Influence of the Auxiliary Air-Duct Outlet and the Brattice Location on the Methane Hazard—Numerical Simulations

Abstract

:1. Introduction

- Active methane prevention methods by ensuring adequate ventilation of the endangered area, methane drainage from the deposit and the use of auxiliary ventilation devices;

- Passive methane prevention methods, including constant monitoring of the methane content in the air with the use of properly arranged sensors and automatic anemometers.

2. Methods

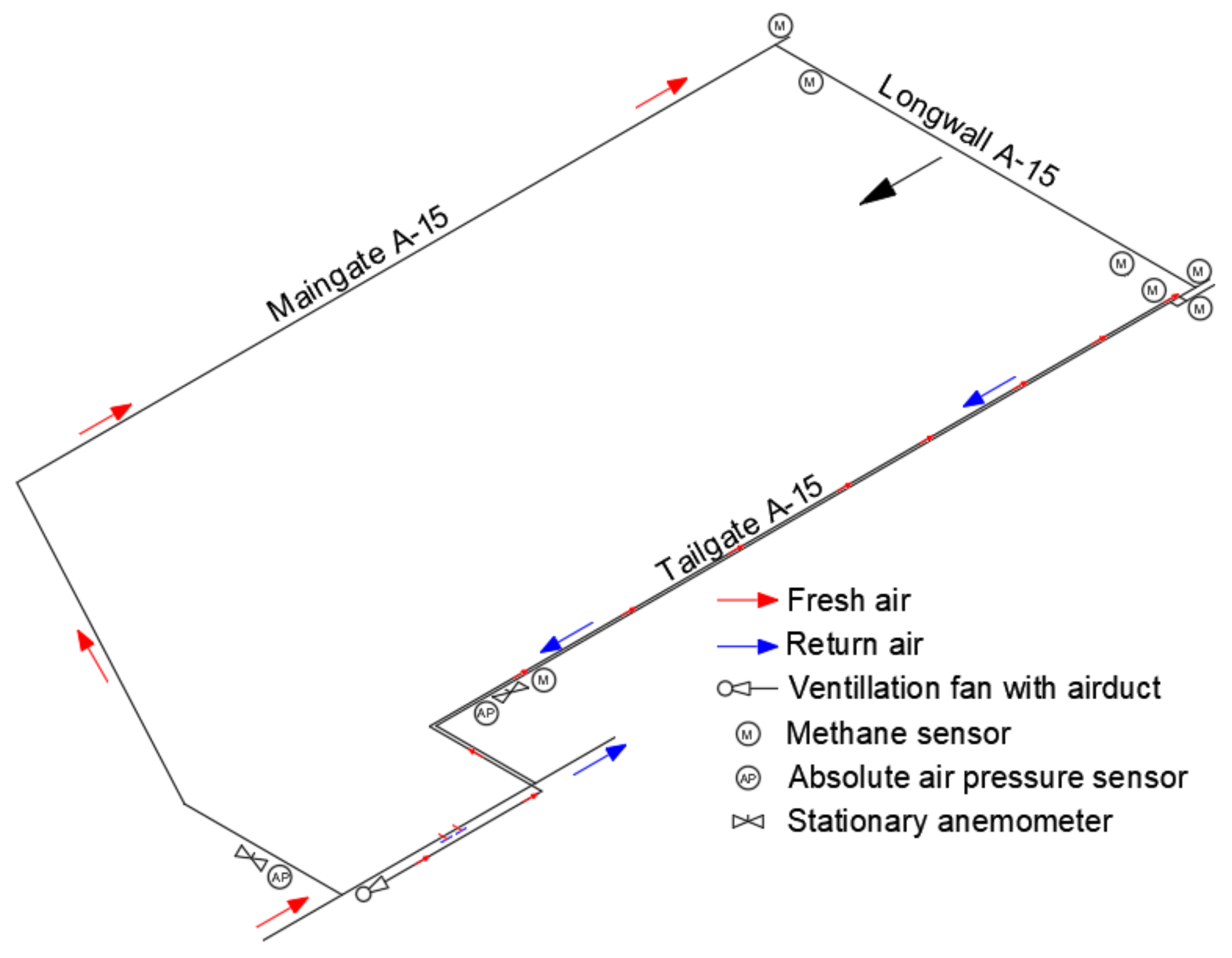

- Detailed meaurements of the geometry of workings in the area of the longwall and tailgate crossing, geometry and location of auxiliary ventilation devices;

- Methane concentrations recorded continuously for 3 months in six locations: in the liquidated part of the tailgate A-15; at the inlet to longwall, up to 10 m from the crossing with the maingate A-15; in the crossing area of the longwall and tailgate, above the longwall scraper conveyor drive; at the brattice location, at a distance of 4 to 6 m from the tailgate cave line; behind the brattice, as well as at the outlet from the longwall area;

- Measurements of pressure, air temperature and volumetric air flow in the maingate and tailgate in the given period.

