Day-Ahead and Intra-Day Optimal Scheduling of Integrated Energy System Considering Uncertainty of Source & Load Power Forecasting

Abstract

:1. Introduction

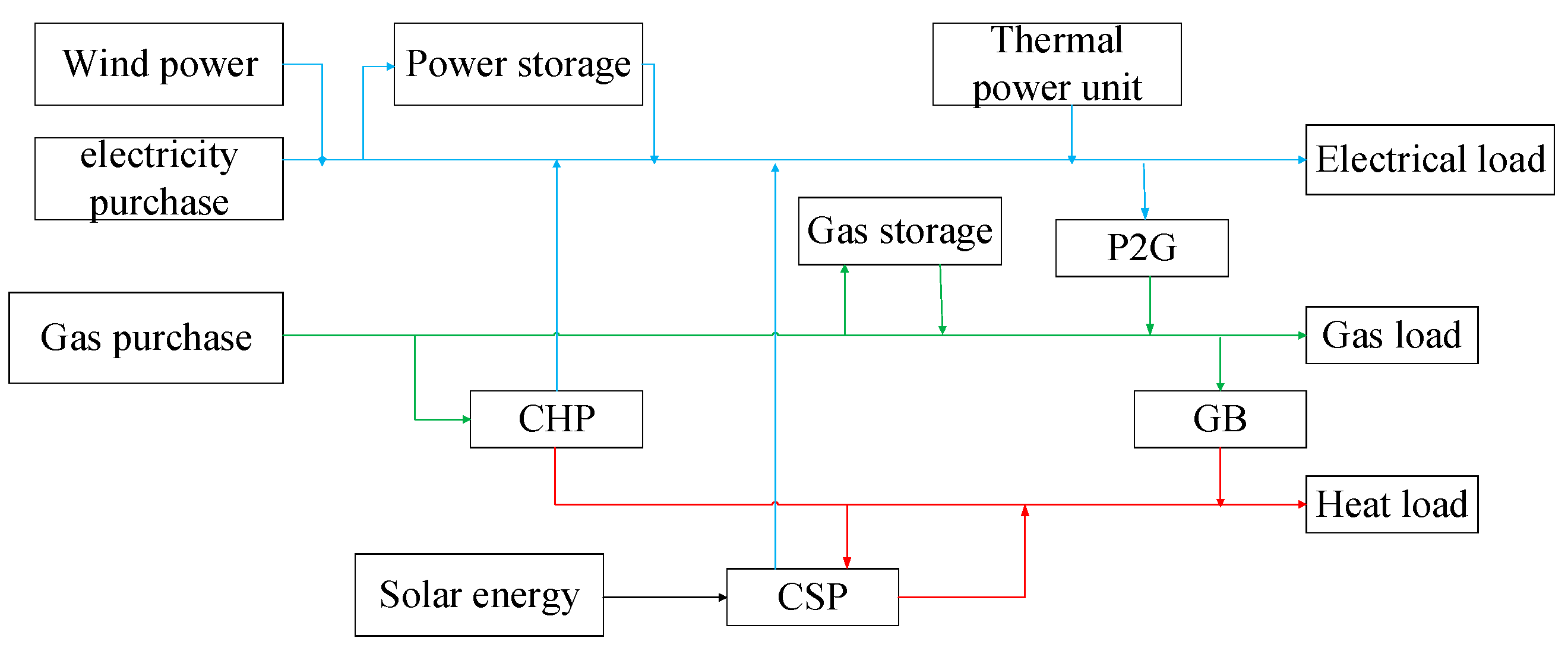

2. Equipment Introduction

2.1. Energy Conversion Equipment

2.1.1. CSP Model

2.1.2. CHP Model

2.1.3. Other Energy Conversion Equipment

2.2. Energy Storage Equipment

3. Problem Formulation

