Abstract

The article presents the methodology of isolating aperiodic phenomena constituting the basis of the energy balance of vehicles for the analysis of electromobility system indicators. The symptom observation matrix (SOM) and experimental input data are used to analyze periodic phenomena symptoms. The multidimensional nature of the engine efficiency shortage has been well defined and analyzed in terms of errors in the general model using neural networks, singular value decomposition, and principal component analysis. A more difficult task is the analysis of a multidimensional decision-making process. The research used a data fusion method and the concept of symptom reliability, which is applied to the generalized failure symptom obtained by applying the singular value decomposition (SVD). The model research has been based on the gray system theory (GST) and GM forecasting models (1,1). Input data were obtained from the assessment of driving cycles and analysis of the failure frequency for 1200 vehicles and mileage of 150,000 km. Based on this analysis, it can be concluded that with the current infrastructure and operating costs and the frequency of failure of PHEV and BEV drives, ICEV vehicles are unrivaled in terms of their operating costs.

1. Introduction

Currently, to reduce the environmental impact of the transport sector, governments and institutions have been introducing increasingly stringent regulations and limits on pollutant emissions [1,2]. To meet such demanding emission standards and reduce fuel consumption while maintaining the required durability of the drive unit, car manufacturers must develop more and more advanced drive systems and energy conversion systems. This is followed by an increasing number of unforeseen aperiodic factors of a stochastic nature that affect the long-term cost of the solution used. Due to the high cost of batteries, electric vehicles are still not able to fully meet the requirements [3,4,5]. The current energy policy objectives result from a correlation between limitations due to the depletion of natural energy resources, the risk of environmental pollution, and the strategy of creating an infrastructure that allows for the efficient use of electromobility systems. Energy is an added value that has various forms; it is a function of the state and thermodynamic potential, which describes the interaction of physical objects, physical and chemical transformations, and processes occurring in nature. The prospect of the conventional energy reserves being exhausted and the restrictive environmental protection measures have boosted the interest in alternative energy sources used in internal combustion engine vehicles (ICEV). The efficient use of alternative energy sources is hampered by technological, economic, political, and legal constraints. Today’s petroleum fuels are used in ICEVs, e.g., gasoline and diesel (fossil fuels). The conversion of the chemical energy in petroleum-based fuels into thermal energy is associated with a harmful impact on the environment, and forecasts for this form of energy resources necessitate the development of alternative fuels that can be used in battery electric vehicles (BEV) and plug-in hybrids (PHEV). Energy is an indispensable factor that determines the chain of obtaining and processing power for specific technologies. Since petroleum-based fuels belong to a group of nonrenewable energy sources, this necessitates their limited use in vehicle propulsion. The extraction, processing, and transport of petroleum fuel for internal combustion engines have a massive impact on the natural environment. Previous research into the use of alternative fuels as the primary form of energy and an efficient replacement for conventional fuels have not produced conclusive results. This is determined by energy conditions and technology that converts a given state of life into the required mechanical work necessary to achieve the desired range and dynamics of passenger vehicles, trucks, and public transport vehicles.

The current studies do not promote the adoption of an unambiguous substitute for petroleum fuels for vehicle propulsion following design parameters, i.e., vehicle range and dynamics, the emission of harmful combustion substances, and the economic factors. Just like gasoline and diesel oil, the currently available alternative fuels, e.g., liquefied petroleum gas (LPG), despite their fairly common use, are a petroleum products. Another example is natural gas, the resources of which are also limited due to the irreversible course of the combustion process. Hydrogen obtained from water through electrolysis is used as an energy source for fuel cells used in electric motors. The introduction of hydrogen propulsion in traction vehicles brings advantages resulting from the overall efficiency of the fuel cell (more generous than in internal combustion engines), fuel energy efficiency (translating into range when compared to vehicles with tanks of equal volume), and environmentally neutral emission. From an economic point of view, alternative fuels from biological products, e.g., ethanol, biodiesel, are a good energy source, limited only by the cultivation capacity of the raw material. Due to the limitation of land available, the demand for biodiesel as a replacement for conventional fuel cannot be met. The use of alternative fuel vehicles (AFV) has been followed by the introduction of a primary terminological differentiation: dedicated—vehicles powered by one energy source, having low emissions to the optimization of the engine operating parameters; dual-fuel—vehicles that use conventional fuel and alternative fuel as energy sources; bifuel—a two-tank car running on traditional fuel (gasoline or diesel) and, depending on the type of fuel system (propane or natural gas), using a single or combined cycle switched by the driver or an automatic control unit based on an algorithm (emission optimization point and vehicle economy); flex-fuel—single-tank vehicles fueled by petrol, methanol or ethanol, which form a homogeneous mixture.

The demand for conventional energy has forced the development of innovative vehicle designs based on alternative sources that promote the correlation between the following parameters: fuel consumption, the emission of toxic exhaust gas components, and the comfort of the vehicle movement. Energy consumption depends mainly on the vehicle’s energy demand, the efficiency of its drive system, and the energy source. In 2030, on the North American market, hybrid cars are expected to account for 10% of the total number of cars. Hybrid and electric motors will create significant competition for internal combustion engines on the European market. Sales of hybrid and electric engines in OECD countries, mainly Australia, New Zealand, and Japan, will secure the leading share of these countries in the automotive industry in the coming years. According to the 2030 forecast, the US market demand for fossil fuel (petroleum derivatives) will remain at a steady level. Internal combustion engine vehicles show a limited capacity to reduce fuel consumption, due to the Euro 6 emission standard for LDVs. Combustion taking place in the cylinder working space translates into the engine’s efficiency and the emission of harmful combustion products. These are unavoidable processes that accompany energy conversion in internal combustion engines.

Fuel cell hybrid electric vehicles are fitted with fuel cells as a source of power. It enables manufacturers to switch from using a piston internal combustion engine and exclude fossil fuels (petroleum derivatives). The hydrogen energy contained in the fuel cells is sufficient for the electric motor to operate. An electric vehicle generates zero emissions of harmful combustion products. Alternative fuels, used as a source of energy to propel vehicles, enable the reduction of substances toxic to the environment to a predefined level. By analyzing driving and energy properties in electric cars, it is possible to determine the operating conditions to maintain a sufficient durability and economic aspects of vehicles equipped with a given drive unit.

The currently adopted energy indicators determine the nature of the experimental research. These include the vehicle range at selected constant speeds depending on the vehicle class or capacity consistent with a speed profile, including the required phases, e.g., acceleration, motion at a constant speed and constant load, deceleration during braking, and standstill (static condition). In electric vehicles, the energy stored in electrochemical batteries may cause well-known repercussions. Scheduled test conditions are determined in terms of the energy balance. The parameters specific to a vehicle model, such as the total weight, the front surface (aerodynamic model), the rolling resistance coefficients, the efficiency of the drive unit and the entire drive train, and other electronic systems of the vehicle, are used to determine the energy status of the car. Many models undergo energy analysis to assess the effective use of the energy source for propulsion. Much attention is also paid to the vehicle’s range, the technical possibility of accumulating energy, and the efficiency of its recovery, e.g., the recovery of kinetic energy during braking. As it turns out, relatively little attention is paid to aperiodic factors of a stochastic nature, contributing to the reduction in the vehicle operating cost. In the case of electric and hybrid vehicles, these are the main factors related to the unforeseen energy capacity loss of the primary energy source, failures of the energy management system pieces, damage to the drive of smaller components, changes in the driving conditions when traveling long-distance in unknown territory. Then, the values recorded by the energy management system are unsuitable for determining the future range of the vehicle. Other factors include the limitations of the charging technology and the availability of spare parts in the event of minor driveline failures. It should be remembered that in cars with an internal combustion engine, unforeseen external losses of, for example, the drive system or other energy management system components can be quickly rectified due to the well-developed service station networks and the availability of spare parts. The same applies to the availability of power supply stations for a given energy system.

The basic limitation for BEVs is their energy source, which in most cases is a set of electrochemical cells, e.g., lithium-ion cells. Their durability over a longer period of operation is insufficient, the charging time is very long, and the purchase cost is very high in relation to the energy benefits [6,7,8]. Additionally, many design measures are required to ensure maximum durability for various drive system operating conditions, energy load resulting from energy consumption by electrical equipment, and the nature of driving over a given distance [9,10]. Apart from these fundamental disadvantages of BEVs, there are also difficulties related to the progress in the development of the fast charging infrastructure in rural areas and smaller towns [11,12,13]. Therefore, these difficulties make long distances traveling in nonurban areas with limited access to the charging infrastructure reduce the energy and economic viability of BEVs [14,15]. In this case, it is necessary to apply appropriate management strategies while introducing BEVs to the automotive market to ensure the maximum efficiency of the electromobility system [16,17]. To reduce certain limitations related to driving system solutions, the use of the PHEV, which combines BEV and ICEV systems, should be considered during the transition period [18,19,20]. The ability to improve the overall efficiency of ICEV’s drive units is minimal. Therefore, it is not possible to achieve a significant reduction in fuel consumption, i.e., 20–30%, assuming the necessary power and torque of the engine [21,22,23]. The problem becomes more complicated in the case of large internal combustion engines designated for trucks and buses, since they require engines of significantly increasing and modified mechanical efficiency to reach the desired reliability and structural strength of the main kinetic unit. The combination of the two power sources in PHEV vehicles may contribute to the vehicle’s range [24,25]. This will significantly extend the time needed for BEVs to adapt to the development of the charging infrastructure in nonurban areas. In real terms, this allows the vehicle range to be increased from about 70–100 km to 600 km [26,27,28], and maintain mobility in case batteries are completely discharged, and the electric drive unit is excluded [29,30,31]. To determine appropriate energy balances, many complex algorithms for forecasting the potential energy consumption are used. They take into account the route to be covered based on satellite navigation [32,33,34]. Such energy management models and strategies are used in various vehicle energy management concepts [35,36,37]. Due to the complexity of the system, the capabilities vary and allow different effects to be achieved depending on route planning and the availability of charging stations [38,39,40].

Modern PHEVs with an electrochemical energy source are still equipped with an internal combustion engine, electric motor, electric generator, and an electrochemical energy source. They can work in series and in parallel. In a series configuration, the total energy of the internal combustion engine with a generator is converted into electric energy, which determines the mechanical work of the drive unit. The piston internal combustion engine drives a direct current or alternating current generator (integrated with rectifier) [41,42]. An automatic transmission coupled with an electric motor drives the wheels. The system consists of primary and secondary energy sources. The power balance in a series configuration distinguishes between two operating states. An energy shortage in an electrochemical energy source is compensated by the internal combustion engine energy surplus resulting from the combustion engine’s work schedule. Internal combustion engine stabilizers force its operation at constant useful power adjusted to the energy balance. This determines the optimal overall efficiency of the internal combustion engine [43,44,45].

Kinetic energy is recovered when braking enables the energy necessary to charge the secondary source with only the electric motor working as a generator. In a parallel hybrid system, electrical energy, transferred from mechanical work to the crankshaft of the internal combustion engine, is converted into energy supplying the secondary energy source and transmitted through the mechanical units to the driving wheels. The drive train clutch enables the separation of the electric and combustion engines. The automatic transmission in the power unit enables the connection in parallel of the electric and combustion engines. The torque measured on the motor output shafts is the sum of the unit torques. When the drive wheels are heavily loaded, the internal combustion engine is supported by an electric motor that uses energy from an electrochemical source. When the nominal useful power of the internal combustion engine exceeds the capacity of motion resistance and the braking mode is applied in a vehicle, the electric motor works as a generator. The main criterion determining the use of a given design solution in a PHEV with electric electrochemical energy accumulation is to fulfill conditions for optimal energy accumulation resulting from the excess useful power of the internal combustion engine and its healing, i.e., secondary recovery of the energy in vehicles with electric or hybrid drive by using an electric motor as a generator and the conversion of the kinetic energy into electricity supplying an electrochemical energy source. The use of secondary energy generation to drive the vehicle significantly increases its overall efficiency. The research carried out as part of the energy accumulation and recuperation project has helped to develop prototype solutions, which have been then implemented into serial production. The hybrid electrochemical drive system in PHEVs that uses a secondary mechanical or hydraulic energy source constitutes a separate group of energy accumulation systems cooperating with the electrochemical energy source.

In traction vehicles, the primary energy source is an internal combustion engine (ICE), from which the chemical energy from the combustion process is converted into mechanical work. The specific mass-energy of the fossil fuel (gasoline) is 9000 J/kg. The efficiency of its use depends on the overall traction efficiency of a piston internal combustion engine and the range of the crankshaft rotation speeds. The combustion engine used in conventional vehicles is characterized by the low overall efficiency of the primary energy source. In hybrid systems, the combustion engine does not require changes in the rotation speed of the crankshaft throughout the vehicle operation mode when generating a constant rated power. The combustion engines used in hybrid systems must have a low weight and increased durability, as well which as their rated power needs to exceed the power demand of a given vehicle. Based on the heat strength tests of the engine materials, it has been found that spark ignition engines, compression ignition engines, rotary engines with a rotating piston, Stirling engines, and gas turbine engines meet the requirements of an electromechanical hybrid drive in PHEVs.

The preliminary analytical studies of the thermal engine as a primary source of energy in LDVs with a hybrid drive have fully confirmed that the original internal combustion engine can fulfill all of the operating conditions. Due to the durability required (piston–rings–cylinder assemblies), a spark-ignition internal combustion engine cannot work continuously while transferring useful work to the crankshaft with loads equal to the rated power more significant than 50%. To rectify the above, it is necessary to improve the kinetic properties of the main engine mechanisms. The optimization of these parameters determines the improvement of the overall efficiency of the engine. The ignition internal combustion engines used in PHEVs need to have a regular output of their rated power at a constant load of 50% to 80% of the maximum capacity. Considerable resistance to wear and tear during the combined operation of the LDV and PHEV drives is characteristic of compression–ignition combustion engines due to their reduced rotation speed of the crankshaft and the combustion process. This comparison shows a specific limitation that depends on the weight of the compression–ignition internal combustion engine, curb weight, which is considerably larger than in spark-ignition internal combustion engines. Rotary combustion engines have the lowest curb weight but a significantly lower overall efficiency. Stirling engines and gas turbine engines require higher quality materials due to thermal loads and operating conditions. This excludes their service as the primary source of energy. The heat engine in traction LDVs with a series connection of a hybrid electromechanical PHEV drive is connected to a direct or alternating current generator. Mechanical work is transformed into electricity in an electric generator. The energy is transferred to the alternator, the second primary energy source in the internal combustion engine assembly.

Regarding the method of excitation, direct current generators can be divided into individually excited and self-excited (shunt, series, and shunt–series). In the first assembly, the excitation current is taken from the secondary energy source, and in the second, from the armature circuit. The demand for mechanical work is proportional to the electrical output power, which is determined by the generator’s efficiency. Losses of the electric energy output result from internal friction in the bearings, conditioned by the construction of the reception unit (electric energy) or the rings. There may also be winding losses, hysteresis losses (magnetization losses), and rectifier losses. The combination of the internal combustion engine with the PHEV hybrid drive of LDV traction vehicles and a variety of energy sources—diesel engines, ZI engines with a flywheel, gas turbines, batteries, and ultracapacitors—may contribute to the compliance with the exhaust gas toxicity standards for ULEV (Ultra Low Emission Vehicle) and SULEV (Super Ultra Low Emission Vehicle).

