Understanding the Potential of Wind Farm Exploitation in Tropical Island Countries: A Case for Indonesia

Abstract

:1. Introduction

2. Methodology

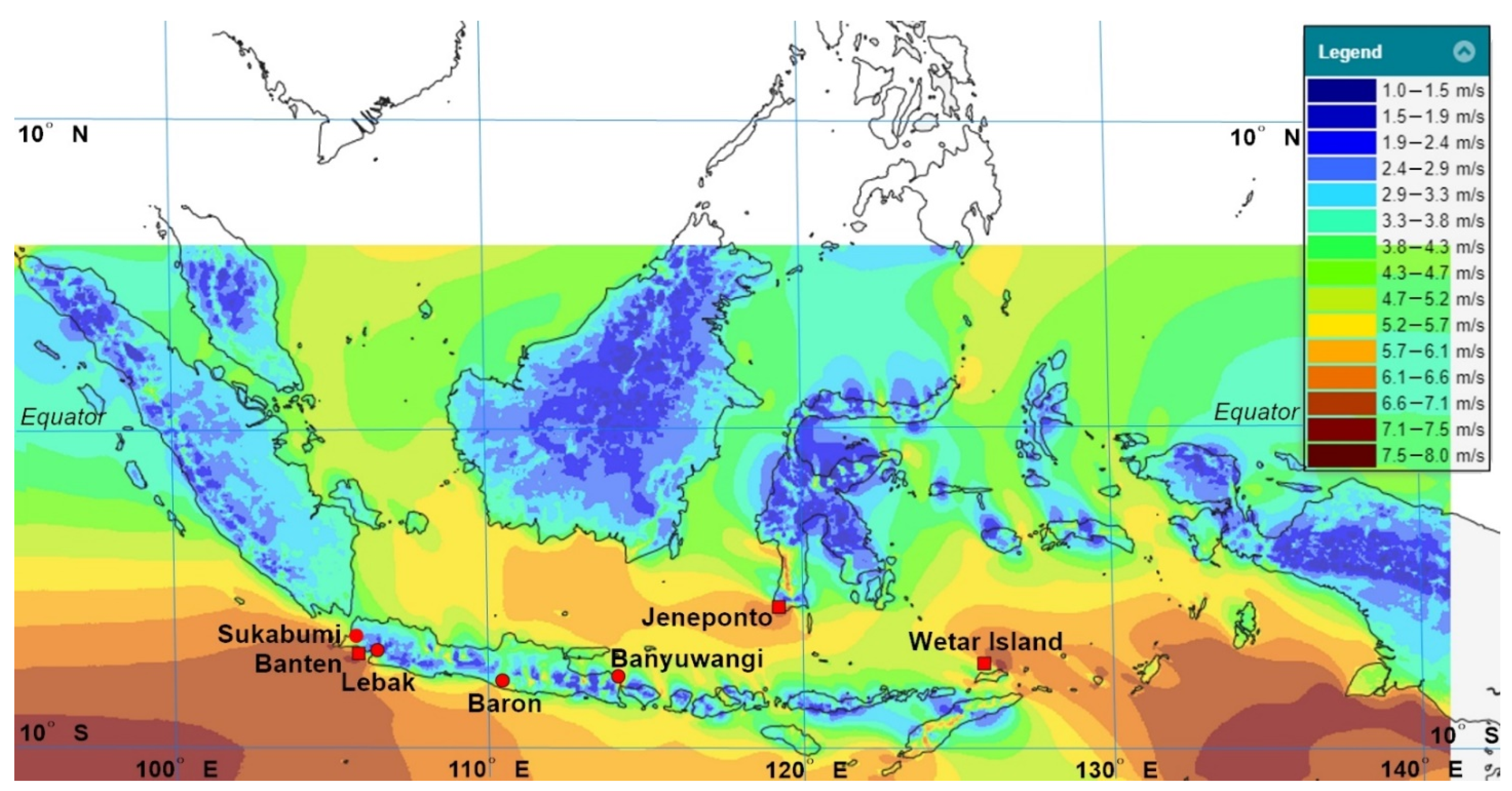

2.1. Sites for Evaluation

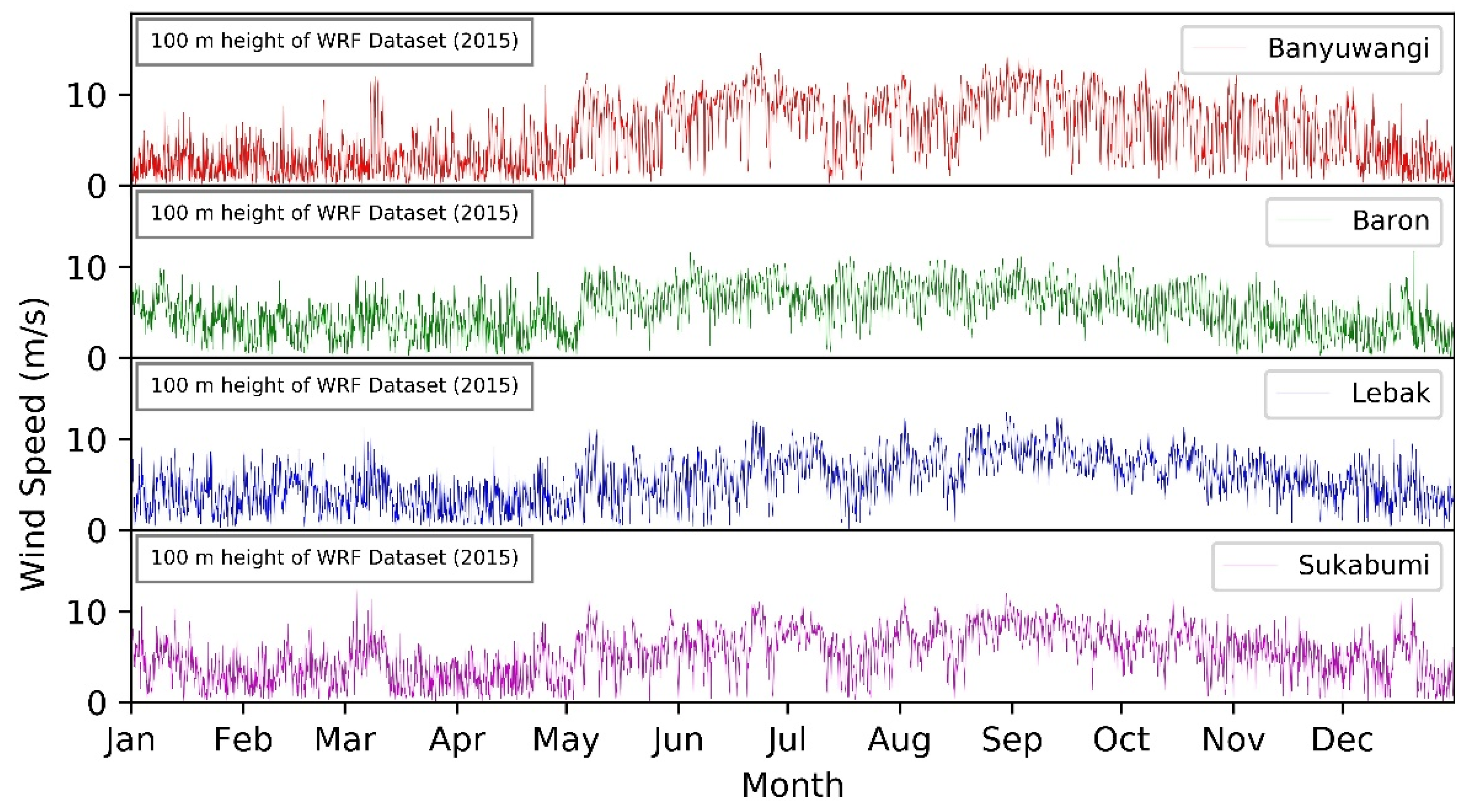

2.2. Wind Dataset

2.3. Wind Characteristics

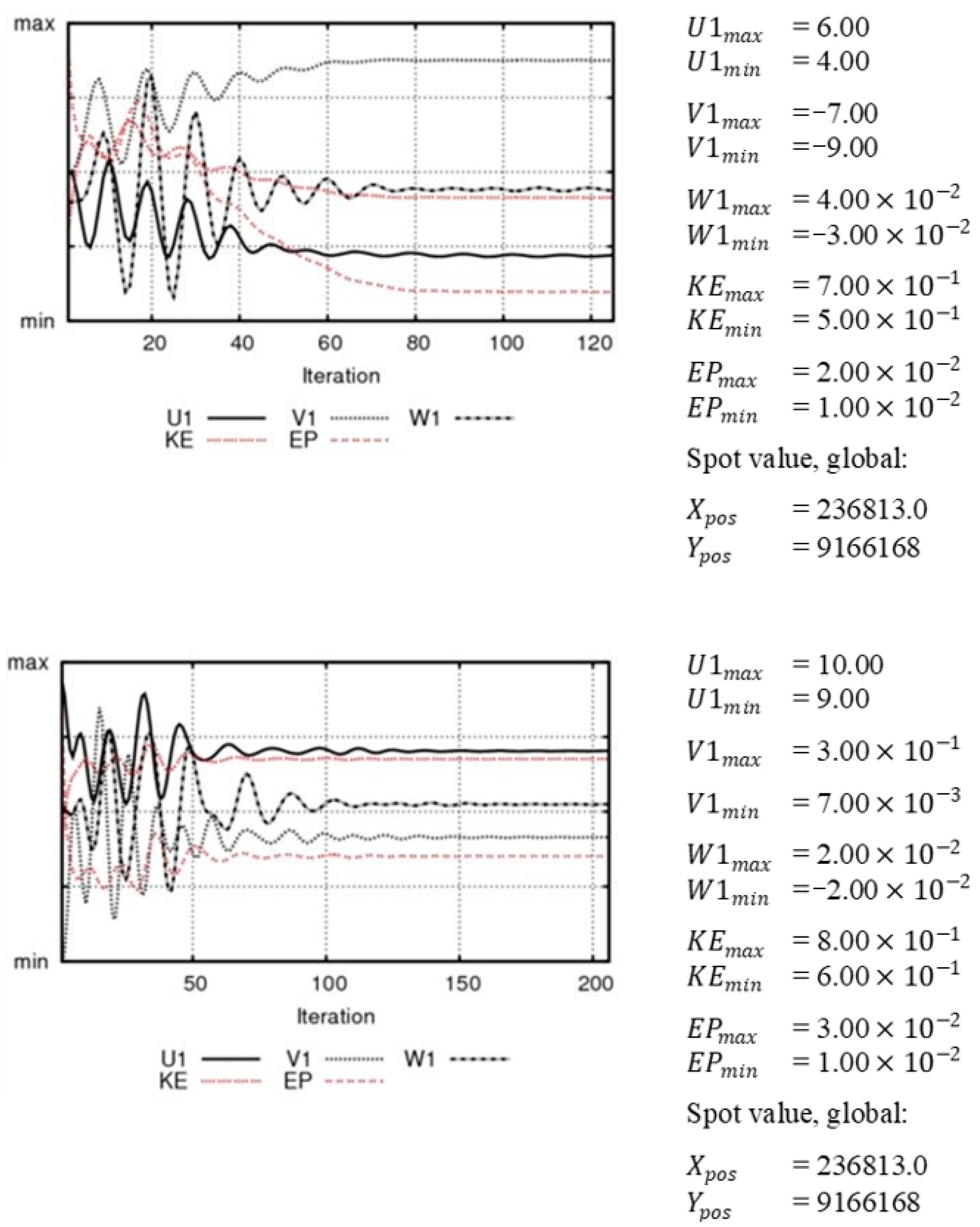

2.4. WindSim

2.5. Wind Farm Performance

2.6. Economic Analysis of Wind Farm Design

3. Wind Characteristics of the Studied Sites

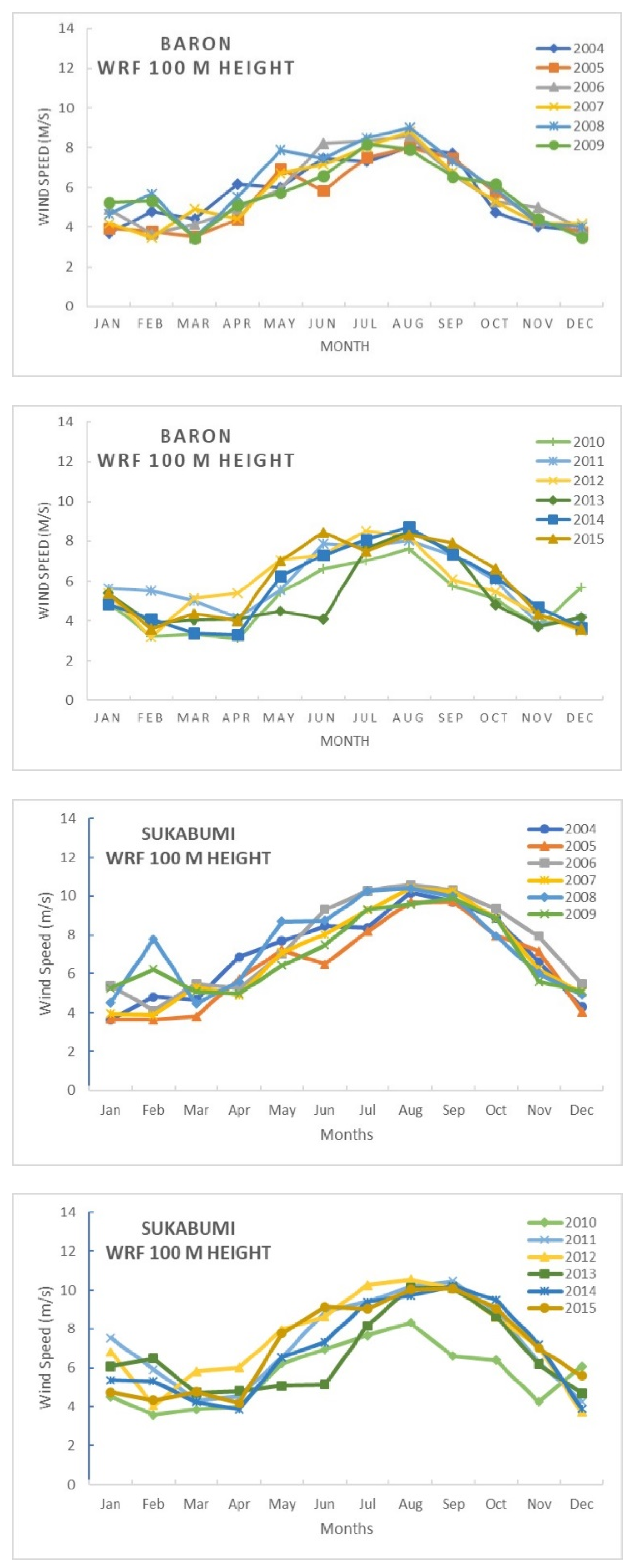

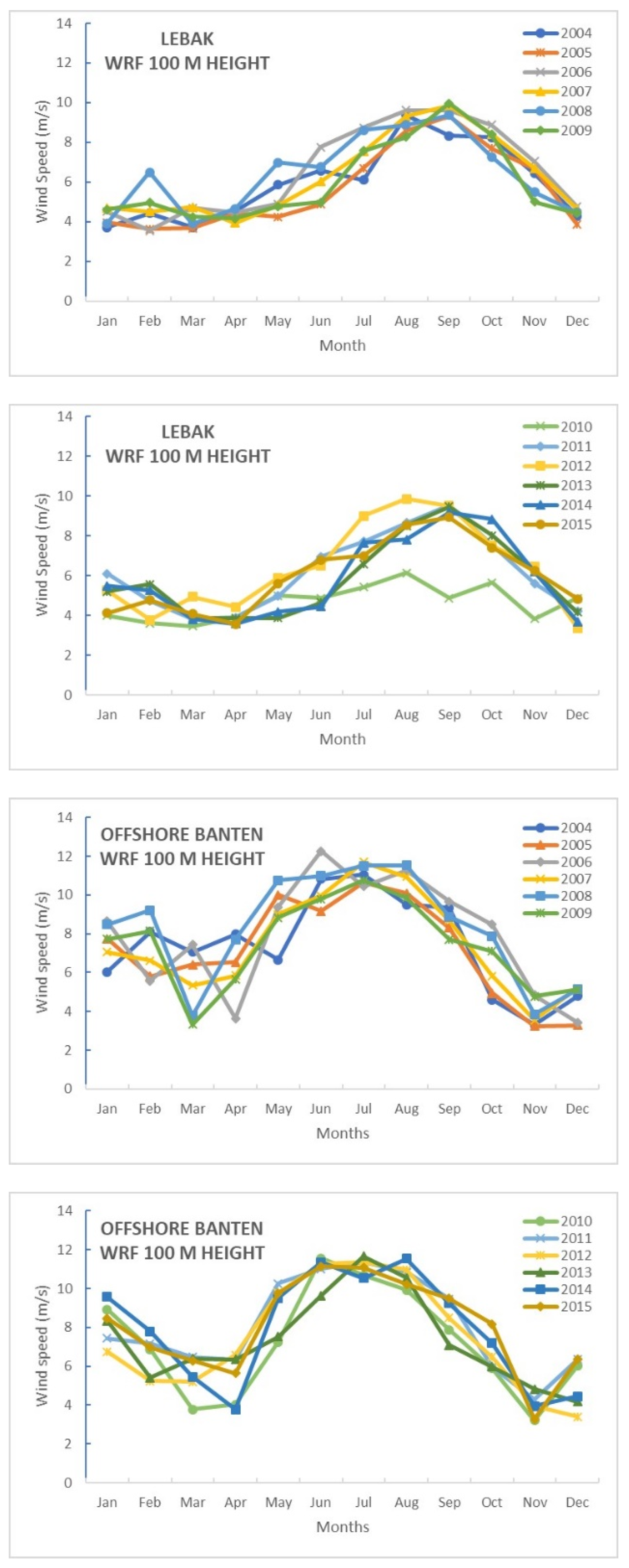

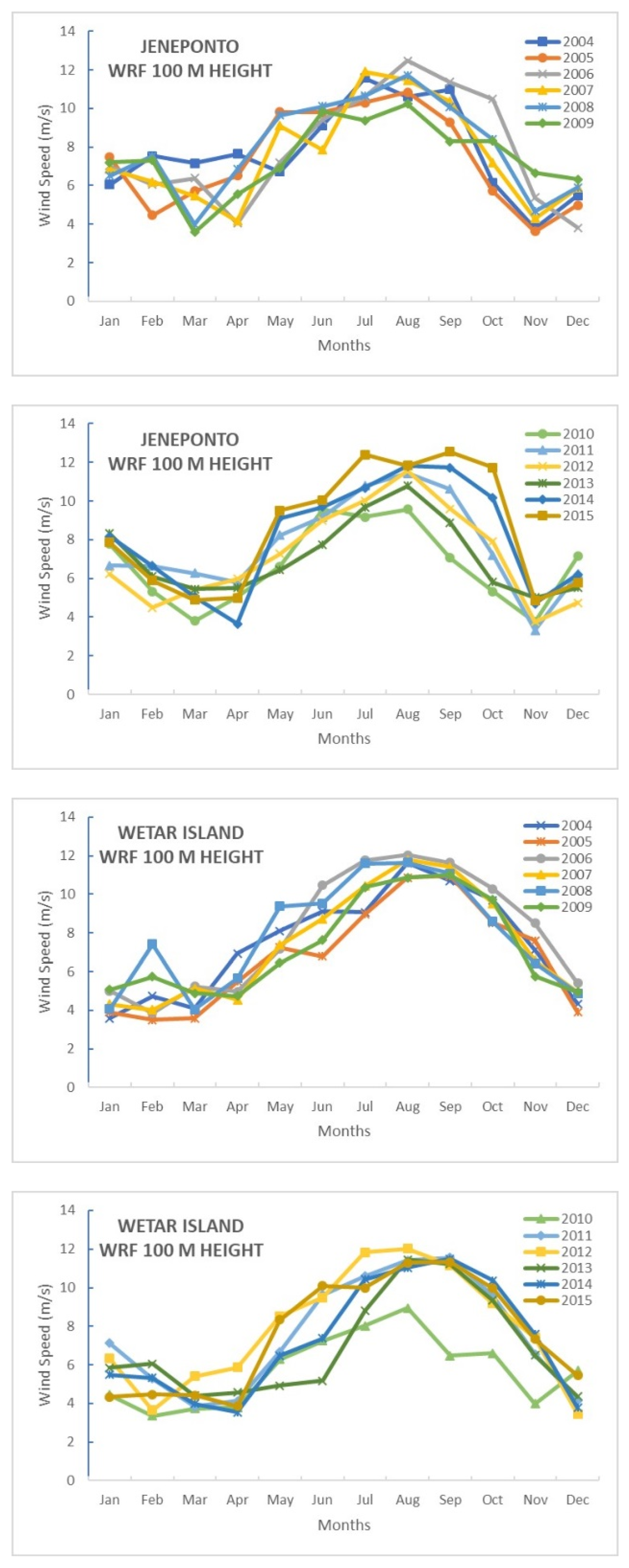

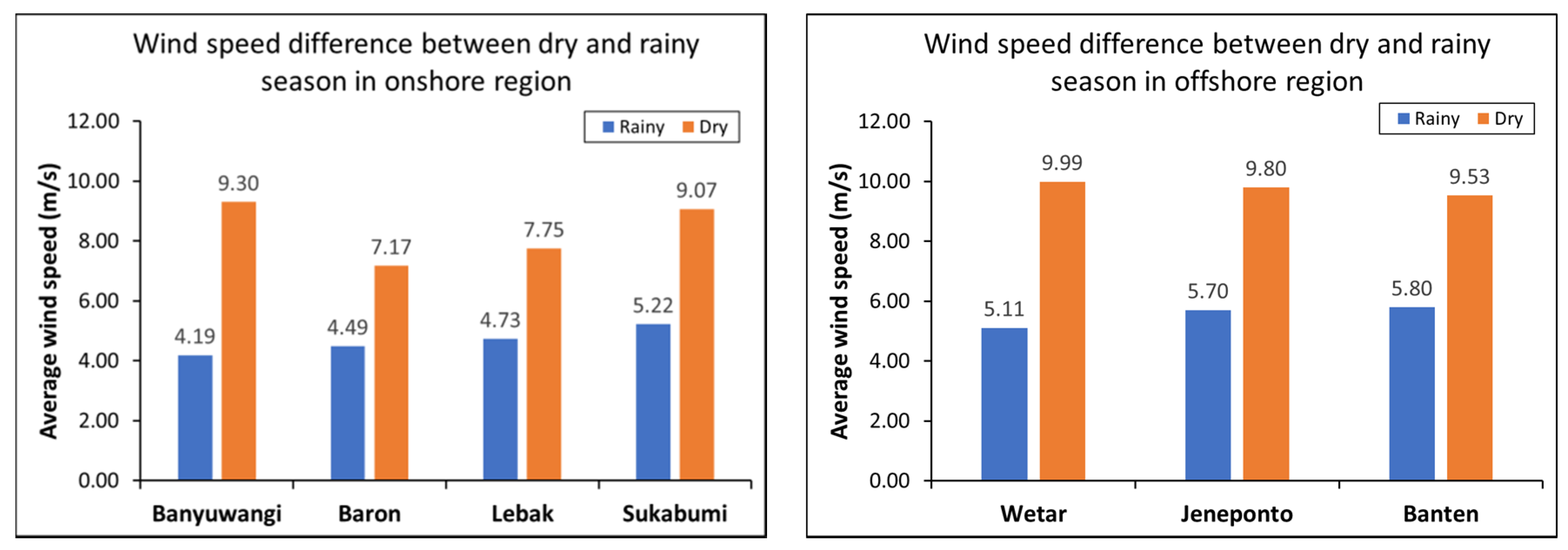

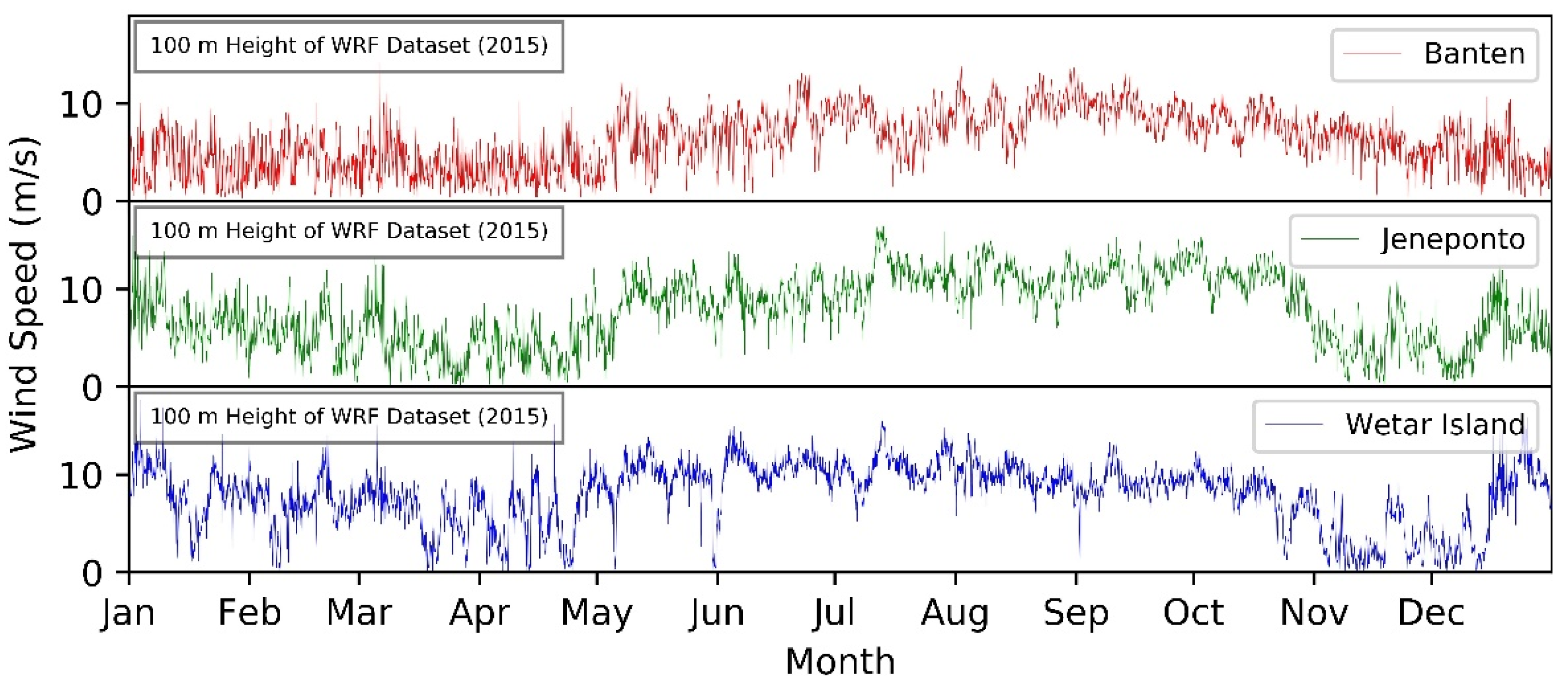

3.1. Wind Speed and Direction

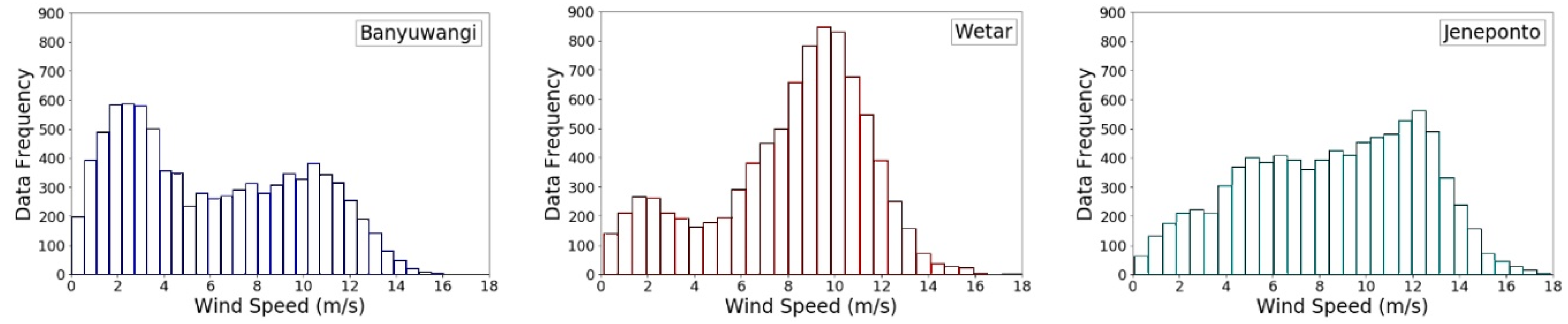

3.2. Comparisons of Wind Speeds Among Sites

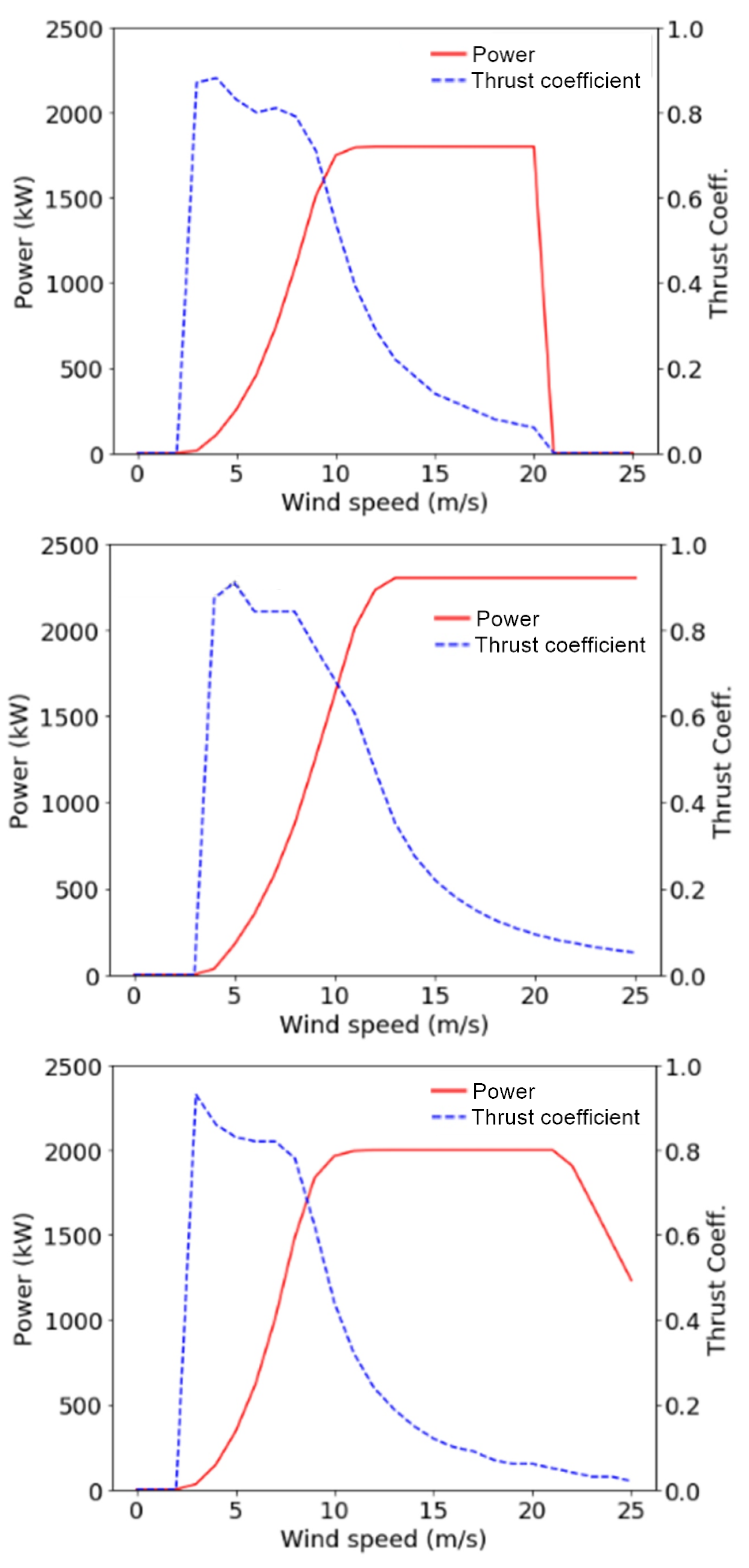

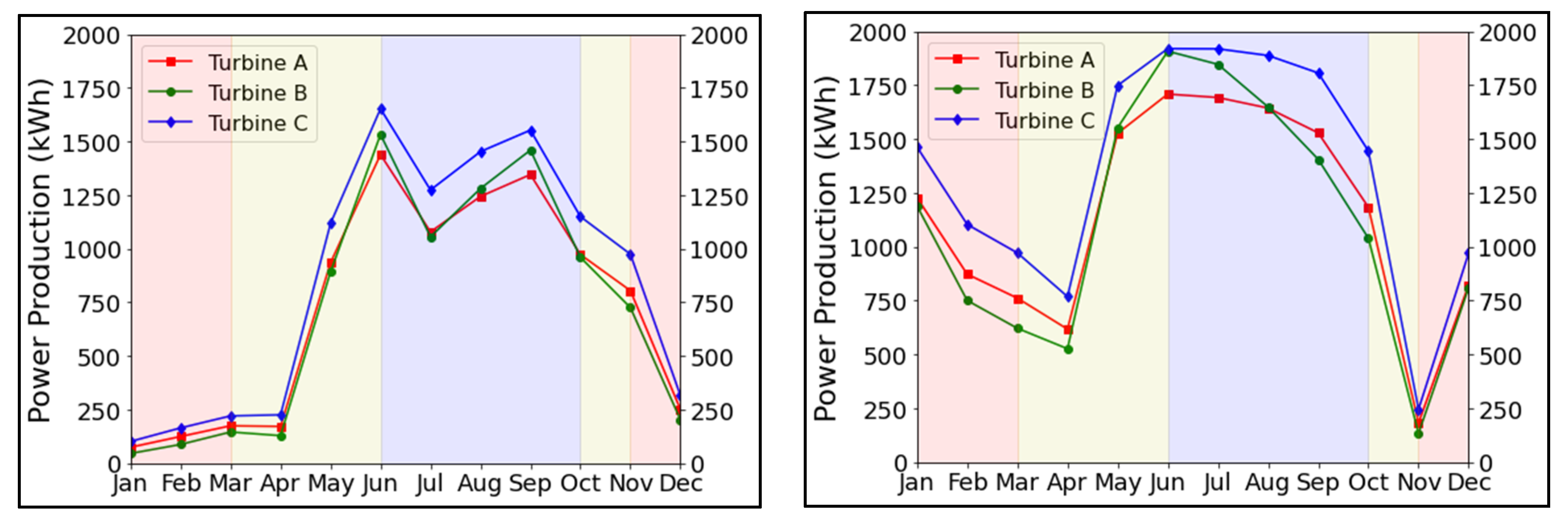

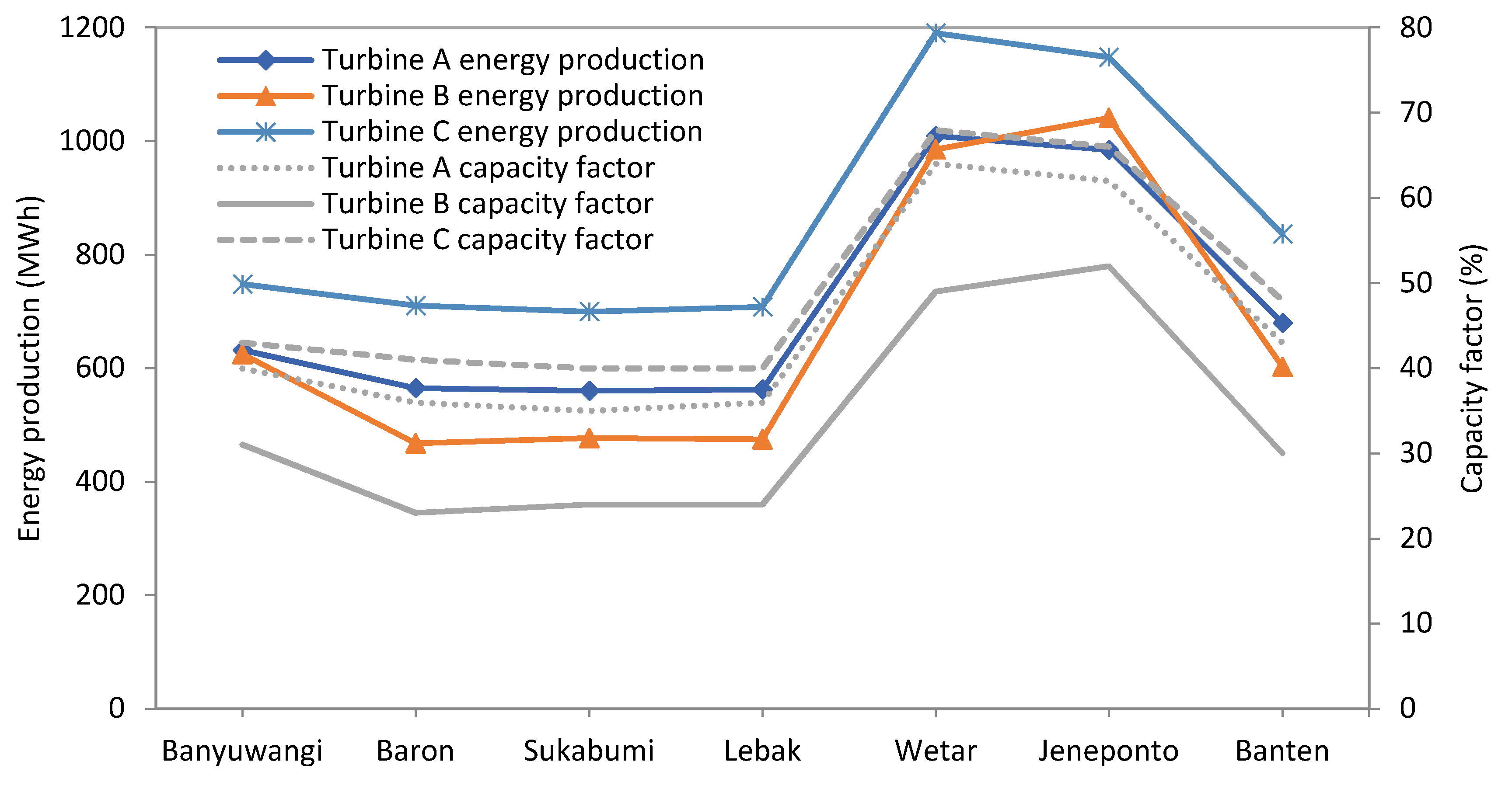

