Analysis of Technologies for Hydrogen Consumption, Transition and Storage at Operating Thermal Power Plants

Abstract

:1. Introduction

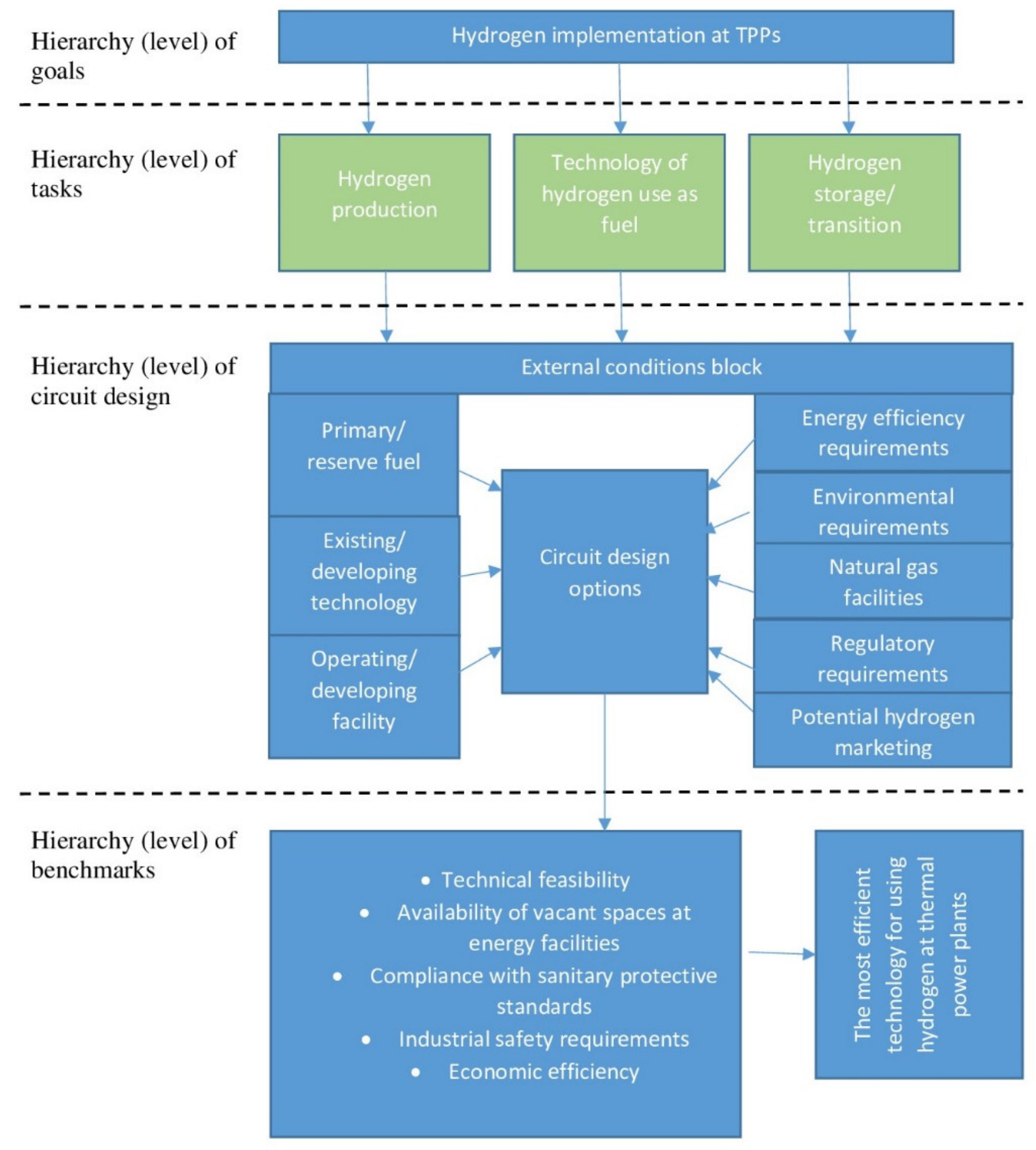

2. Materials and Methods

3. Results and Discussion

- The usage of hydrogen-containing fuel for gas turbine units (GTU), as well as steam and hot water boilers of various capacities.

- The usage of hydrogen to improve the efficiency of TPPs by means of hydrogen-oxygen steam generators and fuel cells.

3.1. The Usage of Hydrogen-Containing Fuel for Gas Turbine Units at Operating TPPs

- The flame temperature for hydrogen under adiabatic and stoichiometric conditions is almost 300 °C higher than for methane.

- The speed of the laminar flame of hydrogen is more than three times the speed of methane.

- The delay time of the spontaneous ignition of hydrogen is more than three times less than that of methane for a flame temperature of 1600 °C.

- Optimization of the combustion chamber design.

- Determination of the most effective composition of the fuel mixture.

- Solving the problem of acoustic pulsations that occur during the combustion of hydrogen fuel.

- Developing measures to minimize emissions of nitrogen oxides NOx.

- The reactivity of hydrogen by upgrading the combustion chamber (one of the possible ways is the use of remote combustion chambers).

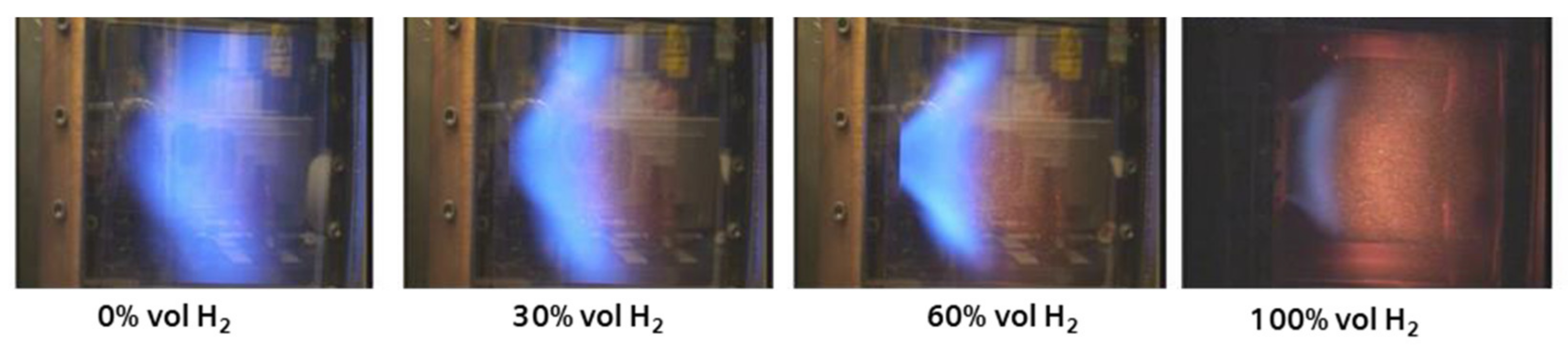

- A flame front (the flame is shorter than when burning natural gas) and flame instability, which leads to an uneven temperature field, is a problem which is poorly understood now and may require air cooling (see Figure 3).

- Hydrogen corrosion (it will be necessary to change not only the design of the combustion chambers, but also the use of other steels, materials, or coatings).

- An increase in the throughput and power of peripheral systems (such as fuel lines, booster units, control valves, etc.) due to the lower density of hydrogen.

3.2. The Usage of Hydrogen as a Boiler Fuel at Operating TPPs of Russia

- The number of changes in the boiler will depend on the boiler model, particularly on the type of burners installed in it (cases in which changes are not required are not excluded).

- The final decision on the proportion of hydrogen in the fuel should be made for each boiler model separately based on the results of the pilot combustion.

- Replacement or modernization of burner devices.

- Development of measures to prevent the possibility of flame spreading upstream, as well as the possibility of its spontaneous combustion.

- Creation of a system for preparing a mixture of hydrogen and natural gas before combustion, including a special system for monitoring the condition of equipment and gas pipelines, development of a mixing device.

- Manufacture of gas pipelines and shut-off valves from materials that avoid hydrogen embrittlement.

- Modernization of the automated control system.

- Increasing the flow sections of gas pipelines and fuel gas treatment system equipment (filters, shut-off valves, heat exchangers) in relation to the flow section of gas pipelines designed to run on natural gas.

