Abstract

In addition to the use of waste heat from the vessel’s exhaust gas to save energy onboard, reduce the carbon emissions of the ship, and combine the characteristics of ship waste heat, mathematical modeling and testing of ship waste heat temperature difference power generation were carried out in this study. Finally, an experimental platform for temperature differential power generation was established to assess the impact of influencing agents on the efficiency of temperature differential power generation. The results show that the effect of different thermally conductive greases on the efficiency of temperature differential power generation tablets is basically the same. In addition, the rate of flow of cooling water, the cooling plate area, and the heat source temperature have more significant effects on the open-circuit voltage and maximum output power. The results show that the maximum power output growth rate increases with increasing cooling water flow, reaching 8.26% at 4 L/min. Likewise, increasing the heat source temperature enhances the maximum output power growth rate by 15.25% at 220 °C. Conversely, the maximum output power of the temperature difference power generation device decreases as the cooling plate area increases, and the maximum output power reduction rate is 15.25% when the cooling plate area is 80 × 200 mm2 compared to the case of using a cooling plate area of 80 × 80 mm2. Moreover, the maximum output power of the temperature differential power generation device reaches 13.6 W under optimal conditions. Assuming that the temperature difference power generation plate is evenly distributed on the tailpipe of the 6260ZCD marine booster diesel engine, it could save approximately 5.44 kW·h electric power per hour and achieve a reduction in CO2 emissions of 0.3435 kg per hour.

1. Introduction

As a major carrier in the maritime transport industry, sea-going ships are less than 50% efficient in their energy use [1]. The majority of the used energy is discharged into the environment in the form of waste heat—causing approximately 25% of the energy of diesel fuel to be emitted into the atmosphere via exhaust gas. Emissions from shipping are potentially set to increase to 18% by 2050 if no action is taken. In this context, temperature differential power generation is an environmentally friendly and non-polluting power generation technology that involves the direct conversion of thermal energy into electrical energy.

Zhu et al. [2] provided a detailed review of steam Rankine Cycle (RC) research in combination with power turbines (PT). The Organic Rankine Cycle (ORC) is recommended for relatively small vessels because of its advantages of high efficiency and the flexibility to recover waste heat from different sources. Di Battista et al. [3] presented a joint solution to increase the conversion efficiency by coupling the Joule–Brayton cycle and the Rankine–Hern cycle. Mariani et al. [4] studied an ORC system that was used to recover heat from the exhaust gases of an internal combustion engine. They used N-pentane (R601) versus R134a as the working fluid for the ORC. Pacheco et al. [5] evaluated the performance and impact of a new temperature-controlled thermoelectric generator (TCTG) in light-duty vehicles. The TCTG was able to provide ground-breaking electrical output for thermoelectric generator systems in such light-duty vehicles, with average and maximum electrical power of up to 572 and 1538 watts, respectively, over a driving cycle. Zoui et al. [6] examined the most advanced thermoelectric generators and their applications, and the latest advances are presented here. The world is currently focused on reducing vehicle fuel consumption and ultimately mitigating the impact of greenhouse gas emissions.

Esrafilian et al. [7] studied the annual average power generation efficiency, annual primary energy savings rate (APESR) and annual total cost savings rate (ATCSR) of the aggregated power system, which were increased by 3.45%, 9.73% and 6.49%, respectively, using multi-effect distillation (MED) and reverse osmosis (RO desalination) technologies. Khalil et al. [8] studied the governing equations from thermal, fluid flow and electrical models, which were coupled and solved using ANSYS software. The results show that the use of a diffuser increases the total output of the generator by 17% and 42% for diffuser lengths of 40 mm and 140 mm, respectively. Omam [9] studied the Stirling cycle, and thermoelectric modules were used to recover waste heat from a petrol engine. Huang et al. [10] used transient chassis dynamometer tests to simulate the effects of various engine failures on the fuel consumption and gaseous emissions of a 16-ton Euro 6 diesel truck. Di Battista et al. [11] studied the most important parameters affecting the possible recovery range (turbine and compressor efficiency, pressure drop), which were evaluated after the study, and the pressure ratio was optimized. Liu et al. [12,13,14] designed a temperature differential generator prototype of the Yu ship incinerator and evaluated its performance. Based on the experimental data, they estimated that the temperature differential generator prototype with a length of 1 m could theoretically generate 9.45 kW.

