Evaluation and Optimization of a Two-Phase Liquid-Immersion Cooling System for Data Centers

Abstract

:1. Introduction

2. Methodology

2.1. Experimental Study

2.2. CFD Simulation

2.2.1. Physical Model and Boundary Conditions

2.2.2. CFD Modeling of Boiling Flow

2.2.3. Material Properties

2.2.4. Grid Independence

2.2.5. CFD Model Validation

2.3. COP and pPUE

2.4. Exergy Analysis

3. Results and Discussion

3.1. COP and pPUE

3.2. Exergy Analysis

3.3. Simulation Results

4. Conclusions

- The COP of this system changed from 19.0 to 26.7 and increased with increasing server power, ranging from 1127 W to 1577 W. The proposed COP was generally 4–20 units higher than that of many previously reported air-cooled or water-cooled cooling systems for data centers;

- The pPUE of this system decreased from 1.053 to 1.037 as the power of the servers increased. This value was relatively smaller than that of the pPUEs for an air-cooled or water-cooled cooling system. The proposed two-phase cooling system was found to be more energy efficient;

- The exergy efficiency of the proposed system ranged from 12.65% to 18.96%, with an average of 14.84%. A majority of the exergy destruction occurred on the tank side.

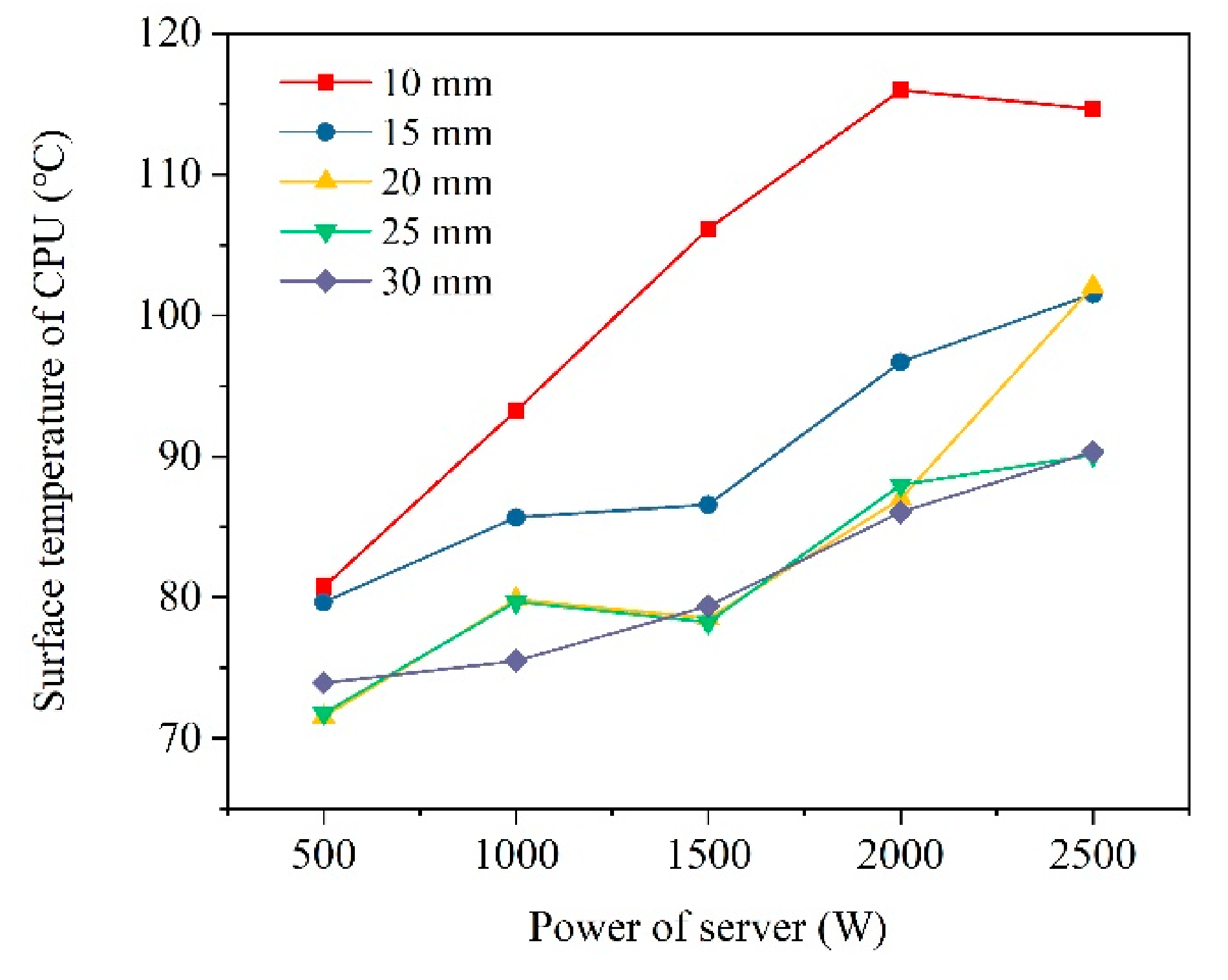

- For a given fluid-containing tank, a closer interval between servers would cause a higher server surface temperature. CFD simulations demonstrated the predicted surface temperatures of the servers under various IT loads;

