Numerical Investigation on the Performance of a Transonic Axial Compressor with Inlet Distortion and Low Reynolds Number

Abstract

:1. Introduction

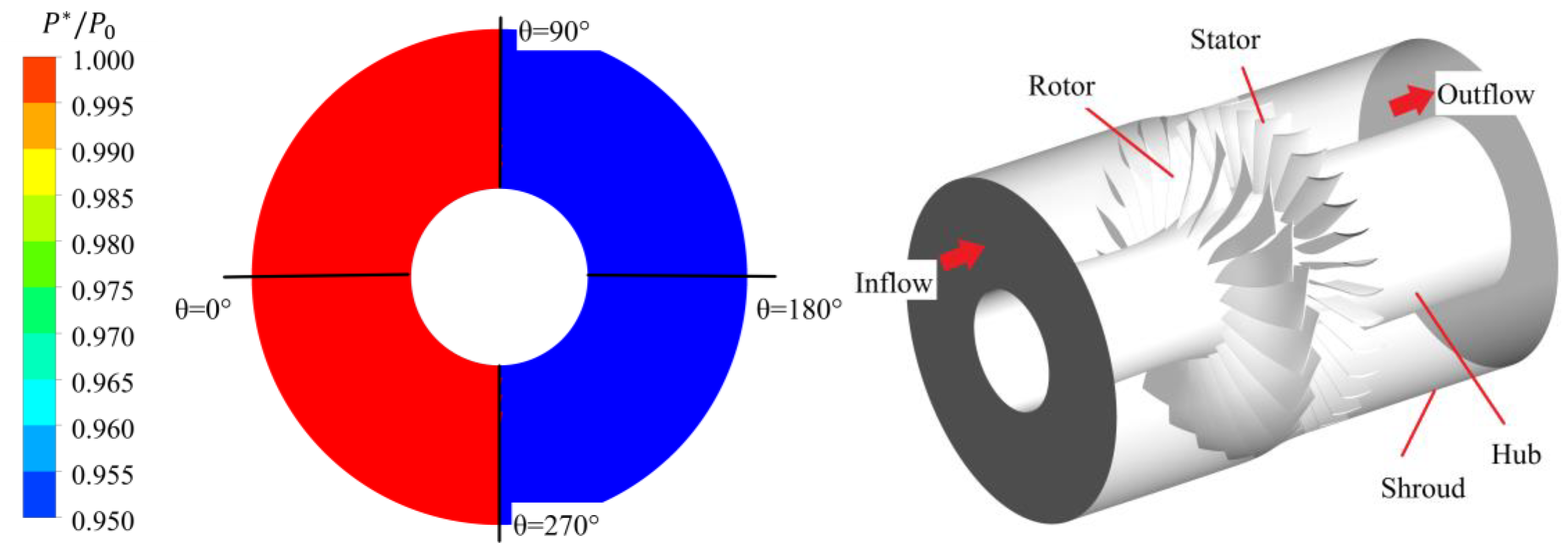

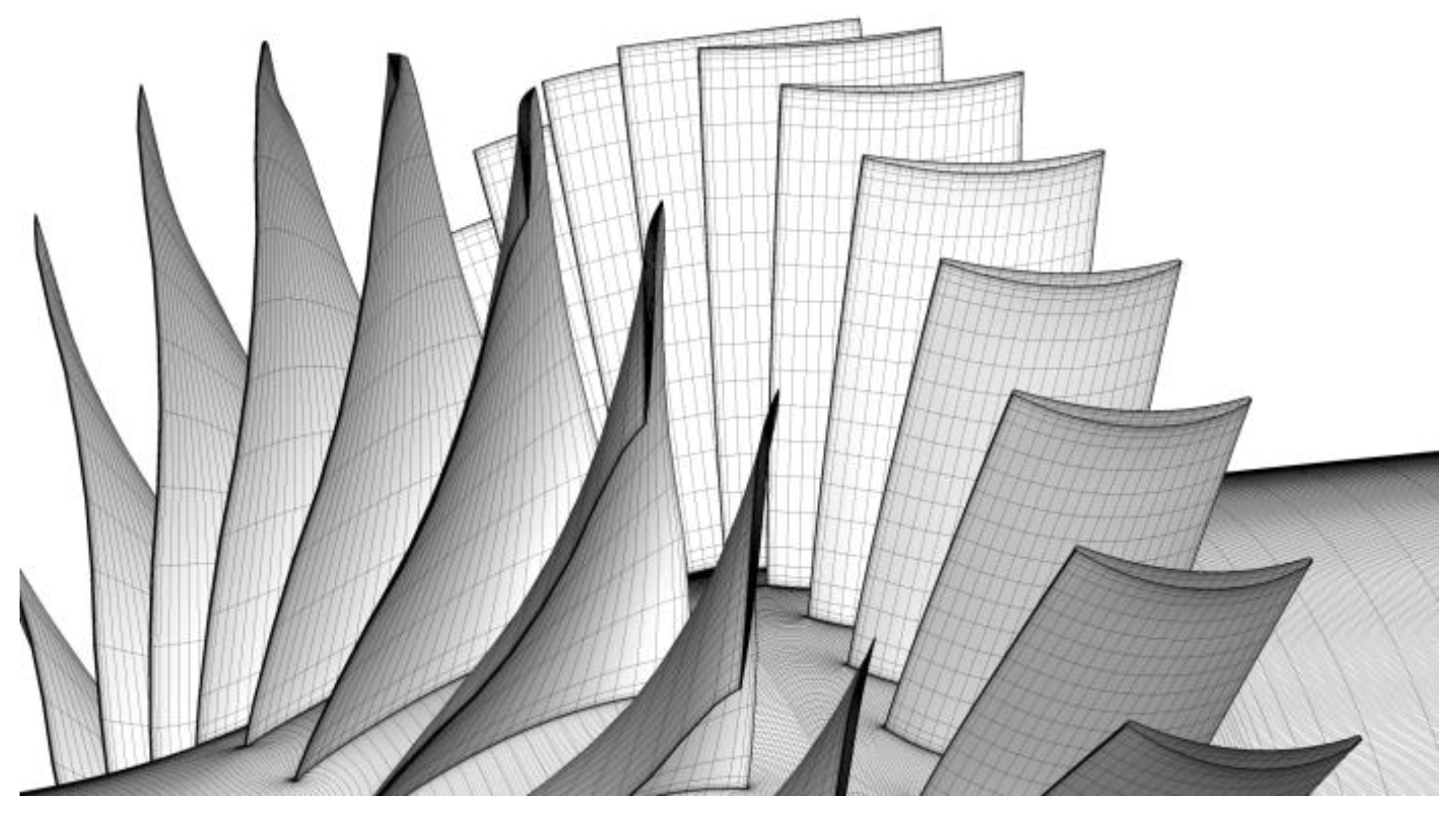

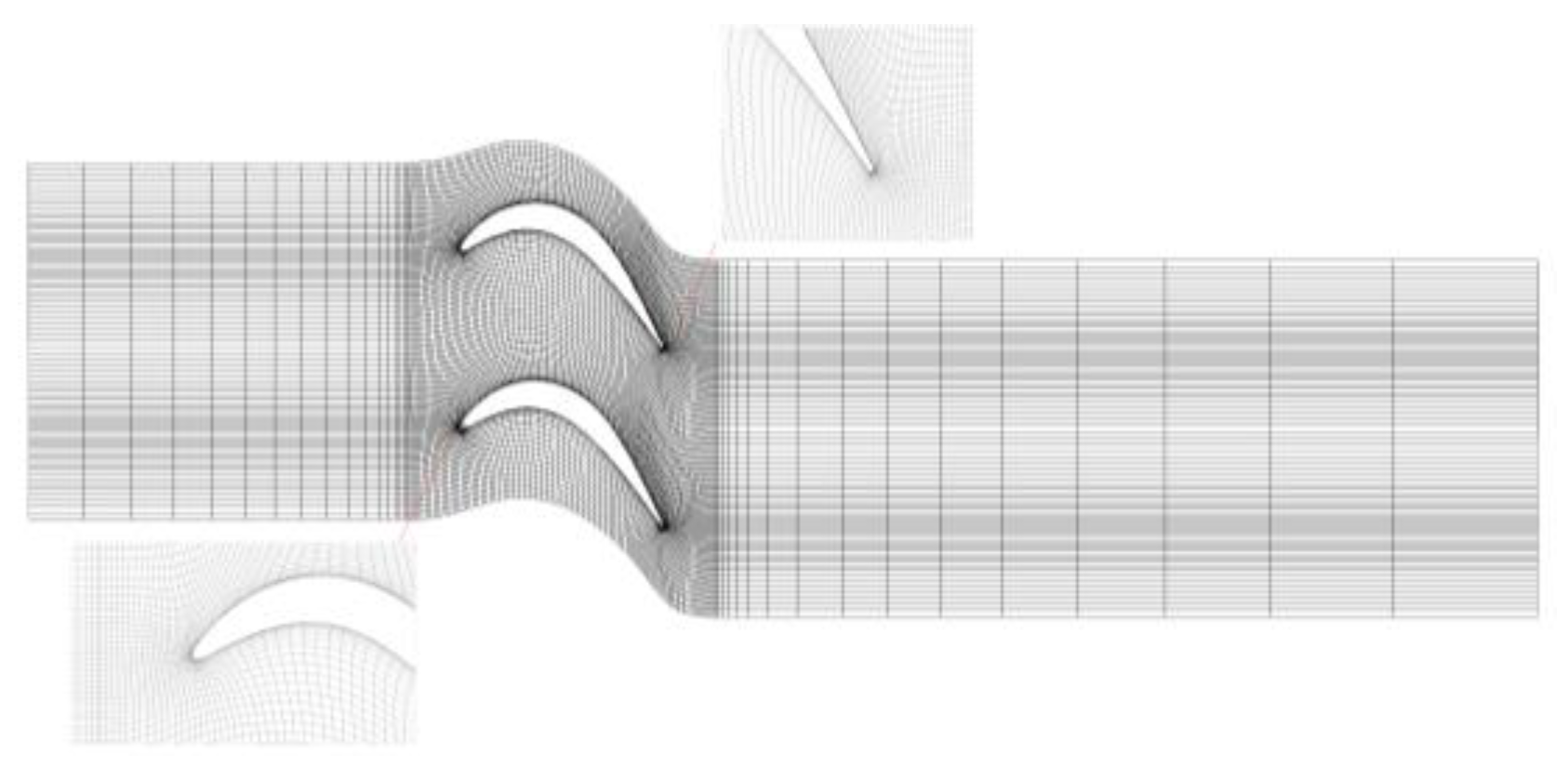

2. Computational Setups

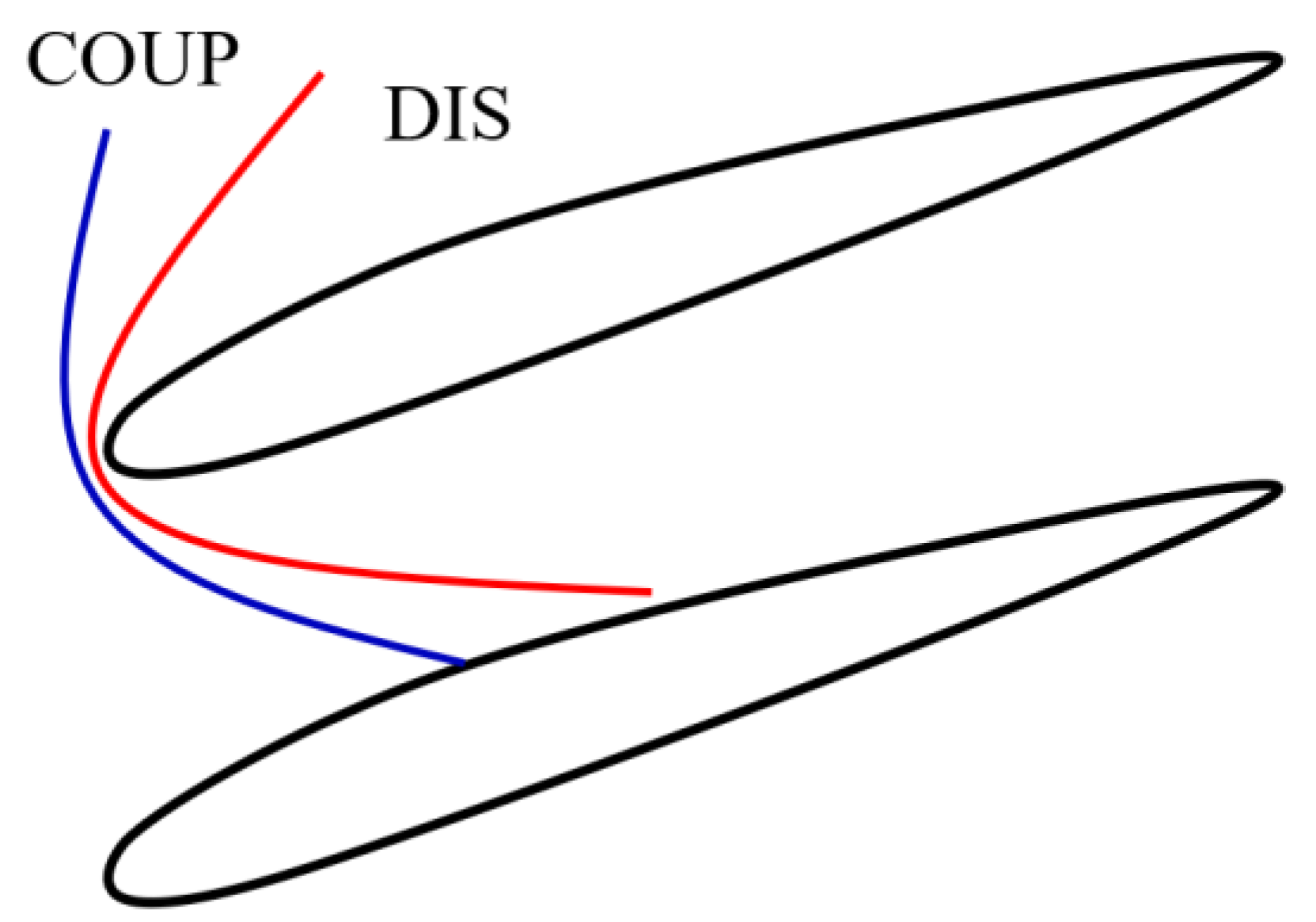

2.1. Research Subject