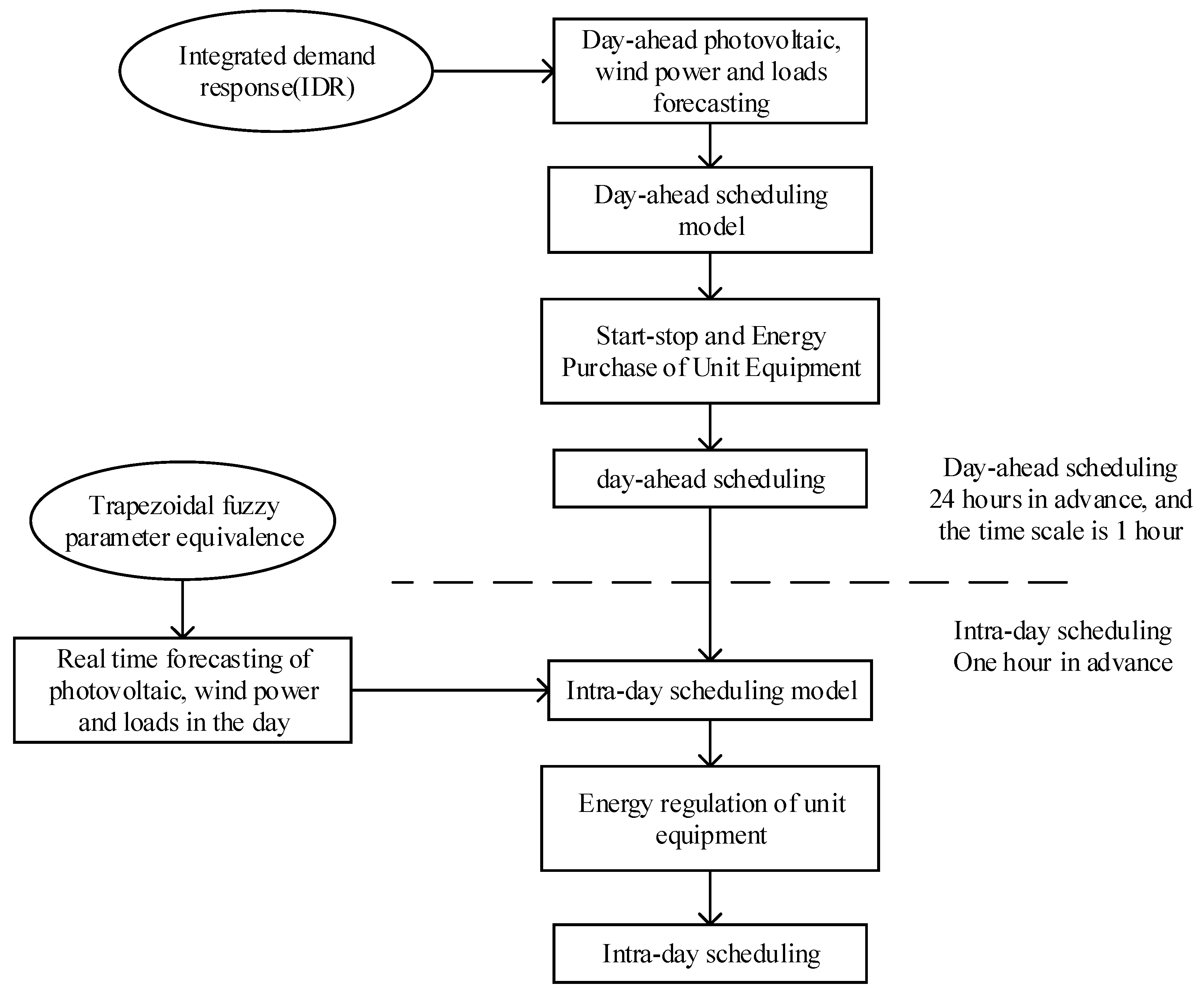

3.1. Day-Ahead Scheduling Model

3.1.1. Objective Function

3.1.2. Constraints

3.2. Intra-Day Scheduling Model

3.2.1. Objective Function

3.2.2. Constraints

3.3. Algorithm for Solving the Model

4. Model Processing Strategy

4.1. Day-Ahead Integrated Demand Response Strategy

4.1.1. Price-Based Demand Response

4.1.2. Alternative Demand Response

