Stationary, Second Use Battery Energy Storage Systems and Their Applications: A Research Review

Abstract

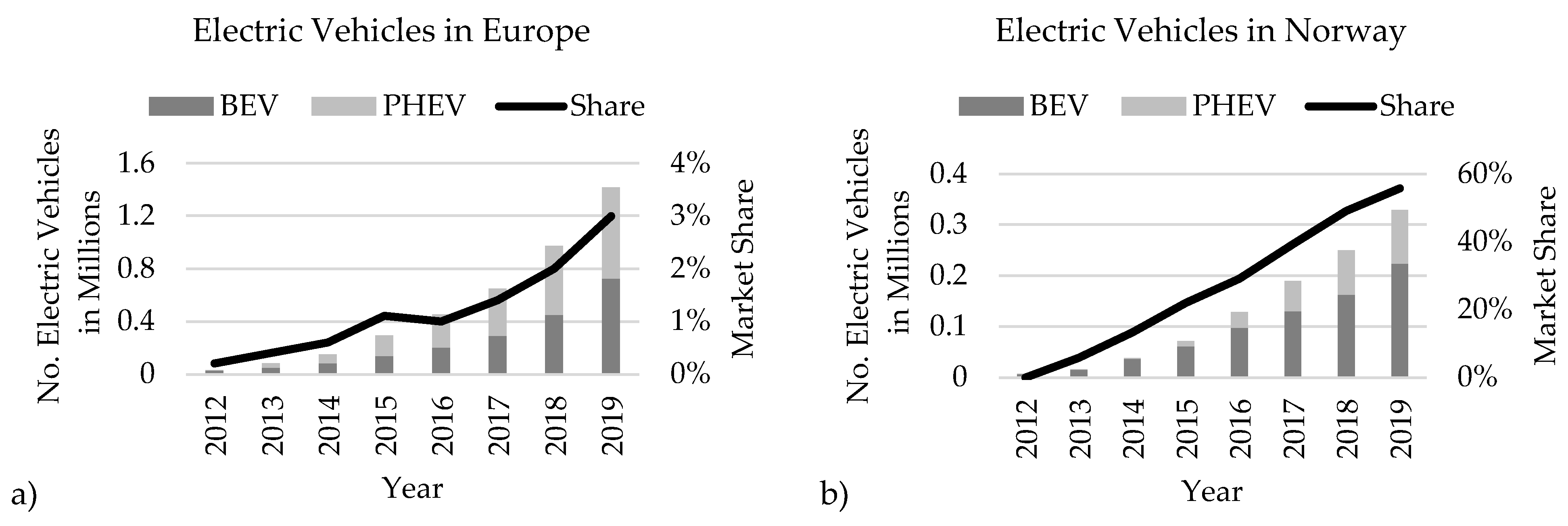

:1. Introduction

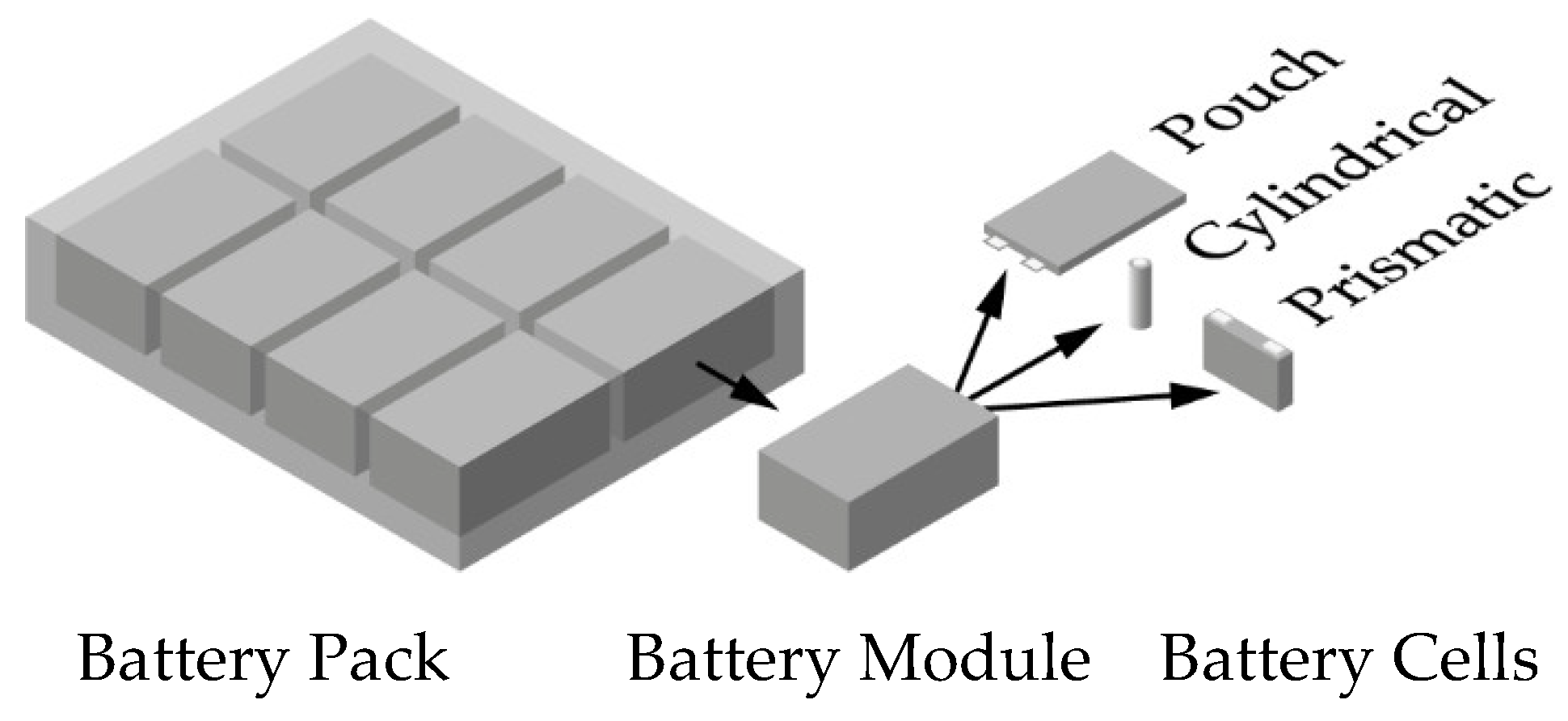

2. Second Use: Terms and Definitions

2.1. Reuse

2.2. Second Use

3. Method

4. Battery Energy Storage Systems: Applications

5. Second Use Storage Systems in Europe

6. Trends and Developments Outside of Europe

6.1. Second Use in North America and Australia

6.2. Second Use in South America and Africa

6.3. Second Use in Asia

7. Barriers and Outlook

7.1. Economic Barriers

7.2. Environmental Barriers

7.3. Technological Barriers

7.4. Regulatory Barriers

8. Discussion and Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | Alternating Current |

| BESS | Battery Energy Storage System |

| BEV | Battery Electric Vehicle |

| DC | Direct Current |

| DOE | Department of Energy |

| EU | European Union |

| EV | Electric Vehicle |

| JRC | Joint Research Centre |

| MONA | Merit Order Netz-Ausbau |

| NMC | Nickel-Manganese-Cobalt |

| PHEV | Plug-in Hybrid Electric Vehicle |

| sim | Simulation |

| US | United States |

References

- United Nations. Paris Agreement; United Nations: Paris, France, 2015; p. 27. [Google Scholar]

