Comprehensive Optimisation of Biodiesel Production Conditions via Supercritical Methanolysis of Waste Cooking Oil

Abstract

:1. Introduction

2. Materials and methods

2.1. Materials

2.2. Experimental Procedures

2.2.1. Preparation of Standard Fatty Acids

2.2.2. Preparation of Standard Derivatised Sample

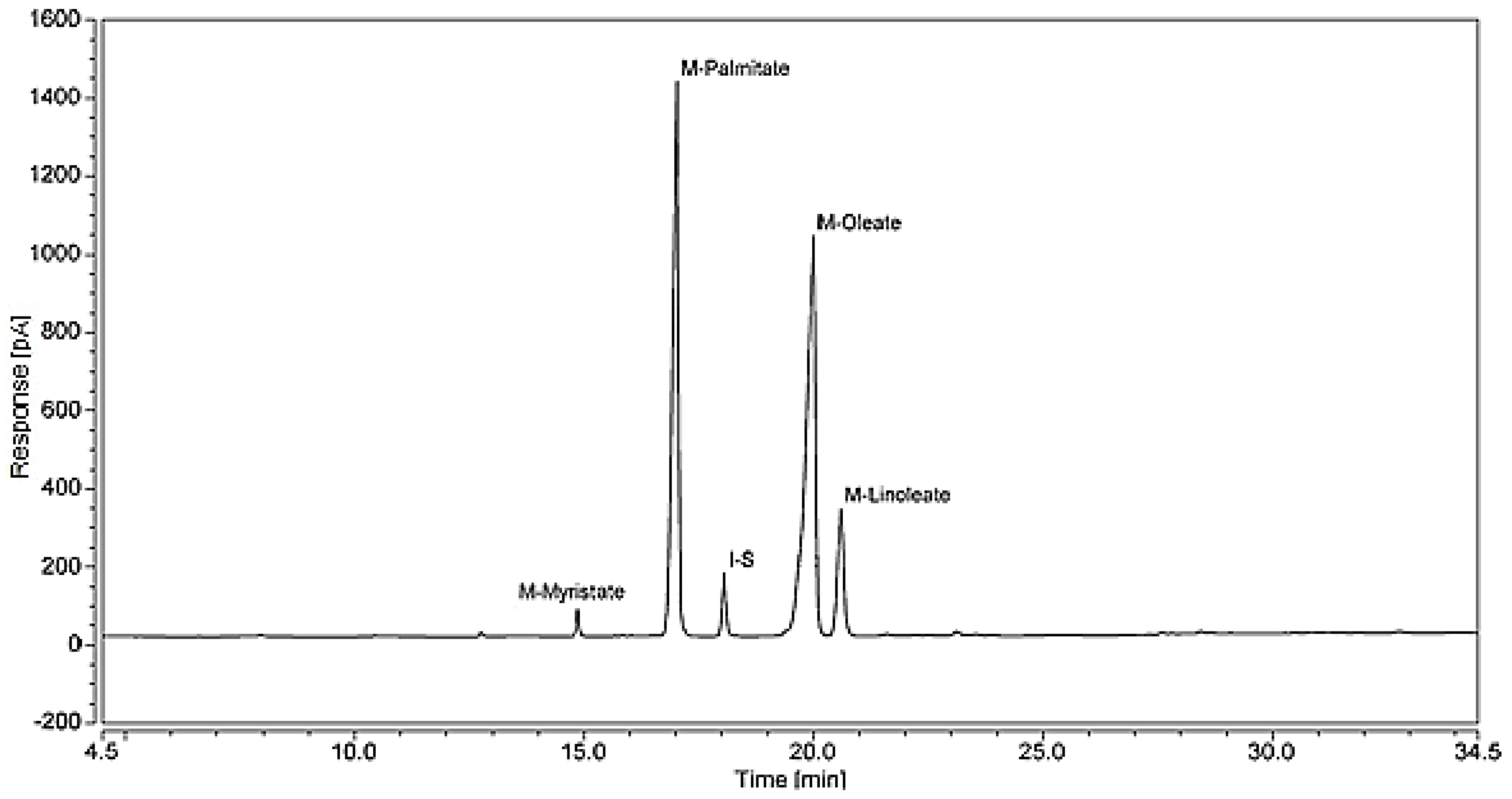

2.2.3. Gas Chromatographic Analysis

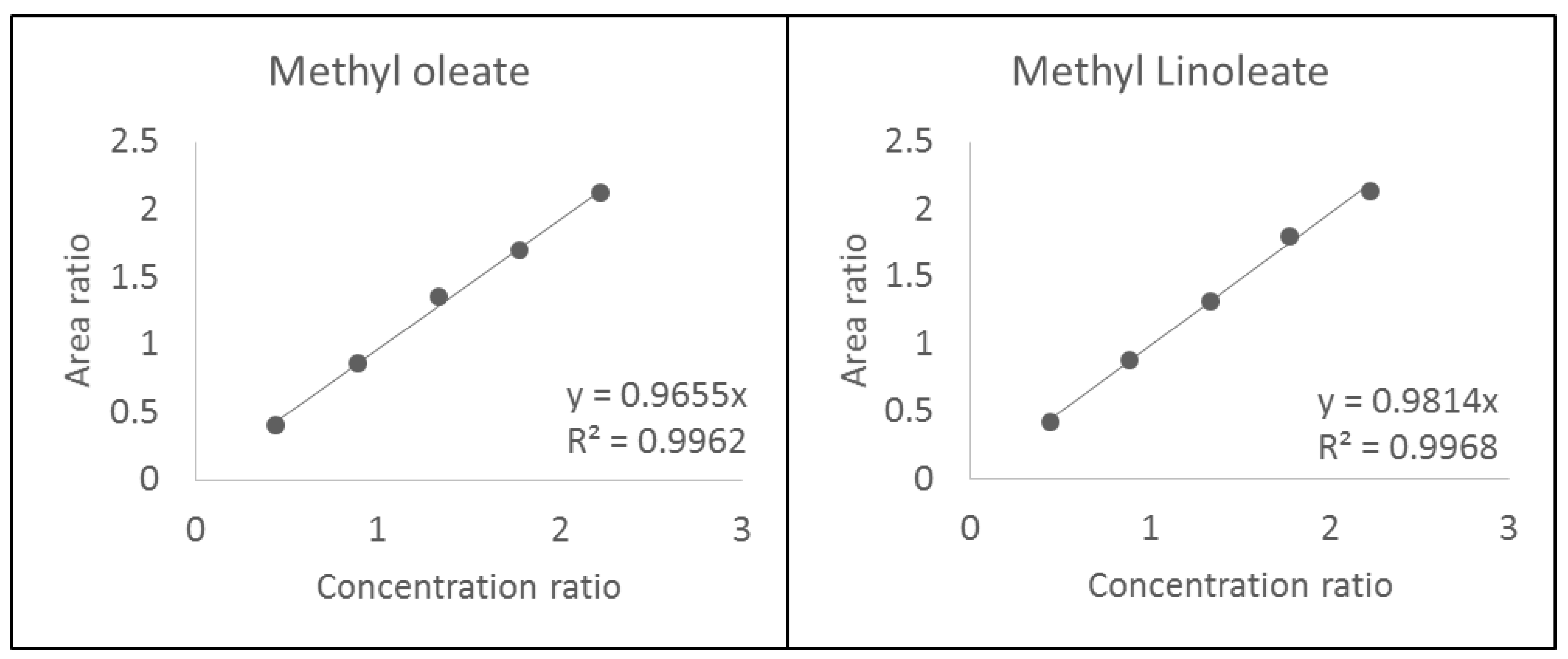

2.2.4. Calibration Curves for Standards

2.2.5. FAME Yield Calculations

2.2.6. Supercritical Methanolysis

2.2.7. Physicochemical Properties

2.3. Experimental Design

2.4. Statistical Analysis

3. Results

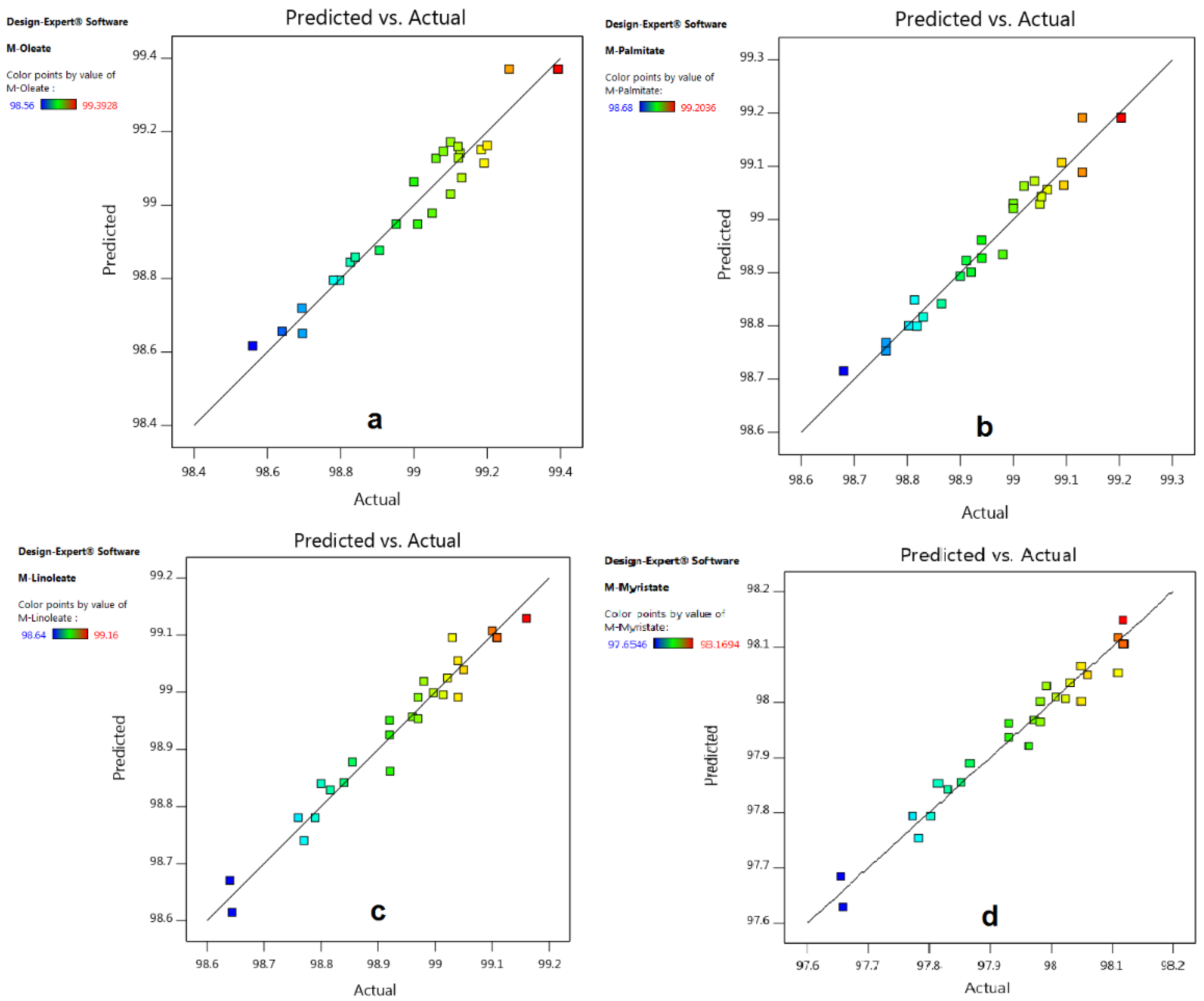

3.1. Models Development and Adequacy Checking

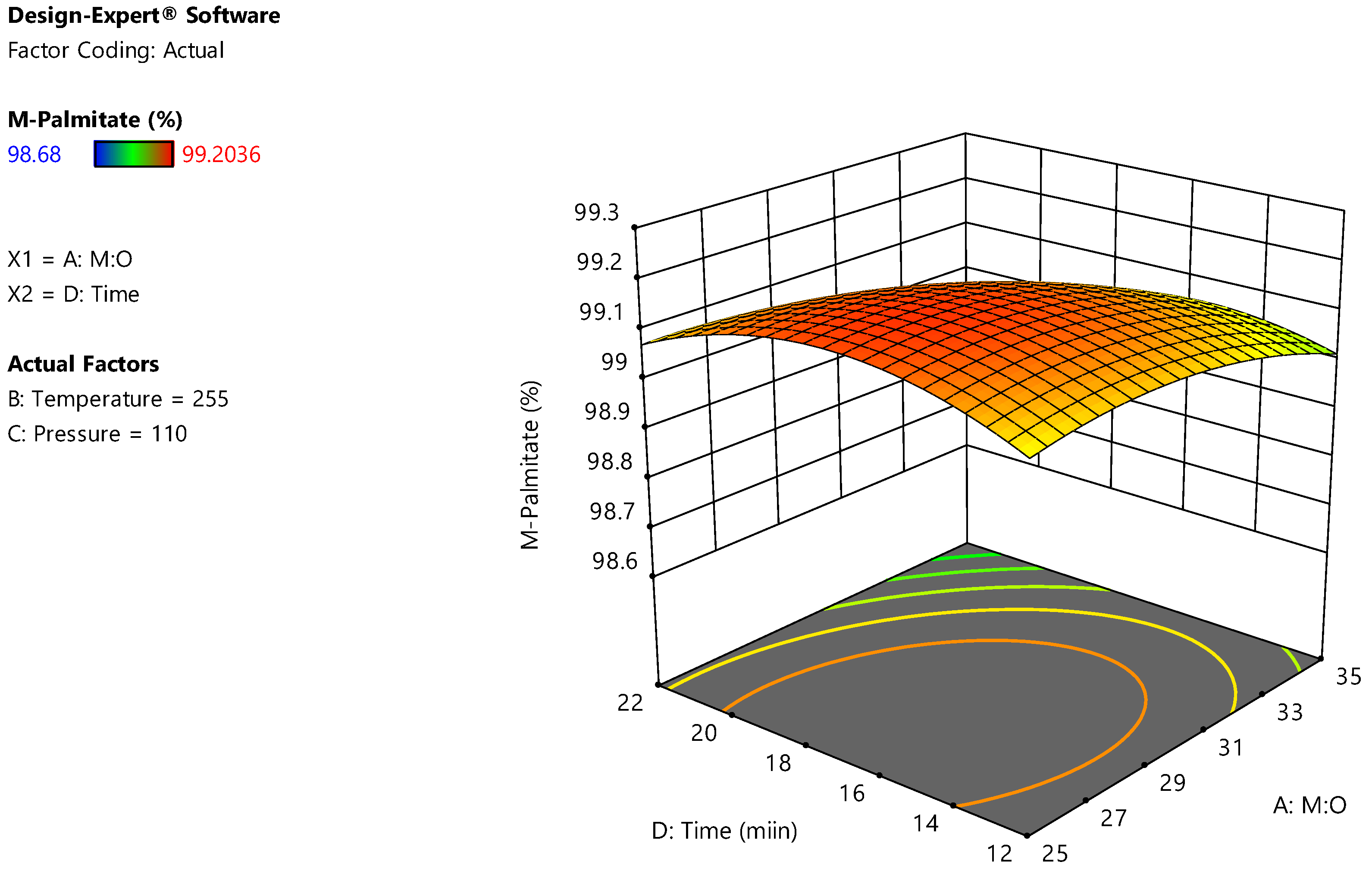

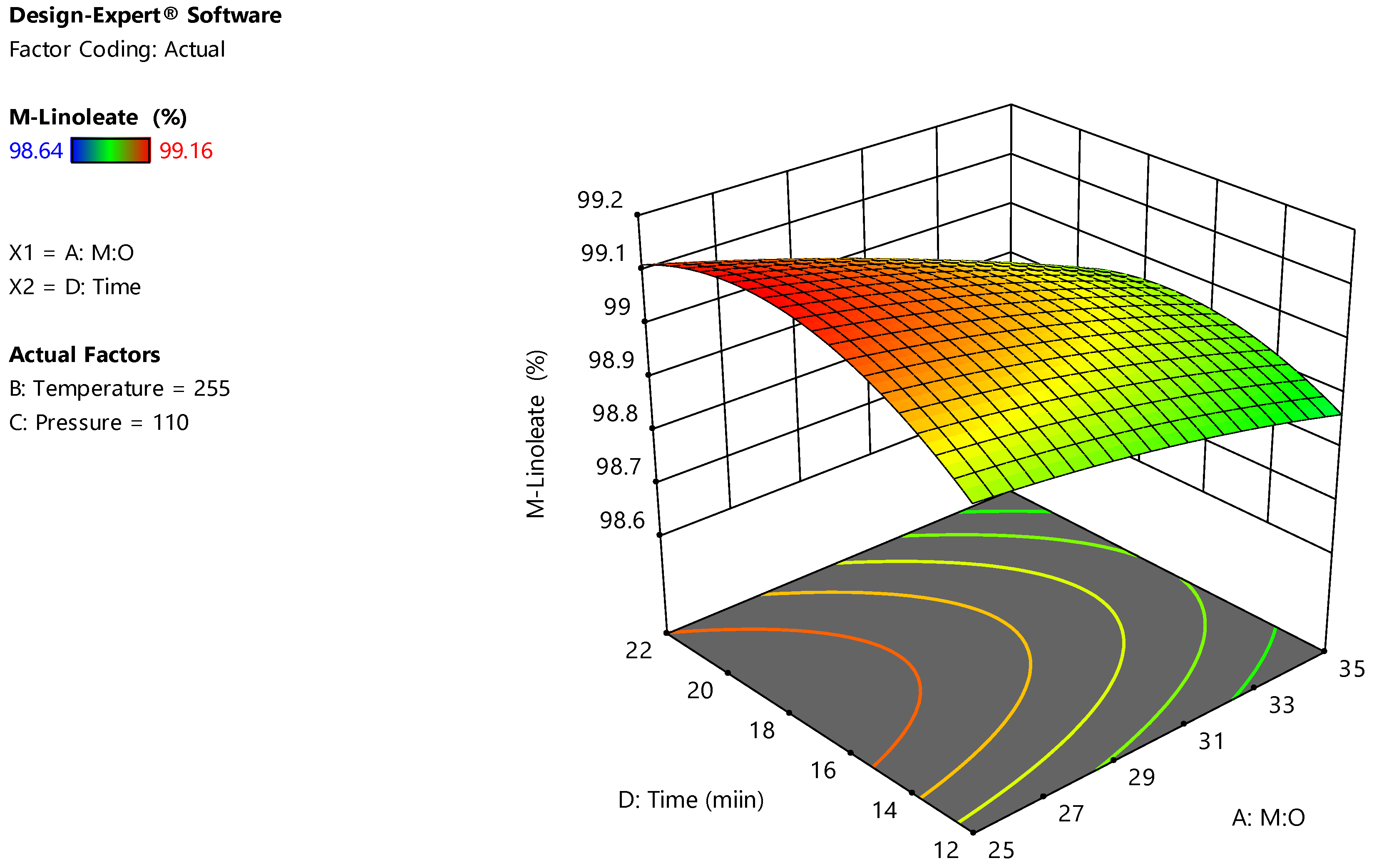

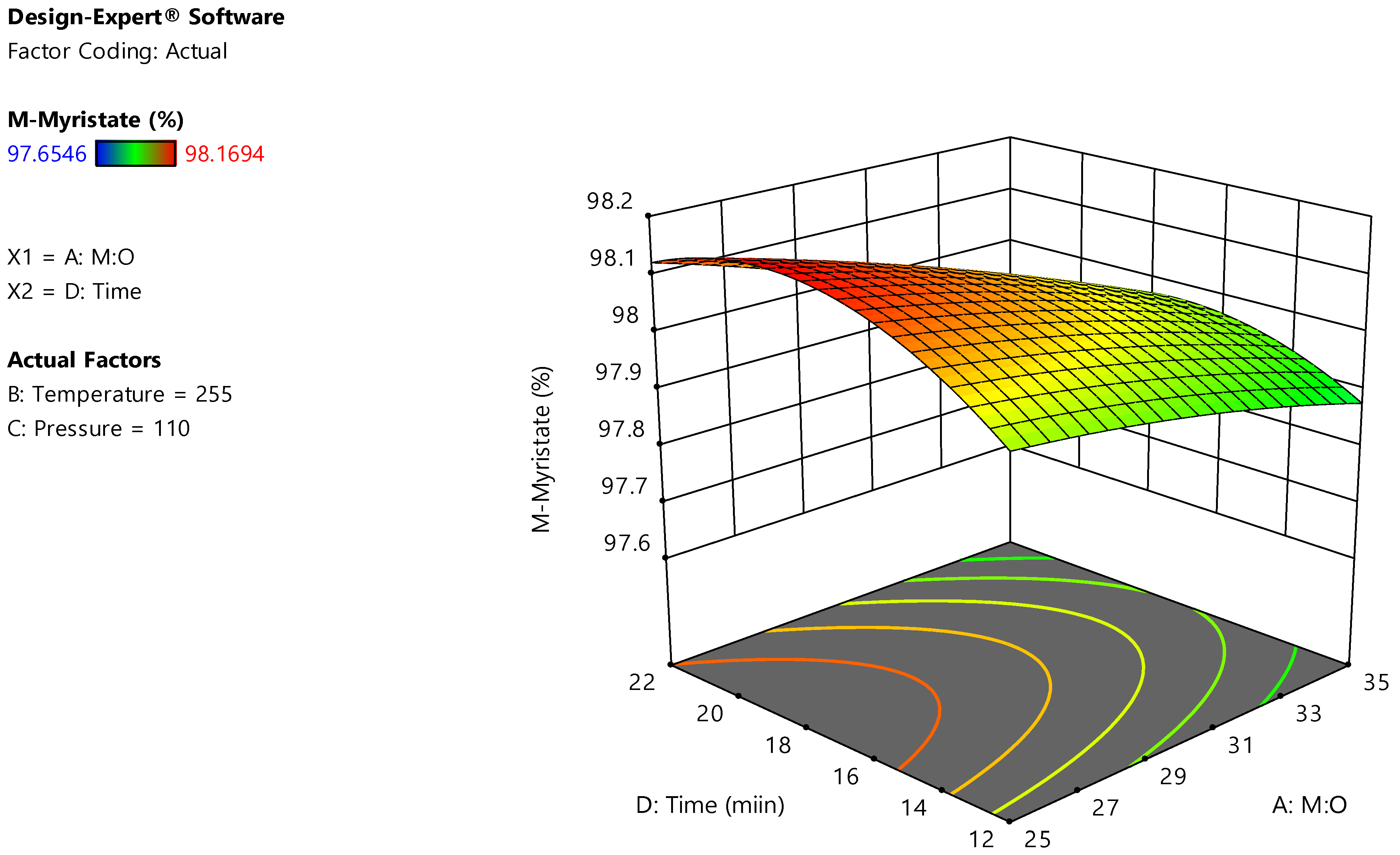

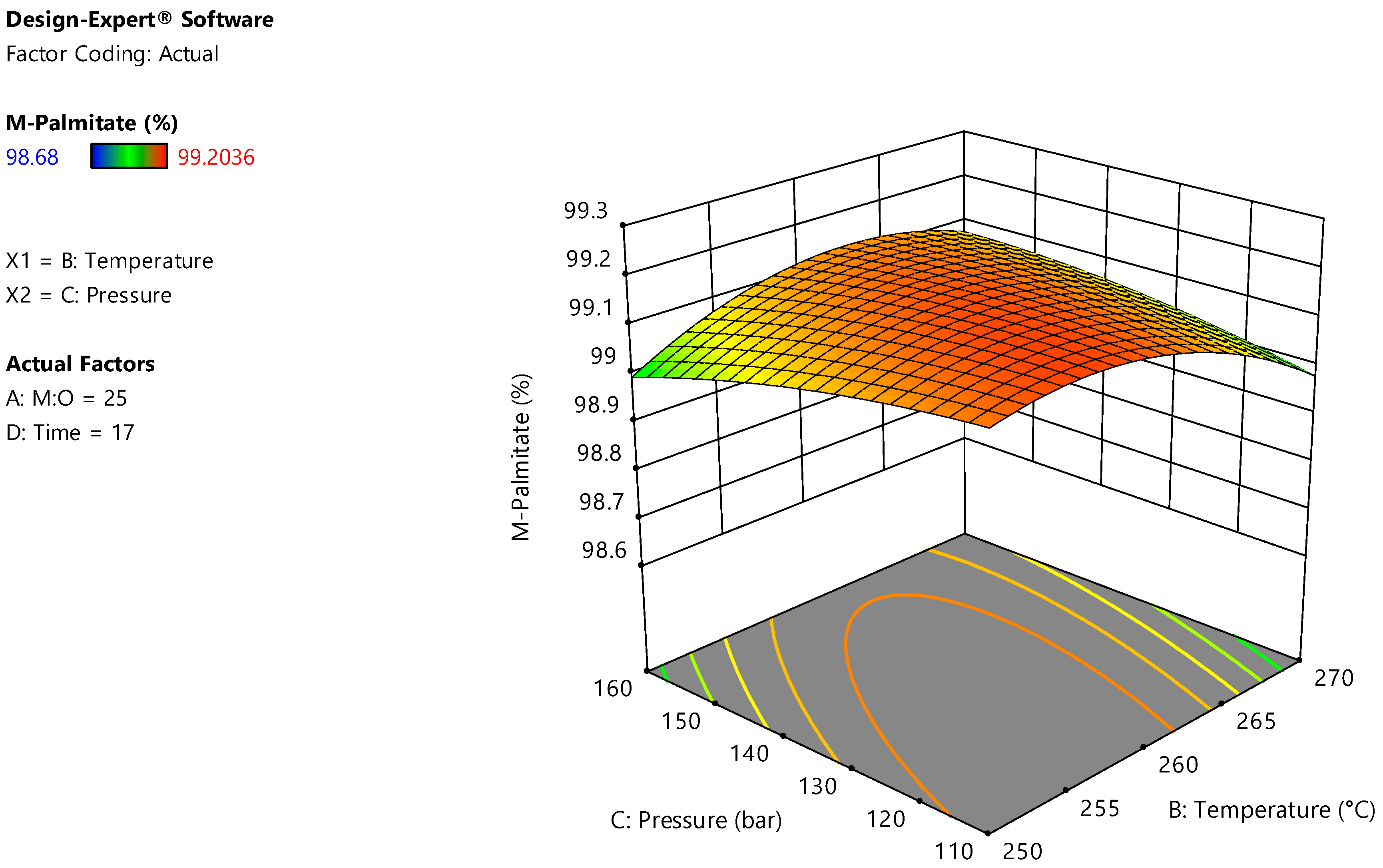