4.2. Intra-Day Trapezoidal Fuzzy Parameter Equivalence Strategy

5. Example Simulation

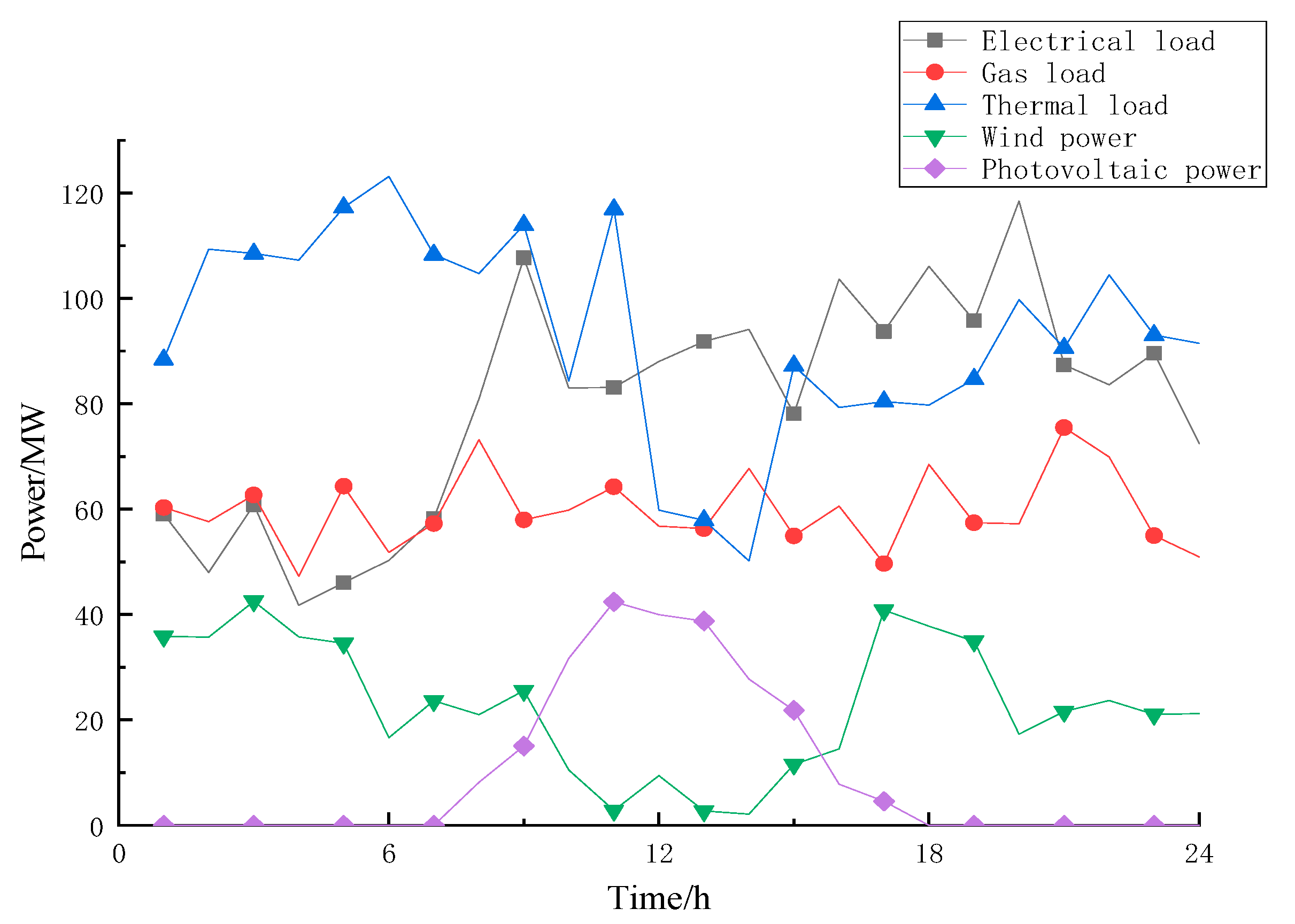

5.1. Example Parameters

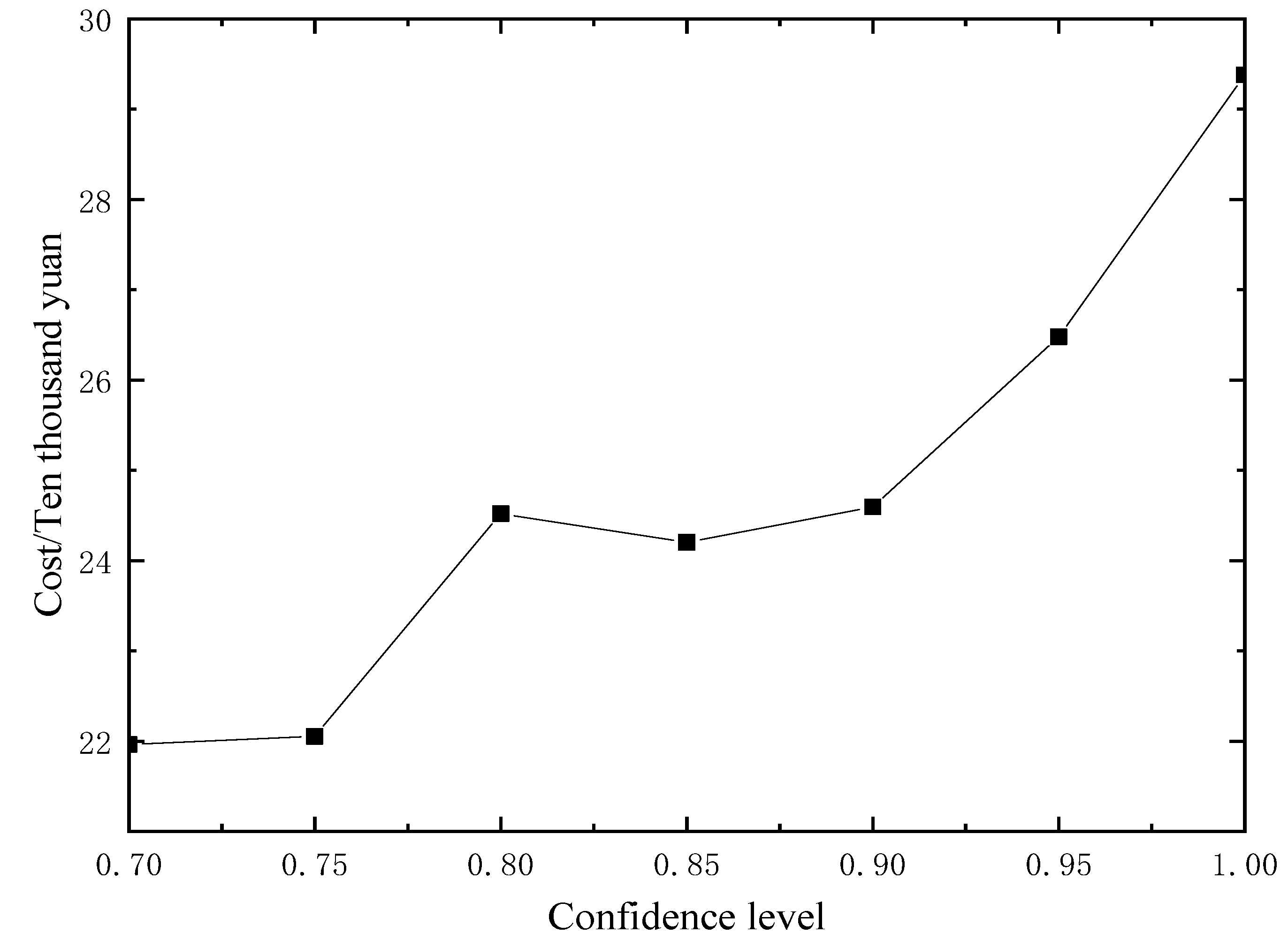

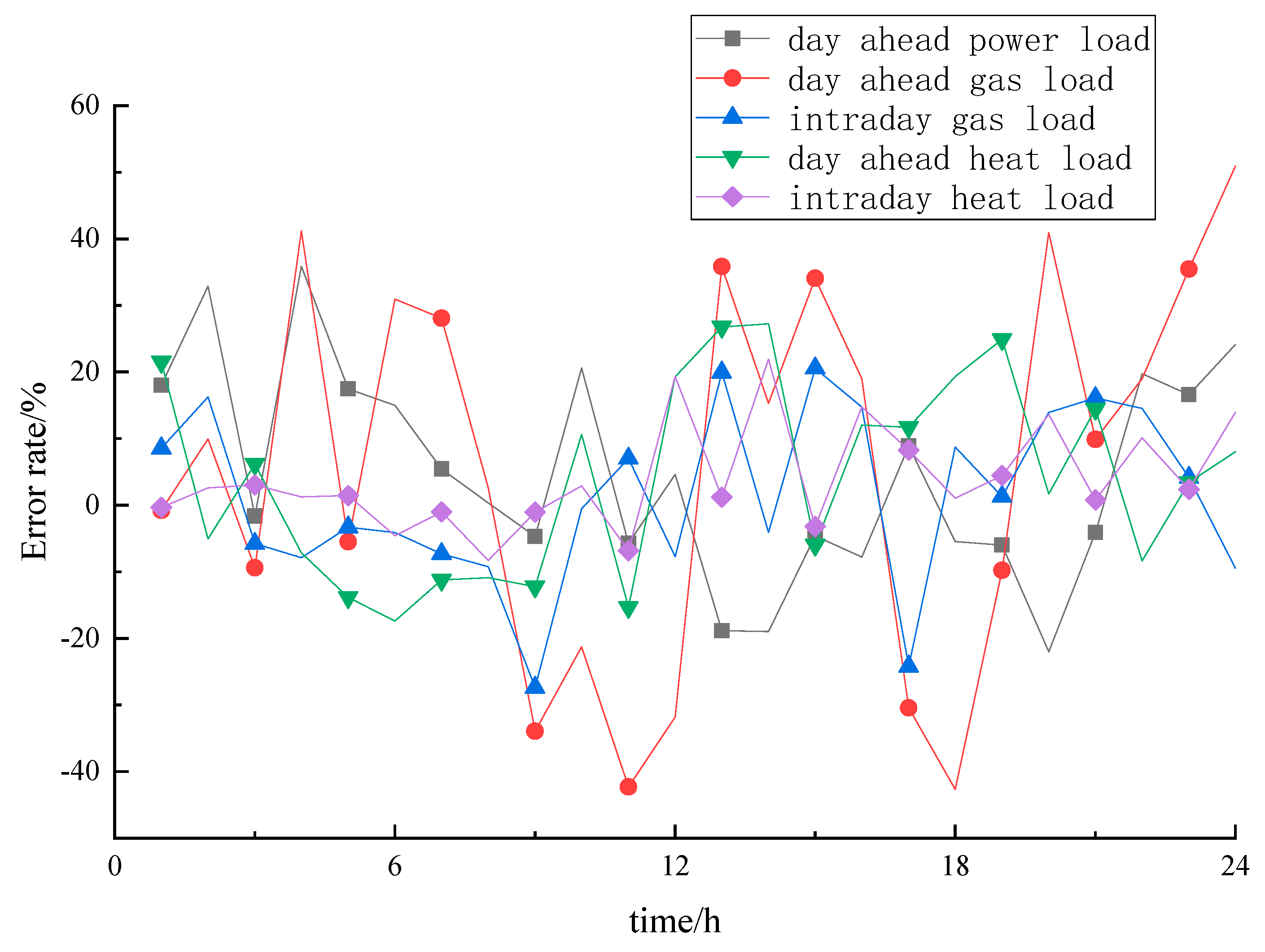

5.2. Result Analysis

6. Conclusions

- (1)

- The system scheduling level can be affected by the integrated demand response. Compared with the absence of IDR, the load curve of the system is obviously improved during the day-ahead scheduling after the implementation of IDR, and the economy and reliability of the system are improved.

- (2)

- The intra-day adjustment cost of the system is related to the confidence level, and the higher the confidence level, the higher the intra-day cost. That is to say, high reliability will lead to high cost, and high risk will bring high return.

- (3)

- After fuzzy parameters are used to represent the intra-day prediction of wind power, solar power and loads power, the optimal confidence level of the model can be obtained through simulation analysis. The optimal scheduling scheme can be determined by decision makers according to the actual demand to improve the system economy.

