Sliding-Mode-Based Current and Speed Sensors Fault Diagnosis for Five-Phase PMSM

Abstract

:1. Introduction

2. Modeling of 5P-PMSM

2.1. 5P-PMSM Model in Natural Frame

2.2. 5P-PMSM Model in Rotating Fram

2.3. Power Converter

3. Speed Backstepping Control Design

4. Currents Backstepping Control

5. Sliding Mode Observer Design

5.1. Current Observer

5.2. Rotor Speed Observer

6. Sensor FTC Strategy

6.1. Residual Generation

6.2. The Proposed Active Fault-Tolerant Control Scheme

- Generating the system switching fault indicators: ;

- Applying the FTC algorithm as follows: in the normal operating condition, the measured signal values, which are the output of the sensors, will be used in the closed loop control system. In the case of a failure event, the estimated value of the SMO is considered in order to calculate the reconstructed output values, as is explained in the following system equations:

6.3. Simulation Results and Discussions

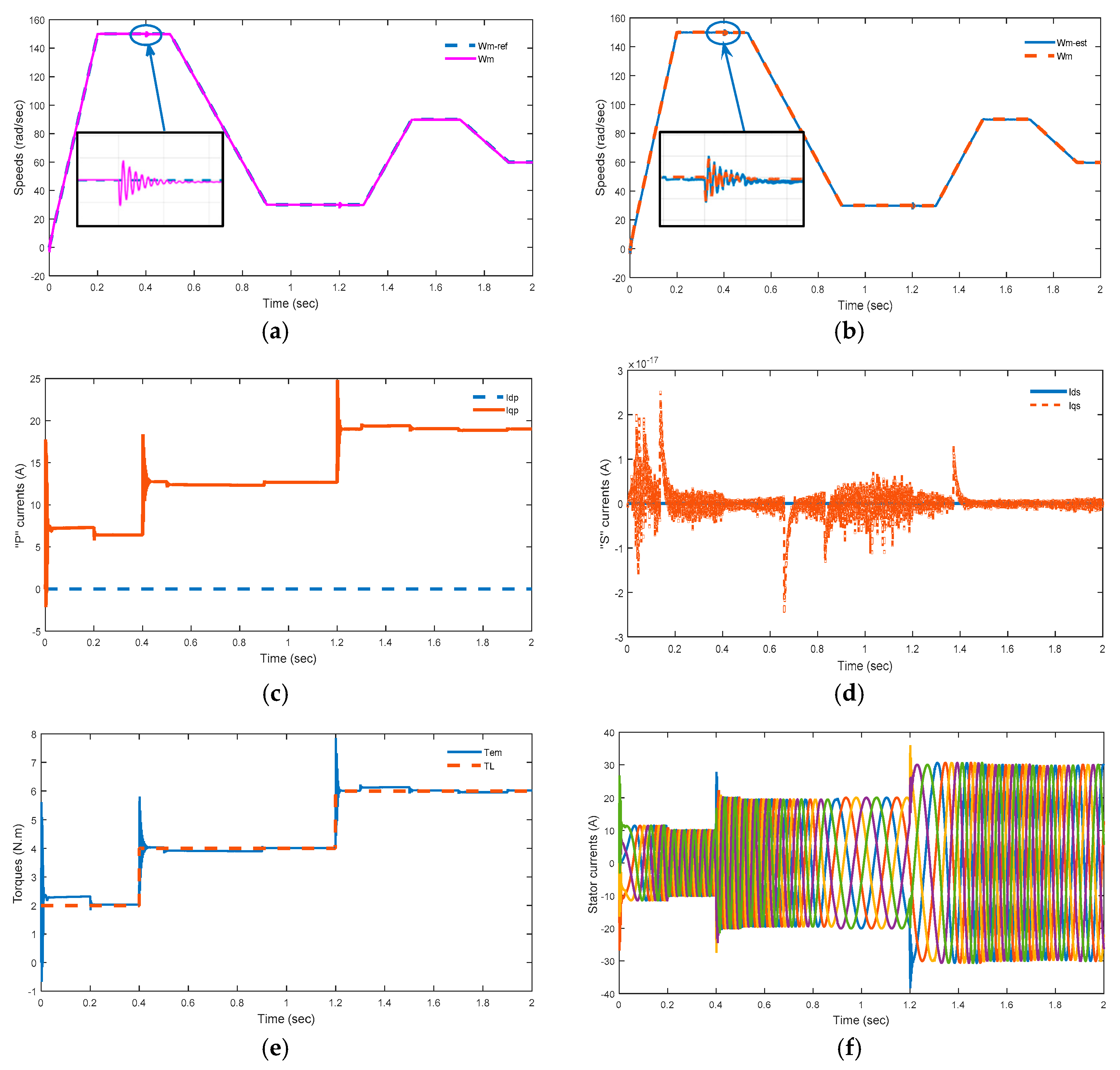

6.3.1. Healthy Operation Condition

6.3.2. Fault Operation Condition

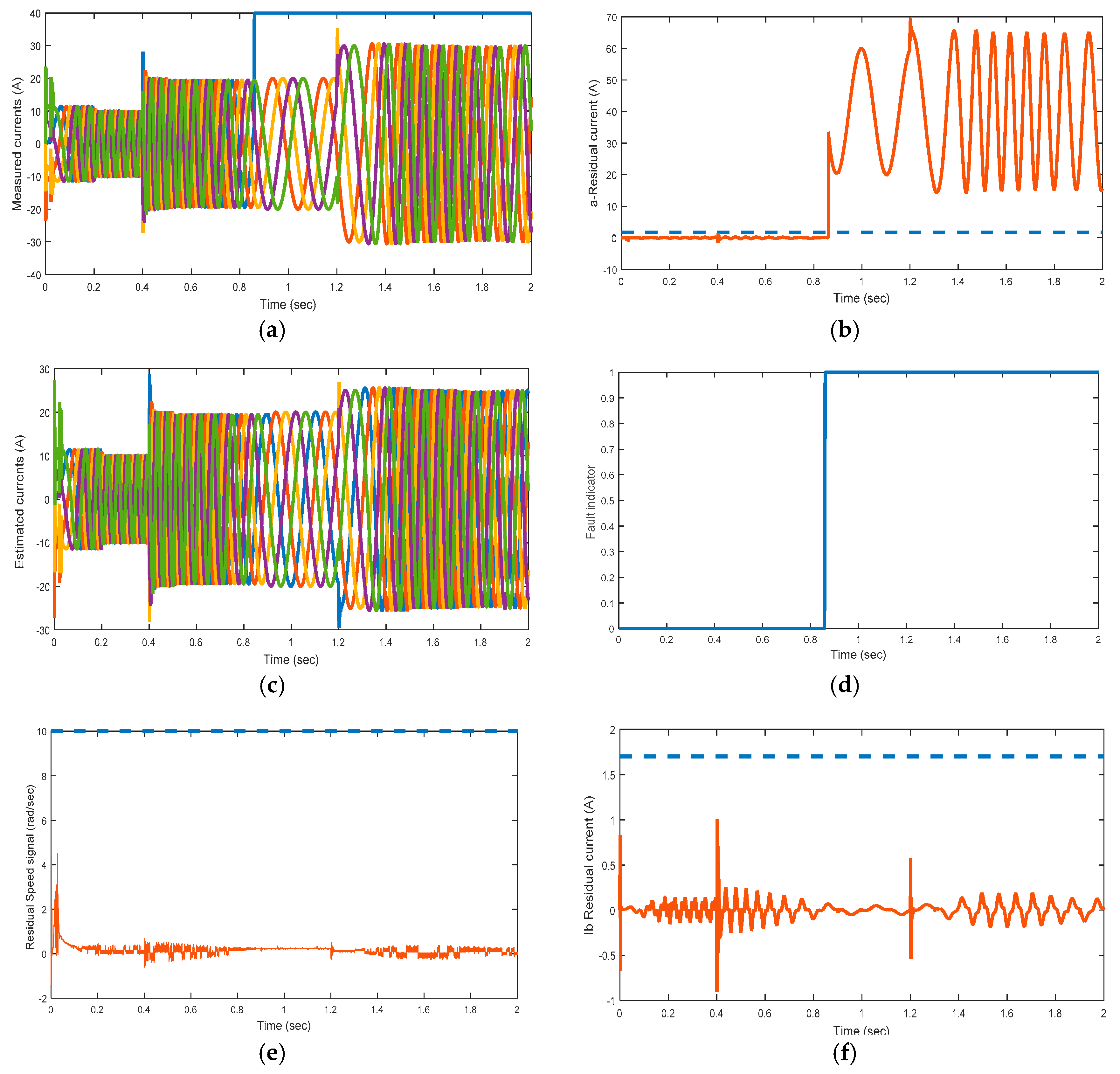