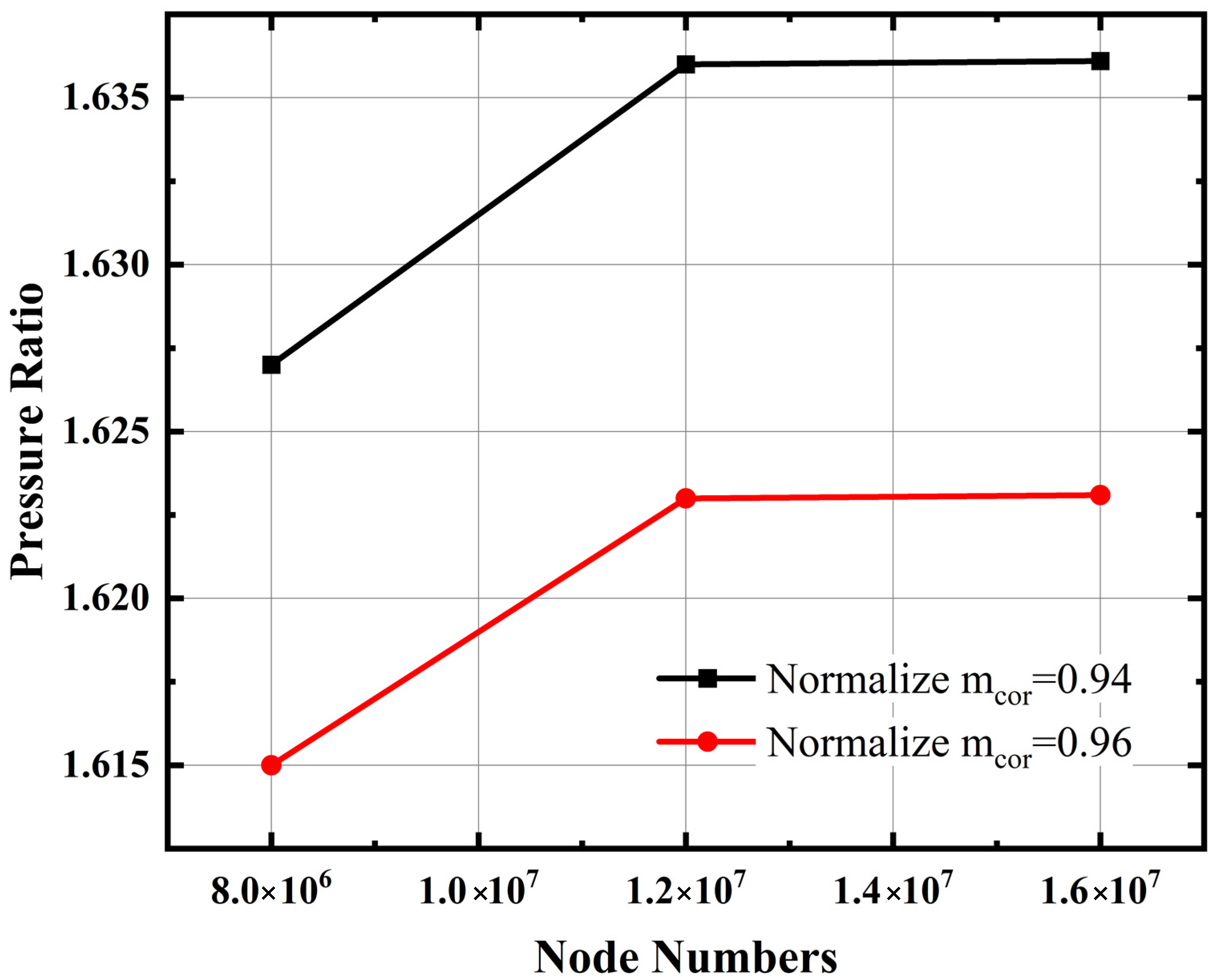

2.2. Numerical Methods

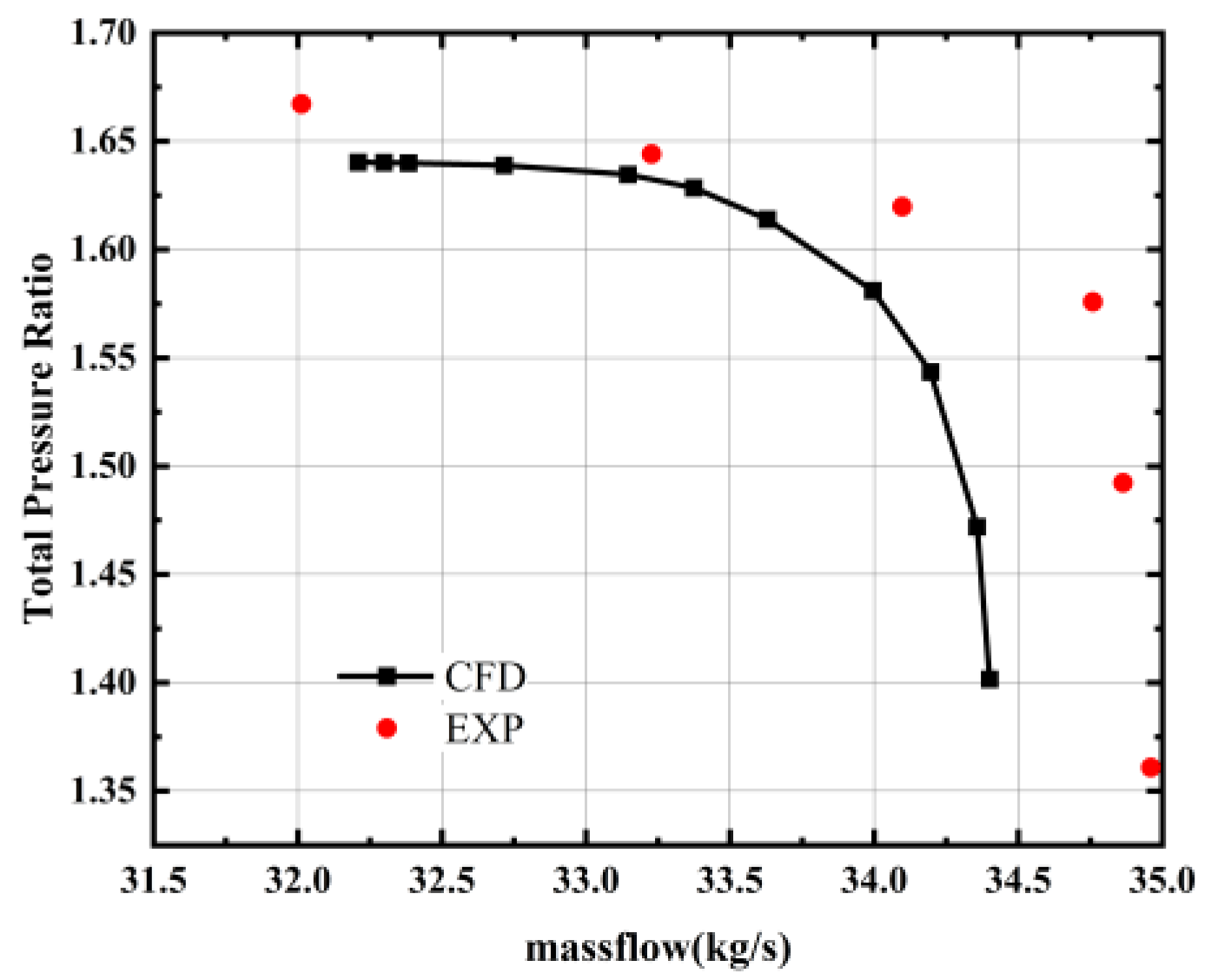

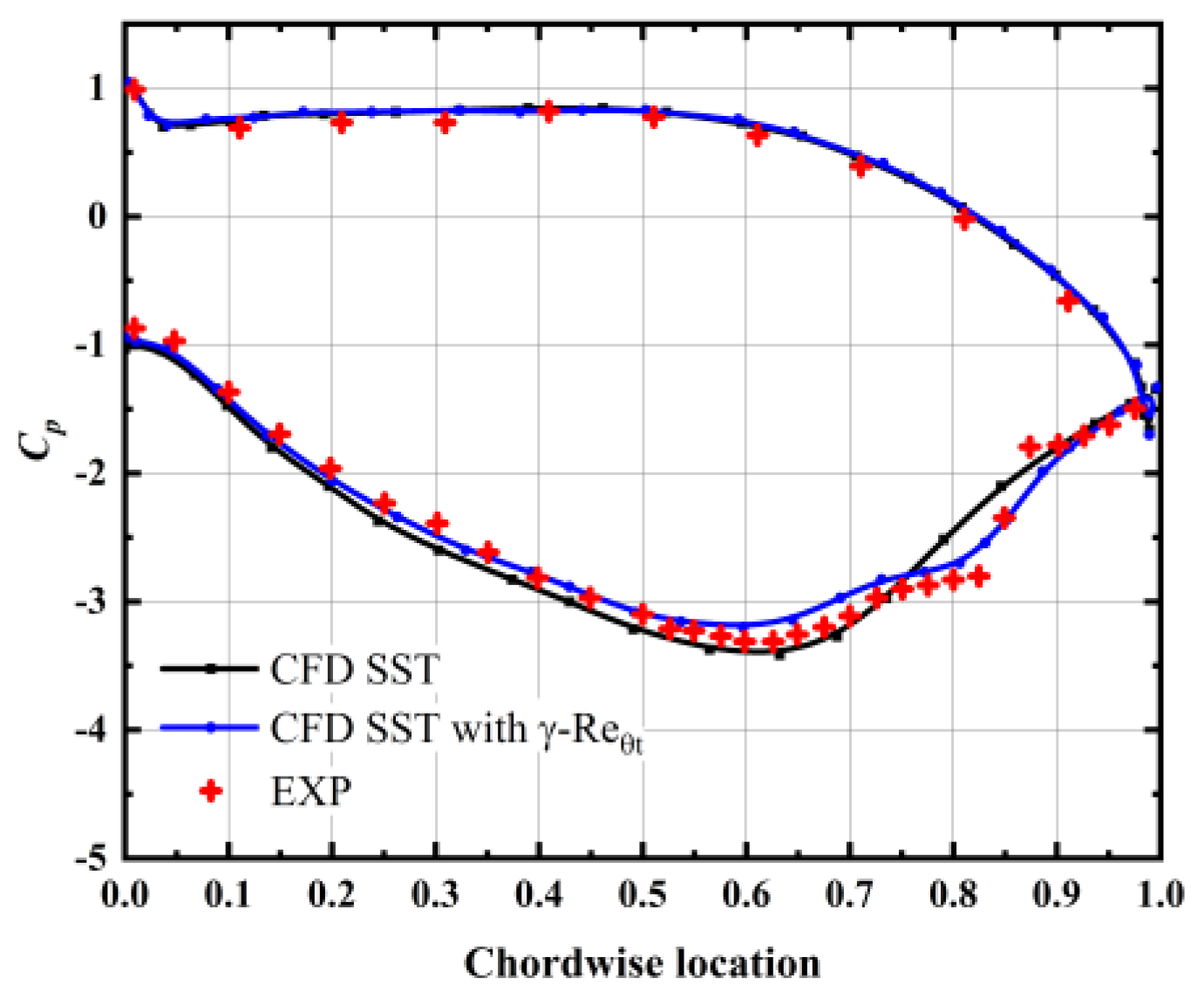

2.3. Validations

3. Problem Descriptions

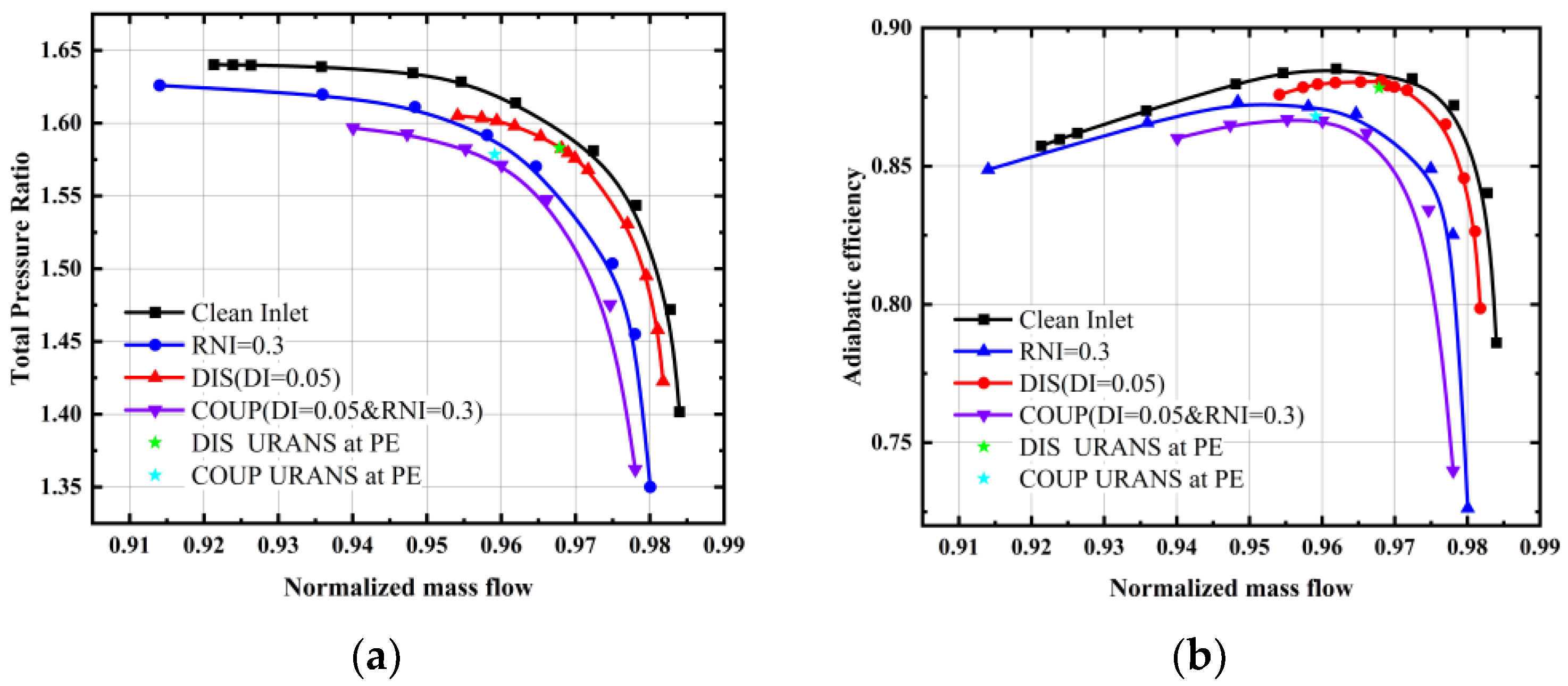

4. Results and Discussions

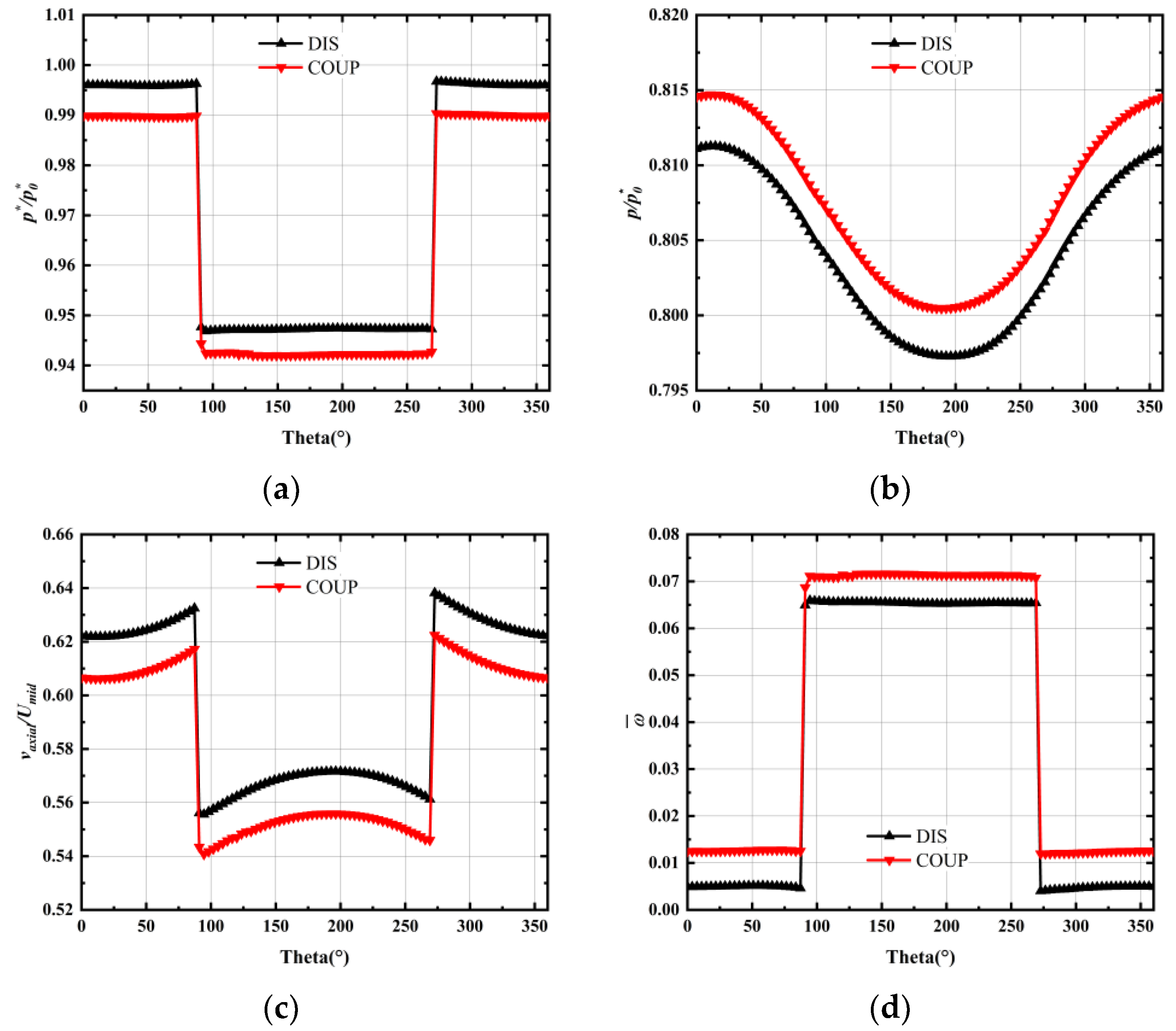

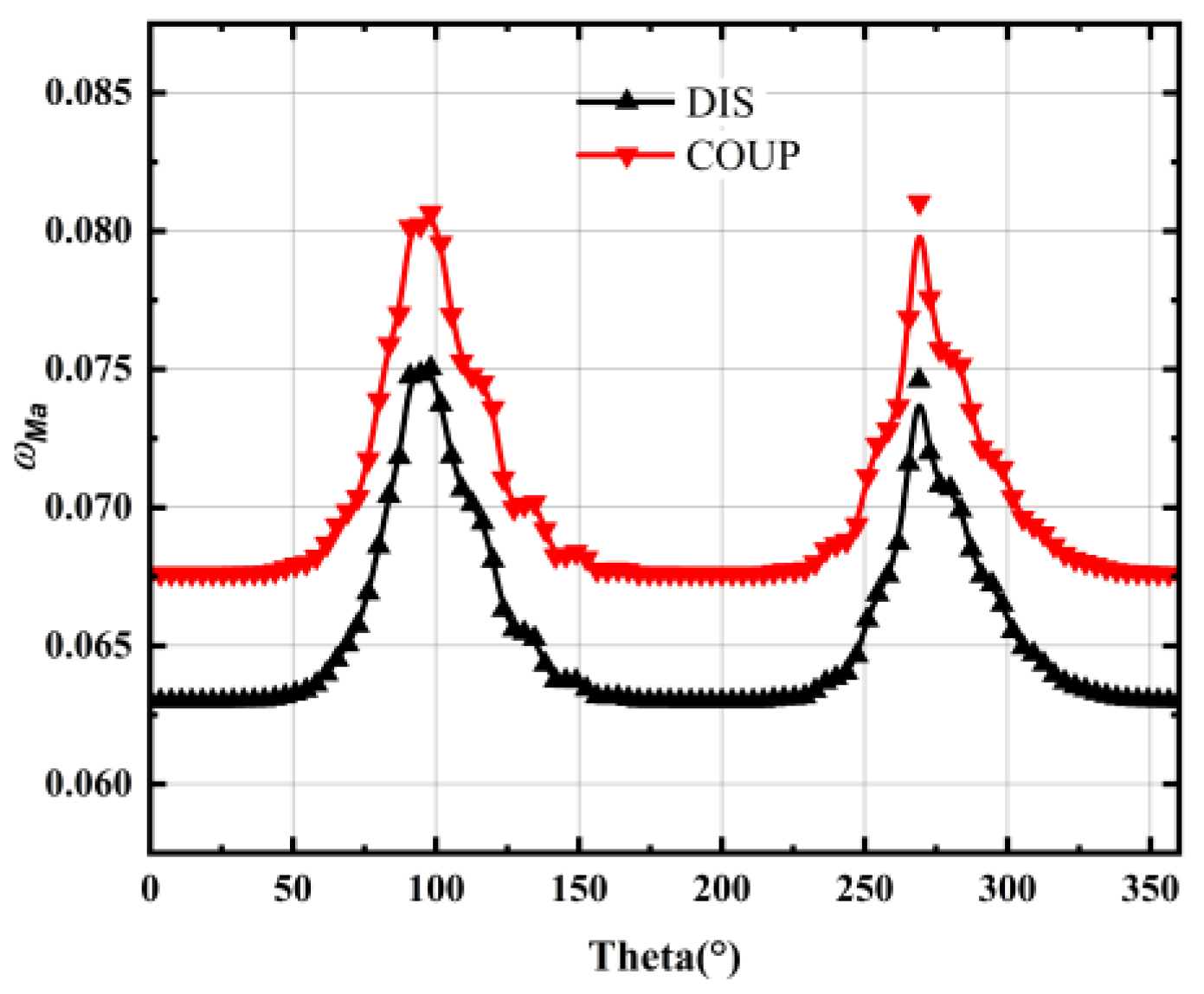

