PEFC System Reactant Gas Supply Management and Anode Purging Strategy: An Experimental Approach

Abstract

:1. Introduction

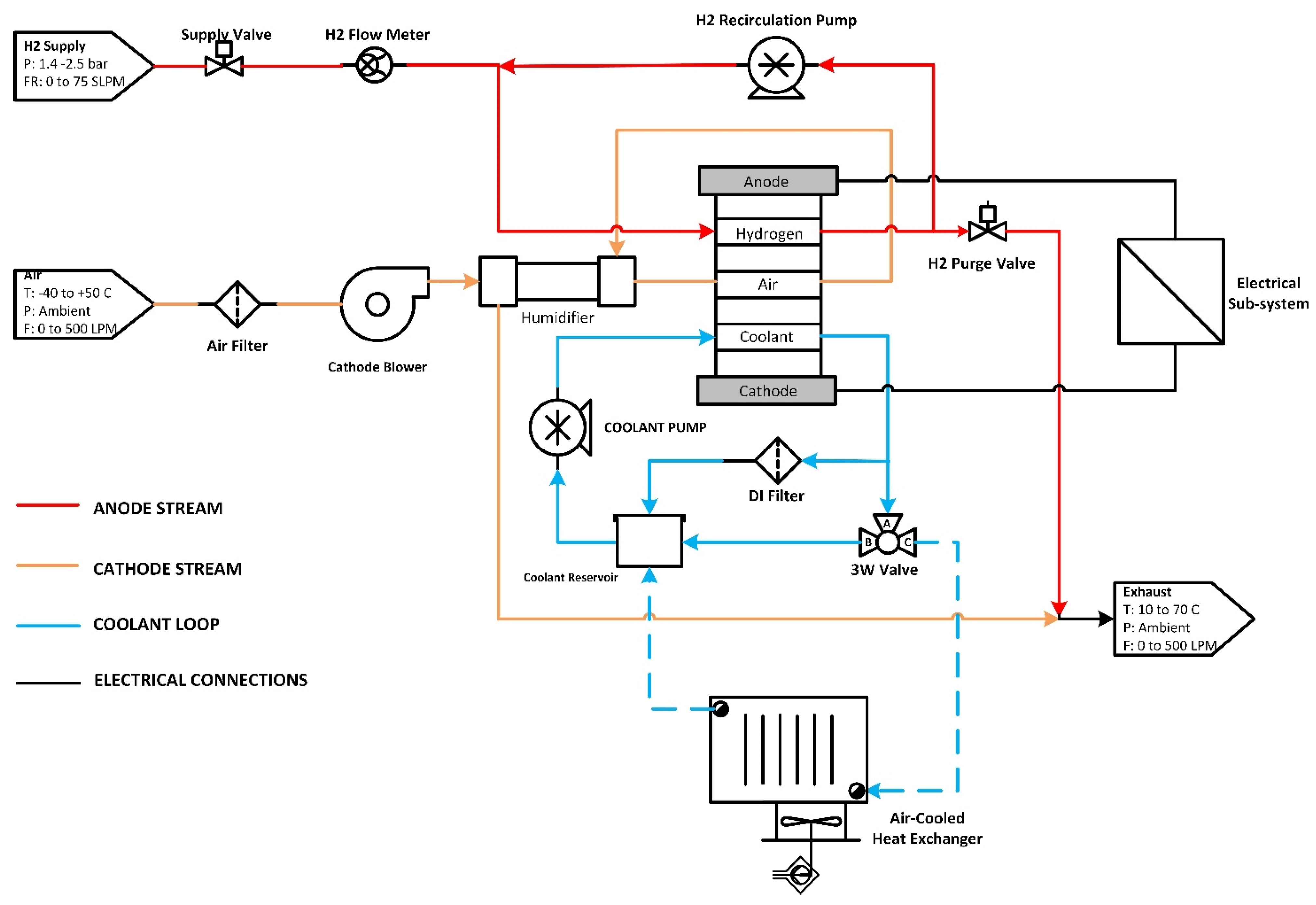

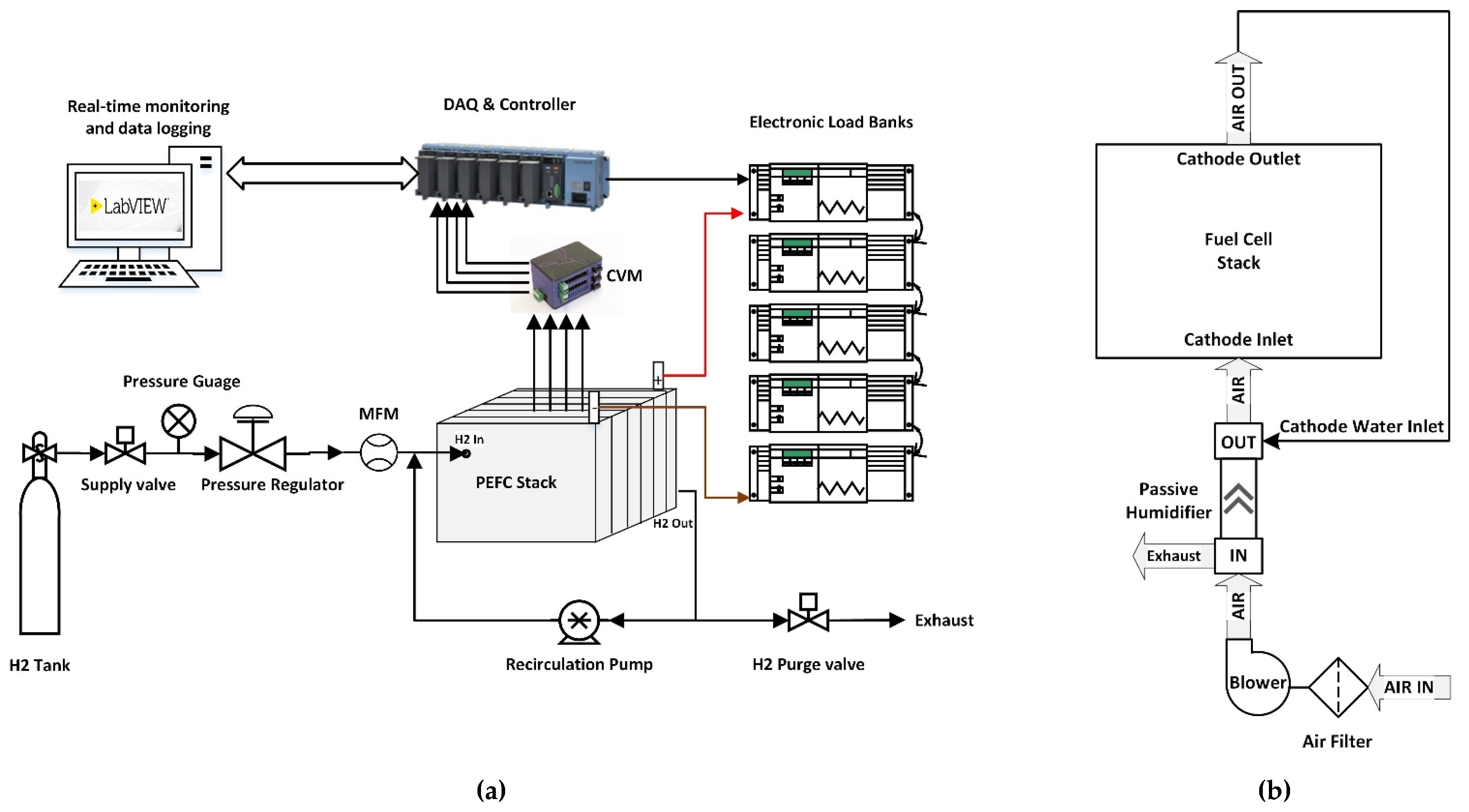

2. Experimental Setup

2.1. Fuel Feed Subsystem

2.2. Oxidant Feed Subsystem

2.3. Thermal Management Subsystem

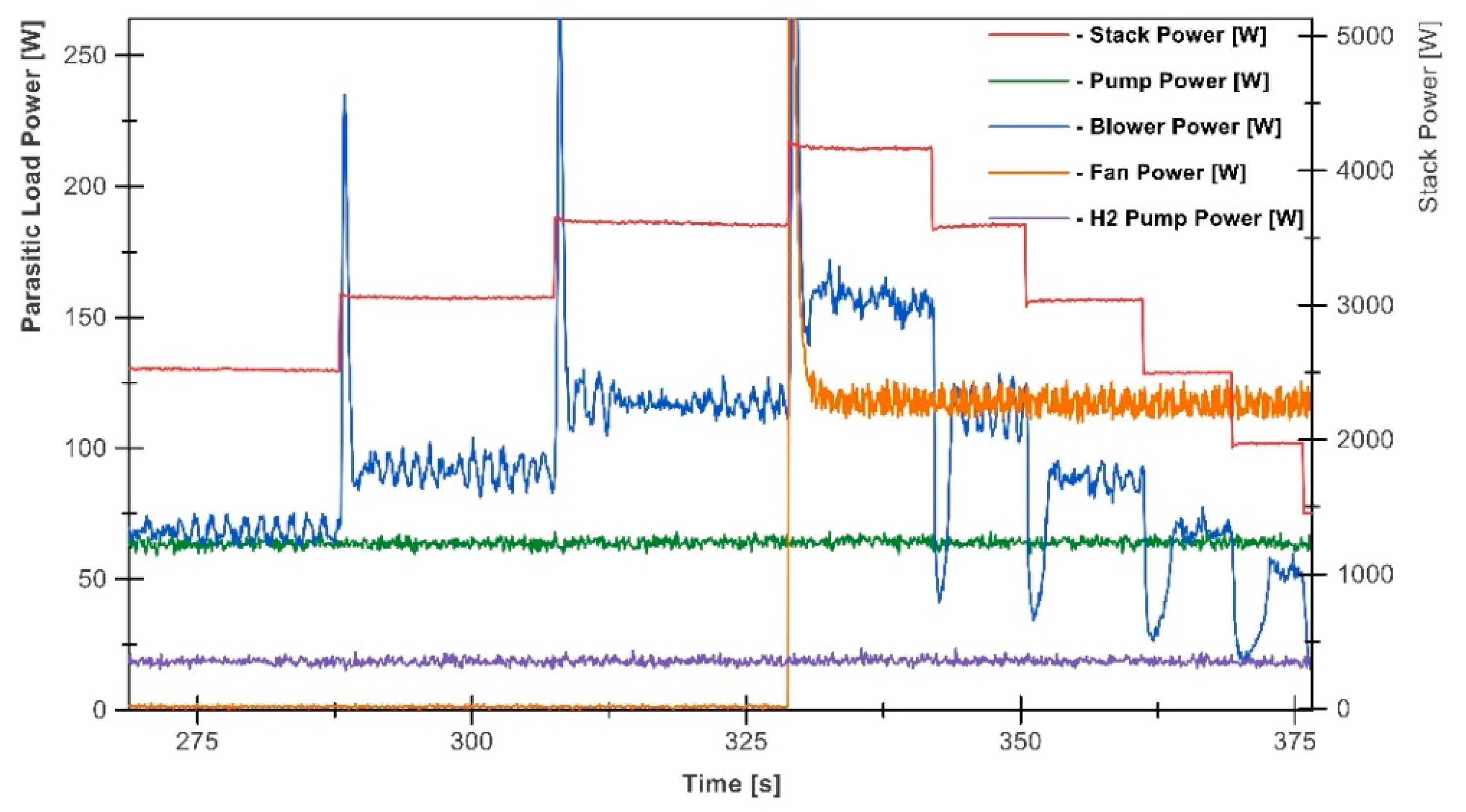

3. Results, Comparisons, and Discussion

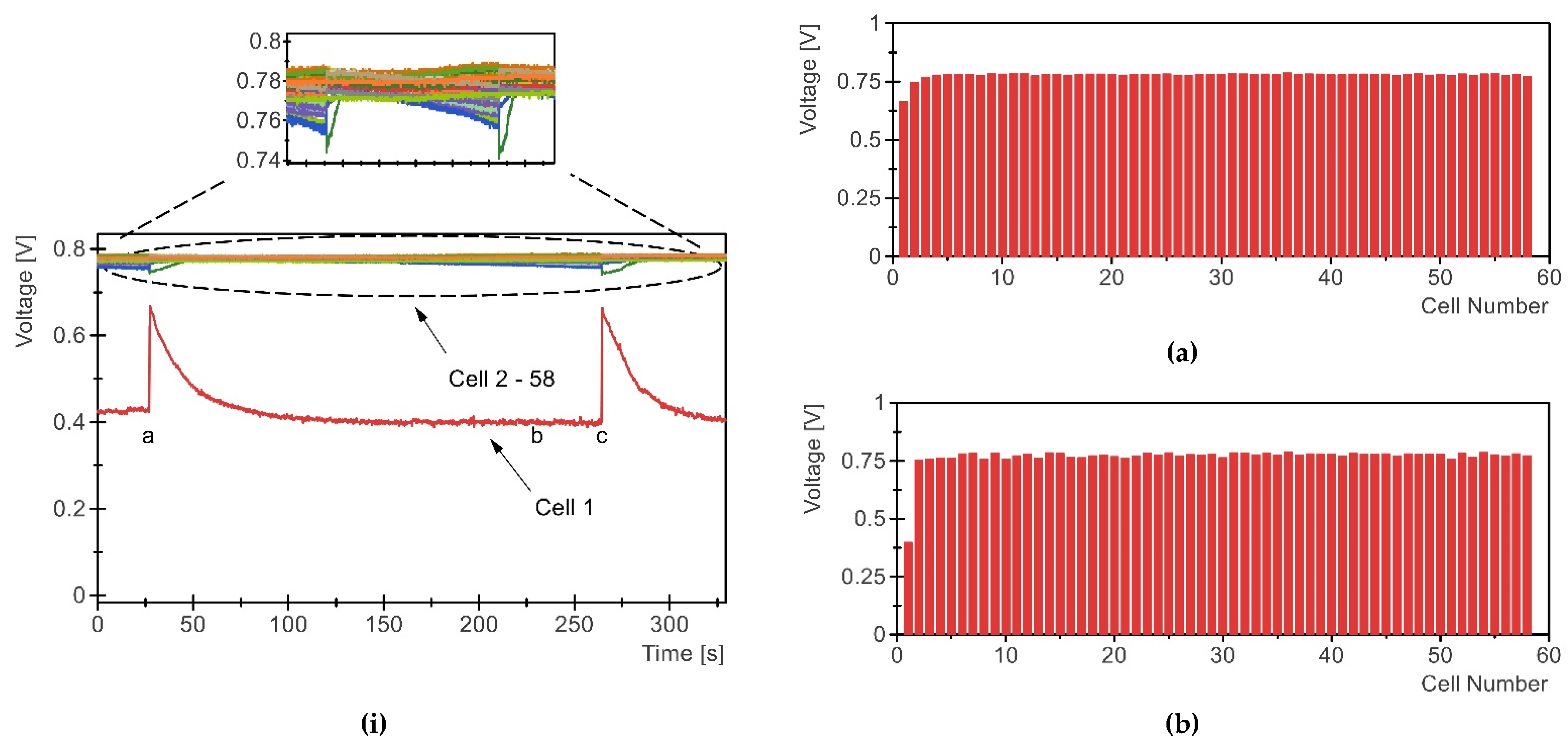

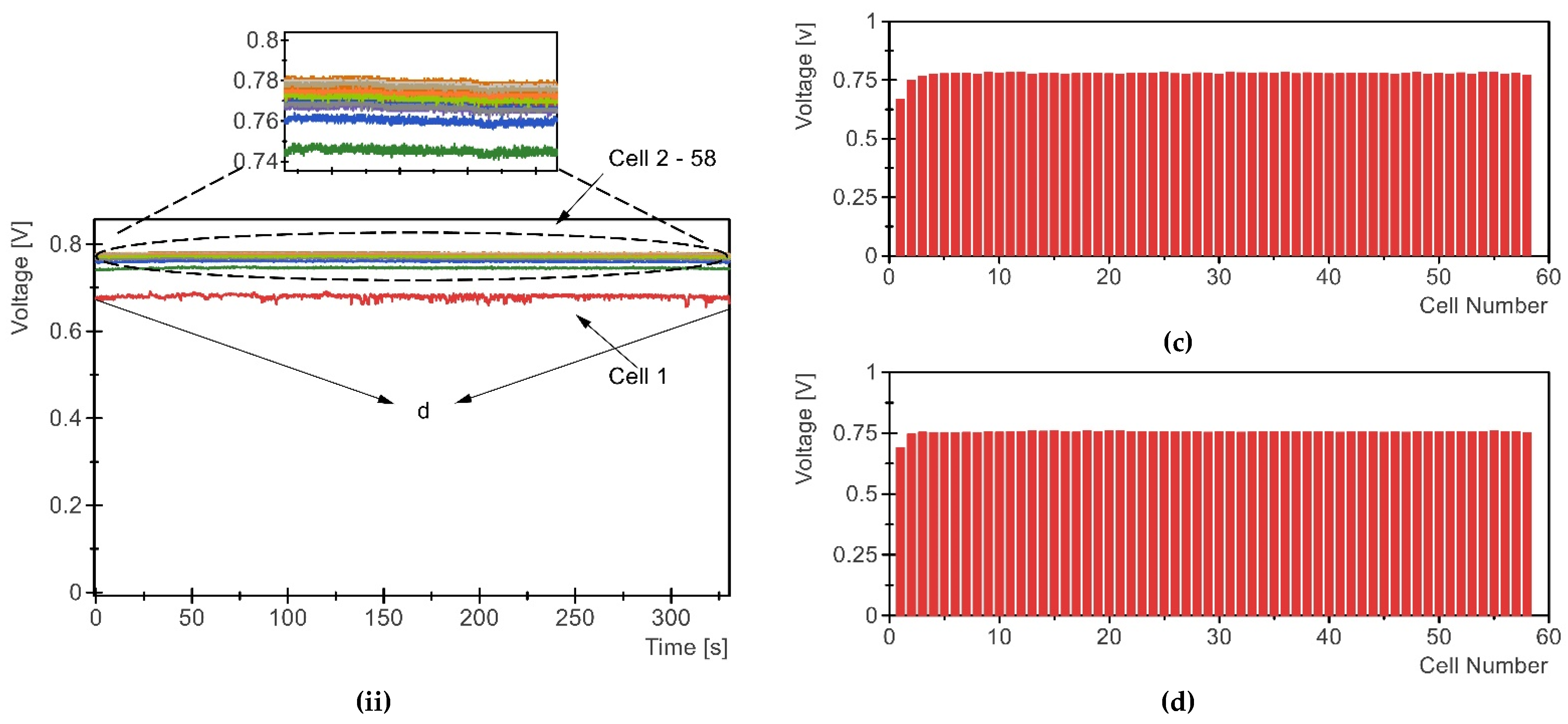

3.1. Preliminary Experiments

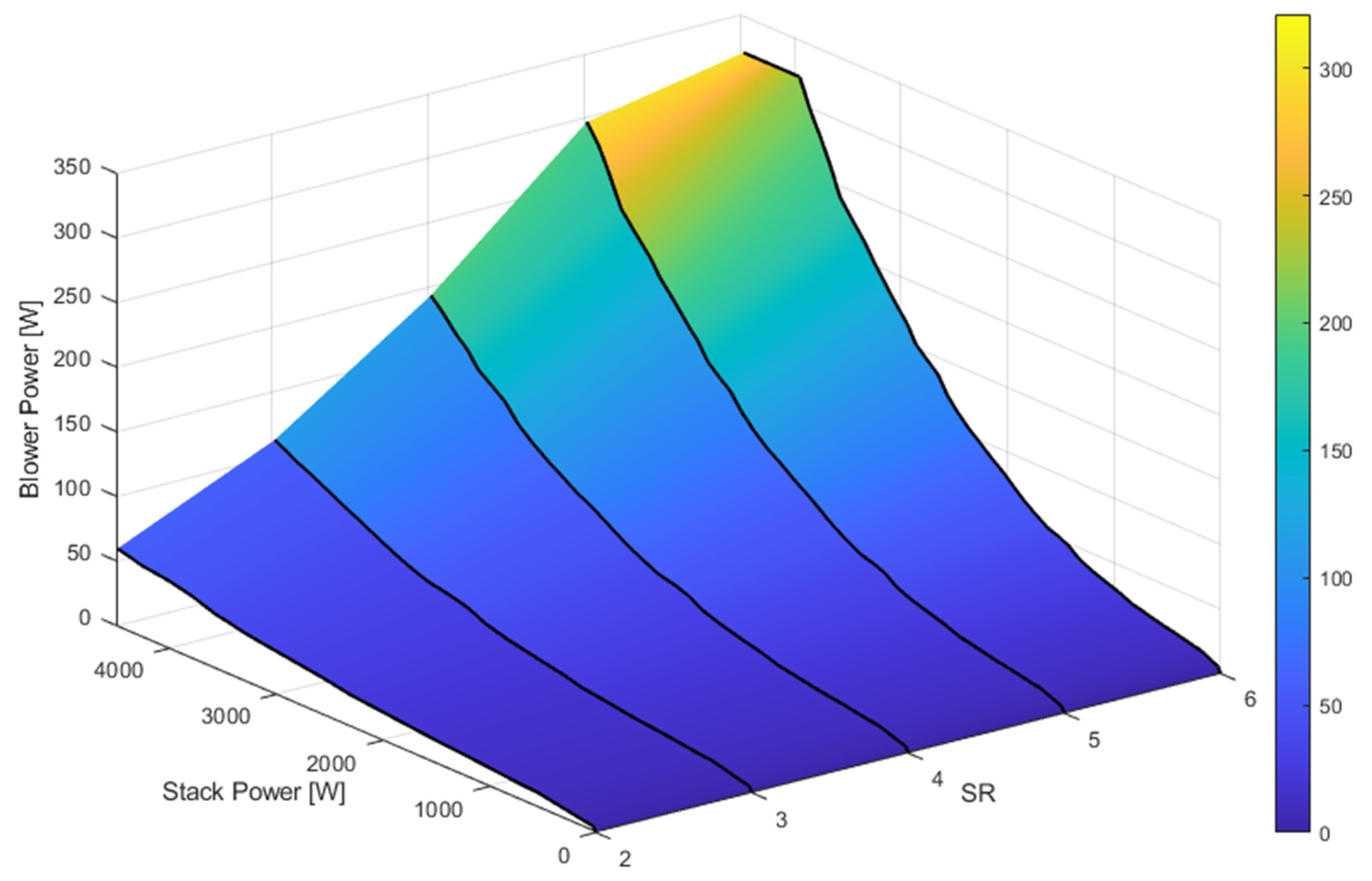

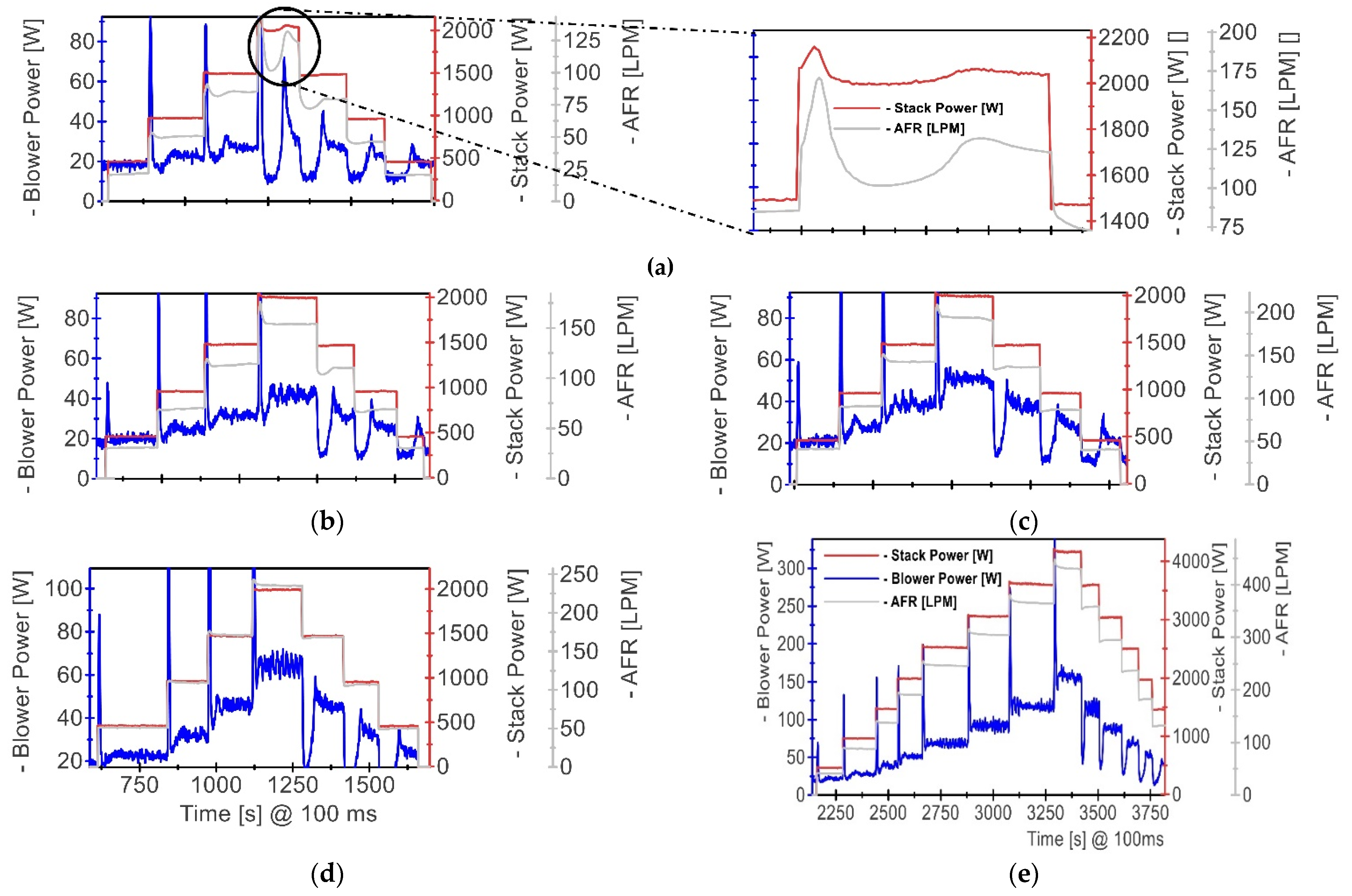

