Analysis and Evaluation of Heat Pipe Efficiency to Reduce Low Emission with the Use of Working Agents R134A, R404A and R407C, R410A

Abstract

1. Introduction

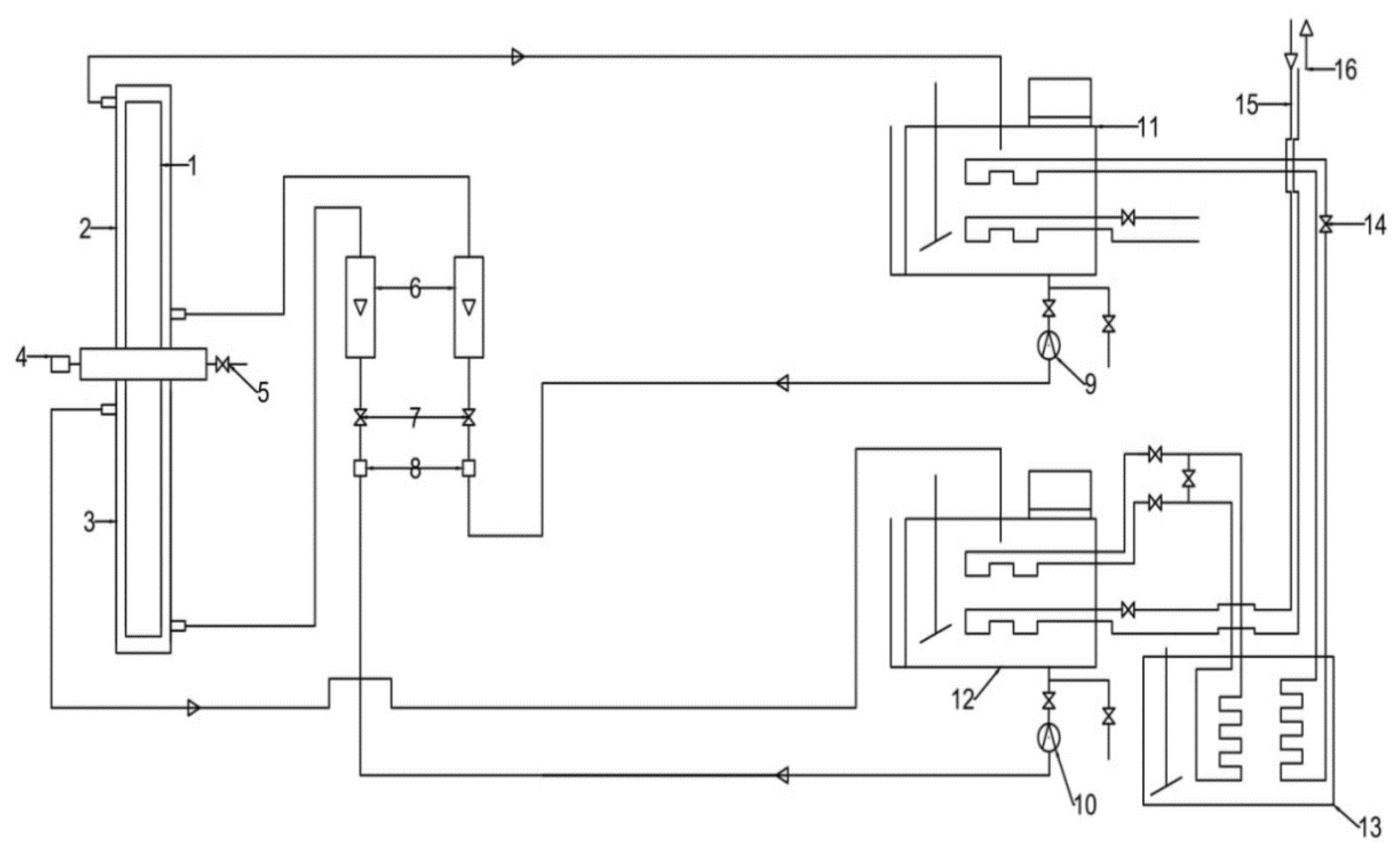

2. Materials and Methods

2.1. Used Materials and Their Properties

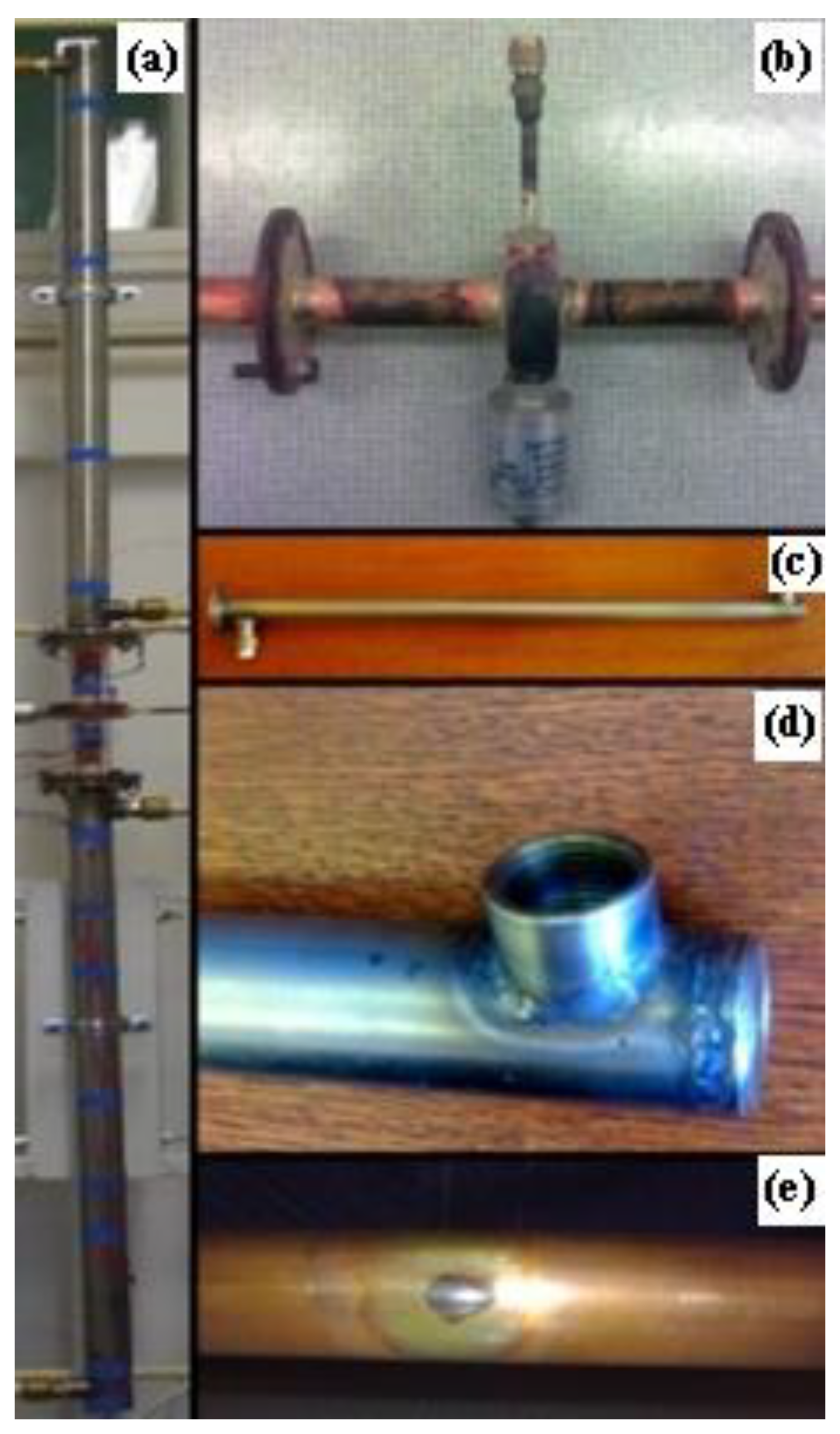

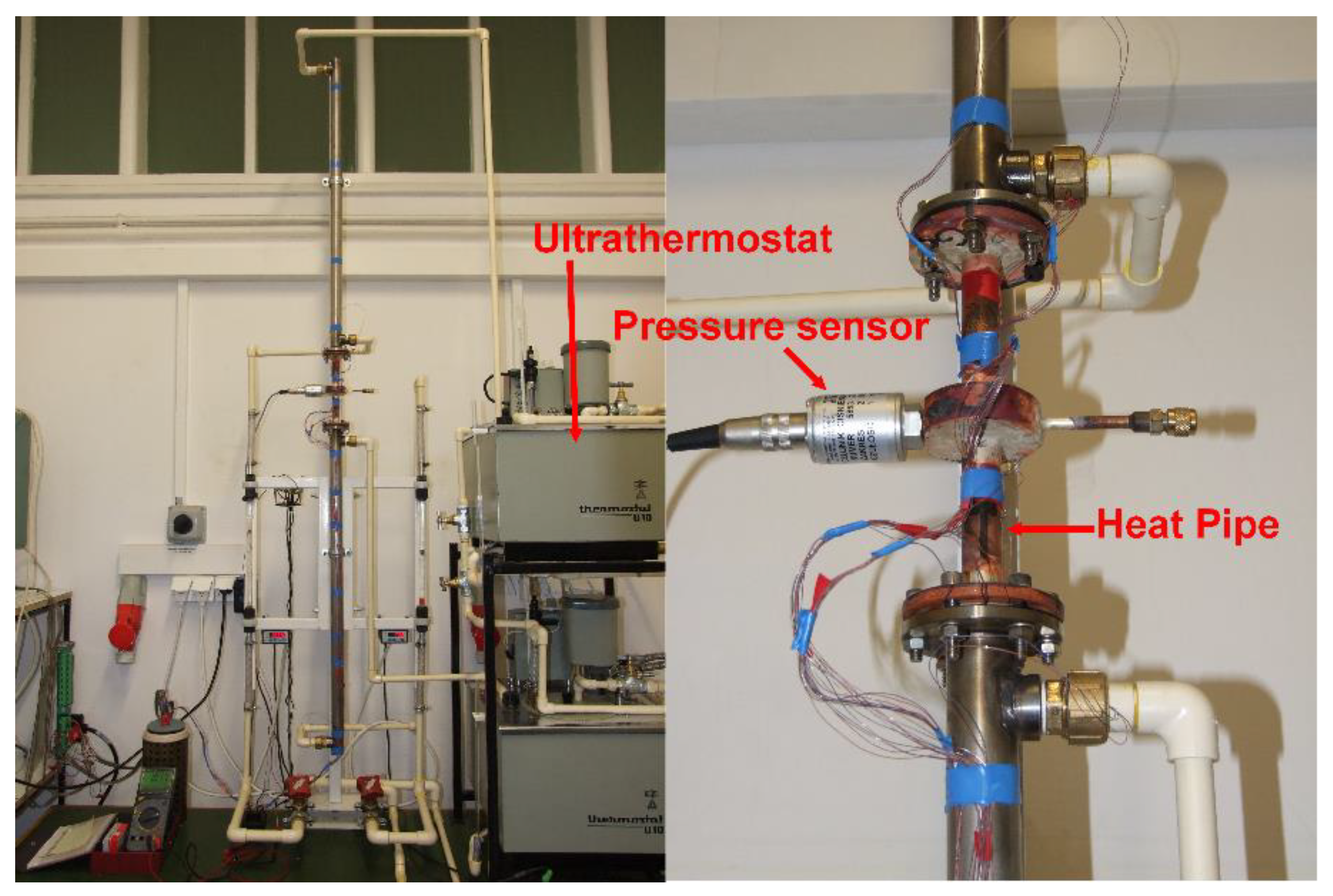

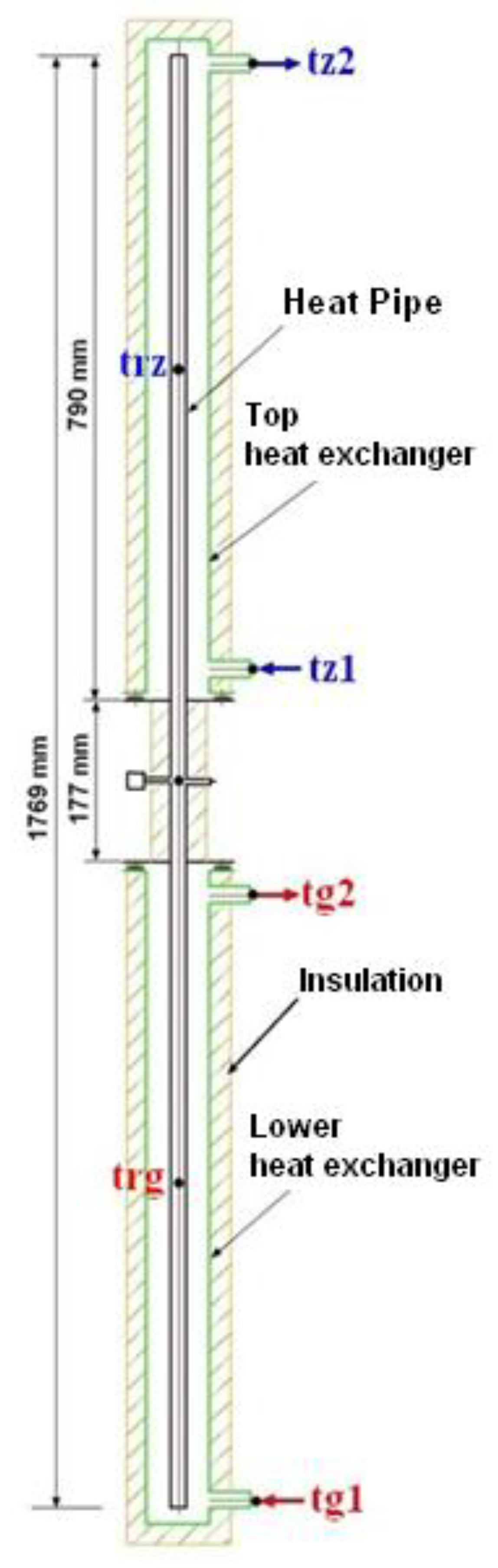

2.2. Assembly of the Test Bench

- -

- internal diameter: dw = 0.016 (m)

- -

- outer diameter: dz = 0.018 (m)

- -

- tube height: h = 1.769 (m)

2.3. Measuring Points and Quantities of Interest

- Emptying the heat pipe (creating a vacuum);

- Filling the heat pipe with an appropriate amount of the working medium;

- Determining the assumed temperatures in the ultrathermostats;

- Pumping heating and cooling factors for the heat pipe;

- Setting the uniform flow of heating and cooling factors in the heat pipe at 15 Lh;

- Determining the resultant temperatures tz2, trg, trz, tg2;

- Reading of measurement data.

