić, B.; Jelenković, B. Synthesis and characterization of nanocrystaline hexagonal boron nitride powders: XRD and luminescence properties. Ceram. Int. 2016, 42, 16655–16658. [Google Scholar] [CrossRef]

- Kuang, Z.; Chen, Y.; Lu, Y.; Liu, L.; Hu, S.; Wen, S.; Mao, Y.; Zhang, L. Fabrication of Highly Oriented Hexagonal Boron Nitride Nanosheet/Elastomer Nanocomposites with High Thermal Conductivity. Small 2015, 11, 1655–1659. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Lee, B.; Park, K.H.; Ryu, H.J.; Jeon, S.; Hong, S.H. Scalable Exfoliation Process for Highly Soluble Boron Nitride Nanoplatelets by Hydroxide-Assisted Ball Milling. Nano Lett. 2015, 15, 1238–1244. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Zhou, Y.; Hai, C.; Shen, Y.; Ren, X.; Zeng, J. Calcium Chloride Hexahydrate/Diatomite/Paraffin as Composite Shape-Stabilized Phase-Change Material for Thermal Energy Storage. Energy Fuels 2017, 32, 916–921. [Google Scholar] [CrossRef]

- Shtrikman, Z.H.S. A variational approach to the theory of the effective magnetic permeability of multiphase materials. J. Appl. Phys. 1962, 33, 3125–3131. [Google Scholar]

- Pal, R. On the Lewis–Nielsen model for thermal/electrical conductivity of composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 718–726. [Google Scholar] [CrossRef]

- Nielsen, L.E. Thermal conductivity of particulate-filled polymers. J. Appl. Polym. Sci. 1973, 17, 2. [Google Scholar] [CrossRef]

- Gu, J.; Meng, X.; Tang, Y.; Li, Y.; Zhuang, Q.; Kong, J. Hexagonal boron nitride/polymethyl-vinyl siloxane rubber dielectric thermally conductive composites with ideal thermal stabilities. Compos. Part A Appl. Sci. Manuf. 2017, 92, 27–32. [Google Scholar] [CrossRef]

- Radhakrishnan, T.S. New method for evaluation of kinetic parameters and mechanism of degradation from pyrolysis—GC studies: Thermal degradation of polydimethylsiloxanes. J. Appl. Polym. Sci. 1999, 73, 441–450. [Google Scholar] [CrossRef]

- Mastali, M.; Foreman, E.; Modjtahedi, A.; Samadani, E.; Amirfazli, A.; Farhad, S.; Fraser, R.A.; Fowler, M. Electrochemical-thermal modeling and experimental validation of commercial graphite/LiFePO4 pouch lithium-ion batteries. Int. J. Therm. Sci. 2018, 129, 218–230. [Google Scholar] [CrossRef]

- Hu, Y.; Yurkovich, S.; Guezennec, Y.; Yurkovich, B.J. Electro-thermal battery model identification for automotive applications. J. Power Sources 2011, 196, 449–457. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A Critical Review of Thermal Issues in Lithium-Ion Batteries. J. Electrochem. Soc. 2011, 158, R1. [Google Scholar] [CrossRef]

- Li, H.; Xiao, X.; Wang, Y.; Lian, C.; Li, Q.; Wang, Z. Performance investigation of a battery thermal management system with microencapsulated phase change material suspension. Appl. Therm. Eng. 2020, 180, 115795. [Google Scholar] [CrossRef]

- An, Z.; Jia, L.; Li, X.; Ding, Y. Experimental investigation on lithium-ion battery thermal management based on flow boiling in mini-channel. Appl. Therm. Eng. 2017, 117, 534–543. [Google Scholar] [CrossRef]

- Aghkand, Z.K.; Dil, E.J.; Ajji, A.; Dubois, C. Simulation of Heat Transfer in Heat Sealing of Multilayer Polymeric Films: Effect of Process Parameters and Material Properties. Ind. Eng. Chem. Res. 2018, 57, 14571–14582. [Google Scholar] [CrossRef]

| Material | Dimensions (mm) | Destiny (kg/m3) | Cp J/(kg·K) | Λ W/(m·K) |

|---|---|---|---|---|

| Battery | 70 × 90 × 27 | 1940 | 1000 | λx = λz = 1.35 λy = 0.98 |

| Al cold plate | 70 × 90 × 2 | 2700 | 903 | 238 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Huang, J.; Cao, M.; Du, G.; Liu, Z.; Li, W. Preparation of Boron Nitride and Silicone Rubber Composite Material for Application in Lithium Batteries. Energies 2021, 14, 999. https://doi.org/10.3390/en14040999

Zhang Y, Huang J, Cao M, Du G, Liu Z, Li W. Preparation of Boron Nitride and Silicone Rubber Composite Material for Application in Lithium Batteries. Energies. 2021; 14(4):999. https://doi.org/10.3390/en14040999

Chicago/Turabian StyleZhang, Yafang, Juhua Huang, Ming Cao, Guoping Du, Ziqiang Liu, and Wang Li. 2021. "Preparation of Boron Nitride and Silicone Rubber Composite Material for Application in Lithium Batteries" Energies 14, no. 4: 999. https://doi.org/10.3390/en14040999

APA StyleZhang, Y., Huang, J., Cao, M., Du, G., Liu, Z., & Li, W. (2021). Preparation of Boron Nitride and Silicone Rubber Composite Material for Application in Lithium Batteries. Energies, 14(4), 999. https://doi.org/10.3390/en14040999