Towhid et al. [15] conducted a thorough sensitivity study to obtain higher energy efficiency by increasing the evaporation temperature and the basic NH3 concentration or decreasing the separator pressure, the heating unit temperature and the terminal temperature difference (TTD) of a steam generator. Hamedi et al. [16] studied a new renewable energy-based multi-energy system, which generates a certain amount of power in both summer and winter. Wang et al. [17] designed a novel system based on the absorption power cycle (APC) and the booster-assisted ejector refrigeration system. They reported that the proposed system assisted by a booster compressor had higher energy efficiency than the traditional APC cycle. Tae-Woo Lim et al. [18] constructed an ORC system to utilize the temperature of LNG to enable its use as a fuel. The results of the study show that R123 has the highest thermal and extrinsic energy efficiency, R227ea has the lowest thermal efficiency, and R134a has the lowest extrinsic energy efficiency. The results of the study conducted by Tian et al. [19] showed that the Organic Rankine Cycle was capable of effectively utilizing the liquefied natural gas (LNG) cold energy and the waste heat from a dual-fuel marine engine. To improve the performance of the LNG cold energy generation system, Yuan et al. [20] investigated the use of a three-stage condensing Rankine Cycle (3C-ORC). The 3C-ORC had the highest output power. Yu et al. [21] studied the use of flue gas compression heat from LNG power plants as a heat source. They reported that the top three working fluids were R170, R143a and R290.

Li et al. [22] developed a new combined cooling and power (CCP) system using liquefied natural gas (LNG) cryogenic energy and low-temperature waste heat. Emadi et al. [23,24] developed a multi-objective optimization procedure using the genetic algorithm and coupling of artificial neural networks. Wu et al. [25] developed a constitutive thermodynamic optimization model for an ocean thermal energy conversion system (OTECS) with a dual-pressure Organic Rankine Cycle (DPORC). The results showed that the system was thermodynamically optimized six times for the highest net output power. Chen et al. [26] investigated the heat transfer and the power output characteristics of thermoelectric modules (TEM) with and without fin installation. The results showed that the performance was significantly influenced by temperature, while the mass flow rate played a secondary role. Moreover, they verified the validity of the transient numerical model experimentally by a transient performance test bench designed by Luo et al. [27]. Kober et al. [28] found the automotive application of thermoelectric generators to be much improved at the system level and performed measurement points where the accuracy of the simulated temperature was over 95%. In addition, they reported that the accuracy of the simulated output power was over 97%, and the waste heat recovery potential of hybrid vehicles was approximately 1.8 times higher than that of conventional vehicles [29]. Simulation scenarios considering the real operating conditions of light vehicles by Ezzitouni et al. [30] allowed for a significant negative impact of thermoelectric module interconnection on electrical energy production under heterogeneous thermal surface conditions. Simulations performed by Heber et al. [31] using commercial thermoelectric module simulations showed better results.

Based on the above literature review, the performance of temperature differential power generators has been investigated to varying degrees, and the experimental results obtained vary widely. In this paper, the influence of external factors on the output power of individual temperature differential power generators is investigated for the theoretical output power of the temperature differential power generators (20.13 W). The influencing factors include different thermal conductive silicone grease, cooling plate area, heat source temperature, etc., so that the output power of individual temperature differential power generators can be brought close to the theoretical value using better experimental conditions. Rough theoretical calculations are then obtained for application on a ship’s tailpipe with the aim of eventual practical application to a real ship.

2. Theoretical Model of Convective Heat Transfer in Cooling Water

The following equations for calculating the average convective heat transfer rate and average convective heat transfer rate for cooling plates provide some theoretical basis for the experimental study of individual temperature differential generation sheets.

Table 1 provides the symbols and names used in the theoretical calculations of temperature differential power plants.

Table 1.

Representation of theoretical calculation symbols.