Most of the complex systems dealing with energy consumption and the development of the energy–mobility infrastructure of motor vehicles, which are considered for aperiodic reasons, e.g., unforeseen damage to drive systems contributing to the loss of vehicle range, are based on incomplete and uncertain information about their structure and behavior. The methods used for their analysis and evaluation (probability, fuzzy and coarse sets), can be extended with the gray system theory (GST). The advantage is that the method does not require many assumptions about the size and distribution of samples relevant for the abovementioned methods, and the minimum number of data that justifies the use of the GST (n ≥ 4). By using the technique, one can predict the future behavior of the system, mainly the occurrence of unforeseen phenomena for a given power source, assess the interdependence of the observation vectors, and evaluate the effectiveness of reactions to possible situations and make optimal decisions, as well as group them and study them. This allows for a realistic comparison of the grounds for using specific systems depending on several side factors not directly related to the promised benefits of a given solution. It also enables the analysis of the stochastic parameters that affect the economic aspects of data application in terms of the territorial nature and available infrastructure supporting the operation and service of ICEV, PHEV, and BEVs.

To optimize energy consumption in hybrid PHEV and BEV electric powertrains, several complex control strategies have been developed. However, not all of these models consider aperiodic phenomena affecting the energy balance in propulsion engines in regional electromobility systems. In such a model, engine efficiency indicators should also be introduced, based on the energy balance regarding the quantity and efficiency of the resources required. The adopted method enables the evaluation of the scale of the compromise between the effective range with the primary batteries, which are fully charged, the payload and the required minimum amount of vehicle resources to create the necessary infrastructure. If the operational parameters of BEVs are similar to those of vehicles powered by internal combustion engines (ICEV), a complete analysis of the vehicle’s energy balance is an effective solution. By adopting the economic compromise criterion, it is necessary to establish whether the increase in the capacity of the main corresponds to the expansion of the fast charging infrastructure in terms of the stochastic operation of the drive units. Intelligent systems analyzing the engine energy balance based on advanced algorithms can contribute to the effective use of electromobility systems not only in urban but also nonurban systems, where the vehicle range is more important.

2. Materials and Methods

2.1. Resistance to Motion in Classic ICEVs, PHEVs, and BEVs in Terms of Energy Consumption by Selected Operation Schedules—Gray System Theory (GST)

The LDV traction vehicle traffic within a metropolitan agglomeration and in the undeveloped area diversifies the actual speed profile. Operating conditions of the drive system determined by the period and frequency of starting and braking phases and standstill periods, are stochastic in terms of the vehicle’s energy demand. This makes it difficult to determine resistance to motion data throughout the drive cycle for different drive units. Each drive system is characterized by various operating conditions. It is challenging to adjust them during one cycle due to energy consumption and the maximum total efficiency of the vehicle. Additionally, there are operational and utility factors of an aperiodic nature, the determination of which can only be performed using predictive methods. For this purpose, one can use a computational system based on the GST, divided into five phases: generation and smoothing of observation vectors, impact analysis, gray cluster analysis, forecasting, and analysis and decision making. The Gray System Theory (GST) was developed in China in 1982. It was created by Juo-Long Deng, a professor at Huazhong University, who presented the concept in a publication [46]. Complex systems encompass different types of notions, such as matter, energy, and information [47,48,49]. To a large extent, their organization is hierarchical, and often heterarchical, where each of the subassemblies are linked to one another and constitute a compatible chain of cause-and-effect relationships. Then, the positive synergy of the activity can be fully manifested. Therefore, we are talking about a wide class of systems, from complex systems in the entire cycle of service, operation, design, and reliability of a vehicle to socio-engineering systems with a several subsystems, e.g., impact of the nature of infrastructure in a given territory on user preferences as to the nature of the speed profile and the scale of traffic resistance [50,51,52].

2.2. Comparison of Drive System General Efficiency and the Character of a Speed Profile

In classic ICEVs, the internal combustion engine operates in a variable, indefinite range of changes at rated power, the rotational speed of the crankshaft, and general efficiency. The kinetic energy released during the deceleration of a vehicle (braking) determines the decrease in the overall efficiency of the classic drive system. The motion of a traction vehicle expressed in the EPA-Highway schedule occurs in constant operating conditions of the drive system. The operating conditions of the ICEV driveline with the LDV variable speed profile significantly reduce the efficiency of the system. This is similar to the use of combustion engines in PHEVs. The research on the balance of LDV traction traffic shows the benefits of an urban speed profile in most areas where motor vehicles are used for passenger transport. The situation is changing in the case of heavy vehicles operated in nonurban areas. There, operating conditions change dramatically. In this timeframe, ICEVs show certain overall advantages. It is worth mentioning that the operational capacity is largely primarily influenced by the support infrastructure in PHEVs and BEVs in the country or the region. Based on a speed profile adapted to the operating conditions of a the vehicle, it is possible to determine the value of the energy generated during the vehicle’s motion that can be accumulated in a secondary energy source. Apart from losses due to air and motion resistance, ideal conditions for the recovery of braking energy determine the overall accumulation of power between the initial speed and the end of the decelerated motion. The urban driving schedule enables the collection of power by recuperating the kinetic energy of the vehicle in the deceleration of the car and taking over the excess of the instantaneous engine rated power over the required output power necessary for the movement of the driving wheels. Due to the way energy is accumulated in secondary sources in traction vehicles with PHEV drive, such vehicles require electrochemical, kinetic (mechanical), hydropneumatic accumulators, and batteries, and ultracapacitors. The efficiency of energy transmission and transformation systems that cooperate with batteries (secondary energy source) is not constant and depends on energy losses.

In LDV traction vehicles, moving at a low speed, the combustion engine is connected to the wheel drive via a generator and an electric (drive) motor. The increase in demand for power applied to driving wheels, which exceeds the rated capacity of the internal combustion engine, is supplemented by energy from the secondary energy source. The surplus energy generated by the internal combustion engine is used to increase energy in the secondary energy source. By introducing a stabilizer into the assembly of an internal combustion engine, it is possible to obtain a constant power output at a constant rotation speed of the crankshaft. Optimal operating conditions of a combustion engine enable a reduction in fuel consumption (i.e., more effective use of the chemical energy contained in the fuel by improving the overall efficiency of the machine). The hybrid drive in series with the PHEV series is more economical than in a parallel arrangement at an unfavorable power-to-weight ratio. The internal combustion engine in series with the PHEV hybrid drive operates in a narrow range of rotational speeds, which improves the stability of the rotational speed and load changes during the assembly operation. This reduces the emission of toxic combustion products. The traction range of the LDV in serial production is much more extensive, provided the dimensions of the interior combustion engine and the power generator are small. For BEVs, there is no internal combustion engine assembly, but only electric drive components such as propulsion motors, power converters, and an energy source. A significant disadvantage of this solution is its low energy efficiency and significant production and operation costs. In case of any failure of the auxiliary equipment used to control the process of charging and propulsion in PHEVs and BEVs, the cost-effectiveness of introducing the system as a replacement for ICEV vehicles is significantly reduced and in the case of traffic in extraurban mode becomes uneconomical.

The only advantage of this solution is the protection of the natural environment. The presented relationships make it difficult to determine the parameters that influence the assumed conditions, i.e., the range of a vehicle, economy, durability, and the optimal overall capacity. The operating needs and the requirements for LDV traction vehicles powered by an alternative energy source must also take into account driving comfort within a given schedule resulting from the intended use of the car. Regardless of its arrangement (parallel or series), a heat engine can operate at reduced consumption of chemical energy (fuel). The target parameter can be met only by the proper selection of the energy parameters, based on assessing the energy consumption and efficiency of the mechanical–electrical assembly. A critical parametric condition for the bodies of the presented hybrid PHEV systems with electric electrochemical energy accumulation provides the possibility of obtaining energy from excess power of the internal combustion engine and regenerative braking. This enables the effective use of the mechanical energy generated by the internal combustion engine based on inner energy transformation determined by general efficiency. The value of the average energy consumption of the vehicle determines its fuel consumption. This enables the optimization of the traveling profile (speed profile), while taking into account partial phases of movement, e.g., acceleration, training at a constant speed, and deceleration, depending on the nature of a given area. The determination of the exact value of the vehicle’s energy consumption with a minor deviation (transient conditions) determines the effectiveness of forecasting and designing these systems. The fuel consumption of the car in real motion and its energy consumption, supported by the general adaptive characteristics of the engine, makes it possible to select the optimal operating conditions for the PHEV hybrid system. The increase in the overall efficiency of the electromechanical drive unit ensures a weight reduction of the secondary energy source (electrochemical batteries) and an increase in the vehicle range, while maintaining constant dynamics of the vehicle’s movement. The main disadvantages of modern electromechanical hybrid drives are the low durability of the batteries depending on the technology, the method of energy resource control, and the frequency of charging. The increase in the overall efficiency and power of the combustion engine–power generator unit enables a weight reduction of the secondary energy source. The efficiency of the LDV traction vehicle, which uses an electrochemical battery to accumulate the energy necessary to increase the vehicle’s range and increase the power with a temporary load increase over the electric motor power, strictly depends on the number of cells of the secondary energy source.

The electrochemical battery requires periodic replacement due to the side reactions (active wear) depending on the number of charging cycles and the value of the charging current delivered through the booster (internal combustion engine–power generator). Providing the optimal conditions for the accumulation and recovery of energy extends the life cycle of the secondary energy source by increasing its durability. These conditions and all other indirect factors influencing the economics of ICEV, PHEV, and BEV systems are aperiodic parameters. Their separation must be determined individually for a given group of vehicles, comfort class, range, and energy source technology. Thus, it is possible to assess the justification of using PHEVs and BEVs in a given area, taking into account all external factors, including technological possibilities of making a given vehicle and adapting it to the site concerned. In this case, the economic efficiency of the solutions is determined by the durability of the batteries, their operation based on forecast traveling profiles, and access to the charging infrastructure and service centers. It is mostly influenced by the frequency of the defects in a given group of vehicles and their potential repair costs.

2.3. General Mathematical Relations Concerning the Determination of Vehicle Energy Losses

ICEVs, PHEVs, and BEVs have common features that affect energy consumption in motion. It is mainly the resistance to motion, which consists of: air resistance, rolling resistance, hill resistance, and acceleration resistance. In general terms, this relation can be expressed by the equation:

The resulting inflow velocity is the vector sum of the vehicle speed and the wind speed . The airflow resistance depends on the air attack angle β and the vehicle motion parameters, which can be expressed by the average drag coefficient at any angle of air attack:

With the incoming air (supporting the movement) or the opposite inflow of air, the equation expressing the air resistance can be derived from the above relations:

In the absence of air, which is an unusual case in reality, this relation can be written as follows:

This enables us to determine the average dependence of the power demand of the drive unit needed to overcome the resistance to motion. This parameter is significantly influenced by components of the total efficiency of all ICEV, PHEV, and BEV systems.

For PHEVs and BEVs, there are additional factors such as braking energy recovery efficiency and the charging efficiency of batteries and capacitors :

Based on these considerations, assuming the same body shape for all drive system solutions, their energy consumption is determined by the efficiency of: drive systems, steering systems, drive transmission systems, systems supporting energy recovery from braking, other systems supporting the charging of batteries, and capacitors, all intermediate mechanisms accompanying the electric and internal combustion drive, and other components necessary to ensure the required comfort and safety of the vehicle. The overall efficiency depends mainly on energy losses resulting from the electrical and mechanical equipment. Therefore, PHEVs are characterized by the highest general energy consumption, followed by ICEVs and BEVs. This means that BEVs can achieve the highest overall efficiency compared to ICEVs and PHEVs. However, other features must also be taken into account, such as the durability and reliability of the BEV system and potential repairs at a low cost. In fact, all service activities for these vehicles are currently not very popular, and the network of private garages is insufficiently developed. This translates into a significant increase in the cost of repair and parts compared to ICEVs. In PHEVs, due to the dual-source of propulsion, the frequency of probable malfunctions of the drive system, drive train, and energy storage system is significantly higher than in other systems. Therefore, appropriate algorithms should be used to assess the economic aspects of using all propulsion sources due to aperiodic features, limiting the efficiency of the system due to the damage of components and unforeseen road situations.