- Dincer, I. Renewable Energy and Sustainable Development: A Crucial Review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Saint Akadiri, S.; Alola, A.A.; Akadiri, A.C.; Alola, U.V. Renewable Energy Consumption in EU-28 Countries: Policy toward Pollution Mitigation and Economic Sustainability. Energy Policy 2019, 132, 803–810. [Google Scholar] [CrossRef]

- Villavicencio Calzadilla, P.; Mauger, R. The UN’s New Sustainable Development Agenda and Renewable Energy: The Challenge to Reach SDG7 While Achieving Energy Justice. J. Energy Nat. Resour. Law 2018, 36, 233–254. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2019; IEA: Paris, France, 2019; p. 810. [Google Scholar]

- Lajunen, A.; Kivekäs, K.; Vepsäläinen, J.; Tammi, K. Influence of Increasing Electrification of Passenger Vehicle Fleet on Carbon Dioxide Emissions in Finland. Sustainability 2020, 12, 5032. [Google Scholar] [CrossRef]

- Dominković, D.F.; Bačeković, I.; Pedersen, A.S.; Krajačić, G. The Future of Transportation in Sustainable Energy Systems: Opportunities and Barriers in a Clean Energy Transition. Renew. Sustain. Energy Rev. 2018, 82, 1823–1838. [Google Scholar] [CrossRef]

- Guminski, A.; Böing, F.; Murmann, A.; von Roon, S. System Effects of High Demand-Side Electrification Rates: A Scenario Analysis for Germany in 2030. Wiley Interdiscip. Rev. Energy Environ. 2019, 8, e327. [Google Scholar] [CrossRef]

- Brinkel, N.B.G.; Schram, W.L.; AlSkaif, T.A.; Lampropoulos, I.; van Sark, W.G.J.H.M. Should We Reinforce the Grid? Cost and Emission Optimization of Electric Vehicle Charging under Different Transformer Limits. Appl. Energy 2020, 276, 115285. [Google Scholar] [CrossRef]

- Kapustin, N.O.; Grushevenko, D.A. Long-Term Electric Vehicles Outlook and Their Potential Impact on Electric Grid. Energy Policy 2020, 137, 111103. [Google Scholar] [CrossRef]

- Janda, K.; Málek, J.; Rečka, L. Influence of Renewable Energy Sources on Transmission Networks in Central Europe. Energy Policy 2017, 108, 524–537. [Google Scholar] [CrossRef]

- Mueller, D. Grid Extension in German Backyards: A Game-Theory Rationale. J. Environ. Plan. Manag. 2017, 60, 437–461. [Google Scholar] [CrossRef]

- Droste-Franke, B.; Paal, B.P.; Rehtanz, C.; Sauer, D.U.; Schneider, J.-P.; Schreurs, M.; Ziesemer, T. Balancing Renewable Electricity; Ethics of Science and Technology Assessment; Springer: Berlin/Heidelberg, Germany, 2012; Volume 40, ISBN 978-3-642-25156-6. [Google Scholar]

- Madlener, R.; Specht, J.M. An Exploratory Economic Analysis of Underground Pumped-Storage Hydro Power Plants in Abandoned Coal Mines. SSRN Electron. J. 2013. [Google Scholar] [CrossRef] [Green Version]

- Palensky, P.; Dietrich, D. Demand Side Management: Demand Response, Intelligent Energy Systems, and Smart Loads. IEEE Trans. Ind. Inform. 2011, 7, 381–388. [Google Scholar] [CrossRef] [Green Version]

- Ogunniyi, E.O.; Pienaar, H. Overview of Battery Energy Storage System Advancement for Renewable (Photovoltaic) Energy Applications. In Proceedings of the 2017 International Conference on the Domestic Use of Energy (DUE), Cape Town, South Africa, 4–5 April 2017; pp. 233–239. [Google Scholar]

- Hesse, H.; Schimpe, M.; Kucevic, D.; Jossen, A. Lithium-Ion Battery Storage for the Grid—A Review of Stationary Battery Storage System Design Tailored for Applications in Modern Power Grids. Energies 2017, 10, 2107. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Wei, Y.-L.; Cao, P.-F.; Lin, M.-C. Energy Storage System: Current Studies on Batteries and Power Condition System. Renew. Sustain. Energy Rev. 2018, 82, 3091–3106. [Google Scholar] [CrossRef]

- Gissey, G.C.; Subkhankulova, D.; Dodds, P.E.; Barrett, M. Value of Energy Storage Aggregation to the Electricity System. Energy Policy 2019, 128, 685–696. [Google Scholar] [CrossRef]

- Regett, A.; Zeiselmair, A.; Wachinger, K.; Heller, C. Merit Order Netz-Ausbau 2030: Szenario-Analyse—Potenzielle Zukünftige Rahmenbedingungen für den Netz-Ausbau: Abschlussbericht; FfE Forschungsstelle für Energiewirtschaft e.V: Munich, Germany, 2017; ISBN 978-3-941802-34-6. [Google Scholar]

- Comello, S.; Reichelstein, S. The Emergence of Cost Effective Battery Storage. Nat. Commun. 2019, 10, 2038. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.-I.; Swierczynski, M.; Goikoetxea, A. Battery Second Life: Hype, Hope or Reality? A Critical Review of the State of the Art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Grelier, F.; Poliscanova, J.; Ambel, C.C.; Bannon, E.; Alexandridou, S. Electric Surge: Carmakers’ Electric Car Plans Across Europe 2019–2025; European Federation for Transport and Environment AISBL: Brussels, Belgium, 2019; p. 39. [Google Scholar]

- IEA. Global EV Outlook 2020; IEA: Paris, France, 2020; p. 276. [Google Scholar]

- European Commission. European Alternative Fuels Observatory: Passenger Cars. Available online: https://www.eafo.eu/vehicles-and-fleet/m1 (accessed on 7 July 2020).