- Current Sensor fault in a-phase

- Current Sensor constant fault in b-phase

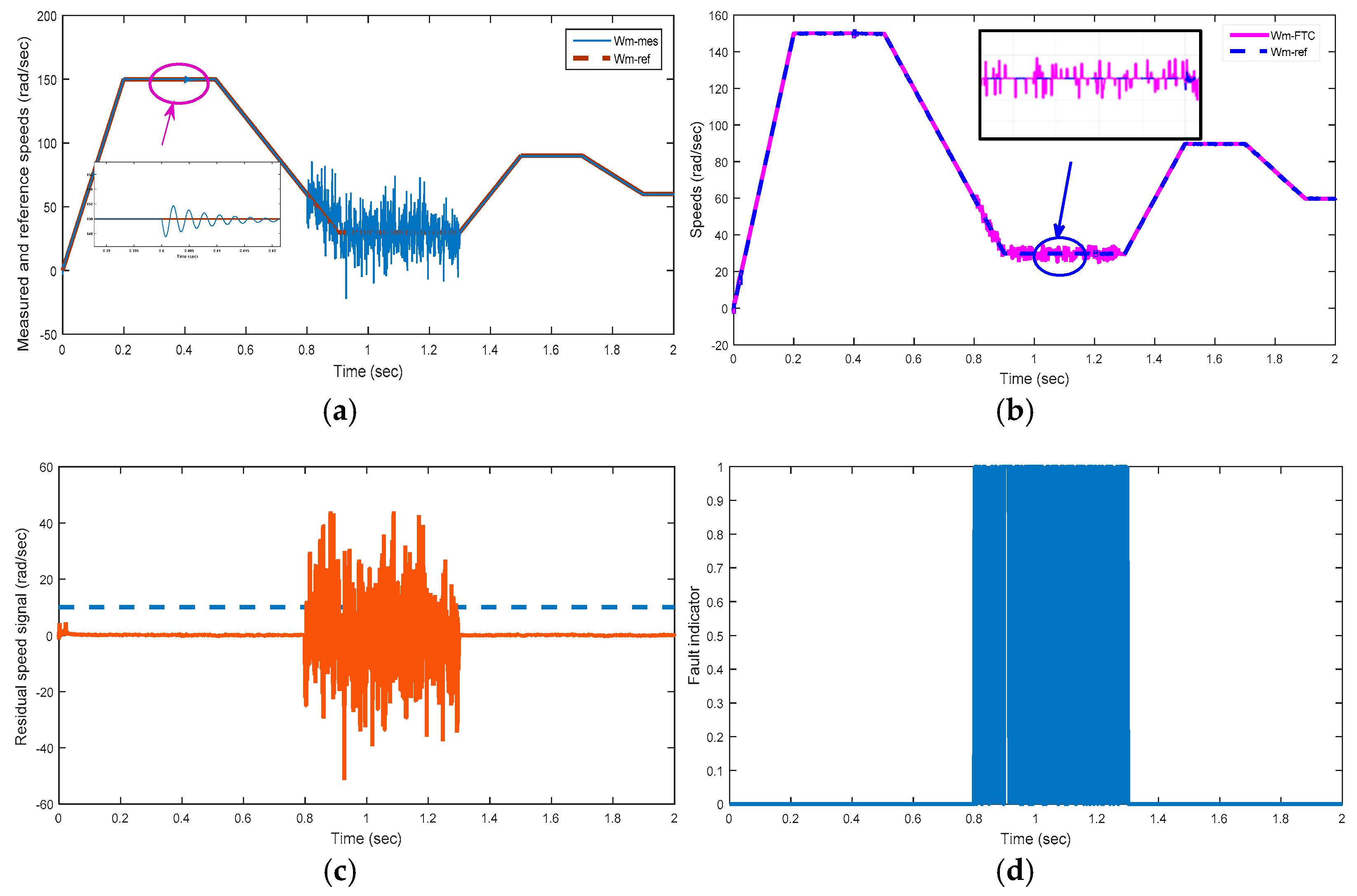

- Rotor speed Sensor noise fault

- Rotor speed sensor constant Fault

- Two sensors a and b are affected with speed sensor constant fault

7. Discussion

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gong, J.; Zahr, H.; Semail, E.; Trabelsi, M.; Aslan, B.; Scuiller, F. Design Considerations of Five-Phase Machine with Double p/3p Polarity. IEEE Trans. Energy Conv. 2019, 34, 12–24. [Google Scholar] [CrossRef]