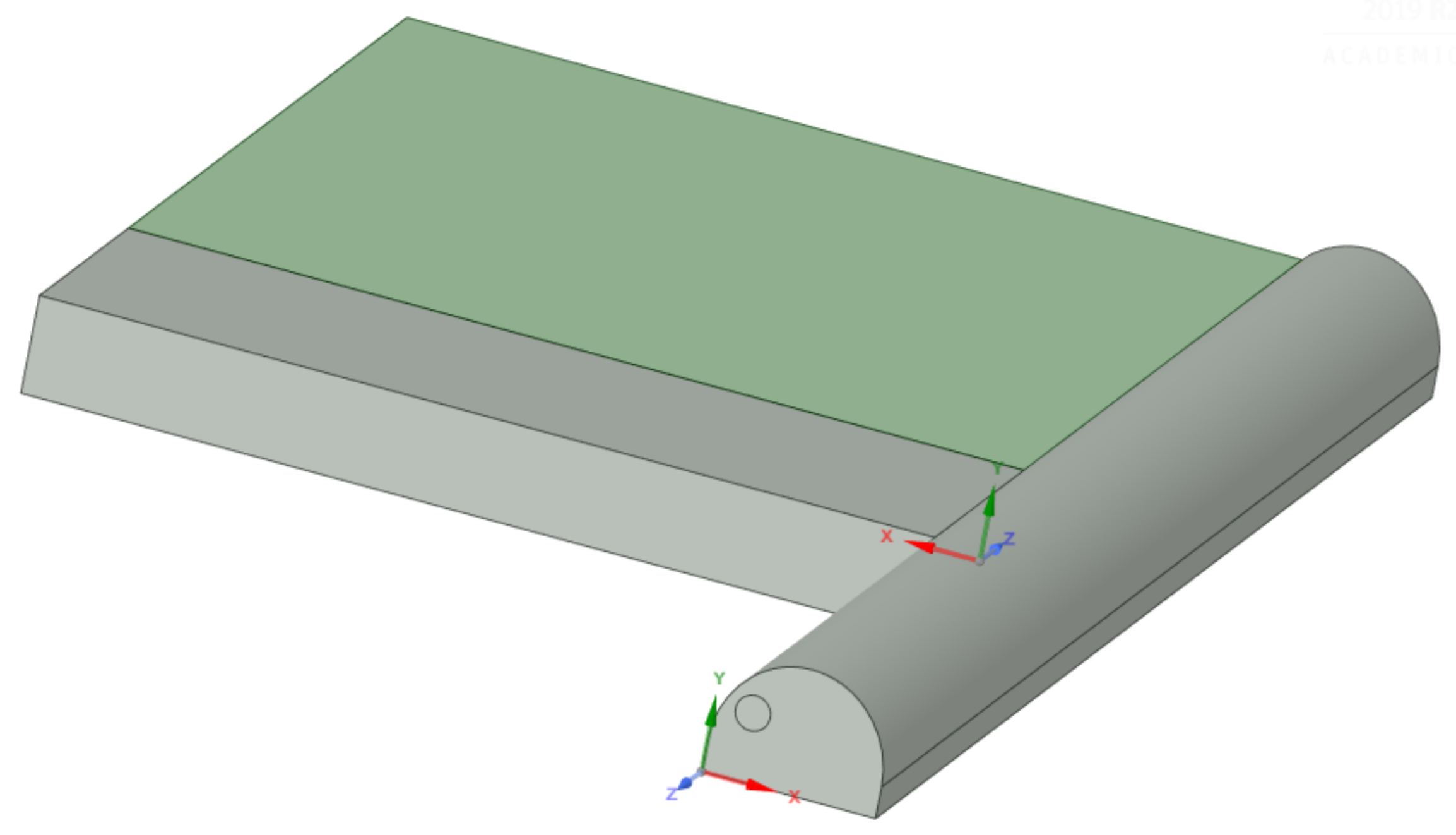

- A section of the tailgate with an assumed length of 30 m and a 20 m liquidated section with the characteristics of the goaf area with a cross-section of 15.2 m2;

- Longwall excavation 25 m long, 3 m high, 8 m wide and with an inclination of 0o, the floor of the longwall was 1 m below the floor of the tailgate. This was due to the uplift of the tailgate floor as a result of a high-stress concentration;

- A 10 m long brattice, located 4 m from the cave line in the tailgate;