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling Lithium-Ion Batteries from Electric Vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cusenza, M.A.; Guarino, F.; Longo, S.; Mistretta, M.; Cellura, M. Reuse of Electric Vehicle Batteries in Buildings: An Integrated Load Match Analysis and Life Cycle Assessment Approach. Energy Build. 2019, 186, 339–354. [Google Scholar] [CrossRef]

- Jafari, M.; Gauchia, A.; Zhao, S.; Zhang, K.; Gauchia, L. Electric Vehicle Battery Cycle Aging Evaluation in Real-World Daily Driving and Vehicle-to-Grid Services. IEEE Trans. Transp. Electrif. 2018, 4, 122–134. [Google Scholar] [CrossRef]

- Jiao, N.; Evans, S. Business Models for Sustainability: The Case of Second-Life Electric Vehicle Batteries. Procedia CIRP 2016, 40, 250–255. [Google Scholar] [CrossRef] [Green Version]

- Lavoie, Y.; Danet, F.; Lombard, B. Lithium-Ion Batteries for Industrial Applications. In Proceedings of the 2017 Petroleum and Chemical Industry Technical Conference (PCIC), Calgary, AB, Canada, 18–20 September 2017; pp. 283–290. [Google Scholar]

- Ahmadi, L.; Young, S.B.; Fowler, M.; Fraser, R.A.; Achachlouei, M.A. A Cascaded Life Cycle: Reuse of Electric Vehicle Lithium-Ion Battery Packs in Energy Storage Systems. Int. J. Life Cycle Assess. 2017, 22, 111–124. [Google Scholar] [CrossRef]

- Schoch, J. Battery Life Optimal Operation of Electric Vehicles. Ph.D. Thesis, Karlsruhe Institute of Technology, Karlsruhe, Germany, 2018. [Google Scholar]

- Mousavi, G.S.M.; Nikdel, M. Various Battery Models for Various Simulation Studies and Applications. Renew. Sustain. Energy Rev. 2014, 32, 477–485. [Google Scholar] [CrossRef]

- Guha, A.; Patra, A. State of Health Estimation of Lithium-Ion Batteries Using Capacity Fade and Internal Resistance Growth Models. IEEE Trans. Transp. Electrif. 2018, 4, 135–146. [Google Scholar] [CrossRef]

- Li, Y.; Liu, K.; Foley, A.M.; Zülke, A.; Berecibar, M.; Nanini-Maury, E.; Van Mierlo, J.; Hoster, H.E. Data-Driven Health Estimation and Lifetime Prediction of Lithium-Ion Batteries: A Review. Renew. Sustain. Energy Rev. 2019, 113, 109254. [Google Scholar] [CrossRef]

- Sidorov, D.; Muftahov, I.; Tomin, N.; Karamov, D.; Panasetsky, D.; Dreglea, A.; Liu, F.; Foley, A. A Dynamic Analysis of Energy Storage With Renewable and Diesel Generation Using Volterra Equations. IEEE Trans. Ind. Inform. 2020, 16, 3451–3459. [Google Scholar] [CrossRef] [Green Version]

- Cadini, F.; Zio, E.; Avram, D. Model-Based Monte Carlo State Estimation for Condition-Based Component Replacement. Reliab. Eng. Syst. Saf. 2009, 94, 752–758. [Google Scholar] [CrossRef]

- Yatsenko, Y.; Hritonenko, N. Discrete-Continuous Analysis of Optimal Equipment Replacement. Int. Trans. Oper. Res. 2010, 17, 577–593. [Google Scholar] [CrossRef] [Green Version]

- Müller, M.; Viernstein, L.; Truong, C.N.; Eiting, A.; Hesse, H.C.; Witzmann, R.; Jossen, A. Evaluation of Grid-Level Adaptability for Stationary Battery Energy Storage System Applications in Europe. J. Energy Storage 2017, 9, 1–11. [Google Scholar] [CrossRef]

- Herdlitschka, M.; Schröder, H. Daimler and Enercity Put Battery Replacement Parts Store for Electric Vehicles on the Grid; Diamler: Stuttgart, Germany, 2017; p. 4. [Google Scholar]

- Herdlitschka, M.; Halwachs, K.; Ballek, D. Shining Example of the Energy Turnaround: Coal-Fired Power Station Becomes Battery Storage Plant; Stuttgart, Germany, 2018; p. 4. Available online: https://media.daimler.com/marsMediaSite/instance/ko.xhtml?oid=40586809&filename=Shining-example-of-the-energy-turnaround-Coal-fired-power-station-becomes-battery-storage-plant (accessed on 15 April 2021).

- Brúch, W.; Hillmer, K.K.; Hoenicke, C. Ein Zweites Leben für Elektroauto-Batterien; Munich/Stuttgart/Hamburg, Germany, June 2016; p. 2. Available online: https://group.vattenfall.com/de/newsroom/pressemitteilungen/2016/ein-zweites-leben-fuer-gebrauchte-batterien (accessed on 15 April 2021).

- Keene, E.R. A Second Life for Batteries: From Energy Usage to Industrial Storage. Available online: https://easyelectriclife.groupe.renault.com/en/outlook/energy/a-second-life-for-batteries-from-energy-usage-to-industrial-storage (accessed on 30 June 2020).

- Reinhardt, R.; Christodoulou, I.; Gassó-Domingo, S.; Amante García, B. Towards Sustainable Business Models for Electric Vehicle Battery Second Use: A Critical Review. J. Environ. Manag. 2019, 245, 432–446. [Google Scholar] [CrossRef]

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Sunny, M.S.H.; Mohammad, N. A Comprehensive Review on Second-Life Batteries: Current State, Manufacturing Considerations, Applications, Impacts, Barriers & Potential Solutions, Business Strategies, and Policies. IEEE Access 2019, 7, 73215–73252. [Google Scholar] [CrossRef]

- Reinhardt, R.; Garcia, B.A.; Casals, L.C.; Domingo, S.G. Critical Evaluation of European Union Legislation on the Second Use of Degraded Traction Batteries. In Proceedings of the 2016 13th International Conference on the European Energy Market (EEM), Porto, Portugal, 6–9 June 2016; pp. 1–5. [Google Scholar]

- Smith, V.M.; Keoleian, G.A. The Value of Remanufactured Engines: Life-Cycle Environmental and Economic Perspectives. J. Ind. Ecol. 2008, 8, 193–221. [Google Scholar] [CrossRef]

- European Commission. Batteries Europe. Available online: https://ec.europa.eu/energy/topics/technology-and-innovation/batteries-europe_en (accessed on 28 August 2020).