3.2. Cathode Blower Experimental Modelling

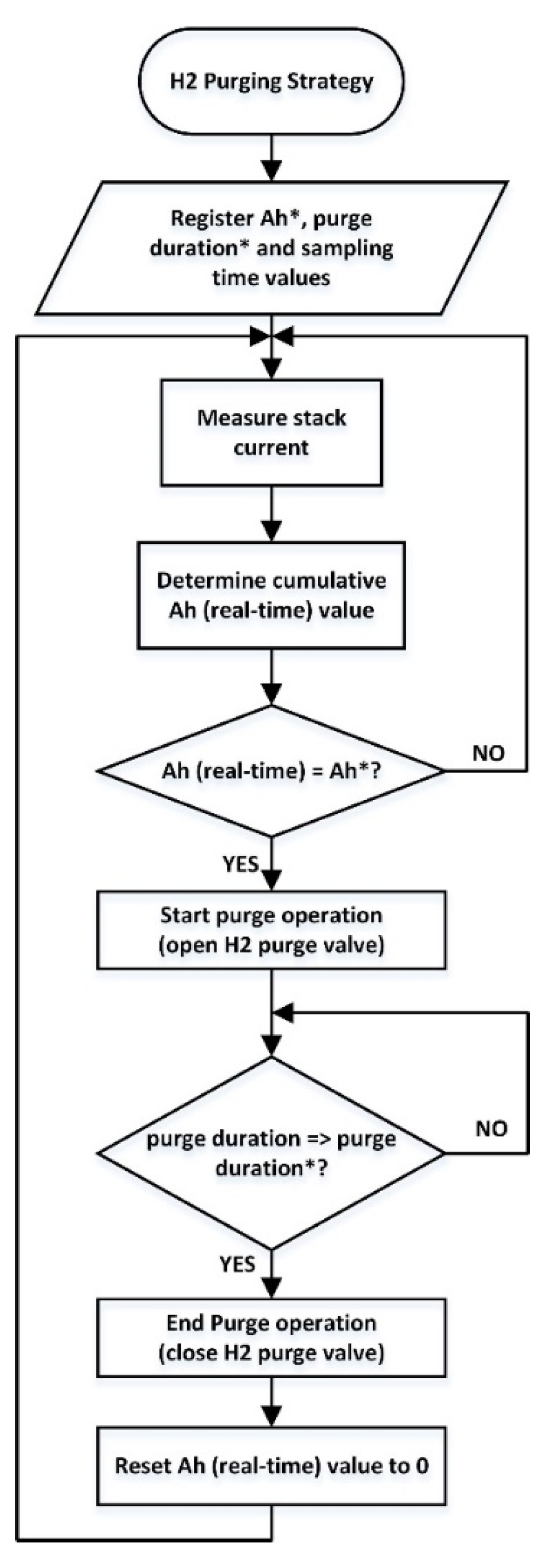

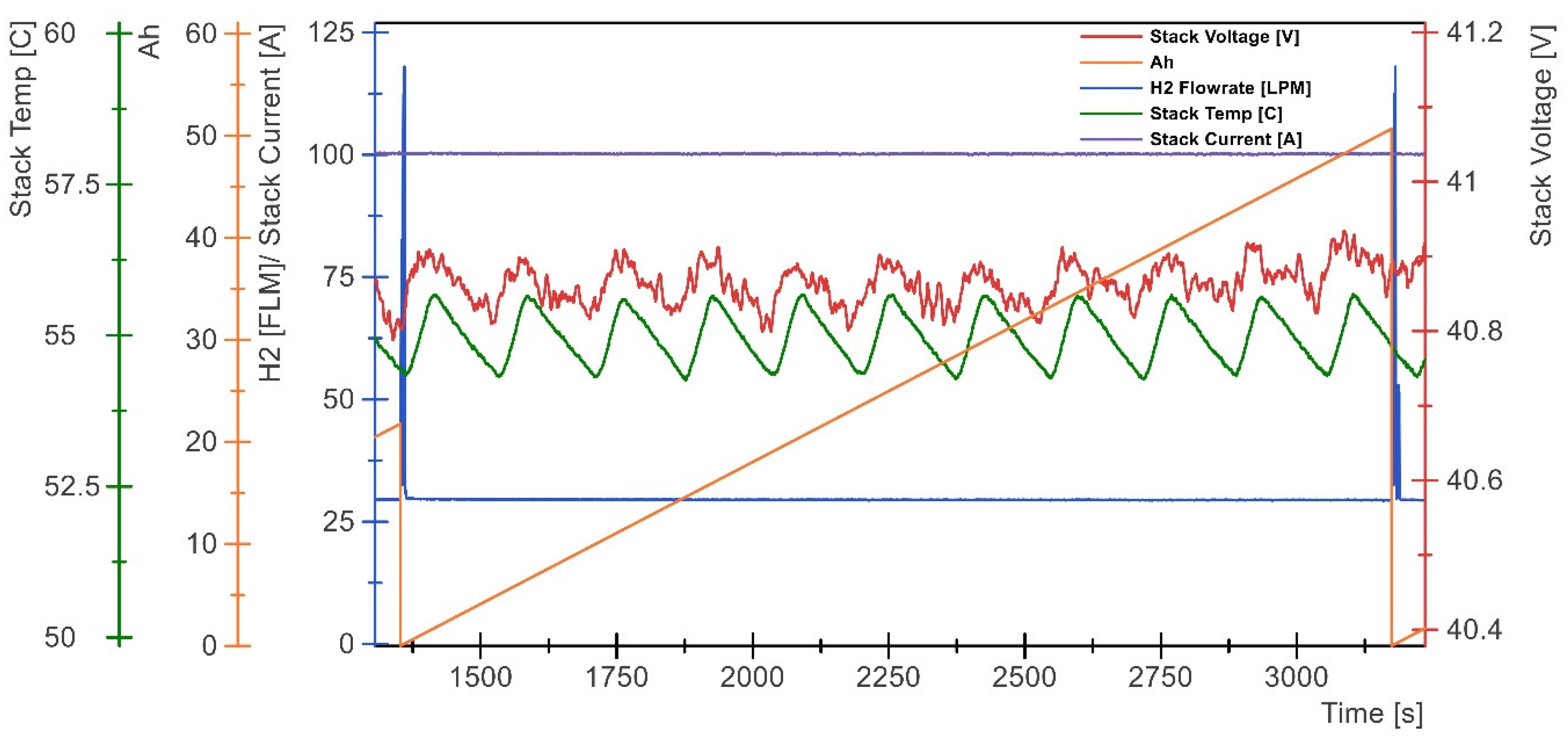

3.3. Hydrogen Purging Strategy

3.4. Comparative Analysis

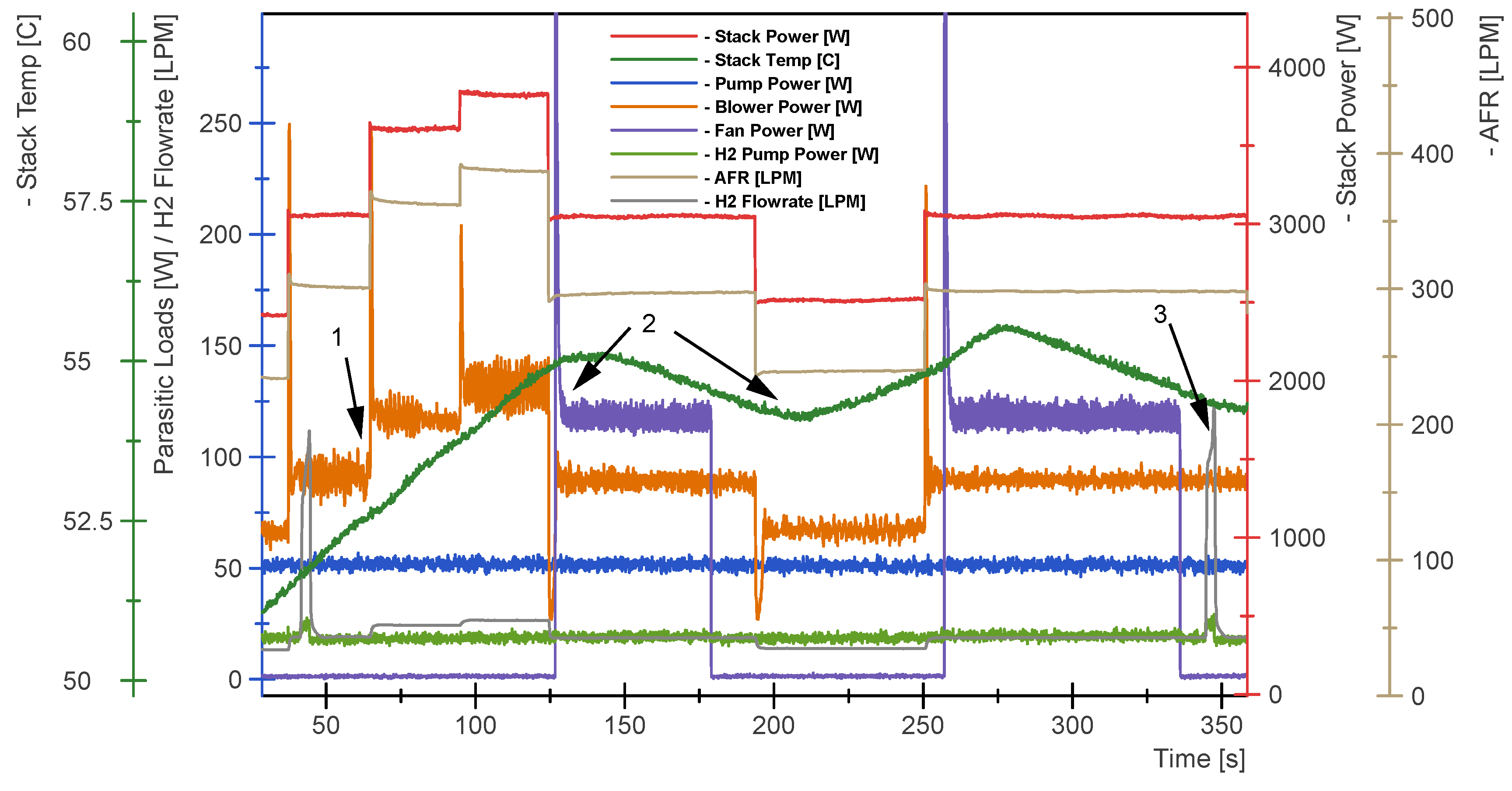

3.5. PEFC System Control

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| η | Efficiency [-] |

| AFR | Air flow rate [slpm] |

| Ah | Amp-hour |

| Vcell | Cell voltage [V] |

| N | Cell number |

| Pstack | Stack power [W] |

| λ | Stoichiometry ratio [-] |

| Istack | Stack current [A] |

| Ts | Sampling time [s] |