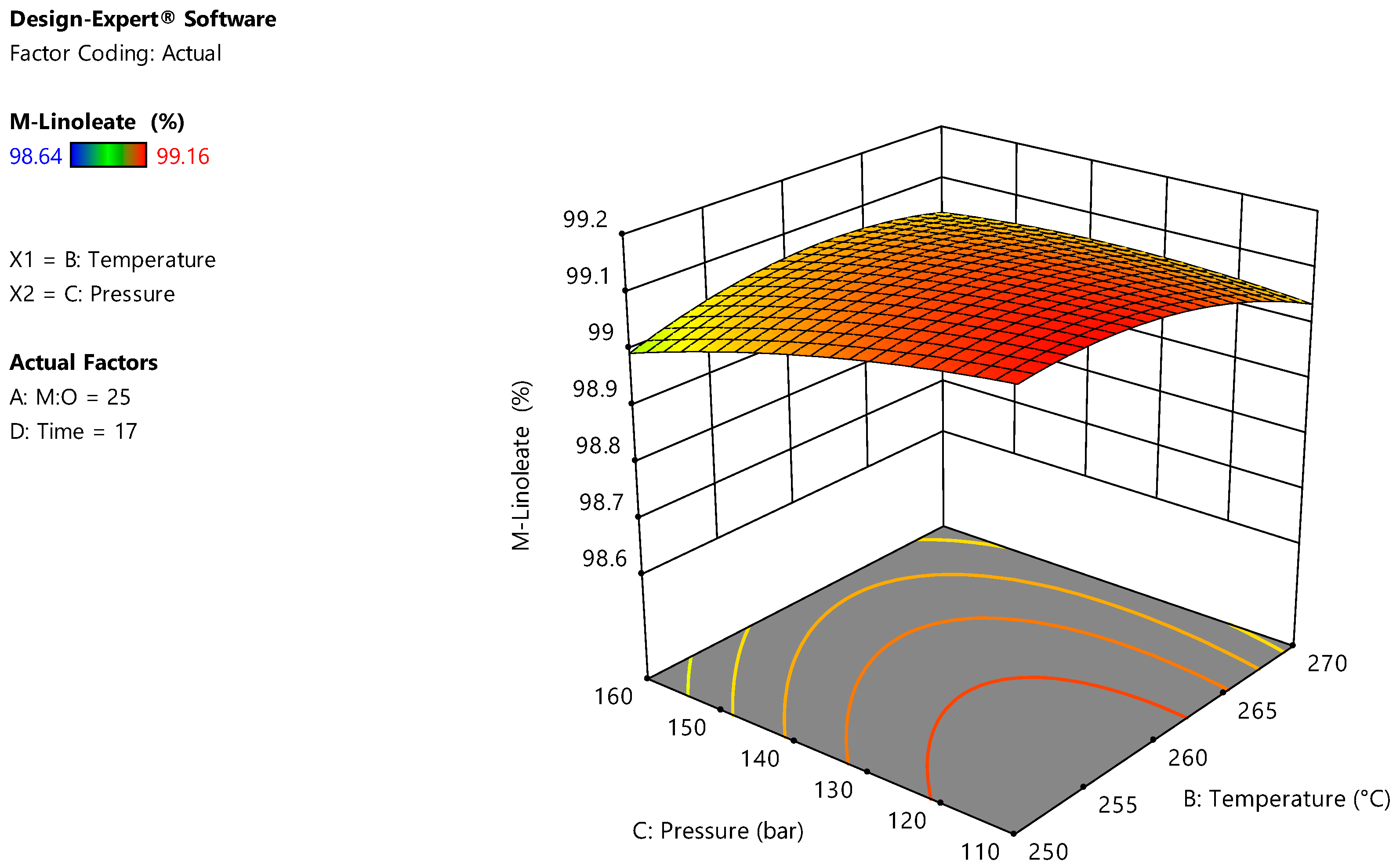

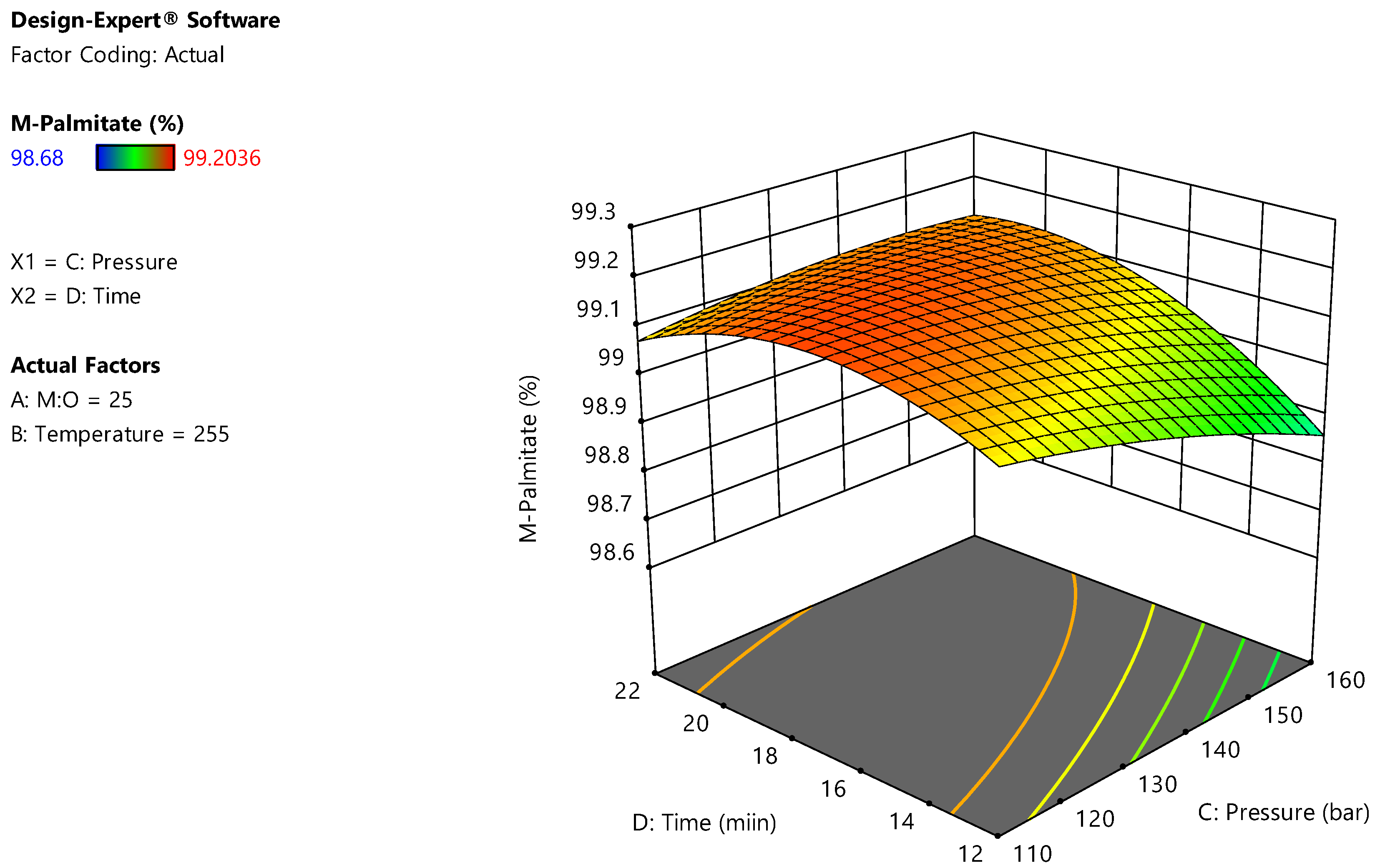

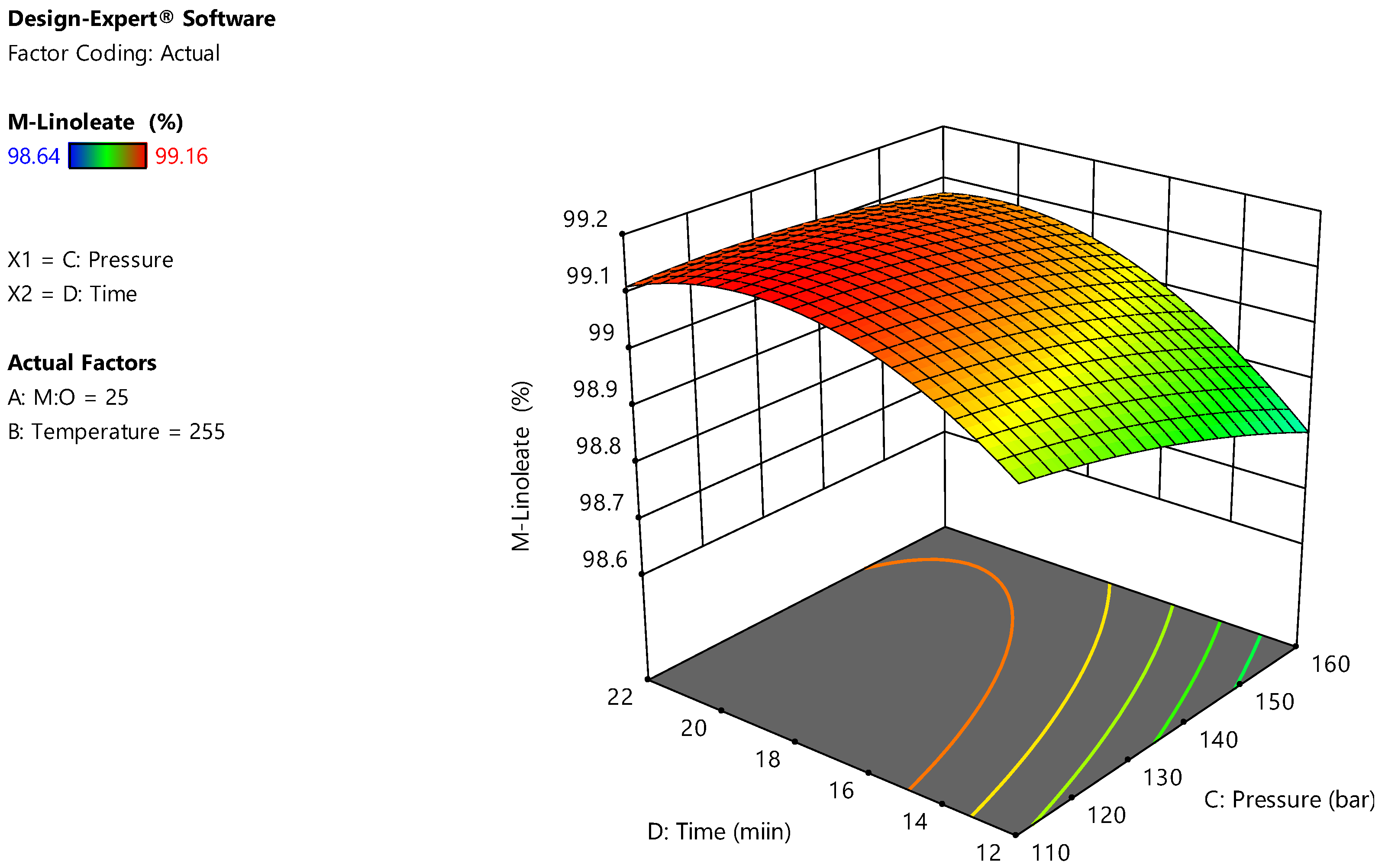

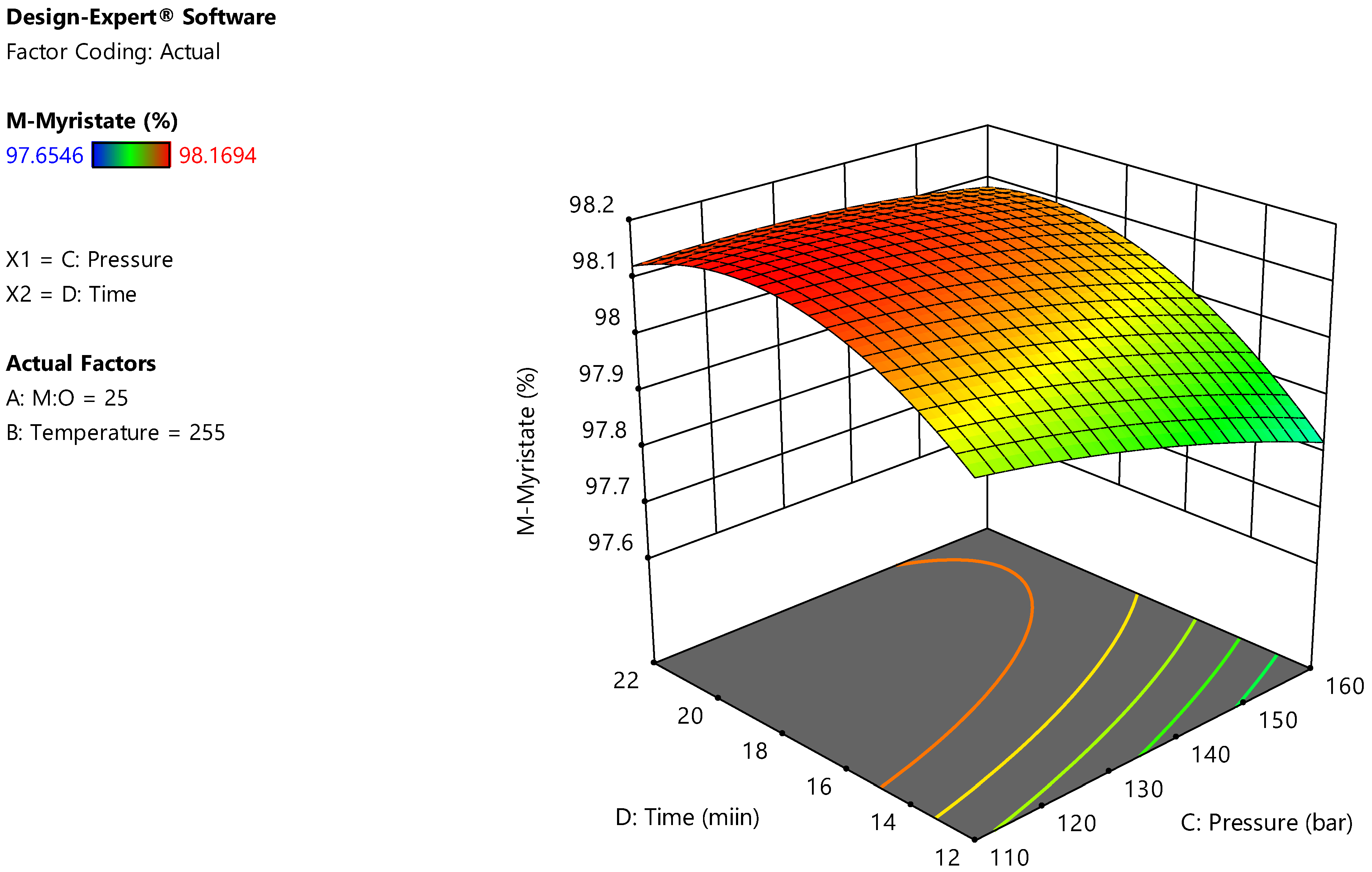

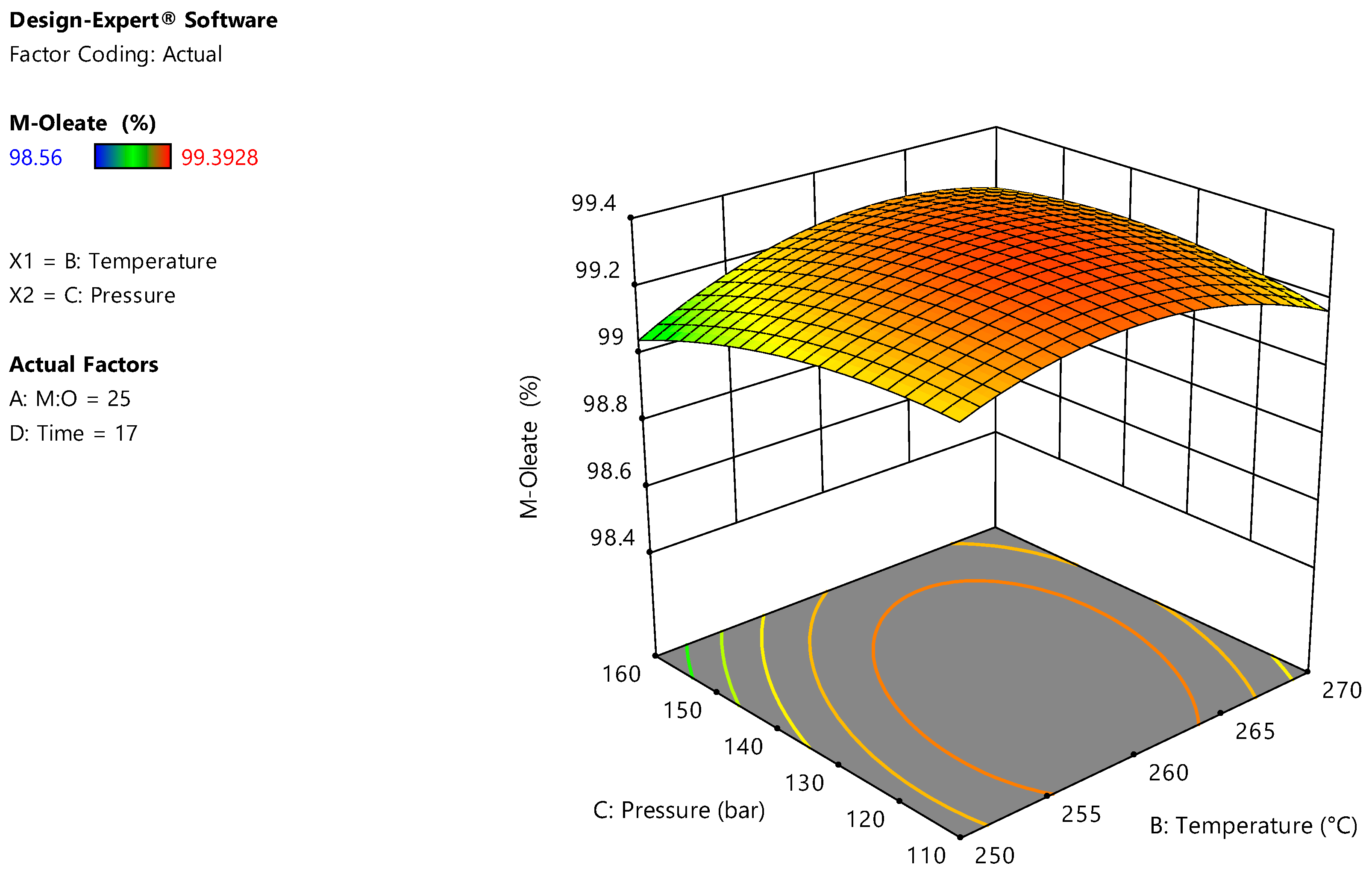

3.2. Effect of Process Variables and Their Interactions

3.2.1. Effect of Methanol to Oil Molar Ratio

3.2.2. Effect of Reaction Time

3.2.3. Effect of Reaction Temperature

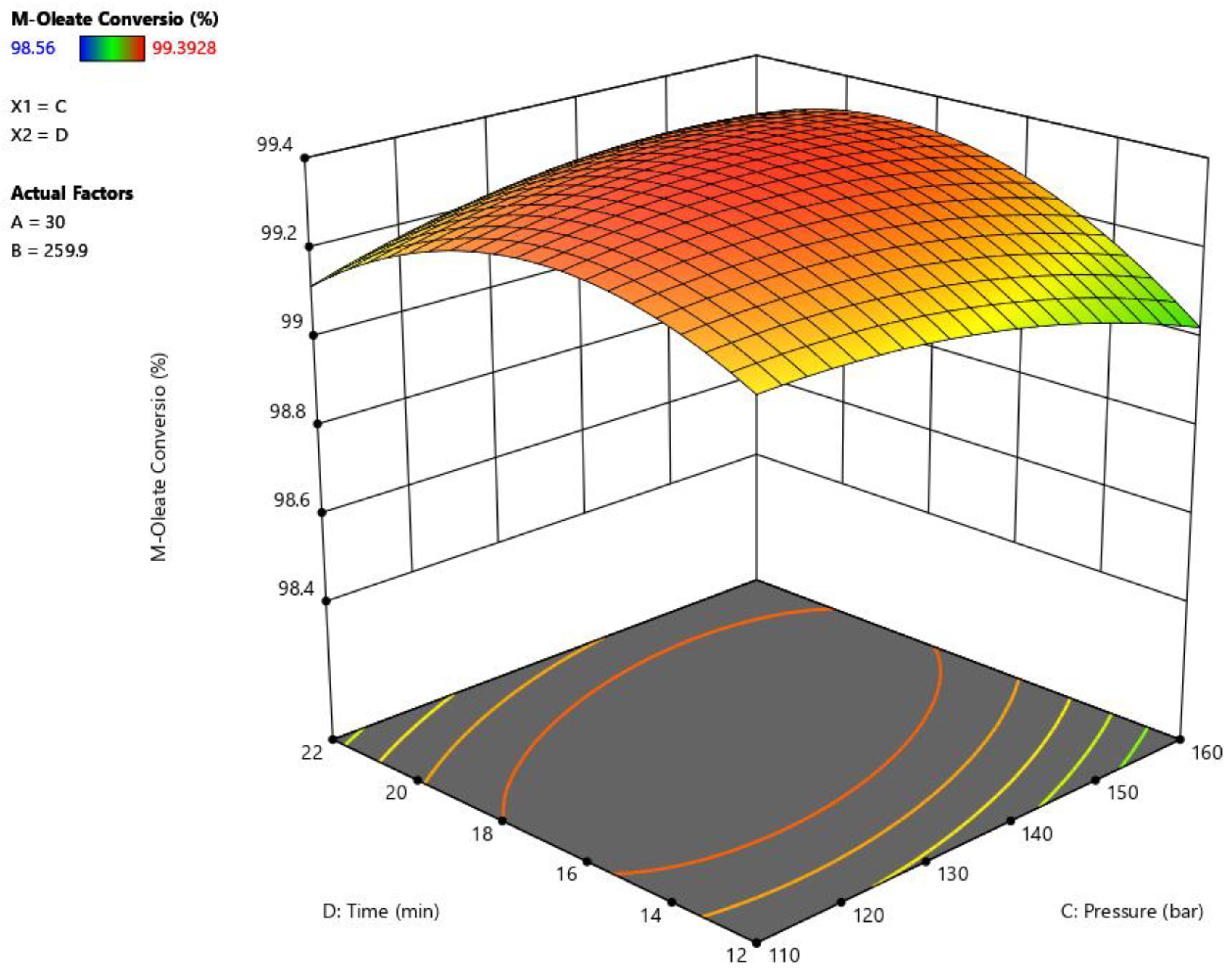

3.2.4. Effect of Reaction Pressure

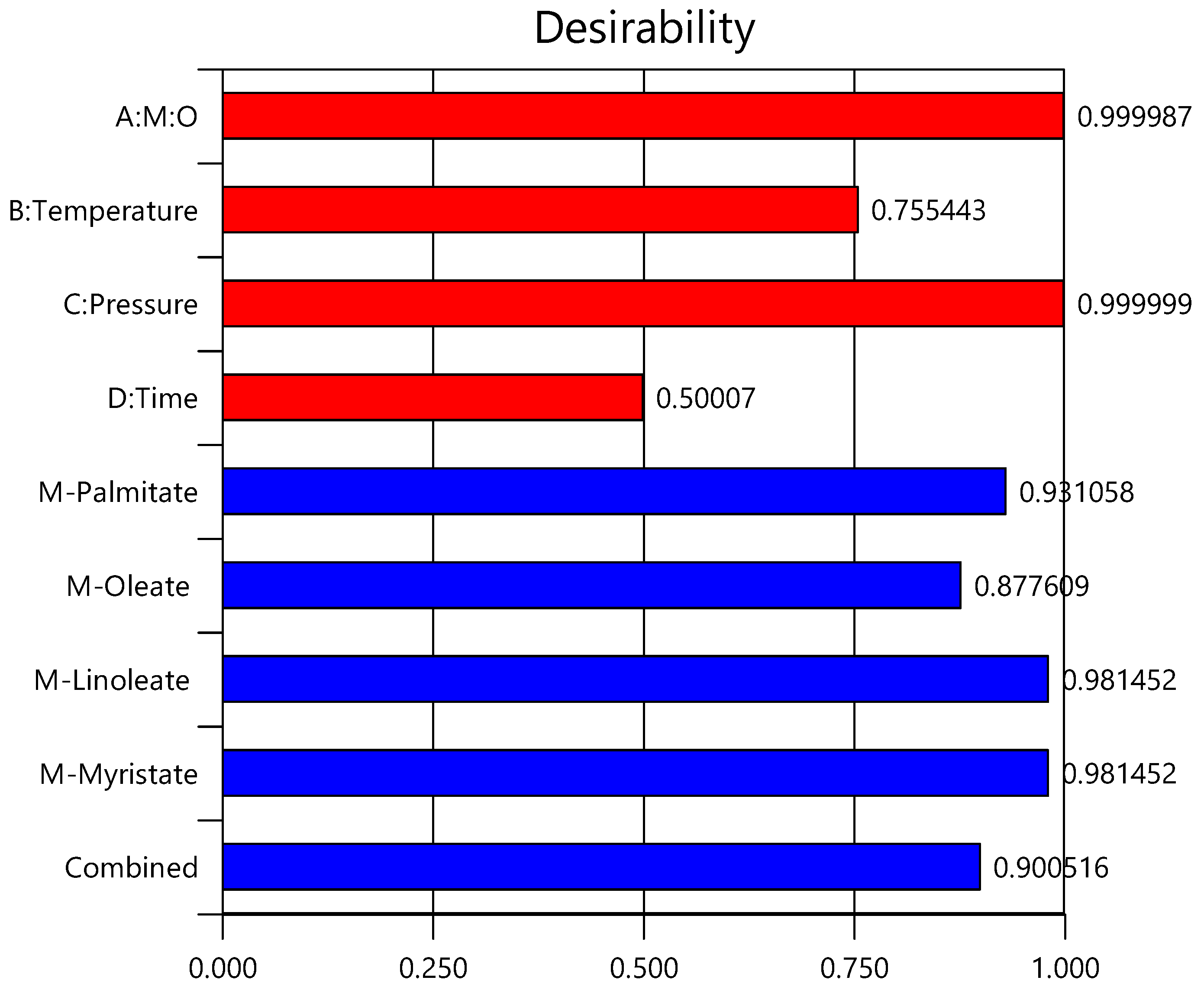

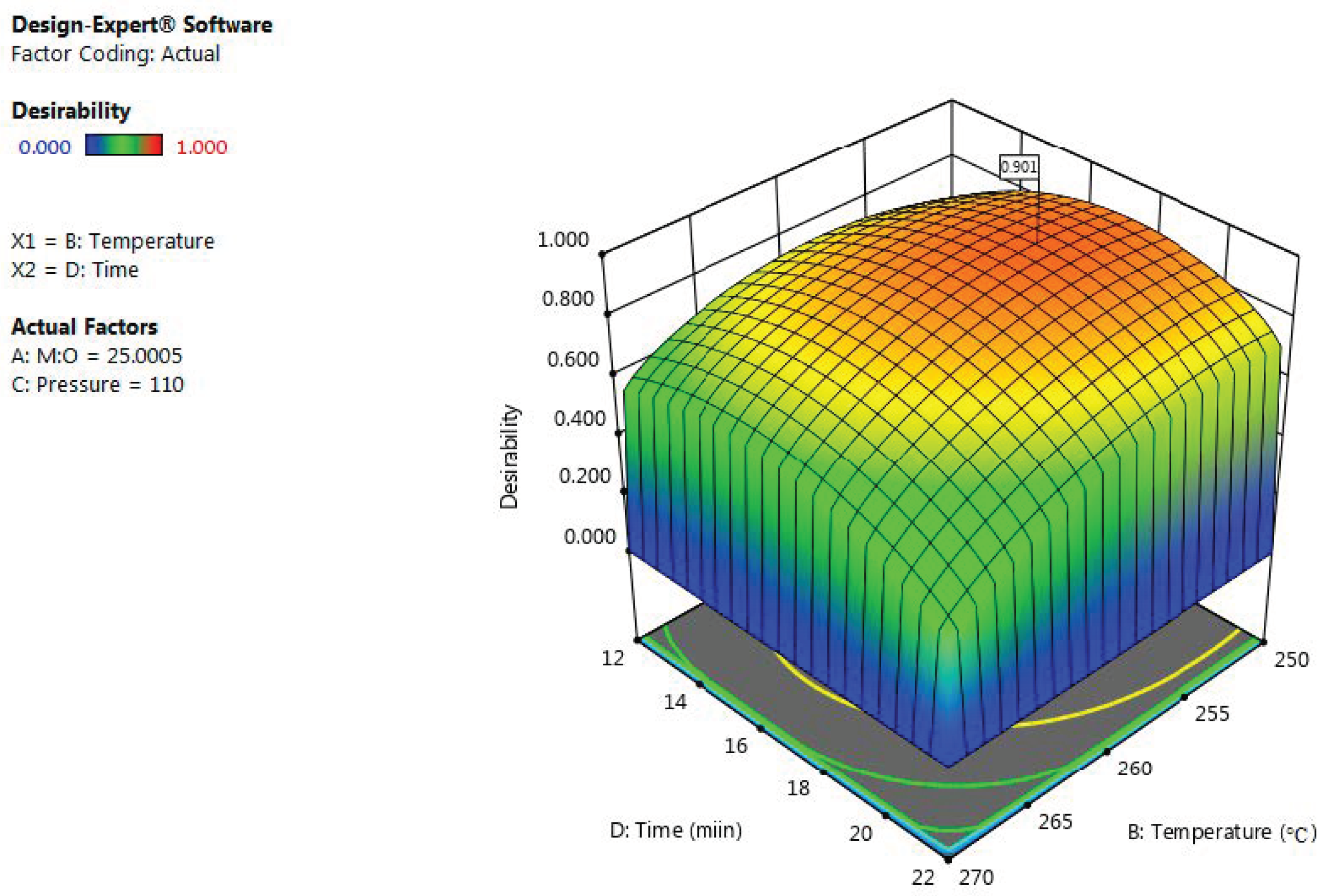

3.3. Process Optimisation

3.4. Selection of Pressurising Gas

3.5. Physicochemical Properties of the Produced Biodiesel

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Run | M:O Ratio (A) | Temperature (°C) (B) | Pressure (bar) (C) | Time (min) (D) | Actual M-Oleate % | Predicted M-Oleate % | Actual M-Palmitate % | Predicted M-Palmitate % | Actual M-Linoleate % | Predicted