A Review of Life Extension Strategies for Offshore Wind Farms Using Techno-Economic Assessments

Abstract

1. Introduction

2. A Review of Current Technical Considerations in Post-Design Life Decisions

2.1. Offshore Oil and Gas Industry

2.2. Environmental Impact of Decommissioning

- First, the question of a total or partial removal. It is a requirement that offshore sites should be vacated and left as they were before the turbines were installed [14]. However, there have been discussions around the positive environmental benefits of only partially removing an offshore wind farm. Regarding the transmission system, the buried subsea cables are usually around 1 to 2 m deep [15]. The process of removal through the use of seabed excavation and extraction for many miles would cause significant disruption to the marine environment, not to mention the sizable costs. A significant research in the [16] details of the ‘renewables-to-reefs’ program in which the positives of partial removal for both the environment and economy are explored. It is worth noting that an offshore structure in use surrounded by wildlife will grow the used to it and an ecosystem will grow, and underwater ‘abandoned’ structures can become habitats for marine wildlife [17,18,19]. This is a clear example which highlights the importance of considering the environmental impact of decommissioning the decision-making process.

- Secondly, decommissioning should be carried out in a sustainable manner through the use of recycling and reusing methods, and must contribute to the circular economy. Wind turbines are mainly made from steel, so as much as 95% of their mass can be recycled [20]. The difficulty comes when trying to recycle the last 5% which is mainly the electronics, lubricants and polymers. The blades are made of polymers and therefore are currently completely non-recyclable [21]. Blades are certainly the biggest challenge for material recycling and transport logistics [22]. Finally, the growing size of wind turbines is going to be a drawback for recyclability. Indeed, the raw materials required for two small wind turbines are less than those for an equivalent capacity single turbine [20]. As a result, the current trend for larger offshore wind turbines means there will have to be better use of raw/re-used materials for the installation in order for the whole life cycle of the turbine to be suitably sustainable when accounting for the whole decommissioning process.

2.3. Corrosion of Offshore Wind Support Structure

3. End of Design Life Scenarios for Offshore Wind Turbines

3.1. Overview of the Decommissioning Process

- Project management and planning;

- The removal of the structures themselves;

- Post decommissioning processes such as the destination of the removed elements or the monitoring of the site’s recovery.

- Partial repowering which within this study is labelled as ‘Life Extension’. This is the process of upgrading minor components such as rotors, blades, gearboxes, drivetrains, power electronics and/or towers.

- Full repowering which within this study is labelled as ‘Repowering’. Replacing old turbines with much larger ones requiring larger changes to the infrastructure found at the site. However, some parts are to be reused.

3.2. Decommissioning

3.2.1. Removal

Turbines

Transition Piece

Foundations

3.2.2. Costs

3.3. Repowering

- Lifetime extension assessment

- Structural stability of a turbine

- Environmental conditions and required documents

- Physical state of the equipment

3.3.1. Lifetime Extension Assessment

3.3.2. Structural Stability of a Turbine

3.3.3. Physical State of the Equipment

3.3.4. Analytical Models

3.4. Life Extension

3.5. Future Financials

3.6. Future Operating Models

- The existing owners/operators—these will likely have seen the initial projections for a field achieved overall, and avoiding the cost of decommissioning is real bonus, thus they have an incentive to sell on an operating asset.

- Financial investors—may well be invested in the farm already. The steady income generated by a farm with suitably de-risked income streams supported by off-take agreements and government incentives based on floor pricing is very desirable in the current low yield world.

- Capital Equipment OEMs, as noted above so that their hardware is installed, are interested in taking a financial stake in the project.

- Nimble second tier O&M operators, like Rockrose, these will be smaller teams who have analysed the data in a different way and by offering to take ‘difficult’ assets off mainstream generators they create a structure which is financeable and meets all parties’ needs.