- To maintain the surface temperature of the servers below 85 °C, an interval of 15 mm was needed for the server power to reach 1000 W. For a power of 1500 W, the interval must at least 20 mm. For a power larger than 2000 W or 3000 W, even an interval of 30 mm was not sufficiently large to maintain the surface temperature below 85 °C.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| CRAC | Computer room air conditioning |

| PUE | Power usage effectiveness |

| pPUE | Partial power usage effectiveness |

| COP | Coefficient performance |

| CFD | Computational fluid dynamic |

| ICT | Information communication technology |

| U | Mean velocity component (m/s) |

| ε | Turbulent dissipation rate |

| h | Enthalpy (kJ/kg) |

| S | Entropy (kJ/kg K) |

| T | Temperature (K) |

| Wserver | Power of server (W) |

| Wtotal | Power total cooling (W) |

| ED | Exergy destruction (W) |

| η | Exergy efficiency |

| SM | Source term in the mass conservation equation (kg/m3 s) |

| SF | Source term in the momentum conservation equation (kg/m2 s2) |

| SE | Source term in the energy equation (J/m3 s) |

| u | Dynamic viscosity (Pa s) |

| ui | Velocity component in the xi-direction (m/s) |

| uj | Velocity component in the xj-direction (m/s) |

| µturb | Turbulent viscosity (Pa s) |

| ρ | Density (kg/m3) |

| Q | Heat exchange (W) |

| m | Mass flow (kg/s) |

| σ | Surface tension (N/m) |

| σc | Condensation coefficient |

| σe | Evaporation coefficient |

| k | Turbulent kinetic energy (m2/s2) |

| Tboiling | Boiling point |

| 0 | Status at reference temperature |

| l | Fluid state |

| g | Vapor state |

| w | Coolant side |

Appendix A

| Temperature (°C) | Density (kg/m3) | Viscosity (m2/s) | Dynamic Viscosity (kg/m s) | Kinematic Viscosity (m2)/s) | Specific Heat (J/kg K) | Thermal Conductivity (W/m K) | Saturated Vapor Pressure(Pa) |