2.4. Test Procedure (Used for the Repetitiveness and Archivibility of the Document, Number of Tests Performer)

2.5. Tests of a Copper (Cu) Heat Pipe 1769 mm Long

3. Results

3.1. Heat Copper Tube Exchanger, 1769 mm Long, 18 mm Outside Diameter and 1 mm Wall Thickness

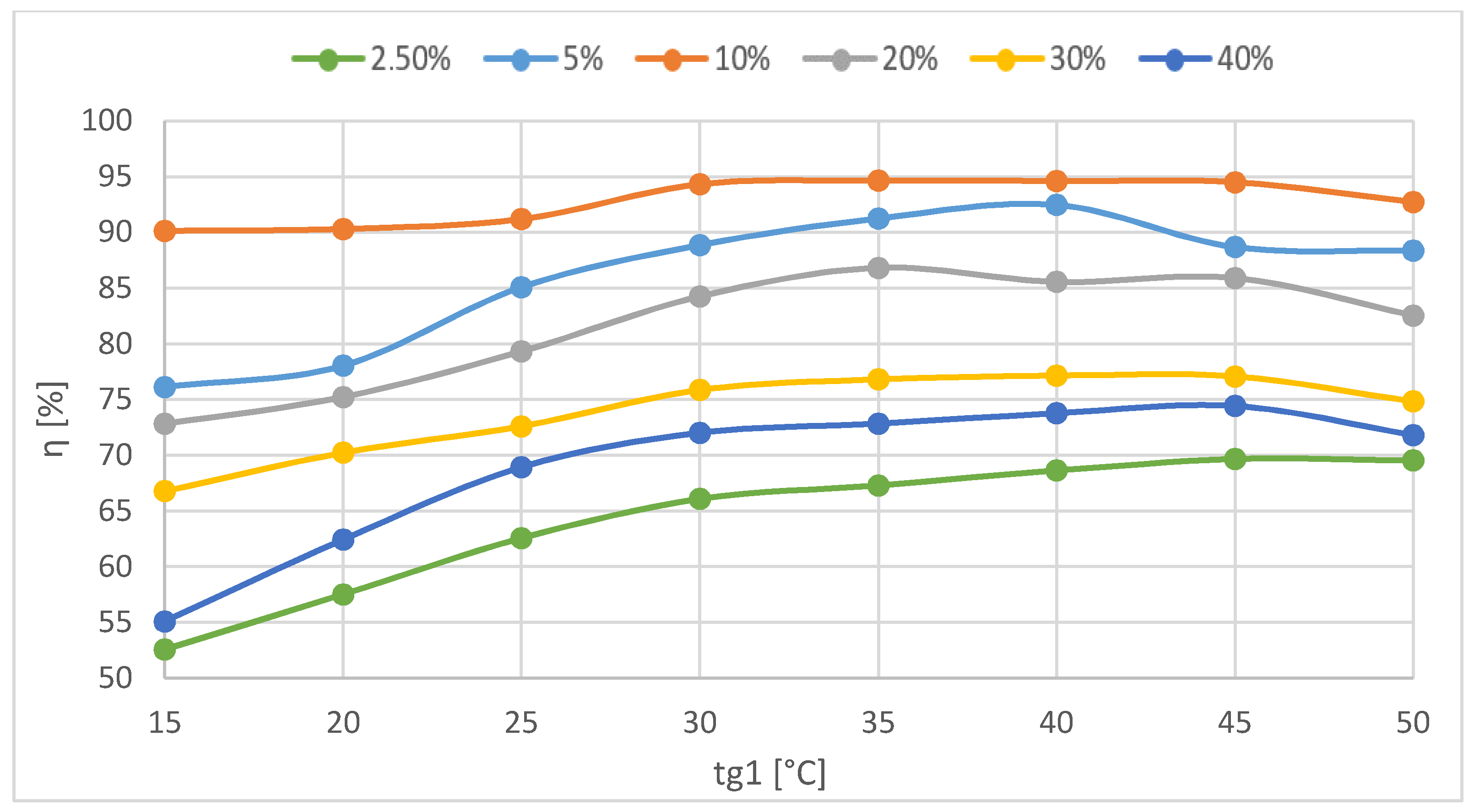

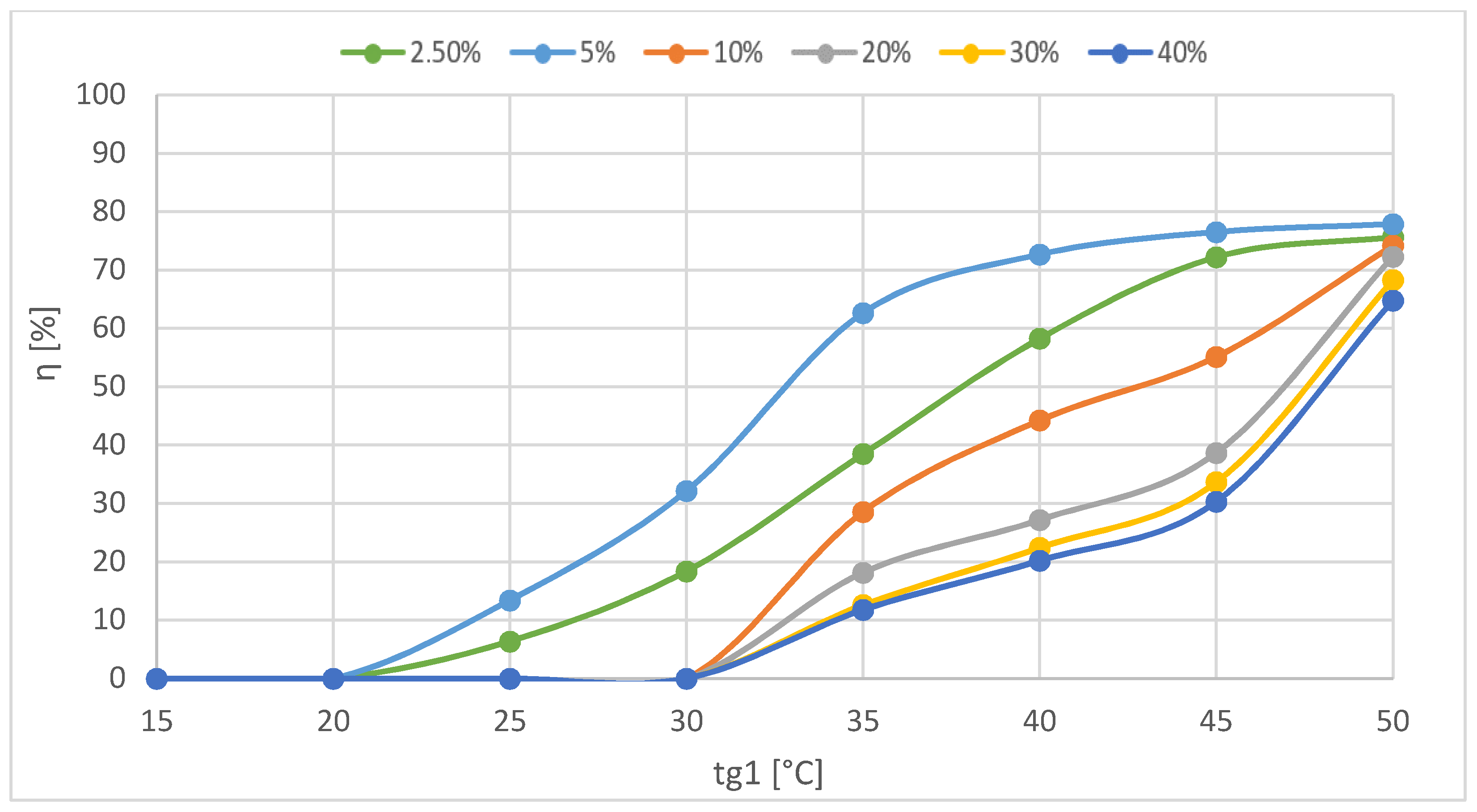

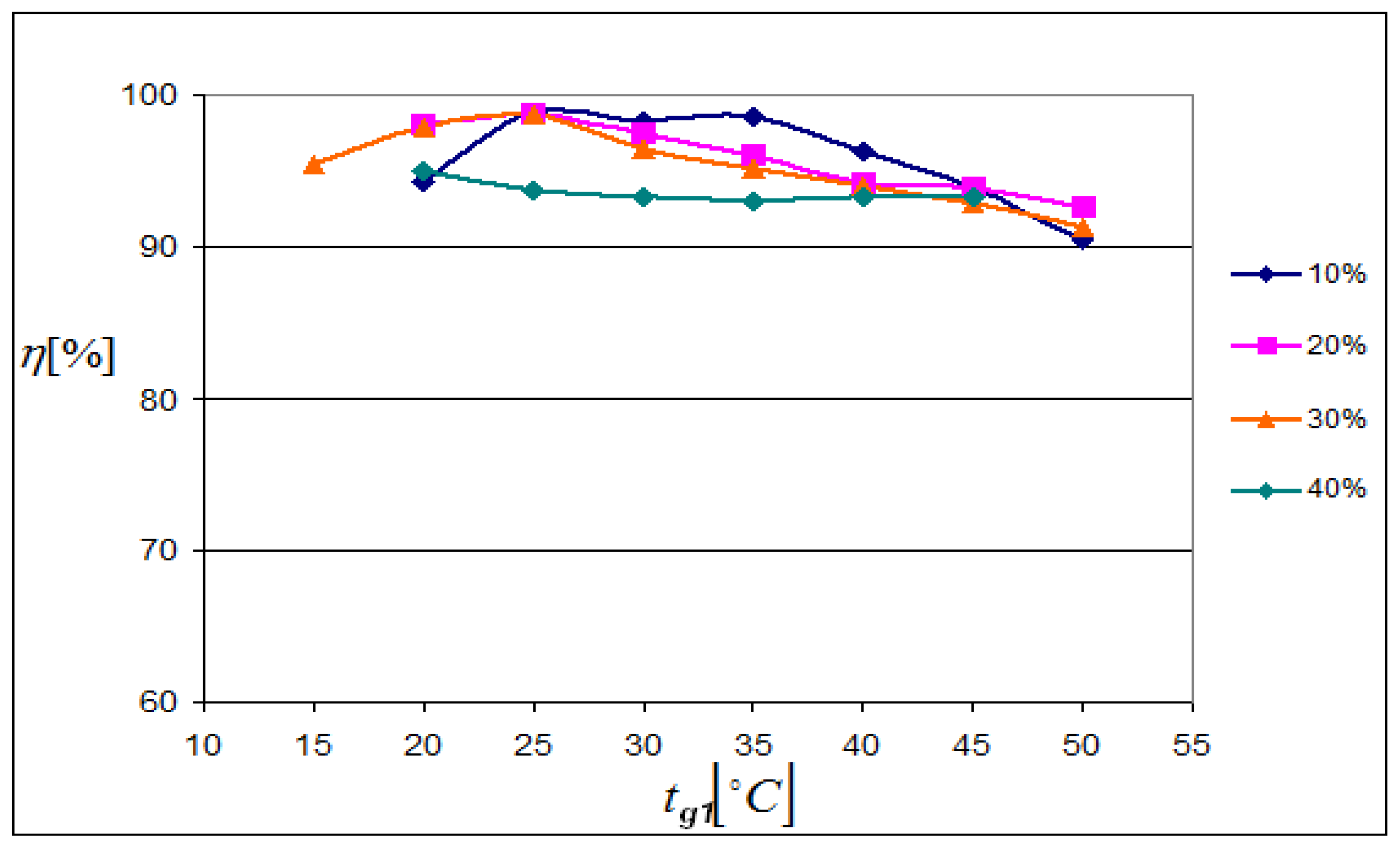

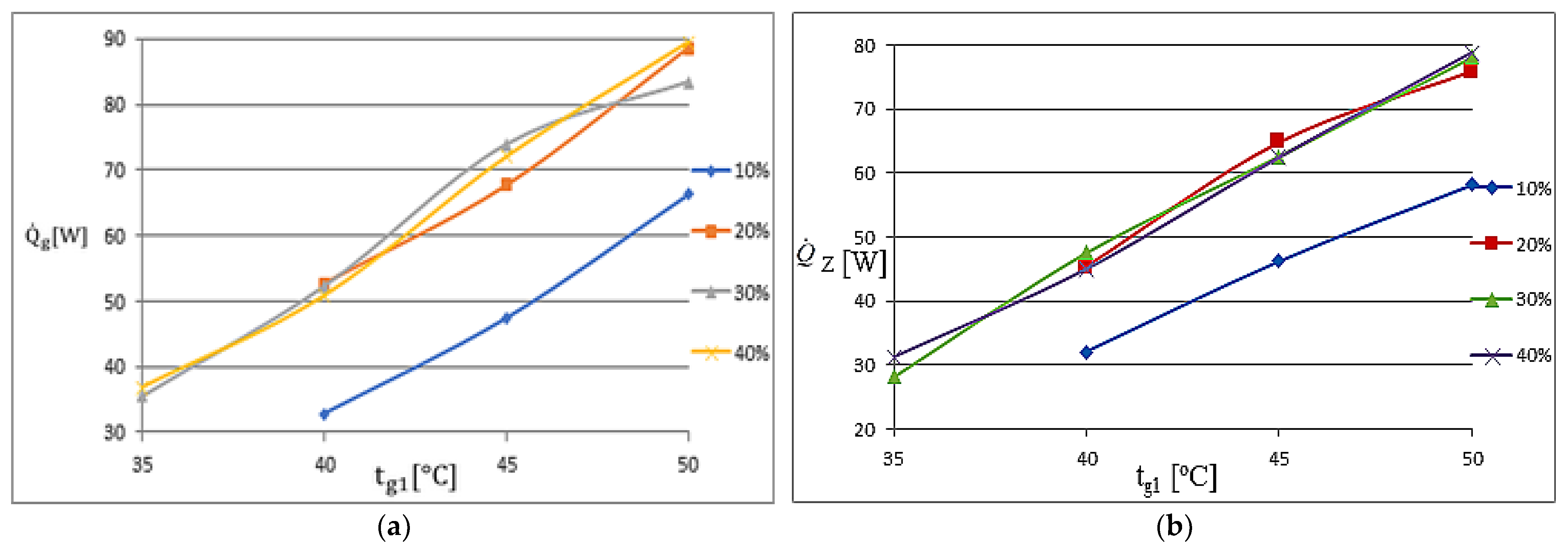

3.1.1. Comparative Analysis of Test Results for Various Charges of the R134A Working Medium

3.1.2. Comparative Analysis of Test Results for Various Charges with the R404A Working Medium

3.1.3. Comparative Analysis of the Test Results for Various Charges with the R407 C Working Medium