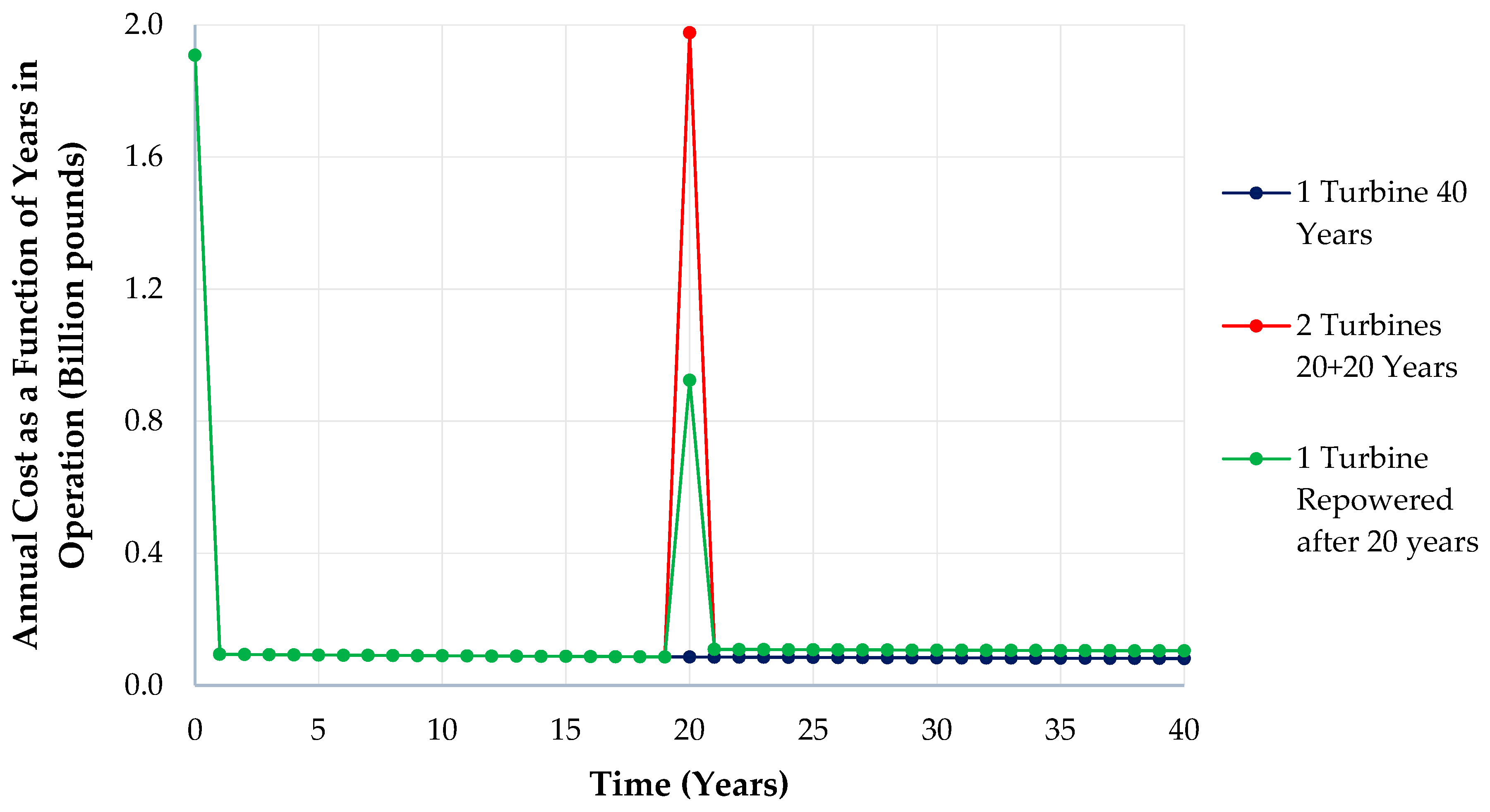

4. Financial Model

4.1. Introduction

4.2. Inputs

4.3. Initial Results

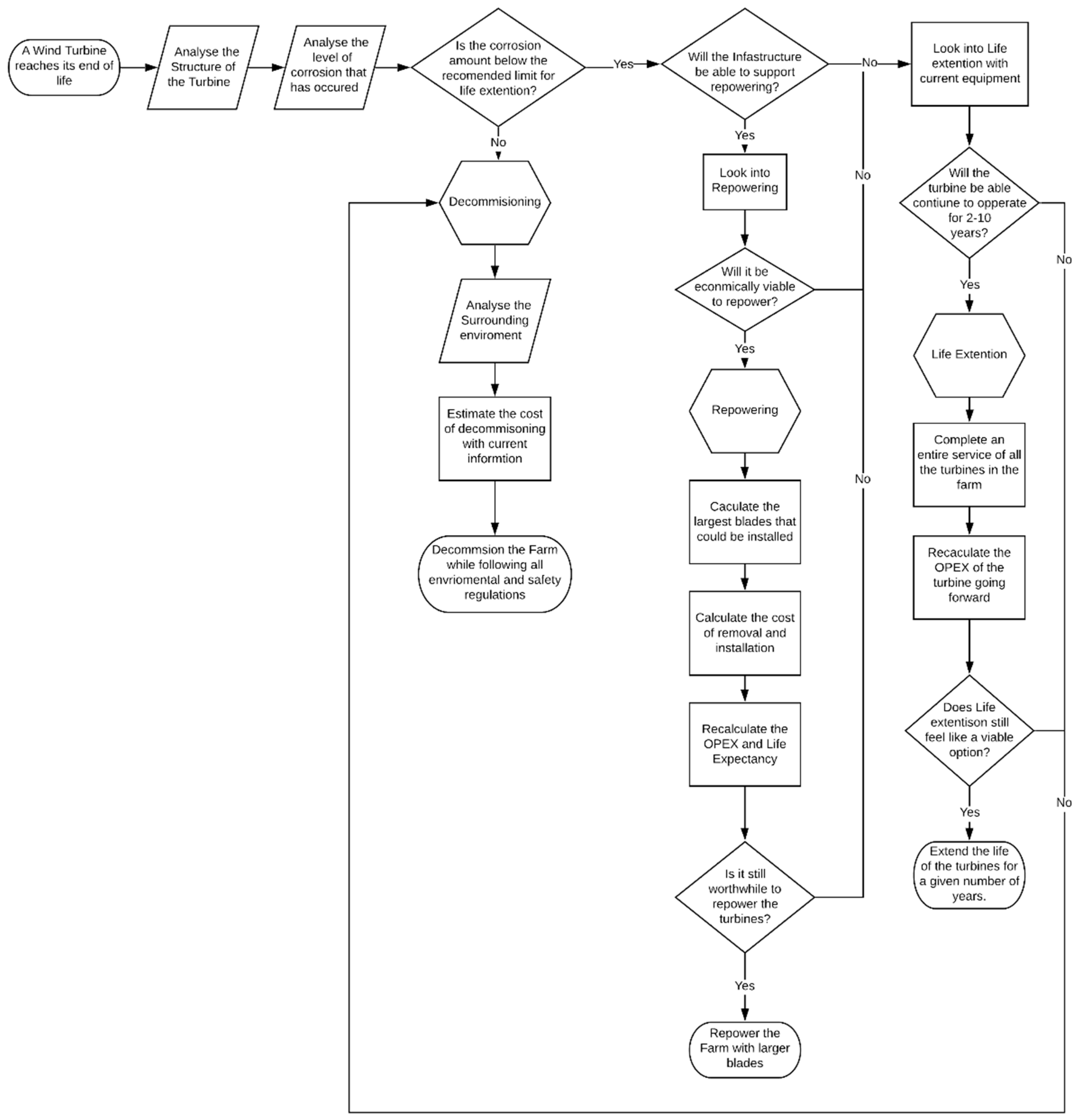

5. Flow Chart of the Proposed Framework for Post-Design Life Decision Making Process

6. Discussion

6.1. Decommissioning Challenges

- 1.

- Safety and Regulations

- 2.

- Public Opinion

6.2. Life Extension and Repowering Scenarios

6.3. Future Research

6.3.1. Pitch Control

6.3.2. Long-Term Corrosion

6.3.3. Digitising O&M

6.3.4. Change in Ownership

7. Conclusions

- It is more than likely to be financially viable to extend life rather than decommissioning.

- Improvements in data capture and the general increase in sensors and observations mean actually operating wind farms are going to get easier as operators will have better knowledge of the issues turbines will face.

- While there might be some mistakes and economic failures in the first-generation farms, these will enlighten the next generations. So, with the lessons learnt, repowering second and third-generation turbines will be easier and allow them to exploit the whole of their 50-year leases.

- Social attitudes to the offshore wind industry will improve markedly if it can demonstrate a greater efficiency in resource and materials utilisation than when the farms were initially installed. While renewable energy has some detractors, over-delivering environmental benefits in one sector will do the whole industry no harm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kraemer, S. Offshore wind farm lifetime extensions: Why the ‘beyond 2020’ energy policy dialogue must start now. New Energy Update 2014. Available online: http://newenergyupdate.com/wind-energy-update/offshore-wind-farm-lifetime-extensions-why-beyond-2020-energy-policy-dialogue (accessed on 6 September 2020).

- Tavner, P.J.; Xiang, J.; Spinato, F. Reliability analysis for wind turbines. Wind Energy 2006, 10, 1–18. [Google Scholar] [CrossRef]