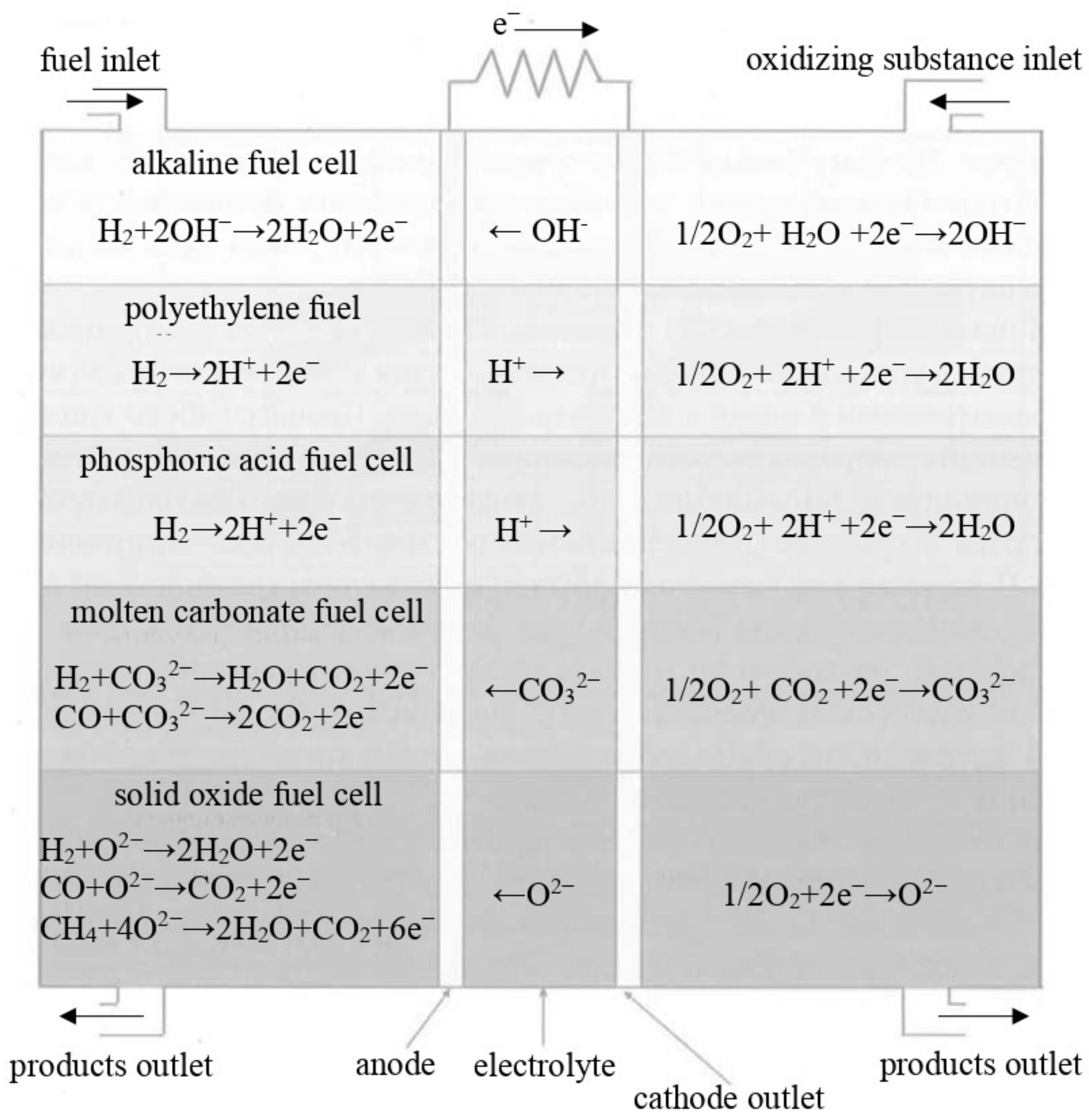

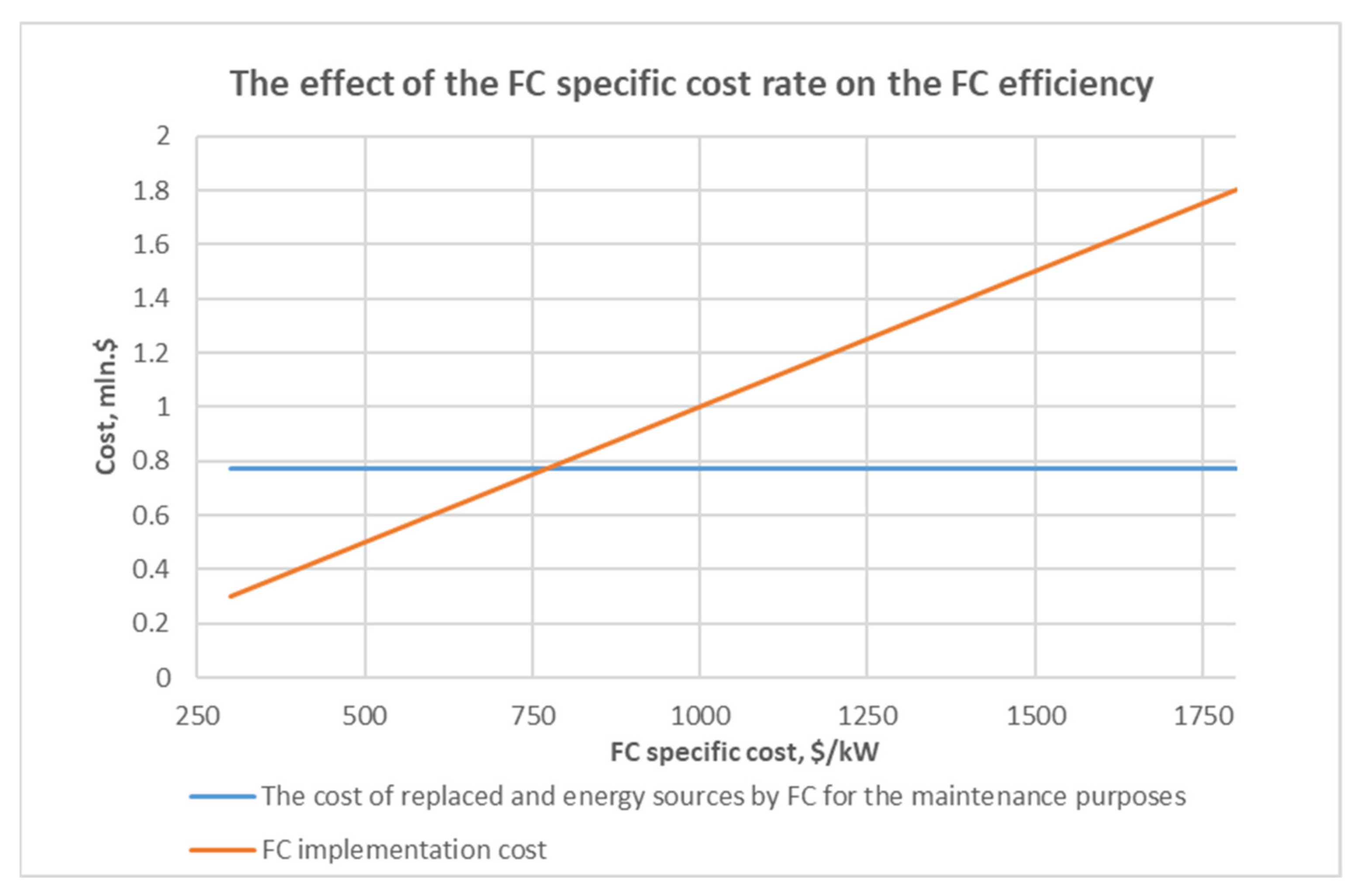

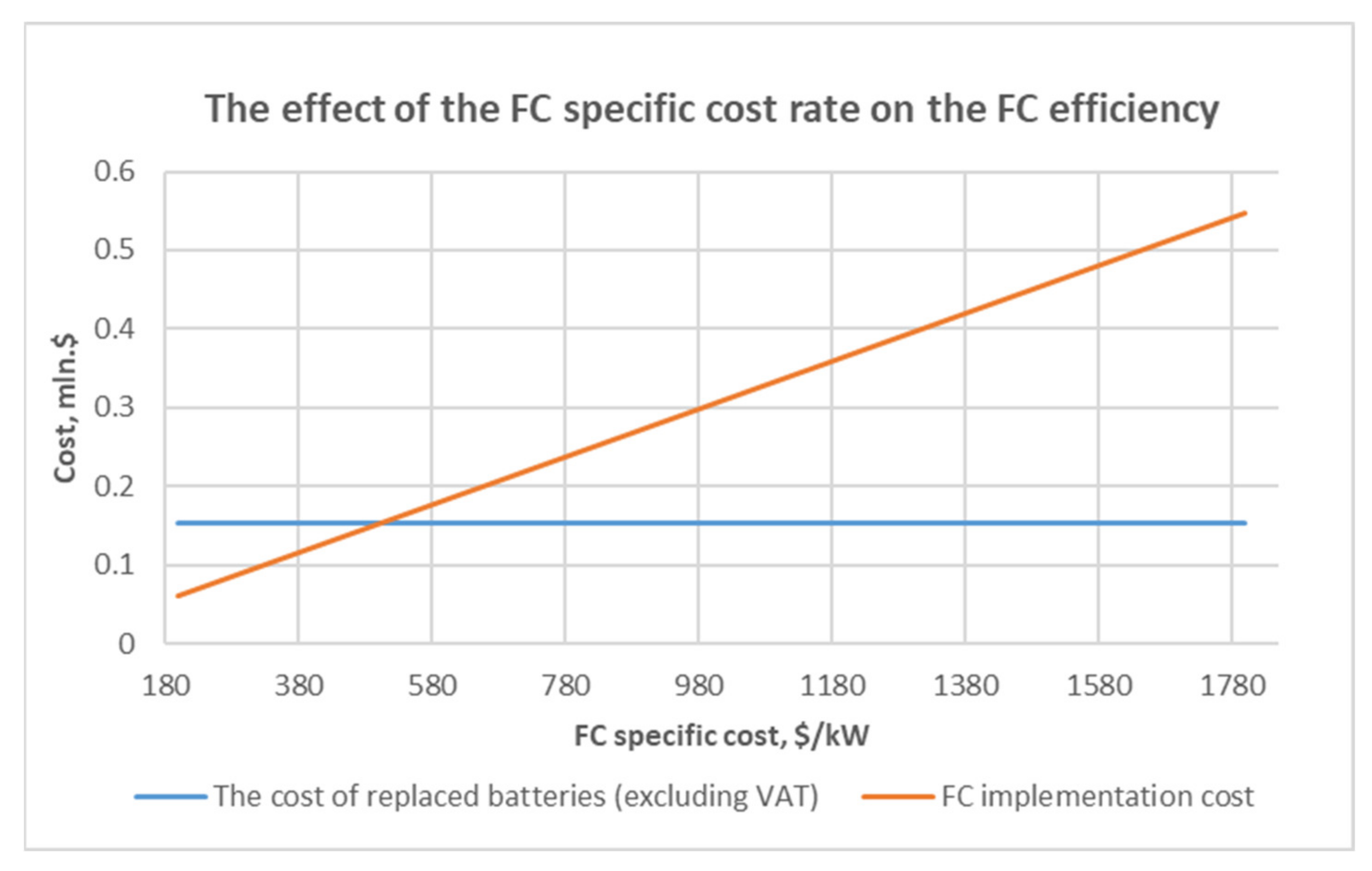

3.3. The Usage of Hydrogen as a Fuel in Fuel Cells at Operating TPPs of Russia

- Covering the economic needs of the station, the capacity of which correlates with the possible prospective serial capacity of the fuel and energy complex.