|---|---|---|---|---|---|---|---|

| −90 | 1825.19 | 6.04 × 10−6 | 0.0110 | 11.025 | 953 | 0.0913 | 12.904 |

| −80 | 1798.27 | 3.64 × 10−6 | 0.0065 | 6.542 | 973 | 0.0893 | 35.987 |

| −70 | 1771.35 | 2.44 × 10−6 | 0.0043 | 4.319 | 993 | 0.0873 | 90.718 |

| −60 | 1744.43 | 1.76 × 10−6 | 0.0030 | 3.075 | 1013 | 0.0854 | 209.684 |

| −50 | 1717.51 | 1.35 × 10−6 | 0.0023 | 2.310 | 1033 | 0.0834 | 449.593 |

| −40 | 1690.59 | 1.07 × 10−6 | 0.0018 | 1.803 | 1053 | 0.0815 | 902.934 |

| −30 | 1663.67 | 8.7 × 10−7 | 0.0014 | 1.446 | 1073 | 0.0795 | 1712.302 |

| −20 | 1636.75 | 7.24 × 10−7 | 0.0011 | 1.185 | 1093 | 0.0776 | 3087.064 |

| −10 | 1609.83 | 6.14 × 10−7 | 0.0009 | 0.988 | 1113 | 0.0756 | 5321.763 |

| 0 | 1582.91 | 5.28 × 10−7 | 0.0008 | 0.835 | 1133 | 0.0737 | 8815.499 |

| 10 | 1555.99 | 4.6 × 10−7 | 0.0007 | 0.715 | 1153 | 0.0717 | 14,091.424 |

| 20 | 1529.07 | 4.05 × 10−7 | 0.0006 | 0.619 | 1173 | 0.0698 | 21,815.442 |

| 30 | 1502.15 | 3.61 × 10−7 | 0.0005 | 0.542 | 1193 | 0.0678 | 32,813.298 |

| 40 | 1475.23 | 3.24 × 10−7 | 0.0004 | 0.478 | 1213 | 0.0658 | 48,085.294 |

| 50 | 1448.31 | 2.94 × 10−7 | 0.0004 | 0.426 | 1233 | 0.0639 | 68,818.070 |

| 60 | 1421.39 | 2.69 × 10−7 | 0.0003 | 0.383 | 1253 | 0.0619 | 96,393.020 |

| 70 | 1394.47 | 2.49 × 10−7 | 0.0003 | 0.346 | 1273 | 0.0600 | 132,391.102 |

| Physical Parameters | Liquid | Vapor |

|---|---|---|

| Density (kg/m3) | y = − 2.692T + 1582 | y = 0.0034T2 − 0.103T + 2.337 |

| Specific heat (J/kgK) | y = 2T + 1133 | y = 216.4 + 4.749T + 0.00144T2 + 4.265 × 10−6T3 + 1.758 × 10−9 T4 |

| Conductive coefficient | y = − 0.00027T + 0.073 | y = 0.01293 + 4.74 × 10−5T |

| Dynamic viscosity (kg/m s) | y = 4 × 10−5T4 − 1 × 10−7T3 + 2 × 10−7T2 –1 × 10−5T + 0.0008 | y = 8.294 × 10−4 − 1.15 × 10−5T + 6.75 × 10−8T2 |

References

- Król, A. The Application of the Artificial Intelligence Methods for Planning of the Development of the Transportation Network. Transp. Res. Procedia 2016, 14, 4532–4541. [Google Scholar] [CrossRef] [Green Version]

- Bae, J.S.; Yong, S.C.; Kim, J.S.; Min, Y.C. Architecture and performance evaluation of MmWave based 5G mobile communication system. In Proceedings of the 2014 International Conference on Information & Communication Technology Convergence, Busan, Korea, 22–24 October 2014. [Google Scholar]

- Fei, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar]

- Amisha, P.M.; Pathania, M.; Rathaur, V.K. Overview of artificial intelligence in medicine. J. Fam. Med. Prim. Care 2019, 8, 2328. [Google Scholar] [CrossRef]

- Yong-Bin, Y.A.N.G. The Application Research of Data Mining Technique in Education. Comput. Sci. 2006, 33, 284–286. [Google Scholar]

- Meng, X.; Zhou, J.; Zhang, X.; Luo, Z.; Gong, H.; Gan, T. Optimization of the thermal environment of a small-scale data center in China. Energy 2020, 196, 117080. [Google Scholar] [CrossRef]

- Weissberger, A. Synergy Research Group: Hyperscale Data Center Count > 500 as of 3Q-2019. Available online: https://techblog.comsoc.org/2019/10/19/synergy-research-group-hyperscale-data-center-count-500-as-of-3q-2019/ (accessed on 19 October 2019).

- Andrae, A.S.G. Total Consumer Power Consumption Forecast. Available online: https://10times.com/nordic-digital-business-summit (accessed on 1 October 2017).

- Davies, G.F.; Maidment, G.G.; Tozer, R.M. Using data centres for combined heating and cooling: An investigation for London. Appl. Therm. Eng. 2016, 94, 296–304. [Google Scholar] [CrossRef]

- Greenpeace, Potential Analysis on Energy Consumption of Data Centers and Renewable Energy in China 2019. Available online: https://www.greenpeace.org.cn/china-data-center-electricity-consumption-and-renewable-energy/ (accessed on 9 September 2019).