- Hezzi, A.; Elghali, S.B.; Salem, Y.B.; Abdelkrim, M.N. Control of five-phase PMSM for electric vehicle application. In Proceedings of the 18th International Conference on Sciences and Techniques of Automatic Control & Computer Engineering—STA’2017, Monastir, Tunisia, 21–23 December 2017. [Google Scholar]

- Li, L.; Ding, S.X.; Luo, H.; Peng, K.; Yang, Y. Performance-Based Fault-Tolerant Control Approaches for Industrial Processes with Multiplicative Faults. IEEE Trans. Ind. Inform. 2020, 16, 4759–4768. [Google Scholar] [CrossRef]

- Kommuri, S.K.; Rath, J.J.; Veluvolu, K.C.; Defoort, M. Robust fault-tolerant cruise control of electric vehicles based on second-order sliding mode observer. In Proceedings of the 2014 14th International Conference on Control, Automation and Systems (ICCAS 2014), Gyeonggi-do, Korea, 22–25 October 2014; pp. 698–703. [Google Scholar] [CrossRef]

- Yang, J.; Dou, M.; Zhao, D. Iterative sliding mode observer for sensoreless control of five-phase permanent magnet synchronous motor. Bulletin of the polish academy of sciences. Tech. Sci. 2017, 65, 845–857. [Google Scholar]

- Nguyen, N.K.; Meinguet, F.; Semail, E.; Kestelyn, X. Fault-tolerant operation of an open-end winding five-phase PMSM drive with short-circuit inverter fault. IEEE Trans. Ind. Electron. 2016, 63, 595–605. [Google Scholar] [CrossRef] [Green Version]

- Mohammadpour, A.; Sadeghi, S.; Parsa, L. A generalized fault-tolerant control strategy for five-phase PM motor drives considering star, pentagon, and pentacle connections of stator windings. IEEE Trans. Ind. Electron. 2014, 61, 63–75. [Google Scholar] [CrossRef]

- Mohammadpour, A.; Parsa, L. A unified fault-tolerant current control approach for five phase PM motors with trapezoidal back EMF under different stator winding connections. IEEE Trans. Power Electron. 2013, 28, 3517–3527. [Google Scholar] [CrossRef]

- Sadeghi, S.; Guo, L.; Toliyat, H.A.; Parsa, L. Wide operation speed range of five-phase permanent machines by using different stator winding configurations. IEEE Trans. Power Electron. 2012, 59, 2621–2631. [Google Scholar]

- Hezzi, A.; Bensalem, Y.; Elghali, S.B.; Abdelkrim, M.N. Sliding mode observer sensoreless control of five-phase PMSM in electric vehicle. In Proceedings of the 19th International Conference on Sciences and Techniques of Automatic Control and Computer Engineering (STA), Sousse, Tunisia, 24–26 March 2019; pp. 530–535. [Google Scholar]

- Tabrizchi, A.M.; Soltani, J.; Shishehgar, J.; Abjadi, N.R. Direct Torque control of Speed Sensorless Five-Phase IPMSM Based on Adaptive Input-Output Feedback Linearization. In Proceedings of the 5th Power Electronics, Drive Systems and Technologies Conference (PEDSTC 2014), Tehran, Iran, 5–6 February 2014. [Google Scholar]

- Bensalem, Y.; Abbassi, R.; Jerbi, H. Fuzzy Logic Based-Active Fault Tolerant control of speed sensor failure for five phase PMSM. J. Electr. Eng. Technol. 2021, 16, 287–299. [Google Scholar] [CrossRef]

- Hosseyni, A.; Trabelsi, R.; Iqbal, A.; Mimouni, M.F. Backstepping Control for a Five-Phase Permanent Magnet Synchronous Motor Drive. J. Power Electron. Drive Syst. 2015, 6, 842–852. [Google Scholar] [CrossRef]

- Hosseyni, A.; Trabelsi, R.; Sanjeevikumar, P.; Iqbal, A.; Mimouni, M.F. Sensorless Back Stepping Control for a Five-Phase Permanent Magnet Synchronous Motor Drive Based on Sliding Mode Observer. In Advances in Power Systems and Energy Management; Lecture Notes in Electrical Engineering; Springer: Singapore, 2018; Volume 436. [Google Scholar] [CrossRef]

- Jinpeng, Y.; Junwei, G.; Yumei, M.; Haisheng, Y. Adaptive Fuzzy Tracking Control for a Permanent Magnet Synchronous Motor via Backstepping Approach. Math. Probl. Eng. 2010, 2010, 391846. [Google Scholar]