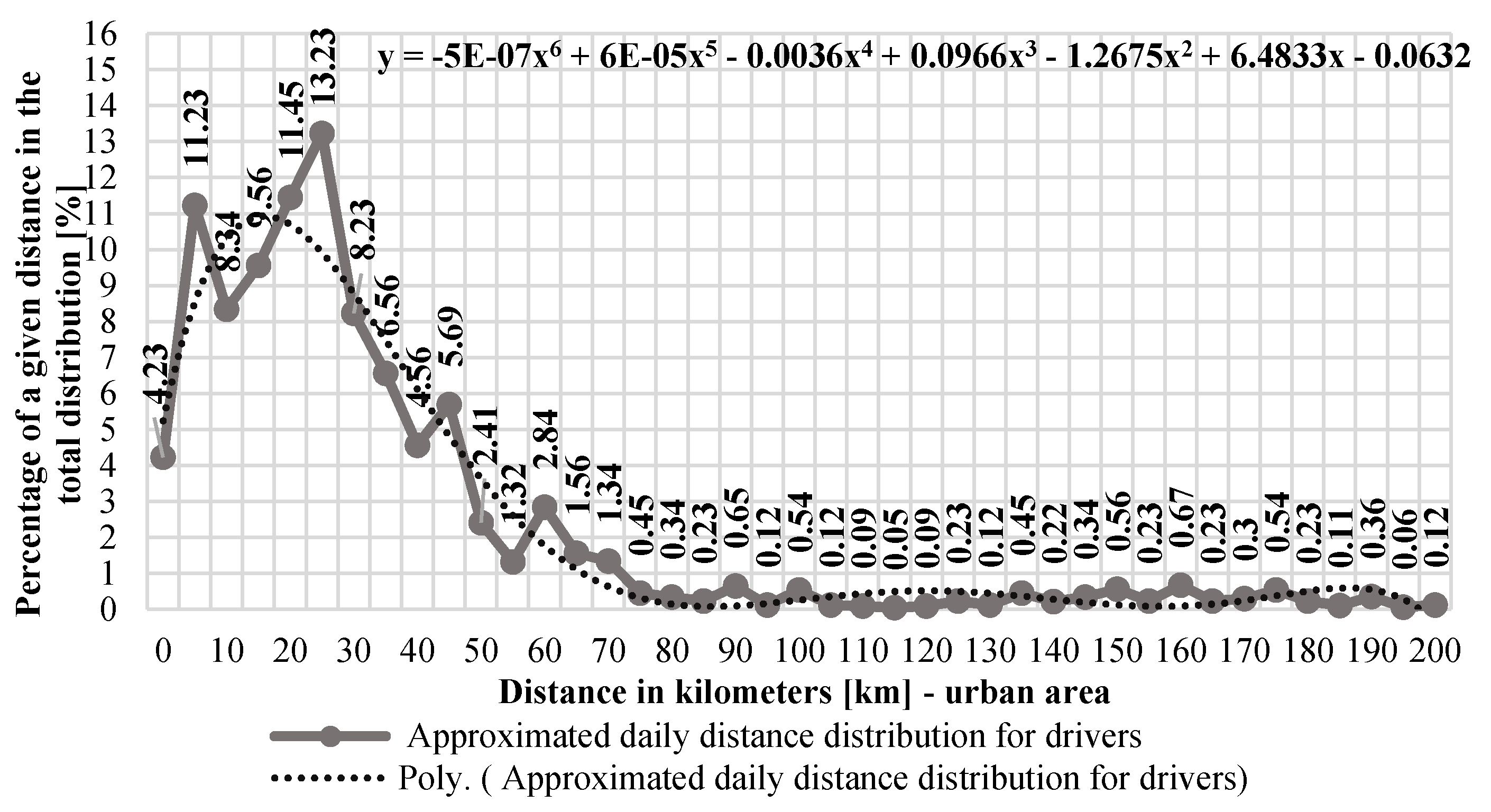

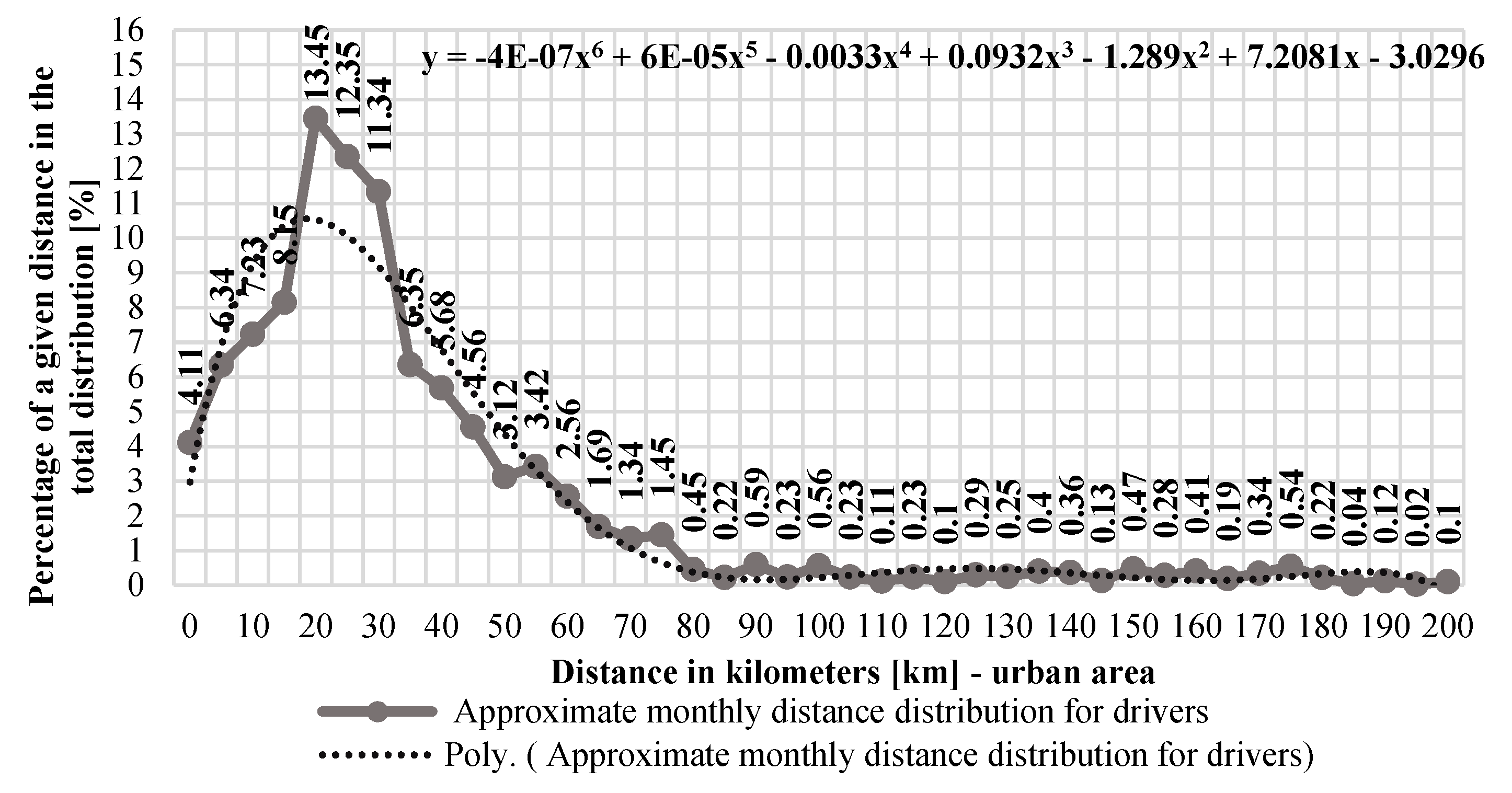

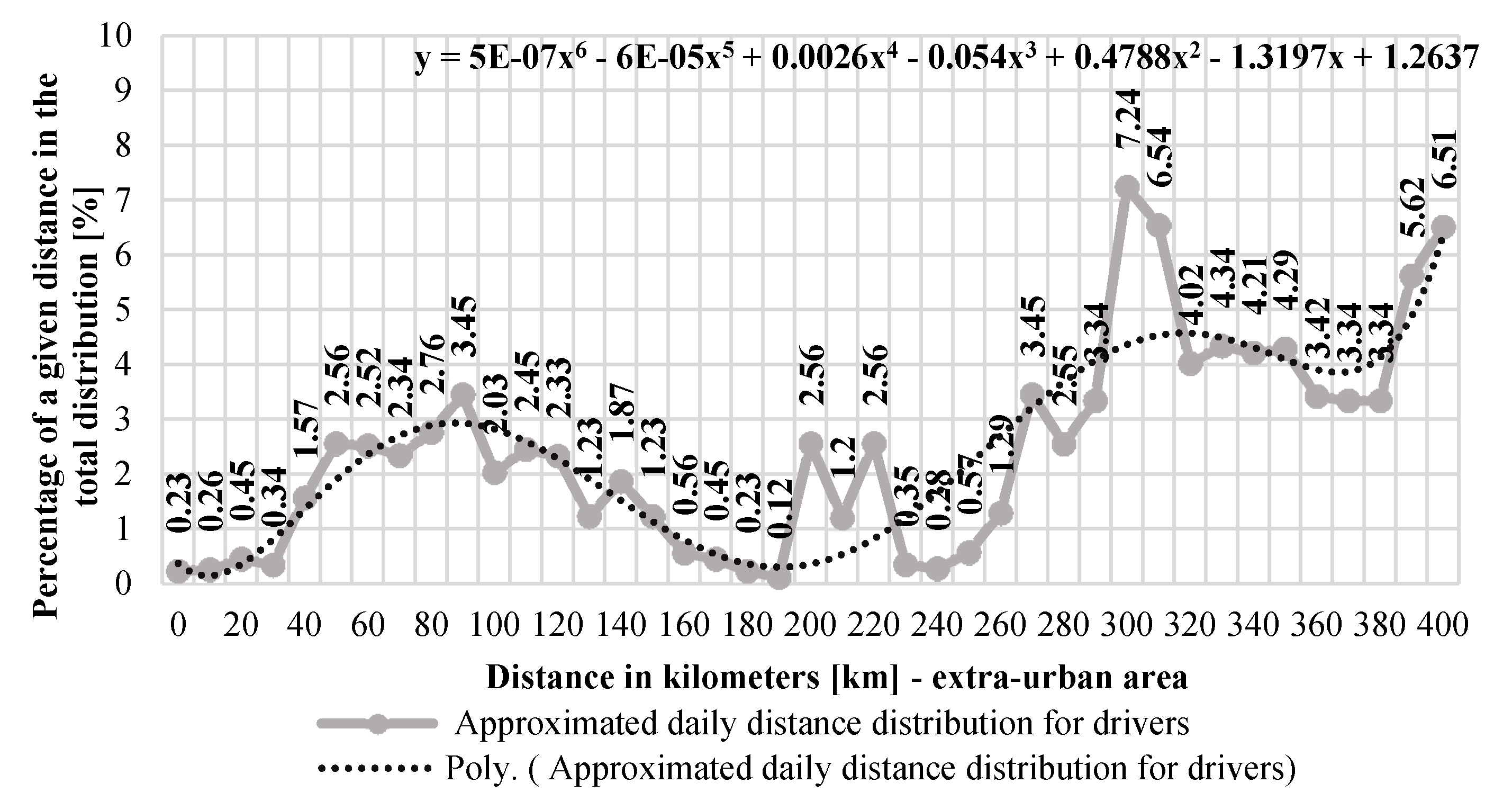

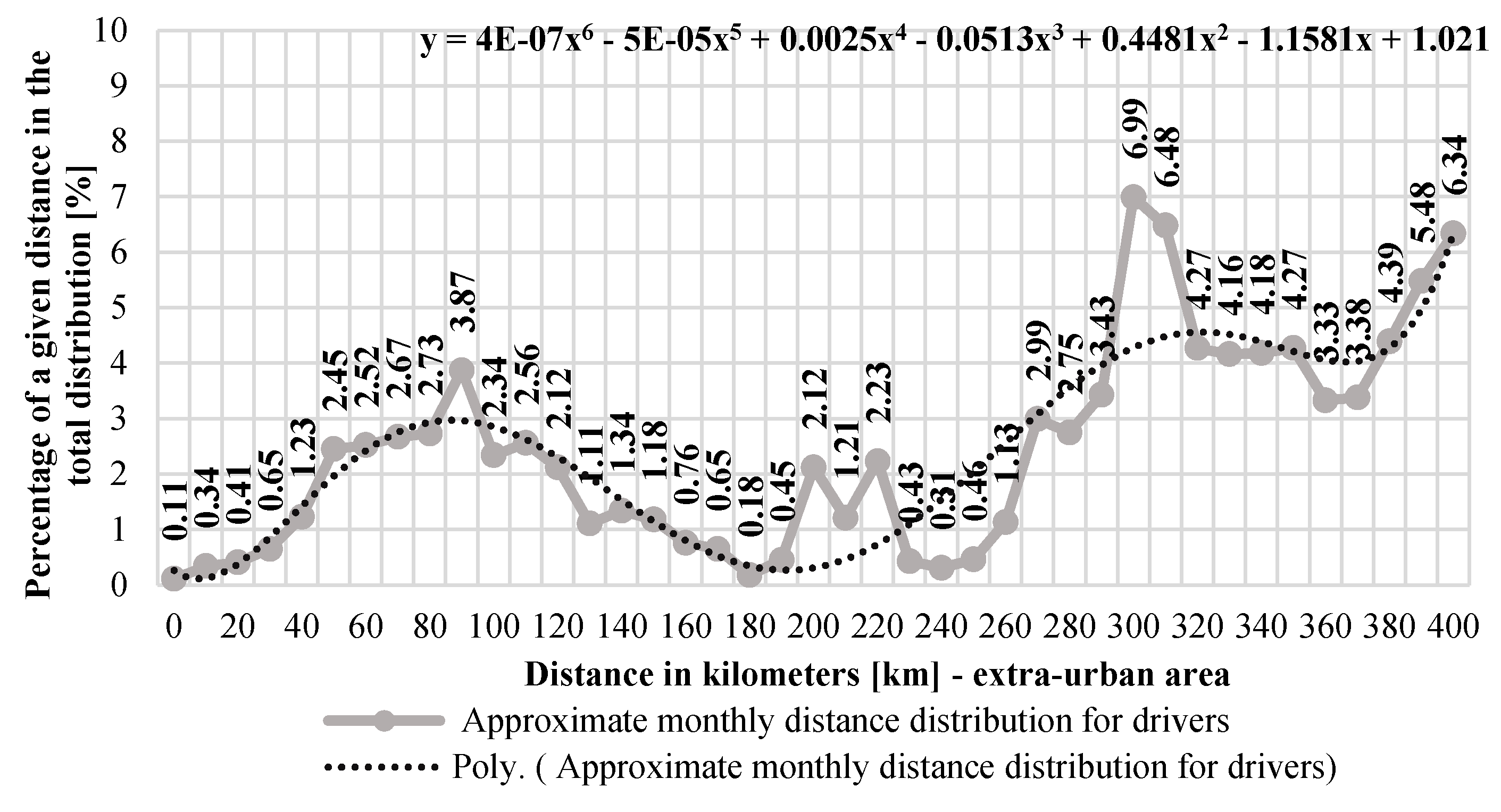

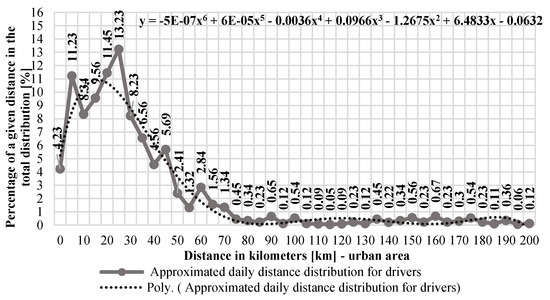

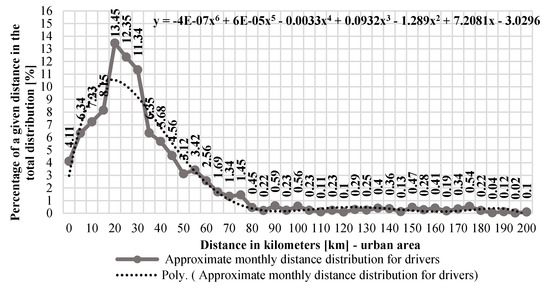

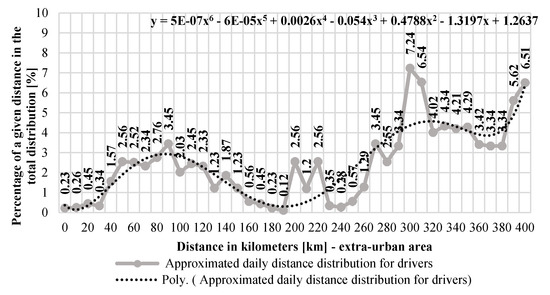

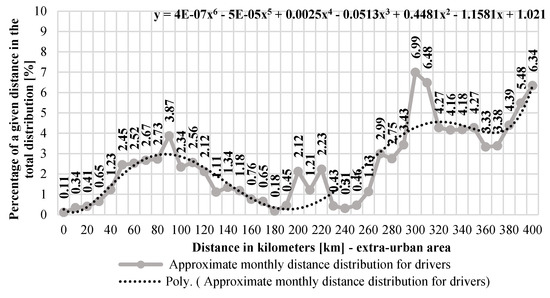

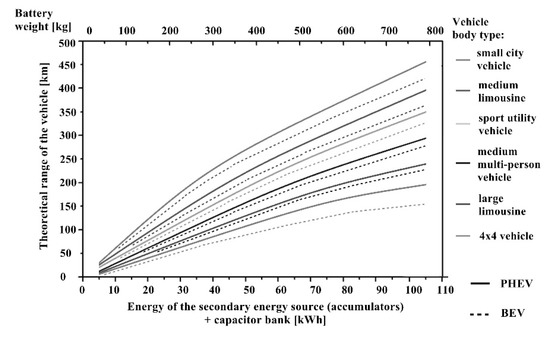

Table 1 shows the characteristics of example vehicles from a given group. The intention was to compare cars with identical values of resistance to motion, total weight, and the power of an electric motor or an electric motor in combination with an internal combustion engine. Therefore, since the given parameters for the PHEV and BEV groups are identical, the effective range of the vehicle was mainly influenced by the energy consumption by individual components. These were included in calculations based on the above mathematical equations. The given algorithmic relations are only examples, and measures have been extended to a more significant number of factors determining the individual efficiency of a given drive system. By taking into account aperiodic phenomena in the general data analysis, it is possible to decide on the economic efficiency of a given group of vehicles. Such studies were carried out on long-distance routes and in urban mode over a more extended vehicle operation of approximately 150,000 km. These data are presented in Figure 1, Figure 2, Figure 3 and Figure 4. Listed below are a few example speed profiles in the daily process. Their repeatability is high. Hence, the conditions of using a given drive system are very similar, which translates into high reliability of statistical data over a more extended period. The approximate operating conditions of individual drive systems, drive train, and energy management systems are necessary for the correct assessment of economic effects. Speed profiles were prepared for 24 vehicles, and average results were calculated in a given group (urban or extraurban). For this purpose, advanced GPS devices were used, with the possibility of recording driving techniques and locations. The analysis of aperiodic factors, such as unforeseen damage to the power and drive systems, which determine the economy of ICEVs, PHEVs, and BEVs, was carried out for a group of 1200 vehicles operating in two areas (urban and long-distance). Data were obtained from websites dealing with servicing selected groups of cars, with their breakdown by comfort class.