- Jin, C.; Bai, X.; Yang, C.; Mao, W.; Xu, X. A review of power consumption models of servers in data centers. Appl. Energy 2020, 265, 114806. [Google Scholar] [CrossRef]

- Chu, W.-X.; Wang, C.-C. A review on airflow management in data centers. Appl. Energy 2019, 240, 84–119. [Google Scholar] [CrossRef]

- ASHRAE. Thermal Guidelines for Data Processing Environments; ASHRAE: Atlanta, GA, USA, 2015. [Google Scholar]

- ASHRAE. PUE: A Comprehensive Examination of the Metric; ASHRAE: Atlanta, GA, USA, 2012. [Google Scholar]

- Beghi, A.; Cecchinato, L.; Mana, G.D.; Lionello, M.; Rampazzo, M.; Sisti, E. Modelling and control of a free cooling system for Data Centers. Energy Procedia 2017, 140, 447–457. [Google Scholar] [CrossRef]

- Ko, J.-S.; Huh, J.-H.; Kim, J.-C. Improvement of Energy Efficiency and Control Performance of Cooling System Fan Applied to Industry 4.0 Data Center. Electronics 2019, 8, 582. [Google Scholar] [CrossRef] [Green Version]

- Khalaj, A.H.; Halgamuge, S.K. A Review on efficient thermal management of air- and liquid-cooled data centers: From chip to the cooling system. Appl. Energy 2017, 205, 1165–1188. [Google Scholar] [CrossRef]

- Daraghmeh, H.M.; Wang, C.-C. A review of current status of free cooling in datacenters. Appl. Therm. Eng. 2017, 114, 1224–1239. [Google Scholar] [CrossRef]

- Weerts, B.A.; Gallaher, D.; Weaver, R. Green Data Center Cooling: Achieving 90% Reduction: Airside Economization and Unique Indirect Evaporative Cooling. In Proceedings of the 2012 IEEE Green Technologies Conference, Tulsa, OK, USA, 19–20 April 2012. [Google Scholar]

- Niemann, J.; Avelar, V. Economizer Modes of Data Center Cooling Systems; White Paper; Schneider Electric: Rueil-Malmaison, France, 2013; p. 132. [Google Scholar]

- Schmidt, R.R.; Cruz, E.E.; Iyengar, M. Challenges of data center thermal management. IBM J. Res. Dev. 2005, 49, 709–723. [Google Scholar] [CrossRef]

- Patankar, S.V. Airflow and cooling in a data center. J. Heat Transf. 2010, 132, 073001. [Google Scholar] [CrossRef]

- Tuma, P.E. The merits of open bath immersion cooling of datacom equipment. In Proceedings of the 2010 26th Annual IEEE Semiconductor Thermal Measurement and Management Symposium (SEMI-THERM), Santa Clara, CA, USA, 21–25 February 2010. [Google Scholar]

- Qiu, L.; Dubey, S.; Choo, F.H.; Duan, F. Recent developments of jet impingement nucleate boiling. Int. J. Heat Mass Transf. 2015, 89, 42–58. [Google Scholar] [CrossRef]

- Robinson, A.J.; Colenbrander, J.; Byrne, G.; Burke, P.; McEvoy, J.; Kempers, R. Passive two-phase cooling of air circuit breakers in data center power distribution systems. Int. J. Electr. Power Energy Syst. 2020, 121, 106138. [Google Scholar] [CrossRef]

- Deymi-Dashtebayaz, M.; Valipour-Namanlo, S. Thermoeconomic and environmental feasibility of waste heat recovery of a data center using air source heat pump. J. Clean Prod. 2019, 219, 117–126. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, W.-L.; Zhang, W.-W.; Peng, Y.-H.; Jiang, L.-J. Energy saving evaluation of a novel energy system based on spray cooling for supercomputer center. Energy 2017, 141, 304–315. [Google Scholar] [CrossRef]

- Cho, J.; Kim, Y. Improving energy efficiency of dedicated cooling system and its contribution towards meeting an energy-optimized data center. Appl. Energy 2016, 165, 967–982. [Google Scholar] [CrossRef]

- Dong, K.; Li, P.; Huang, Z.; Su, L.; Sun, Q.J.P.E. Research on Free Cooling of Data Centers by Using Indirect Cooling of Open Cooling Tower. Procedia Eng. 2017, 205, 2831–2838. [Google Scholar] [CrossRef]