4.1. Nonuniform Flow Fields Upstream of the Rotor Blade Row

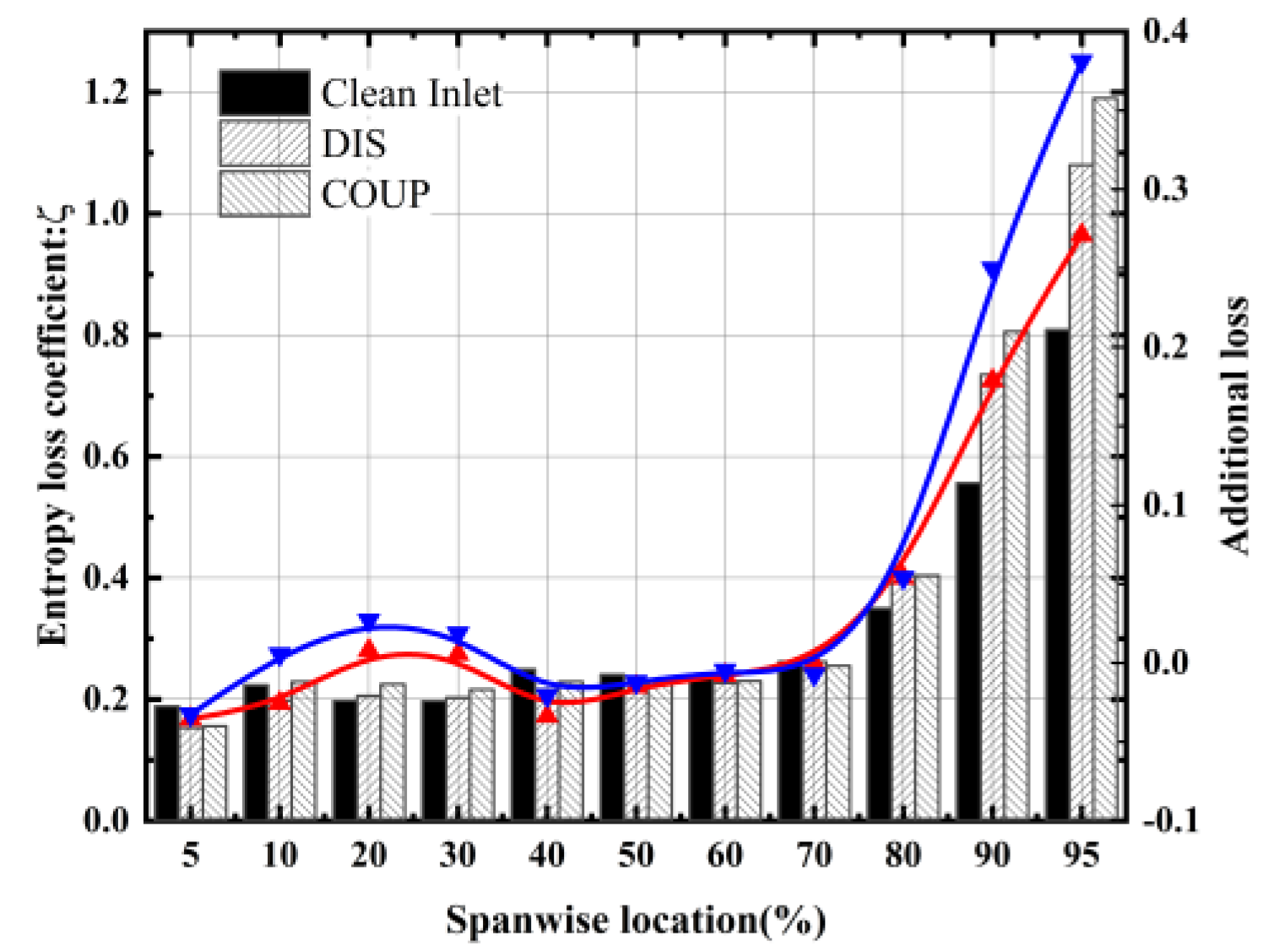

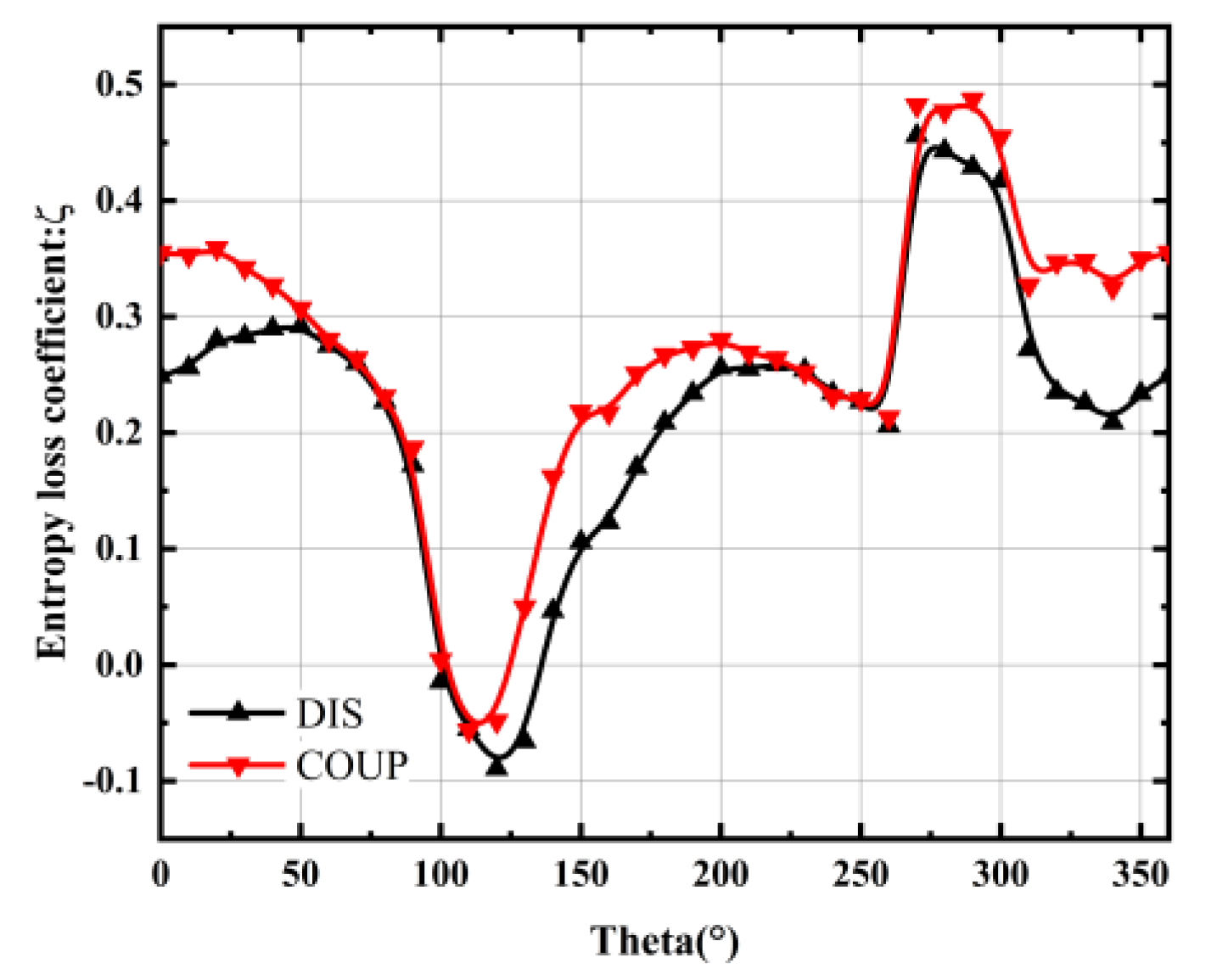

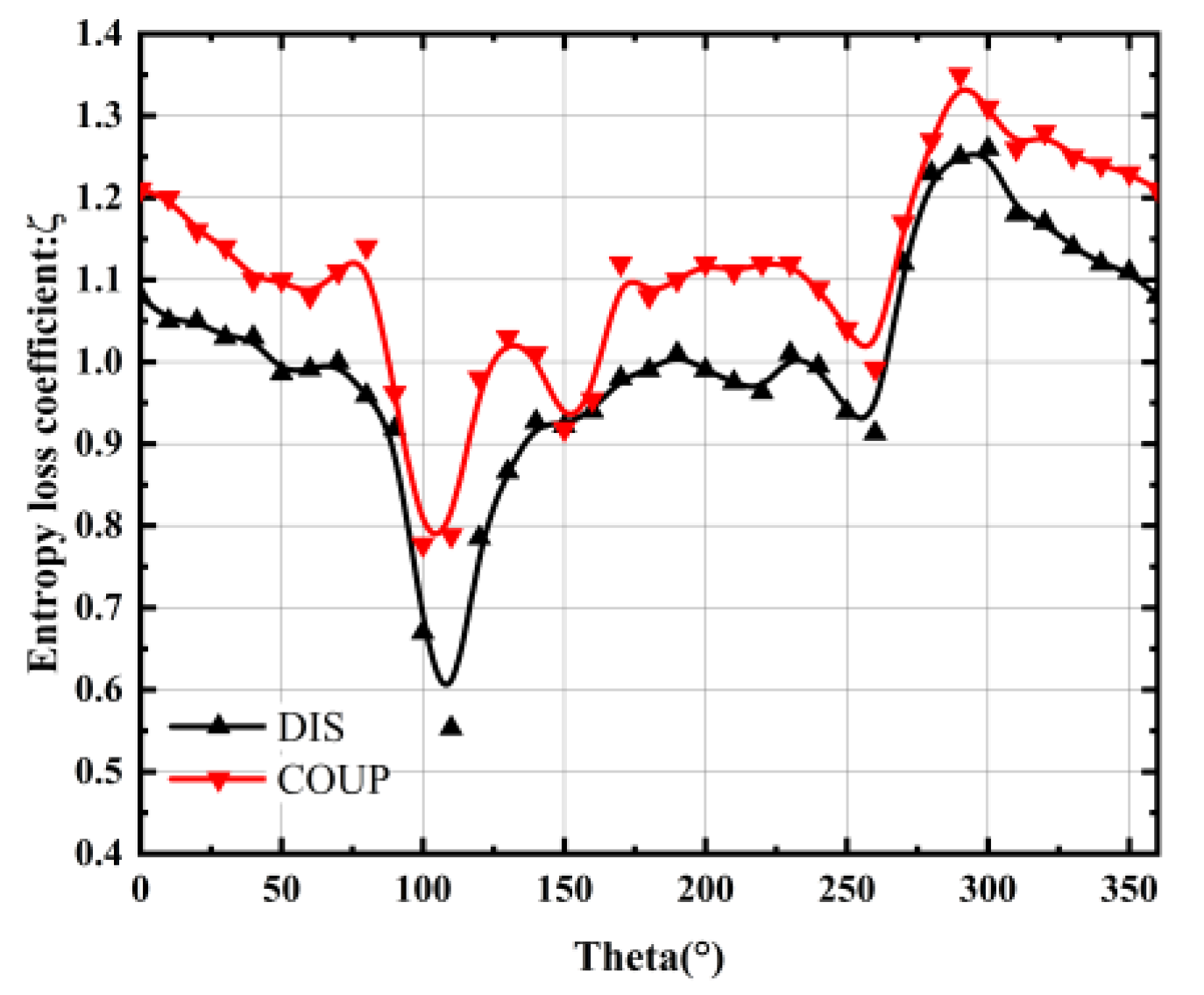

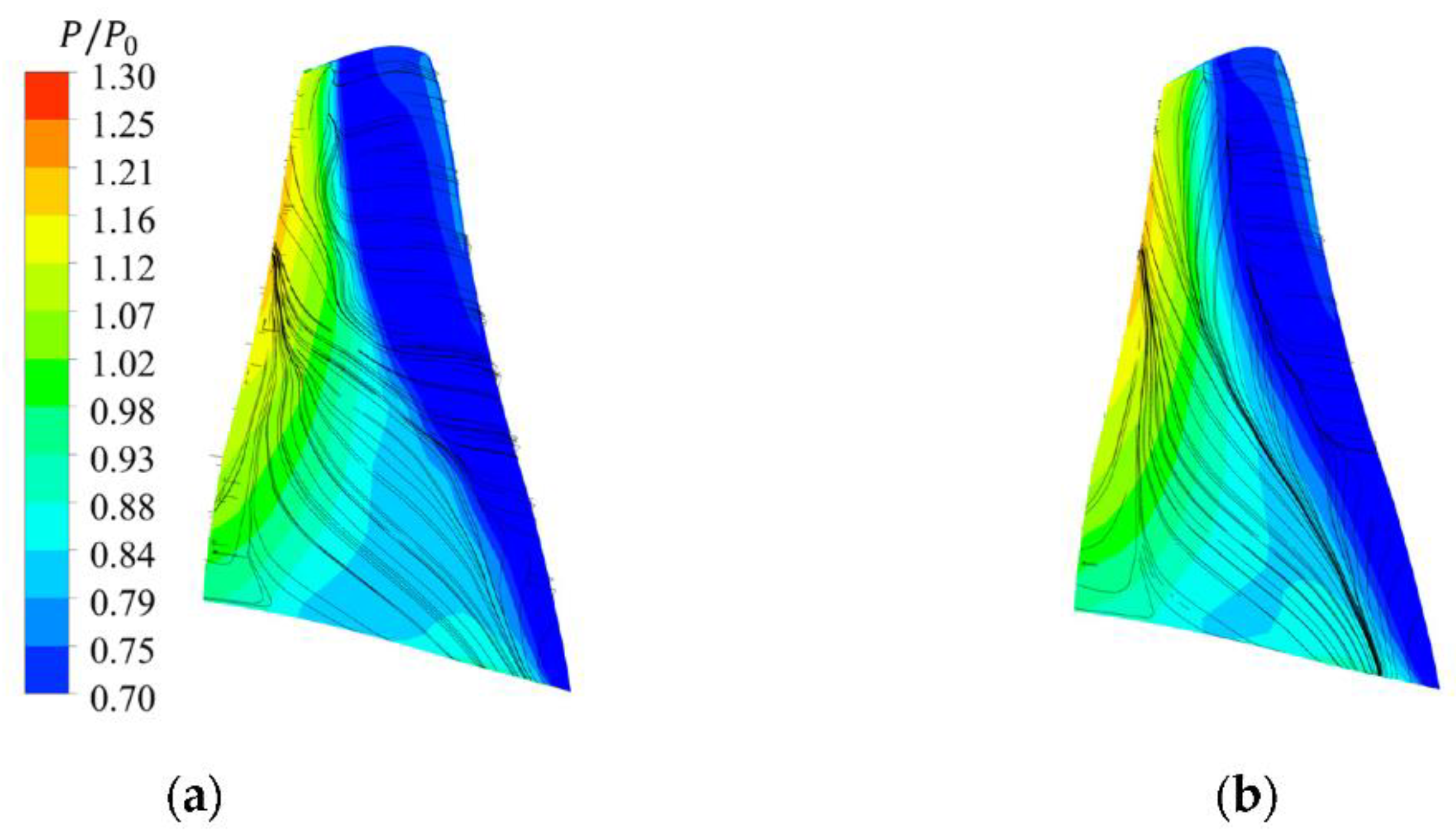

4.2. Loss Sources and Components under Coupling Condition

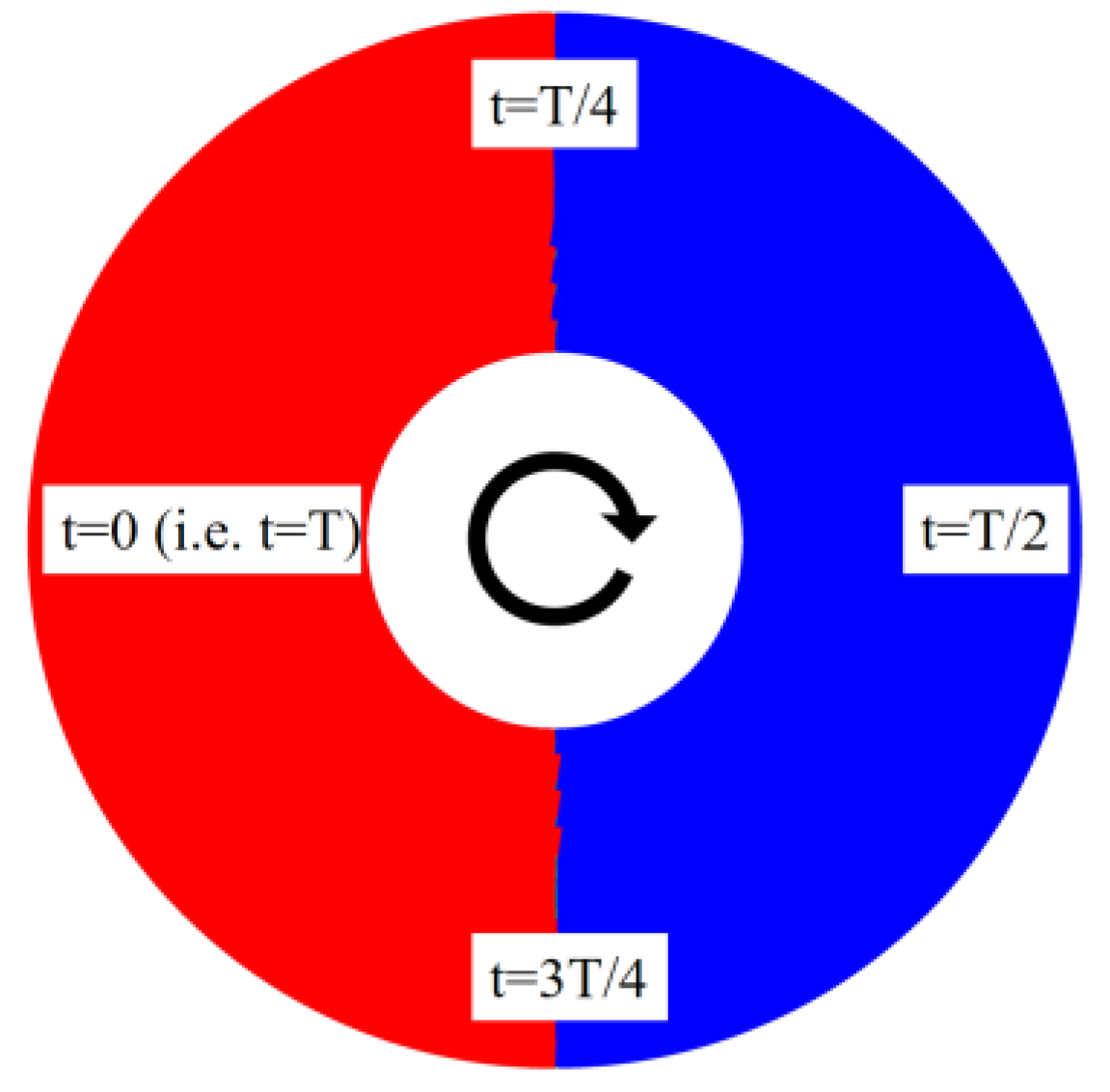

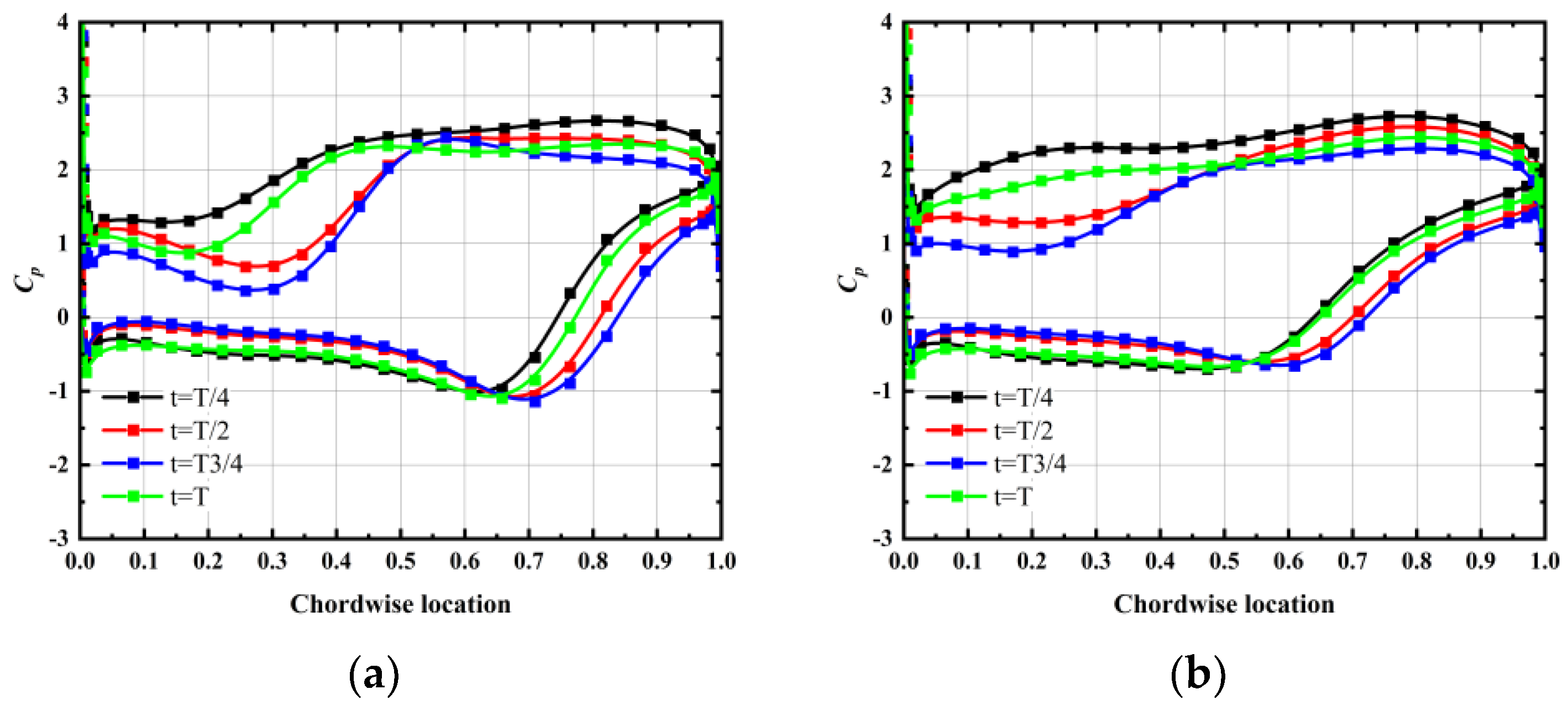