Table 1.

Characteristics of PHEVs and BEVs.

Figure 1.

Daily distance distribution for ICEVs, PHEVs, and BEVs operating in urban mode—approximate value based on experimental studies.

Figure 2.

Monthly distance distribution for ICEVs, PHEVs, and BEVs operated in urban mode—approximate value based on experimental tests.

Figure 3.

Daily distance distribution for ICEVs, PHEVs, and BEVs operated in extraurban mode—approximate value based on experimental tests.

Figure 4.

Monthly distance distribution for ICEVs, PHEVs, and BEVs operated in extraurban mode—approximate value based on experimental tests.

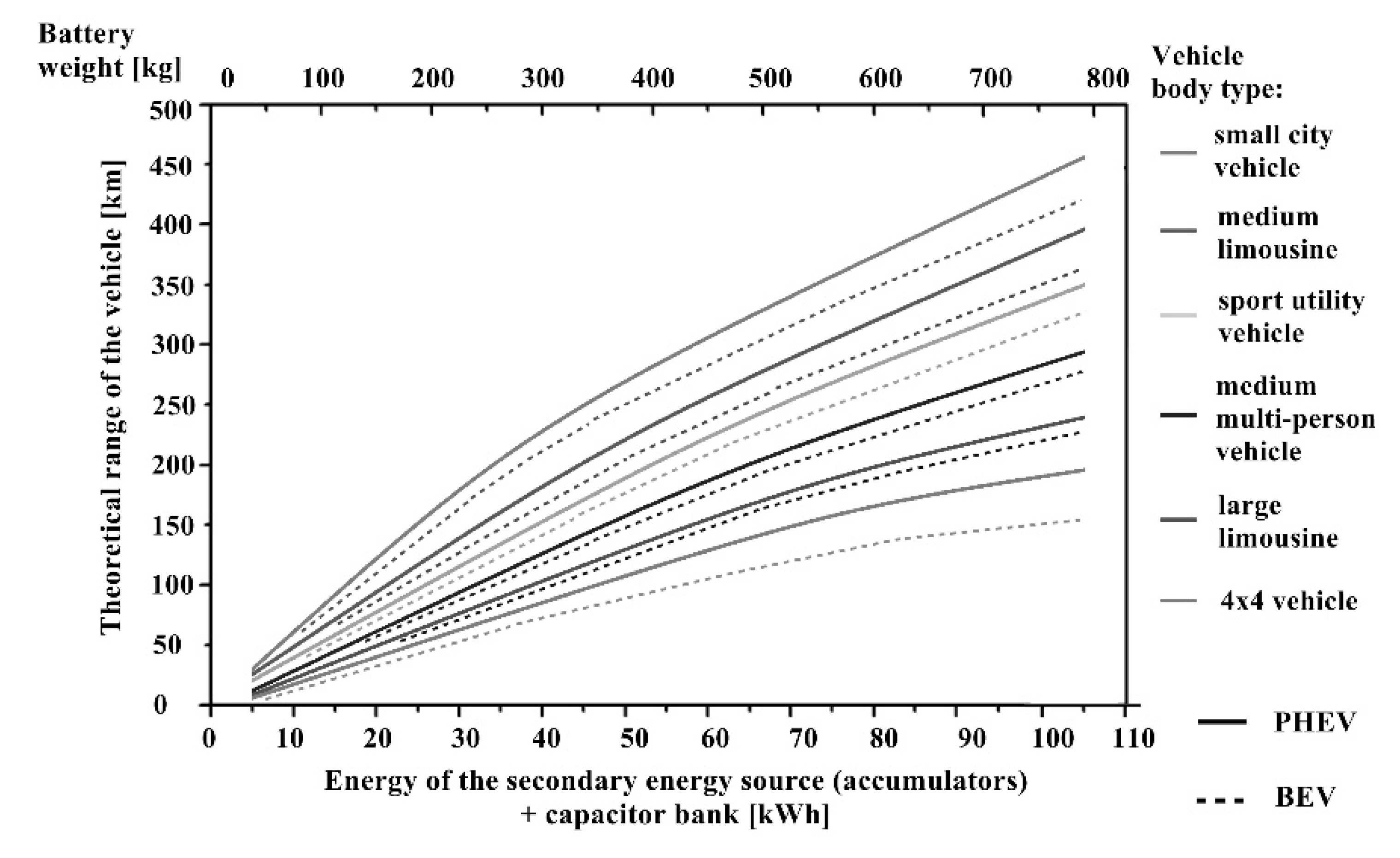

As shown in Figure 5, depending on the type of battery, the demand for power and weight is proportional to the resistance to motion. This means that vehicles with appropriately selected aerodynamics can generate significant energy benefits, especially in the case of BEVs. It is evident that 4x4 vehicles are characterized by the most considerable energy demand. This is related to the design of their drive system. In particular, a significant difference can be seen in the energy demand in BEVs and PHEVs, where PHEVs have a much higher demand for electricity from batteries and capacitors. This is related to additional energy losses associated with the double drive system. This causes a significant increase in the resistance to motion in moving mechanisms and a greater demand for electricity in additional actuating and measuring equipment. Comparing BEVs (small city vehicles) of an appropriate design, e.g., energy demand of about 50 kWh, with higher comfort vehicles (limousines), we can see that the battery weight doubles to ensure the same range. This means that for higher-class vehicles, the theoretical capacity of these vehicles with the permissible curb weight of the energy source must be reduced to maintain an appropriate energy consumption level. The use of larger batteries increases the weight and thus reduces the efficiency of the drive system in PHEVs and BEVs. This means that PHEVs and BEVs must have an appropriate body shape that reduces aerodynamic drag and a low battery weight, that does not exceed 300 kg. Further increase in the mass of the source of electrical energy deteriorates the overall energy efficiency of the vehicle resulting in low cost-efficiency of such solutions. Therefore, in larger vehicles, the ICEV driveline is much more efficient and does not significantly affect the overall efficiency of the drive system.

Figure 5.

Energy demand depending on various vehicle body types, the weight of batteries, and a theoretical range of PHEVs and BEVs.

Despite these shortcomings of PHEVs, a growing number of stringent CO2 emission regulations [53] along with rising fuel prices [54] have led to a significant change in the perception of specific vehicle design solutions, including PHEVs and BEVs. The growing demand for city-type vehicles indicates a positive attitude of vehicle users to this group of cars, despite the inconvenience of battery charging, low range, and low availability of charging stations and repair services. Despite the fact that the operating cost of these vehicles is very high in the event of even a minor failure, users often decide to buy such a car. This is probably related to the social pressure on ecology and low emissions.

For this purpose, we may use integrated systems of operational suitability indicators and intermediate systems based on the energy balance, which depends on the quantity and efficiency of the required resources. The complexity of the system is unlimited and involves the implementation of individual efficiencies for each component of the system. Additionally, we need to introduce a method for assessing the probability and predicting potential aperiodic phenomena affecting the total efficiency of the system in a given area.

2.4. Research Capacity of the Gray System Theory (GST) and Statistical Models While Considering Aperiodic Phenomena in the Energy Consumption Balance

The model studies are based on the GST and GM prognostic models (1,1). Various sizes of windows were adopted for the calculation of energy balance parameters and aperiodic features. Such models have several indirect features that are favorable due to the characteristics of data in the model, e.g., diagnostics and the frequency of failures [55,56,57]. When using a moving window, the GM (1,1) models are especially adaptable. Adopting the wrong window size can amplify the measurement error and lead to wrong conclusions. These models have been developed in several studies. They are mainly used to assess machine reliability and social engineering issues [58,59,60]. If we observe a selected number of damage symptoms to a given component, e.g., a PHEV, we can obtain specific damage information using the so-called Symptomatic Observation Matrix (SOM) [61]. One method of further extracting this Diagnostic information is to use the Specific Value Distribution (SVD) to the SOM [62,63,64].

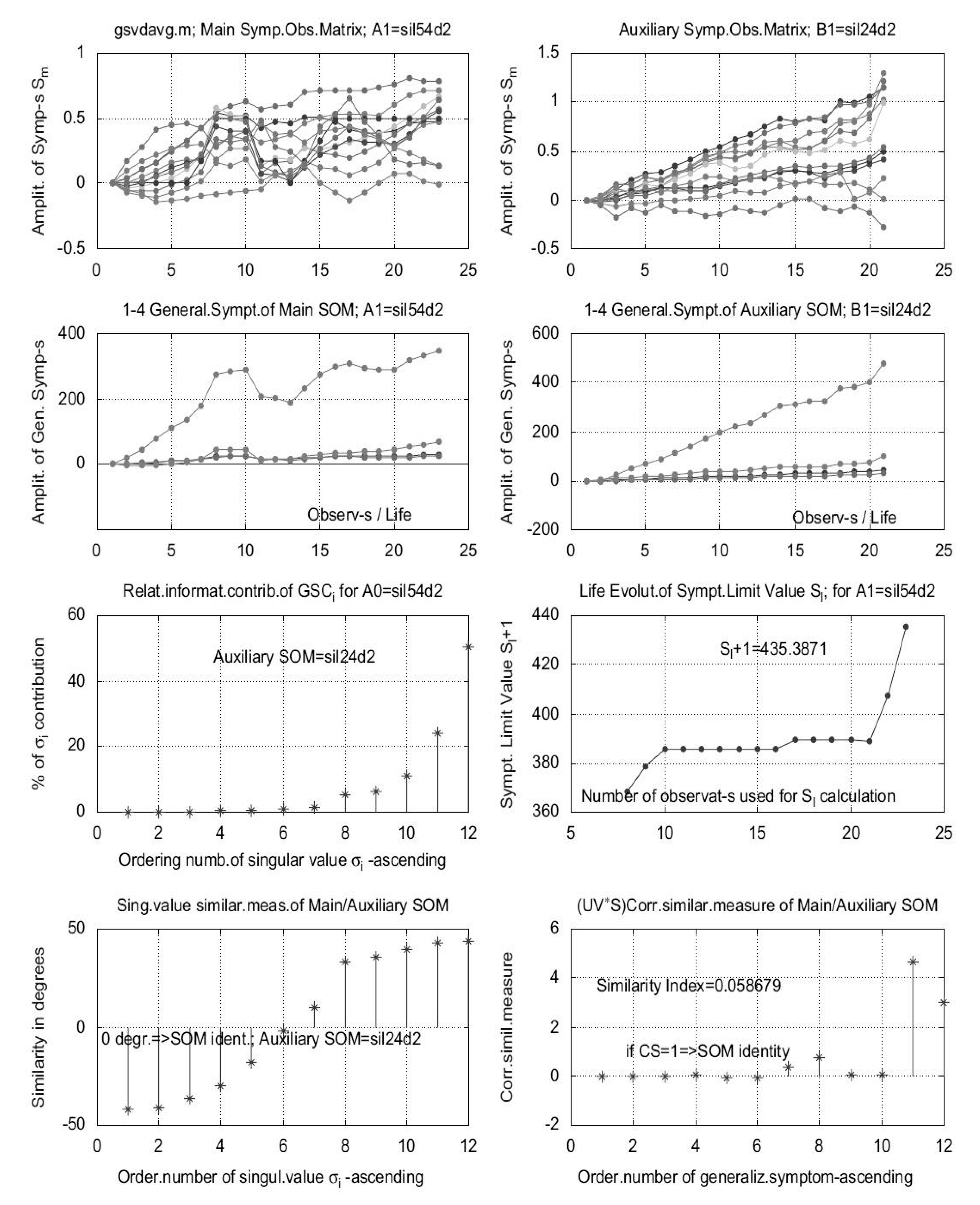

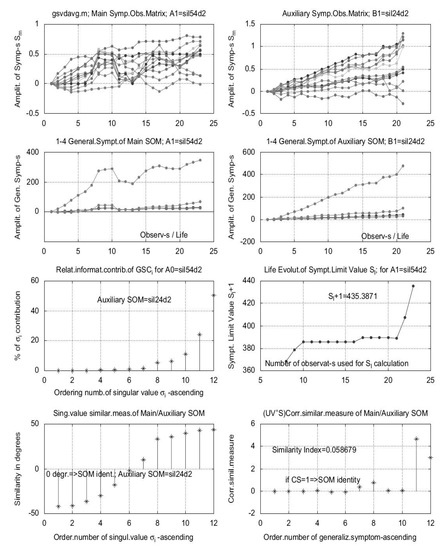

The multidimensional nature of the inefficiency space in machine operation monitoring is now well defined and analyzed in terms of existing model errors through the use of neural networks [65], singular value decomposition [66], or principal component analysis [67]. A more difficult task is the multidimensional decision-making process, where we have a data fusion method [68] and the concept of symptom reliability applied to a general failure obtained by using singular value decomposition (SVD) [69]. Based on the model presented in the above publications, a generalization of the SVD method was used. It considers other SOMs of similar objects with the same number of symptoms (columns); however, the number of rows (observations) may differ [70,71]. The intelligent model learning has been applied [72,73,74]. The GSVD concept based on a prior SVD application has been used until initial results can be seen as possible use of the GSVD in machine condition monitoring, especially when looking for similar symptoms and wear based on aperiodic damage in the entire energy system in ICEVs, PHEVs, and BEVs [75,76,77]. An example of the use of the model has been shown in Figure 6, which shows the results of using the model for a diesel engine.

Figure 6.

GSVD comparison of two different examples of the same diesel engines [78]. Reprinted with permission from ref. [78]. Copyright 2021 Elsevier.

The paper uses a predictive method for the comparative verification of GST models with statistical data about the frequency of aperiodic failures. Six vehicle classes (Figure 5) and three types of ICEV, PHEV, and BEV drivelines were taken into account in a group of 1200 vehicles. It was assumed that speed profiles for individual groups in urban and long-distance modes are very similar for the total population of 1200 vehicles analyzed against aperiodic phenomena during their operation over a distance of 150,000 km.