- Lu, T.; Lü, X.; Remes, M.; Viljanen, M. Investigation of air management and energy performance in a data center in Finland: Case study. Energy Build. 2011, 43, 3360–3372. [Google Scholar] [CrossRef]

- Wu, C.; Tong, W.; Kanbur, B.B.; Duan, F. Full-scale Two-phase Liquid Immersion Cooing Data Center System in Tropical Environment. In Proceedings of the 2019 18th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Las Vegas, NV, USA, 28–31 May 2019. [Google Scholar]

- Kanbur, B.B.; Wu, C.; Fan, S.; Tong, W.; Duan, F. Two-phase liquid-immersion data center cooling system: Experimental performance and thermoeconomic analysis. Int. J. Refrig. 2020, 118, 290–301. [Google Scholar] [CrossRef]

- Choi, E.J.; Park, J.Y.; Kim, M.S. Two-phase cooling using HFE-7100 for polymer electrolyte membrane fuel cell application. Appl. Therm. Eng. 2019, 148, 868–877. [Google Scholar] [CrossRef]

- Ahmadi, V.E.; Erden, H.S. A parametric CFD study of computer room air handling bypass in air-cooled data centers. Appl. Therm. Eng. 2020, 166, 114685. [Google Scholar] [CrossRef]

- Hassan, N.M.S.; Khan, M.M.K.; Rasul, M.G. Temperature Monitoring and CFD Analysis of Data Centre. Procedia Eng. 2013, 56, 551–559. [Google Scholar] [CrossRef]

- Fulpagare, Y.; Bhargav, A.; Joshi, Y. Dynamic thermal characterization of raised floor plenum data centers: Experiments and CFD. J. Build. Eng. 2019, 25, 100783. [Google Scholar] [CrossRef]

- Nada, S.A.; Said, M.A.; Rady, M.A. CFD investigations of data centers’ thermal performance for different configurations of CRACs units and aisles separation. Alex. Eng. J. 2016, 55, 959–971. [Google Scholar] [CrossRef]

- Cheng, C.-C.; Chang, P.-C.; Li, H.-C.; Hsu, F.-I. Design of a single-phase immersion cooling system through experimental and numerical analysis. Int. J. Heat Mass Transf. 2020, 160, 120203. [Google Scholar] [CrossRef]

- Ali, A. Thermal performance and stress analysis of heat spreaders for immersion cooling applications. Appl. Therm. Eng. 2020, 181, 115984. [Google Scholar] [CrossRef]

- An, X.; Arora, M.; Huang, W.; Brantley, W.C.; Greathouse, J.L. 3D Numerical Analysis of Two-Phase Immersion Cooling for Electronic Components. In Proceedings of the 2018 17th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), San Diego, CA, USA, 29 May–1 June 2018; pp. 609–614. [Google Scholar]

- NovecTM 7100 Engineered Fluid; 3MTM Ltd.: Saint Paul, MN, USA, 2020.

- Valizadeh, K.; Farahbakhsh, S.; Bateni, A.; Zargarian, A.; Davarpanah, A.; Alizadeh, A.; Zarei, M. A parametric study to simulate the non-Newtonian turbulent flow in spiral tubes. Energy Sci. Eng. 2020, 8, 134–149. [Google Scholar] [CrossRef] [Green Version]

- de Schepper, S.C.K.; Heynderickx, G.J.; Marin, G.B. Modeling the evaporation of a hydrocarbon feedstock in the convection section of a steam cracker. Comput. Chem. Eng. 2009, 33, 122–132. [Google Scholar] [CrossRef]

- Malalasekera, W.; Versteeg, H. An Introduction to Computational Fluid Dynamics; Pearson Prentice Hall: Madrid, Spain, 2007. [Google Scholar]

- Knudsen, M.; Partington, J.R. The Kinetic. Theoryof Gases. Some Modern Aspects. J. Phys. Chem. 1935, 39, 307. [Google Scholar] [CrossRef]

- Liu, Z.W.; Lin, W.W.; Lee, D.J.; Peng, X.F. Pool Boiling of FC-72 and HFE-7100. J. Heat Transf. 1999, 123, 399–400. [Google Scholar] [CrossRef]