- (4)

- Compared with day-ahead scheduling only, the optimization of IES can improve the accuracy of decision-making by further shortening the time-scale of intra-day scheduling and adjusting unit output based on day-ahead scheduling scheme

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, J.; Li, Y.; Li, H.; Tong, H.; Yuan, Z.; Yang, X.; Huang, W. Application of game theory in integrated energy system systems: A review. IEEE Access 2020, 8, 93380–93397. [Google Scholar] [CrossRef]

- Gong, F.; Li, D.; Tian, S.; Zhang, Y.; Shi, K.; Zhang, P.; Li, J. Review and prospect of core technologies of integrated energy system. Renew. Energy Resour. 2019, 37, 1229–1235. [Google Scholar]

- Jia, H.; Mu, Y.; Yu, X. Thought about the integrated energy system in China. Electr. Power Constr. 2015, 36, 16–25. [Google Scholar]

- Wu, J. Drivers and state-of-the-art of integrated energy systems in Europe. Autom. Electr. Power Syst. 2016, 40, 1–7. [Google Scholar]

- Wei, X.-X.; Liu, S.-W. Analysis on international development in distributed generation and its revelation to China. Electr. Power Technol. Econ. 2010, 22, 58–61. [Google Scholar]

- Li, G.; Huang, Y.; Bie, C.; An, J.; Sun, S.; Qiu, Q.; Gao, X.; Peng, Y.; Lei, Y. Review and prospect of operational reliability evaluation of integrated energy system. Electr. Power Autom. Equip. 2019, 39, 12–21. [Google Scholar]

- Yao, Z.; Wang, Z. Two-level collaborative optimal allocation method of integrated energy system considering wind and solar uncertainty. Power Syst. Technol. 2020, 44, 4521–4531. [Google Scholar]

- Lin, B.; Chen, Y. Impacts of policies on innovation in wind power technologies in China. Appl. Energy 2019, 247, 682–691. [Google Scholar] [CrossRef]

- Lewis, J.I.; Chai, Q.; Zhang, X. Low-carbon electricity development in China: Opportunities and challenge. In Generating Electricity in a Carbon-Constrained World; Academic Press: Cambridge, MA, USA, 2010; pp. 473–500. [Google Scholar]

- Chen, H.; Chen, J.; Duan, X. Fuzzy modeling and optimization algorithm on dynamic economic dispatch in wind power integrated system. Autom. Electr. Power Syst. 2006, 30, 22–26. [Google Scholar]

- Ai, X.; Liu, X.; Sun, C. A fuzzy chance constrained decision model for unit commitment of power grid containing large-scale wind farm. Power Syst. Technol. 2011, 35, 202–207. [Google Scholar]

- Li, G.; Dong, C.; Liang, Z.; Li, X.; Lu, W.; Li, Z. Cross-provincial two level optimal scheduling model considering the uncertainty of photovoltaic power generation. High Voltage Eng. 2021, 1–14. [Google Scholar] [CrossRef]

- Li, G.; Li, X.; Bian, J.; Li, Z. Two level scheduling strategy for inter-provincial DC power grid considering the uncertainty of PV-load prediction. CSEE 2021, 1–18. [Google Scholar] [CrossRef]

- Chen, R.; Sun, H.; Li, Z.; Liu, Y. Grid dispatch model and interconnection benefit analysis of concentrating solar power plants with thermal storage. Autom. Electr. Power Syst. 2006, 38, 22–26. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, K.; Liao, X.; Hu, Z. Multi-time scale source-load coordination dispatch model for power system with large-scale wind power. High Voltage Eng. 2019, 45, 600–608. [Google Scholar]

- Liu, X.; He, C.; Cheng, X.; Bo, L.; Zhang, J.; Zheng, H.; Hao, J. Day-ahead and intra-day scheduling strategy of concentrated solar power station with thermal energy storage and wind farm considering coordination between generation and load. Electr. Power 2021, 1–13. Available online: http://kns.cnki.net/kcms/detail/11.3265.TM.20200921.1349.009.html (accessed on 24 January 2021).

- Yuan, Q.; Wu, Y.; Li, B.; Sun, Y. Multi-timescale coordinated dispatch model and approach considering generation and load uncertainty. Power Syst. Prot. Control 2019, 47, 8–16. [Google Scholar]

- Dong, H.; Fang, L.; Ding, K.; Wang, N.; Zhang, Z. Peak regulation strategy of CSP plants based on operation mode of cogeneration. Acta Energ. Sol. Sin. 2019, 40, 2763–2772. [Google Scholar]

- Yetkin, M.; Inal, C.; Yigit, C.O. Use of the particle swarm optimization algorithm for second order design of levelling networks. J. Appl. Geod. 2009, 3, 171–178. [Google Scholar] [CrossRef]