3. Results

3.1. Costs of Aperiodic Failures in the Entire Balance of Vehicle Operating Costs Resulting from Periodic Inspections and the Replacement of Components Recommended by the Manufacturer

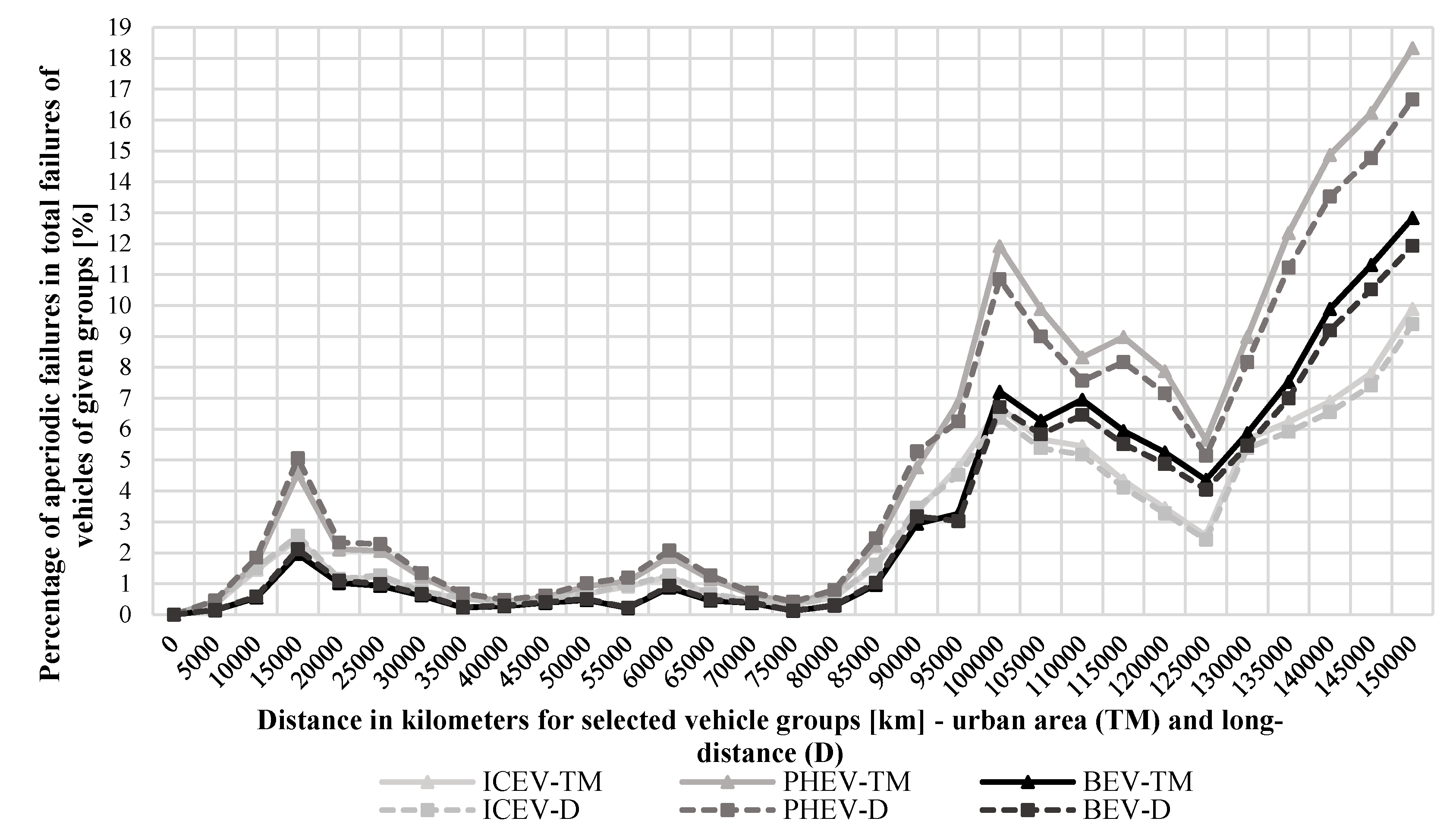

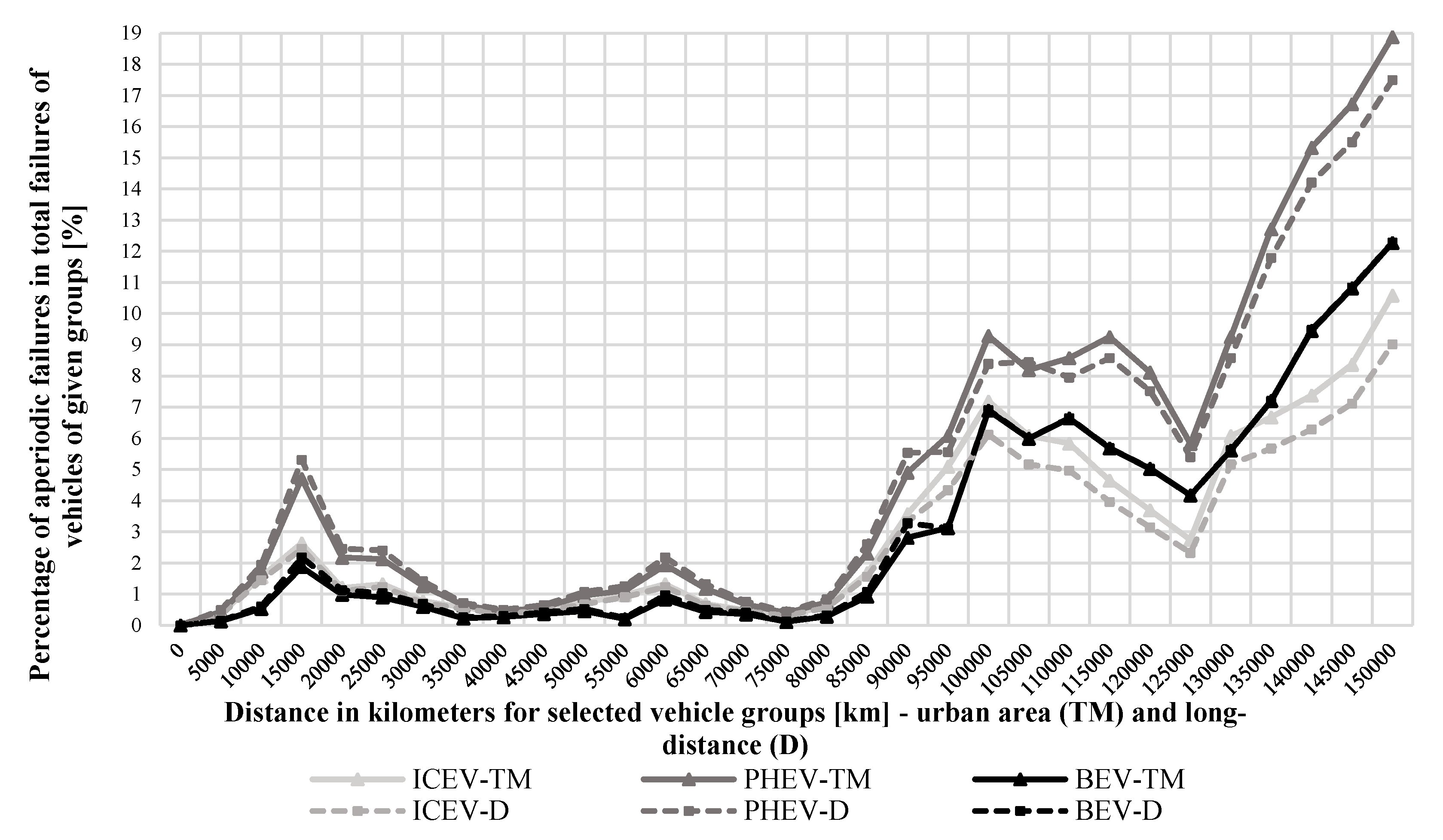

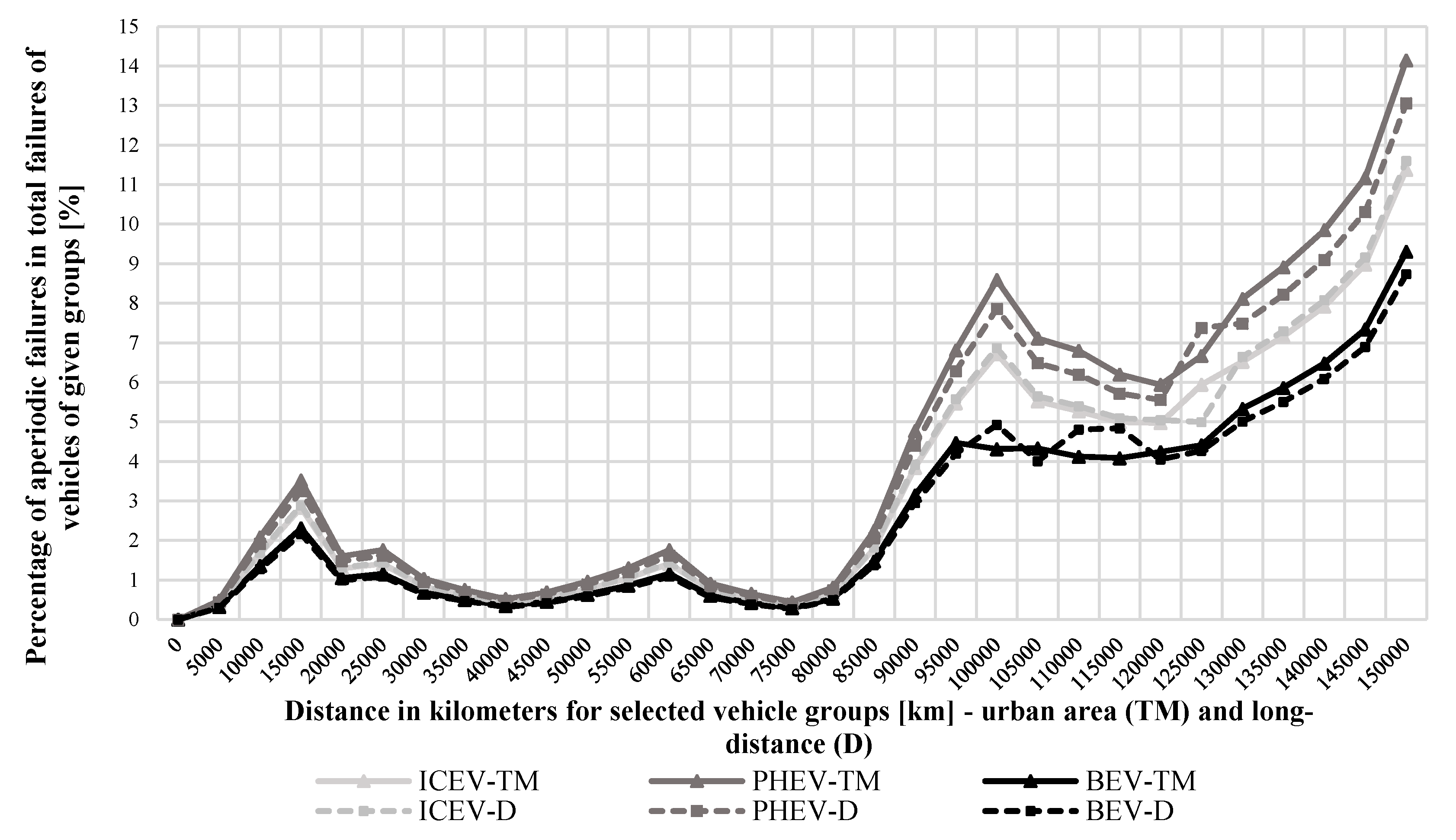

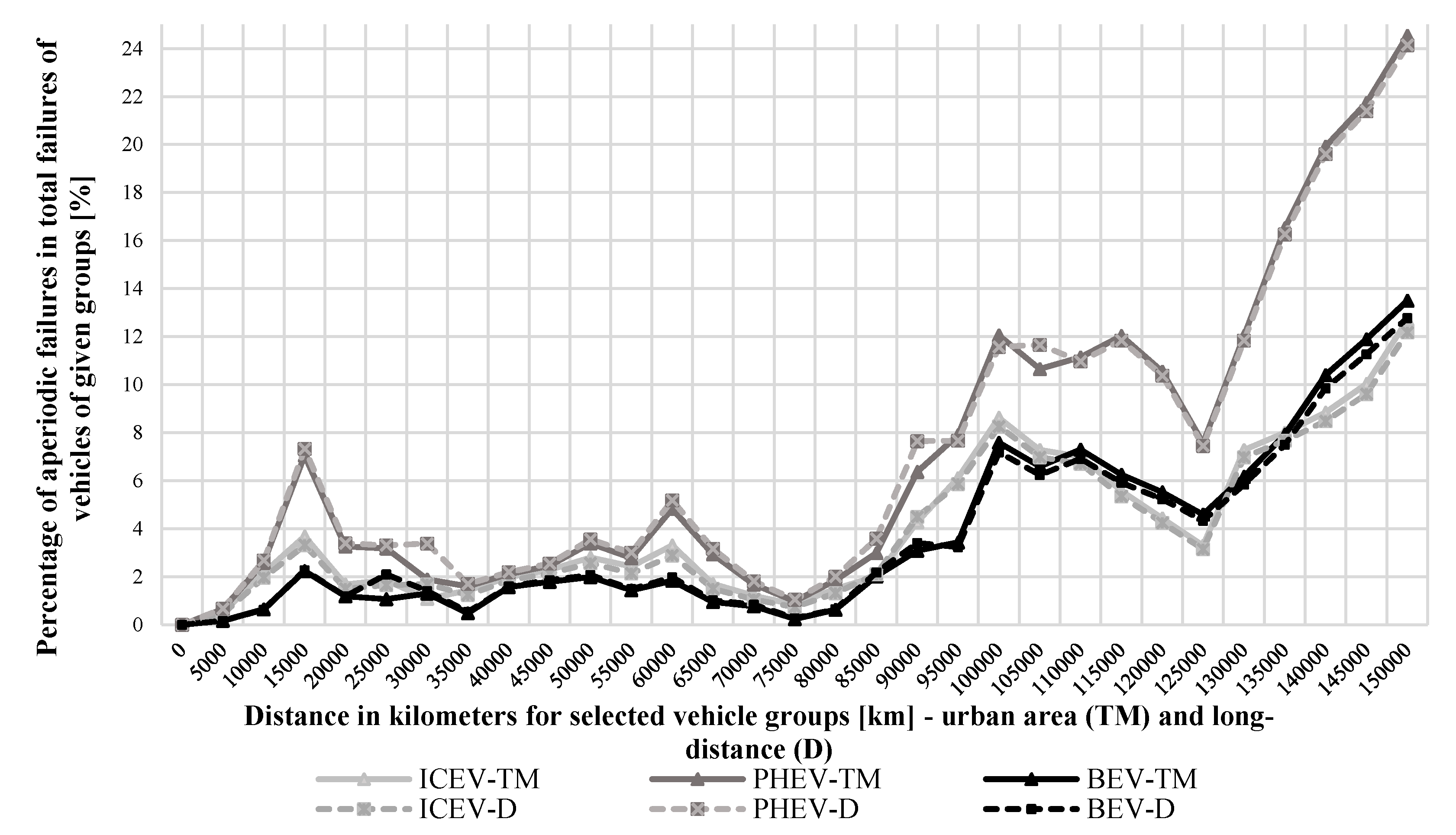

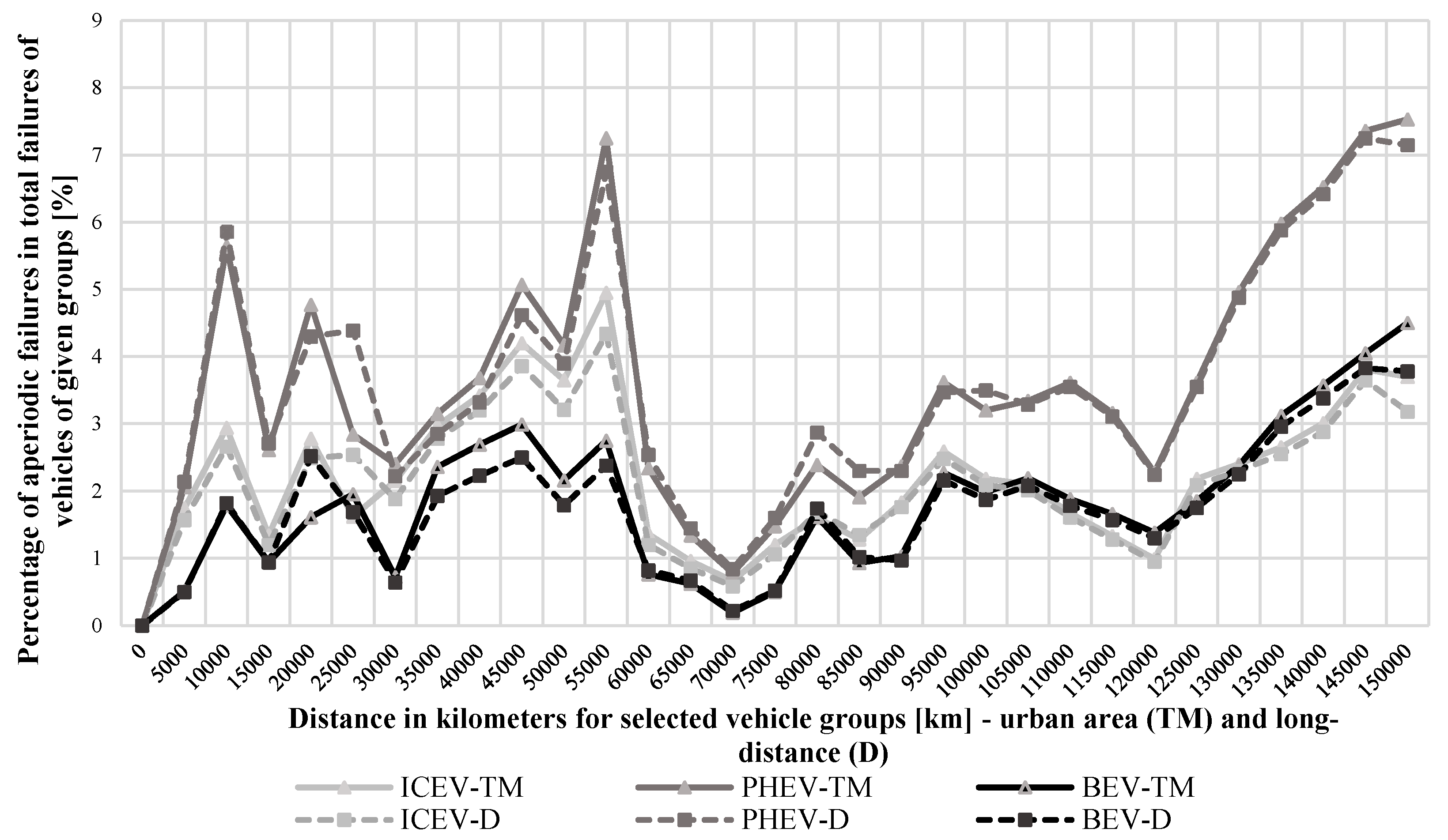

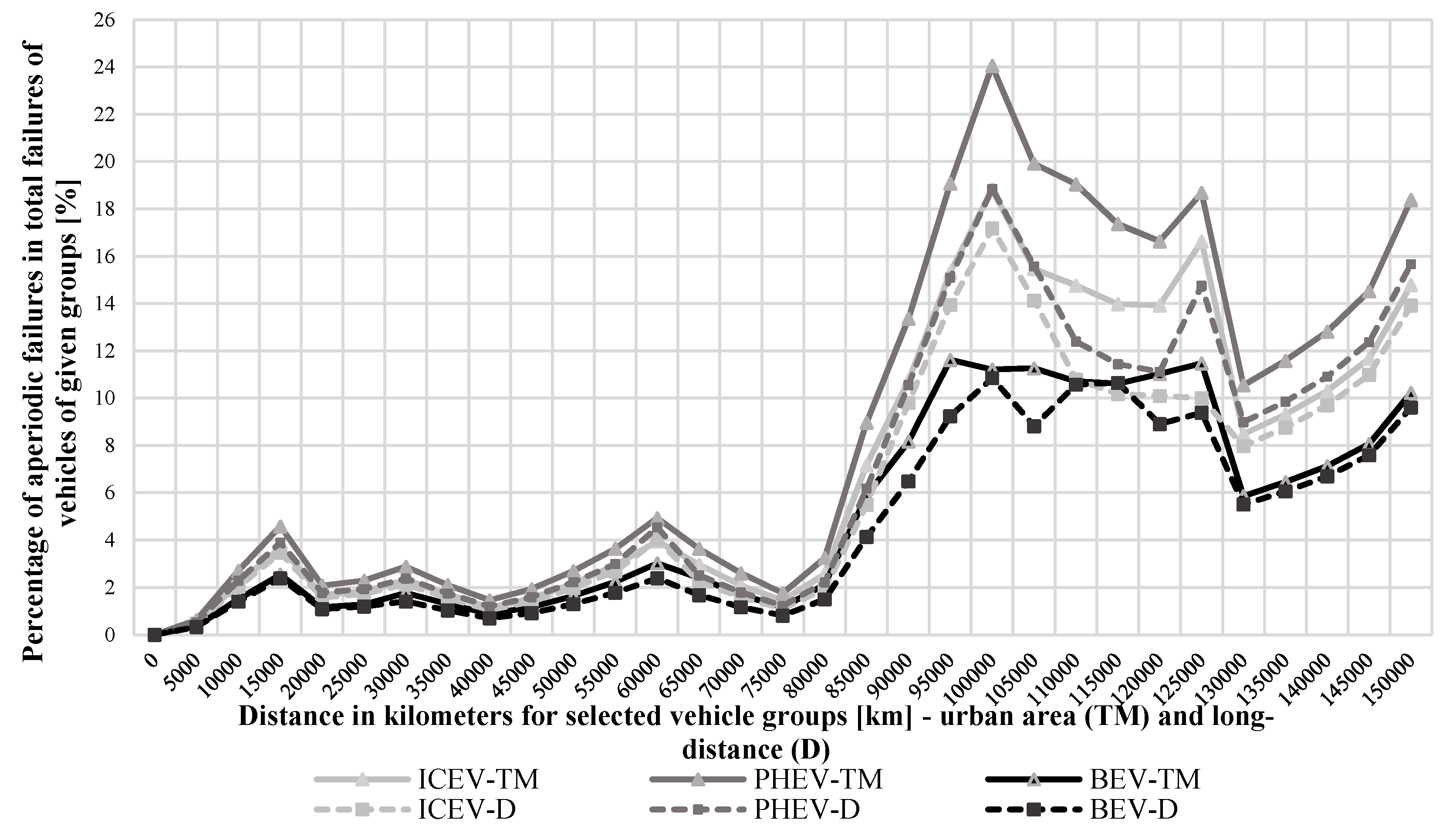

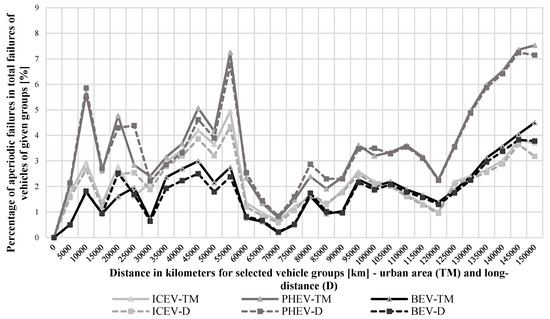

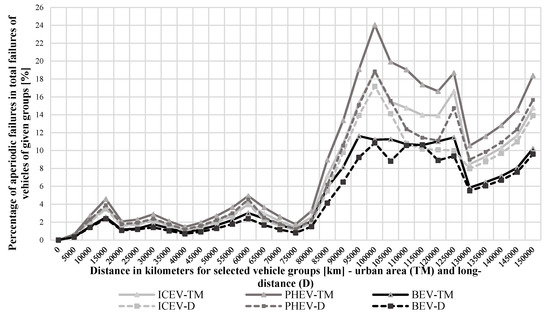

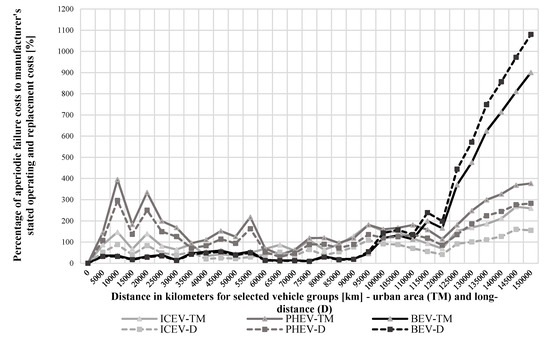

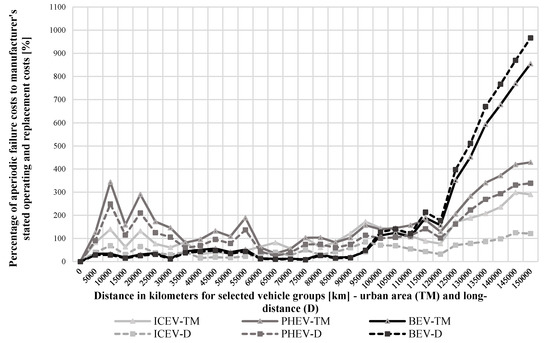

The average values were calculated for individual types of vehicles, their drive systems and speed profiles. The frequency of aperiodic phenomena for particular groups of cars are shown in Figure 7, Figure 8, Figure 9, Figure 10, Figure 11 and Figure 12. The impact on the change in energy consumption regarding phenomena for two extreme groups of cars has been shown in Figure 13 and Figure 14. Based on the data, simple analytical methods have been used to determine coefficients that are decisive regarding the impact of aperiodic phenomena on the reduction of vehicle economics with reliability criteria and the costs of repairing defects.