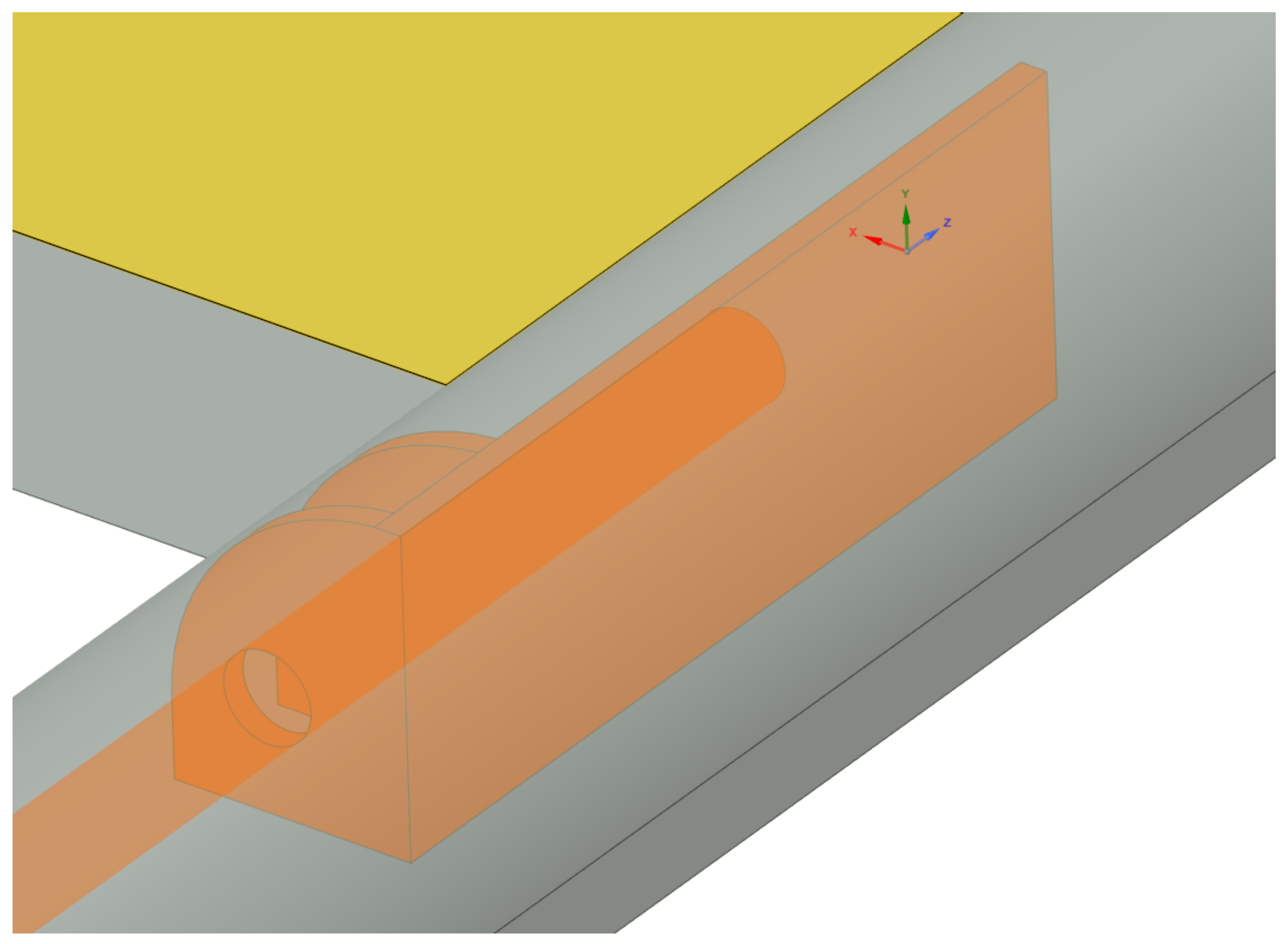

- An auxiliary air-duct, 21 m long and diameter of 1 m, located 0.9 m from the excavation floor, with an outlet located 0.5 m from the longwall;

- A zone filled with sealing foam material from the side of goafs in the liquidated part of the tailgate.

- inlet_duct—fresh air inlet through a air-duct, velocity inlet—8 m/s,

- inlet_longwall—an inlet of methane–air mixture inflow to the longwall, velocity inlet—2.5 m/s, CH4—0.01,

- inlet_longwall_goaf—an inlet of methane–air mixture in the goaf, located parallel to the line of the longwall working, velocity inlet—0.5 m/s, CH4—0.02,

- inlet_top_goaf—an inlet of methane inflow from the above-laying layers located in the goaf ceiling, velocity inlet–0.03 m/s, CH4—0.04,

- inlet_bot_goaf—an inlet of methane inflow from below-laying layers located in the bottom of the goaf velocity inlet—0.01 m/s, CH4—0.04.