- Ma, Z.; Zheng, Y.; Mu, C.; Ding, T.; Zang, H. Optimal trading strategy for integrated energy company based on integrated demand response considering load classifications. Int. J. Electr. Power Energy Syst. 2021, 128. [Google Scholar] [CrossRef]

- He, L.; Lu, Z.; Geng, L.; Zhang, J.; Li, X.; Guo, X. Environmental economic dispatch of integrated regional energy system considering integrated demand response. Int. J. Electr. Power Energy Syst. 2019, 116, 105525. [Google Scholar] [CrossRef]

- Yi, S.; Zhang, P.; Yang, M.; Bai, H.; Yang, Q. Multi-time scale optimal scheduling of integrated energy system considering demand-side response. Proc. CSU-EPSA 2020, 32, 35–42. [Google Scholar]

- Xiong, H.; Xiang, T.; Chen, H.; Lin, F.; Su, J. Research of fuzzy chance constrained unit commitment containing large-scale intermittent power. Proc. CSEE 2013, 33, 36–44. [Google Scholar]

- Zhai, J.; Ren, J.; Zhou, M.; Li, Z. Multi-time scale fuzzy chance constrained dynamic economic dispatch model for power system with wind power. Power System Technol. 2016, 40, 1094–1099. [Google Scholar]

| Equipment | Efficiency | Operation and Maintenance Cost (Yuan/MW) | Output Range (MW) |

|---|---|---|---|

| GT | 0.4 | 41 | (0,100) |

| P2G | 0.6 | 50 | (0.50) |

| GB | 0.85 | 36 | (0,100) |

| WHB | 0.4 | 35 | (0,20) |

| CSP | 0.4 | 50 | (0,20) |

| ES | 0.9 | 18 | (−15,15) |

| GS | 0.9 | 18 | (−20,20) |

| TS | 0.9 | 16 | (−10,10) |

| Class | Segment | Period | Price (Yuan/MWh) |

|---|---|---|---|

| Electric | Peak period | 10:00–15:00 | 1112/1155 |

| 18:00–21:00 | |||

| Normal period | 07:00–10:00 | 667/617 | |

| 15:00–18:00 | |||

| 21:00–23:00 | |||

| Valley period | 00:00–07:00 | 322/298 | |

| 23:00–24:00 | |||

| Gas | Peak period | 08:00–12:00 | 428/441 |

| 16:00–19:00 | |||

| Normal period | 06:00–08:00 | 210/196 | |

| 12:00–16:00 | |||

| 19:00–22:00 | |||

| Valley period | 22:00–06:00 | 162/151 |

| Fuzzy Parameter | ω1 | ω2 | ω3 | ω4 |

|---|---|---|---|---|

| Wind power | 0.6 | 0.9 | 1.1 | 1.4 |

| Solar power | 0.75 | 0.9 | 1.1 | 1.25 |

| Loads | 0.9 | 0.95 | 1.05 | 1.1 |

| Scenario | Total Cost (Yuan) | Electricity Purchase Cost (Yuan) | Gas Purchase Cost (Yuan) |

|---|---|---|---|

| 1 | 2,380,977.356 | 308,359.0327 | 1,700,017.44 |

| 2 | 2,221,565.65 | 287,023.3357 | 1,572,484.016 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhang, Z. Day-Ahead and Intra-Day Optimal Scheduling of Integrated Energy System Considering Uncertainty of Source & Load Power Forecasting. Energies 2021, 14, 2539. https://doi.org/10.3390/en14092539

Li Z, Zhang Z. Day-Ahead and Intra-Day Optimal Scheduling of Integrated Energy System Considering Uncertainty of Source & Load Power Forecasting. Energies. 2021; 14(9):2539. https://doi.org/10.3390/en14092539

Chicago/Turabian StyleLi, Zhengjie, and Zhisheng Zhang. 2021. "Day-Ahead and Intra-Day Optimal Scheduling of Integrated Energy System Considering Uncertainty of Source & Load Power Forecasting" Energies 14, no. 9: 2539. https://doi.org/10.3390/en14092539

APA StyleLi, Z., & Zhang, Z. (2021). Day-Ahead and Intra-Day Optimal Scheduling of Integrated Energy System Considering Uncertainty of Source & Load Power Forecasting. Energies, 14(9), 2539. https://doi.org/10.3390/en14092539