- Kamoshida, J.; Hirata, Y.; Isshiki, N.; Katayama, K.; Sato, K. Thermodynamic Analysis of Resorption Heat Pump Cycle Using Water-Multicomponent Salt Mixture. In Heat Pumps; Pergamon: Oxford, UK, 1990. [Google Scholar]

- ISO/IEC. 30134-2:2016 Information Technology—Data Centres—Key Performance Indicators—Part 2: Power Usage Effectiveness (PUE); ISO/IEC: Geneva, Switzerland, 2016. [Google Scholar]

- Gupta, R.; Asgari, S.; Moazamigoodarzi, H.; Pal, S.; Puri, I.K. Cooling architecture selection for air-cooled Data Centers by minimizing exergy destruction. Energy 2020, 201, 117625. [Google Scholar] [CrossRef]

- Silva-Llanca, L.; Ortega, A.; Fouladi, K.; del Valle, M.; Sundaralingam, V. Determining wasted energy in the airside of a perimeter-cooled data center via direct computation of the Exergy Destruction. Appl. Energy 2018, 213, 235–246. [Google Scholar] [CrossRef]

- Esfandi, S.; Baloochzadeh, S.; Asayesh, M.; Ehyaei, M.A.; Ahmadi, A.; Rabanian, A.A.; Das, B.; Costa, V.A.F.; Davarpanah, A. Energy, Exergy, Economic, and Exergoenvironmental Analyses of a Novel Hybrid System to Produce Electricity, Cooling, and Syngas. Energies 2020, 13, 6453. [Google Scholar] [CrossRef]

- Díaz, A.J.; Cáceres, R.; Cardemil, J.M.; Silva-Llanca, L. Energy and exergy assessment in a perimeter cooled data center: The value of second law efficiency. Appl. Therm. Eng. 2017, 124, 820–830. [Google Scholar] [CrossRef]

- Ebrahimi, K.; Jones, G.F.; Fleischer, A.S. A review of data center cooling technology, operating conditions and the corresponding low-grade waste heat recovery opportunities. Renew. Sustain. Energy Rev. 2014, 31, 622–638. [Google Scholar] [CrossRef]

- Nadjahi, C.; Louahlia, H.; Lemasson, S. A review of thermal management and innovative cooling strategies for data center. Sustain. Comput. Inform. Syst. 2018, 19, 14–28. [Google Scholar] [CrossRef]

| Boiling Point (°C) | Vapor Pressure (kPa) | Molecular Weight (g/mol) | Density Liquid (kg/m3) | Dynamic Viscosity (cSt) | Specific Heat (J/kgK) |

|---|---|---|---|---|---|

| 61 | 27 | 250 | 1510 | 0.38 | 1183 |

| Case | Room Temperature (°C) | CPU Power(W) | Heat Exchanger Coolant Temperature (°C) | Temperature of CPU (°C) | ||

|---|---|---|---|---|---|---|

| Inlet | Outlet | Surface | Core | |||

| 1 | 21.9 | 1127 | 26.5 | 25.1 | 66.0 | 67.4 |

| 2 | 21.6 | 1396 | 27.1 | 25.8 | 68.8 | 71.2 |

| 3 | 22.4 | 1332 | 27.9 | 26.5 | 68.5 | 70.7 |

| 4 | 23.0 | 1494 | 29.2 | 27.6 | 70.5 | 72.3 |

| 5 | 23.3 | 1516 | 29.6 | 28.1 | 71.7 | 72.9 |

| 6 | 23.4 | 1577 | 30.1 | 28.4 | 71.9 | 73.3 |

| Setting Parameters | Type | Settings/Options |

|---|---|---|

| Solver type | Pressure-based | |

| Turbulence model | k–ε realizable model | |

| Near-wall treatment | Standard wall functions | |

| Pressure-velocity coupling scheme | SIMPLE | |

| Spatial discretization | Gradient | Least-squares cell-based |

| Pressure | Body force-weighted | |

| Momentum | QUICK | |

| Turbulent kinetic energy (k) | QUICK | |

| Turbulent dissipation rate (ε) | QUICK | |

| Energy | QUICK | |

| Residuals | Continuity | 0.001 |

| X, Y, Z-Velocity | 0.001 | |

| Energy | 10−6 | |

| k, ε | 0.001 |

| Cell Number | Time Step (s) | Mean Surface Temperature (°C) | Temperature Difference (%) |