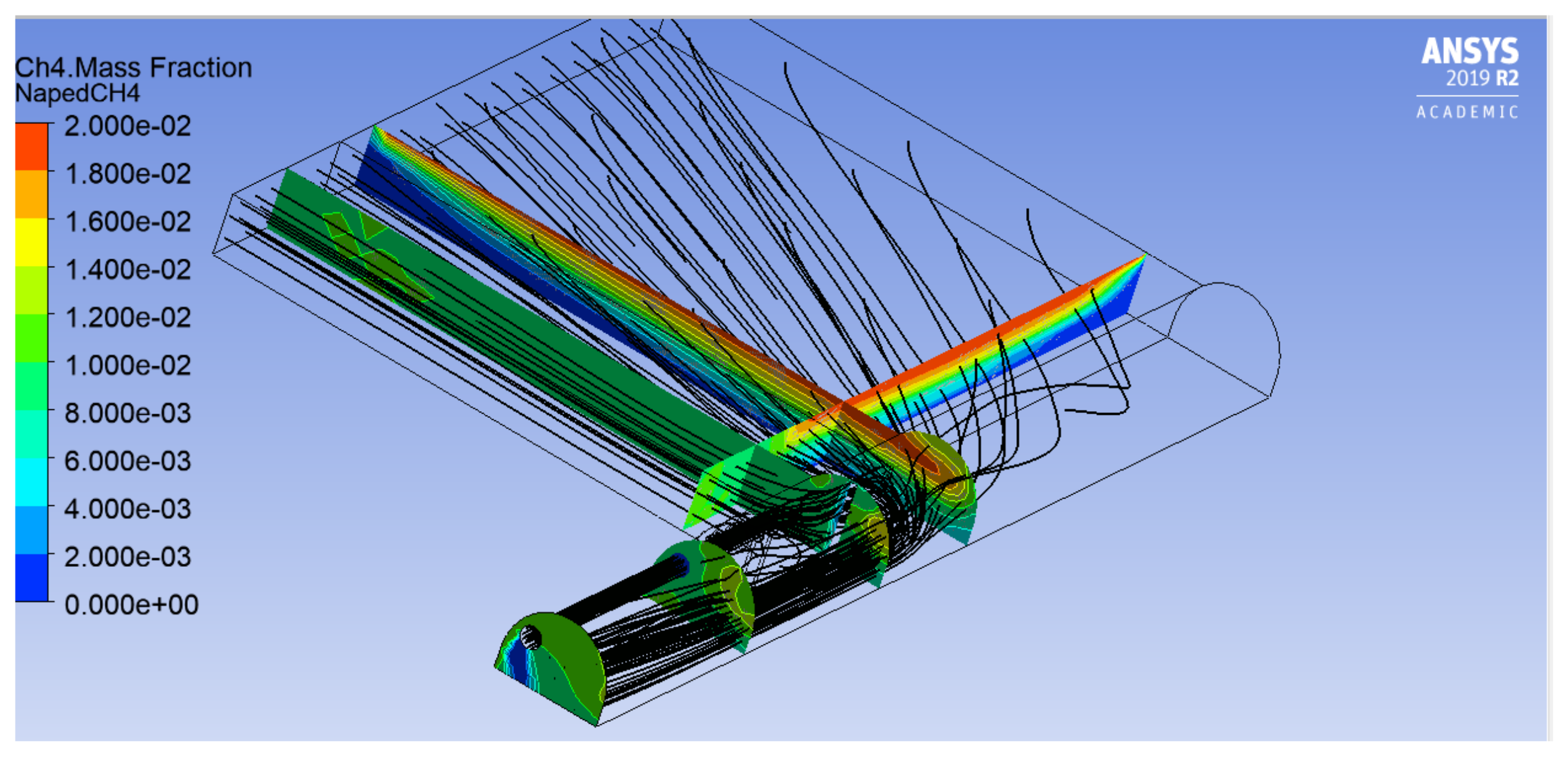

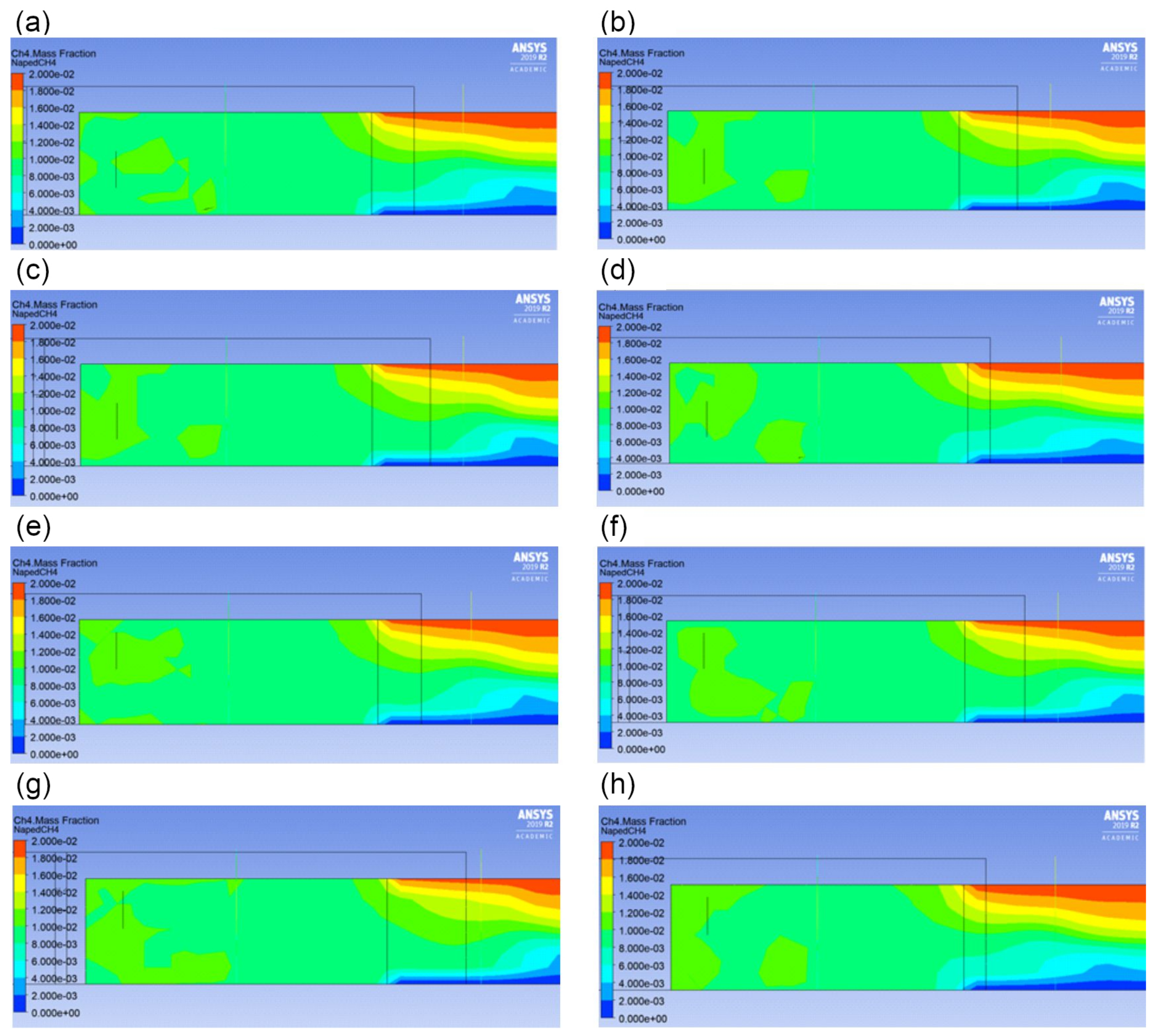

- In the longwall: under the ceiling, in the place where the highest concentrations of methane were registered—location above the conveyor drive (sensor A on the AA plane);

- In the tailgate: under the ceiling, next to the excavation caving line in the mixing zone (sensor B on the BB plane);

- In the tailgate: opposite to the longwall outlet (sensor C on the CC plane).