M-Linoleate % | Actual M-Myristate % |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 30 | 260 | 135 | 17 | 99.26 | 99.37 | 99.1 | 99.1 | 99.0 | 99.0 | 98.0 |

| 2 | 35 | 250 | 160 | 22 | 98.90 | 98.87 | 98.9 | 98.9 | 98.9 | 98.8 | 97.9 |

| 3 | 35 | 250 | 110 | 22 | 98.79 | 98.79 | 98.8 | 98.8 | 98.8 | 98.8 | 97.8 |

| 4 | 35 | 270 | 160 | 22 | 99.08 | 99.14 | 99.0 | 99.0 | 98.9 | 99.0 | 97.9 |

| 5 | 35 | 270 | 110 | 12 | 99.10 | 99.17 | 99.0 | 99.0 | 98.9 | 98.9 | 97.9 |

| 6 | 35 | 250 | 160 | 12 | 98.56 | 98.61 | 98.6 | 98.7 | 98.6 | 98.6 | 97.6 |

| 7 | 25 | 270 | 160 | 22 | 99.12 | 99.14 | 99.0 | 99.0 | 99.0 | 98.9 | 98.0 |

| 8 | 30 | 260 | 135 | 17 | 99.39 | 99.37 | 99.2 | 99.1 | 99.1 | 99.0 | 98.1 |

| 9 | 25 | 250 | 110 | 22 | 99.06 | 99.12 | 99.0 | 99.0 | 99.1 | 99.1 | 98.7 |

| 10 | 25 | 250 | 160 | 22 | 99.19 | 99.11 | 99.0 | 99.0 | 99.0 | 99.0 | 98.0 |