- 2.

- Replacement of TPP batteries by fuel cells.

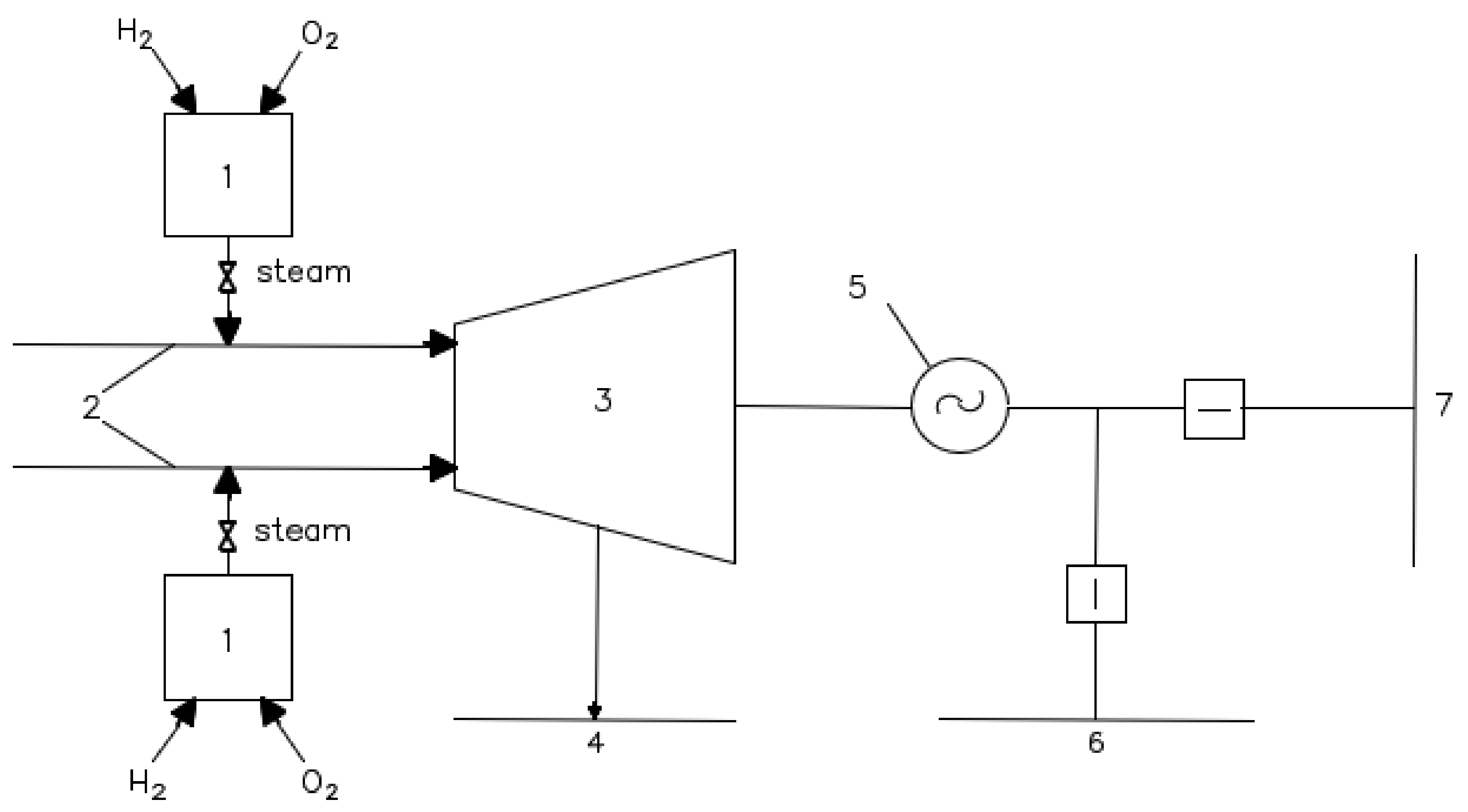

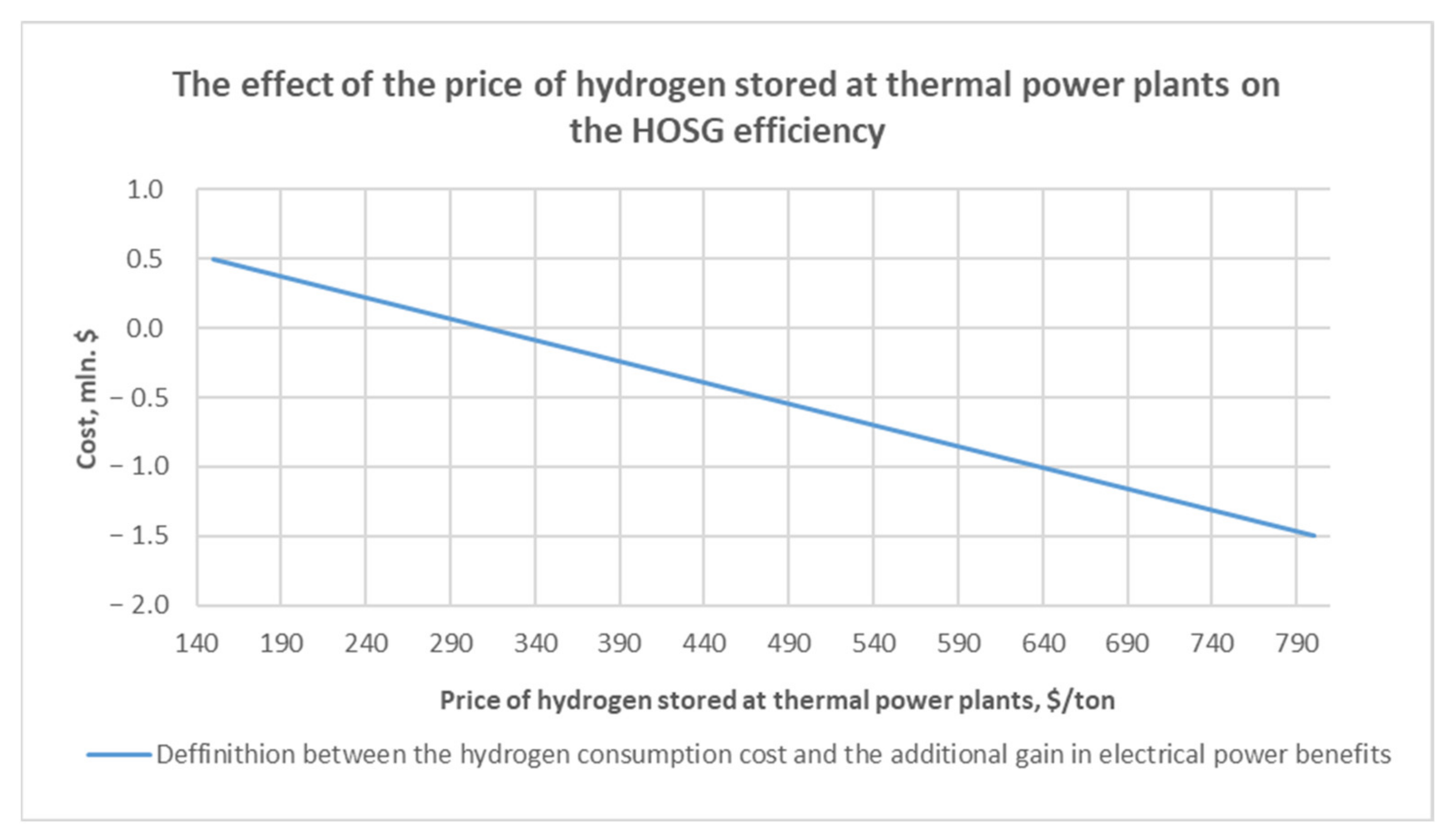

3.4. The Usage of Hydrogen as a Fuel in Hydrogen-Oxygen Steam Generators at Operating TPPs of Russia

- Additional accumulating superstructures to produce peak capacities. It is possible to modernize operating power plants, allowing fulfilling the power reserves of the operating equipment. Increasing the temperature of superheated steam by using the HOSG with the appropriate reconstruction of the central heating system of turbines, fittings, and sections of steam pipelines to work with higher operating temperatures.

