1. Introduction

Due to new cooling comfort demands, caused by higher internal heat gains, better insulation, but also by increasing outdoor temperatures due to climate change, the cooling demand of buildings is rising. According to the International Energy Agency (IEA), the use of energy for space cooling is growing faster than for any other end use in buildings. Annual sales of air conditioning devices more than tripled between 1990 and 2016 [

1]. The IEA forecasting establishes a baseline scenario, which envisages a further tripling in energy needs for space cooling by 2050 [

1]. The climate change may play a decisive role in the cooling demand rise. Yalew et al. [

2] analysed results of 220 studies, published between the years 2002–2019, projecting climate change impacts on energy systems generally, including cooling demands. The literature review shows a global consensus on decreases in heating demand in cold regions and increases in cooling demand in warm regions. The most substantial impact on energy demand is anticipated to occur in the hot summer and warm winter climates, particularly in the built environment where the DHC systems are a suitable solution. The anticipated cooling demand change on regional level ranges from a small variation in the regions of Western Europe and Former Soviet Union, to over 20% increase in Latin America and the Caribbean, Pacific OECD and South Asia. Other recent papers report forecasts of a significant cooling demand rise in historically cold climates. Berardi and Jafarpur [

3] performed simulations for 16 building typologies for Toronto (ON, Canada), using different weather files derived from the North American Regional Climate Change Assessment Program [

4]. The outcome of their study shows an average cooling demand increase in a range of 15–126% by 2070, depending on the baseline climatic file adopted and building typology. Yet, the increases in cooling consumption are also expected to depend strongly on socio-economic development [

3]. The Netherlands Environmental Assessment Agency maintains that the cooling demand for residential sector would surpass the heating one by around 2060 [

5].

Decarbonizing of energy systems in general, and of heating and cooling services particularly, becomes a major challenge. District energy, fed with renewables, low exergy or waste energy sources, is envisaged as an important contributing solution in carbon emission reduction [

6].

Due to cooling demand rise, it is expected that many existing district heating (DH) systems are going to be upgraded with district cooling (DC) infrastructure and thus complemented to provide cooling service, while new district energy systems are going to offer both heating and cooling from the beginning. Nowadays, modern 4th generation district energy systems frequently include both heating and cooling provision to the clients [

7]. Also, the 5th generation district energy systems conceptualization takes into account both heating and cooling provision [

8].

The assessment of a DHC system, providing both heating and cooling, is becoming more challenging when the same equipment or system elements are used for purposes of producing heating and cooling, either simultaneously or alternatively. This is particularly truth for complex systems, which involves different energy sources and technologies in a single ensemble of a district energy systems. Indeed, many components of such a system may be used for both heating and cooling: reversible heat pumps, heat generation or recovery applied to thermally driven cooling technologies, geothermal probes coupled with ground source heat pumps, and photovoltaics among other. Moreover, a growing endeavour of energy vector coupling, including renewable heat, electricity, green hydrogen, and syngas, is going to lead to even more complex district energy systems.

A split assessment of each service to be provided is needed in order to be able to assess correctly a given complex system, to follow the decarbonizing evolution of an existing DHC over time, to perform a comparison between different district energy configurations or a comparison among district energy and conventional solutions.

The question of DH systems assessment has been treated from the standpoint of tariff benchmarking [

9,

10], tariffs, cost efficiency and profitability [

11] or environmental behavior of systems. Noussan [

12] analysed the performance of 140 Italian district heating systems, by calculating the primary energy factor and the CO

2 emission factor of the heat supplied to the end-users, using the current methodology defined by the European Standards.

The Euro Heat & Power (EHP) Association has developed guidelines for evaluation of district heating (DH) systems [

13], establishing the KPI which focus on heating supply in terms of renewable energy contribution, non-renewable primary energy and carbon emission factor, for a given district heating system. The EHP set of indicators does not cover economy assessment nor local emissions impact. Kveselis et al. [

14] applied EHP guidelines to perform a comparison among 28 Lithuanian DH companies were analysed, where required data about their performance indicators was available through data basis of Lithuanian District Heating Association.