| 11 | 30 | 260 | 85 | 17 | 99.20 | 99.16 | 99.1 | 99.0 | 99.0 | 99.0 | 98.0 |

| 12 | 25 | 270 | 110 | 12 | 99.00 | 99.06 | 98.9 | 98.9 | 98.9 | 98.9 | 97.9 |

| 13 | 25 | 250 | 160 | 12 | 98.64 | 98.65 | 98.7 | 98.7 | 98.7 | 98.7 | 97.7 |

| 14 | 30 | 260 | 135 | 17 | 99.39 | 99.37 | 99.2 | 99.1 | 99.1 | 99.0 | 98.1 |

| 15 | 35 | 250 | 110 | 12 | 98.82 | 98.84 | 98.9 | 98.9 | 98.7 | 98.7 | 97.8 |

| 16 | 30 | 240 | 135 | 17 | 98.69 | 98.71 | 98.8 | 98.7 | 98.8 | 98.8 | 97.8 |

| 17 | 30 | 260 | 185 | 17 | 99.12 | 99.12 | 99.0 | 99.1 | 98.9 | 98.9 | 98.0 |

| 18 | 35 | 270 | 160 | 12 | 99.18 | 99.15 | 99.0 | 99.0 | 99.0 | 99.0 | 98.0 |

| 19 | 30 | 260 | 135 | 17 | 99.39 | 99.37 | 99.2 | 99.1 | 99.1 | 99.0 | 98.1 |

| 20 | 30 | 260 | 135 | 27 | 98.78 | 98.79 | 98.8 | 98.8 | 98.7 | 98.7 | 97.7 |

| 21 | 30 | 260 | 135 | 7 | 98.69 | 98.65 | 98.8 | 98.8 | 98.6 | 98.6 | 97.6 |

| 22 | 25 | 270 | 160 | 12 | 98.95 | 98.94 | 98.9 | 98. | 98.8 | 98.8 | 97.8 |