3.3. Estimated Power Production

4. Wind Farm Design and Analysis for Wetar Island

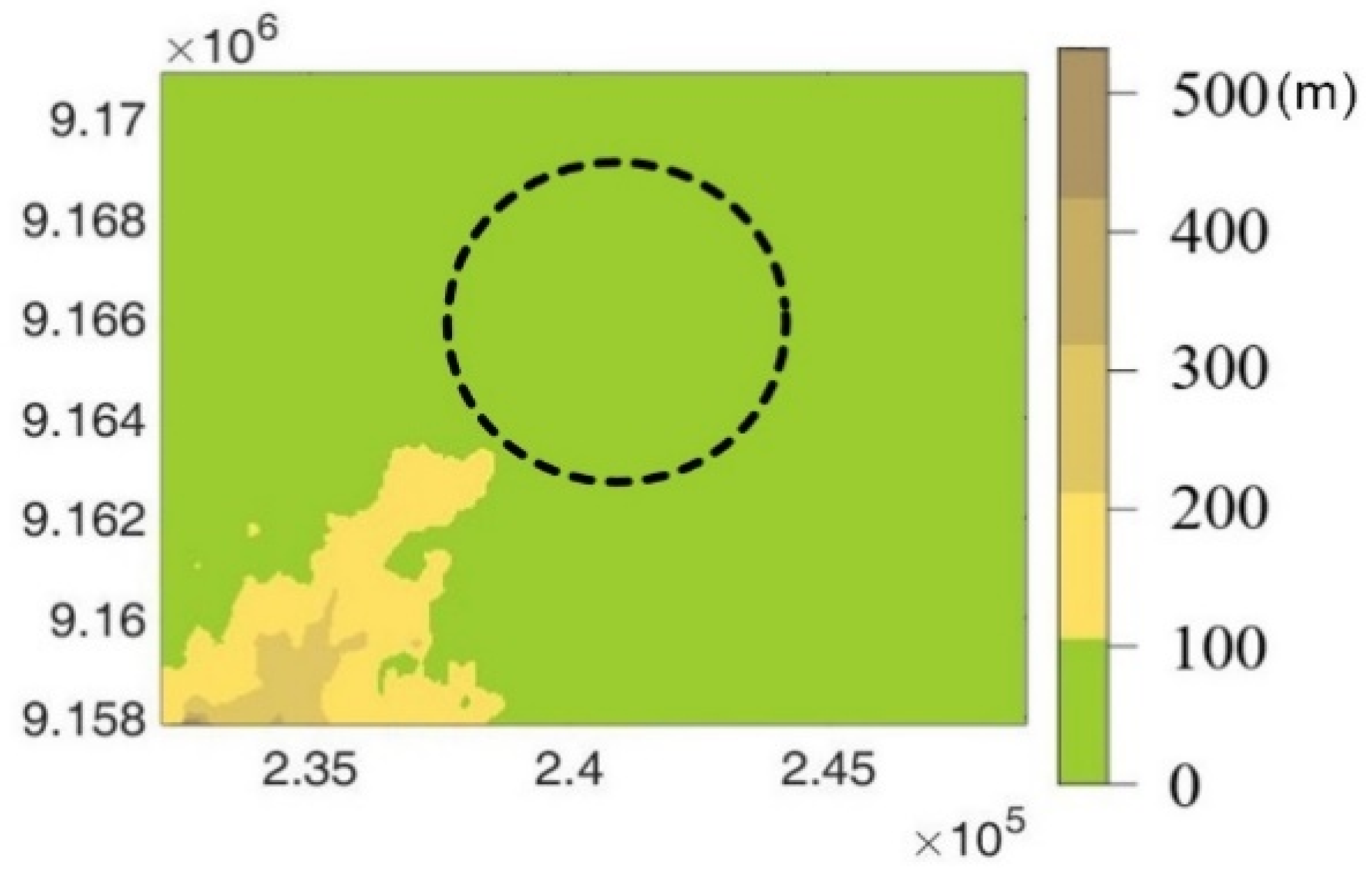

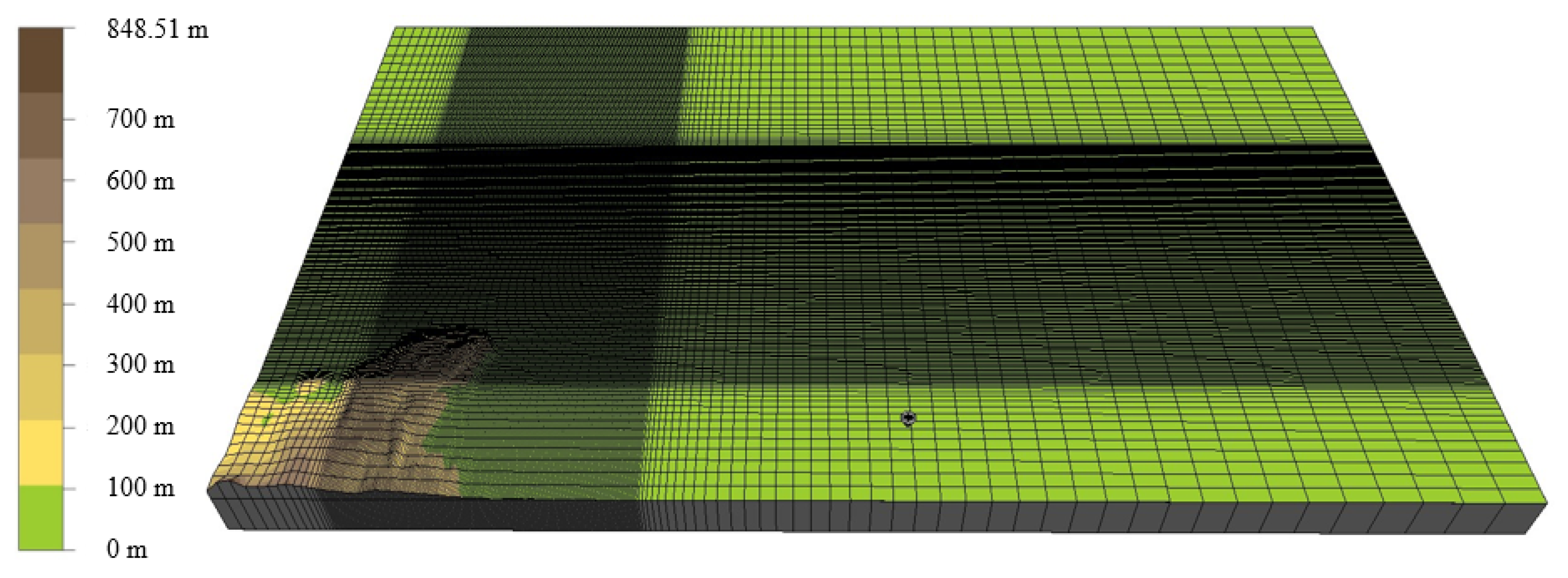

4.1. Terrain Setup

4.2. Boundary Conditions

4.3. Wind Farm Layout Optimization

4.4. Power Production Simulations

5. Economic Analysis of Wind Farm Investment

5.1. Wind Farm Investment Cost

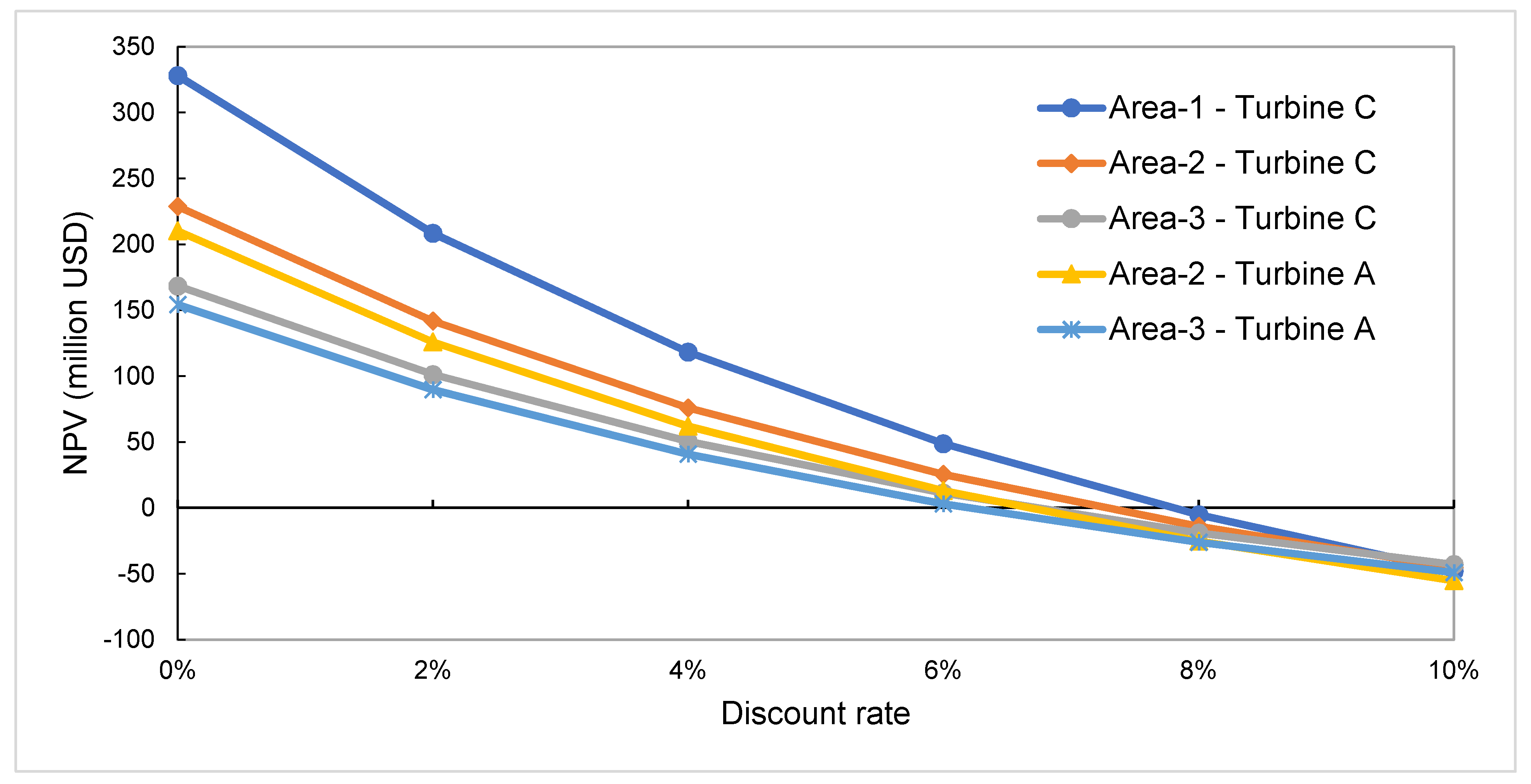

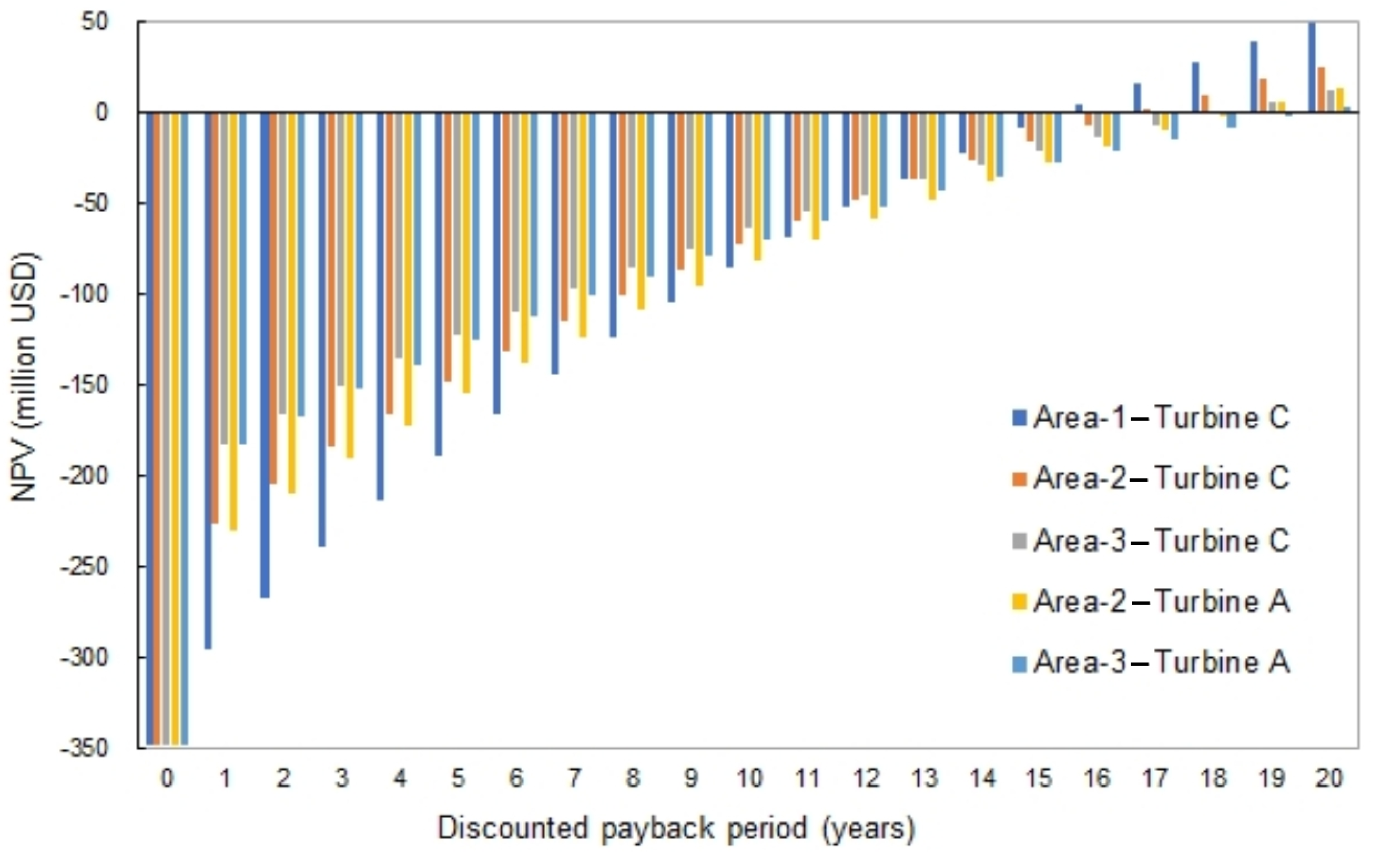

5.2. Investment Indicator

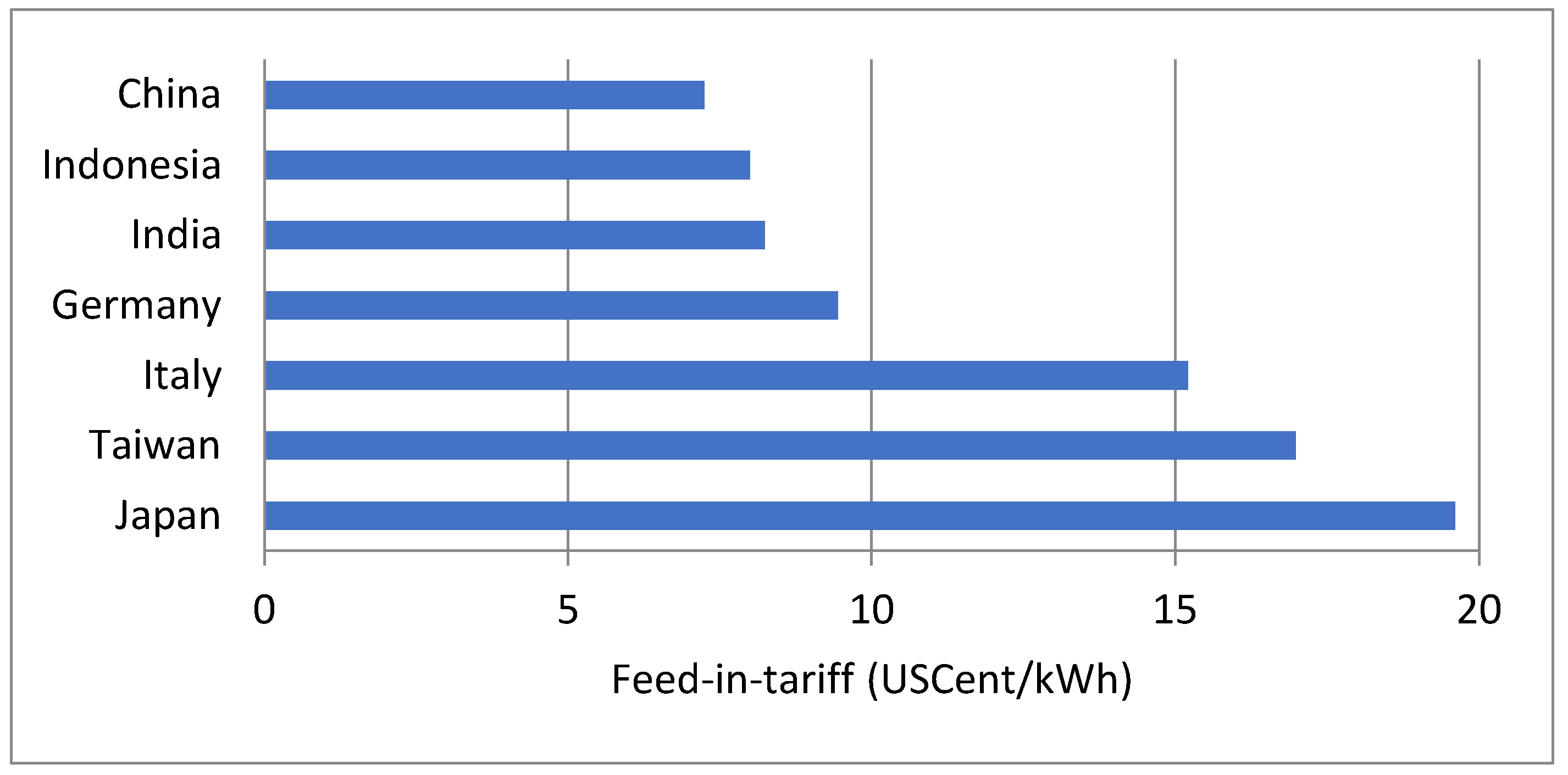

5.3. Implications for Energy Policy

6. Conclusions

- The tropical regions of Southeast Asia are generally characterized by scarce wind resources. However, the mean annual wind speeds offshore Jeneponto and Wetar Island reached 8.51 m/s and 8.04 m/s, respectively, in 2015. The capacity factor and power-based availability of a wind farm for each location reached 46% and 76%, respectively, exhibiting an excellent potential for wind energy production;