- Fitzgerald, G.; Mandel, J.; Morris, J.; Touati, H. The Economics of Battery Energy Storage: How Multi-Use, Customer-Sited Batteries Deliver the Most Services and Value to Customers and the Grid; Rocky Mountain Institute: Boulder, CO, USA, 2015; p. 41. [Google Scholar]

- Reid, D.; Julve, J. Second Life-Batterien Als Flexible Speicher Für Erneuerbare Energien; Berlin, Germany, 2016; p. 46. Available online: https://speicherinitiative.at/wp-content/uploads/sites/8/2020/11/05-SecondLife-Batterienflexible-EE-Speicher.pdf (accessed on 15 April 2021).

- Van den Bergh, K.; Couckuyt, D.; Delarue, E.; D’haeseleer, W. Redispatching in an Interconnected Electricity System with High Renewables Penetration. Electr. Power Syst. Res. 2015, 127, 64–72. [Google Scholar] [CrossRef]

- Faessler, B.; Kepplinger, P.; Petrasch, J. Decentralized Price-Driven Grid Balancing via Repurposed Electric Vehicle Batteries. Energy 2017, 118, 446–455. [Google Scholar] [CrossRef]

- Faessler, B.; Bogunović Jakobsen, A. Autonomous Operation of Stationary Battery Energy Storage Systems—Optimal Storage Design and Economic Potential. Energies 2021, 14, 1333. [Google Scholar] [CrossRef]

- McLennan, S. Europe’s Largest Energy Storage System Now Live at the Johan Cruijff Arena; Amsterdam, The Netherlands, June 2018; p. 2. Available online: https://uk.nissannews.com/en-GB/releases/release-426229477-europe-s-largest-energy-storage-system-is-now-live-at-the-johan-cruijff-arena (accessed on 15 April 2021).

- Tim Vogel Projekt. Covalion; Tim Vogel Projekt: Wendelstein, Germany, 2017. [Google Scholar]

- Lindner, S.; Sluga, C. Second Life Energy Storage: VHH and MAN Testing Use of Second Life of Batteries for EBus Charging Station. Available online: https://press.mantruckandbus.com/second-life-energy-storage-vhh-and-man-testing-use-of-second-life-of-batteries-for-ebus-charging-station (accessed on 30 June 2020).

- The Mobility House. A Second Life for Electric Car Batteries: Stationary Storage Projects of The Mobility House. Available online: https://www.mobilityhouse.com/int_en/magazine/company/second-life-storage-projects.html (accessed on 30 June 2020).

- de Latude, A.; Farissier, C. Groupe Renault Is Launching “Advanced Battery Storage”, the Biggest Stationary Energy Storage System from Electric Vehicle (EV) Batteries in Europe; Boulogne-Billancourt, France, September 2018; Available online: https://en.media.groupe.renault.com/assets/groupe-renault-is-launching-advanced-battery-storage-the-biggest-stationary-energy-storage-system-from-electric-vehicle-ev-batteries-in-europe-21216357-989c5.html?lang=en (accessed on 15 April 2021).

- Schimpe, M.; Piesch, C.; Hesse, H.; Paß, J.; Ritter, S.; Jossen, A. Power Flow Distribution Strategy for Improved Power Electronics Energy Efficiency in Battery Storage Systems: Development and Implementation in a Utility-Scale System. Energies 2018, 11, 533. [Google Scholar] [CrossRef] [Green Version]

- Botelho, A.; Simões, M. The Second Life of Batteries. Available online: https://www.edp.com/en/innovation/second-life-batteries (accessed on 4 June 2020).

- Stevens, P.; (EDF SA, France). Personal communication, 25 June 2020.

- BeePlanet Factory Sustainable Energy for Our Planet. Available online: https://beeplanetfactory.com/en (accessed on 17 August 2020).

- EcarACCU. Affordable Energy Storage. Available online: https://ecaraccu.nl/homebatteries (accessed on 9 September 2020).

- Second Life Storage Community Second Life Storage Community. Available online: https://secondlifestorage.com/index.php (accessed on 30 June 2020).

- Gohla-Neudecker, B.; Maiyappan, V.S.; Juraschek, S.; Mohr, S. Battery 2nd Life: Presenting a Benchmark Stationary Storage System as Enabler for the Global Energy Transition. In Proceedings of the 2017 6th International Conference on Clean Electrical Power (ICCEP), Santa Margherita Ligure, Italy, 27–29 June 2017; pp. 103–109. [Google Scholar]

- Faessler, B.; Kepplinger, P.; Petrasch, J. Field Testing of Repurposed Electric Vehicle Batteries for Price-Driven Grid Balancing. J. Energy Storage 2019, 21, 40–47. [Google Scholar] [CrossRef]

- Urbanová, G.; Taťáková, Z.; Kallab, O. SCORES: D 2.3 Market Analysis on Hybrid Storage Components. October 2019. Available online: https://zenodo.org/record/3706656#.YH1Xx2czaUk (accessed on 15 April 2021).

- Koell, R.; (AEE INTEC, Austria). Personal communication, 25 August 2020.

- Mosbæk, R. Battery Pack Solution for Demonstration and the Integration with an Energy System with a High Amount of Renewables—READY. Available online: http://www.smartcity-ready.eu/d-4-2-4-battery-pack-solution-for-demonstration-and-the-integration-with-an-energy-system-with-a-high-amount-of-renewables (accessed on 5 June 2020).

- Kruse, L.; (Lithium Balance A/S, Denmark). Personal communication, 24 September 2020.

- ELSA Consortium. ELSA Pilot: Ampere Building at La Défense (SOGEPROM). Available online: https://www.elsa-h2020.eu/Ampere_Building.html (accessed on 5 June 2020).

- Lapedra, A.; Croce, V.; Ziu, D.; Le Cam, M.; Bode, G.; Gross, S.; Eberl, T. ELSA: D6.3 Results of Service Evaluation; ELSA: Munich, Germany, 2018; p. 163. [Google Scholar]

- ELSA Consortium. ELSA Pilot: Nissan Europe Office. Available online: https://www.elsa-h2020.eu/Nissan_Europe_Office.html (accessed on 5 June 2020).

- Barre, P.-J.; Bochetaz, L.; Breitwiller, A.; Caccavelli, D.; Chateau, A.; Chea, D.; De Canson, S.; Guiot, T.; Huerre, G.; Keim, C.; et al. IRIS: Deliverable 6.3—Launch of T.T.#1 Activities on Smart Renewables and near Zero Energy District; (Nice). January 2020. Available online: https://irissmartcities.eu/system/files/private/irissmartcities/d6.3_launch_of_t.t1_activities_on_smart_renewables_and_near_zero_energy_district_nice.pdf (accessed on 15 April 2021).

- Quinard, H.; (IMREDD, France). Personal communication, 30 September 2020.