| SLPM | Standard litres per minute |

References

- Jayakumar, A. A comprehensive assessment on the durability of gas diffusion electrode materials in PEM fuel cell stack. Front. Energy 2019, 13, 325–338. [Google Scholar] [CrossRef]

- Dicks, A.; Larminie, J.; Dicks, A.; Larminie, J.; Dicks, A. Fuel Cell Systems Explained, 2nd ed.; Wiley: West Sussex, Englan, 2003; ISBN 047084857X. [Google Scholar]

- Matsuura, T.; Chen, J.; Siegel, J.B.; Stefanopoulou, A.G. Degradation phenomena in PEM fuel cell with dead-ended anode. Int. J. Hydrogen Energy 2013, 38, 11346–11356. [Google Scholar] [CrossRef]

- Abbou, S.; Dillet, J.; Spernjak, D.; Mukundan, R.; Borup, R.L.; Maranzana, G.; Lottin, O. High Potential Excursions during PEM Fuel Cell Operation with Dead-Ended Anode. J. Electrochem. Soc. 2015, 162, F1212–F1220. [Google Scholar] [CrossRef]

- Dumercy, L.; Péra, M.C.; Glises, R.; Hissel, D.; Hamandi, S.; Badin, F.; Kauffmann, J.M. PEFC stack operating in anodic dead end mode. Fuel Cells 2004, 4, 352–357. [Google Scholar] [CrossRef]

- Knobbe, M.W.; He, W.; Chong, P.Y.; Nguyen, T.V. Active gas management for PEM fuel cell stacks. J. Power Sources 2004, 138, 94–100. [Google Scholar] [CrossRef]