|---|---|---|---|

| 121,471 | 0.01 | 72.65 | - |

| 246,680 | 0.01 | 72.28 | −0.5% |

| 510,438 | 0.01 | 71.63 | −0.9% |

| Power (W) | Experimental Average Surface Temperature (°C) | Numerical Average Surface Temperature (°C) | Error (%) | Numerical Heat Transfer Coefficients (kW/m2 K) | Experimental Average Liquid Temperature (°C) | Numerical Average Liquid Temperature (°C) |

|---|---|---|---|---|---|---|

| 1127 | 66.0 | 69.43 | 4.95 | 7.98 | 58.5 | 61.40 |

| 1332 | 68.5 | 71.56 | 4.28 | 10.16 | 61.5 | 64.13 |

| 1577 | 71.9 | 74.67 | 3.71 | 10.46 | 63.8 | 66.17 |

| Ref. [43] | - | - | - | 6.1 − 18.5 (∆T = 10 °C) |

| Case | Wserver (W) | Wfan+pump (W) | hf,l (kJ/kg) | sf,l (kJ/kg K) | hf,g (kJ/kg) | sf,g (kJ/kg K) | hf,w,1 (kJ/kg) | sf,w,1 (kJ/kg K) | hf,w,2 (kJ/kg) | sf,w,1,2 (kJ/kg K) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1127 | 59.2 | 114.120 | 0.407 | 228.943 | 0.749 | 105.286 | 0.367 | 111.558 | 0.387 |

| 2 | 1396 | 59.4 | 114.120 | 0.407 | 229.802 | 0.750 | 108.631 | 0.376 | 113.649 | 0.394 |

| 3 | 1332 | 59.1 | 114.120 | 0.407 | 231.090 | 0.753 | 111.558 | 0.386 | 116.994 | 0.405 |

| 4 | 1494 | 59.0 | 114.120 | 0.407 | 231.520 | 0.753 | 116.158 | 0.402 | 122.430 | 0.423 |

| 5 | 1516 | 59.0 | 114.120 | 0.407 | 232.379 | 0.755 | 117.621 | 0.408 | 124.102 | 0.429 |

| 6 | 1577 | 59.0 | 114.120 | 0.407 | 233.238 | 0.756 | 119.503 | 0.412 | 126.193 | 0.436 |

| Power (W) | Ed,1 (W) | Ed,2 (W) | Ed,3 (W) | Ed,4 (W) | Ed | Exergy Efficiency (%) | |

|---|---|---|---|---|---|---|---|

| Case 1 | 1127 | 864.91 | 19.8 | 27.27 | 14.28 | 926.26 | 18.96% |

| Case 2 | 1396 | 1092.95 | 19.54 | 74.99 | 45.64 | 1233.12 | 15.24% |

| Case 3 | 1332 | 1038.41 | 29.85 | 70.79 | 38.37 | 1177.42 | 12.65% |

| Case 4 | 1494 | 1163.08 | 37.61 | 45.91 | 60.92 | 1307.52 | 13.41% |

| Case 5 | 1516 | 1176.93 | 46.45 | 33.15 | 31.86 | 1288.39 | 15.90% |

| Case 6 | 1577 | 1190.93 | 56.82 | 107.42 | 33.01 | 1388.18 | 12.86% |

| Ref. [30] | 1150 | - | - | - | - | - | 18.94% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Yu, H. Evaluation and Optimization of a Two-Phase Liquid-Immersion Cooling System for Data Centers. Energies 2021, 14, 1395. https://doi.org/10.3390/en14051395

Liu C, Yu H. Evaluation and Optimization of a Two-Phase Liquid-Immersion Cooling System for Data Centers. Energies. 2021; 14(5):1395. https://doi.org/10.3390/en14051395

Chicago/Turabian StyleLiu, Cheng, and Hang Yu. 2021. "Evaluation and Optimization of a Two-Phase Liquid-Immersion Cooling System for Data Centers" Energies 14, no. 5: 1395. https://doi.org/10.3390/en14051395

APA StyleLiu, C., & Yu, H. (2021). Evaluation and Optimization of a Two-Phase Liquid-Immersion Cooling System for Data Centers. Energies, 14(5), 1395. https://doi.org/10.3390/en14051395