Ghafghazi et al. [

15] proposed a multicriteria methodology approach for DH source election. The methodology uses six indicators, three of them quantitative: costs, GHG emissions, particulate matter emission and other three qualitative: maturity of the technology, use of local sources and traffic load. The decision process includes analytic hierarchy process (AHP) which helps to weights the criteria, taking into account different interest groups: developer, environmental group, and community representative group. Pakere et al. [

16] suggested the use of a climate index as a common indicator to evaluate the performance of DH system efficiency, environmental impact and sustainability. Seven different criteria are used for the evaluation: share of RES, share of RES CHP, specific CO

2 emissions, environmental costs, specific distribution heat losses, primary energy factor and share of heat delivered by industrial activity. The criteria are weighted according to the AHP method which reflects the relative importance of the criteria. In both [

15,

16] some of the indicators used are not defined with proper precision: “industrial heat” [

16] or has qualitative indicators with binary value—yes/no, which allows subjective interpretation [

15].

Volkova et al. [

17] proposed a methodology for assessing the transition of the existing systems towards 4th generation DH. The authors use five key performance indicators (KPIs), namely: DH supply and return average temperatures, network effective average heat transmission coefficient, the share of consumers covered by intelligent metering, annual total renewable (non-fuel) energy, CHP heat capacity and the share of short-term thermal energy storage.

After the literature review, we can conclude that: (1) none of the identified district energy system performance assessment methodologies and benchmarking studies include district cooling, even if the cooling is becoming more and more significant part of buildings energy demand, as explained above; (2) comprehensive methodology for performance analysis of combined DHC systems has not been reported within the existing bibliography.

The motivation of the present investigation resides in the need for a proper environmental, but also energy and economic assessment of DHC system performance. An assessment of such kind should provide quantitative information, which is calculated in transparent and traceable manner, by a robust standardized methodology. This kind of assessment may be carried out throughout a set of KPIs. Moreover, besides the assessment of a DHC system with independent infrastructures for, on one side heating and on the other side cooling, the methodology should be capable of assessing correctly the cases where some of the equipment or infrastructure is shared, means used for both heating and cooling purposes. During the accomplished literature review we have identified a lack of methodologies to calculate an appropriate KPI for such a purpose.

It is worth clarifying here that the shared equipment or infrastructure is limited to the production plant for the 3rd and 4th generation systems, as they operate with four pipe networks forming independent loops for heating and for cooling, while for the 5th generation systems, besides the production plant equipment also the distribution infrastructure may become common.

The present methodology proposes and defines a set of eleven KPIs as a tool for assessing a district energy system (DHC) behaviour in separate fashion for heating service and for cooling service, including the case when both services are sharing some of the system elements. The suggested KPIs are designed to reflect the most significant aspects of a district heating and cooling system behaviour, in terms of energy, environment, economic, and social aspects. Each KPI is defined for heating service and for cooling service. According to this, the methodology proposes a demand-based and an investment-based share factors that facilitate the heating and cooling KPI calculation.

The paper is structured as follows: In

Section 2 the methodology is explained, detailing the analysis boundaries and establishes parameters that are later used for KPI definition and calculation, including the share factors.

Section 3 is dedicated to the KPI definition and calculation formulas. It includes the definition and description of each KPI, and it is divided in four parts: energy, environment, economics, and socio-economics. The energy chapter presents the indicators for analysing the decarbonisation and implementation of renewables in district energy systems, on one hand establishing the calculation of the renewable energy ratio (

RER) and on the other hand indicating its impact on the overall non-renewable energy use. Obviously, the final goal of the implementation of renewables is to reduce the greenhouse gas (GHG) missions and the local pollution. Hence, the environment chapter describes the calculation of the emissions related KPI. On top of achieving the environmental goals, the renewable DHC concept must be made economically feasible, hence the economics section addresses the indicators for measuring the investment required, the operation cost, as well as the cost of energy. Finally, financial evaluation of the DHC cost may not include the overall social economy benefits of introducing renewables, as the reduction of emissions and pollution drops the negative impacts on health and environment. This can be related in reduced cost on the health system, which is introduced in social cost indicator.

Section 4 is dedicated to an implementation example which refers to the district energy system in Olot (Spain). In

Section 5 the proposed methodology is discussed, while in

Section 6 summary and conclusions are drafted. The results presented here are the outcome of the wider methodological development carried out within the EU Horizon 2020 research project WEDISTRICT [

18].