| 23 | 20 | 260 | 135 | 17 | 99.12 | 99.15 | 99.0 | 99.0 | 99.1 | 99.1 | 98.1 |

| 24 | 25 | 250 | 110 | 12 | 99.05 | 98.97 | 99.0 | 99.0 | 98.9 | 98.9 | 97.9 |

| 25 | 30 | 280 | 135 | 17 | 99.13 | 99.07 | 98.9 | 98.8 | 99.0 | 98.9 | 98.0 |

| 26 | 30 | 260 | 135 | 17 | 99.39 | 99.37 | 99.2 | 99.1 | 99.1 | 99.9 | 98.1 |

| 27 | 40 | 260 | 135 | 17 | 99.10 | 99.03 | 98.9 | 98.9 | 98.9 | 98.9 | 97.9 |

| 28 | 25 | 270 | 110 | 22 | 99.01 | 98.94 | 98.8 | 98.8 | 98.9 | 98.9 | 97.9 |

| 29 | 30 | 260 | 135 | 17 | 99.39 | 99.37 | 99.2 | 99.1 | 99.1 | 99.0 | 98.1 |

| 30 | 35 | 270 | 110 | 22 | 98.84 | 98.85 | 98.7 | 98.7 | 98.8 | 98.8 | 97.8 |

| Fatty Acid | Sum of Squares | df | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 30.31 | 14 | 2.17 | 38.09 | <0.0001 | HS |

| A- M:O (molar ratio) | 0.88 | 1 | 0.88 | 15.45 | 0.0013 | HS |

| B-Temperature | 2.93 | 1 | 2.93 | 51.61 | <0.0001 | HS |

