Life-Cycle Assessment of a Rural Terraced House: A Struggle with Sustainability of Building Renovations

Abstract

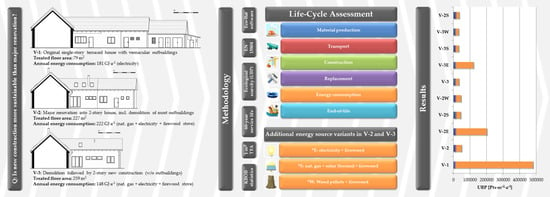

:1. Introduction

2. Methods and Case Study Description

2.1. LCA and Its Boundary Conditions

- The LCA results are presented in following building life cycle stages and modules defined in EN 15978 to increase their clarity and comparability with other studies: A1–A3 Product stage, A4–A5 Construction process stage (necessary material transport, excavations, and demolitions), B4 Replacement, B6 Operational energy, C1–C4 End of life stage. Other stages and modules defined in the EN standard are not included in the software as their impacts would be presumably negligible. It should be also noted that the structure of the result presentation in the software differs from the standardized structure. Further processing and rearrangement were therefore necessary. As a result, the environmental impacts related to material manufacturing (equivalent to Product stage) and elimination (equivalent to End-of-life stage) cannot be broken down into individual modules (A1–A3 and C1–C4, respectively);

- The Ecological Scarcity (UBP) method described in [53] is used for the presentation of results. Eco-Bat 4.0 software provides results in four impact categories: UBP, Cumulative Energy Demand (CED), Non-Renewable Energy (NRE), and Global Warming Potential (GWP). The UBP is selected over other impact categories in the software or impact categories in EN 15978 (and other reviewed sources) due to the simplicity of presentation. It is a single value representing multiple environmental impacts (e.g., GWP, CED or land use), which increases the clarity of the results to the general public. It should be noted that the version of the method utilized in the software is adjusted for Switzerland. A pan-European version [54] was not available at the time of the development of the software;

- The 60-year reference service life of the house is considered. It starts with the completion of the “initial” renovation (V-1 and V-2) or the new construction (V-3) is considered. The value is selected based on ISO 15686-1 [55] standard and Annex 56 methodology [56]. The service life of individual building parts and systems is predefined in the Eco-Bat 4.0 software: 60 years for load-bearing parts, 30 years for non-loadbearing parts above ground, and 20–30 for building-integrated technical systems (BITS);

- The Eco-Bat 4.0 database includes several hundred material and energy datasets from the ecoinvent v2.2 database. Still, several small-scale materials included in the designs had to be replaced by closest similar materials. For example, plastic windowsills are represented by “PVC pipe” dataset in the LCA;

- The following energy-related datasets were utilized for calculation of OEIs in individual variants: “low-voltage Czech Republic” as electricity, “boiler, condensing (<100 kW), with modulation” as natural gas, “logs, hardwood (6 kW)” as firewood for the stove, and “wood pellets (50 kW)” as firewood for pellet boiler. The LCA does not consider the EEIs and OEIs of the original house prior to the start of the renovation (or demolition). Only demolition and waste management of the original construction materials removed from the site are included in the calculations;

- The LCA considers 5% construction material losses for the materials that are processed on site such as concrete or masonry based on consultations with contractors and literature such as [58,59]. The amount of these materials in the inventory is rounded up to full packages or pieces: e.g., one pack of insulation panels or 25 kg bag of cement;

- Transport distances of construction materials predefined in Eco-Bat 4.0 software are used;

- The LCA uses average dimensions of BITS (e.g., length of piping and wiring) predefined in Eco-Bat 4.0 software. These are based on Swiss KBOB statistics [60].