- Jian, Q.; Luo, L.; Huang, B.; Zhao, J.; Cao, S.; Huang, Z. Experimental study on the purge process of a proton exchange membrane fuel cell stack with a dead-end anode. Appl. Therm. Eng. 2018, 142, 203–214. [Google Scholar] [CrossRef]

- Koski, P.; Viitakangas, J.; Ihonen, J. Determination of fuel utilisation and recirculated gas composition in dead-ended PEMFC systems. Int. J. Hydrogen Energy 2020, 45, 23201–23226. [Google Scholar] [CrossRef]

- Koski, P.; Pérez, L.C.; Ihonen, J. Comparing Anode Gas Recirculation with Hydrogen Purge and Bleed in a Novel PEMFC Laboratory Test Cell Configuration. Fuel Cells 2015, 15, 494–504. [Google Scholar] [CrossRef]

- Xu, L.; Fang, C.; Li, J.; Ouyang, M.; Lehnert, W. Nonlinear dynamic mechanism modeling of a polymer electrolyte membrane fuel cell with dead-ended anode considering mass transport and actuator properties. Appl. Energy 2018, 230, 106–121. [Google Scholar] [CrossRef]

- Tsai, S.W.; Chen, Y.S. A mathematical model to study the energy efficiency of a proton exchange membrane fuel cell with a dead-ended anode. Appl. Energy 2017, 188, 151–159. [Google Scholar] [CrossRef]