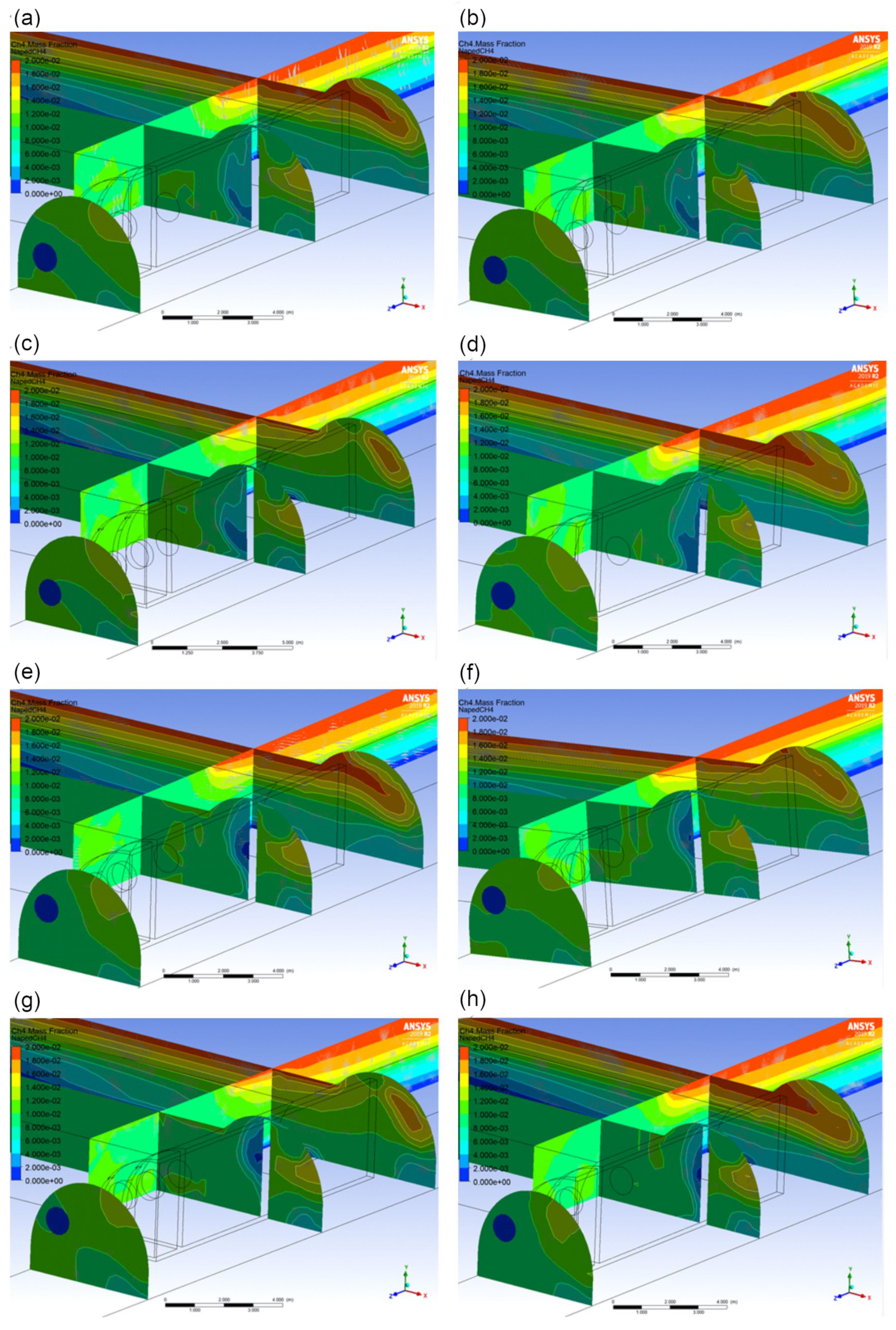

- lp—an increase in the length of the brattice;

- xp—a change in the position of the brattice along the axis of the tailgate run;

- hl—an increase in the height of the outlet of the air-duct;

- xl—a change in the position of the outlet of the air-duct along the axis of the tailgate run.

3. Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, H.; Deng, J.; Chen, X.; Shu, C.M.; Kuo, C.H.; Zhai, X.; Wang, Q.; Hu, X. Qualitative and quantitative characterisation for explosion severity and gaseous–solid residues during methane–coal particle hybrid explosions: An approach to estimating the safety degree for underground coal mines. Process Saf. Environ. Prot. 2020, 141, 150–160. [Google Scholar] [CrossRef]

- Liu, H.; Mao, S.; Li, M. A Case Study of an Optimized Intermittent Ventilation Strategy Based on CFD Modeling and the Concept of FCT. Energies 2019, 12, 721. [Google Scholar] [CrossRef] [Green Version]

- Niewiadomski, A.P.; Badura, H.; Pach, G. Recommendations for methane prognostics and adjustment of short-term prevention measures based on methane hazard levels in coal mine longwall. E3S Web Conf. 2021, 266, 08001. [Google Scholar] [CrossRef]

- Ray, S.K.; Khan, A.M.; Mohalik, N.K.; Mishra, D.; Mandal, S.; Pandey, J.K. Review of preventive and constructive measures for coal mine explosions: An Indian perspective. Int. J. Min. Sci. Technol. 2022, in press. [Google Scholar] [CrossRef]

- Shi, L.; Wang, J.; Zhang, G.; Cheng, X.; Zhao, X. A risk assessment method to quantitatively investigate the methane explosion in underground coal mine. Process Saf. Environ. Prot. 2017, 107, 317–333. [Google Scholar] [CrossRef]

- Szlązak, N.; Korzec, M.; Piergies, K. The Determination of the Methane Content of Coal Seams Based on Drill Cutting and Core Samples from Coal Mine Roadway. Energies 2022, 15, 178. [Google Scholar] [CrossRef]

- Cygankiewicz, J.; Prusek, S. Zagrożenia aerologiczne w kopalniach węgla kamiennego – profilaktyka, zwalczanie, modelowanie, monitoring; Wydawnictwo Głównego Instytutu Górnictwa: Katowice, Poland, 2013. [Google Scholar]

- Konopko, W. Bezpieczeństwo pracy w kopalniach węgla kamiennego. Tom 2: Zagrożenia naturalne; Wydawnictwo Głównego Instytutu Górnictwa: Katowice, Poland, 2013. [Google Scholar]

- WorkSafe New Zeland. Ventilation in Underground Mines and Tunnels. Approved Code of Practice. New Zeland Goverment. Available online: https://worksafe.govt.nz/dmsdocument/140-acop-ventilation-in-underground-mines-and-tunnels (accessed on 10 January 2022).