- The use of hydrogen superstructures to increase the manoeuvrability and efficiency of the CCGT, as well as to increase the overall stability of power grids. An important property of the HOSG is a quick start with an output to the nominal mode in less than 10 s. Another important property for power control is the ease of obtaining the required temperature of the generated steam, which is determined by the amount of injected ballast water.

- Implementation of HOSG technology into existing schemes of thermal power plants with CCGT.

- 2.

- Implementation of the HOSG technology into the existing schemes of thermal power plants with a T-100 turbine and a T-250 turbine.

- 2.1.

- Replacement of a part of the steam generated by the boiler unit with the help of the HOSG. In this case, the generated electric power remains nominal and the steam capacity of the steam boiler decreases.

- 2.2.

- Superheating of the hot steam at the outlet of the boiler unit to the maximum currently possible temperature of 565 °C [60].

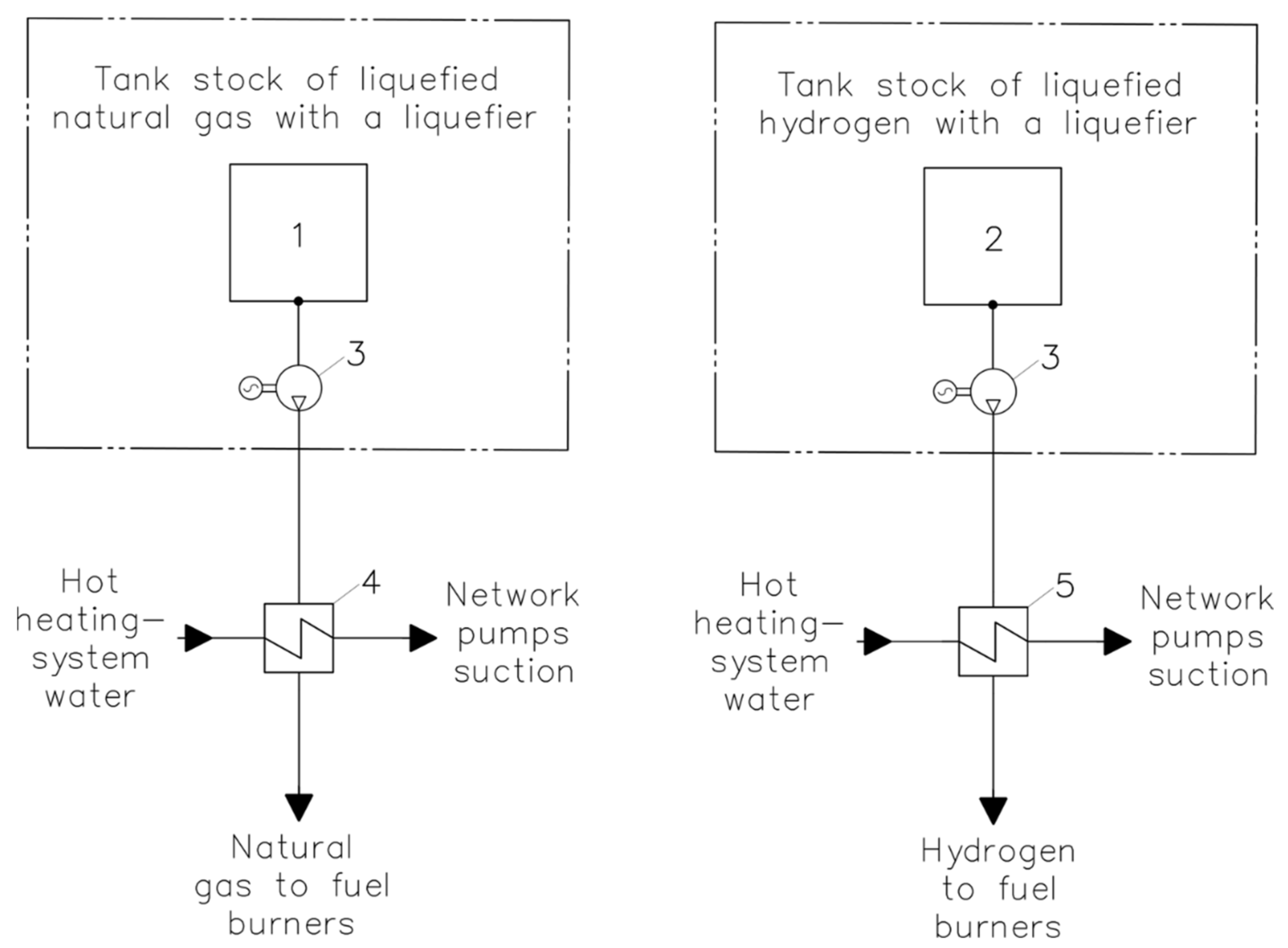

3.5. Hydrogen Storage at Operating TPPs of Russia

- Storage of compressed hydrogen gas in high-pressure tanks.

- Storage of liquid hydrogen.

- Storage of hydrogen gas at normal and elevated pressure in underground storage facilities.

- Storage of hydrogen in the form of various types of hydride carriers in microspheres in capillary structures, etc.

- The design of the tank must ensure its long-term safe operation.

- The consumption of liquid hydrogen for pre-cooling of the storage should be minimal.

- The tank must be equipped with devices for rapid filling and rapid delivery of the stored product.

- Hydrogen can be used on existing TPP equipment only in a mixture with gas fuel in volume concentrations up to 20%, but not in pure form.

- The use of hydrogen together with the existing reserve fuel of the CHP-fuel oil (fuel warehouses with a stock are available at site of facility) on the operating equipment is practically excluded.

- Cryogenic tanks.

- Liquefiers of steam cryogenic gases.

- Cryogenic pumps.

- Hydrogen and LNG regasification plants powered by mains water after mains pumps with the return of the heating medium to the return line.

- Pipeline strapping.

- LNG and hydrogen filling stations.

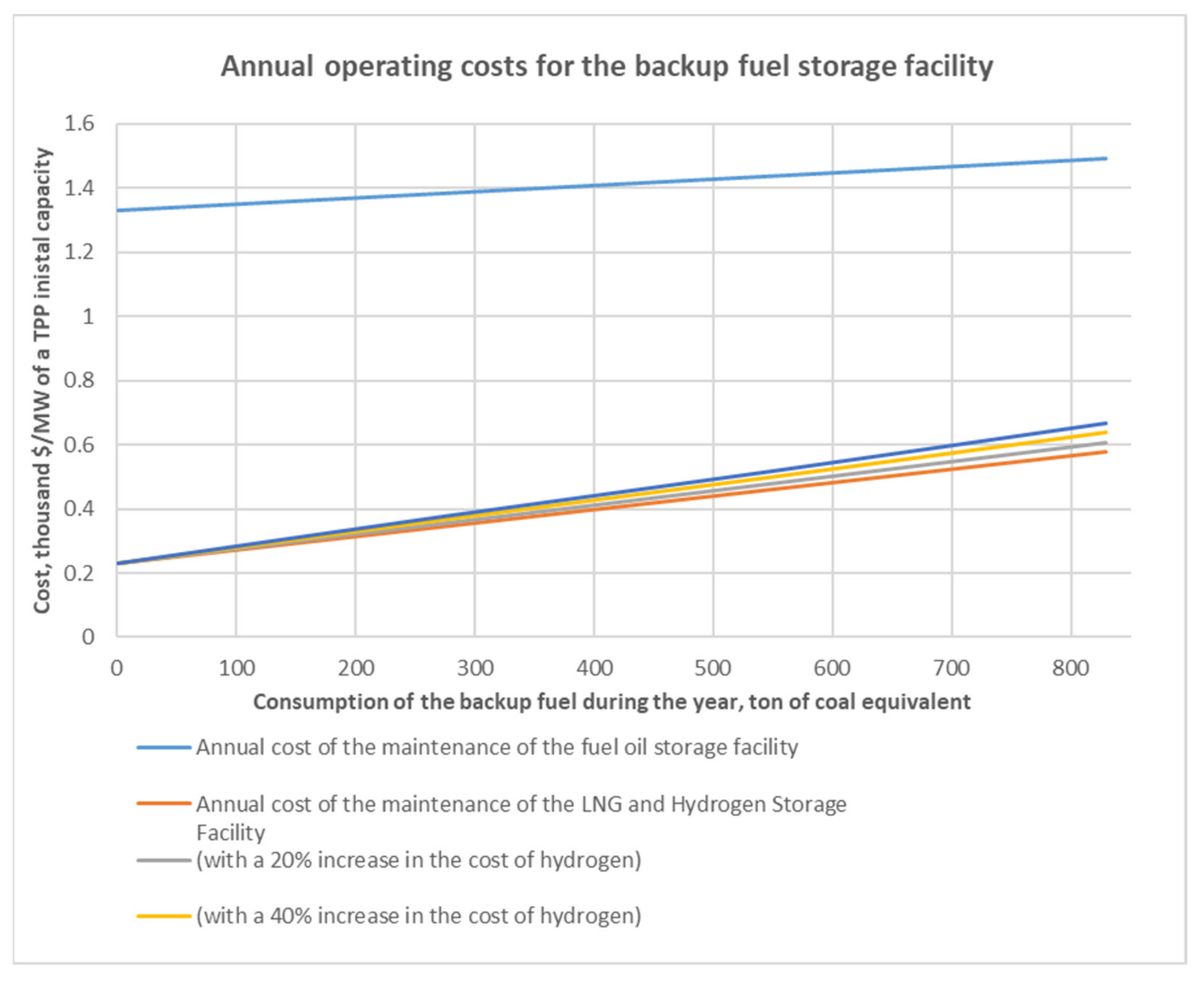

- Saving on maintenance steam of the oil fuel facility.