- Jang, J.H.; Yan, W.M.; Chiu, H.C.; Lui, J.Y. Dynamic cell performance of kW-grade proton exchange membrane fuel cell stack with dead-ended anode. Appl. Energy 2015, 142, 108–114. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, X.; Guo, L.; Liu, H. Overall and local effects of operating conditions in PEM fuel cells with dead-ended anode. Int. J. Hydrogen Energy 2017, 42, 4690–4698. [Google Scholar] [CrossRef] [Green Version]

- Lee, Y.; Kim, B.; Kim, Y. An experimental study on water transport through the membrane of a PEFC operating in the dead-end mode. Int. J. Hydrogen Energy 2009, 34, 7768–7779. [Google Scholar] [CrossRef]

- Zhao, J.; Jian, Q.; Huang, Z.; Luo, L.; Huang, B. Experimental study on water management improvement of proton exchange membrane fuel cells with dead-ended anode by periodically supplying fuel from anode outlet. J. Power Sources 2019, 435, 226775. [Google Scholar] [CrossRef]

- Ahluwalia, R.K.; Wang, X. Buildup of nitrogen in direct hydrogen polymer-electrolyte fuel cell stacks. J. Power Sources 2007, 171, 63–71. [Google Scholar] [CrossRef]

- Siegel, J.B.; Soc, J.E.; Siegel, J.B.; Bohac, S.V.; Stefanopoulou, A.G. Nitrogen Front Evolution in Purged Polymer Electrolyte Membrane Fuel Cell with Dead-Ended Anode Nitrogen Front Evolution in Purged Polymer Electrolyte Membrane Fuel Cell with Dead-Ended Anode. J. Electrochem. Soc. 2010, 157, B1081. [Google Scholar] [CrossRef] [Green Version]

- Chen, B.; Zhou, H.; He, S.; Meng, K.; Liu, Y.; Cai, Y. Numerical simulation on purge strategy of proton exchange membrane fuel cell with dead-ended anode. Energy 2021, 234, 121265. [Google Scholar] [CrossRef]

- Steinberger, M.; Geiling, J.; Oechsner, R.; Frey, L. Anode recirculation and purge strategies for PEM fuel cell operation with diluted hydrogen feed gas. Appl. Energy 2018, 232, 572–582. [Google Scholar] [CrossRef]

- Nikiforow, K.; Karimäki, H.; Keränen, T.M.; Ihonen, J. Optimization study of purge cycle in proton exchange membrane fuel cell system. J. Power Sources 2013, 238, 336–344. [Google Scholar] [CrossRef]

- Hu, Z.; Yu, Y.; Wang, G.; Chen, X.; Chen, P.; Chen, J.; Zhou, S. Anode purge strategy optimization of the polymer electrode membrane fuel cell system under the dead-end anode operation. J. Power Sources 2016, 320, 68–77. [Google Scholar] [CrossRef]

- He, H.; Quan, S.; Wang, Y.X. Hydrogen circulation system model predictive control for polymer electrolyte membrane fuel cell-based electric vehicle application. Int. J. Hydrogen Energy 2020, 45, 20382–20390. [Google Scholar] [CrossRef]

- Xie, C.; Xu, X.; Bujlo, P.; Shen, D.; Zhao, H.; Quan, S. Fuel cell and lithium iron phosphate battery hybrid powertrain with an ultracapacitor bank using direct parallel structure. J. Power Sources 2015, 279, 487–494. [Google Scholar] [CrossRef]

- Wang, B.; Deng, H.; Jiao, K. Purge strategy optimization of proton exchange membrane fuel cell with anode recirculation. Appl. Energy 2018, 225, 1–13. [Google Scholar] [CrossRef]

- Karimäki, H.; Pérez, L.C.; Nikiforow, K.; Keränen, T.M.; Viitakangas, J.; Ihonen, J. The use of on-line hydrogen sensor for studying inert gas effects and nitrogen crossover in PEMFC system. Int. J. Hydrogen Energy 2011, 36, 10179–10187. [Google Scholar] [CrossRef]

- Okedi, T.I.; Meyer, Q.; Hunter, H.M.A.; Shearing, P.R.; Brett, D.J.L. Development of a polymer electrolyte fuel cell dead-ended anode purge strategy for use with a nitrogen-containing hydrogen gas supply. Int. J. Hydrogen Energy 2017, 42, 13850–13859. [Google Scholar] [CrossRef] [Green Version]

- Nishizawa, A.; Kallo, J.; Garrot, O.; Weiss-Ungethüm, J. Fuel cell and Li-ion battery direct hybridization system for aircraft applications. J. Power Sources 2013, 222, 294–300. [Google Scholar] [CrossRef]

- Liu, Z.; Li, L.; Ding, Y.; Deng, H.; Chen, W. Modeling and control of an air supply system for a heavy duty PEMFC engine. Int. J. Hydrogen Energy 2016, 41, 16230–16239. [Google Scholar] [CrossRef]

- Kim, B.J.; Kim, M.S. Studies on the cathode humidification by exhaust gas recirculation for PEM fuel cell. Int. J. Hydrogen Energy 2012, 37, 4290–4299. [Google Scholar] [CrossRef]

- Calili, F.; Ismail, M.S.; Ingham, D.B.; Hughes, K.J.; Ma, L.; Pourkashanian, M. A dynamic model of air-breathing polymer electrolyte fuel cell (PEFC): A parametric study. Int. J. Hydrogen Energy 2021, 46, 17343–17357. [Google Scholar] [CrossRef]

- Yang, D.; Pan, R.; Wang, Y.; Chen, Z. Modeling and control of PEMFC air supply system based on T-S fuzzy theory and predictive control. Energy 2019, 188, 116078. [Google Scholar] [CrossRef]

- Lee, H.Y.; Su, H.C.; Chen, Y.S. A gas management strategy for anode recirculation in a proton exchange membrane fuel cell. Int. J. Hydrogen Energy 2018, 43, 3803–3808. [Google Scholar] [CrossRef]

- Chen, B.; Cai, Y.; Yu, Y.; Wang, J.; Tu, Z.; Hwa, S. Gas purging effect on the degradation characteristic of a proton exchange membrane fuel cell with dead-ended mode operation II. Under different operation pressures. Energy 2017, 131, 50–57. [Google Scholar] [CrossRef]

- Shen, K.; Park, S.; Kim, Y. Hydrogen utilization enhancement of proton exchange membrane fuel cell with anode recirculation system through a purge strategy. Int. J. Hydrogen Energy 2020, 45, 16773–16786. [Google Scholar] [CrossRef]

- Brunner, D.A.; Marcks, S.; Bajpai, M.; Prasad, A.K.; Advani, S.G. Design and characterization of an electronically controlled variable flow rate ejector for fuel cell applications. Int. J. Hydrogen Energy 2011, 37, 4457–4466. [Google Scholar] [CrossRef]

- Zhang, Q.; Tong, Z.; Tong, S. Effect of cathode recirculation on high potential limitation and self-humidification of hydrogen fuel cell system. J. Power Sources 2020, 468, 228388. [Google Scholar] [CrossRef]