- May, A.; McMillan, D.; Thöns, S. Economic analysis of condition monitoring systems for offshore wind turbine sub-systems. IET Renew. Power Gener. 2015, 9, 900–907. [Google Scholar] [CrossRef]

- Weinzettelab, J.; Reenaasc, M.; Sollic, C.; Hertwich, E.G. Life cycle assessment of a floating offshore wind turbine. Renew. Energy 2009, 34, 742–747. [Google Scholar]

- Caglayan, D.G.; Ryberg, D.S.; Heinrichs, H.; Linßen, J.; Stolten, D.; Robinius, M. The techno-economic potential of offshore wind energy with optimized future turbine designs in Europe. Appl. Energy 2019, 255, 12. [Google Scholar] [CrossRef]

- Ioannou, A.; Angus, A.; Brennan, F. A lifecycle techno-economic model of offshore wind energy for different entry and exit instances. Appl. Energy 2018, 221, 7. [Google Scholar] [CrossRef]

- Mytilinou, V.; Kolios, A. Techno-economic optimisation of offshore wind farms based on life cycle cost analysis on the UK. Renew. Energy 2019, 132, 3. [Google Scholar] [CrossRef]

- Casey, J. Asset Life Extension: Viable in the Long Term for Oil and Gas? 2020. Available online: https://www.offshore-technology.com/features/asset-life-extension-viable-in-the-long-term-for-oil-and-gas/ (accessed on 6 September 2020).

- HSE. Ageing Plant and Life Extension. 2012. Available online: https://www.iosh.co.uk/~/media/Documents/Networks/Group/Offshore/Ageing_plant_and_life_extension.pdf?la=en (accessed on 27 January 2021).

- Mehmanparast, A.; Brennan, F.; Tavares, I. Fatigue crack growth rates for offshore wind monopile weldments in air and seawater: SLIC inter-laboratory test results. Mater. Des. 2017, 114, 494–504. [Google Scholar] [CrossRef]

- DNV GL. Recommended Practice. DNV-RP-C203 Fatigue Design of Offshore Steel Structures. October 2011. Available online: https://wiki.unece.org/download/attachments/26902968/R55_11_03-C203_DNVGL-RP-0005_2014-06.pdf?api=v2 (accessed on 11 March 2021).

- Global Offshore Wind Health and Safety Organisation, 2021. Available online: https://www.gplusoffshorewind.com/ (accessed on 20 February 2021).