- Salamonowicz, Z.; Krauze, A.; Majder-Lopatka, M.; Dmochowska, A.; Piechota-Polanczyk, A.; Polanczyk, A. Numerical Reconstruction of Hazardous Zones after the Release of Flammable Gases during Industrial Processes. Processes 2021, 9, 307. [Google Scholar] [CrossRef]

- Botao, Q.; Lin, L.; Dong, M.; Yi, L.; Zhong, X.; Jia, Y. Control technology for the avoidance of the simultaneous occurence of a methane explosion and spontaneous coal combustion in a coal mine: Case study. Process Saf. Environ. Prot. 2016, 103, 203–211. [Google Scholar]

- Qin, J.; Qu, Q.; Guo, H. CFD simulations for longwall gas drainage design optimisation. Int. J. Min. Sci. Technol. 2017, 27, 777–782. [Google Scholar] [CrossRef]

- Zapletal, P.; Kosowski, M. Selection of methane collector diameter based on computer simulationof fluid mechanics in mining and geological conditions JSW S.A. Prz. Gor. 2020, 76, 34–38. [Google Scholar]

- Cao, J.; Li, W. Numerical simulation of gas migration into mining-induced fracture network in the goaf. Int. J. Min. Sci. Technol. 2017, 27, 681–695. [Google Scholar] [CrossRef]

- Skotniczy, P. Three-dimensional numerical simulation of the mass exchange between longwall headings and goafs, in the pressence of methane drainage in U-type ventillated longwall. Arch. Min. Sci. 2013, 58, 705–718. [Google Scholar]

- Wang, G.Q.; Shi, G.Q.; Wang, Y.M.; Shen, H.Y. Numerical study on the evolution of methane explosion regions in the process of coal mine fire zone sealing. Fuel 2021, 289, 119744. [Google Scholar] [CrossRef]

- Juganda, A.; Strebinger, C.; Brune, J.F.; Bogin, G.E., Jr. Computational Fluid Dynamics Modeling of a Methane Gas Explosion in a Full-Scale, Underground Longwall Coal Mine. Min. Metall. Exploaration 2022, 39, 897–916. [Google Scholar] [CrossRef]

- Hasheminasab, F.; Bagherpour, R.; Aminossadati, S.M. Numerical simulation of methane distribution in development zones of underground coal mines equipped with auxiliary ventilation. Tunn. Undergr. Space Technol. 2019, 89, 68–77. [Google Scholar] [CrossRef]

- Zhou, L.; Pritchard, C.; Zheng, Y. CFD modeling of methane distribution at a continuous miner face with various curtain setback distances. Int. J. Min. Sci. Technol. 2015, 25, 635–640. [Google Scholar] [CrossRef]

- Mishra, D.P.; Kumar, P.; Panigrahi, D.C. Dispersion of methane in tailgate of a retreating longwall mine: A computational fluid dynamics study. Env. Earth Sci 2016, 75, 475. [Google Scholar] [CrossRef]

- Daloğlu, G.; Önder, M.; Parra, T. Modeling of Methane and Air Velocity Behavior in an Auxiliary Ventilated Coal Heading. Arch. Min. Sci. 2021, 66, 69–84. [Google Scholar]

- Kurnia, J.C.; Sasmito, A.P.; Majumdar, A.S. CFD simulation of methane dispersion and innovative methane management in underground mining faces. Appl. Math. Model. 2014, 38, 3467–3484. [Google Scholar] [CrossRef]

- Wierzbiński, K. Wykorzystanie metod CFD w prognozowaniu przestrzennym rozkładu koncentracji metanu w chodniku wentylacyjnym–opracowanie i walidacja modeli numerycznych 3D. Przegląd Górniczy 2016, 72, 44–55. [Google Scholar]

- Janoszek, T.; Krawczyk, J. Methodology Development and Initial Results of CFD Simulations of Methane Distribution in the Working of a Longwall Ventilated in a Short “Y” Manner. Arch. Min. Sci. 2022, 67, 3–24. [Google Scholar]

- Borowski, M.; Kuczera, Z. Comparison of Methane Control Methods in Polish and Vietnamese Coal Mines. E3S Web Conf. 2018, 35, 01004. [Google Scholar] [CrossRef] [Green Version]

- Wierzbiński, K. Geometria skrzyżowań ścian z chodnikami wentylacyjnymi – konfiguracja pomocniczych urządzeń wentylacyjnych. Przegląd Górniczy 2016, 72, 66–79. [Google Scholar]

- Regulation—Code of Federal Regulations. Title 30 Mineral Resources. Office of the Federal Register, US (ver. 01/28/2022). Available online: https://www.ecfr.gov/current/title-30 (accessed on 10 January 2022).

- Regulation—Occupational Health and Safety Regulations. Part XXIX Underground Operations 2012. Government of Newfoundland and Labrador, Canada (ver. 01/03/2020). Available online: https://www.gov.nl.ca/dgsnl/ohs/guide/ (accessed on 10 January 2022).

- Regulation—Work Health and Safety (Mines and Petroleum Sites) 2014. New South Wales Government, Australia (ver. 12/11/2021). Available online: https://legislation.nsw.gov.au/view/html/inforce/current/sl-2014-0799 (accessed on 10 January 2022).