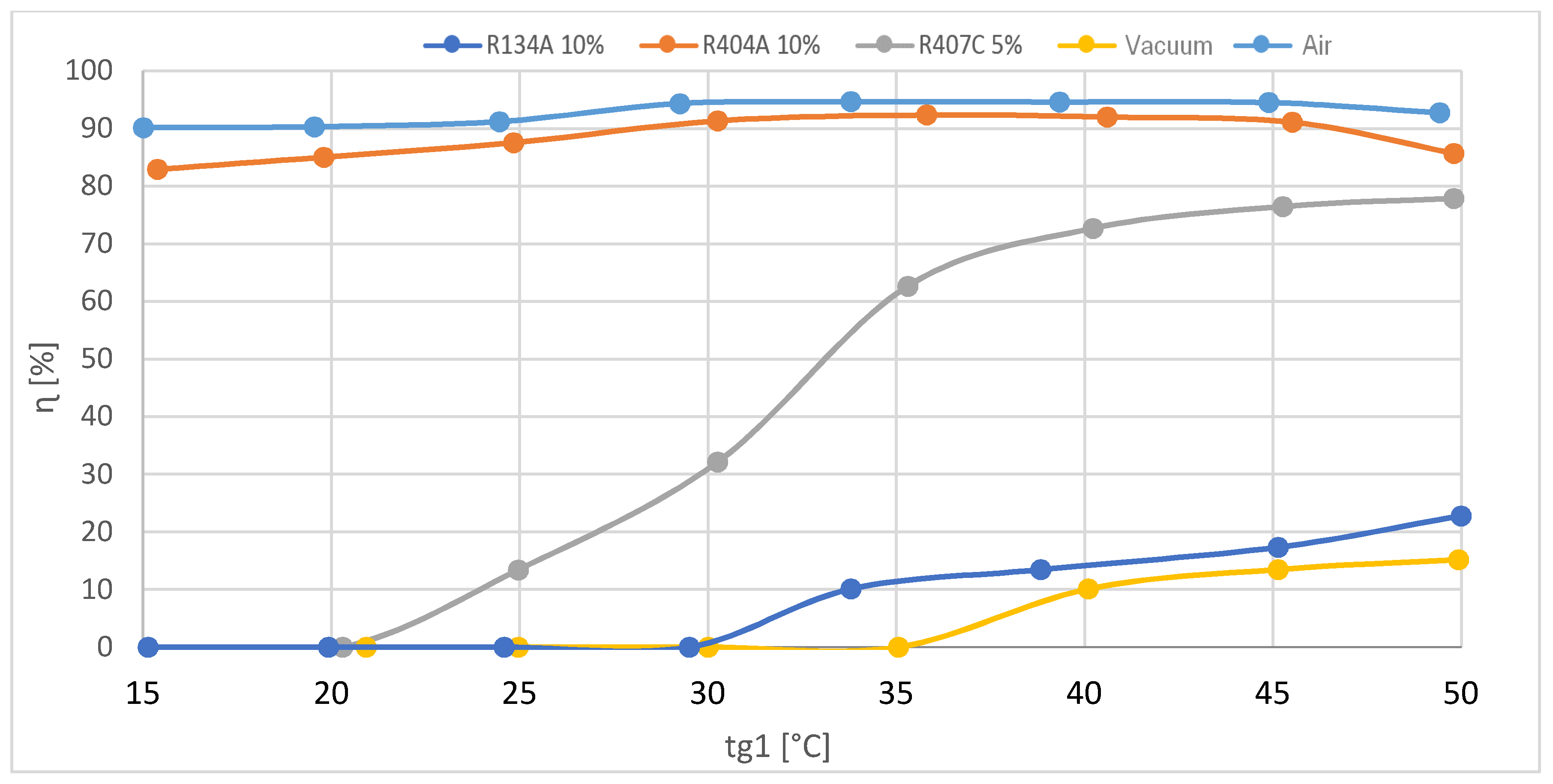

3.1.4. Analysis of the Most Favorable Refrigerants: R134A, R404A, R407C

3.1.5. Thermographic Analysis of the Heat Pipe during Operation

3.2. Tests of a Brass (CuZn39Pb3) Heat Pipe 550 mm Long

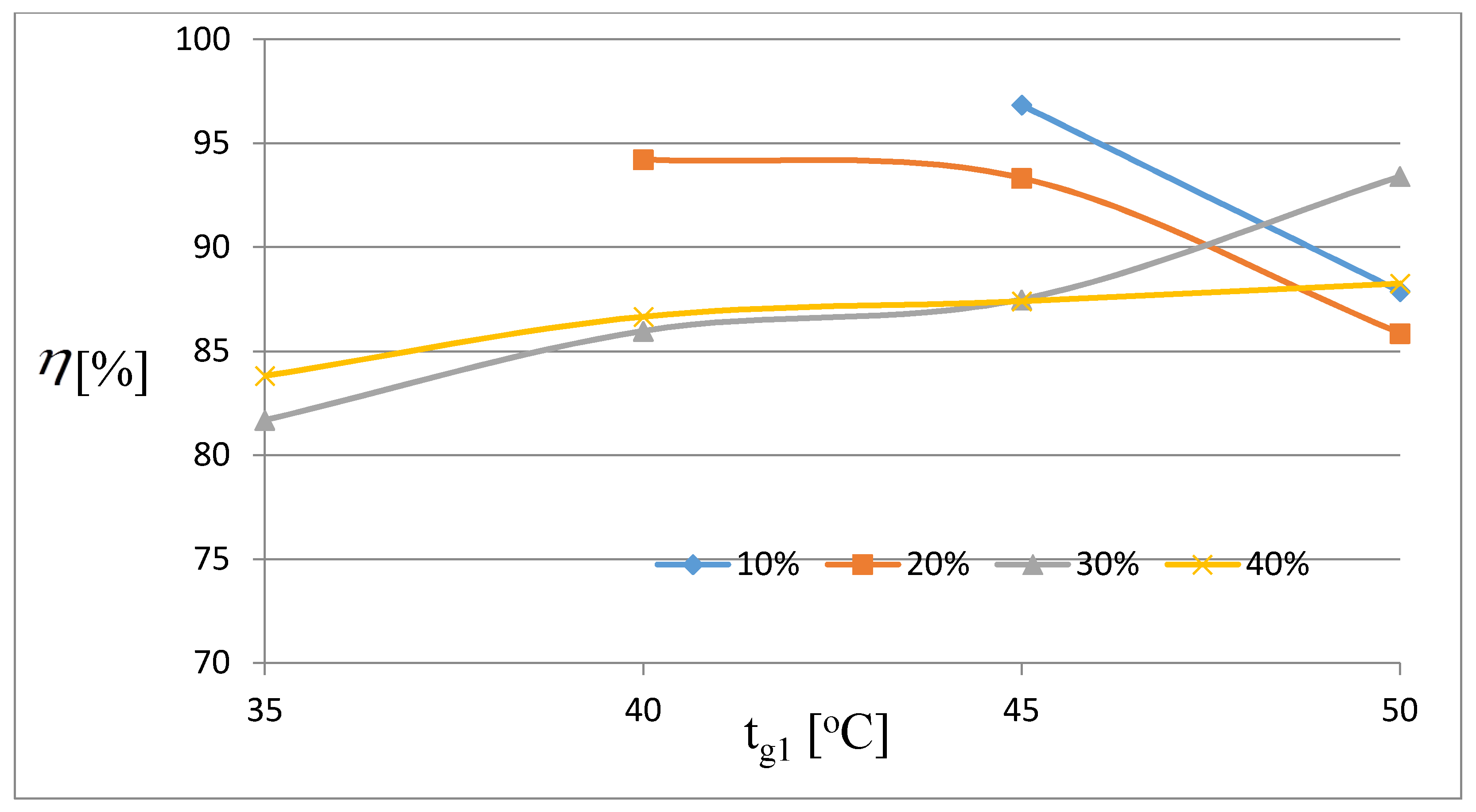

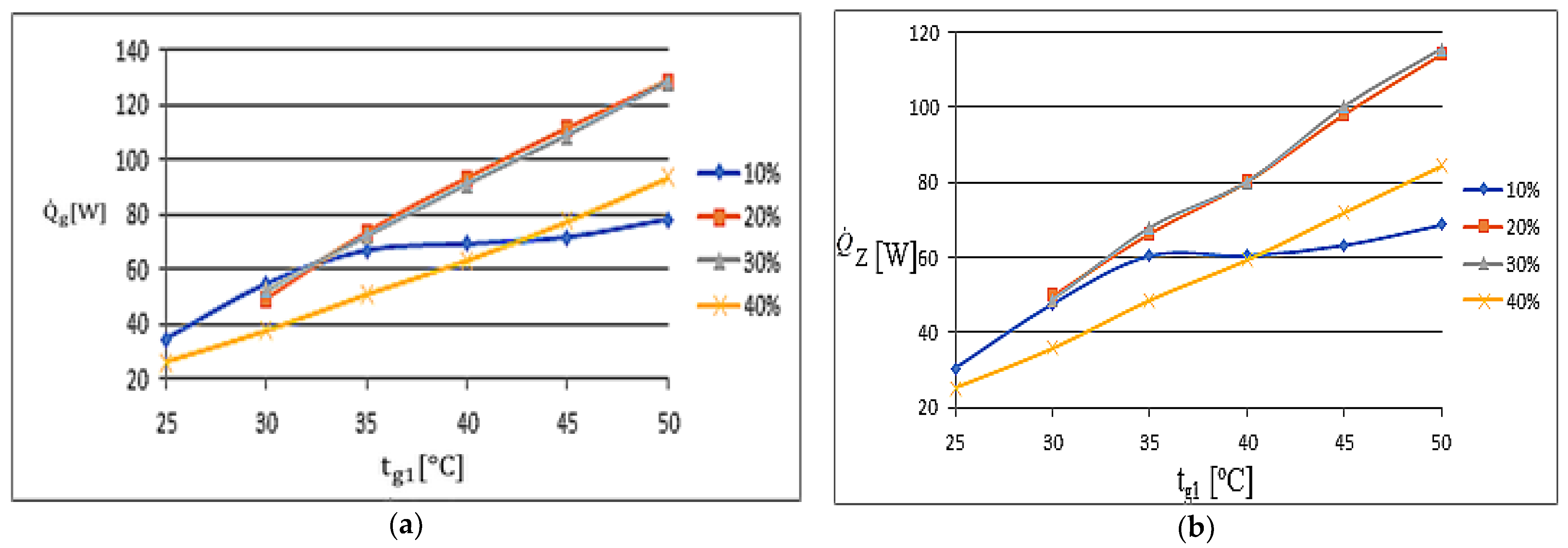

3.2.1. Comparative Analysis of Test Results for Various Charges of the R134A Working Medium

3.2.2. Comparative Analysis of Test Results for Various Charges with the R404A Working Medium

3.2.3. Comparative Analysis of Test Results for Various Fillings with the R407C Working Medium

3.2.4. Comparative Analysis of Test Results for Various Charges with the R410A Working Medium