- Kaldellis, J.K.; Apostolou, D.; Kapsali, M.; Kondili, E. Environmental and social footprint of offshore wind energy. Comparison with onshore counterpart. Renew. Energy 2016, 92, 543–556. [Google Scholar] [CrossRef]

- Department of Energy and Climate. Decommissioning of Offshore Renewable Energy Installations under the Energy Act 2004—Guidance Notes for Industry. January 2011 (Revised). Available online: https://www.gov.uk/government/publications/decommissioning-offshore-renewable-energy-installations (accessed on 30 January 2021).

- Topham, E.; Gonzalez, E.; McMillan, D.; João, E. Challenges of decommissioning offshore wind farms: Overview of the European experience. J. Phys. Conf. Ser. 2019, 1222, 1–9. [Google Scholar] [CrossRef]

- Smyth, K.; Christie, N.; Burdon, D.; Atkins, J.P.; Barnes, R.; Elliott, M. Renewables-to-reefs?—Decommissioning options for the offshore wind power industry. Mar. Pollut. Bull. 2015, 90, 247–258. [Google Scholar] [CrossRef]

- Gartman, V.; Bulling, L.; Dahmen, M.; Geissler, G.; Köppel, J. Mitigation Measures for Wildlife in Wind Energy Development, Consolidating the State of Knowledge-Part 2: Operation, Decommissioning. J. Environ. Assess. Policy Manag. 2016. [Google Scholar] [CrossRef]

- Fowler, A.M.; Jørgensen, A.M.; Svendsen, J.C.; Macreadie, P.I.; Jones, D.O.; Boon, A.R.; Booth, D.J.; Brabant, R.; Callahan, E.; Claisse, J.T.; et al. Environmental benefits of leaving offshore infrastructure in the ocean. Front. Ecol. Environ. 2018. [Google Scholar] [CrossRef]

- Salvador, S.; Gimeno, L.; Larruga, F.J.S. The influence of regulatory framework on environmental impact assessment in the development of offshore wind farms in Spain: Issues, challenges and solutions. Ocean Coast. Manag. 2018. [Google Scholar] [CrossRef]

- Topham, E.; McMillan, D.; Bradley, S.; Hart, E. Recycling offshore wind farms at decommissioning stage. Energy Policy 2019, 129, 698–709. [Google Scholar] [CrossRef]

- Gonzalez, E.; Ortego, A.; Topham, E.; Valero, A. Is the future development of wind energy compromised by the availability of raw materials? J. Phys. Conf. Ser. 2018. [Google Scholar] [CrossRef]

- Jensen, J.P. Evaluating the environmental impacts of recycling wind turbines. Wind Energy 2019. [Google Scholar] [CrossRef]

- Re-Wind. Available online: https://www.re-wind.info/ (accessed on 6 September 2020).

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef]

- European Technology & Innovation Platform on Wind Energy. How Wind Is Going Circular—Blade Recycling. 2019. Available online: https://etipwind.eu/files/reports/ETIPWind-How-wind-is-going-circular-blade-recycling.pdf (accessed on 20 December 2020).

- Ijsseling, F.P. General guidelines for corrosion testing of materials for marine applications: Literature review on sea water as test environment. Br. Corros. J. 1989, 24, 53–78. [Google Scholar] [CrossRef]

- Melchers, R.E.; Jeffrey, R. Corrosion of long vertical steel strips in the marine tidal zone and implications for ALWC. Corros. Sci. 2012, 65, 26–36. [Google Scholar] [CrossRef]

- North Sea Solutions for Innovation in Corrosion for Energy. State of the Art Study on Materials and Solutions against Corrosion in Offshore Structures. 2019. Available online: http://nessieproject.com/library/reports-and-researches/NeSSIE%20Report%20Study%20on%20Materials%20and%20Solutions%20in%20Corrosion (accessed on 15 March 2021).

- Hilbert, L.R.; Black, A.; Andersen, F.; Mathiesen, T. Inspection and monitoring of corrosion inside monopile foundations for offshore wind turbines. Eur. Corros. Congr. 2011, 3, 2187–2201. [Google Scholar]

- Jeffrey, R.; Melchers, R.E. Corrosion of vertical mild steel strips in seawater. Corros. Sci. 2009, 51, 2291–2297. [Google Scholar] [CrossRef]

- Hilbert, L.R.; Mathiesen, T.; Black, A.R.; Christensen, C.; Technology, F. Mud zone corrosion in offshore renewable energy structures. In Eurocorr 2013; Eurocorr: Lisbon, Portugal, 2013; pp. 1–5. [Google Scholar]

- DNV GL AS. Corrosion protection for wind turbines DNVGL-RP-0416. Recomm. Pract. 2016. Available online: https://rules.dnvgl.com/docs/pdf/DNVGL/RP/2016-03/DNVGL-RP-0416.pdf (accessed on 1 March 2021).

- Jeffrey, R.; Melchers, R.E. The changing topography of corroding mild steel surfaces in seawater. Corros. Sci. 2007, 49, 2270–2288. [Google Scholar] [CrossRef]

- Topham, E.; McMillan, D. Sustainable decommissioning of an offshore wind farm. Renew. Energy 2017, 102, 470–480. [Google Scholar] [CrossRef]

- Climate Change Capital. Offshore Renewable Energy Installation Decommissioning Study. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/608023/900-offshore-renewable-installation-decom.pdf (accessed on 30 November 2020).