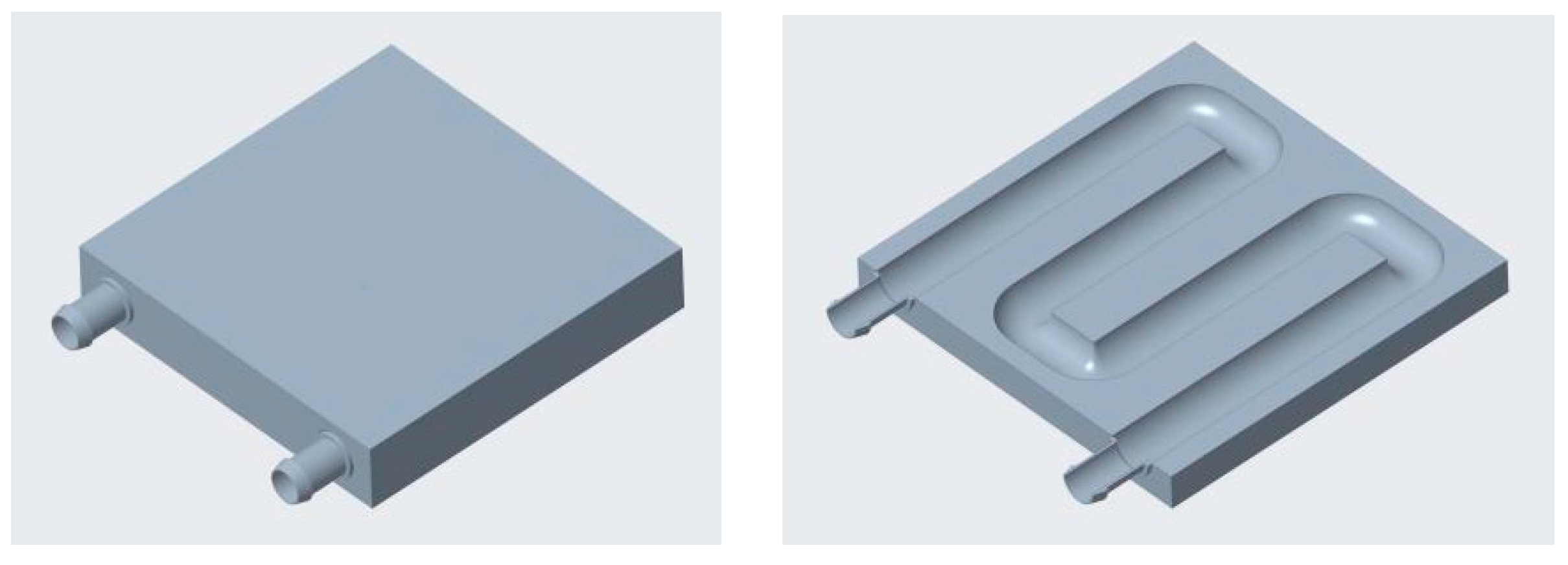

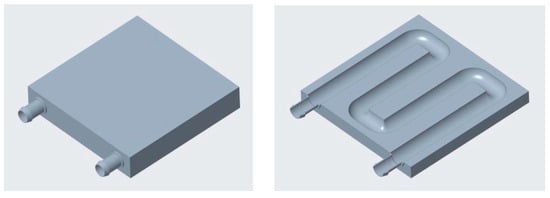

All the heat flowing from the cold end of the temperature differential power generation sheet flows into the cooling plate. Figure 1 shows the structure of the cooling plate and the internal circular cooling water channel.

Figure 1.

Cooling plate construction.

The diameter of the cooling water channel is Dch, and the total length is Lch. Assuming that the wall temperature of the cooling plate is Ts, the heat of a thermoelectric power generation module flowing into the cooling plate from the cold end of the thermoelectric power generation sheet per unit time is qc, and then, the heat flowing into a cooling plate per unit time is qc,l = qc. The inlet average temperature and the volume flow rate of the cooling water entering the cooling plate are Tw,i and Qw,l, respectively. Therefore, the average convection heat transfer coefficient of cooling water, as well as unit time cooling water to take away heat qc, l, can be calculated as follows.

2.1. Average Convective Heat Transfer Coefficient

By calculating the Reynolds number, the cooling water flow form is determined, thus determining the Nusselt number, from which the average convective heat transfer coefficient can be obtained. The cooling water flow rate uw is defined as follows:

where Ach represents the cross-sectional area of the circular channel of cooling water.

Therefore, the Reynolds number can be calculated as

where vw,i is the kinematic viscosity of the cooling water when the temperature is Tw,i.

When the flow is laminar, i.e., ReD,w ≤ 2300, then NuD,w = 3.66. When the flow is in the transition zone and turbulent, i.e., 2300 ≤ ReD,W ≤ 106 and 0.6 ≤ Prw,i ≤ 105, the Grelinsky relation is used

where Prw,i is the Prandtl number of cooling water when the temperature is Tw,i, and f is the Darcy resistance coefficient for turbulent flow in the tube. According to the Filonenko formula, f can be calculated as follows:

Because the cooling water channel is filled with liquid, ct (dimensionless number) can be calculated as follows:

where Prs is the Prandtl number of the cooling water at the wall temperature Ts.