- Krause, E.; Łukowicz, K. Instrukcja Głównego Instytutu Górnictwa nr 17 – Zasady prowadzenia ścian w warunkach zagrożenia metanowego.; Wydawnictwo Głównego Instytutu Górnictwa: Katowice, Poland, 2004. [Google Scholar]

- Regulation—Rozporządzenie Ministra Energii z dnia 9 czerwca 2017r. w sprawie szczegółowych wymagań dotyczących prowadzenia ruchu podziemnych zakładów górniczych (Dz.U. 2017 poz. 1118 z późn. zm.). Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20170001118 (accessed on 10 January 2022).

- Ansys Inc. Ansys Fluent User’s Guide; Ansys Inc.: Canonsburg, PA, USA, 2012. [Google Scholar]

- Fernández-Alaiz, F.; Castañón, A.M.; Gómez-Fernández, F.; Bernardo-Sánchez, A.; Bascompta, M. Determination and Fire Analysis of Gob Characteristics Using CFD. Energies 2020, 13, 5274. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Y.; Liu, H.; Zhai, X.; Zhao, S.; Yu, Z. Numerical analysis on the potential danger zone of compound hazard in gob under mining condition. Process Saf. Environ. Prot. 2021, 147, 1125–1134. [Google Scholar] [CrossRef]

- Szlązak, J.; Szlązak, N. The Numerical determination of methane concentration in goaf space. Arch. Min. Sci. 2004, 49, 587–599. [Google Scholar]

- Niewiadomski, A.P.; Badura, H. Evaluation of a one-day average methane concentrations forecast at the outlet from the longwall ventilation region as tool of supporting selection of methane prevention measures. In Proceedings of the Topical Issues of Rational Use of Natural Resources 2019, St. Petersburg, Russia, 13–17 May 2019. [Google Scholar]

- Niewiadomski, A.P.; Badura, H.; Ivanova, T.N.; Repko, A.; Yury, N.R. Analysis of Methane Concentration Distribution at U-Ventilated Longwall Outlet—Case Study. New Trends Prod. Eng. 2020, 3, 149–168. [Google Scholar] [CrossRef]

| Number of Computational Cells | Skewness Value | Orthogonal Quality Value |

|---|---|---|

| 132049 | 0.86862 | 0.13138 |

| 172113 | 0.82903 | 0.17097 |

| 487895 | 0.79166 | 0.20834 |

| 1607431 | 0.79991 | 0.20009 |

| 4813395 | 0.79806 | 0.20194 |

| solver | pressure-based |

|---|---|

| time discretization | steady state |

| sub-models | turbulent flow (k-epsilon standard), species transport (methane–air mixture) |

| computational scheme | coupled |

| scheme of the analysis | all sub-models as second-order |

| initialization method | hybrid |

| The Case | Sensor | Measured Methane Concentration Value, %CH4 | Modeled Methane Concentration Value,%CH4 | Absolute Error, %CH4 |

|---|---|---|---|---|

| 1 | A | 1.5 | 1.6 | 0.1 |

| B | 1.1 | 1.2 | 0.1 | |

| C | 1.2 | 1.2 | 0.0 | |

| 2 | A | 1.2 | 1.4 | 0.2 |

| B | 1.1 | 1.2 | 0.1 | |

| C | 1.1 | 1.4 | 0.3 | |

| 3 | A | 1.6 | 1.8 | 0.2 |

| B | 1.3 | 1.4 | 0.1 | |

| C | 1.2 | 1.4 | 0.2 |

| Model | lp | xp | hl | xl |

|---|---|---|---|---|

| M_1 | 0 | 0 | 0 | 0 |

| M_2 | 0 | +0.5 | 0 | 0 |

| M_3 | 0 | +1 | 0 | 0 |

| M_4 | 0 | −0.5 | 0 | 0 |

| M_5 | 0 | 0 | ½ hl | 0 |

| M_6 | 0 | +0.5 | ½ hl | 0 |

| M_7 | 0 | +1 | ½ hl | 0 |

| M_8 | 0 | −0.5 | ½ hl | 0 |

| M_9 | +2.5 | 0 | ½ hl | 0 |

| M_10 | +2.5 | +0.5 | ½ hl | 0 |

| M_11 | +2.5 | +1 | ½ hl | 0 |

| M_12 | +2.5 | −0.5 | ½ hl | 0 |

| M_13 | +2.5 | 0 | 0 | 0 |

| M_14 | +2.5 | +0.5 | 0 | 0 |

| M_15 | +2.5 | +1 | 0 | 0 |

| M_16 | +2.5 | −0.5 | 0 | 0 |

| M_17 | +2.5 | 0 | 0 | +3 |

| M_18 | +2.5 | +0.5 | 0 | +3 |

| M_19 | +2.5 | +1 | 0 | +3 |

| M_20 | +2.5 | −0.5 | 0 | +3 |

| M_21 | +2.5 | 0 | ½ hl | +3 |

| M_22 | +2.5 | +0.5 | ½ hl | +3 |

| M_23 | +2.5 | +1 | ½ hl | +3 |

| M_24 | +2.5 | −0.5 | ½ hl | +3 |

| M_25 | 0 | 0 | 0 | +3 |

| M_26 | 0 | +0.5 | 0 | +3 |

| M_27 | 0 | +1 | 0 | +3 |

| M_28 | 0 | −0.5 | 0 | +3 |

| M_29 | 0 | 0 | ½ hl | +3 |

| M_30 | 0 | +0.5 | ½ hl | +3 |

| M_31 | 0 | +1 | ½ hl | +3 |

| M_32 | 0 | −0.5 | ½ hl | +3 |

| Model | Amax, %CH4 | A½, %CH4 | Bmax, %CH4 | B½, %CH4 | Cmax, %CH4 | C½, %CH4 | Dmax, %CH4 | D½, %CH4 |