- Chamberlain, K. Offshore Operators Act on Early Decommissioning Data to Limit Costs. 2016. Available online: https://analysis.newenergyupdate.com/wind-energy-update/offshore-operators-act-early-decommissioning-data-limit-costs (accessed on 6 September 2020).

- Dodd, J. Decommissioning—Should they stay or should they go? Windpower Monthly, 2015. Available online: https://www.windpowermonthly.com/article/1349270/decommissioning-stay-go (accessed on 17 January 2021).

- Department of Business Energy and Industrial Strategy. Cost Estimation and Liabilities in Decommissioning Offshore Wind Installations Public Report. 2018. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/725316/Cost_and_liabilities_of_OWF_decommissioning_public_report.pdf (accessed on 26 November 2020).

- Siemens Gamesa. Life Extension Program. 2014. Available online: https://www.siemensgamesa.com/-/media/siemensgamesa/downloads/en/products-and-services/services/life-extension/siemens-gamesa-wind-service-life-extension-flyer-en.pdf (accessed on 15 December 2020).

- Mehmanparast, A.; Taylor, J.; Brennan, F.; Tavares, I. Experimental investigation of mechanical and fracture properties of offshore wind monopile weldments: SLIC interlaboratory test results. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2485–2501. [Google Scholar] [CrossRef]

- Schumacher, C.; Weber, F. How to extend the lifetime of wind turbines. Renew. Energy World 2019. Available online: https://www.renewableenergyworld.com/2019/09/20/how-to-extend-the-lifetime-of-wind-turbines/ (accessed on 7 September 2020).

- Norris, R. 30% annual growth in global pipeline of offshore wind energy projects. Renewable UK 2020. Available online: https://www.renewableuk.com/news/518217/30-annual-growth-in-global-pipeline-of-offshore-wind-energy-projects.htm (accessed on 6 September 2020).

- Nathan, S. The Big Project: London Array. The Engineer, 2012. Available online: https://www.theengineer.co.uk/the-big-project-london-array/ (accessed on 6 September 2020).

- Weston, D. London Array Breaks Offshore Production Record. Wind Power Offshore, 2016. Available online: https://www.windpowermonthly.com/article/1378756/london-array-breaks-offshore-production-record (accessed on 6 September 2020).

- Teather, D. Thames Offshore Wind Farm Gets Green Light from Investors. The Guardian, 2009. Available online: https://www.theguardian.com/business/2009/may/12/wind-farm-electricity-london-array (accessed on 6 September 2020).

- Rubert, T.; McMillan, D.; Niewczas, P. A decision support tool to assist with lifetime extension of wind turbines. Renew. Energy 2018, 120, 423–433. [Google Scholar] [CrossRef]

- Shell UK. Limited. Brent Spar Dossier. 2008. Available online: https://www.shell.co.uk/sustainability/decommissioning/brent-spar-dossier/_jcr_content/par/textimage.stream/1426853000847/32a2d94fa77c57684b3cad7d06bf6c7b65473faa/brent-spar-dossier.pdf (accessed on 1 March 2021).

- Astolfi, D.; Byrne, R.; Castellani, F. Estimation of the Performance Aging of the Vestas V52 Wind Turbine through Comparative Test Case Analysis. Energies 2021, 14, 915. [Google Scholar] [CrossRef]

- Astolfi, D.; Byrne, R.; Castellani, F. Analysis of Wind Turbine Aging through Operation Curves. Energies 2020, 13, 5623. [Google Scholar] [CrossRef]

- Opie, R. Pitch Control Critical for Wind Power. MachineDesign 2018. Available online: https://www.machinedesign.com/mechanical-motion-systems/article/21836463/pitch-control-critical-for-wind-power. (accessed on 6 September 2020).

- Igwemezie, V.; Mehmanparast, A.; Kolios, A. Current trend in offshore wind energy sector and material requirements for fatigue resistance improvement in large wind turbine support structures—A review. Renew. Sustain. Energy Rev. 2016, 101, 181–196. [Google Scholar] [CrossRef]

- Igwemezie, V.; Mehmanparast, A.; Brennan, F. The influence of microstructure on the fatigue crack growth rate in marine steels in the Paris Region. Fatigue Fract. Eng. Mater. Struct. 2020, 2416–2440. [Google Scholar] [CrossRef]

- Igwemezie, V.; Dirisu, P.; Mehmanparast, A. Critical assessment of the fatigue crack growth rate sensitivity to material microstructure in ferrite-pearlite steels in air and marine environment. Mater. Sci. Eng. A 2019, 754, 750–765. [Google Scholar] [CrossRef]

- Jacob, A.; Mehmanparast, A.; D’Urzo, R.; Kelleher, J. Experimental and numerical investigation of residual stress effects on fatigue crack growth behaviour of S355 steel weldments. Int. J. Fatigue 2019, 128, 105196. [Google Scholar] [CrossRef]

- Igwemezie, V.; Mehmanparast, A. Waveform and frequency effects on corrosion-fatigue crack growth behaviour in modern marine steels. Int. J. Fatigue 2020, 134, 105484. [Google Scholar] [CrossRef]

- Grey, L. How digital technologies can help with unplanned wind turbine repairs. NS Energy 2020. Available online: https://www.nsenergybusiness.com/features/wind-turbine-repairs-digital-automation/ (accessed on 6 September 2020).