Thus, according to Equations (3)–(5), the Nusselt number can be obtained, and then, the average convective heat transfer coefficient can be calculated as follows:

where kw,j is the thermal conductivity of the cooling water at the temperature of Tw,i.

2.2. Heat Transfer Rate

The relationship between the wall temperature Ts, the average inlet temperature Tw,i and the average outlet temperature Tw,o can be obtained by analyzing and deriving the energy balance of the control micro-element

where P is the circumference of the circular channel. Moreover, ρp,i and cp,i are the density and the specific heat capacity of the cooling water at the average inlet temperature Tw,i, respectively.

By solving Equation (7), the heat qc,l that the cooling plate extracts per unit time can be calculated as follows:

where ρave and cp,ave are the density and the specific heat capacity of the cooling water at the arithmetic mean temperature of the cooling water Tave.

Therefore, regarding the cooling plate, the heat extracted per unit time by the cooling water qc for a temperature difference power generation module is related to the average cooling water inlet temperature Tw,i, the cooling water volume flow rate Qw,l for a single cooling plate, and the cooling plate wall temperature Ts [1]. Equation (9) can thus be obtained:

3. Performance Influencing Factors

The open-circuit voltage of the temperature difference generator is measured without a load, and the output power is measured with the internal resistance of the temperature difference generator equal to the load resistance (where the load resistance is manually adjusted and the output power approximates the maximum output power of the temperature difference generator).