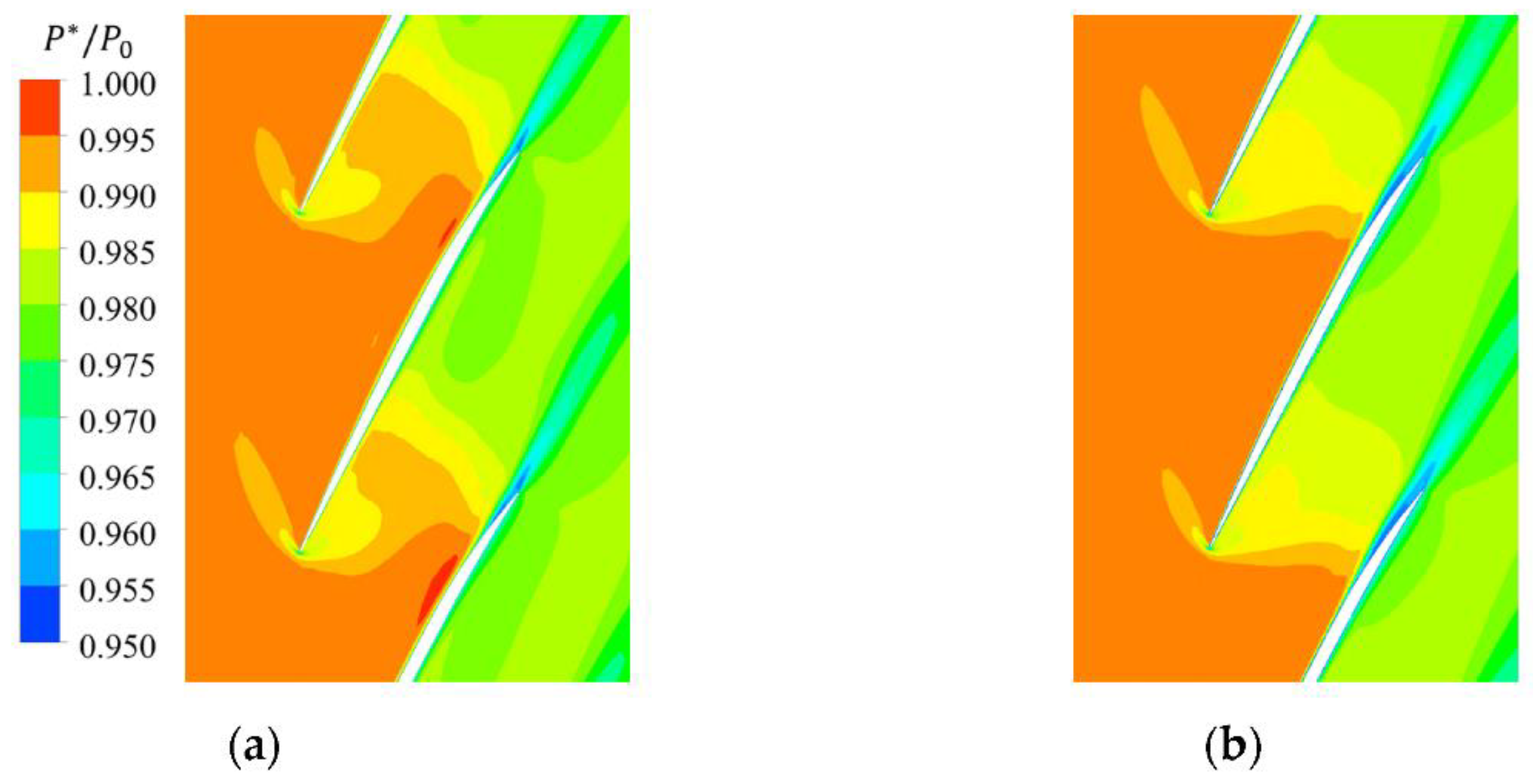

4.3. Time Evolution of Blade Loading Distribution

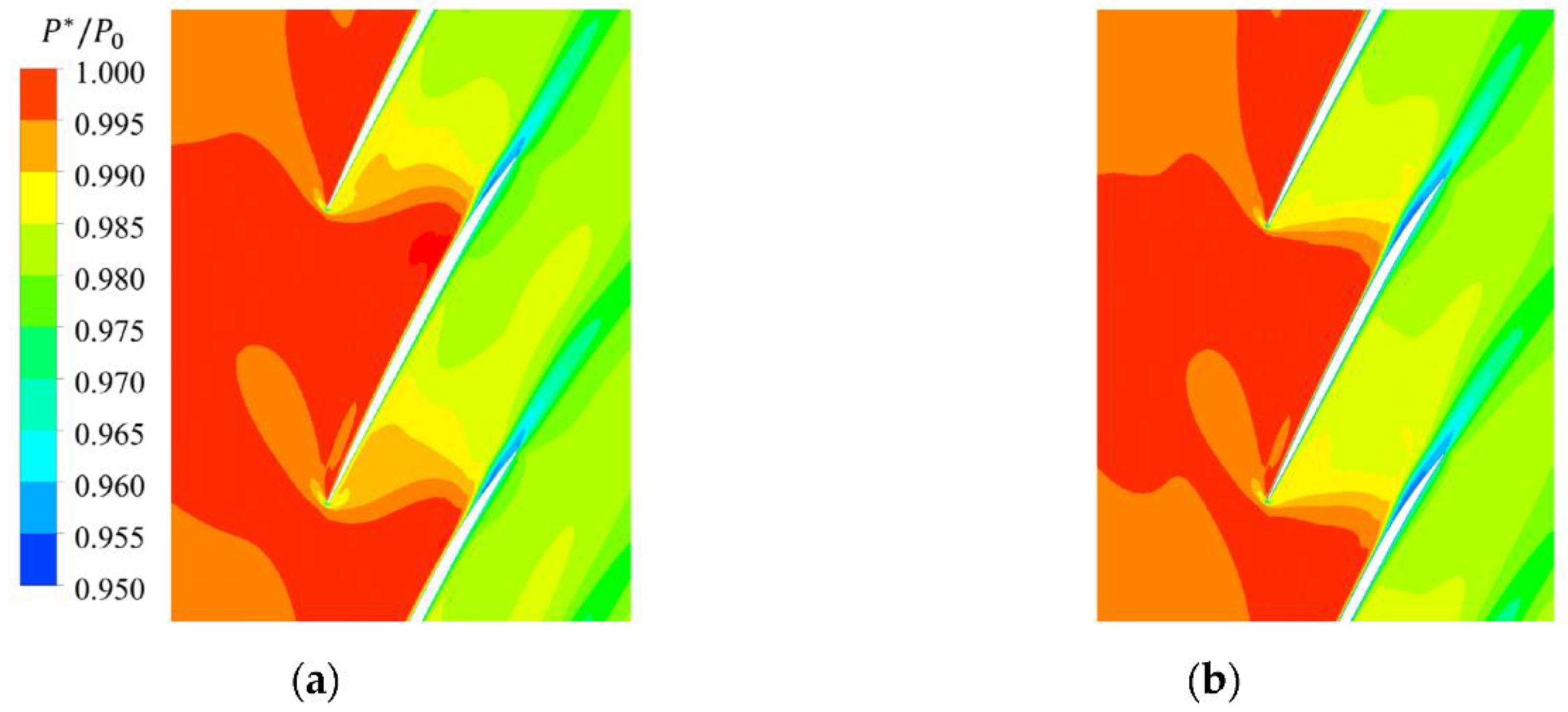

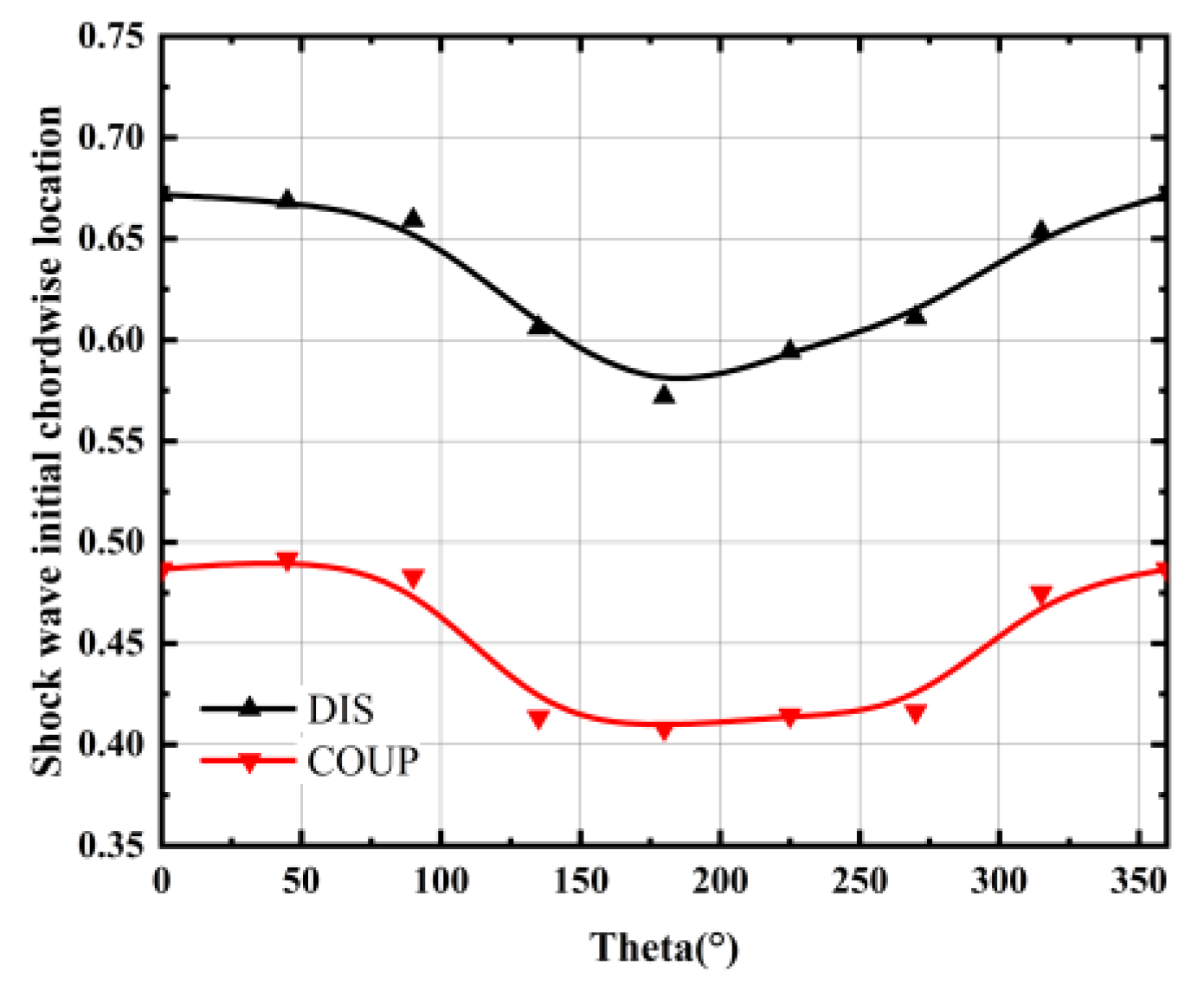

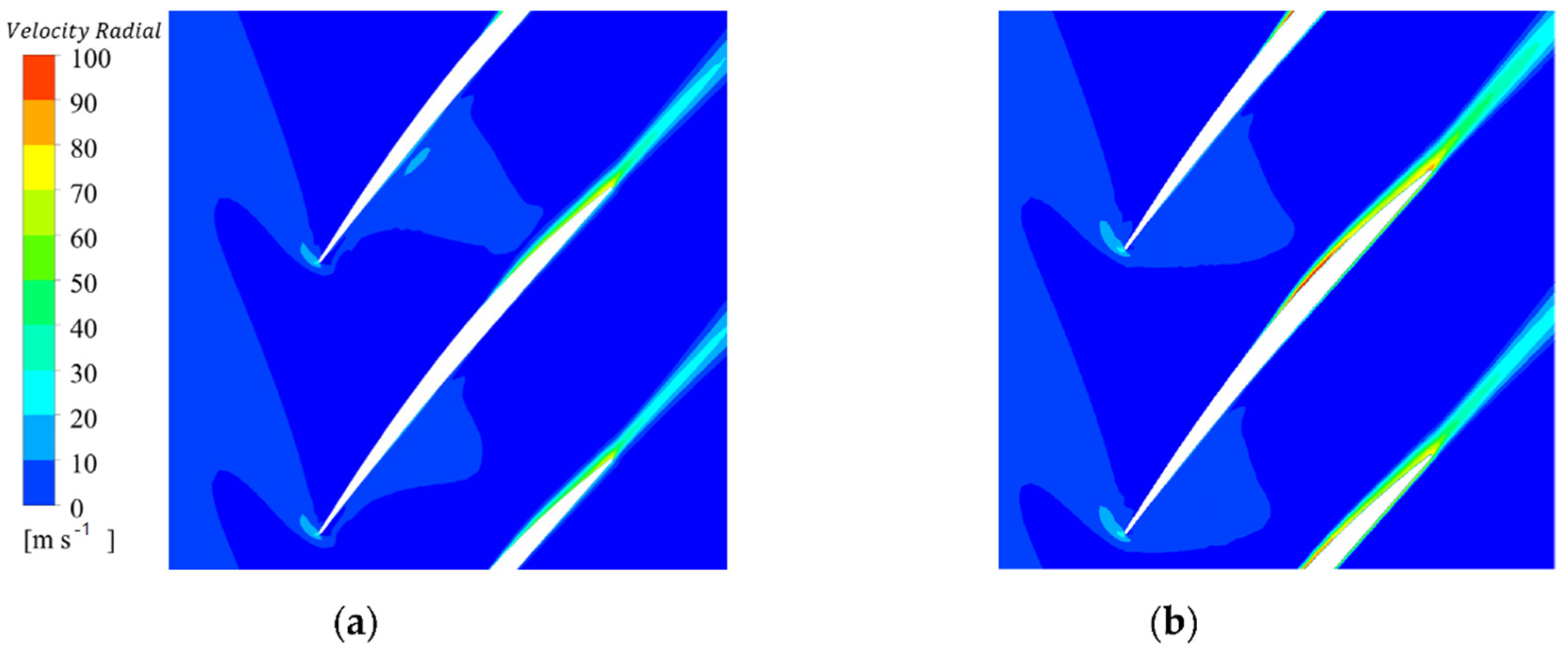

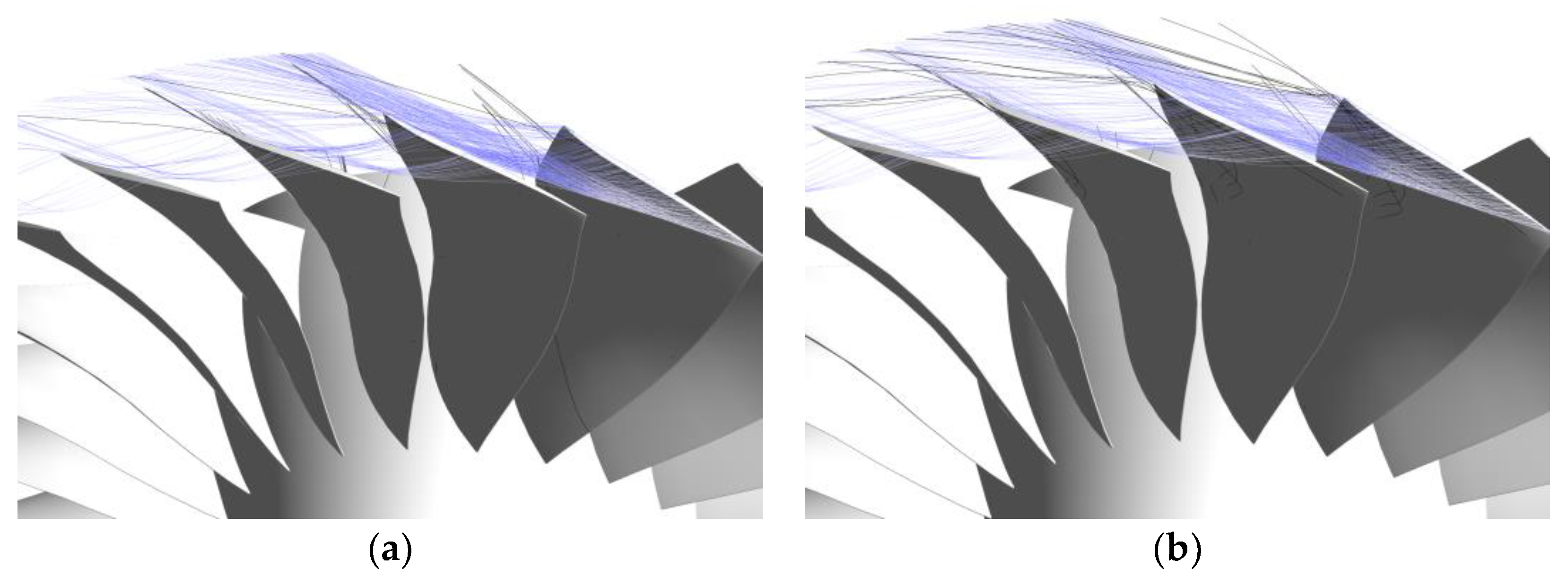

4.4. TLF Structure and Compressor Stability Boundary

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| additional loss | |

| chord length | |

| DI | distortion intensity |

| boundary layer form factor | |

| m | mass flow |

| momentum | |

| MAPE | mean absolute percentage error |

| total pressure | |

| static pressure | |

| axial momentum ratio of the TLF to main stream | |

| Reynolds number index | |

| entropy | |

| TLF | tip leakage flow |

| static temperature | |

| total temperature | |

| dynamic viscosity coefficient | |

| entropy loss coefficient | |

| total pressure loss coefficient | |

| profile loss | |

| shock loss | |

| boundary layer momentum thickness | |

| air angle measured from axial direction | |

| blade angle of attack | |

| Subscripts: | |

| a | axial direction |

| cor | corrected |

| clean | clean sector |

| COUP | coupling condition |

| dis | distortion sector |

| DIS | distortion condition |

| sea | sea level |

| Min | minimum |

References

- Ehrich, F. Circumferential Inlet Distortions in Axial Flow Turbomachinery. J. Aeronaut. Sci. 1957, 24, 413–417. [Google Scholar] [CrossRef]