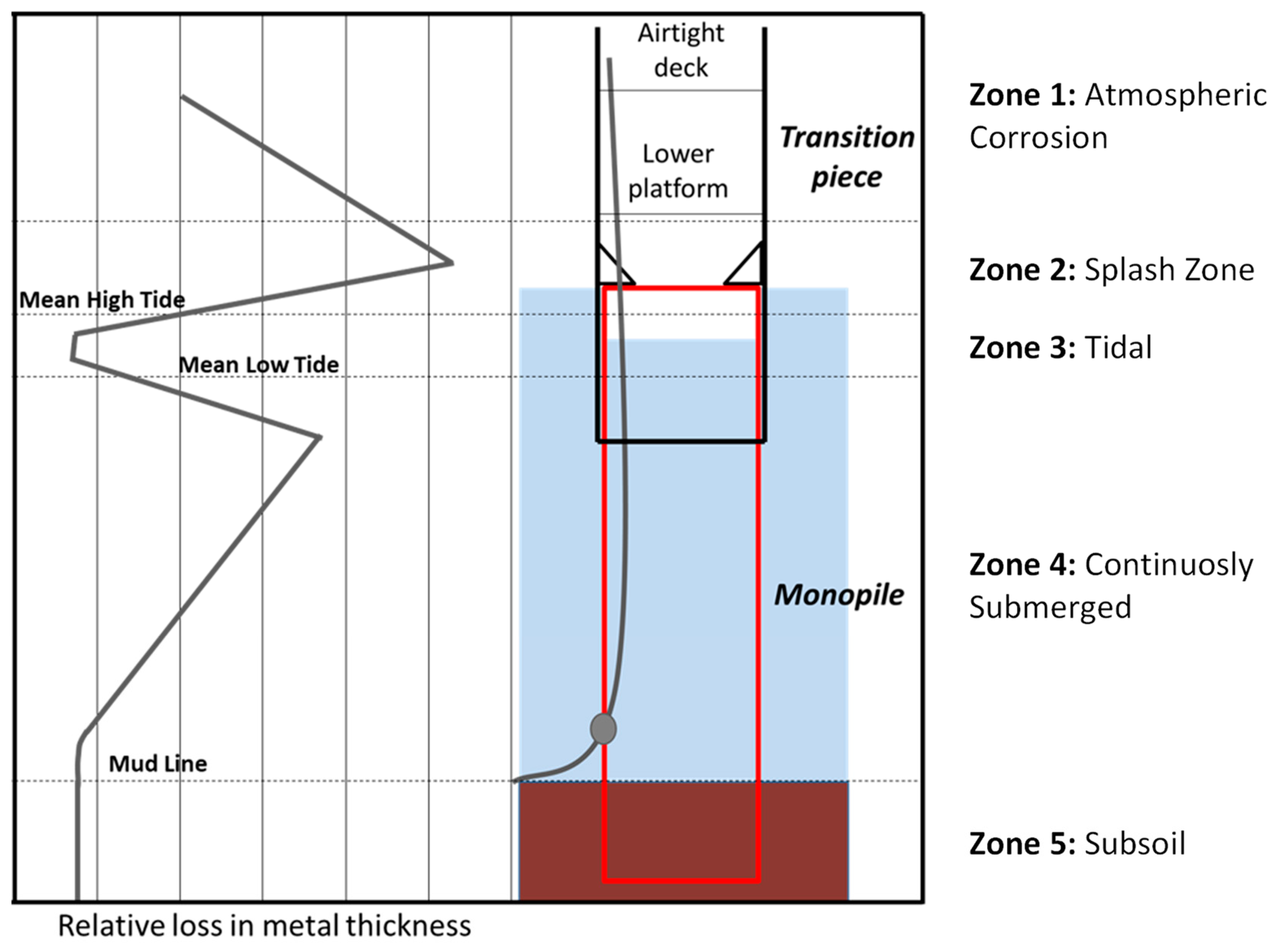

| Zone 1 Atmospheric corrosion | The atmospheric zone has the least amount of corrosion due to the only contact with seawater coming in the form of droplets from seawater spray, the protection method is a coating on the outside of the turbine. Corrosion rates 0.050–0.075 mm/year [28]. |