4. Implementation Example: Olot (Spain) District Energy

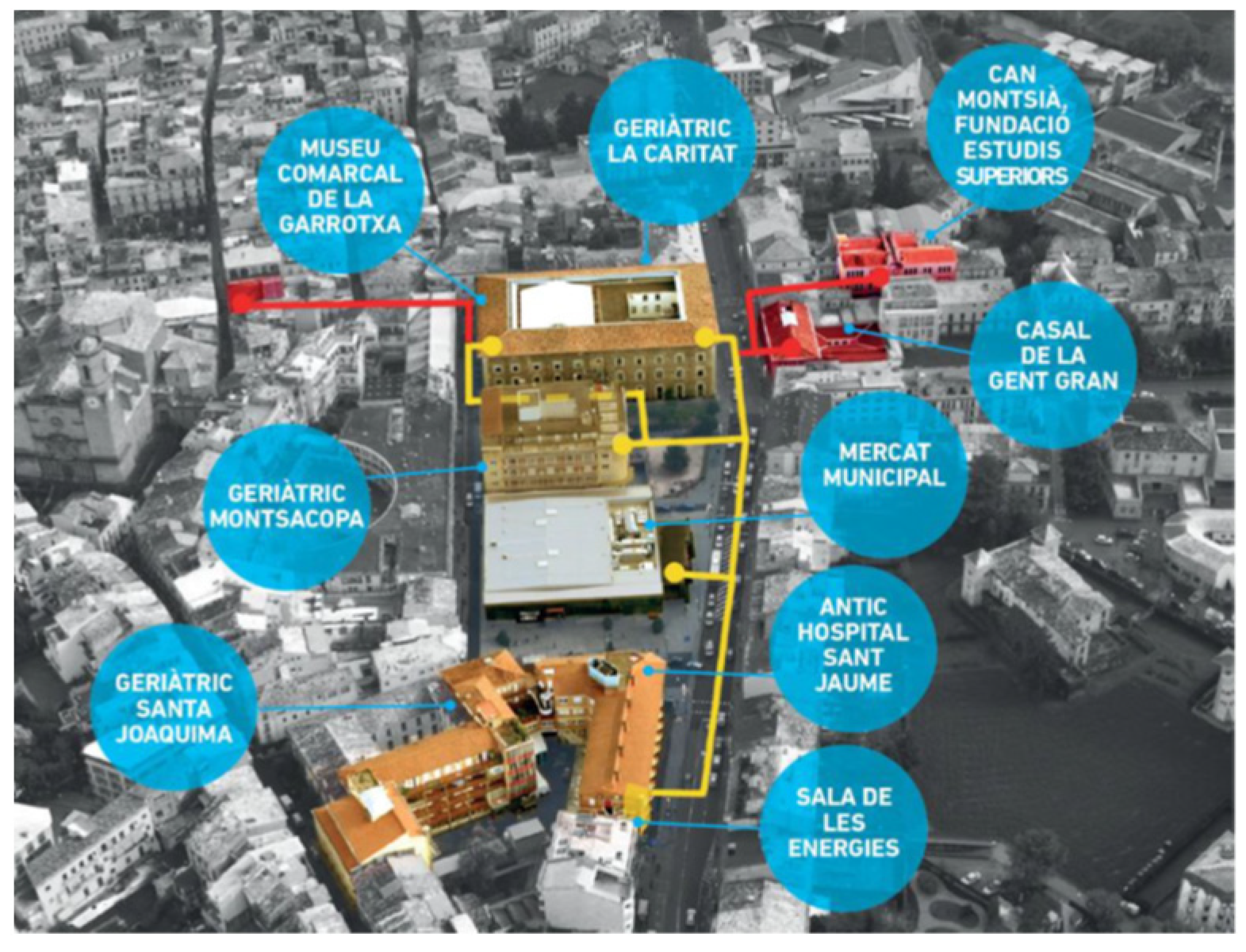

The Olot (Catalonia, Spain) district heating and cooling system is an example of a small high renewable use network. The district has a generation plant composed of two biomass boilers, three heat pumps coupled with a geothermal field, and PV panels. The heat pumps are providing both heat in winter season and cooling in summer season. Currently five buildings are connected to the network, see yellow connections in

Figure 5, with prevision to extend to further clients (red connections).