2.2. Description of the Original House Assessed in V-1 LCA

2.3. Description of the Hypothetical Renovation Assessed in V-2 LCA

2.4. Description of the Executed Demolition and New Construction in V-3 LCA

2.5. Description of the Assessed Sub-Variants

- V-2E and V-3E, where the natural gas boiler is replaced with an electric boiler, similar to the original V-1 house. These sub-variants should enable better comparison of the renovation efficiency;

- V-2S and V-3S, where 20% of heating and 80% DHW is covered by a solar thermal system (STS) with 25 m2 (V-2S) and 15 m2 (V-3S) of flat plate collectors installed on the roof. A larger collector area was not considered for two reasons. Firstly, suitable area of the roof is limited by its shape and size as well as position and size of adjacent shading houses. Secondly, the designed boiler room has less than 5 m2 in both V-2 and V-3. This fact limits maximum size of storage tank for heat accumulation;

- V-2W and V-3W, where the natural gas boiler is replaced with a wooden pellet boiler.

3. Results

4. Discussion and Conclusions

4.1. Efficiency of Assessed Renovation and New Construction

4.2. Role of Energy Sources in Reducing Environmental Impacts of Buildings

- The benefits of solar energy in V-2S and V-3S are reduced due to increased EEIs related with installation and use of the STS and the fact that the system provides only 20% of heating energy. It should be noted that accuracy of this result is influenced by the limitations of the Eco-Bat 4.0 software. It is impossible to model state-of-art solutions such as STS utilizing latent heat storage (Phase Change Materials) that could have higher efficiency than traditional systems [62,63];

- The benefits of biomass in V-2W and V-3W are reduced due to the UBP methodology, as wood pellets and natural gas have similar environmental impacts in UBP: 27.8 and 31.5 Pts MJ−1, respectively (compared to 204.3 Pts MJ−1 in case of electricity). The result could therefore change if different impact categories are considered. For example, wood pellets have 98% lower environmental impacts than natural gas in GWP according to Eco-Bat 4.0 software;

- The benefits of renewables in general are seemingly reduced due to the inefficiency of the original V-1 house. A closer look at the results in Table 3 shows that the utilization of a wood pellet boiler results in up to 6.4% reduction of environmental impacts in V-2W and V-3W compared to V-2 and V-3, respectively. Similarly, OEIs of V-2S and V-3S are up to 10.2% lower compared to V-2 and V-3. This makes the STS the most (environmentally) desirable heating source for the described house. Literature such as [64,65] show that larger STS could provide even above 90% reduction environmental impacts compared to natural gas (depending on assessed impact categories). However, a larger solar system was not considered in the presented case study due to limitations described in Section 2.5.

4.3. Possible Simplification in Life-Cycle Inventory of Buildings

4.4. Concluding Remarks and Future Research Prospects

- Influence of boundary conditions on LCA results;

- Sensitivity analysis on the omission of construction materials with minimum share on total weight of the house;

- Accuracy of the described LCAs and their conclusions for wider sample of buildings;

- Limits and benefits of wide-spread application of renewable energy sources, optimum mix of renewable energy sources for different building types and regions, and possible overuse of resources.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IPCC. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the In-Tergovernmental Panel on Climate Change, 1st ed.; Core Writing Team, Pachauri, R.K., Meyer, L.A., Eds.; Intragovernmental Panel for Climate Change (IPCC): Geneva, Switzerland, 2014; 151p. Available online: https://bit.ly/3m9EHM7 (accessed on 29 March 2021).

- IPCC. Summary for Policymakers. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty, 1st ed.; Masson-Delmotte, V., Zhai, P., Pörtner, H.-O., Roberts, D., Skea, J., Shukla, P.R., Pirani, A., Moufouma-Okia, W., Péan, C., Pidcock, R., et al., Eds.; Intragovernmental Panel for Climate Change (IPCC): Geneva, Switzerland, 2018; p. 24. Available online: https://bit.ly/3cuaHHE (accessed on 29 March 2021).

- UN. Paris Agreement; United Nations (UN): Paris, France, 2015; p. 27. Available online: http://unfccc.int/paris_agreement/items/9485.php (accessed on 29 March 2021).

- EC. The European Green Deal; European Commission (EC): Brussels, Belgium, 2019; p. 24. Available online: https://bit.ly/3sxKhdK (accessed on 29 March 2021).