|---|---|---|---|---|---|---|---|---|

| M_1 | 1.0 | 1.6 | 1.4 | 1.8 | 1.2 | 1.2 | 1.2 | 1.2 |

| M_2 | 1.0 | 1.6 | 1.4 | 1.8 | 1.2 | 1.2 | 1.2 | 1.2 |

| M_3 | 1.0 | 1.6 | 1.4 | 1.8 | 1.2 | 1.2 | 1.2 | 1.2 |

| M_4 | 1.0 | 1.6 | 1.4 | 1.8 | 1.0 | 1.0 | 1.2 | 1.0 |

| M_5 | 1.0 | 1.6 | 1.4 | 1.8 | 1.0 | 1.0 | 1.2 | 1.2 |

| M_6 | 1.0 | 1.6 | 1.4 | 1.8 | 1.2 | 1.2 | 1.2 | 1.2 |

| M_7 | 1.0 | 1.6 | 1.4 | 1.8 | 1.0 | 1.0 | 1.2 | 1.2 |

| M_8 | 1.0 | 1.6 | 1.4 | 1.8 | 1.0 | 1.0 | 1.2 | 1.0 |

| M_9 | 1.0 | 1.6 | 1.6 | 2.0 | 1.0 | 1.0 | 1.2 | 1.0 |

| M_10 | 1.0 | 1.6 | 1.6 | 1.8 | 1.0 | 1.2 | 1.2 | 1.2 |

| M_11 | 1.0 | 1.6 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.0 |

| M_12 | 1.0 | 1.6 | 1.6 | 1.8 | 1.2 | 1.2 | 1.2 | 1.0 |

| M_13 | 1.0 | 1.6 | 1.6 | 2.0 | 1.2 | 1.0 | 1.2 | 1.0 |

| M_14 | 1.0 | 1.6 | 1.6 | 1.8 | 1.2 | 1.0 | 1.2 | 1.2 |

| M_15 | 1.0 | 1.6 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| M_16 | 1.0 | 1.6 | 1.6 | 1.8 | 1.2 | 1.2 | 1.2 | 1.0 |

| M_17 | 1.0 | 1.6 | 1.4 | 1.8 | 1.2 | 1.0 | 1.2 | 1.0 |

| M_18 | 1.0 | 1.6 | 1.4 | 1.6 | 1.2 | 1.2 | 1.2 | 1.0 |

| M_19 | 1.0 | 1.6 | 1.4 | 1.2 | 1.2 | 1.2 | 1.2 | 1.0 |

| M_20 | 1.0 | 1.6 | 1.4 | 1.8 | 1.0 | 1.2 | 1.2 | 1.0 |

| M_21 | 1.2 | 1.6 | 1.4 | 1.8 | 1.2 | 1.2 | 1.2 | 1.0 |

| M_22 | 1.2 | 1.6 | 1.4 | 1.6 | 1.0 | 1.2 | 1.2 | 1.0 |

| M_23 | 1.2 | 1.6 | 1.4 | 1.2 | 1.2 | 1.2 | 1.2 | 1.0 |

| M_24 | 1.2 | 1.6 | 1.4 | 1.8 | 1.2 | 1.0 | 1.2 | 1.0 |

| M_25 | 1.0 | 1.6 | 1.4 | 1.8 | 1.0 | 1.0 | 1.2 | 1.0 |

| M_26 | 1.0 | 1.6 | 1.4 | 1.8 | 1.2 | 1.0 | 1.2 | 1.0 |

| M_27 | 1.2 | 1.4 | 1.4 | 1.4 | 1.0 | 1.0 | 1.2 | 1.0 |

| M_28 | 1.0 | 1.6 | 1.4 | 1.8 | 1.2 | 1.2 | 1.0 | 1.0 |

| M_29 | 1.2 | 1.6 | 1.4 | 1.8 | 1.2 | 1.2 | 1.0 | 1.0 |

| M_30 | 1.2 | 1.6 | 1.4 | 1.8 | 1.2 | 1.2 | 1.2 | 1.0 |

| M_31 | 1.2 | 1.6 | 1.4 | 1.8 | 1.2 | 1.2 | 1.2 | 1.0 |

| M_32 | 1.2 | 1.6 | 1.4 | 1.8 | 1.0 | 1.0 | 1.2 | 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niewiadomski, A.P.; Pach, G.; Różański, Z.; Wrona, P.; Musioł, D.; Zapletal, P.; Sofranko, M. Influence of the Auxiliary Air-Duct Outlet and the Brattice Location on the Methane Hazard—Numerical Simulations. Energies 2022, 15, 3672. https://doi.org/10.3390/en15103672

Niewiadomski AP, Pach G, Różański Z, Wrona P, Musioł D, Zapletal P, Sofranko M. Influence of the Auxiliary Air-Duct Outlet and the Brattice Location on the Methane Hazard—Numerical Simulations. Energies. 2022; 15(10):3672. https://doi.org/10.3390/en15103672

Chicago/Turabian StyleNiewiadomski, Adam P., Grzegorz Pach, Zenon Różański, Paweł Wrona, Dariusz Musioł, Pavel Zapletal, and Marian Sofranko. 2022. "Influence of the Auxiliary Air-Duct Outlet and the Brattice Location on the Methane Hazard—Numerical Simulations" Energies 15, no. 10: 3672. https://doi.org/10.3390/en15103672

APA StyleNiewiadomski, A. P., Pach, G., Różański, Z., Wrona, P., Musioł, D., Zapletal, P., & Sofranko, M. (2022). Influence of the Auxiliary Air-Duct Outlet and the Brattice Location on the Methane Hazard—Numerical Simulations. Energies, 15(10), 3672. https://doi.org/10.3390/en15103672