3.3. Comparative Analysis of the Most Advantageous Fillings of the Heat Pipe 550 mm Long Compared to the Heat Pipe 1769 mm Long

4. Discussion

4.1. Discussion on the Choice of the Working Medium and the Selection of Its Quantity

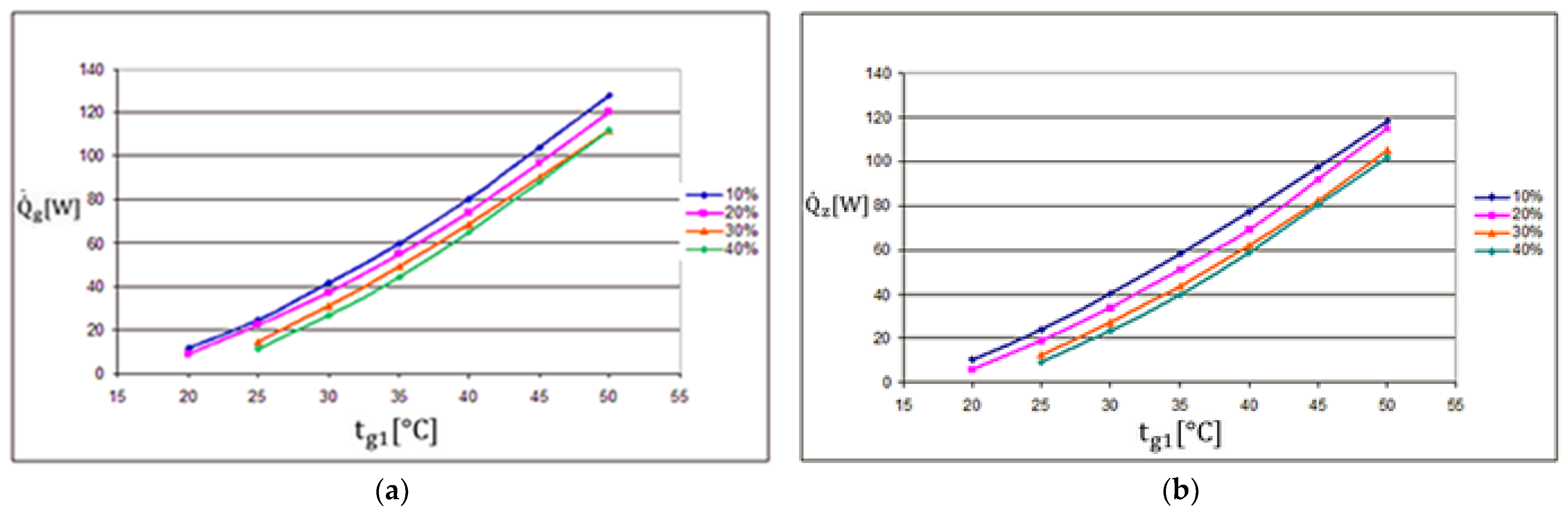

4.2. Discussion on the Efficiency of Heat Pipes and the Value of the Heat Flux Transferred by Them

4.3. Discussions on the Advisability of Using Heat Pipe Heat Exchangers for the Needs of Civil Engineering and Air Conditioning to Reduce Low Emissions

5. Conclusions

- selection of the best working medium and determination of its optimal quantity;

- the efficiency of the heat pipes and the value of the heat flux transmitted by them;

- the desirability of using heat pipe heat exchangers for structural engineering and air conditioning to reduce low emissions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Prager, R.C.; Nikitkin, M.; Cullimore, B. Heat Pipes, Spacecraft Thermal Control Handbook; Aerospace Corporation: El Segundo, CA, USA, 2002. [Google Scholar]

- Sabiniak, H.G.; Wiśnik, K. Zastosowanie Ożebrowanych rur Grzewczych w Ogrzewaniu Płaszczyznowym. Czasopismo, Instal, Ośrodek Informacji Technika Instalacyjna w Budownictwie’. 2013. Available online: https://www.wentylacyjny.pl/903-31-230-miesiecznik-instal-1-11--teoria-i-praktyka-w-instalacjach.html (accessed on 1 February 2021). (In Polish).