- Bauer, A.; Menrad, K. Standing up for the Paris Agreement: Do global climate targets influence individuals’ greenhouse gas emissions? Environ. Sci. Policy 2019, 99, 72–79. [Google Scholar] [CrossRef]

- D’Agostino, D.; Mazzarella, L. What is a Nearly zero energy building? Overview, implementation and comparison of definitions. J. Build. Eng. 2019, 21, 200–212. [Google Scholar] [CrossRef]

- European Union. Energy Data—2020 Edition, 1st ed.; Publications Office of the European Union: Luxembourg, 2020; p. 334. Available online: https://bit.ly/3w9Unne (accessed on 29 March 2021).

- Birgisdottir, H.; Moncaster, A.; Wiberg, A.H.; Chae, C.; Yokoyama, K.; Balouktsi, M.; Seo, S.; Oka, T.; Lützkendorf, T.; Malmqvist, T. IEA EBC annex 57 ‘evaluation of embodied energy and CO2eq for building construction’. Energy Build. 2017, 154, 72–80. [Google Scholar] [CrossRef] [Green Version]

- Satola, D.; Balouktsi, M.; Lützkendorf, T.; Wiberg, A.H.; Gustavsen, A. How to define (net) zero greenhouse gas emissions buildings: The results of an international survey as part of IEA EBC annex 72. Build. Environ. 2021, 192, 107619. [Google Scholar] [CrossRef]

- Wei, W.; Skye, H.M. Residential net-zero energy buildings: Review and perspective. Renew. Sustain. Energy Rev. 2021, 142, 110859. [Google Scholar] [CrossRef]

- Thibodeau, C.; Bataille, A.; Sié, M. Building rehabilitation life cycle assessment methodology-state of the art. Renew. Sustain. Energy Rev. 2019, 103, 408–422. [Google Scholar] [CrossRef]

- Terés-Zubiaga, J.; Bolliger, R.; Almeida, M.G.; Barbosa, R.; Rose, J.; Thomsen, K.E.; Montero, E.; Briones-Llorente, R. Cost-effective building renovation at district level combining energy efficiency & renewables—Methodology assessment proposed in IEA EBC Annex 75 and a demonstration case study. Energy Build. 2020, 224, 110280. [Google Scholar] [CrossRef]

- Sesana, M.M.; Rivallain, M.; Salvalai, G. Overview of the Available Knowledge for the Data Model Definition of a Building Renovation Passport for Non-Residential Buildings: The ALDREN Project Experience. Sustainability 2020, 173, 642. [Google Scholar] [CrossRef] [Green Version]

- D’Agostino, D.; Zangheri, P.; Castellazzi, L. Towards Nearly Zero Energy Buildings in Europe: A Focus on Retrofit in Non-Residential Buildings. Energies 2017, 10, 117. [Google Scholar] [CrossRef]

- Göswein, V.; Silvestre, J.D.; Monteiro, C.S.; Habert, G.; Freire, F.; Pittau, F. Influence of material choice, renovation rate, and electricity grid to achieve a Paris Agreement-compatible building stock: A Portuguese case study. Build. Environ. 2021, 195, 107773. [Google Scholar] [CrossRef]

- Awadh, O. Sustainability and green building rating systems: LEED, BREEAM, GSAS and Estidama critical analysis. J. Build. Eng. 2017, 11, 25–29. [Google Scholar] [CrossRef]

- Qiu, Y.; Kahn, M.E. Impact of voluntary green certification on building energy performance. Energy Econ. 2019, 80, 461–475. [Google Scholar] [CrossRef]

- Bottero, M.; Dell’Anna, F.; Morgese, V. Evaluating the Transition Towards Post-Carbon Cities: A Literature Review. Sustainability 2021, 13, 567. [Google Scholar] [CrossRef]

- Li, Y.; Kubicki, S.; Guerriero, A.; Rezgui, Y. Review of building energy performance certification schemes towards future improvement. Renew. Sustain. Energy Rev. 2019, 113, 109244. [Google Scholar] [CrossRef]