- Savings on steam satellites of fuel oil pipelines and on steam cooling of fuel oil injectors.

- Saving on electricity for the drive of recirculation pumps and main fuel oil feed pumps.

- Saving steam for heating fuel oil to operating temperature.

- Saving on a couple of own needs of the electrolyze unit.

- The expenses for the management of LNG and liquefied hydrogen consist of the cost of spent fuel per year, the cost of electricity for liquefaction of steam cryogenic gases, the cost of heat for regasification when using reserve fuel.

- Electricity costs for liquefaction of steam cryogenic gases.

- Heat costs for regasification when using reserve fuel (hot water).

3.6. Specifics of Hydrogen Transportation via Gas Pipelines

4. Conclusions

- Feasible. For implementing decarbonization and hydrogen energy strategies, as well as the compliance of the Russian Federation with the global decarbonization trend, it is possible to implement projects on testing the use of hydrogen as a fuel at operating TPPs.

- Mix with natural gas. For the implementation of the goals of the first stage of the hydrogen strategy implementation at operating gas fired TPPs, it is advisable to consider the technology of burning a mixture of hydrogen and natural gas in gas turbines and gas-oil steam boilers in volume fractions of 20% and 80%, respectively. This ratio can be burned in existing installations with minimal structural changes to the main boiler and gas turbine equipment without replacing it. In the future, after solving several problems, it is possible to create both a gas turbine and steam and hot water boilers that completely burn 100% hydrogen and the use of this equipment.

- Convert non-gas-fired TPPs. In the case of non-gas-fired thermal power plants, it is advisable to consider transferring them to the combustion of hydrogen and natural gas, with the creation of a gas transmission system of hydrogen and natural gas, in shares of 20% and 80%, respectively. The storage site of liquefied natural gas and hydrogen can be located either at the thermal power plant itself, or at the sites of LNG and hydrogen transhipment terminals (if there is a prospect of creating such transit ports). A mixture of hydrogen and natural gas can be used to transfer existing power equipment of thermal power plants, especially those operating on fuel oil, to more environmentally friendly fuel. When this is the situation, with a relatively close location of the TPP site, it is possible to refuse to store fuel directly at the power plant. The positive economic effect of the implementation of the use of hydrogen is possible due to savings in the cost of storing and using the main and reserve fuel. At the same time, the conversion of solid fuel boilers to hydrogen gas fuel in terms of structural changes is closer to the complete replacement of boiler units, an order of magnitude higher than the cost of replacing burner devices, and it seems impractical within the first stage of decarbonization of power engineering.

- Hydrogen storage options. The option of storing hydrogen gas as both the main and reserve fuel at this stage of technology development, in view of the required area of the tank farm exceeding the available areas of any of the operating TPP sites, is not applicable. Hydrogen storage systems in the form of various types of carriers (metal hydrides, borohydrides, and amides) are difficult to adapt in the conditions of thermal power plants due to their low capacity. It is possible to use it in the future after increasing the unit energy intensity of the equipment and reducing the cost. Storage of hydrogen gas at normal and elevated pressure in underground storage facilities requires several studies and testing. It is possible in the conditions of new industrial construction with the proper development of technology. Currently, the usage of these technologies is not recommended due to the limited time frame of implementation within the first stage of the implementation of the hydrogen strategy.

- Warehouses of liquefied hydrogen and LNG. Considering the limited territorial capabilities of the sites of operating thermal power plants for the implementation of the goals of the first stage of the implementation of the hydrogen strategy, the only practical solution for using hydrogen as a backup fuel is to create warehouses of liquefied hydrogen and LNG in the necessary calculated quantities for the subsequent use of their mixture as a backup energy fuel. It is estimated that the specific economic effect of the event on the transition to storage of cryogenic fuel instead of fuel oil storage is from $485 to $727 per MW of installed capacity of thermal power plants.

- Hydrogen as a main fuel. It is impossible to use hydrogen as the main fuel in the conditions of operating thermal power plants, as it is not practicable to place a tank farm at the available sites of any of the operating thermal power plants. In the case of the prospective development of the MHM gas transmission system and the organization of the MHM supply to the TPP site by two independent gas pipelines, hydrogen storage at the station will not be required–the restriction on the use of MHM as the main fuel will be lifted. It is recommended to consider the possibility of replacing the economy of reserve liquid fuel (fuel oil) with the technology of storage of reduced hydrogen in combination with natural gas (which is also stored in liquefied form and is a backup), or the creation of a gas transmission network with a fraction of hydrogen.

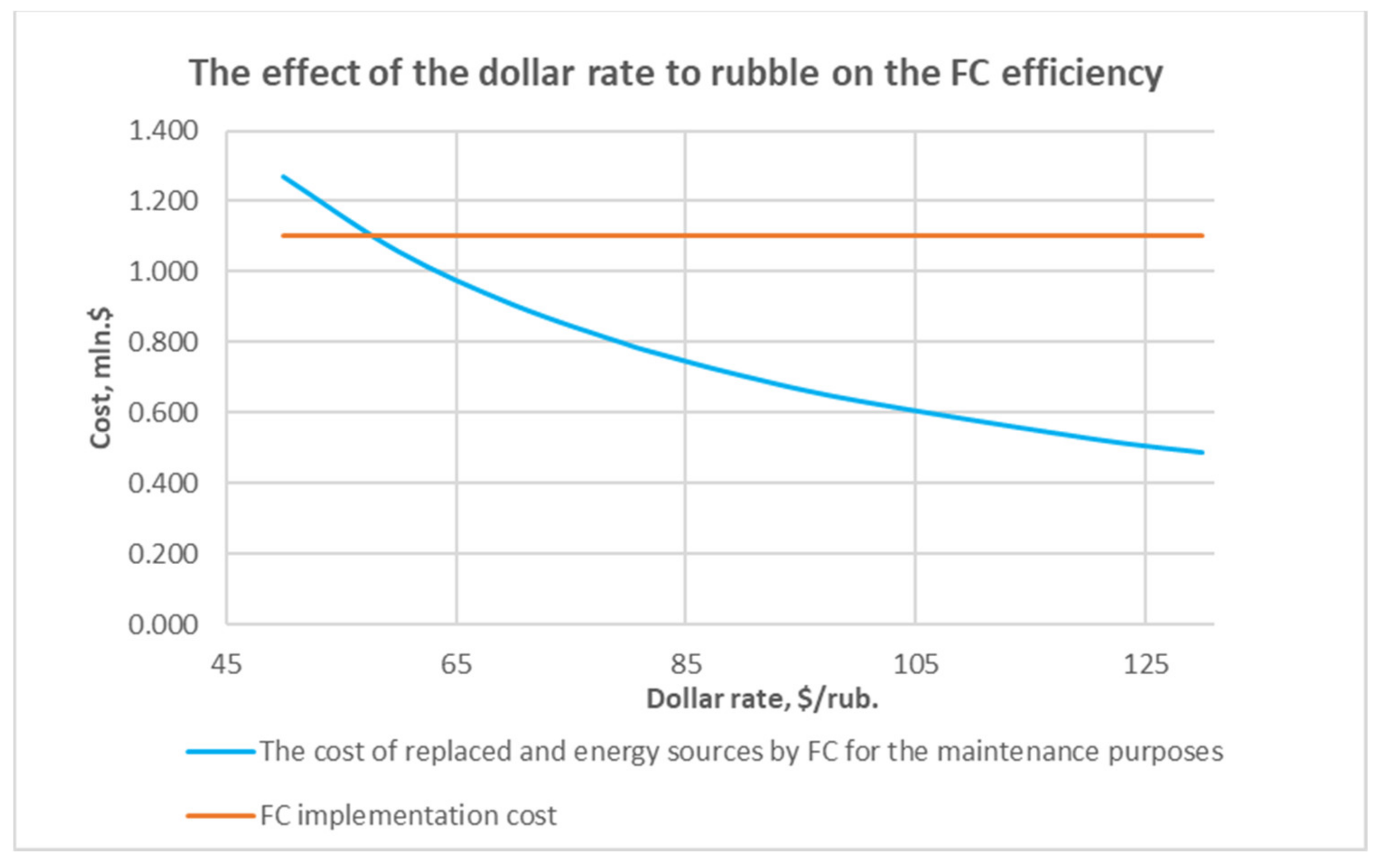

- Fuel cells. Fuel cells are currently not applicable to operating thermal power plants due to low unit capacity and short FC lifetime duration. The limiting factor is also the high cost of the device (the unit cost, according to the research results, should be lower than 500–750 $/kW), and the lack of large-scale technologies. In the future, they can be used as sources of autonomous and, possibly, backup power supply after increasing the unit energy intensity of the equipment and reducing the cost, since now there is no economic effect within the first stage of the implementation of the hydrogen strategy.