- ELSA Consortium. ELSA Pilot: E.ON Energy Research Center (ERC) at RWTH Aachen University. Available online: https://www.elsa-h2020.eu/EON_Research_Center.html (accessed on 5 June 2020).

- ELSA Consortium. ELSA Pilot: City of Kempten (Allgäu Region). Available online: https://www.elsa-h2020.eu/City_of_Kempten.html (accessed on 5 June 2020).

- Tilley, A. NETfficient: Second Life EV Batteries (WAE); Grove: Oxfordshire, UK, 2018; p. 1. [Google Scholar]

- Look, O. NETfficient: Deliverable 5.2—Verified and Validated Storage and Energy Resources, Control Devices and Communication Systems Deployed on Borkum; Borkum, Germany, November 2017; p. 19. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5b651b108&appId=PPGMS (accessed on 15 April 2021).

- Zackrisson, M.; Hildenbrand, J. Including grid storage to increase the use of renewables case of an island in the North sea. In Proceedings of the Going Green CARE INNOVATION 2018, Conference Program & Abstract Book: Paper presented at 7th International Symposium and Environmental Exhibition, Vienna, Austria, 26–29 November 2018; p. 7. [Google Scholar]

- The Mobility House. Multi-Use Storage at EUREF Campus; The Mobility House: Munich, Germany, 2019; p. 1. [Google Scholar]

- ELSA Consortium. ELSA Pilot: City of Terni, Italy. Available online: https://www.elsa-h2020.eu/City_of_Terni.html (accessed on 5 June 2020).

- Staal, J. Volkswagen Golf Variant 150 kW ECE. Available online: http://autogetest.nl/ecotests/item/ecotests/volkswagen-golf-variant-150kw-ece.html (accessed on 11 September 2020).

- Groen, B. Driving Towards Decarbonisation of Transport: Safety, Performance, Second Life and Recycling of Automotive Batteries for e-Vehicles. September 2016. Available online: https://ec.europa.eu/jrc/en/publication/eur-scientific-and-technical-research-reports/putting-science-standards-workshop-summary-outcomes-driving-towards-decarbonisation (accessed on 15 April 2021).

- De Ingenieur Hergebruik Autobatterij op Pampus. Available online: https://www.deingenieur.nl/artikel/hergebruik-autobatterij-op-pampus (accessed on 11 September 2020).

- Broess, K.; (DNV GL AS, Netherlands). Personal communication, 9 September 2020.

- SIM Holland Pampus Eiland. Available online: https://www.simholland.nl/energie/noodstroomgeneratoren/referenties/categorie/pampus-eiland.html (accessed on 11 September 2020).

- Casals, L.C.; Amante García, B.; Canal, C. Second Life Batteries Lifespan: Rest of Useful Life and Environmental Analysis. J. Environ. Manag. 2019, 232, 354–363. [Google Scholar] [CrossRef]

- Manteca, F. Giulio Mazzolo Stardust. Available online: https://stardustproject.eu (accessed on 25 June 2020).

- Pueyo, C. BeePlanet Factory—2nd Use Storages; BeePlanet Factory: Navarra, Spain, 2020. [Google Scholar]

- Fernandez, G.; Almajano, J.; Garcia, E.; Bludszuweit, H.; Machin, S.; Sanz, J.F. Control Structure for Optimal Demand-Side Management with a Multi-Technology Battery Storage System. In Proceedings of the 2019 24th IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Zaragoza, Spain, 10–13 September 2019; pp. 754–759. [Google Scholar]

- Fernandez, G.; (CIRCE Foundation, Spain). Personal communication, 1 July 2020.

- Canals Casals, L.; Barbero, M.; Corchero, C. Reused Second Life Batteries for Aggregated Demand Response Services. J. Clean. Prod. 2019, 212, 99–108. [Google Scholar] [CrossRef]

- Löveryd, P.; Selberg, P. IRIS: Deliverable 7.4—Launch of T.T. #2Activities on Smart Energy Management and Storage for Flexibility (Gothenburg). February 2020. Available online: https://irissmartcities.eu/system/files/private/irissmartcities/d7.4_launch_of_tt2_activities_on_smart_energy_management_and_storage_for_flexibility_gothenburg.pdf (accessed on 15 April 2021).

- Antoniadou-Plytaria, K. Optimal Energy Scheduling of Grid-Connected Microgrids with Battery Energy Storage. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2020. [Google Scholar]

- ELSA Consortium. ELSA Pilot: Gateshead College at Its Skills Academy for Sustainable Manufacturing and Innovation (SASMI) Facility. Available online: https://www.elsa-h2020.eu/Gateshead_College.html (accessed on 5 June 2020).

- Farmen, S. Grid Connected Second-Life EV Battery-Pack; University of Agder: Grimstad, Norway, 2018; p. 61. [Google Scholar]

- Pål Erling Johnsen Energipakke Borg Havn. Available online: https://www.enova.no/om-enova/om-organisasjonen/teknologiportefoljen/energipakke-borg-havn---batteriretur (accessed on 5 June 2020).

- Wingstedt, A.; (Smart Innovation Norway AS, Norway). Personal communication, 4 September 2020.

- Gjerløw, P. Invade: Deliverable D10.1—Pilot Specifications; Oslo, Norway, February 2018; p. 86. Available online: https://zenodo.org/record/3626686#.YH18hWczaUk (accessed on 15 April 2021).

- EATON. Datasheet–XStorage Home. May 2018. Available online: https://www.eaton.com/content/dam/eaton/products/energy-storage/xstorage-home/en-gb/Eaton%20xStorage%20Home%20technical%20sheet.pdf (accessed on 15 April 2021).

- Hentunen, A.; (VTT Technical Research Centre of Finland Ltd., Finland). Personal communication, 14 September 2020.

- Post, S. Energy Storage Unit Pilot Project; Post CH Ltd.: Bern, Switzerland, 2017; p. 1. [Google Scholar]

- U.S. Department of Energy. Solving Challenges in Energy Storage; U.S. Department of Energy: Washington, DC, USA, 2019; p. 51.

- Dann Chow Creating a Second Life for EV/PHEV Batteries. Available online: https://nrc.canada.ca/en/stories/creating-second-life-evphev-batteries (accessed on 1 July 2020).

- ARENA. The Future of Energy Storage Looks Bright—ARENAWIRE. Available online: https://arena.gov.au/blog/energy-storage-future-looks-bright (accessed on 7 July 2020).

- Energywise Electric Vehicle Batteries. Available online: https://www.energywise.govt.nz/on-the-road/electric-vehicles/electric-vehicle-batteries (accessed on 7 July 2020).