- Li, C.Z.; Lai, X.; Xiao, B.; Tam, V.W.; Guo, S.; Zhao, Y. A holistic review on life cycle energy of buildings: An analysis from 2009 to 2019. Renew. Sustain. Energy Rev. 2020, 134, 110372. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, K.; Zhang, Z. Life cycle carbon emissions of two residential buildings in China: Comparison and uncertainty analysis of different assessment methods. J. Clean. Prod. 2020, 266, 122037. [Google Scholar] [CrossRef]

- Piccardo, C.; Dodoo, A.; Gustavsson, L. Retrofitting a building to passive house level: A life cycle carbon balance. Energy Build. 2020, 223, 110135. [Google Scholar] [CrossRef]

- Strantzali, E.; Aravossis, K. Decision making in renewable energy investments: A review. Renew. Sustain. Energy Rev. 2016, 55, 885–898. [Google Scholar] [CrossRef]

- Laurin, L. Overview of LCA—History, Concept, and Methodology. In Encyclopedia of Sustainable Technologies, 1st ed.; Abraham, M.A., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 217–222. [Google Scholar]

- International Organization for Standardization. ISO 14040:1997 Environmental Management—Life Cycle Assessment—Principles and Framework, 1st ed.; International Organization for Standardization: Geneva, Switzerland, 1997; p. 12. [Google Scholar]

- ISO. ISO 21931-1:2010 Sustainability in Building Construction—Framework for Methods of Assessment of the Environmental Performance of Construction Works—Part 1: Buildings, 1st ed.; International Organization for Standardization (ISO): Geneva, Switzerland, 2010; p. 26. [Google Scholar]

- CEN. EN 15978:2011 Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method, 1st ed.; European Committee for Standardization (CEN): Brussels, Belgium, 2011; p. 64. [Google Scholar]

- CEN. EN 15804:2012+A2:2019 Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products, 1st ed.; European Committee for Standardization (CEN): Brussels, Belgium, 2019; p. 76. [Google Scholar]

- Cabeza, L.F.; Rincón, L.; Vilariño, V.; Pérez, G.; Castell, A. Life cycle assessment (LCA) and life cycle energy analysis (LCEA) of buildings and the building sector: A review. Renew. Sustain. Energy Rev. 2014, 29, 394–416. [Google Scholar] [CrossRef]

- Anand, C.K.; Amor, B. Recent developments, future challenges and new research directions in LCA of buildings: A critical review. Renew. Sustain. Energy Rev. 2017, 67, 408–416. [Google Scholar] [CrossRef]

- Saade, M.R.M.; Guest, G.; Amor, B. Comparative whole building LCAs: How far are our expectations from the documented evidence? Build. Environ. 2020, 167, 106449. [Google Scholar] [CrossRef]

- Röck, M.; Hollberg, A.; Habert, G.; Passer, A. LCA and BIM: Integrated Assessment and Visualization of Building Elements’ Embodied Impacts for Design Guidance in Early Stages. Procedia CIRP 2018, 69, 218–223. [Google Scholar] [CrossRef]

- Nwodo, M.N.; Anumba, C.J. A review of life cycle assessment of buildings using a systematic approach. Build. Environ. 2019, 162, 106290. [Google Scholar] [CrossRef]

- Christensen, T.; Damgaard, A.; Levis, J.; Zhao, Y.; Björklund, A.; Arena, U.; Barlaz, M.; Starostina, V.; Boldrin, A.; Astrup, T.; et al. Application of LCA modelling in integrated waste management. Waste Manag. 2020, 118, 313–322. [Google Scholar] [CrossRef] [PubMed]

- Hossain, U.; Ng, S.T. Critical consideration of buildings’ environmental impact assessment towards adoption of circular economy: An analytical review. J. Clean. Prod. 2018, 205, 763–780. [Google Scholar] [CrossRef]

- Hopkinson, P.; Chen, H.-M.; Zhou, K.; Wang, Y.; Lam, D.; Wong, Y. Recovery and reuse of structural products from end-of-life buildings. Eng. Sustain. 2019, 172, 119–128. [Google Scholar] [CrossRef] [Green Version]

- Francart, N.; Larsson, M.; Malmqvist, T.; Erlandsson, M.; Florell, J. Requirements set by Swedish municipalities to promote construction with low climate change impact. J. Clean. Prod. 2019, 208, 117–131. [Google Scholar] [CrossRef] [Green Version]