- HOSG technology. The implementation of the HOSG technology into operating thermal power plant schemes of a similar afterburning technology would lead to a decrease in the efficiency of the cycle. An increase in the steam temperature in front of steam turbines by means of the HOSG for operating steam power units is limited due to restrictions on the maximum temperature of steam pipelines. In addition, the HOSG on steam power units is similar to the conversion of boilers to hydrogen in terms of fuel consumption. This will also require the creation of an infrastructure for the storage and delivery of hydrogen as the main fuel, which in the conditions of the existing facility can be provided only with the appearance of a gas transmission system of the Ministry of Internal Affairs. Moreover, the existing HOSG technology is small-scale. The technology is promising, requires several studies and is not recommended for implementation at the first stage of the first hydrogen strategy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- The Rio Declaration on Environment and Development. Available online: https://www.un.org/ru/documents/decl_conv/declarations/riodecl.shtml (accessed on 12 September 2021).

- The United Nations Framework Convention on Climate Change (UNFCCC). Available online: https://www.un.org/ru/documents/decl_conv/conventions/climate_framework_conv.shtml (accessed on 12 September 2021).

- The Kyoto Protocol. Available online: https://www.un.org/ru/documents/decl_conv/conventions/kyoto.shtml (accessed on 12 September 2021).

- The Paris Agreement. Available online: https://unfccc.int/files/meetings/paris_nov_2015/application/pdf/paris_agreement_russian_pdf (accessed on 12 September 2021).

- A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 12 September 2021).

- EU Strategy on Energy System Integration. Available online: https://ec.europa.eu/energy/topics/energy-system-integration/eu-strategy-energy-system-integration_en (accessed on 19 September 2021).

- European Clean Hydrogen Alliance. Available online: https://ec.europa.eu/growth/industry/strategy/industrial-alliances/european-clean-hydrogen-alliance_en (accessed on 11 September 2021).

- Russian Federal Law, No. 296 on Limiting Greenhouse Gas Emissions. Available online: http://publication.pravo.gov.ru/Document/View/0001202107020031 (accessed on 12 September 2021).

- Decree of the Government of the Russian Federation No. 3052-r Dated 29 October 2021. On the Approval of the Strategy of Socio-Economic Development of the Russian Federation with Low Greenhouse Gas Emissions until 2050. Available online: https://rospatent.gov.ru/ru/documents/rasporyazhenie-3052-r-29102021 (accessed on 1 February 2022).

- Yulkin, M.A. Global Decarbonization and Its Impact on the Russian Economy. ANO “Environmental Investment Center”. Available online: http://downloads.igce.ru/news/Yulkin_M_A_ext_abstract_IGCE_06022019.pdf (accessed on 10 September 2021).

- Decree of the President of the Russian Federation No. 208 dated 13 May 2017. On the Approval of the Economic Security Strategy of the Russian Federation for the Period up to 2030. Available online: http://www.kremlin.ru/acts/bank/41921 (accessed on 12 September 2021).

- Decree of the Government of the Russian Federation No. 1523-r of 9 June 2020. On the Approval of the Energy Strategy of the Russian Federation for the Period up to 2035. Available online: https://docs.cntd.ru/document/565068231 (accessed on 12 September 2021).

- Decree of the President of the Russian Federation No. 176 dated 19 April 2017. On the Strategy of Environmental Safety of the Russian Federation for the Period up to 2025. Available online: http://government.ru/docs/all/111285/ (accessed on 15 October 2021).

- Decree of the Government of the Russian Federation No. 2162-r of 5 August 2021. On Approval of the Concept of Development of Hydrogen Energy in the Russian Federation. Available online: http://government.ru/docs/42971/ (accessed on 15 October 2021).

- Sinyak, Y.V. Prospects for the use of hydrogen in decentralized power and heat supply systems. Stud. Russ. Econ. Dev. 2007, 18, 264–275. [Google Scholar] [CrossRef]

- Report on the State of Heat Power and District Heating in the Russian Federation in 2019. Available online: https://minenergo.gov.ru/node/20641 (accessed on 1 February 2021).

- Balasubramanian, B.; Ortiz, A.L.; Kaytakoglu, S.; Harrison, D.P. Hydrogen from methane in a single-step process. Chem. Eng. Sci. 1999, 54, 3543–3552. [Google Scholar] [CrossRef]

- Abbas, H.F.; Wan Daud, W.M.A. Hydrogen production by methane decomposition: A review. Int. J. Hydrogen Energy 2010, 35, 1160–1190. [Google Scholar] [CrossRef]

- Romano, M.C.; Cassotti, E.N.; Chiesa, P.; Meyer, J.; Mastin, J. Application of the Sorption Enhanced-Steam Reforming process in combined cycle-based power plants. Energy Procedia 2011, 4, 1125–1132. [Google Scholar] [CrossRef] [Green Version]

- Carapellucci, R.; Giordano, L. Upgrading existing gas-steam combined cycle power plants through steam injection and methane steam reforming. Energy 2019, 173, 229–243. [Google Scholar] [CrossRef]

- Navarro, R.M.; Peña, M.A.; Fierro, J.L.G. Hydrogen production reactions from carbon feedstocks: Fossil fuels and biomass. Chem. Rev. 2007, 107, 3952–3991. [Google Scholar] [CrossRef]

- He, M.; Hu, Z.; Xiao, B.; Li, J.; Guo, X.; Luo, S.; Liu, S. Hydrogen-rich gas from catalytic steam gasification of municipal solid waste (MSW): Influence of catalyst and temperature on yield and product composition. Int. J. Hydrogen Energy 2009, 34, 195–203. [Google Scholar] [CrossRef]

- Janajreh, I.; Raza, S.S.; Valmundsson, A.S. Plasma gasification process: Modeling, simulation and comparison with conventional air gasification. Energy Convers. Manag. 2013, 65, 801–809. [Google Scholar] [CrossRef]

- Holladay, J.D.; Hu, J.; King, D.L.; Wang, Y. An overview of hydrogen production technologies. Catal. Today 2009, 139, 244–260. [Google Scholar] [CrossRef]

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrogen Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Aminov, R.Z.; Bairamov, A.N. System efficiency of hydrogen cycles on the basis of the off-peak electric power of atomic power station. Energy 2011, 4, 52–61. (In Russian) [Google Scholar]

- Aminov, R.Z.; Egorov, A.N. Assessment of the thermodynamic efficiency of hydrogen cycles at wet-steam NPP. Therm. Power Eng. 2013, 4, 27. (In Russian) [Google Scholar] [CrossRef]

- Kolbantsev, Y.A.; Konjushin, M.V.; Kalyutik, A.A. The usage of probabilistic assessment for cost calculations of using NPP with hydrogen industrial production. Power Eng. Res. Equip. Technol. 2021, 23, 14–26. [Google Scholar] [CrossRef]

- Hori, M. Hydrogen production using nuclear energy. J. Atoms. Energy Soc. Jpn. 2001, 43, 30. [Google Scholar]

- Bolfo, L.; Devia, F.; Lomonaco, G. Nuclear Hydrogen Production: Modeling and Preliminary Optimization of a Helical Tube Heat Exchanger. Energies 2021, 14, 3113. [Google Scholar] [CrossRef]

- International Atomic Energy Agency. Current Status and Future Development of Modular High Temperature Gas Cooled Reactor Technology; IAEA: Vienna, Austria, 2001. [Google Scholar]

- Ponomarev-Stepnoy, N.N.; Alekseev, S.V.; Petrunin, V.V.; Zhang, Z. Nuclear power engineering complex with high-temperature gas-cooled reactors for large-scale environmentally friendly production of hydrogen from water and natural gas. Gas Ind. 2018, 11, 94–102. (In Russian) [Google Scholar]

- Krylov, O.V. Industrial methods for obtaining hydrogen. Catal. Ind. 2007, 2, 13–29. (In Russian) [Google Scholar]

- Cerullo, N.; Lomonaco, G. Corrosion Issues in High Temperature Gas-Cooled Reactor (HTR) Systems; Elsevier: Amsterdam, The Netherlands, 2012; pp. 731–772. [Google Scholar]

- Sultanov, M.M.; Kuryanova, E.V. Technical and economic assessment of the parameters of thermal schemes of thermal power plants with a hydrogen generator. Power Eng. Res. Equip. Technol. 2021, 23, 84–92. (In Russian) [Google Scholar] [CrossRef]

- Nozdrenko, G.V.; Shchinnikov, P.A.; Borush, O.V.; Grigoryeva, O.K.; Kuzmin, A.G. Combined production of electricity, heat, synthesis gas and hydrogen from coal. Energy Saf. Energy Sav. 2011, 1, 18–23. [Google Scholar]

- Filimonova, A.A.; Chichirov, A.A.; Chichirova, N.D.; Filimonov, A.G.; Pechenkin, A.V. Prospects for the development of hydrogen power engineering in Tatarstan. Power Eng. Res. Equip. Technol. 2020, 22, 79–91. [Google Scholar] [CrossRef]

- Rybako, B.A.; Burov, V.D. Burning of hydrogen-containing gas in GTU and PSU. New Russ. Electr. Power Ind. 2021, 10, 30–41. [Google Scholar]

- Savchenko, M.A.; Rybakov, B.A. The Use of Hydrogen in Power Engineering: Environmental Issues. Turbines and Diesels. 2021. January–February. 10–16. Available online: http://www.turbine-diesel.ru/sites/default/files/n1-2021/H.pdf (accessed on 22 January 2022).