- Park, H. Effect of the hydrophilic and hydrophobic characteristics of the gas diffusion medium on polymer electrolyte fuel cell performance under non-humidification condition. Energy Convers. Manag. 2014, 81, 220–230. [Google Scholar] [CrossRef]

- Chen, X.; Xu, J.; Liu, Q.; Chen, Y.; Wang, X.; Li, W.; Ding, Y.; Wan, Z. Active disturbance rejection control strategy applied to cathode humidity control in PEMFC system. Energy Convers. Manag. 2020, 224, 113389. [Google Scholar] [CrossRef]

- Daud, W.R.W.; Rosli, R.E.; Majlan, E.H.; Hamid, S.A.A.; Mohamed, R.; Husaini, T. PEM fuel cell system control: A review. Renew. Energy 2017, 113, 620–638. [Google Scholar] [CrossRef]

- Zou, W.J.; Kim, Y.B. Temperature Control for a 5 kW Water-Cooled PEM Fuel Cell System for a Household Application. IEEE Access 2019, 7, 144826–144835. [Google Scholar] [CrossRef]

- Lee, H.S.; Cho, C.W.; Seo, J.H.; Lee, M.Y. Cooling performance characteristics of the stack thermal management system for fuel cell electric vehicles under actual driving conditions. Energies 2016, 9, 320. [Google Scholar] [CrossRef] [Green Version]

- Steiner, N.; Marra, D.; Sorrentino, M.; Pianese, C.; Wang, K.; Hissel, D.; Pe, M.C.; Monteverde, M.; Cardone, P.; Saarinen, J. A Review on solid oxide fuel cell models. Int. J. Hydrogen Energy 2011, 6. [Google Scholar] [CrossRef]

- O’Hayre, R.; Cha, S.; Colella, W.G.; Prinz, F.B. Fuel Cell Fundamentals, 3rd ed.; Wiley: Hoboken, NJ, USA; ISBN 9781119113805.

- Pei, P.; Chen, H. Main factors affecting the lifetime of Proton Exchange Membrane fuel cells in vehicle applications: A review. Appl. Energy 2014, 125, 60–75. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, X.; Zhang, T.; Pei, P. The reactant starvation of the proton exchange membrane fuel cells for vehicular applications: A review. Energy Convers. Manag. 2019, 182, 282–298. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, L.; Mao, Z.; Zhuge, W.; Zhang, Y.; Wang, L. Behavior of PEMFC in starvation. J. Power Sources 2006, 157, 166–176. [Google Scholar] [CrossRef]

- Palani, S.; Subramanian, S.C.; Chetty, R. Component sizing based on multi-objective optimization for a fuel cell hybrid vehicle. Proceedings of 2019 6th International Conference on Control, Decision and Information Technologies (CoDIT), Paris, France, 23–26 April 2019; pp. 434–439. [Google Scholar] [CrossRef]

- Ramos-paja, C.A.; Member, S.; Giral, R.; Martinez-salamero, L.; Romano, J.; Romero, A.; Spagnuolo, G.; Member, S. A PEM Fuel-Cell Model Featuring Oxygen-Excess-Ratio Estimation and Power-Electronics Interaction. IEEE Trans. Ind. Electron. 2010, 57, 1914–1924. [Google Scholar] [CrossRef]

- Lin, Y.F.; Chen, Y.S. Experimental study on the optimal purge duration of a proton exchange membrane fuel cell with a dead-ended anode. J. Power Sources 2017, 340, 176–182. [Google Scholar] [CrossRef]

- Migliardini, F.; Di Palma, T.M.; Gaele, M.F.; Corbo, P. Hydrogen purge and reactant feeding strategies in self-humidified PEM fuel cell systems. Int. J. Hydrogen Energy 2017, 42, 1758–1765. [Google Scholar] [CrossRef]

| Item | Value | |

|---|---|---|

| PEFC Stack | Number of cells | 58 |

| Open circuit voltage (V) | 56.5 | |

| Nominal power (W) | 5000 | |

| Peak power (W) | 5600 | |

| Estimated active cell area (cm2) | 200 | |

| Flow field material (design) | Graphite | |

| Weight (kg) | 52 | |

| Stack voltage range (V) | 39–56.5 | |

| Peak stack current (A) | 130 | |

| Hydrogen/fuel supply subsystem | Controllable BLDC (*) diaphragm recirculation pump Recirculation flow rate range (slpm) | 24VDC, 2.5 A 0–66 |

| Hydrogen feed pressure (bar) | 1.3 | |

| Purge solenoid valve (normally closed) | 24 VDC | |

| Purge frequency at max power (DE mode) | 10 per hour | |

| Purge frequency at max power (recirculation mode) | 2 per hour | |

| Air feed subsystem | Controllable BLDC cathode air blower | 48 VDC, 400 W |

| Blower max. flow rate (slpm) | 2689 | |

| Blower range with stack geometry (slpm) | 0–675 | |

| Max required air flow rate (slpm) | 658 | |

| External/passive air humidifier | Shell and tube | |

| Thermal management subsystem | Radiator | Air-cooled, fin type |

| Coolant type | De-ionised water | |

| Coolant pump | 48 VDC, 1.5 A | |

| Data Acquisition/Control System | National Instruments | cRIO 9054 |

| Maximum Sampling rate | 250 kS/s | |

| Electronic Load | Modular variable DC (I-mode, U-mode or G-mode) | |

| Max voltage and current | 800 V, 200 A | |

| Sensors | Cell voltage monitoring (CVM) unit | |

| Temperature sensor × 2 | ||

| Current transducers × 6 | ||

| Voltage transducers × 2 | ||

| Pressure sensor × 1 | ||

| Relative humidity sensor × 1 | ||

| Mass flow meterHydrogen sensor × 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, N.; Al-Sagheer, Y.; Steinberger-Wilckens, R. PEFC System Reactant Gas Supply Management and Anode Purging Strategy: An Experimental Approach. Energies 2022, 15, 288. https://doi.org/10.3390/en15010288

Khan N, Al-Sagheer Y, Steinberger-Wilckens R. PEFC System Reactant Gas Supply Management and Anode Purging Strategy: An Experimental Approach. Energies. 2022; 15(1):288. https://doi.org/10.3390/en15010288

Chicago/Turabian StyleKhan, Naseruddin, Yousif Al-Sagheer, and Robert Steinberger-Wilckens. 2022. "PEFC System Reactant Gas Supply Management and Anode Purging Strategy: An Experimental Approach" Energies 15, no. 1: 288. https://doi.org/10.3390/en15010288

APA StyleKhan, N., Al-Sagheer, Y., & Steinberger-Wilckens, R. (2022). PEFC System Reactant Gas Supply Management and Anode Purging Strategy: An Experimental Approach. Energies, 15(1), 288. https://doi.org/10.3390/en15010288