- Zhang, B.; Su, S.; Zhu, Y.; Li, X. An LCA-based environmental impact assessment model for regulatory planning. Environ. Impact Assess. Rev. 2020, 83, 106406. [Google Scholar] [CrossRef]

- González-García, S.; Caamaño, M.R.; Moreira, M.T.; Feijoo, G. Environmental profile of the municipality of Madrid through the methodologies of Urban Metabolism and Life Cycle Analysis. Sustain. Cities Soc. 2021, 64, 102546. [Google Scholar] [CrossRef]

- Schlegl, F.; Gantner, J.; Traunspurger, R.; Albrecht, S.; Leistner, P. LCA of buildings in Germany: Proposal for a future benchmark based on existing databases. Energy Build. 2019, 194, 342–350. [Google Scholar] [CrossRef]

- Durão, V.; Silvestre, J.D.; Mateus, R.; de Brito, J. Assessment and communication of the environmental performance of construction products in Europe: Comparison between PEF and EN 15804 compliant EPD schemes. Resour. Conserv. Recycl. 2020, 156, 104703. [Google Scholar] [CrossRef] [Green Version]

- Sartori, T.; Drogemuller, R.; Omrani, S.; Lamari, F. A schematic framework for Life Cycle Assessment (LCA) and Green Building Rating System (GBRS). J. Build. Eng. 2021, 38, 102180. [Google Scholar] [CrossRef]

- Vilches, A.; Garcia-Martinez, A.; Sanchez-Montañes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- Galimshina, A.; Hollberg, A.; Moustapha, M.; Sudret, B.; Favre, D.; Padey, P.; Lasvaux, S.; Habert, G. Probabilistic LCA and LCC to identify robust and reliable renovation strategies. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012058. [Google Scholar] [CrossRef] [Green Version]

- Palacios-Munoz, B.; Peuportier, B.; Gracia-Villa, L.; López-Mesa, B. Sustainability assessment of refurbishment vs. new constructions by means of LCA and durability-based estimations of buildings lifespans: A new approach. Build. Environ. 2019, 160, 106203. [Google Scholar] [CrossRef]

- Hasik, V.; Escott, E.; Bates, R.; Carlisle, S.; Faircloth, B.; Bilec, M.M. Comparative whole-building life cycle assessment of renovation and new construction. Build. Environ. 2019, 161, 106218. [Google Scholar] [CrossRef]

- Shirazi, A.; Ashuri, B. Embodied Life Cycle Assessment (LCA) comparison of residential building retrofit measures in Atlanta. Build. Environ. 2020, 171, 106644. [Google Scholar] [CrossRef]

- Langston, C.; Chan, E.H.W.; Yung, E.H.K. Hybrid Input-Output Analysis of Embodied Carbon and Construction Cost Differences between New-Build and Refurbished Projects. Sustainability 2018, 10, 3229. [Google Scholar] [CrossRef] [Green Version]

- Weiler, V.; Harter, H.; Eicker, U. Life cycle assessment of buildings and city quarters comparing demolition and reconstruction with refurbishment. Energy Build. 2017, 134, 319–328. [Google Scholar] [CrossRef]

- ISO. ISO 14044: 2006 Environmental Management—Life Cycle Assessment—Requirements and Guidelines, 1st ed.; International Organization for Standardization: Geneva, Switzerland, 2006; p. 20. [Google Scholar]

- Favre, D.; Citherlet, S. Eco-Bat: A design tool for assessing environmental impacts of buildings and equipment. Build. Simul. 2008, 1, 83–94. [Google Scholar] [CrossRef] [Green Version]

- Romagnoni, P.; Cappelletti, F.; Peron, F.; Dalla Mora, T.; Ruggeri, P.; Almeida, M.; Ferreira, M. Tools and Procedures to Support Decision Making for Cost-Effective Energy and Carbon Emissions Optimization in Building Renovation (Annex 56), 1st ed.; University of Minho: Minho, Portugal, 2017; p. 80. Available online: https://bit.ly/32seuPP (accessed on 18 April 2021).