- Official Website of Mitsubishi Power. Available online: https://power.mhi.com (accessed on 18 December 2021).

- Official Website of General Electrics. Available online: https://www.ge.com (accessed on 18 December 2021).

- Official Website of Ansaldo Energia. Available online: https://www.ansaldoenergia.com (accessed on 18 December 2021).

- Official Website of Siemens. Available online: https://www.siemens.com (accessed on 18 December 2021).

- Pasquariello, R. Gas Turbine Innovation, with or without Hydrogen. Turbomachinery Magazine. Available online: https://www.turbomachinerymag.com/view/gas-turbine-innovation-with-or-without-hydrogen (accessed on 21 November 2021).

- Official Website of JSC “UEC-Gas Turbines”. Available online: http://odk-gt.ru (accessed on 19 November 2021).

- Official Website of PJSC “Power Machines”. Available online: https://power-m.ru (accessed on 19 November 2021).

- Taimarov, M.A.; Akhmetova, R.V.; Chiklyaev, E.G.; Sungatullin, R.G. Indicators of operating parameters of TGM-84B boilers during combustion of methane-hydrogen fraction in them. Bull. Mater. Sci. Eng. 2017, 1, 58–63. [Google Scholar]

- Official Website of LLC “Belenergomash-BZEM”. Available online: http://www.energomash.ru (accessed on 12 October 2021).

- Official Website of PJSC “Taganrog Boiler-Building Plant Krasny Kotelshchik”. Available online: https://tkz.su (accessed on 12 October 2021).

- Official Website of Sibenergomash-BKZ LLC. Available online: http://www.sibem-bkz.com (accessed on 12 October 2021).

- Official Website of Interenergo LLC. Available online: https://www.interenergo.info (accessed on 12 October 2021).

- Savitenko, M.A.; Rybakov, B.A. Burning of Hydrogen-Containing Gas in Hydrogen and Steam Boilers of ANO “Center for Research and Scientific Developments in the Field of Energy” “Hydrogen Technological Solutions”. Available online: https://ww-h2.com/services/combustion-of-hydrogen-containing-gas-in-hydrogen-and-steam-boilers (accessed on 19 November 2021).

- Kozlov, S.I.; Fateev, V.N. Hydrogen Power Engineering: Current State, Problems, Prospects; Gazprom VNIIGAZ: Moscow, Russia, 2009; p. 518. [Google Scholar]

- Gardner, F.J.; Day, M.J.; Brandon, N.P.; Pashley, M.N.; Cassidy, M. SOFC technology development at Rolls-Royce. J. Power Sources 2000, 86, 122–129. [Google Scholar] [CrossRef]

- Singhal, S.C. Advances in solid oxide fuel cell technology. Solid State Ion. 2000, 135, 305–313. [Google Scholar] [CrossRef]

- Appleby, A.J. Fuel cell technology: Status and future prospects. Energy 1996, 21, 521–653. [Google Scholar] [CrossRef]

- Basu, S. Recent Trends in Fuel Cell Science and Technology; Springer: Berlin/Heidelberg, Germany; Anamaya Publishers: New Delhi, India, 2007; pp. 1–375. [Google Scholar]

- International Energy Agency; Nuclear Energy Agency. Projected Costs of Generating Electricity; International Energy Agency: Paris, France, 2015; p. 215. [Google Scholar]

- Malyshenko, S.P.; Prigozhin, V.I.; Savich, A.R. Efficiency of steam generation into hydrogen of oxygen steam generators of megawatt power class. Thermophys. High Temp. 2012, 50, 820–829. [Google Scholar]

- Lucky, A.I.; Dunikov, D.O.; Borzenko, V.I.; Shmatov, D.P. Hydrogen-oxygen installations for power engineering. Thermophys. High Temp. 2020, 58, 809–822. [Google Scholar]

- Shapiro, V.I.; Malyshenko, S.P.; Reutov, B.F. Increasing the maneuverability of PSU when using hydrogen-oxygen steam generators. Therm. Power Eng. 2011, 9, 35–40. [Google Scholar]

- Malyshenko, S.P. Research and development of the Russian Academy of Sciences in the field of hydrogen energy technologies (To the 50th anniversary of the Russian Academy of Sciences). Int. Sci. J. Altern. Energy Ecol. 2011, 3, 10–34. [Google Scholar]

- Shapiro, V.I.; Borisova, E.V.; Schastlivtsev, A.I. The use of hydrogen-oxygen steam generators to improve the reliability of the functioning of the UES. In Hydrogen Energy Technologies: Materials of the Seminar of the Laboratory of the VET Institute of the Russian Academy of Sciences: Collection of Scientific Papers; Federal State Budgetary Institution of Science Joint Institute of High Temperatures of the Russian Academy of Sciences: Moscow, Russia, 2017; pp. 67–77. [Google Scholar]

- Tsanev, S.V.; Burov, V.D.; Remezov, A.N. Gas Turbine and Combined-Cycle Installations of Thermal Power Plants; Publishing House of the Federal State Budgetary Educational Institution of Higher Professional Education National Research University: Moscow, Russia, 2009; p. 579. [Google Scholar]

- Babenko, I.A.; Shulman, V.L. Technologies of Super-Supercritical Steam Parameters in Modern Power Engineering. In Proceedings of the Third Scientific and Technical Conference of Young Scientists of the Ural Energy Institute, Yekaterinburg, Russia, 21–25 May 2018. [Google Scholar]

- Order of the Ministry of Energy of the Russian Federation No. 469 Dated 22 August 2013. On Approval of the Procedure for the Creation and Use of Fuel Reserves by Thermal Power Plants, Including during the Heating Period. Available online: http://pravo.gov.ru/proxy/ips/?doc_itself=&backlink=1&nd=602167469&page=1&rdk=0 (accessed on 21 December 2021).

- Fateev, V.N.; Alekseeva, O.K.; Korobtsev, S.V. Problems of hydrogen accumulation and supply. Kim. Probl. 2018, 16, 453–483. [Google Scholar]

- Hamburg, D.Y.; Dubovkina, N.F. Hydrogen, Properties, Fields, Crunch, Transportation, Application; Chemistry: Moscow, Russia, 1989; p. 671. [Google Scholar]

- Yılmaz, C. Thermodynamic performance analysis of gas liquefaction cycles for cryogenic applications. J. Therm. Eng. 2019, 5, 62–75. [Google Scholar] [CrossRef]

- Sarkisov, S.V.; Vakulenko, V.A.; Stukalo, S.A.; Smelik, A.A. Analysis of existing storage facilities for storage of liquefied natural gas. Actual Probl. Mil. Sci. Res. 2020, S5, 38–47. [Google Scholar]

- Ivantsova, S.G. Analysis of technical solutions in the manufacture and construction of membrane isothermal tanks of liquefied natural gas. Transp. Storage Pet. Prod. Hydrocarb. Raw Mater. 2018, 2, 44–48. [Google Scholar]

- Mitrova, T.; Kapitonov, S.; Klimentyev, A. Russian Low- and Medium-Tonnage LNG. Regional Series. Baltic. 2019. Available online: https://energy.skolkovo.ru/downloads/documents/SEneC/Research/SKOLKOVO_EneC_RU_Baltika_Vol1.pdf (accessed on 8 February 2022).

- Safarov, A.E. Regasification of LNG. Transp. Altern. Fuel 2019, 5, 52–57. [Google Scholar]

- Alida, I.B. Methods of regasification of liquefied natural gas. Symb. Sci. Int. Sci. J. 2016, 10, 10–15. [Google Scholar]

- Skoblikova, E.S.; Timonin, I.I. The World LNG Market: The Illusion of Excess. p. 43. 2018. Available online: https://vygon.consulting/upload/iblock/542/vygon_consulting_lng_world_balance_2018.pdf (accessed on 7 December 2021).

- Kippers, M.A.; Laat, J.D.; Herkens, R. Small step into the hydrogen future. Gas Russ. 2012, 1, 28–36. [Google Scholar]

- Varzin, M. Eco-Friendly Transportation of Hydrogen through Natural Gas Pipelines. Available online: https://teo.ru/analiz/publ_26.html (accessed on 29 December 2021).