- Using wind turbine C with the highest hub height, largest rotor diameter, and lowest cut-in and rated wind speed achieved the largest capacity factor among the selected commercial wind turbines, indicating that these features may enhance the efficiency of wind power generation;

- Wake loss was affected more by the performance of individual turbines rather than the size of the farm. Using turbines with smaller rotor diameters often leads to a layout with a higher number of turbines, increasing wake loss in the area;

- The LCOE of various wind farm sizes indicated that LCOE slowly increased as farm size shrank. Increasing the size of a wind farm may enhance the economic effectiveness of investment;

- The LCOE of offshore wind farms can be as low as 0.082 USD/kWh, which is comparable to that of power generation from fossil fuels (between 0.07 and 0.15 USD/kWh) in Indonesia. The current FIT for wind power (0.08 USD/kWh) would require enhancement to attract investment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| AEP | Annual energy production |

| Vw | Wind speed |

| Vi | Cut-in wind speed |

| Vr | Rated wind speed |

| Vo | Cut out wind speed |

| Pw | Power output |

| Pi | Power output interpolated from power curve |

| Pr | Rated power output |

| At | Time-based availability |

| To | Turbine operating hours |

| Tt | Total hours in one year |

| Ap | Power-based availability |

| E | Power production in the wind farm |

| Ex | Expected power production in the wind farm |

| CapEx | Capital expenditure |

| OpEx | Operational expenditure |

| NPV | Net present value |

| LCOE | Levelized cost of electricity |

| DPBP | Discounted payback period |

| FIT | Feed-in-tariff |

| T | Total lifespan of wind farm |

| r | Annual discount rate |