- Frischknecht, R.; Büsser Knöpfel, S. Swiss Eco-Factors 2013 According to the Ecological Scarcity Method. Methodological Fundamentals and Their Application in Switzerland. Environmental Studies no. 1330, 1st ed.; Federal Office for the Environment: Bern, Switzerland, 2013; p. 254. Available online: https://bit.ly/3u4BjVr (accessed on 29 March 2021).

- Muhl, M.; Berger, M.; Finkbeiner, M. Development of Eco-factors for the European Union based on the Ecological Scarcity Method. Int. J. Life Cycle Assess. 2019, 24, 1701–1714. [Google Scholar] [CrossRef]

- ISO. ISO 15686-1: 2011 Building and Constructed Assets—Service Life Planning: Part 1, General Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2011; p. 21. [Google Scholar]

- De Almeida, M.G.; Ferreira, M.A.P.S. Cost effective energy and carbon emissions optimization in building renovation (Annex 56). Energy Build. 2017, 152, 718–738. [Google Scholar] [CrossRef]

- Lasvaux, S.; Favre, D.; Périsset, B.; Bony, J.; Hildbrand, C.; Citherlet, S. Life Cycle Assessment of Energy Related Building Renovation: Methodology and Case Study. Energy Procedia 2015, 78, 3496–3501. [Google Scholar] [CrossRef] [Green Version]

- Delem, L.; Wastiels, L.; Van Dessel, J. Assessing the Construction Phase in Building Life Cycle Assessment. In Proceedings of the [avniR] LCA Conference 2013, Lille, France, 4–5 November 2013; Available online: https://bit.ly/3dk6JjT (accessed on 29 March 2021).

- Kleemann, F.; Laner, D.; Laner, D. Waste Prevention in the Prefabricated Building Sector. Appl. Mech. Mater. 2019, 887, 361–368. [Google Scholar] [CrossRef]

- Koordinationskonferenz der Bau- und Liegenschaftsorgane der Öffentlichen Bauherren KBOB. Available online: https://www.kbob.admin.ch/kbob/de/home.html (accessed on 29 March 2021).

- Gaspar, P.L.; Santos, A.L. Embodied energy on refurbishment vs. demolition: A southern Europe case study. Energy Build. 2015, 87, 386–394. [Google Scholar] [CrossRef]

- Allred, P.M. Phase Change Materials for Solar Thermal Energy Storage. Master’s Thesis, Dalhousie University, Halifax, NS, Canada, 2014; p. 83. [Google Scholar]

- Bonamente, E.; Aquino, A. Environmental Performance of Innovative Ground-Source Heat Pumps with PCM Energy Storage. Energies 2019, 13, 117. [Google Scholar] [CrossRef] [Green Version]

- Comodi, G.; Bevilacqua, M.; Caresana, F.; Pelagalli, L.; Venella, P.; Paciarotti, C. LCA Analysis of Renewable Domestic Hot Water Systems with Unglazed and Glazed Solar Thermal Panels. Energy Procedia 2014, 61, 234–237. [Google Scholar] [CrossRef] [Green Version]

- Ozturk, M.; Dincer, I. Comparative environmental impact assessment of various fuels and solar heat for a combined cycle. Int. J. Hydrogen Energy 2019, 44, 5043–5053. [Google Scholar] [CrossRef]

| Treated/Gross Floor Area [m2] | Treated Volume [m3] | Average U-Value of the Envelope [W·m−2·K−1] | Energy Consumption | ||||

|---|---|---|---|---|---|---|---|

| Heating [GJ·a−1] | DHW [GJ·a−1] | Lighting, etc. [GJ·a−1] | Total [GJ·a−1] | ||||