- Amos, W.A. Costs of Storing and Transporting Hydrogen National Renewable Energy. Laboratories. 1998. Available online: http://www1.eere.energy.gov/hydrogenandfuelcells/pdfs/25106.pdf (accessed on 8 January 2022).

| Characteristics (under Standard Conditions) | Natural Gas | Methane CH4 | Hydrogen H2 |

|---|---|---|---|

| Volumetric heat of combustion, MJ/m3 | 36.6 | 35.88 | 10.79 |

| Density, kg/m3 | 0.746 | 0.717 | 0.09 |

| Relative density | 0.58 | 0.55 | 0.07 |

| Mass heat of combustion, MJ/kg | 49 | 50 | 120 |

| Volumetric Wobbe value (WI), MJ/kg | 48 | 48.2 | 40.7 |

| Type of FC | Specific Investment Costs, $/kW | Efficiency, % | Operational Resource of FC, h |

|---|---|---|---|

| SOFC | 1100–1800 | 55–60 | 40,000–60,000 |

| MCFC | 1600–3500 | 50–55 |

| Characteristic | Value |

|---|---|

| FC lifetime duration, h. | 43,800 |

| FC specific cost, $/kW | 1100 |

| FC power generation over the tour, million kWh | 43.8 |

| Cost of electricity purchase, $/kWh | 0.018 |

| FC implementation cost, million $ | 1.1 |

| The cost of replaced and energy sources by FC for the maintenance purposes, million $ | 0.77 |

| Characteristic | Value |

|---|---|

| Electric power generation by the battery over the service life, kWh | 303.6 |

| FC specific cost, $/kW | 1100 |

| FC implementation cost, million $ | 0.33 |

| The cost of replaced batteries (excluding VAT), million $ | 0.15 |

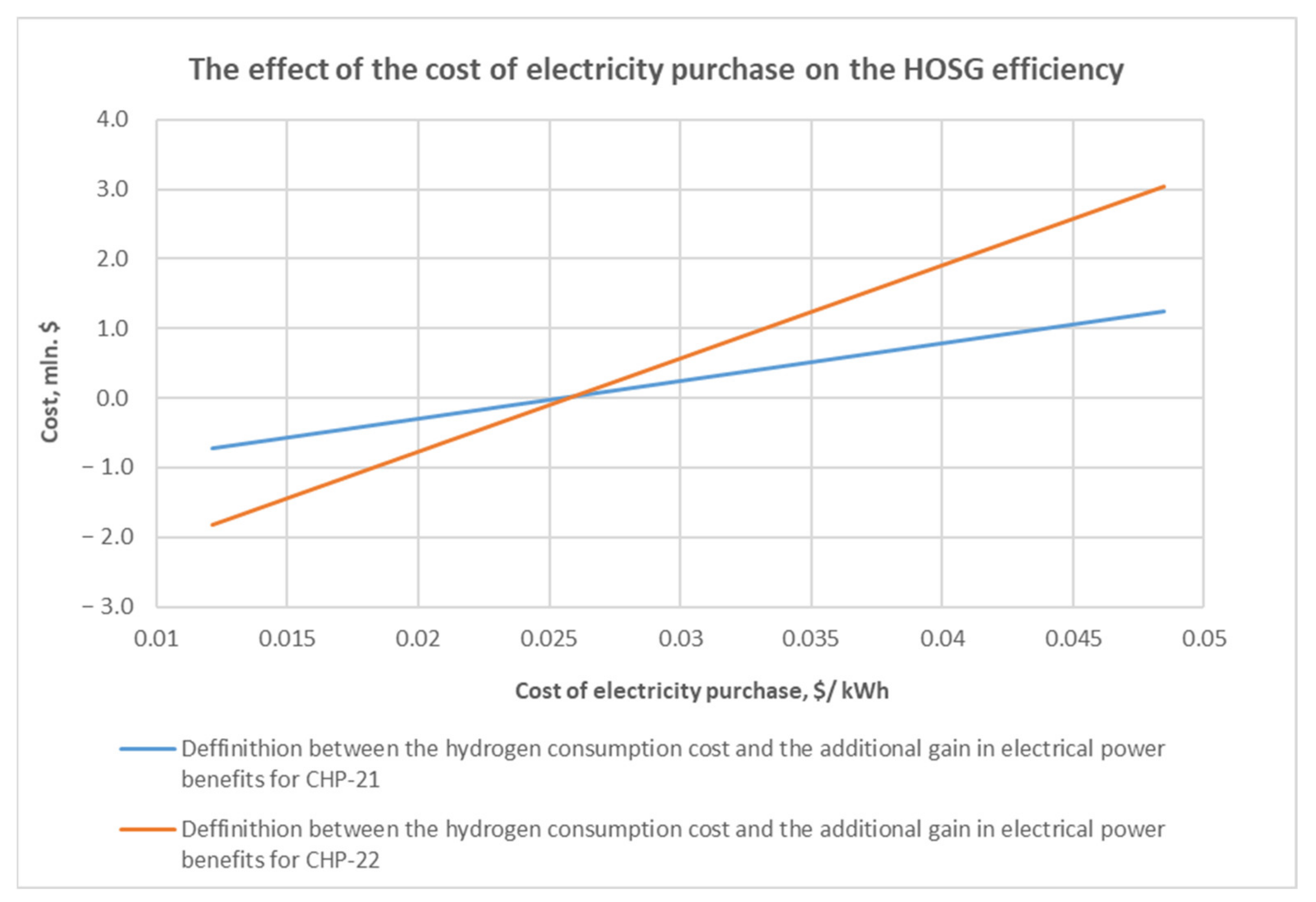

| Characteristic | CHP-21 | CHP-22 |

|---|---|---|

| Installed steam boilers type | TGM-96B | TGMP-344A |

| Pressure of the main steam at the outlet of the steam boiler, MPa | 12.5 | 25.5 |

| Temperature of the main steam at the outlet of the steam boiler, MPa | 545 | 545 |

| Steam capacity of the single boiler unit, kg/sec | 133.3 | 277.8 |

| Installed turbines type | T-100/120-130 | T-250/300-240-2 |

| Rated electric power of the turbine, MW | 100 | 250 |

| Maximum electric power of the turbine, MW | 120 | 300 |

| Thermal power of the turbine, MW | 195 | 395.4 |

| Characteristic | Not Using HOSG at CHP-21 | Using HOSG at CHP-21 | Not Using HOSG at CHP-22 | Using HOSG at CHP-22 |

|---|---|---|---|---|

| Fuel costs per boiler unit, k$/hour | 2.21 | 2.39 | 4.38 | 4.56 |

| Characteristic | CHP-21 | CHP-22 |

|---|---|---|

| Gain from the additional electricity produced, million $/year | 0.95 | 2.36 |

| The cost of hydrogen consumed at HOSG without consideration of the cost of oxygen consumed, million $/year | 1.38 | 3.45 |

| Characteristic | Hydrogen Storage as the Main Fuel | Hydrogen Storage as the Backup Fuel | ||

|---|---|---|---|---|

| Compressed Hydrogen | Liquefied Hydrogen | Compressed Hydrogen | Liquefied Hydrogen | |

| Maximum capacity of a single tank, m3 | 200 | 1400 | 200 | 1400 |

| Diameter of a single tank, m | 4 | 16 | 4 | 16 |

| Required quantity of tanks, pcs. | 1336 | 223 | 23 | 4 |

| Required area for placing the tanks, hectares | 10.27 | 2.17 | 3.10 | 0.46 |

| Characteristic | Value |

|---|---|

| The price of fuel oil, $/ton | 119.3 |

| The price of LNG, $/ton [75] | 175.7 |

| The price of hydrogen, $/kg | 6.0 |

| The price of electricity, $/kWh | 0.04 |

| The price of steam heat, $/GJ | 2.55 |

| The price of hot water heat, $/Gcal | 9.7 |

| $ rate to Russian ruble, $/ruble | 82.5 |

| Characteristic | Value |

|---|---|

| Annual steam consumption for the maintenance of the fuel oil storage facility, thousand tons of steam/year | 98.7 |

| Annual electricity consumption for the maintenance of the fuel oil storage facility, million kWh/year | 1.1 |

| Annual electricity consumption for stripping gas liquefiers, thousand kWh/year | 6.5 |

| Annual heat consumption in hot water for regasification plants, GJ/year | 456.5 |

| Capital expenditures on the backup fuel storage infrastructure based on data from Russian manufacturers (excluding VAT), including construction and installation works (taken as 30% of capital expenditures), million $ | 84.2 |

| Capital expenditures on the backup fuel storage infrastructure based on data from Russian manufacturers (excluding VAT), including construction and installation works (taken as 30% of capital expenditures), thousand $/MW of installed TPP capacity | 168.4 |

| Annual savings in operating costs for the backup fuel storage facility (depending on the consumption of the backup fuel during the year), million $/year | 0.24–0.36 |

| Annual savings in operating costs for the backup fuel storage facility (depending on the consumption of the backup fuel during the year), $/MW of installed TPP capacity | 485–727 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kolbantseva, D.; Treschev, D.; Trescheva, M.; Anikina, I.; Kolbantsev, Y.; Kalmykov, K.; Aleshina, A.; Kalyutik, A.; Vladimirov, I. Analysis of Technologies for Hydrogen Consumption, Transition and Storage at Operating Thermal Power Plants. Energies 2022, 15, 3671. https://doi.org/10.3390/en15103671

Kolbantseva D, Treschev D, Trescheva M, Anikina I, Kolbantsev Y, Kalmykov K, Aleshina A, Kalyutik A, Vladimirov I. Analysis of Technologies for Hydrogen Consumption, Transition and Storage at Operating Thermal Power Plants. Energies. 2022; 15(10):3671. https://doi.org/10.3390/en15103671

Chicago/Turabian StyleKolbantseva, Daria, Dmitriy Treschev, Milana Trescheva, Irina Anikina, Yuriy Kolbantsev, Konstantin Kalmykov, Alena Aleshina, Aleksandr Kalyutik, and Iaroslav Vladimirov. 2022. "Analysis of Technologies for Hydrogen Consumption, Transition and Storage at Operating Thermal Power Plants" Energies 15, no. 10: 3671. https://doi.org/10.3390/en15103671

APA StyleKolbantseva, D., Treschev, D., Trescheva, M., Anikina, I., Kolbantsev, Y., Kalmykov, K., Aleshina, A., Kalyutik, A., & Vladimirov, I. (2022). Analysis of Technologies for Hydrogen Consumption, Transition and Storage at Operating Thermal Power Plants. Energies, 15(10), 3671. https://doi.org/10.3390/en15103671