| C-Pressure | 5.91 | 1 | 5.91 | 104.04 | <0.0001 | HS |

| D-Time | 4.85 | 1 | 4.85 | 85.23 | <0.0001 | HS |

| AB | 0.73 | 1 | 0.73 | 12.89 | 0.0027 | HS |

| AC | 1.00 | 1 | 1.00 | 17.65 | 0.0008 | HS |

| AD | 0.067 | 1 | 0.067 | 1.18 | 0.2938 | NS |

| BC | 0.38 | 1 | 0.38 | 6.61 | 0.0213 | S |

| BD | 0.021 | 1 | 0.021 | 0.36 | 0.5558 | NS |

| CD | 0.063 | 1 | 0.063 | 1.10 | 0.3099 | NS |

| A2 | 0.0051 | 1 | 50.0051 | 0.097 | 0.7597 | NS |

| B2 | 0.023 | 1 | 0.023 | 0.40 | 0.5376 | NS |

| C2 | 5.66 | 1 | 5.66 | 99.54 | <0.0001 | HS |

| D2 | 5.87 | 1 | 5.87 | 103.24 | <0.0001 | HS |

| Residual | 0.85 | 15 | 0.057 | |||

| Lack of Fit | 0.42 | 10 | 0.042 | 0.49 | 0.8451 | NS |

| Pure Error | 0.43 | 5 | 0.087 | |||

| Cor Total | 31.17 | 29 |

| Fatty Acid | Sum of Squares | df | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 30.31 | 14 | 2.17 | 38.09 | <0.0001 | HS |