The Olot DHC concept is somewhat singular, trying to cover previously existing demands in the most efficient manner. It is based on the supply of high temperature heating, low temperature heating and cooling, providing all these services through two loops network (four pipes distribution). One loop is dedicated all year around to the high temperature heat demands (conventional heating systems and domestic hot water) and corresponds to the usual heat distribution in DHC systems. The other loop supplies the low temperature demands (floor heating systems) during the winter season and delivers cooling during the summer period.

The KPI input parameters are summarized, in

Appendix A, as follows. The delivered thermal energy and both fuel and electricity consumption are described in

Table A1 and

Table A2, with the economic parameters are summarized in

Table A3. Finally, the factor for primary energy, emissions, and social cost are taken from ISO52000 [

26] and European Environmental Agency [

37], as summarized in

Table A4 and

Table A5. As described in the methodology section, the first step in the KPI calculation is to obtain the energy share factor and the investment share factor, according Equations (1) and (2). Being a heating dominant system, heating demand being almost 27 times de cooling demand, and with the equipment serving cooling also used for heating in winter, both share factor have very low values, as summarized in

Table 1.

With all the data collected and the share factor obtained, the KPI can be calculated. It is important to notice that the district does not export energy outside the system, with all the PV energy used to power the circulation pumps and the heat pump. Moreover, the air pollutants emissions are only considered as local impacts, hence those related to the energy grid are no taken into account in the calculation. This causes the cooling supply to have zero emissions of NOx, SO2, and PM2.5 associated to it.

The results are presented in

Table 2, showing that the heating part has a higher renewable share, hence lower CO

2 emissions. However, as the biomass produces local air pollutants, the social health impact is also much higher.

From the obtained share factors one can observe that the major part of both the energy provided by the system and the investment go for heating service. What we can also see from the results of the present example is that the heating service is almost totally fed with renewable sources (93.9%) while the cooling service is much less covered with renewable energy (19.9%). Both services perform good in terms of carbon emissions, yet the heating reaches better figure. However, the heating service provokes local pollutants emissions, due to the intense use of biomass.

5. Discussion

By applying the proposed methodology to the Olot example, we can conclude that with a complete overview and the detailed information on the project, the assessment of all the KPIs is clear and straightforward process. Having in mind that the system architecture of this case is not the most common one but rather complex, with shared ground source heat pumps and PV, and a 4-pipe distribution system consisting of one loop for high temperature heating and domestic hot water all year around, and another for low temperature demands (floor heating systems) during the winter season and cooling demands during the summer period.

The introduction of share factors is considered as a major contribution of the present methodology as it permits to assess correctly the common element used for both heating and cooling production and supply. The use of such shared elements adds value to overall district energy system, both in terms of economy by reducing

CAPEX and

OPEX, as in terms of energy efficiency and environmental impact. In fact, use of heat pumps for simultaneous production of heating and cooling is becoming frequent in big DHC systems [

25,

38].

The choice of the KPIs is considered appropriate and complete enough for a proper system overall assessment. It provides a tool which can assess the achievement of measurable objectives, which in general terms should be the 100% or near 100% renewable energy DHC, or carbon neutral DHC systems, although each case or benchmark study may have it particular objectives.

Yet, the methodology in its present formulation does not facilitate a straightforward benchmarking by comparison of a single unified indicator, like methodologies used in [

15] or [

16]. Yet, departing from the defined set of KPIs it is possible to apply Analytical Hierarchy Process (AHP) methodology to define the weight factors for each KPI and to calculate a weighted average as the final score of the assessment. If needed, this further step should be performed for each individual assessment case, as the right factors strongly depend the local circumstances and thus of the assessment process targets.

The proposed set of system KPIs is expected to be useful to technology integrators and utilities, but also to public administration, in order to check and benchmark the resource, environmental, economic, and social impacts of the systems. Yet, the proposed assessment methodology of district energy system will become a useful tool only if it proves useful in the engineering practice and energy planning decision making.