- Sobanski, P.; Ortowska-Kowalska, T. Detection of single and multiple IGBTs open-circuit faults in a field-oriented controlled induction motor drive. Arch. Electr. Eng. 2017, 66, 89–104. [Google Scholar] [CrossRef]

- Kummuri, S.; Michael, D.; Karimi, H.R.; Veluvolu, K.C. A Robust Observer-Based sensor fault-tolerant control for PMSM in Electric Vehicules. IEEE Trans. Ind. Electron. 2016, 63, 7671–7681. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, B.; Ningyun, L. A Multi-mode Incipient Sensor Fault Detection and Diagnosis Method for Electrical Traction Systems. Int. J. Control Autom. Syst. 2018, 16, 1783–1793. [Google Scholar] [CrossRef]

- Zhongyi, Y.; Yiguang, C. Interturn Short-Circuit Fault Detection of a Five-Phase Permanent Magnet Synchronous Motor. Energies 2021, 14, 434. [Google Scholar]

- Li, T.; Ruiqing, M.; Zhen, Z. Diagnosis of open-phase fault of five-phase permanent magnet synchronous motor by harmonic current analysis. Microelectron. Reliab. 2021, 126, 114205. [Google Scholar] [CrossRef]

- Gang, H.; Li, Z.; Edwardo, F.F.; Zhang, C.; He, J. An equivalent-input-disturbance approach for current sensor faults estimation and rejection in permanent magnet synchronous motor drives. Trans. Inst. Meas. Control 2020, 42, 365–373. [Google Scholar]

- Kamila, J.; Mateusz, D. A Current Sensor Fault Tolerant Control Strategy for PMSM Drive Systems Based on Cri Markers. Energies 2021, 14, 3443. [Google Scholar]

- Kummuri, S.; Veluvolu, K.C. Robust Sensors-Fault-Tolerance with Sliding Mode Estimation and Control for PMSM Drives. IEEE/ASME Trans. Mechatron. 2018, 23, 17–28. [Google Scholar] [CrossRef]

- Klimkowski, K.; Dybkowski, M. An influence of the chosen sensors faults to the performance of the vector controlled induction motor drive system. Comput. Appl. Electr. Eng. 2014, 12, 294–301. [Google Scholar]

- Yu, Y.; Zhao, Y.; Wang, B.; Huang, X.; Xu, D. Current Sensor Fault Diagnosis and Tolerant Control for VSI-Based Induction Motor Drives. IEEE Trans. Power Electron. 2018, 33, 4238–4248. [Google Scholar] [CrossRef]

- Huang, G.; Huang, W.; Zhengtan, L.; Jiajun, L.; Jing, H.; Changfan, Z.; Zhao, K. An improved sliding-mode observer-based equivalent-input-disturbance approach for permanent magnet synchronous motor drives with faults in current measurement circuits. Trans. Inst. Meas. Control 2021, 43, 2589–2598. [Google Scholar] [CrossRef]

- Jlassi, I.; Estima, J.; Khil, S.; Bellaaj, N.M.; Cardoso, A.J.M. A robust observer-based method for IGBTs and current sensors fault diagnosis in voltage-source inverters of PMSM drives. IEEE Trans. Ind. Appl. 2017, 53, 2894–2905. [Google Scholar] [CrossRef]

- Khil, S.; Jlassi, I.; Estima, J.; Bellaaj, N.M.; Cardoso, A.J.M. Current sensor fault detection and isolation method for PMSM drives, using average normalised currents. IET Electron. Lett. 2016, 52, 1434–1436. [Google Scholar] [CrossRef]

- Yin, S.; Luo, H.; Ding, S.X. Real-time implementation of fault-tolerant control systems with performance optimization. IEEE Trans. Ind. Electron. 2014, 61, 2402–2411. [Google Scholar] [CrossRef]

- Tabbache, B.; Benbouzid, M.E.; Kheloui, A.; Bourgeot, J. Virtual sensor based maximum likelihood voting approach for fault tolerant control of electric vehicle powertrains. IEEE Trans. Veh. Technol. 2013, 62, 1075–1083. [Google Scholar] [CrossRef] [Green Version]

- Tahri, A.; Said, H.; Moreau, S. A hybrid active fault-tolerant control scheme for wind energy conversion system based on permanent magnet synchronous generator. Arch. Electr. Eng. 2018, 67, 485–497. [Google Scholar]