- Adrian, Ł.; Piersa, P.; Szufa, S.; Romanowska-Duda, Z.; Grzesik, M.; Cebula, A.; Kowalczyk, S.; Ratajczyk-Szufa, J. Experimental research and thermographic analysis of heat transfer processes in a heat pipe heat exchanger utilizing as a working fluid R134A. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer: Berlin/Heidelberg, Germany, 2018; pp. 413–421. [Google Scholar] [CrossRef]

- Pochwała, S.; Gardecki, A.; Lewandowski, P.; Somogyi, V.; Anweiler, S. Developing of Low-Cost Air Pollution Sensor—Measurements with the Unmanned Aerial Vehicles in Poland. Sensors 2020, 20, 3582. [Google Scholar] [CrossRef] [PubMed]

- Pochwała, S.; Makiola, D.; Anweiler, S.; Böhm, M. The Heat Conductivity Properties of Hemp–Lime Composite Material Used in Single-Family Buildings. Materials 2020, 13, 1011. [Google Scholar] [CrossRef] [PubMed]

- Adrian, Ł.; Szufa, S.; Piersa, P.; Romanowska-Duda, Z.; Grzesik, M.; Cebula, A.; Kowalczyk, S.; Ratajczyk-Szufa, J. Thermographic analysis and experimental work using laboratory installation of heat transfer processes in a heat pipe heat exchanger utilizing as a working fluid R404A and R407A. In Renewable Energy Sources: Engineering, Technology, Innovation; Wróbel, M., Jewiarz, M., Szlęk, A., Eds.; Springer Proceedings in Energy; Springer: Cham, Switzerland, 2020; pp. 799–807. ISBN 978-3-030-13887-5. [Google Scholar] [CrossRef]

- Grzebielec, A.; Pluta, Z.; Ruciński, A.; Rusowicz, A. Czynniki Chłodnicze i Nośniki Energii; Oficyna Wydawnicza, Politechniki Warszawskiej: Warszawa, Poland, 2011. Available online: https://coolpack.software.informer.com/ (accessed on 30 January 2021).

- Rossomme, S. Modélisation de L’évaporation des Lms Liquides Minces, y Compris au Voisinage des Lignes de Contact: Application aux Caloducs à Rainures. Ph.D. Thesis, Université libre de Bruxelles, Bruxelles, Belgique, 2008. [Google Scholar]

- Mediavilla, M.D.; Peña, D.G.; Miguel, I.A.; Barrio, S.R. Experimental characterization of heat pipes. In Proceedings of the Conference: XI National II International Engineering Thermodynamics Congress, Albacete, Spain, 12–14 June 2019. [Google Scholar]

- Stelmach, J.; Kuncewicz, C.; Adrian, L.; Jirout, T.; Rieger, F. Change of mixing power of a two PBT impellers when empty-ing a Tank. Processes 2021, 9, 341. [Google Scholar] [CrossRef]

- Metin Kaya, A. Experimental investigation on thermal efficiency of two-phase closed thermosyphon (TPCT) filled with CuO/water nanofluid. Eng. Sci. Technol. Int. J. 2020, 23. [Google Scholar] [CrossRef]

- Haque, M.E.; Efthakher, M.; Mashud, H. Performance Analysis of a Heat Pipe with Stainless Steel Wick. J. Eng. Adv. 2020, 1, 16–22. [Google Scholar] [CrossRef]

- Rao, M.T.; Rao, S.S. Steam condensation by heat pipes. In Journal of Physics: Conference Series 1473, Proceedings of the International Conference on Thermo-Fluids and Energy Systems (ICTES2019), Bengaluru, India, 27–28 December 2019; IOP Publishing: Bristol, UK, 2020. [Google Scholar] [CrossRef]

- Abdullahi, B.; Al-Dadah, R.K.; Mahmoud, S. Thermosyphon Heat Pipe Technology; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Pszczoła, J. Doświadczalne badanie rurki ciepła pod względem jej sprawności z zastosowaniem turbulizatorów przepływu. In Praca Inżynierska; Politechnika Łódzka: Łódź, Poland, 2014. (In Polish) [Google Scholar]

- Stelmach, J.; Kuncewicz, C.; Szufa, S.; Jirout, T.; Rieger, F. The Influence of Hydrodynamic Changes in a System with a Pitched Blade Turbine on Mixing Power. Processes 2021, 9, 68. [Google Scholar] [CrossRef]

- Kryszak, D.; Bartoszewicz, A.; Szufa, S.; Piersa, P.; Obraniak, A.; Olejnik, T.P. Modeling of Transport of Loose Products with the Use of the Non-Grid Method of Discrete Elements (DEM). Processes 2020, 8, 1489. [Google Scholar] [CrossRef]

- Schepper, S.C.K.; Heynderickx, G.J.; Marin, G.B. CFD modeling of all gas–liquid and vapor–liquid flow regimes predicted by the Baker chart. Chem. Eng. J. 2008, 138, 349–357. [Google Scholar] [CrossRef]

- Wong, S.-C. The Evaporation Mechanism in the Wick of Copper Heat Pipes; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 13:978-3319044941. [Google Scholar] [CrossRef]

- Smirnov, H.; Henry, F. Transport Phenomena in Capillary-Porous Structures and Heat Pipes; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar] [CrossRef]

- Tadeusz, R.F. Pomiary Cieplne cz. 1 Podstawowe Pomiary Cieplne; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 2000. [Google Scholar]

- Pszczółkowska, K. Badanie wydajności cieplnej wymiennika ciepła typu rurka ciepła. In Praca Inżynierska; Politechnika Łódzka: Łódź, Poland, 2014. (In Polish) [Google Scholar]

- Chen, Q.; Shi, Y.; Zhuang, Z.; Weng, L.; Xu, C.; Zhou, J. Numerical Analysis of Liquid–Liquid Heat Pipe Heat Exchanger Based on a Novel Model. Energies 2021, 14, 589. [Google Scholar] [CrossRef]

- Gao, Q.; Zhang, P.; Peng, W.; Chen, S.; Zhao, G. Structural Design Simulation of Bayonet Heat Exchanger for Sulfuric Acid Decomposition. Energies 2021, 14, 422. [Google Scholar] [CrossRef]

- Li, J.-Q.; Kwon, J.-T.; Jang, S.-J. The Power and Efficiency Analyses of the Cylindrical Cavity Receiver on the Solar Stirling Engine. Energies 2020, 13, 5798. [Google Scholar] [CrossRef]

- Song, E.-H.; Lee, K.-B.; Rhi, S.-H.; Kim, K. Thermal and Flow Characteristics in a Concentric Annular Heat Pipe Heat Sink. Energies 2020, 13, 5282. [Google Scholar] [CrossRef]

- Xiang, J.; Chen, X.-B.; Huang, J.; Zhang, C.; Zhou, C.; Zheng, H. Thermal Performances Investigation of Anti-Gravity Heat Pipe with Tapering Phase-Change Chamber. Energies 2020, 13, 5036. [Google Scholar] [CrossRef]