- Schmidt, T.; Ligi, A.; Kevin, M.K. GM and ABB Demonstrate Chevrolet Volt Battery Reuse—World’s First Use of Electric Vehicle Batteries for Homes; San Francisco, CA, USA, November 2012; p. 2. Available online: https://new.abb.com/news/detail/13214/gm-and-abb-demonstrate-chevrolet-volt-battery-reuse-worlds-first-use-of-electric-vehicle-batteries-for-homes (accessed on 15 April 2021).

- Relectrify Relectrify—Making Energy Storage Affordable. Available online: https://www.relectrify.com (accessed on 3 July 2020).

- Tong, S.; Klein, M. Second Life Battery Pack as Stationary Energy Storage for Smart Grid; SAE: Warrendale, PA, USA, 2014; pp. 1–342. [Google Scholar]

- Smith, K.A. Battery Second Use Analysis and Demonstration: Cooperative Research and Development Final Report, CRADA Number CRD-13 -537; Golden, CO, USA, October 2018; p. 1476983. Available online: https://www.nrel.gov/docs/fy19osti/72557.pdf (accessed on 15 April 2021).

- Malcho, M.; Kelly, K.; Basel, S. Used Chevrolet Volt Batteries Help Power New IT Building; Milford, MI, USA, June 2015; p. 2. Available online: https://studylib.net/doc/6773333/used-chevrolet-volt-batteries-help-power-new-it-building (accessed on 15 April 2021).

- Hartline, J. Toyota Flips the Switch to Sustainable Power at Yellowstone National Park; Torrance, CA, USA, May 2015; p. 3. Available online: https://pressroom.toyota.com/toyota-sustainable-power-yellowstone-may12/ (accessed on 15 April 2021).

- Falk, J.; Nedjalkov, A.; Angelmahr, M.; Schade, W. Applying Lithium-Ion Second Life Batteries for Off-Grid Solar Powered System—A Socio-Economic Case Study for Rural Development. Z. Energ. 2020, 44, 47–60. [Google Scholar] [CrossRef] [Green Version]

- Chowdhury, H. Government-Backed Start-up Aceleron to Roll out 4000 Batteries to Kenya. The Telegraph, 25 November 2019. [Google Scholar]

- University of Oxford Multi-Chemistry Battery Pack Using Second Life Batteries for off-Grid Systems in Developing Countries. Available online: https://globalresearch.admin.ox.ac.uk/article/multi-chemistry-battery-pack-using-second-life-batteries-grid-systems-developing-countries (accessed on 1 July 2020).

- Ayetor, G.K.; Quansah, D.A.; Adjei, E.A. Towards Zero Vehicle Emissions in Africa: A Case Study of Ghana. Energy Policy 2020, 143, 111606. [Google Scholar] [CrossRef]

- 4R Energy. 4R Energy Corporation. Available online: http://www.4r-energy.com (accessed on 7 July 2020).

- ITOCHU. ITOCHU Announces Capital and Business Alliance with Automotive Battery Reuse and Recycling Company. Available online: https://www.itochu.co.jp/en/news/press/2019/191028.html (accessed on 6 July 2020).

- Okuda, K.; Maxfield, N. Japan Benex, Sumitomo Corp. to Power Plant with Nissan EVs, Batteries; Tokyo/Isahaya/Yokohama, Japan, April 2018; p. 1. Available online: https://global.nissannews.com/en/releases/release-36a71146ed04eaba0f0dff94b509cd44-japan-benex-sumitomo-corp-to-power-plant-with-nissan-evs-batteries (accessed on 15 April 2021).

- Jiang, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Gao, Y.; Li, N. State of Health Estimation of Second-Life LiFePO4 Batteries for Energy Storage Applications. J. Clean. Prod. 2018, 205, 754–762. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Y.; Luo, F. Operational Planning of Centralized Charging Stations Using Second-Life Battery Energy Storage Systems. IEEE Trans. Sustain. Energy 2020, 1. [Google Scholar] [CrossRef]

- La, P.-H.; Choi, S.-J. Novel Dynamic Resistance Equalizer for Parallel-Connected Battery Configurations. Energies 2020, 13, 3315. [Google Scholar] [CrossRef]

- Gu, F.; Guo, J.; Yao, X.; Summers, P.A.; Widijatmoko, S.D.; Hall, P. An Investigation of the Current Status of Recycling Spent Lithium-Ion Batteries from Consumer Electronics in China. J. Clean. Prod. 2017, 161, 765–780. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Pang, B.; Sun, B.; Kokko, A. Second Use Value of China’s New Energy Vehicle Battery: A View Based on Multi-Scenario Simulation. Sustainability 2020, 12, 341. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Liu, X.; Hao, H.; Zhao, F.; Amer, A.A.; Babiker, H. Research on the Critical Issues for Power Battery Reusing of New Energy Vehicles in China. Energies 2020, 13, 1932. [Google Scholar] [CrossRef] [Green Version]

- GEM Vice President Soichiro Matsudaira, Etc. from Toyota Tsusho Corporation Visited GEM Circulation Industrial Park on Business Tour. Available online: http://en.gem.com.cn/index.php/News/2018/10-16/2369.html (accessed on 25 August 2020).

- Minter, A. China’s Giving Batteries a Second Life. Available online: https://www.bloombergquint.com/opinion/china-s-giving-batteries-a-second-life (accessed on 25 August 2020).

- Zhu, C.; Liu, K.; Xu, J.; Lu, R.; Yin, B.; Yuan, L.; Chan, C.C. Effect of Remaining Cycle Life on Economy of Retired Electric Vehicle Lithium-Ion Battery Second- Use in Backup Power for Communication Base Station. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo, Asia-Pacific (ITEC Asia-Pacific), Harbin, China, 2–5 August 2017; pp. 1–6. [Google Scholar]

- Wang, Y.; Wang, B.; Chu, C.-C.; Pota, H.; Gadh, R. Energy Management for a Commercial Building Microgrid with Stationary and Mobile Battery Storage. Energy Build. 2016, 116, 141–150. [Google Scholar] [CrossRef] [Green Version]

- Dusonchet, L.; Favuzza, S.; Massaro, F.; Telaretti, E.; Zizzo, G. Technological and Legislative Status Point of Stationary Energy Storages in the EU. Renew. Sustain. Energy Rev. 2019, 101, 158–167. [Google Scholar] [CrossRef]

- Hannan, M.A.; Hoque, M.M.; Hussain, A.; Yusof, Y.; Ker, P.J. State-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications: Issues and Recommendations. IEEE Access 2018, 6, 19362–19378. [Google Scholar] [CrossRef]

- Bai, B.; Xiong, S.; Song, B.; Xiaoming, M. Economic Analysis of Distributed Solar Photovoltaics with Reused Electric Vehicle Batteries as Energy Storage Systems in China. Renew. Sustain. Energy Rev. 2019, 109, 213–229. [Google Scholar] [CrossRef]