| V-1 | 79/169 | 224 | 1.40 | 171.01 | 8.33 | 1.41 | 180.76 |

| V-2 | 227/244 | 761 | 0.66 | 202.30 | 17.32 | 2.80 | 222.42 |

| V-3 | 259/297 | 766 | 0.34 | 136.94 | 7.53 | 3.31 | 147.78 |

| Heating | DHW | Lighting, etc. | |

|---|---|---|---|

| V-1 | 100% Electricity | 100% Electricity | 100% Electricity |

| V-2 | 90% Natural gas 10% Firewood | 100% Natural gas | 100% Electricity |

| V-2E | 90% Electricity 10% Firewood | 100% Electricity | 100% Electricity |

| V-2S | 70% Natural gas 20% Solar thermal 10% Firewood | 80% Solar thermal 20% Natural gas | 100% Electricity |

| V-2W | 90% Wood pellets 10% Firewood | 100% Wood pellets | 100% Electricity |

| V-3 | 90% Natural gas 10% Firewood | 100% Natural gas | 100% Electricity |

| V-3E | 90% Electricity 10% Firewood | 100% Electricity | 100% Electricity |

| V-3S | 70% Natural gas 20% Solar thermal 10% Firewood | 80% Solar thermal 20% Natural gas | 100% Electricity |

| V-3W | 90% Wood pellets 10% Firewood | 100% Wood pellets | 100% Electricity |

| UBP [Pts·m−2·a−1] | V-1 | V-2 | V-2E | V-2S | V-2W | V-3 | V-3E | V-3S | V-3W |

|---|---|---|---|---|---|---|---|---|---|

| A1–A3 Product stage | 5.24 × 103 | 8.24 × 103 | 8.24 × 103 | 9.43 × 103 | 8.24 × 103 | 7.55 × 103 | 7.55 × 103 | 8.18 × 103 | 7.55 × 103 |

| A4 Transport | 6.47 × 102 | 4.59 × 102 | 4.59 × 102 | 4.59 × 102 | 4.59 × 102 | 3.98 × 102 | 3.98 × 102 | 3.98 × 102 | 3.98 × 102 |

| A5 Construction | 6.69 × 102 | 7.85 × 102 | 7.85 × 102 | 7.85 × 102 | 7.85 × 102 | 8.05 × 102 | 8.05 × 102 | 8.05 × 102 | 8.05 × 102 |

| B4 Replacement | 6.01 × 103 | 6.11 × 103 | 6.11 × 103 | 7.30 × 103 | 6.11 × 103 | 5.36 × 103 | 5.36 × 103 | 5.98 × 103 | 5.36 × 103 |

| B6 Operational en. | 4.68 × 105 | 3.38 × 104 | 1.86 × 105 | 2.62 × 104 | 3.05 × 104 | 2.06 × 104 | 1.08 × 105 | 1.64 × 104 | 1.87 × 104 |

| C1–C4 End of life st. | 7.71 × 102 | 1.72 × 102 | 1.72 × 102 | 1.72 × 102 | 1.72 × 102 | 1.42 × 102 | 1.42 × 102 | 1.42 × 103 | 1.42 × 102 |

| Hypothetical Total Energy Consumption [GJ·a−1] | UBP [Pts·m−2·a−1] | |

|---|---|---|

| V-2 | V-3 | |

| 222.42 (equalling that of V-2) | 5.11 × 105 | 5.15 × 105 |

| 147.78 (equalling that of V-3) | 4.08 × 105 | 4.12 × 105 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Struhala, K.; Ostrý, M. Life-Cycle Assessment of a Rural Terraced House: A Struggle with Sustainability of Building Renovations. Energies 2021, 14, 2472. https://doi.org/10.3390/en14092472

Struhala K, Ostrý M. Life-Cycle Assessment of a Rural Terraced House: A Struggle with Sustainability of Building Renovations. Energies. 2021; 14(9):2472. https://doi.org/10.3390/en14092472

Chicago/Turabian StyleStruhala, Karel, and Milan Ostrý. 2021. "Life-Cycle Assessment of a Rural Terraced House: A Struggle with Sustainability of Building Renovations" Energies 14, no. 9: 2472. https://doi.org/10.3390/en14092472

APA StyleStruhala, K., & Ostrý, M. (2021). Life-Cycle Assessment of a Rural Terraced House: A Struggle with Sustainability of Building Renovations. Energies, 14(9), 2472. https://doi.org/10.3390/en14092472