- Adrian, Ł. Badania Termowizyjne i Przykłady ich Zastosowań. Rozdział w Poradniku, Wentylacja, Klimatyzacja, Ogrzewanie; Fodemskiego, T.R., Ed.; Verlag Dashofer: Warszawa, Poland, 2014; ISBN 83-88285-86-6. [Google Scholar]

- Pokorska-Silva, I.; Kadela, M.; Fedorowicz, L. A reliable numerical model for assessing the thermal behavior of a dome building. J. Build. Eng. 2020, 32, 101706. [Google Scholar] [CrossRef]

- Park, J.E.; Vakili-Farahani, F.; Consolini, L.; Thome, J.R. Experimental study on condensation heat transfer in vertical minichannels for new refrigerant R1234ze(E) versus R134a and R236fa. Exp. Therm. Fluid Sci. 2011, 35, 442–454. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Adrian, Ł.; Sielski, J.; Grzesik, M.; Romanowska-Duda, Z.; Piotrowski, K.; Lewandowska, W. Acquisition of Torrefied Biomass from Jerusalem Artichoke Grown in a Closed Circular System Using Biogas Plant Waste. Molecules 2020, 25, 3862. [Google Scholar] [CrossRef] [PubMed]

- Szufa, S. Use of superheated steam in the process of biomass torrefaction. Przem. Chem. 2020, 99, 1797–1801. (In Polish) [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Adrian, Ł.; Czerwińska, J.; Lewandowski, A.; Lewandowska, W.; Sielski, J.; Dzikuć, M.; Wróbel, M.; Jewiarz, M.; et al. Sustainable Drying and Torrefaction Processes of Miscanthus for Use as a Pelletized Solid Biofuel and Biocarbon-Carrier for Fertilizers. Molecules 2021, 26, 1014. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M.; Wachowski, M. Mechanical and Material Properties of Mortar Reinforced with Glass Fiber: An Experimental Study. Materials 2021, 14, 698. [Google Scholar] [CrossRef] [PubMed]

| Tg1 [°C] | R134A 10% | R404A 10% | R407C 5% | Vacuum | Air | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Qg [W] | Qz [W] | ɳ [%] | Qg [W] | Qz [W] | ɳ [%] | Qg [W] | Qz [W] | ɳ [%] | Qg [W] | Qz [W] | ɳ [%] | Qg [W] | Qz [W] | ɳ [%] | |

| 15.00 | 30.76 | 27.73 | 90.00 | 24.17 | 20.03 | 83.00 | 0.44 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.22 | 0.00 | 0.00 |

| 20.00 | 39.48 | 35.65 | 90.00 | 37.29 | 31.70 | 85.00 | 0.88 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.66 | 0.00 | 0.00 |

| 25.00 | 63.48 | 57.88 | 91.00 | 59.11 | 51.72 | 88.00 | 13.13 | 1.76 | 13.00 | 0.00 | 0.00 | 0.00 | 1.09 | 0.00 | 0.00 |

| 30.00 | 83.05 | 78.33 | 94.00 | 78.68 | 71.85 | 91.00 | 34.93 | 11.23 | 32.00 | 0.00 | 0.00 | 0.00 | 2.18 | 0.00 | 0.00 |

| 35.00 | 104.60 | 99.04 | 95.00 | 109.00 | 100.70 | 92.00 | 54.47 | 34.12 | 63.00 | 1.09 | 0.00 | 0.00 | 4.36 | 0.44 | 10.00 |

| 40.00 | 134.90 | 127.60 | 95.00 | 135.10 | 124.20 | 92.00 | 84.84 | 61.64 | 73.00 | 2.18 | 0.22 | 10.00 | 6.53 | 0.88 | 13.00 |

| 45.00 | 160.70 | 151.80 | 94.00 | 154.50 | 140.70 | 91.00 | 128.10 | 97.97 | 76.00 | 3.26 | 0.44 | 13.00 | 7.61 | 1.32 | 17.00 |

| 50.00 | 199.30 | 184.80 | 93.00 | 176.00 | 150.80 | 86.00 | 162.50 | 126.60 | 78.00 | 4.34 | 0.66 | 15.00 | 8.69 | 1.98 | 23.00 |

| Tg1 [°C] | Copper Tube. 1769 mm Long. 18 mm in Diameter. Filled with 10% of the Total Volume of R134A | A Brass Heat Pipe. 550 mm Long. 22 mm in Diameter. Filled with 20% of the Total Volume of R404A | ||||

|---|---|---|---|---|---|---|

| Qg [W] | Qz [W] | ɳ [%] | Qg [W] | Qz [W] | ɳ [%] | |

| 15.00 | 30.76 | 27.73 | 90.15 | 7.00 | 6.48 | 0.00 |

| 20.00 | 39.48 | 35.65 | 90.30 | 21.00 | 20.23 | 0.00 |

| 25.00 | 63.48 | 57.88 | 91.19 | 39.28 | 38.73 | 98.59 |

| 30.00 | 83.05 | 78.33 | 94.32 | 58.26 | 55.03 | 94.23 |

| 35.00 | 104.64 | 99.04 | 94.64 | 75.25 | 75.02 | 99.70 |

| 40.00 | 134.92 | 127.65 | 94.61 | 91.84 | 88.30 | 96.68 |

| 45.00 | 160.70 | 151.86 | 94.50 | 117.90 | 106.57 | 90.39 |

| 50.00 | 199.38 | 184.87 | 92.72 | 134.89 | 125.73 | 93.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adrian, Ł.; Szufa, S.; Piersa, P.; Kuryło, P.; Mikołajczyk, F.; Kurowski, K.; Pochwała, S.; Obraniak, A.; Stelmach, J.; Wielgosiński, G.; et al. Analysis and Evaluation of Heat Pipe Efficiency to Reduce Low Emission with the Use of Working Agents R134A, R404A and R407C, R410A. Energies 2021, 14, 1926. https://doi.org/10.3390/en14071926

Adrian Ł, Szufa S, Piersa P, Kuryło P, Mikołajczyk F, Kurowski K, Pochwała S, Obraniak A, Stelmach J, Wielgosiński G, et al. Analysis and Evaluation of Heat Pipe Efficiency to Reduce Low Emission with the Use of Working Agents R134A, R404A and R407C, R410A. Energies. 2021; 14(7):1926. https://doi.org/10.3390/en14071926

Chicago/Turabian StyleAdrian, Łukasz, Szymon Szufa, Piotr Piersa, Piotr Kuryło, Filip Mikołajczyk, Krystian Kurowski, Sławomir Pochwała, Andrzej Obraniak, Jacek Stelmach, Grzegorz Wielgosiński, and et al. 2021. "Analysis and Evaluation of Heat Pipe Efficiency to Reduce Low Emission with the Use of Working Agents R134A, R404A and R407C, R410A" Energies 14, no. 7: 1926. https://doi.org/10.3390/en14071926

APA StyleAdrian, Ł., Szufa, S., Piersa, P., Kuryło, P., Mikołajczyk, F., Kurowski, K., Pochwała, S., Obraniak, A., Stelmach, J., Wielgosiński, G., Czerwińska, J., & Kubiak, P. (2021). Analysis and Evaluation of Heat Pipe Efficiency to Reduce Low Emission with the Use of Working Agents R134A, R404A and R407C, R410A. Energies, 14(7), 1926. https://doi.org/10.3390/en14071926