| A- M:O (molar ratio) | 0.88 | 1 | 0.88 | 15.45 | 0.0013 | HS |

| B-Temperature | 2.93 | 1 | 2.93 | 51.61 | <0.0001 | HS |

| C-Pressure | 5.91 | 1 | 5.91 | 104.04 | <0.0001 | HS |

| D-Time | 4.85 | 1 | 4.85 | 85.23 | <0.0001 | HS |

| AB | 0.73 | 1 | 0.73 | 12.89 | 0.0027 | HS |

| AC | 1.00 | 1 | 1.00 | 17.65 | 0.0008 | HS |

| AD | 0.067 | 1 | 0.067 | 1.18 | 0.2938 | NS |

| BC | 0.38 | 1 | 0.38 | 6.61 | 0.0213 | S |

| BD | 0.021 | 1 | 0.021 | 0.36 | 0.5558 | NS |

| CD | 0.063 | 1 | 0.063 | 1.10 | 0.3099 | NS |

| A2 | 0.0051 | 1 | 50.0051 | 0.097 | 0.7597 | NS |

| B2 | 0.023 | 1 | 0.023 | 0.40 | 0.5376 | NS |

| C2 | 5.66 | 1 | 5.66 | 99.54 | <0.0001 | HS |

| D2 | 5.87 | 1 | 5.87 | 103.24 | <0.0001 | HS |

| Residual | 0.85 | 15 | 0.057 | |||

| Lack of Fit | 0.42 | 10 | 0.042 | 0.49 | 0.8451 | NS |

| Pure Error | 0.43 | 5 | 0.087 | |||

| Cor Total | 31.17 | 29 |

| Fatty Acid | Sum of Squares | df | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 30.31 | 14 | 2.17 | 38.09 | <0.0001 | HS |

| A- M:O (molar ratio) | 0.88 | 1 | 0.88 | 15.45 | 0.0013 | HS |

| B-Temperature | 2.93 | 1 | 2.93 | 51.61 | <0.0001 | HS |

| C-Pressure | 5.91 | 1 | 5.91 | 104.04 | <0.0001 | HS |

| D-Time | 4.85 | 1 | 4.85 | 85.23 | <0.0001 | HS |

| AB | 0.73 | 1 | 0.73 | 12.89 | 0.0027 | HS |

| AC | 1.00 | 1 | 1.00 | 17.65 | 0.0008 | HS |

| AD | 0.067 | 1 | 0.067 | 1.18 | 0.2938 | NS |

| BC | 0.38 | 1 | 0.38 | 6.61 | 0.0213 | S |

| BD | 0.021 | 1 | 0.021 | 0.36 | 0.5558 | NS |

| CD | 0.063 | 1 | 0.063 | 1.10 | 0.3099 | NS |

| A2 | 0.0051 | 1 | 50.0051 | 0.097 | 0.7597 | NS |

| B2 | 0.023 | 1 | 0.023 | 0.40 | 0.5376 | NS |

| C2 | 5.66 | 1 | 5.66 | 99.54 | <0.0001 | HS |

| D2 | 5.87 | 1 | 5.87 | 103.24 | <0.0001 | HS |

| Residual | 0.85 | 15 | 0.057 | |||

| Lack of Fit | 0.42 | 10 | 0.042 | 0.49 | 0.8451 | NS |

| Pure Error | 0.43 | 5 | 0.087 | |||

| Cor Total | 31.17 | 29 |

References

- Sahar, S.S.; Iqbal, J.; Ullah, I.; Bhatti, H.N.; Nouren, S.; Habib-ur-Rehman; Nisar, J.; Iqbal, M. Biodiesel production from waste cooking oil: An efficient technique to convert waste into biodiesel. Sustain. Cities Soc. 2018, 41, 220–226. [Google Scholar] [CrossRef]

- Kurowska, K.; Marks-Bielska, R.; Bielski, S.; Kryszk, H.; Jasinskas, A. Food security in the context of liquid biofuels production. Energies 2020, 13, 6247. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Sher, F.; Farooq, M.U.; Jamil, M.A.; Kausar, Z.; Sabah, N.U.; Shah, M.F.; Rehman, H.Z.U.; Rehman, A.U. Potential of Waste Cooking Oil Biodiesel as Renewable Fuel in Combustion Engines: A Review. Energies 2021, 14, 2565. [Google Scholar] [CrossRef]

- Çamur, H.; Alassi, E. Physicochemical Properties Enhancement of Biodiesel Synthesis from Various Feedstocks of Waste/Residential Vegetable Oils and Palm Oil. Energies 2021, 14, 4928. [Google Scholar] [CrossRef]

- Xie, W.; Gao, C.; Wang, H. Biodiesel Production from Low-Quality Oils Using Heterogeneous Cesium Salts of Vanadium-Substituted Polyoxometalate Acid Catalyst. Catalysts 2020, 10, 1060. [Google Scholar] [CrossRef]

- Poudel, J.; Karki, S.; Sanjel, N.; Shah, M.; Oh, S. Comparison of Biodiesel Obtained from Virgin Cooking Oil and Waste Cooking Oil Using Supercritical and Catalytic Transesterification. Energies 2017, 10, 546. [Google Scholar] [CrossRef] [Green Version]

- Aboelazayem, O.; El-Gendy, N.S.; Abdel-Rehim, A.A.; Ashour, F.; Sadek, M.A. Biodiesel production from castor oil in Egypt: Process optimisation, kinetic study, diesel engine performance and exhaust emissions analysis. Energy 2018, 157, 843–852. [Google Scholar] [CrossRef]

- Hsiao, M.-C.; Liao, P.-H.; Lan, N.V.; Hou, S.-S. Enhancement of Biodiesel Production from High-Acid-Value Waste Cooking Oil via a Microwave Reactor Using a Homogeneous Alkaline Catalyst. Energies 2021, 14, 437. [Google Scholar] [CrossRef]

- Nisar, S.; Hanif, M.A.; Rashid, U.; Hanif, A.; Akhtar, M.N.; Ngamcharussrivichai, C. Trends in Widely Used Catalysts for Fatty Acid Methyl Esters (FAME) Production: A Review. Catalysts 2021, 11, 1085. [Google Scholar] [CrossRef]

- Budžaki, S.; Miljić, G.; Tišma, M.; Sundaram, S.; Hessel, V. Is there a future for enzymatic biodiesel industrial production in microreactors? Appl. Energy 2017, 201, 124–134. [Google Scholar] [CrossRef]

- Hassan, A.A.; Smith, J.D. Laboratory-Scale Research of Non-Catalyzed Supercritical Alcohol Process for Continuous Biodiesel Production. Catalysts 2021, 11, 435. [Google Scholar] [CrossRef]

- Aboelazayem, O.; Gadalla, M.; Saha, B. Derivatisation-free characterisation and supercritical conversion of free fatty acids into biodiesel from high acid value waste cooking oil. Renew. Energy 2019, 143, 77–90. [Google Scholar] [CrossRef]

- Ganev, E.; Ivanov, B.; Vaklieva-Bancheva, N.; Kirilova, E.; Dzhelil, Y. A Multi-Objective Approach toward Optimal Design of Sustainable Integrated Biodiesel/Diesel Supply Chain Based on First- and Second-Generation Feedstock with Solid Waste Use. Energies 2021, 14, 2261. [Google Scholar] [CrossRef]

- Qadeer, M.U.; Ayoub, M.; Komiyama, M.; Khan Daulatzai, M.U.; Mukhtar, A.; Saqib, S.; Ullah, S.; Qyyum, M.A.; Asif, S.; Bokhari, A. Review of biodiesel synthesis technologies, current trends, yield influencing factors and economical analysis of supercritical process. J. Clean. Prod. 2021, 309, 127388. [Google Scholar] [CrossRef]

- Aboelazayem, O.; Gadalla, M.; Saha, B. An experimental-based energy integrated process for Biodiesel production from waste cooking oil using supercritical methanol. Chem. Eng. Trans. 2017, 61, 1645–1650. [Google Scholar] [CrossRef]

- Aboelazayem, O.; Gadalla, M.; Alhajri, I.; Saha, B. Advanced process integration for supercritical production of biodiesel: Residual waste heat recovery via organic Rankine cycle (ORC). Renew. Energy 2021, 164, 433–443. [Google Scholar] [CrossRef]

- Farobie, O.; Matsumura, Y. State of the art of biodiesel production under supercritical conditions. Prog. Energy Combust. Sci. 2017, 63, 173–203. [Google Scholar] [CrossRef]

- Aboelazayem, O.; Gadalla, M.; Saha, B. Valorisation of high acid value waste cooking oil into biodiesel using supercritical methanolysis: Experimental assessment and statistical optimisation on typical Egyptian feedstock. Energy 2018, 162, 408–420. [Google Scholar] [CrossRef]

- Umar, Y.; Velasco, O.; Abdelaziz, O.Y.; Aboelazayem, O.; Gadalla, M.A.; Hulteberg, C.P.; Saha, B. A renewable lignin-derived bio-oil for boosting the oxidation stability of biodiesel. Renew. Energy 2022, 182, 867–878. [Google Scholar] [CrossRef]

- Eze, V.C.; Phan, A.N.; Harvey, A.P. Intensified one-step biodiesel production from high water and free fatty acid waste cooking oils. Fuel 2018, 220, 567–574. [Google Scholar] [CrossRef]

- Onyenkeadi, V.; Aboelazayem, O.; Saha, B. Systematic multivariate optimisation of butylene carbonate synthesis via CO2 utilisation using graphene-inorganic nanocomposite catalysts. Catal. Today 2020, 346, 10–22. [Google Scholar] [CrossRef]

- Zhou, D.; Qiao, B.; Li, G.; Xue, S.; Yin, J. Continuous production of biodiesel from microalgae by extraction coupling with transesterification under supercritical conditions. Bioresour. Technol. 2017, 238, 609–615. [Google Scholar] [CrossRef] [PubMed]

- Torrentes-Espinoza, G.; Miranda, B.C.; Vega-Baudrit, J.; Mata-Segreda, J.F. Castor oil (Ricinus communis) supercritical methanolysis. Energy 2017, 140, 426–435. [Google Scholar] [CrossRef]

- Aboelazayem, O.; Gadalla, M.; Saha, B. Biodiesel production from waste cooking oil via supercritical methanol: Optimisation and reactor simulation. Renew. Energy 2018, 124, 144–154. [Google Scholar] [CrossRef]

- Lee, K.T.; Tan, K.T.; Ooi, S.N.; Mohamed, A.R.; Ang, G.T. Optimization and kinetic studies of sea mango (Cerbera odollam) oil for biodiesel production via supercritical reaction. Energy Convers. Manag. 2015, 99, 242–251. [Google Scholar] [CrossRef]