- Bobba, S.; Cusenza, M.A.; Di Persio, F.; Eynard, U.; Mathieux, F.; Messagie, M.; Pfrang, A.; Podias, A.; Tecchio, P.; European Commission; et al. Sustainability Assessment of Second Life Application of Automotive Batteries (SASLAB): JRC Exploratory Research (2016-2017): Final Technical Report: August 2018; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-92835-2. [Google Scholar]

- Stöhr, M. ELSA: Summary; ELSA: Munich, Germany, 2019; p. 3. [Google Scholar]

- DeRousseau, M.; Gully, B.; Taylor, C.; Apelian, D.; Wang, Y. Repurposing Used Electric Car Batteries: A Review of Options. JOM 2017, 69, 1575–1582. [Google Scholar] [CrossRef]

- Stephan, A.; Battke, B.; Beuse, M.D.; Clausdeinken, J.H.; Schmidt, T.S. Limiting the Public Cost of Stationary Battery Deployment by Combining Applications. Nat. Energy 2016, 1, 16079. [Google Scholar] [CrossRef]

- Li, X.; Wang, S. A Review on Energy Management, Operation Control and Application Methods for Grid Battery Energy Storage Systems. CSEE J. Power Energy Syst. 2019, 1–15. [Google Scholar] [CrossRef]

- Lacey, G.; Putrus, G.; Salim, A. The Use of Second Life Electric Vehicle Batteries for Grid Support. In Proceedings of the Eurocon 2013, Zagreb, Croatia, 1–4 July 2013; pp. 1255–1261. [Google Scholar]

- Ballinger, B.; Stringer, M.; Schmeda-Lopez, D.R.; Kefford, B.; Parkinson, B.; Greig, C.; Smart, S. The Vulnerability of Electric Vehicle Deployment to Critical Mineral Supply. Appl. Energy 2019, 255, 113844. [Google Scholar] [CrossRef]

- Li, M.; Lu, J. Cobalt in Lithium-Ion Batteries. Science 2020, 367, 979–980. [Google Scholar] [CrossRef]

- Mossali, E.; Picone, N.; Gentilini, L.; Rodrìguez, O.; Pérez, J.M.; Colledani, M. Lithium-Ion Batteries towards Circular Economy: A Literature Review of Opportunities and Issues of Recycling Treatments. J. Environ. Manag. 2020, 264, 110500. [Google Scholar] [CrossRef]

- Manahan, S.E. Environmental Chemistry, 8th ed.; CRC Press: Boca Raton, FL, USA, 2005; ISBN 978-1-56670-633-9. [Google Scholar]

- Ordoñez, J.; Gago, E.J.; Girard, A. Processes and Technologies for the Recycling and Recovery of Spent Lithium-Ion Batteries. Renew. Sustain. Energy Rev. 2016, 60, 195–205. [Google Scholar] [CrossRef]

- Rallo, H.; Canals Casals, L.; De La Torre, D.; Reinhardt, R.; Marchante, C.; Amante, B. Lithium-Ion Battery 2nd Life Used as a Stationary Energy Storage System: Ageing and Economic Analysis in Two Real Cases. J. Clean. Prod. 2020, 272, 122584. [Google Scholar] [CrossRef]

- Zheng, X.; Zhu, Z.; Lin, X.; Zhang, Y.; He, Y.; Cao, H.; Sun, Z. A Mini-Review on Metal Recycling from Spent Lithium Ion Batteries. Engineering 2018, 4, 361–370. [Google Scholar] [CrossRef]

- Danino-Perraud, R. The Recycling of Lithium-Ion Batteries: A Strategic Pillar for the European Battery Alliance; Études de l’Ifri; Ifri: Paris, France, 2020; ISBN 979-10-373-0135-2. [Google Scholar]

- European Commission. Circular Economy Action Plan—For a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020; p. 28. [Google Scholar]

- Herrmann, C.; Raatz, A.; Andrew, S.; Schmitt, J. Scenario-Based Development of Disassembly Systems for Automotive Lithium Ion Battery Systems. Adv. Mater. Res. 2014, 907, 391–401. [Google Scholar] [CrossRef]

- Quinard, H.; Redondo-Iglesias, E.; Pelissier, S.; Venet, P. Fast Electrical Characterizations of High-Energy Second Life Lithium-Ion Batteries for Embedded and Stationary Applications. Batteries 2019, 5, 33. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Gaustad, G.; Babbitt, C.W. Targeting High Value Metals in Lithium-Ion Battery Recycling via Shredding and Size-Based Separation. Waste Manag. 2016, 51, 204–213. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alamerew, Y.A.; Brissaud, D. Modelling Reverse Supply Chain through System Dynamics for Realizing the Transition towards the Circular Economy: A Case Study on Electric Vehicle Batteries. J. Clean. Prod. 2020, 254, 120025. [Google Scholar] [CrossRef]

- European Parliament. Council of the European Union Directive 2006/66/EC of the European Parliament and of the Council of 6 September 2006 on Batteries and Accumulators and Waste Batteries and Accumulators and Repealing Directive 91/157/EEC; European Parliament: Brussels, Belgium, 2006.

- European Commission. Commission Staff Working Document on the Evaluation of the Directive 2006/66/EC on Batteries and Accumulators and Waste Batteries and Accumulators and Repealing Directive 91/157/EEC; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. Inception Impact Assessment: Modernising the EU’s Batteries Legislation; European Commission: Brussels, Belgium, 2020. [Google Scholar]

| Stakeholder Groups | Applications | Description |

|---|---|---|

| In-front-of-the-meter | Energy arbitrage | Electrical energy is purchased and stored when the energy prices are low and sold or used when the energy prices are high. |

| Frequency control | Frequency control ensures that the grid frequency is held within a defined tolerance band to avoid grid instability. Primary, secondary, and tertiary frequency control, which act in different time domains, are done to balance supply and demand. | |

| Spinning/Non-spinning reserve | Spinning reserves are online generation capacities that can compensate for unexpected events like generation outages. Non-spinning reserves can compensate for such unexpected events within a short period of time. | |

| Voltage support | The grid voltage is maintained within a defined range to ensure that real and reactive power generation matches demand. | |

| Black start | Black start generation units are needed to restart generation at larger power stations, mainly thermal power stations, after a blackout, to recover the grid operation. | |

| Resource adequacy | Existing power plants can be combined with energy storage units to manage peak demand without adding generation capacity, thus reducing investment costs and associated risks. | |

| Transmission/Distribution deferral | Reduces utility investments in transmission/distribution system upgrades which are necessary to meet future demands. | |