- Seidel, B.S. Asymmetric Inlet Flow in Axial Turbomachines. J. Eng. Power 1964, 86, 18–28. [Google Scholar] [CrossRef]

- Greitzer, E.M. Upstream Attenuation and Quasi-Steady Rotor Lift Fluctuations in Asymmetric Flows in Axial Flow Compressors. In Proceedings of the ASME 1973 International Gas Turbine Conference and Products Show, Washington, DC, USA, 8–12 April 1973. [Google Scholar] [CrossRef] [Green Version]

- Biesiadny, T.J.; Braithwaite, W.M.; Soeder, R.H.; Abdelwahab, M. Summary of Investigations of Engine Response to Distorted Inlet Conditions. Available online: https://ntrs.nasa.gov/citations/19860016864 (accessed on 20 April 2022).

- Reid, C. The Response of Axial Flow Compressors to Intake Flow Distortion. In Proceedings of the ASME 1969 Gas Turbine Conference and Products Show, Cleveland, OH, USA, 9–13 March 1969. [Google Scholar]

- Longley, J.P. Measured and Predicted Effects of Inlet Distortion on Axial Compressors. In Proceedings of the ASME 1990 International Gas Turbine and Aeroengine Congress and Exposition, Brussels, Belgium, 11–14 June 1990. [Google Scholar]

- Longley, J.P.; Shin, H.W.; Plumley, R.E.; Silkowski, P.D.; Day, I.J.; Greitzer, E.M.; Tan, C.S.; Wisler, D.C. Effects of Rotating Inlet Distortion on Multistage Compressor Stability. J. Turbomach. 1996, 118, 181–188. [Google Scholar] [CrossRef]

- Gunn, E.J.; Tooze, S.E.; Hall, C.A.; Colin, Y. An Experimental Study of Loss Sources in a Fan Operating with Continuous Inlet Stagnation Pressure Distortion. J. Turbomach. 2013, 135, 051002. [Google Scholar] [CrossRef]

- Rademakers, R.P.M.; Bindl, S.; Niehuis, R. Effects of Flow Distortions as They Occur in S-Duct Inlets on the Performance and Stability of a Jet Engine. J. Eng. Gas Turbines Power 2016, 138, 022605. [Google Scholar] [CrossRef]

- Naseri, A.; Sammak, S.; Boroomand, M.; Alihosseini, A.; Tousi, A.M. Experimental Investigation of Inlet Distortion Effect on Performance of a Micro Gas Turbine. J. Eng. Gas Turbines Power 2018, 140, 092604. [Google Scholar] [CrossRef] [Green Version]

- Perovic, D.; Hall, C.A.; Gunn, E.J. Stall Inception in a Boundary Layer Ingesting Fan. J. Turbomach. 2019, 141, 091007. [Google Scholar] [CrossRef]

- Fidalgo, V.J.; Hall, C.A.; Colin, Y. A Study of Fan-Distortion Interaction within the NASA Rotor 67 Transonic Stage. J. Turbomach. 2012, 134, 051011. [Google Scholar] [CrossRef]

- Zhang, W.; Vahdati, M. Influence of the Inlet Distortion on Fan Stall Margin at Different Rotational Speeds. In Proceedings of the GPPS Conference, Shanghai, China, 30 October–1 November 2017. [Google Scholar]

- Zhang, W.; Stapelfeldt, S.; Vahdati, M. Influence of the Inlet Distortion on Fan Stall Margin at Different Rotational Speeds. Aerosp. Sci. Technol. 2020, 98, 105668. [Google Scholar] [CrossRef]

- Zhang, W.; Vahdati, M. A Parametric Study of the Effects of Inlet Distortion on Fan Aerodynamic Stability. J. Turbomach. 2019, 141, 011011. [Google Scholar] [CrossRef]

- Zhang, W.; Vahdati, M. Stall and Recovery Process of a Transonic Fan With and Without Inlet Distortion. J. Turbomach. 2019, 142, 011003. [Google Scholar] [CrossRef]

- Ma, Y.; Cui, J.; Vadlamani, N.R.; Tucker, P. A Mixed-Fidelity Numerical Study for Fan–Distortion Interaction. J. Turbomach. 2018, 140, 091003. [Google Scholar] [CrossRef] [Green Version]

- Wallner, L.E.; Lubick, R.J.; Chelko, L.J. Preliminary Results of the Determination of Inlet-Pressure Distortion Effects on Compressor Stall and Altitude Operating Limits of the J57-P-1 Turbojet Engine. Available online: https://ntrs.nasa.gov/citations/20090023603 (accessed on 20 April 2022).

- Cousins, W.T.; Dalton, K.K.; Andersen, T.T.; Bobula, G.A. Pressure and Temperature Distortion Testing of a Two-Stage Centrifugal Compressor. In Proceedings of the International Gas Turbine and Aeroengine Congress and Exposition, Cincinnati, OH, USA, 24–27 May 1993. [Google Scholar]

- Lee, K.; Lee, B.; Kang, S.; Yang, S.; Lee, D. Inlet Distortion Test with Gas Turbine Engine in the Altitude Engine Test Facility. In Proceedings of the 27th AIAA Aerodynamic Measurement Technology and Ground Testing Conference, Chicago, IL, USA, 28 June–1 July 2010. [Google Scholar] [CrossRef]

- Strazisar, A.J.; Wood, J.R.; Hathaway, M.D.; Suder, K.L. Laser Anemometer Measurements in a Transonic Axial-Flow Fan Rotor. J. Eng. Gas Turbines Power 1981, 103, 430–437. [Google Scholar] [CrossRef] [Green Version]

- Van Zante, D.E.; Podboy, G.G.; Miller, C.J.; Thorp, S.A. Testing and Performance Verification of a High Bypass Ratio Turbofan Rotor in an Internal Flow Component Test Facility. In Proceedings of the 27th AIAA Aerodynamic Measurement Technology and Ground Testing Conference, Chicago, IL, USA, 28 June–1 July 2010. [Google Scholar]

- Spotts, N. Unsteady Reynolds-Averaged Navier-Stokes Simulations of Inlet Flow Distortion in the Fan System of a Gas-Turbine Aero-Engine; Colorado State University: Fort Collins, CO, USA, 2015. [Google Scholar]

- Lake, J.; King, P.; Rivir, R. Reduction of Separation Losses on a Turbine Blade with Low Reynolds Numbers. In Proceedings of the 37th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 11–14 January 1999. [Google Scholar] [CrossRef]

- Bons, J.; Sondergaard, R.; Rivir, R. Control of Low-Pressure Turbine Separation Using Vortex Generator Jets. In Proceedings of the 37th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 11–14 January 1999. [Google Scholar]

- Huang, J.; Corke, T.C.; Thomas, F.O. Plasma Actuators for Separation Control of Low-Pressure Turbine Blades. AIAA J. 2006, 44, 51–57. [Google Scholar] [CrossRef]

- Yang, Z.; Lu, H.; Pan, T.; Li, Q. Numerical Investigation on the Influences of Boundary Layer Ingestion on Tip Leakage Flow Structures and Losses in a Transonic Axial-Flow Fan. J. Fluids Eng. 2021, 143, 111207. [Google Scholar] [CrossRef]

- Boyer, K.M.; O’Brien, W.F. An Improved Streamline Curvature Approach for Off-Design Analysis of Transonic Axial Compression Systems. J. Turbomach. 2003, 125, 475–481. [Google Scholar] [CrossRef]

- König, W.M.; Hennecke, D.K.; Fottner, L. Improved Blade Profile Loss and Deviation Angle Models for Advanced Transonic Compressor Bladings: Part I—A Model for Subsonic Flow. J. Turbomach 1996, 118, 73–80. [Google Scholar] [CrossRef]

- König, W.M.; Hennecke, D.K.; Fottner, L. Improved Blade Profile Loss and Deviation Angle Models for Advanced Transonic Compressor Bladings: Part II—A Model for Supersonic Flow. J. Turbomach 1996, 118, 81–87. [Google Scholar] [CrossRef]

- Koch, C.C.; Smith, L.H., Jr. Loss Sources and Magnitudes in Axial-Flow Compressors. J. Eng. Power 1976, 98, 411–424. [Google Scholar] [CrossRef]

- Bloch, G.S.; Copenhaver, W.W.; O’Brien, W.F. A Shock Loss Model for Supersonic Compressor Cascades. J. Turbomach. 1999, 121, 28–35. [Google Scholar] [CrossRef]

| Characteristic | Value |

|---|---|

| Number of blades | 22 |

| Design rotational speed (rpm) | 16,043 |

| Design mass flow rate (kg/s) | 33.25 |

| Design pressure ratio | 1.63 |

| Tip clearance (mm) | 1.006 |

| Inlet hub/tip radius ratio | 0.375 |

| Aspect ratio | 1.56 |

| Tip Mach Number | 1.38 |

| Cases | Total Pressure Ratio Loss (Relative Value) | Adiabatic Efficiency Loss (Absolute Value) |

|---|---|---|

| DI = 0.05 | −1.94% | −0.45% |

| DIS (RNI = 0.3) | −0.18% | −1.19% |

| COUP (DI = 0.05 & RNI = 0.3) | −1.95% | −1.83% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Zhu, X.; Yan, Z.; Pan, T. Numerical Investigation on the Performance of a Transonic Axial Compressor with Inlet Distortion and Low Reynolds Number. Energies 2022, 15, 3612. https://doi.org/10.3390/en15103612

Li Z, Zhu X, Yan Z, Pan T. Numerical Investigation on the Performance of a Transonic Axial Compressor with Inlet Distortion and Low Reynolds Number. Energies. 2022; 15(10):3612. https://doi.org/10.3390/en15103612

Chicago/Turabian StyleLi, Zhiping, Xingyu Zhu, Zhaoqi Yan, and Tianyu Pan. 2022. "Numerical Investigation on the Performance of a Transonic Axial Compressor with Inlet Distortion and Low Reynolds Number" Energies 15, no. 10: 3612. https://doi.org/10.3390/en15103612