- García-Martínez, N.; Andreo-Martínez, P.; Quesada-Medina, J.; de los Ríos, A.P.; Chica, A.; Beneito-Ruiz, R.; Carratalá-Abril, J. Optimization of non-catalytic transesterification of tobacco (Nicotiana tabacum) seed oil using supercritical methanol to biodiesel production. Energy Convers. Manag. 2017, 131, 99–108. [Google Scholar] [CrossRef]

- Imahara, H.; Minami, E.; Hari, S.; Saka, S. Thermal stability of biodiesel in supercritical methanol. Fuel 2008, 87, 1–6. [Google Scholar] [CrossRef]

- Jazzar, S.; Olivares-Carrillo, P.; Pérez de los Ríos, A.; Marzouki, M.N.; Acién-Fernández, F.G.; Fernández-Sevilla, J.M.; Molina-Grima, E.; Smaali, I.; Quesada-Medina, J. Direct supercritical methanolysis of wet and dry unwashed marine microalgae (Nannochloropsis gaditana) to biodiesel. Appl. Energy 2015, 148, 210–219. [Google Scholar] [CrossRef]

- Ghoreishi, S.M.; Moein, P. Biodiesel synthesis from waste vegetable oil via transesterification reaction in supercritical methanol. J. Supercrit. Fluids 2013, 76, 24–31. [Google Scholar] [CrossRef]

- Han, H.; Cao, W.; Zhang, J. Preparation of biodiesel from soybean oil using supercritical methanol and CO2 as co-solvent. Process Biochem. 2005, 40, 3148–3151. [Google Scholar] [CrossRef]

- Qiao, B.-Q.; Zhou, D.; Li, G.; Yin, J.-Z.; Xue, S.; Liu, J. Process enhancement of supercritical methanol biodiesel production by packing beds. Bioresour. Technol. 2017, 228, 298–304. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.-Q.; Li, Q.; Yin, J.-Z.; Guo, D.; Qiao, B.-Q. Continuous production of biodiesel from soybean flakes by extraction coupling with transesterification under supercritical conditions. Fuel Process. Technol. 2016, 144, 37–41. [Google Scholar] [CrossRef]

- Muthukumaran, C.; Praniesh, R.; Navamani, P.; Swathi, R.; Sharmila, G.; Manoj Kumar, N. Process optimization and kinetic modeling of biodiesel production using non-edible Madhuca indica oil. Fuel 2017, 195, 217–225. [Google Scholar] [CrossRef]

- Yuliana, M.; Santoso, S.P.; Soetaredjo, F.E.; Ismadji, S.; Ayucitra, A.; Angkawijaya, A.E.; Ju, Y.H.; Tran-Nguyen, P.L. A one-pot synthesis of biodiesel from leather tanning waste using supercritical ethanol: Process optimization. Biomass Bioenergy 2020, 142, 105761. [Google Scholar] [CrossRef]

- Can, Ö.; Öztürk, E.; Yücesu, H.S. Combustion and exhaust emissions of canola biodiesel blends in a single cylinder DI diesel engine. Renew. Energy 2017, 109, 73–82. [Google Scholar] [CrossRef]

| Fatty Acid | Composition (wt%) |

|---|---|

| Oleic acid | 48.2 |

| Linoleic acid | 9.3 |

| Palmitic acid | 41.6 |

| Myristic acid | 0.8 |

| Property | Standard Method | Units | Results |

|---|---|---|---|

| Kinematic viscosity | ASTM D-445 | cSt | 60.5 |

| Density | ATM D-4052 | g/cm3 | 0.93 |

| TAN | ASTM-D974 | mg KOH/g oil | 18 |

| water content | wt% | 4 |

| Fatty Acid | Code | Levels | ||||

|---|---|---|---|---|---|---|

| −2 | −1 | 0 | 1 | 2 | ||

| M:O (molar ratio) | A | 20 | 25 | 30 | 35 | 40 |

| Temperature (°C) | B | 240 | 250 | 260 | 270 | 280 |

| Pressure (bar) | C | 85 | 110 | 135 | 160 | 185 |

| Time (min) | D | 7 | 12 | 17 | 22 | 27 |

| Run | M:O Ratio (A) | Temperature (°C) (B) | Pressure (bar) (C) | Time (min) (D) | Actual M-Oleate (%) | Predicted M-Oleate (%) |

|---|---|---|---|---|---|---|

| 1 | 30 | 260 | 135 | 17 | 99.26 | 99.37 |

| 2 | 35 | 250 | 160 | 22 | 98.90 | 98.87 |

| 3 | 35 | 250 | 110 | 22 | 98.79 | 98.79 |

| 4 | 35 | 270 | 160 | 22 | 99.08 | 99.14 |

| 5 | 35 | 270 | 110 | 12 | 99.10 | 99.17 |

| 6 | 35 | 250 | 160 | 12 | 98.56 | 98.61 |

| 7 | 25 | 270 | 160 | 22 | 99.12 | 99.14 |

| 8 | 30 | 260 | 135 | 17 | 99.39 | 99.37 |

| 9 | 25 | 250 | 110 | 22 | 99.06 | 99.12 |

| 10 | 25 | 250 | 160 | 22 | 99.19 | 99.11 |

| 11 | 30 | 260 | 85 | 17 | 99.20 | 99.16 |

| 12 | 25 | 270 | 110 | 12 | 99.00 | 99.06 |

| 13 | 25 | 250 | 160 | 12 | 98.64 | 98.65 |

| 14 | 30 | 260 | 135 | 17 | 99.39 | 99.37 |

| 15 | 35 | 250 | 110 | 12 | 98.82 | 98.84 |

| 16 | 30 | 240 | 135 | 17 | 98.69 | 98.71 |

| 17 | 30 | 260 | 185 | 17 | 99.12 | 99.12 |

| 18 | 35 | 270 | 160 | 12 | 99.18 | 99.15 |

| 19 | 30 | 260 | 135 | 17 | 99.39 | 99.37 |

| 20 | 30 | 260 | 135 | 27 | 98.78 | 98.79 |

| 21 | 30 | 260 | 135 | 7 | 98.69 | 98.65 |

| 22 | 25 | 270 | 160 | 12 | 98.95 | 98.94 |

| 23 | 20 | 260 | 135 | 17 | 99.12 | 99.15 |

| 24 | 25 | 250 | 110 | 12 | 99.05 | 98.97 |

| 25 | 30 | 280 | 135 | 17 | 99.13 | 99.07 |

| 26 | 30 | 260 | 135 | 17 | 99.39 | 99.37 |

| 27 | 40 | 260 | 135 | 17 | 99.10 | 99.03 |

| 28 | 25 | 270 | 110 | 22 | 99.01 | 98.94 |

| 29 | 30 | 260 | 1I5 | 17 | 99.39 | 99.37 |

| 30 | 35 | 270 | 110 | 22 | 98.84 | 98.85 |

| Fatty Acid | Sum of Squares | df | Mean Square | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 1.577 | 14 | 0.112 | 24.822 | <0.0001 |

| A-MeOH:Oil | 0.025 | 1 | 0.025 | 5.517 | 0.032 |

| B-Temperature | 0.189 | 1 | 0.189 | 41.682 | <0.0001 |

| C-Pressure | 0.001 | 1 | 0.001 | 0.379 | 0.547 |

| D-Time | 0.031 | 1 | 0.031 | 6.923 | 0.018 |

| AB | 0.058 | 1 | 0.058 | 12.93 | 0.002 |

| AC | 0.008 | 1 | 0.008 | 1.961 | 0.181 |

| AD | 0.039 | 1 | 0.039 | 8.647 | 0.010 |

| BC | 0.042 | 1 | 0.042 | 9.414 | 0.007 |

| BD | 0.07 | 1 | 0.070 | 15.430 | 0.001 |

| CD | 0.095 | 1 | 0.095 | 21.060 | 0.0003 |

| A2 | 0.130 | 1 | 0.130 | 28.710 | <0.0001 |

| B2 | 0.384 | 1 | 0.384 | 84.72 | <0.0001 |

| C2 | 0.086 | 1 | 0.086 | 19.153 | 0.0005 |

| D2 | 0.718 | 1 | 0.718 | 158.412 | <0.0001 |

| Residual | 0.068 | 15 | 0.004 | ||

| Lack of Fit | 0.053 | 10 | 0.005 | 1.815 | 0.264 |

| Factor | Code | Goal | Importance | Limits | |

|---|---|---|---|---|---|

| Scale 1–5 | Lower | Upper | |||

| M:O (molar ratio) | A | Minimise | 3 | 25 | 35 |

| Temperature (°C) | B | Minimise | 4 | 250 | 270 |

| Pressure (bar) | C | Minimise | 3 | 110 | 160 |

| Time (min) | D | Minimise | 4 | 12 | 22 |

| Methyl-oleate FAME yield | Y1 | Maximise | 5 | 98.3 | 100 |

| Methyl-palmitate FAME yield | Y2 | Maximise | 5 | 98.1 | 100 |

| Methyl-linoleate FAME yield | Y3 | Maximise | 5 | 98.2 | 100 |

| Methyl-myristate FAME yield | Y4 | Maximise | 5 | 97.6 | 100 |

| Factor | Code | Unit | ||

|---|---|---|---|---|

| Biodiesel | EN14214 | |||

| Kinematic viscosity | ASTM-D445 | cSt | 4.54 | 3.5–5 |

| Density | ATM-D4052 | g/cm3 | 0.886 | 0.86–0.9 |

| TAN | ASTM-D974 | mg KOH/g oil | 0.28 | <0.5 |

| CFPP | ASTM-D6371 | °C | –1 | <0 |

| Flashpoint | ASMT-D93 | °C | 135 | <101 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aboelazayem, O.; Gadalla, M.; Saha, B. Comprehensive Optimisation of Biodiesel Production Conditions via Supercritical Methanolysis of Waste Cooking Oil. Energies 2022, 15, 3766. https://doi.org/10.3390/en15103766

Aboelazayem O, Gadalla M, Saha B. Comprehensive Optimisation of Biodiesel Production Conditions via Supercritical Methanolysis of Waste Cooking Oil. Energies. 2022; 15(10):3766. https://doi.org/10.3390/en15103766

Chicago/Turabian StyleAboelazayem, Omar, Mamdouh Gadalla, and Basudeb Saha. 2022. "Comprehensive Optimisation of Biodiesel Production Conditions via Supercritical Methanolysis of Waste Cooking Oil" Energies 15, no. 10: 3766. https://doi.org/10.3390/en15103766

APA StyleAboelazayem, O., Gadalla, M., & Saha, B. (2022). Comprehensive Optimisation of Biodiesel Production Conditions via Supercritical Methanolysis of Waste Cooking Oil. Energies, 15(10), 3766. https://doi.org/10.3390/en15103766