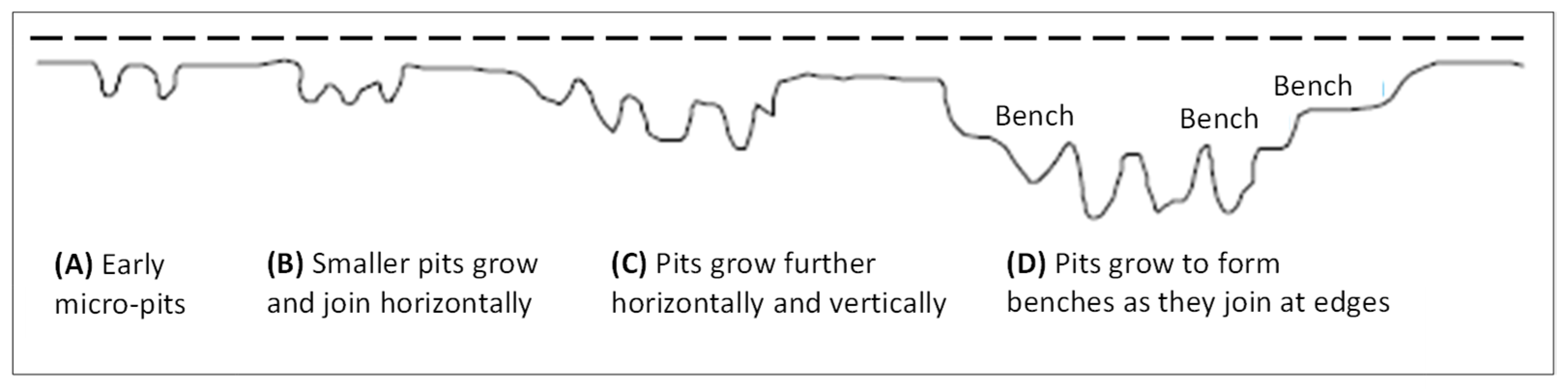

| Zone 2 Splash zone | In the splash zone, the corrosion effects are amplified compared to that of the atmospheric zone. The waves continually splashing on the surface causes there to be a continual wetting and then removal of water to allow for the movement of ions. This allows for deep pits to form in this area if left unprotected. Heavier external protection would be used in the area but internally there is usually no protection and corrosion is allowed due to the less of a wave effect internally. Corrosion rates 0.20–0.40 mm/year [28]. |

| Zone 3 Tidal zone | The tidal zone has a mix between both Splash and Submerged zone. The wetting and drying effect aren’t as aggressive here with it only happening as the tide rises and falls. This causes there to be an overall lower rate of corrosion but there can be more aggressive local corrosion spots. The cathodic protection is designed to help this area when in high tide. Corrosion rates 0.05–0.25 mm/year [28] with localised corrosion rates up to 0.50 mm/year [29]. |

| Zone 4 Submerged zone | When submerged, the main corrosion protection method is the use of cathodic protection. This has to be changed regularly and maintained. This is often used internally but might not be checked and changed as regularly, with some corrosion allowance. Pits in immersed zones are usually broad and shallow with growth rates 0.20–0.30 mm/year [30]. Uniform corrosion rates 0.10–0.20 mm/year [28]. |

| Zone 5 Buried zone | When looking at the structure underneath the seabed it can be assumed that there is low uniform corrosion but there can be pockets of localised corrosion around the mudline. While it is not yet decided in the industry what is the best course of protection for buried areas, cathodic protection is most likely the best though [31]. Corrosion rates of 0.06–0.10 mm/year are expected [28], however [29] reports show possible pitting rates up to 0.25 mm/year. |

| Wind Farm/Specifications | Gunfileet Sands | Thanet | Lincs | Ormonde | Sheringham Shoal | Greater Gabbard | Gwynt Y Mor |

|---|---|---|---|---|---|---|---|

| Commission Year | 2010 | 2010 | 2012 | 2012 | 2012 | 2013 | 2014 |

| Capacity (MW) | 172.8 | 300 | 270 | 150 | 316.8 | 504 | 576 |

| Distance (km) | 8.5 | 11.3 | 8 | 9.5 | 17–23 | 26 | 13–15 |

| Depth (m) | 2–15 | 20–25 | 8–18 | 17–22 | 15–23 | 20–32 | 12–34 |

| Seabed Material | Partially lithified cross-bedded sands | - | Glacial till, cretaceous chalk * | - | Soft clay, chalk | Silty clay, clayey, sandy silts, sand | Granular sediments, sand, glacial till |

| Turbines (MW) | 48 × 3.6 (SWT-3.6-107) | 100 × 3 (V90-3) | 75 × 3.6 (SWT-3.6-120) | 30 × 5 (5M) | 88 × 3.6 (SWT-3.6-107) | 140 × 3.6 (SWT-3.6-107) | 160 × 3.6 (SWT-3.6-107) |

| Weight (t) | 475 | 396 | 435 | 661 | 475 | 475 | 475 |

| Expected Life (years) | 20 | 20 × 2 | 20 × 2 | - | 20 × 2 | 25 × 2 | (20–23) |

| Meteorological Mast and Foundation Type | Monopile | Monopile | Monopile | - | - | Monopile | Jacket |

| Weight Transition Piece (t) | 230 | - | 290 | 500 | 200 | 300 | - |

| Foundation Type | Steel Monopile: Cut (1 m) | Steel Monopile: Cut (2 m) | Steel Monopile: Cut (1 m) | Steel Jacket: Lifted + Cut (1 m) | Steel Monopile: Cut | Steel Monopile: Cut | Steel Monopile: Cut |

| Weight (t) | 225–423 | - | 225–320 | 250 | 370–500 | 660 | 200–700 |

| Foundational Depth into Seabed (m) | 27–38 | - | 15–30 | - | 23–37 | 30 | - |

| Offshore Substation | Monopile Cut (1 m) | Jacket lifted + Piles Cut (2 m) | Jacket lifted + Piles Cut (1 m) | Jacket lifted + Piles Cut (1 m) | Monopile Cut | Jacket lifted + Piles Cut (1 m) | Jacket lifted + Piles Cut (1 m) |