| Transmission congestion relief | In order to reduce congestion along transmission lines with high demand and the resulting requests for redispatch [51], battery storage units can be installed downstream of the transmission lines. | |

| Behind-the-meter | Time-of-use bill management | Shifting energy purchases to periods of low prices and using stored energy when the prices are high (price incentivised demand optimisation [52,53]). |

| Increased self-consumption | Minimising the export of locally generated electricity, e.g., by photovoltaic systems, while increasing self-consumption, or by using locally generated electricity to provide an auxiliary source for power demands such as EV fast-charging. | |

| Demand charge reduction | Demand reduction (peak shaving) during times of peak demand to reduce the quantity of power bought at premium prices. This applies mostly to commercial customers but, based on regional/national tariffs, also to residential customers. | |

| Backup power | Backup power can be obtained from storage systems for short or medium time periods if a grid failure occurs. | |

| Off-grid | Off-grid | Off-grid systems are systems that are not connected to the main electrical grid and are mostly small. Such systems need generation units, consumers, as well as buffer capacities to balance supply and demand. |

| State | Project | Duration | Battery Technology | First Use | Applications | Comment | Capacity (kWh) | AC Power in/out (kW) | New/ Old | Source |

|---|---|---|---|---|---|---|---|---|---|---|

| Austria | Smart City Rheintal | 2012–2015 | Sodium– nickel chloride | Think City |

| Two storage systems | 28.2 | 1.5/8.2 | 0/100 | [66] |

| 28.2 | 1.5/8.2 | 0/100 | ||||||||

| SCORES | 2017–2021 | Lithium-ion | Formula E charging stations |

| 31.95 | 80/80 | 0/100 | [67,68] | ||

| Denmark | READY | 2014–2019 | Lithium-ion | Nissan Leaf |

| Hybrid storage using spent and new batteries | 130 | 40/40 | 60/40 | [69,70] |

| France | ELSA | 2015–2018 | Lithium-ion | Renault Kangoo |

| Applications tested and simulated | 88 | 80/80 | 0/100 | [71,72] |

| ELSA | 2015–2018 | Lithium-ion | Nissan Leaf |

| 192 | 144/144 | 0/100 | [72,73] | ||

| SCORES | 2017–2021 | Lithium-ion | Formula E charging stations |

| 63.9 | 160/160 | 0/100 | [67,68] | ||

| IRIS | 2017–2022 | Lithium-ion | Renault Kangoo |

| 30 | 10/10 | 0/100 | [74,75] | ||

| Germany | ELSA | 2015–2018 | Lithium-ion | Renault Kangoo |

| 66 | 72/72 | 0/100 | [72,76] | |

| ELSA | 2015–2018 | Lithium-ion | Renault Kangoo |

| Applications tested and simulated | 66 | 18/72 | 0/100 | [72,77] | |

| NETfficient | 2015–2018 | Lithium-ion | Nissan Leaf |

| Two storage systems | 24 | 5/5 | 0/100 | [78,79,80] | |

| 24 | 5/5 | 0/100 | ||||||||

| Mobility2Grid | 2019- | Lithium-ion | Audi e-tron |

| Applications planned | 1900 | 1250/1250 | 0/100 | [81] | |

| Italy | ELSA | 2015–2018 | Lithium-ion | Renault Kangoo |

| Applications tested in two different scenarios | 66 | 72/72 | 0/100 | [72,82] |

| Nether-lands | Pampus Project | 2015 | Lithium-ion | Custom made electric VW Golf |

| System upgrade from 24 kWh to 40 kWh, recently replaced | 24 to 40 | 30/30 | 0/100 | [83,84,85,86,87] |

| Spain | Sunbatt | 2014–2015 | Lithium-ion | VW Golf GTE |

| System setup further used in simulation studies | 35.2 | 40/40 | 0/100 | [88] |

| Stardust | 2017–2022 | Lithium-ion | Nissan Leaf |

| Three storage systems, partly under development | 60 | 60/100 | 0/100 | [89,90] | |

| 200 | 40/40 | 0/100 | ||||||||

| 60 | --- | 0/100 | ||||||||

| EV-Optimanager | 2015–2019 | Lithium-ion and lead-acid | Lithium-ion from renewable facilities, lead-acid from forklifts |

| Two lithium-ion storage systems | 12 each | 10/10 each (DC/DC converter) | 0/100 each | [91,92] | |

| One lead-acid storage system | 12 | 10/10 (DC/DC converter) | 0/100 | |||||||

| REFER Project | 2016–2019 | Lithium-ion | Renault Kangoo |

| 23 | 10/10 | 0/100 | [93] | ||

| Sweden | IRIS | 2017–2022 | Lithium-ion | Volvo Bus |

| 196 | 84/84 | 0/100 | [94,95] | |

| United Kingdom | ELSA | 2015–2018 | Lithium-ion | Nissan Leaf |

| Applications tested and simulated | 48 | 10/36 | 0/100 | [72,96] |

| Norway | ReLIEVe | 2018 | Lithium-ion | Nissan Leaf |

| 3.5 | 3.3/3.3 | 0/100 | [97] | |

| Energipakke Borg Havn | 2018–2020 | Lithium-ion | Different EV manufacturers (Mitsubishi, VW, Tesla) |

| Each storage system is built from a different EV battery | 120 | 20/20 | 0/100 | [98,99] | |

| 90 | 10/10 | 0/100 | ||||||||

| 120–150 | 60/60 | 0/100 | ||||||||

| INVADE | 2017–2019 | Lithium-ion | Nissan Leaf |

| 15 storage systems | 4.6 each | 6/6 each | 0/100 each | [100,101,102] | |

| 6 storage systems | 10.08 each | 6/6 each | 0/100 each | |||||||

| Switzer-land | Second Life | 2017- | Lithium-ion | KYBURZ DXP vehicle |

| Several pilot storage systems | 6 | 3/3 | 0/100 | [103] |

| 8 | 3/3 | 0/100 | ||||||||

| 10 | 3/3 | 0/100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faessler, B. Stationary, Second Use Battery Energy Storage Systems and Their Applications: A Research Review. Energies 2021, 14, 2335. https://doi.org/10.3390/en14082335

Faessler B. Stationary, Second Use Battery Energy Storage Systems and Their Applications: A Research Review. Energies. 2021; 14(8):2335. https://doi.org/10.3390/en14082335

Chicago/Turabian StyleFaessler, Bernhard. 2021. "Stationary, Second Use Battery Energy Storage Systems and Their Applications: A Research Review" Energies 14, no. 8: 2335. https://doi.org/10.3390/en14082335

APA StyleFaessler, B. (2021). Stationary, Second Use Battery Energy Storage Systems and Their Applications: A Research Review. Energies, 14(8), 2335. https://doi.org/10.3390/en14082335