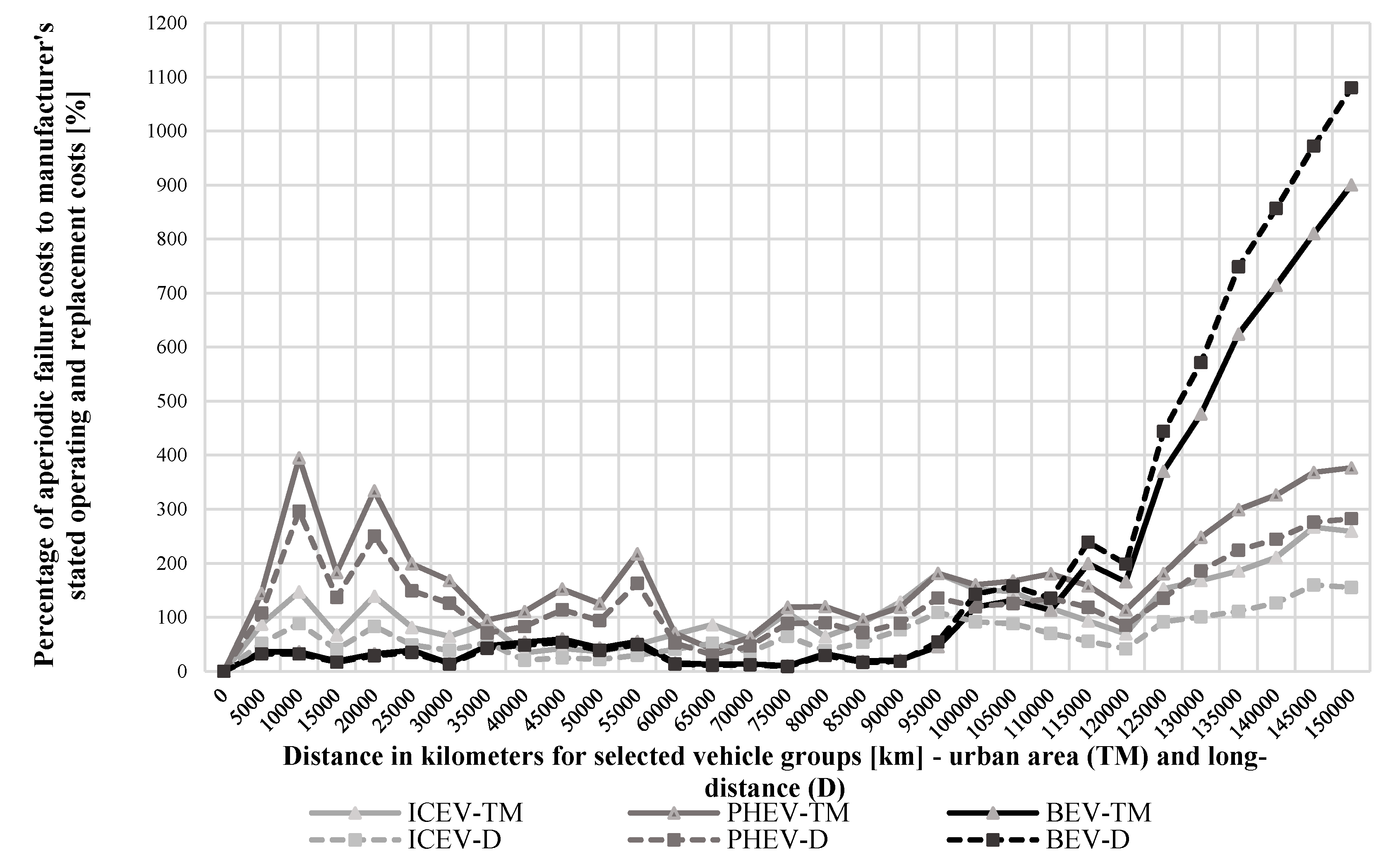

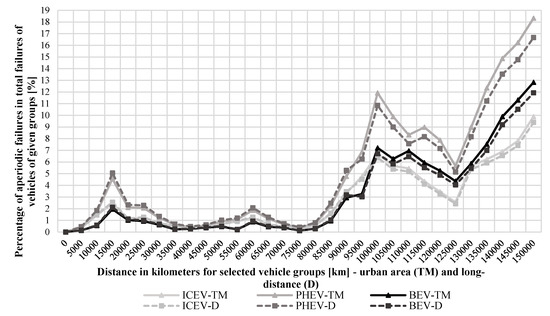

Figure 7.

Distribution of aperiodic failures for a small city vehicle with ICEV, PHEV, and BEV propulsion for urban and long-distance speed profiles over a distance of 150,000 km.

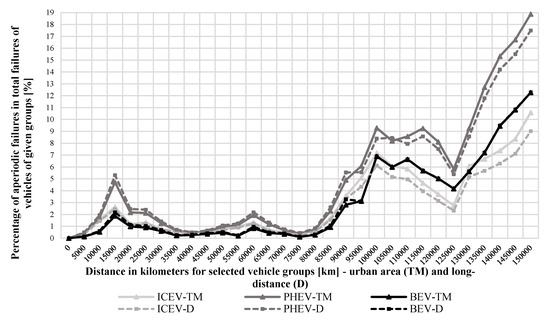

Figure 8.

Distribution of aperiodic failures for a medium limousine with ICEV, PHEV, and BEV propulsion for urban and long-distance speed profiles over a distance of 150,000 km.

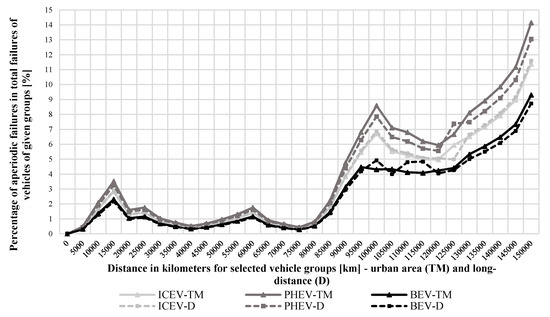

Figure 9.

Distribution of aperiodic failures for a sport utility vehicle with ICEV, PHEV, and BEV propulsion for urban and long-distance speed profiles over a distance of 150,000 km.

Figure 10.

Distribution of aperiodic failures for a medium multiperson vehicle with ICEV, PHEV, and BEV propulsion for urban and long-distance speed profiles over a distance of 150,000 km.

Figure 11.

Distribution of aperiodic failures for a large limousine with ICEV, PHEV, and BEV propulsion for urban and long-distance speed profiles over a distance of 150,000 km.