| Weight: Topside, | 1315, 414 | 1460, 820 | 2250, 970 | 900, 540 | 875, - | 500, 850 | 1415, 400–1000 |

| Scour Material Interray Cables | Left in situ Copper 33 kV: Left*b | Copper 33 kV: Left (buried 1–2 m) | Left in situ Copper 33 kV: Left | Copper 33 kV: Left (buried 0.6 m) | Left in situ Copper 36 kV: Left | Left in situ Copper 33 kV: Left (buried 1–1.5 m) | Left in situ Copper 33 kV: Left |

| Total Length (km), Section (mm2) | 36, 500/150 | 65, 95/300/400 | 185/630 | 27, 150/300/500 | 3, 400/185 | 173, 150 | 148, 185/500 |

| Export Cables | Copper 1 × 132 kV: Left (buried 2 m) | Copper 2 × 132 kV: Left (buried 1–2 m) | Copper 2 × 132 kV: Left (buried 1–3 m) | Copper 1 × 132 kV: Left (buried 2 m) | Copper 2 × 145 kV: Left (buried 1 m) | Copper 4 × 132 kV: Left (buried 1–1.5 m) | Copper 4 × 132 kV: Left (buried 0.5–1 m) |

| Total Length (km), Section (mm2) | 9.3, 800 | 51, 1000/630 | 96, 630 | 43, 800 | 44, 630/1000 | 4 × 45.5, 800 | 85.2, 500 |

| Decommission Time (days) | 100 | 270 | 1339 | 570 | 1350 | 260 | 730 |

| Costs (£/MW) | - | 40,000 | 101,200 | - | 31,900 | - | 111,000 |

| Variable | Symbol/Calculation | Value |

|---|---|---|

| System Specifications | ||

| Rated size of Wind Farm (MW) | A | 630 |

| Capacity Factor | B | 45.300% |

| Planned Repowered (MW) | C | 1100 |

| Degradation rate per year | D | 0.0% |

| Energy Output (Rated) MWh per year | E = B × 365 × 24 × A | 2,500,016.4 |

| Associated Costs | ||

| Cost per Watt of System installed (£/W) | F | 3 |

| Total installed cost (Million £) | G = F × A × 1,000,000 | 1890 |

| Insurance (1%) (Million £) | H = 0.01 × G | 18.9 |

| Initial Annual Maintenance Cost (3%) (Million £) | I = 0.03 × G | 75.6 |

| Annual increase in Maintenance Cost | J | 3.00% |

| Other Annual Operation Cost | K | £- |

| Other Annual Maintenance Cost | L | £- |

| Cost Per Watt of Repowering (£/W) | M | 1.5 |

| Repowering Cost (Million £) | N = M × C × 1,000,000 | 1650 |

| New Install Cost (Million £) | O = F × C × 1,000,000 | 3300 |

| Financing | ||

| Annual discount rate for present-value calculations | P | 3.0% |

| Interest rate for loan | Q | 3.0% |

| Down payment (initial capital) | R | 1890 |

| Decommissioning Cost (Million £) | S = A × 400,000 | 252 |

| New Install Decommissioning Cost (Million £) | T = C × 400,000 | 440 |

| Loan Term (Years): | 20-Year | 25-Year | 30-Year | 40-Year | 40-Years (20 Years + 20 Years Reinstalled) | 40-Years (20 Years + 20 Years Repowered) |

|---|---|---|---|---|---|---|

| LCOE (£GBP/MWh): | £ 93.27 | £89.67 | £88.30 | £89.07 | £71.82 | £62.03 |

| Life Extension Cost (20+ years) (£GBP/MWh): | N/A | £38.81 | £70.60 | £79.80 | £59.34 | £44.15 |

| Total project cost (current pounds): (Million £) | 4379 | 5220 | 6181 | 8536 | 13,121 | 11,219 |

| Total project cost (Projected Value): (Million £) | 3702 | 4128 | 4547 | 5370 | 7729 | 6676 |

| Total project cost With Decommissioning (Projected value): (Million £) | 3954 | 4128 | 4799 | 5622 | 8169 | 6676 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pakenham, B.; Ermakova, A.; Mehmanparast, A. A Review of Life Extension Strategies for Offshore Wind Farms Using Techno-Economic Assessments. Energies 2021, 14, 1936. https://doi.org/10.3390/en14071936

Pakenham B, Ermakova A, Mehmanparast A. A Review of Life Extension Strategies for Offshore Wind Farms Using Techno-Economic Assessments. Energies. 2021; 14(7):1936. https://doi.org/10.3390/en14071936

Chicago/Turabian StylePakenham, Benjamin, Anna Ermakova, and Ali Mehmanparast. 2021. "A Review of Life Extension Strategies for Offshore Wind Farms Using Techno-Economic Assessments" Energies 14, no. 7: 1936. https://doi.org/10.3390/en14071936

APA StylePakenham, B., Ermakova, A., & Mehmanparast, A. (2021). A Review of Life Extension Strategies for Offshore Wind Farms Using Techno-Economic Assessments. Energies, 14(7), 1936. https://doi.org/10.3390/en14071936