- Bunasla, N.; Barkat, S.; Benyoussef, E.; Tounsi, K. Sensoreless sliding mode control of a five-phase PMSM using Extended Kalman Filter. In Proceedings of the International Conference on Modeling, Identification and Control (ICMIC-2016), Algiers, Algeria, 15–17 November 2016. [Google Scholar]

- Chakraborty, C.; Verma, V. Speed and current sensor fault detection and isolation technique for induction motor drive using axes transformation. IEEE Trans. Ind. Electron. 2015, 62, 1943–1954. [Google Scholar] [CrossRef]

- Mateusz, D.; Kamil, K. Artificial Neural Network Application for Current Sensors Fault Detection in the Vector Controlled Induction Motor Drive. Sensors 2019, 19, 571. [Google Scholar] [CrossRef] [Green Version]

- Kamil, K.; Mateusz, D. A Fault Tolerant Control Structure for an Induction Motor Drive System. Automatika 2016, 3, 638–647. [Google Scholar]

- Mateusz, D.; Kamil, K. Stator current sensor fault detection and isolation for vector-controlled induction motor drive. In Proceedings of the IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–28 September 2016. [Google Scholar]

- Parsa, L.; Toliyat, H.A. Multi-phase permanent magnet motor drives. In Proceedings of the 38th IAS Annual Meeting on Conference Record of the Industry Applications Conference, Salt Lake City, UT, USA, 12–16 October 2003; Volume 1, pp. 401–408. [Google Scholar] [CrossRef]

- Khan, M.R.; Iqbal, A. Experimental investigation of five-phase induction motor drive using extended Kalman-filter. Asian Power Electron. J. 2009, 3, 1–7. [Google Scholar]

- Hosseyni, A.; Trabelsi, R.; Iqbal, A.; Padmanaban, S.; Mimouni, M.F. An improved sensorless sliding mode control/adaptive observer of a five-phase permanent magnet synchronous motor drive. Int. J. Adv. Manuf. Technol. 2017, 93, 1029–1039. [Google Scholar] [CrossRef]

- Hezzi, A.; Elghali, S.B.; Bensalem, Y.; Zhibin, Z.; Benbouzid, M.; Abdelkrim, M.N. ADRC-Based Robust and Resilient Control of a 5-phase PMSM driven Electric Vehicle. Machines 2020, 8, 17. [Google Scholar] [CrossRef]

- Qinyue, Z.; Zhaoyang, L.; Xitang, T.; Xie, D.; Dai, W. Sensors Fault Diagnosis and Active Fault-Tolerant Control for PMSM Drive Systems Based on a Composite Sliding Mode Observer. Energies 2019, 12, 1695. [Google Scholar] [CrossRef] [Green Version]

- Jiwen, Z.; Lijun, W.; Liang, X.; Fei, D.; Juncai, S.; Xing, Y. Uniform Demagnetization Diagnosis for Permanent Magnet Synchronous Linear Motor Using a Sliding-Mode Velocity Controller and an ALN-MRAS Flux Observer. IEEE Trans. Ind. Electron. 2021, 69, 890–899. [Google Scholar]

| Parameter Name | Symbol | Value |

|---|---|---|

| Number of pole pairs | np | 2 |

| Stator resistance | R | 5 Ω |

| Principal machine inductance | Lp | 0.1228 H |

| Seconder machine inductance | Ls | 0.0222 H |

| First harmonic constants | K1 | 2 |

| Third harmonic constants | K3 | 0.66 |

| Inertia moment | J | 0.00075 Kg·m2 |

| Viscous friction coefficient | B | 0.000457 N·m·s/rad |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bensalem, Y.; Kouzou, A.; Abbassi, R.; Jerbi, H.; Kennel, R.; Abdelrahem, M. Sliding-Mode-Based Current and Speed Sensors Fault Diagnosis for Five-Phase PMSM. Energies 2022, 15, 71. https://doi.org/10.3390/en15010071

Bensalem Y, Kouzou A, Abbassi R, Jerbi H, Kennel R, Abdelrahem M. Sliding-Mode-Based Current and Speed Sensors Fault Diagnosis for Five-Phase PMSM. Energies. 2022; 15(1):71. https://doi.org/10.3390/en15010071

Chicago/Turabian StyleBensalem, Yemna, Abdellah Kouzou, Rabeh Abbassi, Houssem Jerbi, Ralph Kennel, and Mohamed Abdelrahem. 2022. "Sliding-Mode-Based Current and Speed Sensors Fault Diagnosis for Five-Phase PMSM" Energies 15, no. 1: 71. https://doi.org/10.3390/en15010071