Appendix A

Appendix B

Appendix C

Appendix D

References

- UNEP. Emissions Gap Report 2019; United Nations Environment Programme (UNEP): Nairobi, Kenya, 2019. [Google Scholar]

- Lin, Y.R. Global Coal-Fired Power Generation is Increasing While European and American Investors Raise the Stakes, Awakening News Networks. Available online: https://udn.com/news/story/6811/4298905?from=udn-catelistnews_ch2 (accessed on 20 January 2020).

- IRENA; ACE. Renewable Energy Outlook for ASEAN: A REmap Analysis; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates; ASEAN Centre for Energy (ACE): Jakarta, Indonesia, 2016. [Google Scholar]

- Yuliani, D. Is feed-in-tariff policy effective for increasing deployment of renewable energy in Indonesia? In The Political Economy of Clean Energy Transitions; Arent, D., Arndt, C., Miller, M., Tarp, F., Zinaman, O., Eds.; Oxford University Press: Oxford, UK, 2017; Available online: https://www.oxfordscholarship.com/view/10.1093/oso/9780198802242.001.0001/oso-9780198802242-chapter-8?print=pdf (accessed on 2 April 2019).

- Lutgens, F.K.; Tarbuck, E.J. The Atmosphere: An Introduction to Meteorology; Prentice Hall: New York, NY, USA, 2001. [Google Scholar]

- Hardianto, T.; Supeno, B.; Saleh, A.; Setiawan, D.K.; Gunawan; Indra, S. Potential of Wind Energy and Design Configuration of Wind Farm on Puger Beach at Jember Indonesia. Energy Procedia 2017, 143, 579–584. [Google Scholar] [CrossRef]

- Martosaputro, S.; Murti, N. Blowing the Wind Energy in Indonesia. Energy Procedia 2014, 47, 273–282. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, D.; Rocha, A.; Gómez-Gesteira, M.; Silva-Santos, C. Off-shore winds and wind energy production estimates derived from ASCAT, OSCAT, numerical weather prediction models and buoys e a comparative study for the Iberian Peninsula Atlantic coast. Renew. Energy 2017, 102, 433–444. [Google Scholar] [CrossRef]

- Mattar, C.; Borvarán, D. Off-shore wind power simulation by using WRF in the central coast of Chile. Renew. Energy 2016, 94, 22–31. [Google Scholar] [CrossRef]

- De Linaje, N.G.-A.; Mattar, C.; Borvarán, D. Quantifying the wind energy potential differences using different WRF initial conditions on Mediterranean coast of Chile. Energy 2019, 188, 116027. [Google Scholar] [CrossRef]

- Grell, G.; Peckham, S.; Schmitz, R.; McKeen, S.; Frost, G.; Skamarock, W.; Eder, B. Fully coupled “online” chemistry within the WRF model. Atmos. Environ. 2005, 39, 6957–6975. [Google Scholar] [CrossRef]

- Skamarock, W.; Klemp, J.; Dudhia, J.; Gill, D.; Barker, D.; Duda, M.; Huang, X.; Wanf, W.; Powers, J. A Description of the Advanced Research WRF Version 3 [Online]. 2008. Available online: http://www2.mmm.ucar.edu/wrf/users/docs/arw_v3.pdf (accessed on 13 April 2021).