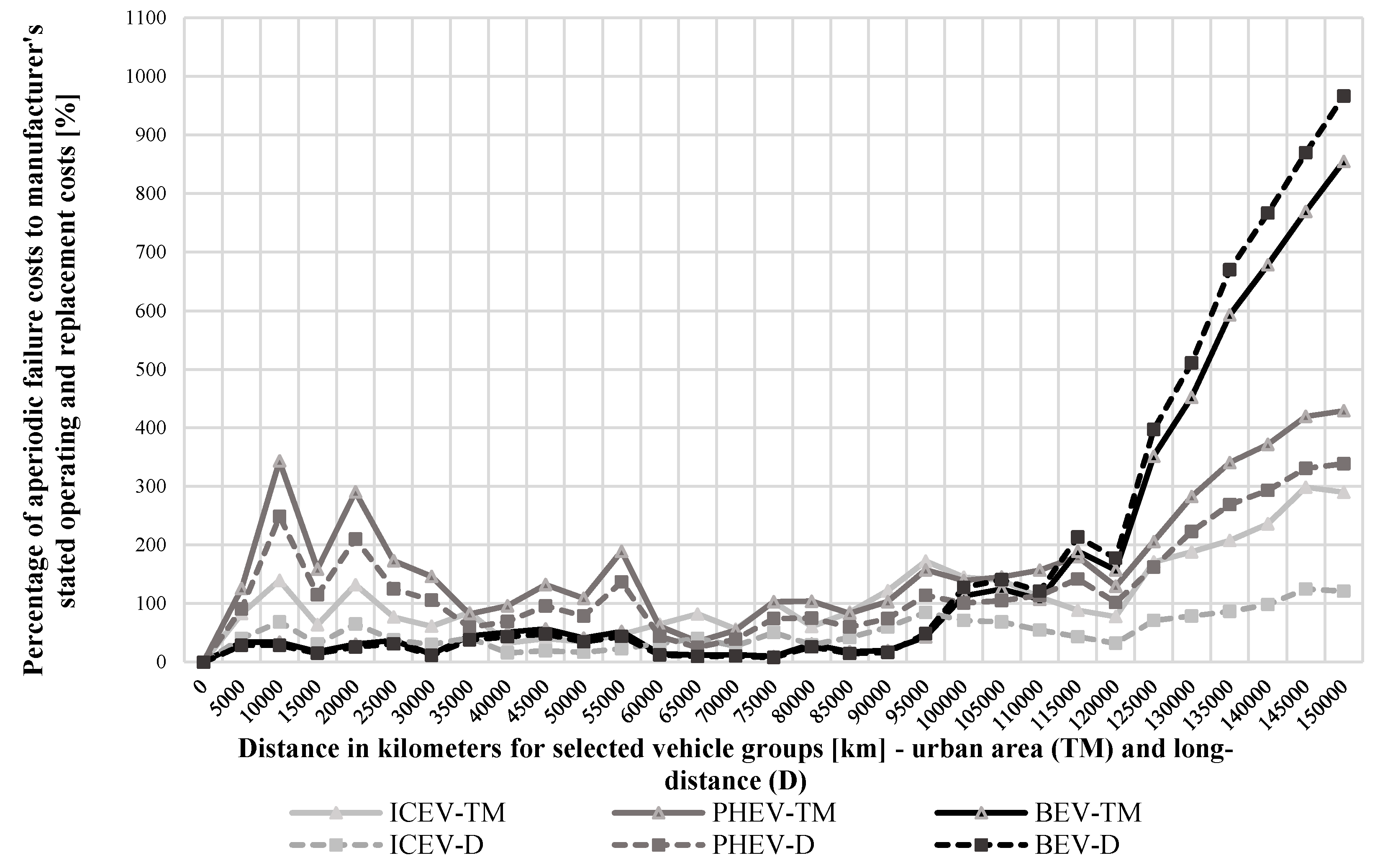

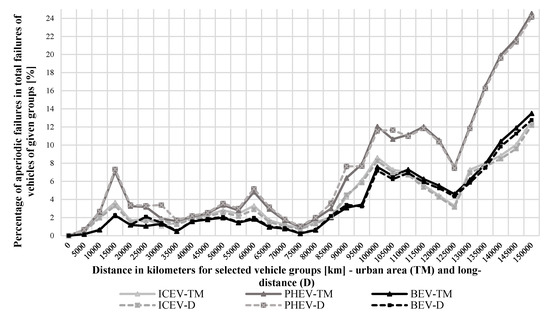

Figure 12.

Distribution of aperiodic failures for a 4x4 vehicle with ICEV, PHEV, and BEV propulsion for urban and long-distance speed profiles over a distance of 150,000 km.

Figure 13.

Percentage of aperiodic failures cost in the entire balance of vehicle operating costs resulting from periodic inspections and replacement of components recommended by the manufacturer—a high-class limousine.

Figure 14.

Percentage of aperiodic failures cost in the entire balance of vehicle operating costs resulting from periodic inspections and replacement of components recommended by the manufacturer—4x4 vehicle.

Based on Figure 7, Figure 8, Figure 9, Figure 10, Figure 11 and Figure 12, it can be concluded that the occurrence of aperiodic failures after covering certain distances depends on the vehicle body type. In all cases, the BEV drive showed the lowest percentage of aperiodic shortcomings in the overall failure balance. The PHEV drive was the worst. ICEVs showed a high frequency of aperiodic failures after a distance of 100,000 km. Therefore, it can be concluded that the PHEV drive is the worst with regard to this evaluation criterion. The frequency of aperiodic failures, in this case, is the result of the dual-drive, which consists of an electric motor and an internal combustion engine, as well as many of the additional components in the energy management system. All this contributes to a large number of failures in the initial period of vehicle operation and after the distance of 80,000 km. It should be mentioned that even a high percentage of these failures in the overall balance does not have to translate into a reduced range and deterioration of the overall efficiency of a given drive system. This directly influences the economy of a given drive system. The relation is verified in Figure 13 and Figure 14. The study covered two extreme body systems for high-class limousines and a 4x4 vehicle. Higher class limousines (Figure 11) are characterized by a low percentage of aperiodic failures throughout their life cycle compared to other types of vehicle bodies—regardless of the drive system used (ICEV, PHEV, BEV). For this type of body, many failures occur in the initial period of operation, and such failures are mainly associated with the comfort and safety systems. This does not translate into the loss of the drive unit efficiency.

Unfortunately, the cost of removing such failures is also high, although it is still much less than for other body types. In 4x4 vehicles, the frequency of aperiodic failures after a distance of around 80,000 km is at an average level, i.e., 1% to 5%. Their percentage significantly increases beyond this mileage, even over 24% from 90 to 110,000 km. After this distance, the rate of failures decreases, but it is still very high. In this system, the losses are most often associated with the drivetrain or the drivetrain in combination with the four-wheel drive, which significantly worsens the economy of these vehicles, especially with the PHEV drive.

In most cases, the failure frequency is the highest for cars moving in city traffic. It is related to the high frequency of braking and accelerating and the poor condition of the road surface. All this translates into a greater frequency of aperiodic failures in the suspension and steering systems.

3.2. Proportion of Aperiodic Failure Costs in the Entire Vehicle Balance by Body Type and Speed Profile

Based on Figure 13 and Figure 14, it can be concluded that indicators of aperiodic operation incidents are high due to the number of failures. After taking their costs into account, it is possible to assess their impact on the vehicle’s economy. As shown in Figure 13 and Figure 14, the prices of aperiodic failures attributable to PHEVs and ICEVs are much higher than for BEVs in the initial period of operation up to about 50,000 km. Nevertheless, these costs are relatively acceptable to users. They occur mainly due to construction errors and minor glitches in the electronic equipment.

During further operation above 50,000 km, in terms of operating costs, the share of this type of failure as part of the total number of operational and maintenance failures decreases. The cost of aperiodic losses is much higher after driving a distance of about 100,000 km. It increases several times compared to the cost of essential operation provided by the manufacturer for all drive types. It can be seen that the costs of aperiodic failures in BEVs after 120,000 km increase dramatically. They are larger than those for PHEVs, despite a much smaller number of random failures. This is mainly related to the maintenance of the primary and auxiliary batteries and the cost of their replacement. On this basis, it can be said that despite an insignificant number of failures in BEVs after driving a distance of 120,000 km, their repair cost is strongly related to their nature. The difference between the price of aperiodic losses in PHEVs and BEVs is related to the higher-rated capacities of the primary batteries in BEVs. After the batteries lose their full power, their purchase or regeneration cost is very high.

In the case of both body types of ICEVs (4x4 drive and high-class limousine), the cost of replacing components as compared to PHEV and BEV drive systems is the lowest despite a much larger number of aperiodic failures of the ICEV drive. The nature of failures is also closely related to the speed profile and the area of operation. In the case of BEVs, the vehicle’s long-distance operation contributes to a faster loss of the efficiency of the primary batteries as a result of their deep discharge. In a city mode, failures related to the power unit and the driveline are much more frequent and depend on operating conditions. Based on the analysis, considering the current infrastructure and operating costs and the frequency of aperiodic failures in PHEV and BEV drives, ICEVs are unrivaled in their operating costs. BEVs are promising, but so far, the cost of battery replacement is too high and determines the overall economy of the vehicle. Since their range is limited, PHEVs perform well in cities, but their dual drivetrain worsens their operating costs compared to ICEVs.

4. Discussion and Conclusions

The adopted method of examining the engine energy balance allows assessing the measurable benefits generated by the massive use of electric vehicles (EV) in comparison to conventional combustion engines and other alternative vehicle propulsion instruments. The presented model, based on the gray system theory (GST) to assess the impact of drive unit energy balance regarding economic and environmental parameters, and the adjustment of infrastructure to specific drive units in use, can be applied in complex multiple-parameter stochastic analyses. The model can be used to verify decisions on selecting electric vehicles (BEVs), plug-in hybrids (PHEVs), and combustion engine vehicles (ICEVs). As shown by the extensive experimental mobility study for ICEVs, PHEVs, and BEVs, the impact of aperiodic failures of the economic operation of a given drive system is huge. It is closely related to the nature of the speed profile, and it mainly affects drive system operating conditions and energy consumption, regardless of the solution used.

The introduction of a given electromobility system depends on economic factors. This indicates that the currently developed infrastructure and well-established production technology adversely influence the development of mass electromobility despite the findings of ICEVs operation and the energy balance analysis of the individual drive units. The results suggest that all vehicle technologies will play an essential role in transforming a sustainable mobility system.

Using discrete selection behavioral mix models and taking into account hidden variables, mainly the energy balance of the engine, it is also possible to determine the impact of various alternatives on potential vehicle demand (EV). It can be concluded that the engine power does not have much influence on the market for electric vehicles, since primary factors include their range and the availability of charging infrastructure, and the operating cost in comparison with ICEVs. The research conducted based on the adopted models has shown a large role of the drive system energy balance for electric vehicles (BEV), plug-in hybrids (PHEV), and internal combustion vehicles (ICEV) on the implementation of specific concepts in a given area.

Aperiodic phenomena during the operation of selected drive systems in motor vehicles, and environmental and infrastructural factors, determine the application of a given electromobility concept during the transition period. The impact of aperiodic phenomena on the suitability of a given drive system is significant. The high frequency of such phenomena worsens the economic justification for electric vehicles in comparison to conventional solutions. It is estimated that this impact may exceed 10% of the total energy balance for PHEVs and more than 7% for BEVs due to additional failures in the drivetrain and energy supply mechanisms. To a large extent, awareness of the potential benefits of using a given power system can be a decisive factor that adds to the demand.

The abovementioned models predict that the impact of aperiodic failures on the development of electromobility systems in a given area may contribute to an increase in demand for electric vehicles and improvement of infrastructure during the adaptation period.

Author Contributions

Conceptualization, methodology, validation, formal analysis, investigation, writing: P.W. Original draft preparation, visualization: P.W. Writing—review and editing, supervision: P.W. and W.D. Project administration: P.W., W.D., W.L. and P.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by University of Szczecin; Research Center for Management of Energy Sector, Institute of Management, Cukrowa Street 8, 71-004 Szczecin, Poland.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| the power of the internal combustion engine to overcome the resistance to motion of the ICEV vehicle: | |

| the power of the combustion engine and electric engine to overcome resistance to motion for PHEV vehicles, | |

| electric power necessary to overcome resistance to motion for BEVs, | |

| total force on the driving wheels of the ICEV [N], | |

| total force on the drive wheels of the PHEV [N], | |

| total force on the driving wheels of the BEV [N], | |

| average drag coefficient considering the lateral airflow, | |

| tangential resistance coefficient, | |

| air density [kg/m3], | |

| the resultant velocity of inflow [m/s], | |

| vehicle speed [m/s], | |

| the speed of air inflow [m/s], | |

| air resistance [N], | |

| frontal (roundabout) surface [m2], | |

| total efficiency of the drive system components with the internal combustion engine, | |

| total efficiency of components of the drive train with an internal combustion engine, | |

| total efficiency of the drive system components with an electric motor, | |

| total efficiency of components of the drive train with an electric motor, | |

| total efficiency of charging batteries and capacitors, | |

| total efficiency of braking energy recovery, | |

| total efficiency of the steering system components, | |

| driving resistance power [W], | |

| the power of the electric vehicle drive [W], | |

| the power to recover energy from decelerated (braking) motion [W], | |

| electric machine braking power [W] |

References

- Drozdz, W. The development of electromobility in Poland. Virtual Econ. 2019, 2, 61–69. [Google Scholar] [CrossRef]

- Rabe, M.; Streimikiene, D.; Drożdż, W.; Bilan, Y.; Kasperowicz, R. Sustainable regional energy planning: The case of hydro. Sustain. Dev. 2020, 28, 1652–1662. [Google Scholar] [CrossRef]

- Pilecki, B. Infrastruktura Społeczna i Jej Znaczenie w Rozwoju Regionalnym; Wydawnictwo Naukowe Uniwersytetu Szczecińskiego: Szczecin, Poland, 2019; pp. 79–85. [Google Scholar]

- Lewicki, W. The case study of the impact of the costs of operational repairs of cars on the development of electromobility in Poland. Arch. Automot. Eng. 2017, 78, 107–116. [Google Scholar]

- Drożdż, W.; Dowejko, J. Electromobility in Selected National Economies Electromobility as a Megatrend of Contemporary Economy; PWN: Warszawa, Poland, 2021; pp. 44–46. [Google Scholar]

- Barkenbus, J. Our electric automotive future: CO2 savings through a disruptive technology. Policy Soc. 2009, 27, 399–410. [Google Scholar] [CrossRef]

- Devloo, T.; Leemput, N.; Member, G.S.; Roy Geth, F.; Driesen, J.; Member, S. Component Improvements in the Electrification of Passenger Vehicles Drivetrains. In Proceedings of the 2013 IEEE Transportation Electrification Conference and Expo (ITEC), Detroit, MI, USA, 16–19 June 2013. [Google Scholar]

- Drożdż, W.; Miśkiewicz, R.; Pokrzywniak, J.; Elżanowski, F. Urban Electromobility in the Context of Industry 4.0; Adam Marszałek: Torun, Poland, 2019; pp. 48–56. [Google Scholar]

- Chrenko, D.; Gan, S.; Gutenkunst, C.; Kriesten, R.; Moyne, L.L. Novel Classification of Control Strategies for Hybrid Electric Vehicles. In Proceedings of the 2015 IEEE Vehicle Power Propulsion Conference, Montreal, QC, Canada, 19–22 October 2015; pp. 1–6. [Google Scholar]

- Liu, T.; Wang, B.; Yang, C. Online Markov Chain-based energy management for a hybrid tracked vehicle with speedy Q-learning. Energy 2018, 160, 544–555. [Google Scholar] [CrossRef]

- Zhang, P.; Yan, F.; Du, C. A comprehensive analysis of energy management strategies for hybrid electric vehicles based on bibliometrics. Renew. Sustain. Energy Rev. 2015, 48, 88–104. [Google Scholar] [CrossRef]

- Moura, S.J.; Fathy, H.K.; Callaway, D.S.; Stein, J.L. A Stochastic Optimal Control Approach for Power Management in Plug-In Hybrid Electric Vehicles. IEEE Trans. Control Syst. Technol. 2011, 19, 545–555. [Google Scholar] [CrossRef]