- Ulazia, A.; Saenz, J.; Ibarra-Berastegui, G. Sensitivity to the use of 3DVAR data assimilation in a mesoscale model for estimating off-shore wind energy potential. A case study of the Iberian northern coastline. Appl. Energy 2016, 180, 617–627. [Google Scholar] [CrossRef]

- Olaofe, Z. Quantification of the near-surface wind conditions of the African coast: A comparative approach (satellite, NCEP CFSR and WRF-based). Energy 2019, 189, 116232. [Google Scholar] [CrossRef]

- Salvação, N.; Soares, C.G. Wind resource assessment offshore the Atlantic Iberian coast with the WRF model. Energy 2018, 145, 276–287. [Google Scholar] [CrossRef]

- Prósper, M.A.; Otero-Casal, C.; Fernández, F.C.; Miguez-Macho, G. Wind power forecasting for a real onshore wind farm on complex terrain using WRF high resolution simulations. Renew. Energy 2019, 135, 674–686. [Google Scholar] [CrossRef]

- Bansal, J.C.; Farswan, P. Wind farm layout using biogeography based optimization. Renew. Energy 2017, 107, 386–402. [Google Scholar] [CrossRef]

- Patel, J.; Savsani, V.; Patel, V.; Patel, R. Layout optimization of a wind farm using geometric pattern-based approach. Energy Procedia 2019, 158, 940–946. [Google Scholar] [CrossRef]

- Park, J.; Law, K.H. Layout optimization for maximizing wind farm power production using sequential convex programming. Appl. Energy 2015, 151, 320–334. [Google Scholar] [CrossRef]

- EMD. WindPROSPECTING: Wind Energy Resources of Indonesia. EMD International A/S. Available online: http://indonesia.windprospecting.com/ (accessed on 24 March 2016).

- Cali, U.; Erdogan, N.; Kucuksari, S.; Argin, M. Techno-economic analysis of high potential offshore wind farm locations in Turkey. Energy Strategy Rev. 2018, 22, 325–336. [Google Scholar] [CrossRef]

- Brower, M. Wind Resource Assessment: A Practical Guide to Developing a Wind Project; John Wiley & Sons: New York, NY, USA, 2012. [Google Scholar]

- NASA/METI/AIST/Japan Space Systems; U.S./Japan ASTER Science Team. ASTER Global Digital Elevation Model [Data Set]. NASA EOSDIS Land Processes DAAC. 2009. Available online: https://doi.org/10.5067/ASTER/ASTGTM.002 (accessed on 6 December 2020).

- Yakhot, V.; Orszag, S.A.; Thangam, S.; Gatski, T.B.; Speziale, C.G. Development of turbulence models for shear flows by a double expansion technique. Phys. Fluids A Fluid Dyn. 1992, 4, 1510–1520. [Google Scholar] [CrossRef] [Green Version]

- Shakoor, R.; Hassan, M.Y.; Raheem, A.; Wu, Y.-K. Wake effect modeling: A review of wind farm layout optimization using Jensen’s model. Renew. Sustain. Energy Rev. 2016, 58, 1048–1059. [Google Scholar] [CrossRef]

- Dicorato, M.; Forte, G.; Pisani, M.; Trovato, M. Guidelines for assessment of investment cost for offshore wind generation. Renew. Energy 2011, 36, 2043–2051. [Google Scholar] [CrossRef]

- Gonzalez-Rodriguez, A.G. Review of offshore wind farm cost components. Energy Sustain. Dev. 2017, 37, 10–19. [Google Scholar] [CrossRef]

- Quinonez-Varela, G.; Ault, G.W.; Anaya-Lara, O.; McDonald, J.R. Electrical collector system options for large offshore wind farms. IET Renew. Power Gener. 2007, 1, 107–114. [Google Scholar] [CrossRef]

- MMRI. Ministry of Mineral Resources of Indonesia Regulation No. 50/2017; Ministry of Mineral Resources of Indonesia (MMRI): Jakarta, Indonesia, 2017.

- IRENA. Renewable Energy Prospects: Indonesia. International Renewable Energy Agency (IRENA). Available online: https://irena.org/2017 (accessed on 24 April 2020).

- IEA. Fossil Fuel Subsidy Database. Available online: http://www.worldenergyoutlook.org/resources/energysubsidies/fossilfuelsubsidydatabase/ (accessed on 24 February 2016).

- MEAROC. Feed-In Tariff of Electricity Generated from Renewable Energy Sources and its Calculation Formula; Ministry of Economic Affairs of the Republic of China (MEAROC): Taipei, Taiwan, 2019.

- OECD. Renewable Energy Feed-In Tariffs. Available online: https://stats.oecd.org/Index.aspx?DataSetCode=RE_FIT (accessed on 24 April 2020).

| Turbine | IEC Class | Rated Output (kW) | Hub Height (m) | Rotor Diameter (m) | Cut-In Wind Speed (m/s) | Rated Wind Speed (m/s) | Cut-Out Wind Speed (m/s) |

|---|---|---|---|---|---|---|---|

| A | IIIA | 1800 | 90 | 100 | 4 | 12 | 20 |

| B | IIB | 2300 | 80 | 90 | 4 | 13 | 25 |

| C | IIIA | 2000 | 93 | 114 | 2 | 10 | 25 |

| Parameter | Banyuwangi | Baron | Lebak | Sukabumi | Banten | Jeneponto | Wetar |

|---|---|---|---|---|---|---|---|

| Scale c (m/s) | 6.78 | 6.68 | 6.75 | 5.90 | 7.04 | 9.60 | 9.05 |

| Shape k | 1.55 | 2.39 | 2.39 | 2.19 | 2.46 | 2.41 | 2.61 |

| Variance | 15.95 | 6.95 | 7.10 | 6.34 | 8.08 | 14.08 | 10.95 |

| Mean wind speed (m/s) | 6.09 | 5.92 | 5.98 | 5.23 | 6.56 | 8.51 | 8.04 |

| Landscape | Roughness Length (m) |

|---|---|

| Cultivated Land | 0.050 |

| Forest | 0.180 |

| Grassland | 0.150 |

| Shrubland | 0.040 |

| Wetland | 0.003 |

| Water Bodies | 0.003 |

| Tundra | 0.200 |

| Artificial Surfaces | 0.150 |

| Bare land | 0.030 |

| Permanent Snow and Ice | 0.001 |

| Sea | 0.002 |

| x | y | z | Total | |

|---|---|---|---|---|

| Grid spacing, min–max (m) | 54.1–1179.5 | 54.4–648.0 | Variable | - |

| Number of cells | 217 | 230 | 20 | 998,200 |

| Area | Turbine A | Turbine B | Turbine C |

|---|---|---|---|

| 1 | 61 | 75 | 48 |

| 2 | 42 | 50 | 35 |

| 3 | 32 | 39 | 27 |

| Area | 1 | 2 | 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Type of Turbine | A | B | C | A | B | C | A | B | C |

| CapEx | |||||||||

| Wind turbine | 121,716.6 | 229,293.3 | 117,685.6 | 83,804.9 | 152,862.2 | 85,812.5 | 63,851.4 | 119,232.5 | 66,198.2 |

| Support system a | 103,710.4 | 155,467.7 | 95,764.0 | 71,407.2 | 103,645.1 | 69,827.9 | 54,405.5 | 80,843.2 | 53,867.2 |

| Electrical system | |||||||||

| Collection system | |||||||||

| Inner cable | 22,528.1 | 25,193.7 | 19,666.6 | 14,215.0 | 18,074.3 | 13,179.2 | 10,623.2 | 8870.6 | 9663.9 |

| Buried cable | 21,883.0 | 24,450.6 | 19,769.2 | 15,861.2 | 20,703.9 | 15,004.5 | 12,907.3 | 11,106.7 | 12,275.8 |

| Onshore substation | 11,199.3 | 15,427.0 | 10,205.3 | 7729.9 | 10,320.6 | 7441.9 | 5902.8 | 8054.6 | 5741.9 |

| Transmission line | 36,656.6 | 40,756.1 | 36,845.5 | 38,056.2 | 52,028.7 | 37,471.0 | 36,146.2 | 32,647.4 | 36,759.8 |

| Grid connection | 28.5 | 42.8 | 33.9 | 28.5 | 42.8 | 33.9 | 28.5 | 42.8 | 33.9 |

| Project development | 30,785.7 | 48,365.6 | 26,916.5 | 21,196.7 | 32,243.7 | 19,626.6 | 16,149.9 | 25,150.1 | 15,140.5 |

| Total | 348,508.2 | 538,996.7 | 326,886.7 | 252,299.6 | 389,921.4 | 248,397.4 | 200,014.7 | 285,947.9 | 199,681.3 |

| OpEx (per year) | 6.6 | 10.2 | 6.2 | 4.8 | 7.4 | 4.7 | 3.8 | 5.4 | 3.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fauzy, A.; Yue, C.-D.; Tu, C.-C.; Lin, T.-H. Understanding the Potential of Wind Farm Exploitation in Tropical Island Countries: A Case for Indonesia. Energies 2021, 14, 2652. https://doi.org/10.3390/en14092652

Fauzy A, Yue C-D, Tu C-C, Lin T-H. Understanding the Potential of Wind Farm Exploitation in Tropical Island Countries: A Case for Indonesia. Energies. 2021; 14(9):2652. https://doi.org/10.3390/en14092652

Chicago/Turabian StyleFauzy, Annas, Cheng-Dar Yue, Chien-Cheng Tu, and Ta-Hui Lin. 2021. "Understanding the Potential of Wind Farm Exploitation in Tropical Island Countries: A Case for Indonesia" Energies 14, no. 9: 2652. https://doi.org/10.3390/en14092652