- Wang, H.; Huang, Y.; Khajepour, A.; He, H.; Cao, D. A novel energy management for hybrid off-road vehicles without future driving cycles as a priori. Energy 2007, 133, 929–940. [Google Scholar] [CrossRef]

- Katrašnik, T. Hybridization of powertrain and downsizing of IC engine—A way to reduce fuel consumption and pollutant emissions—Part 1. Energy Convers. Manag. 2007, 48, 1411–1423. [Google Scholar] [CrossRef]

- Petris, C.D.; Giglio, V.; Police, G.; Police, G. Can Hybrid Vehicles Reduce the Pollutant Emission in Urban Environments? SAE Tech. Paper 1993, 930046. [Google Scholar] [CrossRef]

- Demirdöven, N.; Deutch, J. Hybrid cars now, fuel cell cars later. Science 2004, 305, 974–976. [Google Scholar] [CrossRef]

- Wróblewski, P. Technology for Obtaining Asymmetries of Stereometric Shapes of the Sealing Rings Sliding Surfaces for Selected Anti-Wear Coatings. In Proceedings of the SAE Powertrains, Fuels & Lubricants Meeting, Krakow, Poland, 22–24 September 2020. [Google Scholar] [CrossRef]

- Wróblewski, P.; Iskra, A. Problems of Reducing Friction Losses of a Piston-Ring-Cylinder Configuration in a Combustion Piston Engine with an Increased Isochoric Pressure Gain. In Proceedings of the SAE Powertrains, Fuels & Lubricants Meeting, Krakow, Poland, 22–24 September 2020. [Google Scholar] [CrossRef]

- Wróblewski, P.; Iskra, A. Geometry of shape of profiles of the sliding surface of ring seals in the aspect of friction losses and oil film parameters. Combust. Engines 2016, 167, 24–38. [Google Scholar] [CrossRef]

- Wróblewski, P. Effect of asymmetric elliptical shapes of the sealing ring sliding surface on the main parameters of the oil film. VII International Congress on Combustion Engines. Combust. Engines 2017, 168, 84–93. [Google Scholar] [CrossRef]

- Wróblewski, P. The effect of the distribution of variable characteristics determining the asymmetry of the sealing rings sliding surfaces on the values of friction loss coefficients and other selected parameters of oil film. Combus. Engines 2017, 171, 107–116. [Google Scholar] [CrossRef]

- Ericsson, E. Variability in urban driving patterns. Transp. Res. Part D 2000, 5, 337–354. [Google Scholar] [CrossRef]

- Wirasingha, S.G.; Schofield, N.; Emadi, A. Plug-in hybrid electric vehicle developments in the US: Trends, barriers, and economic feasibility. In Proceedings of the 2008 IEEE Vehicle Power Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–8. [Google Scholar]

- Ericsson, E. Independent driving pattern factors and their influence on fuel-use and exhaust emission factors. Transp. Res. Part D 2001, 6, 325–345. [Google Scholar] [CrossRef]

- Wirasingha, S.G.; Emadi, A. Classification and Review of Control Strategies for Plug-In Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2011, 60, 111–122. [Google Scholar] [CrossRef]

- Khan, M.; Kockelma, K.M. Predicting the market potential of plug-in electric vehicles using multiday GPS data. Energy Policy 2012, 46, 225–233. [Google Scholar] [CrossRef]

- Gong, Q.; Li, Y.; Peng, Z.R. Trip Based Power Management of Plug-in Hybrid Electric Vehicle with Two-Scale Dynamic Programming. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Arlington, TX, USA, 9–12 September 2007; pp. 12–19. [Google Scholar]

- Mehar, S.; Senouci, S.M.; Remy, G. EV-planning: Electric vehicle itinerary planning. In Proceedings of the Smart Communications in Network Technologies (SaCoNeT), 2013 International Conference, Paris, France, 17–19 June 2013; pp. 1–5. [Google Scholar]

- Larsson, V.; Mårdh, L.J.; Egardt, B.; Karlsson, S. Commuter Route Optimized Energy Management of Hybrid Electric Vehicles. IEEE Trans. Intell. Transp. Syst. 2014, 15, 1145–1154. [Google Scholar] [CrossRef]

- Karden, E.; Ploumen, S.; Fricke, B.; Miller, T.; Snyder, K. Energy storage devices for future hybrid electric vehicles. J. Power Sources 2007, 168, 2–11. [Google Scholar] [CrossRef]

- Li, M.; Xu, H.; Li, W.; Liu, Y.; Li, F.; Hu, Y.; Liu, L. The structure and control method of hybrid power source for electric vehicle. Energy 2016, 112, 1273–1285. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J. Implementation methodology of powertrain for series-hybrid military vehicles applications equipped with hybrid energy storage. Energy 2017, 120, 229–240. [Google Scholar] [CrossRef]

- Borhan, H.; Vahidi, A.; Phillips, A.M.; Kuang, M.L.; Kolmanovsky, I.V.; Cairano, S.D. MPC-Based Energy Management of a Power-Split Hybrid Electric Vehicle. IEEE Trans. Control Syst. Technol. 2012, 20, 593–603. [Google Scholar] [CrossRef]

- Du, J.; Chen, J.; Song, Z.; Gao, M.; Ouyang, M. Design method of a power management strategy for variable battery capacities range-extended electric vehicles to improve energy efficiency and cost-effectiveness. Energy 2017, 121, 32–42. [Google Scholar] [CrossRef]

- Shen, P.; Zhao, Z.; Zhan, X.; Li, J. Particle swarm optimization of driving torque demand decision based on fuel economy for plug-in hybrid electric vehicle. Energy 2017, 123, 89–107. [Google Scholar] [CrossRef]

- Vinot, E.; Trigui, R. Optimal energy management of HEVs with hybrid storage system. Energy Convers. Manag. 2013, 76, 437–452. [Google Scholar] [CrossRef]

- Shen, P.; Zhiguo, Z.; Xiaowen, Z.; Jingwei, L.; Iuyi, G. Optimal energy management strategy for a plug-in hybrid electric commercial vehicle based on velocity prediction. Energy 2018, 155, 838–852. [Google Scholar] [CrossRef]

- Birrell, S.; Taylor, J.; McGordon, A.; Son, J.; Jennings, P. Analysis of three independent real-world driving studies: A data driven and expert analysis approach to determining parameters affecting fuel economy. Transp. Res. Part D 2014, 33, 74–86. [Google Scholar] [CrossRef]

- Pasaoglu, G.; Fiorello, D.; Martino, A.; Scarcella, G.; Alemanno, A.; Zubaryeva, C.; Thiel, C. European Commission. Joint Research Centre. Institute for Energy and Transport. In Driving and Parking Patterns of European Car Drivers: A Mobility Survey; Publications Office of the European Union: Brussels, Belgium, 2012; ISBN 9789279277399. [Google Scholar]

- Iglesias-Émbil, M.; Valero, A.; Ortego, A.; Villacampa, M.; Vilaró, J.; Villalba, G. Raw material use in a battery electric car—A thermodynamic rarity assessment. Resour. Conserv. Recycl. 2020, 158, 104820. [Google Scholar] [CrossRef]

- Sanguinetti, A.; Kurani, K.; Davies, J. The many reasons your mileage may vary: Toward a unifying typology of eco-driving behaviors. Transp. Res. Part D Transp. Environ. 2017, 52, 73–84. [Google Scholar] [CrossRef]

- Armoogum, J.; Bouffard-Savary, É.; Caenen, Y.; Couderc, C.; Courel, J.; Delisle, F.; Duprat, P.; Fouin, L.; François, D.; Gascon, M.-O. La Mobilité des Français, Panorama Issu de l’Enquête Nationale Transports et Déplacements 2008; Ministère de l’écologie: Paris, France, 2010.

- Asus, Z.; Chrenko, D.; Aglzim, E.H.; Kéromnès, A.; Moyne, L.L. Simple method of estimating consumption of internal combustion engine for hybrid application. In Proceedings of the 2012 IEEE Transportation Electrification Conference and Expo, ITEC 2012, Dearborn, MI, USA, 18–20 June 2012; IEEE: New York, NY, USA, 2012; pp. 1–6, ISBN 978-1-4673-1408-4. [Google Scholar]

- Chrenko, D.; Garcia Diez, I.; Moyne, L.L. Artificial Driving cycles for the evaluation of energetic needs for electric vehicles. In Proceedings of the iTEC, Dearborn, IL, USA, 17–20 June 2012; pp. 18–20. [Google Scholar]

- Horrein, L.; Bouscayrol, A.; Cheng, Y.; Fassi, M.E. Dynamical and quasi-static multi-physical models of a diesel internal combustion engine using Energetic Macroscopic Representation. Energy Convers. Manag. 2015, 91, 280–291. [Google Scholar] [CrossRef]

- Caposi, A.; Myers, M. Systems for All; Imperial College Press: London, UK, 2001; p. 375. [Google Scholar]

- Li, G.-D.; Yamaguchi, D.; Nagai, M. A GM(1,1)–Markov chain combined model with an application to predict the number of Chinese international airlines. Technol. Forecast. Soc. Chang. 2007, 74, 1465–1481. [Google Scholar] [CrossRef]

- Li, G.-D.; Yamaguchi, D.; Nagai, M. Prediction of relative dynamic elasticity modulus by extending grey system theory. Meas. Sci. Technol. 2007, 18, 827–834. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, J.-Z. A grey rough set model for evaluation and selection of software cost estimation methods. Grey Syst. Theory Appl. 2014, 4, 3–12. [Google Scholar] [CrossRef]

- Liu, S.F.; Dang, Y.G.; Li, B.J.; Li, X.; Wang, L. Computational analysis on the periodic contribution of technological advances in Henan Province. J. Henan Agric. Univ. 1998, 32, 203–207. [Google Scholar]

- Liu, S.F. Grey forecast of drought and inundation in Henan Province. J. Grey Syst. 1994, 6, 279–288. [Google Scholar]

- Liu, S.F.; Lin, Y. Grey System—Theory and Applications; Springer: Berlin, Germany, 2010; p. 379. [Google Scholar]

- Fontaras, G.; Dilara, P. The evolution of European passenger car characteristics 2000–2010 and its effects on real-world CO2 emissions and CO2 reduction policy. Energy Policy 2012, 49, 719–730. [Google Scholar] [CrossRef]

- Macharis, C.; van Hoeck, E.; Pekin, E.; van Lier, T. A decision analysis framework for intermodal transport: Comparing fuel price increases and the internal is ation of external costs. Transport. Res. Part A Policy Practice 2010, 44, 550–561. [Google Scholar] [CrossRef]

- Kayacan, E.; Ulutas, B.; Kaynak, O. Grey system theory-based models in time series prediction. Expert Syst. Appl. 2010, 37, 1784–1789. [Google Scholar] [CrossRef]

- Lin, Z.; Zhang, Q.; Liu, H. Parameters optimization of GM(1,1) model based on artificial fish swarm algorithm. Grey Syst. Theory Appl. 2012, 2, 166–177. [Google Scholar] [CrossRef]

- Yao Albert, W.L.; Chi, S.C. Analysis and design of a Taguchi–Grey based electricity demand predictor for energy management systems. Energy Convers. Manag. 2004, 45, 1205–1217. [Google Scholar]

- Trivedi, H.V.; Singh, K.J. Application of grey system theory in the development of a runoff prediction model. Biosyst. Eng. 2005, 92, 521–526. [Google Scholar] [CrossRef]

- Deng, J.L. Control problems of grey systems. Syst. Control Lett. 1982, 5, 288–294. [Google Scholar]

- Guo, R. Repairable system modelling via grey differential equations. J. Grey Syst. 2005, 8, 69–91. [Google Scholar]

- Lin, C.T.; Yang, S.Y. Forecast of the output value of Taiwan’s optoelectronics industry using the grey forecasting model. Technol. Forecast. Soc. Chang. 2003, 70, 177–186. [Google Scholar] [CrossRef]

- Sijing, C.; Guangxu, T.; Hualin, G. Grey system theory applied to rock mechanics. Geomech. Abstr. 1993, 30, 473–478. [Google Scholar]

- Lim, D.; Anthony, P.; Mun, H.C. Maximizing bidder’s profit in online auctions using grey system theory’s predictor agent. Grey Syst. Theory Appl. 2012, 2, 105–128. [Google Scholar] [CrossRef]

- Dang, L.; Song, B. Analysis of the income elasticity of the consumer demand of Chinese rural residents and prediction of its trend. Grey Syst. Theory Appl. 2012, 2, 148–156. [Google Scholar]

- Pantopian, N.H.; Larsen, J. Unsupervised condition detection in large diesel engines. In Proceedings of the IEEE Workshop on Neural Networks, Toulouse, France, 22–25 August 1999. [Google Scholar]

- Cempel, C. Innovative developments in systems condition monitoring. Key Eng. Mater. 1999, 167–168, 172–188. [Google Scholar] [CrossRef]

- Tumer, I.Y.; Huff, E.M. Principal component analysis of tri-axial vibration data from helicopter transmission. In Proceedings of the 56th Meeting of the Society of Machine Failure Prevention Technology, Virginia Beach, VI, USA, 15–19 April 2002. [Google Scholar]

- Gui, L.; Wu, X. KPCA based multisensor data fusion for the machine fault diagnosis. In Proceedings of the ICME06, Chengdu, China, 15–18 October 2006; pp. 342–352. [Google Scholar]

- Cempel, C.; Natke, H.G.; Yao, J.P.T. Symptom reliability and hazard for systems condition monitoring. Mech. Syst. Signal Process. 2000, 14, 495–505. [Google Scholar] [CrossRef]

- Liu, C.; Gao, Y.; Liu, L. Toward safe rapid battery charging: Design optimal fast charging strategies thorough a physics-based model considering lithium plating. Int. J. Energy Res. 2021, 45, 2303–2320. [Google Scholar] [CrossRef]

- Liu, L.; Zhu, M. Modeling of SEI Layer Growth and Electrochemical Impedance Spectroscopy Response using a Thermal-Electrochemical Model of Li-ion Batteries. ECS Meet. Abstr. 2014, 61, 43–58. [Google Scholar] [CrossRef]

- Liu, C.; Liu, L. Optimizing Battery Design for Fast Charge through a Genetic Algorithm Based Multi-Objective Optimization Framework. ECS Meet. Abstr. 2017, 77, 257–270. [Google Scholar] [CrossRef]

- Liu, L.; Guan, P. Phase-Field Modeling of Solid Electrolyte Interphase (SEI) Evolution: Considering Cracking and Dissolution during Battery Cycling. ECS Meet. Abstr. 2019, 89, 101–109. [Google Scholar] [CrossRef]

- Jiang, K.; Liu, X.; Lou, G.; Wen, Z.; Liu, L. Parameter sensitivity analysis and cathode structure optimization of a non-aqueous Li-O2 battery model. J. Power Sources 2020, 451, 227821. [Google Scholar] [CrossRef]

- Liu, S.; Liu, X.; Dou, R.; Zhou, W.; Wen, Z.; Liu, L. Experimental and simulation study on thermal characteristics of 18,650 lithium-iron-phosphate battery with and without spot-welding tabs. Appl. Therm. Eng. 2020, 166, 114648. [Google Scholar] [CrossRef]

- Mu, W.; Liu, X.; Wen, Z.; Liu, L. Numercial simulation of the factors affecting the growth of lithium dendrites. J. Energy Storage 2019, 26, 100921. [Google Scholar] [CrossRef]

- O’Malley, R.; Liu, L.; Depcik, C. Comparative study of various cathodes for lithium ion batteries using an enhanced Peukert capacity model. J. Power Sources 2018, 396, 621–631. [Google Scholar] [CrossRef]

- Cempel, C. Generalized singular value decomposition in multidimensional condition monitoring of machines-A proposal of comparative diagnostics. Mech. Syst. Signal Process. 2009, 23, 701–711. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).