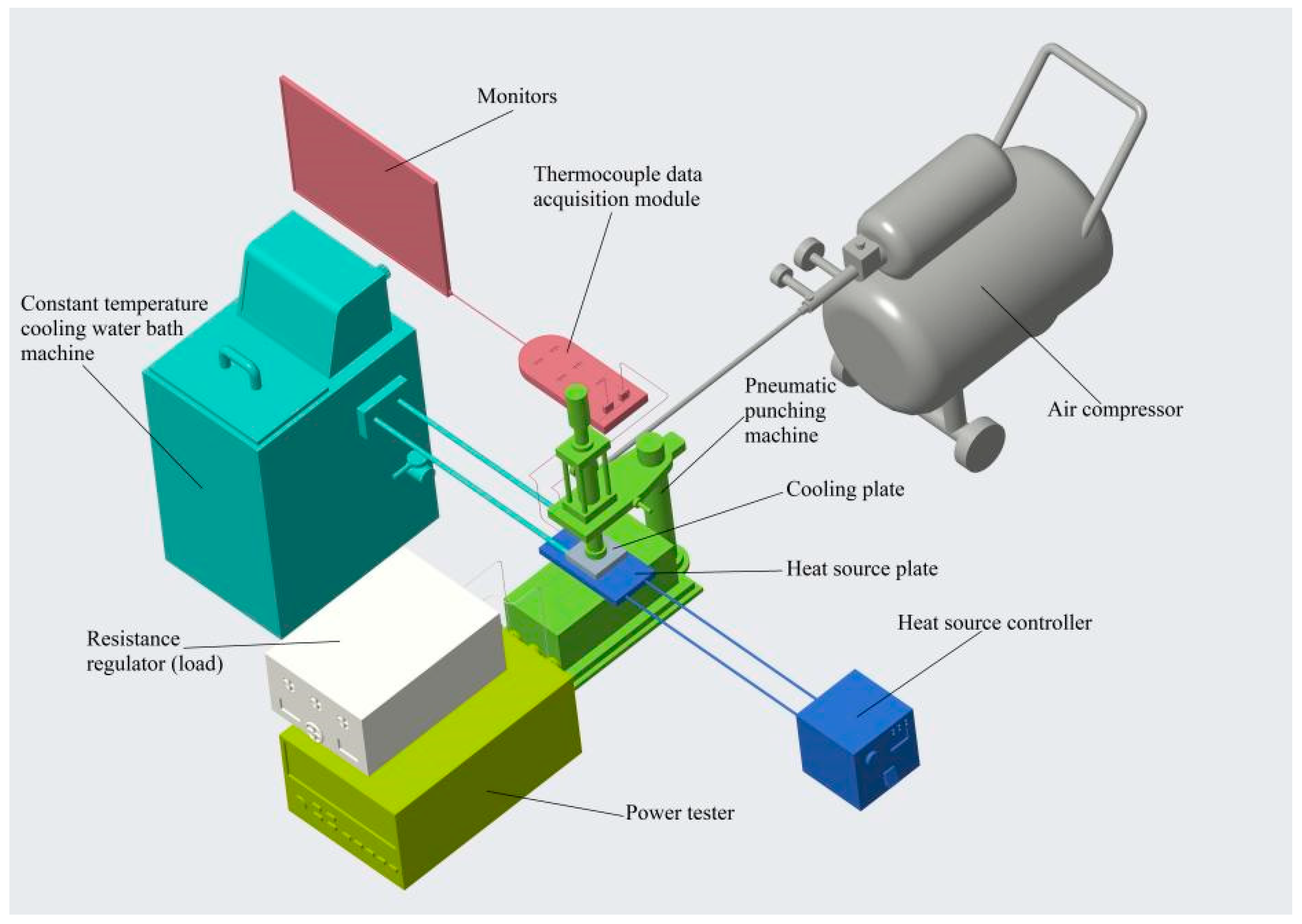

The temperature differential power generation module efficiency test platform consists of a temperature differential power generation module, a heat source device, a cold source device, an installation pressure regulator, an output current, an output voltage, an output power measurement device, an external load regulator, and a temperature measurement device.

3.1. Experimental Conditions

The experimental device was mainly designed to evaluate the effect of different external conditions, including cooling water flow rate, thermal grease, cooling plate area, and heat source temperature on the performance of the temperature difference power generation module. Cooling water flow rates of 1 L/min, 2 L/min, and 4 L/min were used during the experiment, while two cooling plate areas, 80 × 80 mm2 and 80 × 200 mm2, were selected. Moreover, the heat source temperatures included 200 °C and 220 °C, while four different types of thermal grease were chosen for the experiment. The experimental conditions are summarized in Table 2.

Table 2.

Experimental conditions for temperature difference power module performance testing.

3.2. Experimental Platform Construction Process

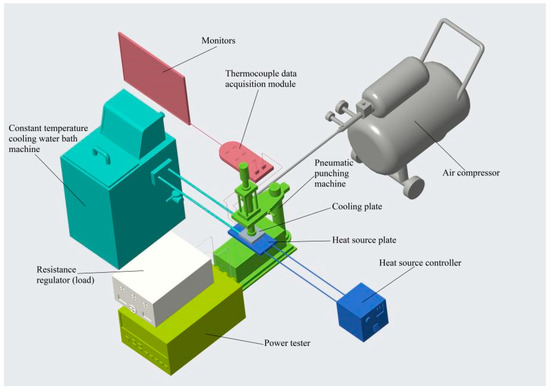

The whole process of building the platform is as follows. Firstly, the pneumatic press is fixed on a platform, and the pneumatic press base is placed on a heat source plate, which is connected to the heat source controller via wires, and the different heat source temperatures are adjusted by adjusting the temperature of the plate. The upper part of the heat source plate is near the hot end of the thermoelectric sheet, and the upper part of the thermoelectric sheet (cold end) is near the cooling plate. The upper and lower surfaces of the thermoelectric sheet can be coated with different thermally conductive silicone greases to measure their effect; different layers of thermal insulation can also be placed between the cooling plate and the heat source plate to test the effect of different temperature differences in power generation. The water cooling plate is connected to the thermostatic cooling water bath via a water pipe; the heat transfer medium in the thermostatic cooling water bath can be different media of different concentrations to study the effect of different types of heat transfer on the cold end. The thermostatic cooling water bath can be set at different cooling water temperatures to test the effect of different cooling water temperatures on the power generation efficiency of the temperature differential generators; the thermostatic cooling water bath can be set at different cooling water flow rates to test the effect of different cooling water flow rates on the power generation efficiency of the temperature differential generators. The air compressor transmits pressure to the pneumatic press through the air pipe to regulate the pressure between the temperature differential generators and the cold and hot plates. The thermocouple data material module is connected to the surface of the cooling plate and the heat source plate through thermal conductivity; the thermocouple data material module collects the temperature of the cooling plate and the heat source plate in time and outputs it to the display, where the temperature of the heat source plate is detected as the heat source temperature and the temperature of the surface of the cooling plate is detected as the cooling plate temperature. A power tester is connected by a wire to the positive and negative terminals of the thermoelectric generator and can detect the current, voltage, and power generated by the thermoelectric power at any time. The resistance regulator is connected to the positive and negative terminals of the power tester by means of a wire. By adjusting the resistance of the resistance regulator (load) to be equal to the internal resistance of the thermoelectric generator, the thermoelectric generator can output the maximum power. The overall schematic of the experimental platform is shown in Figure 2.

Figure 2.

Experimental platform assembly structure diagram.

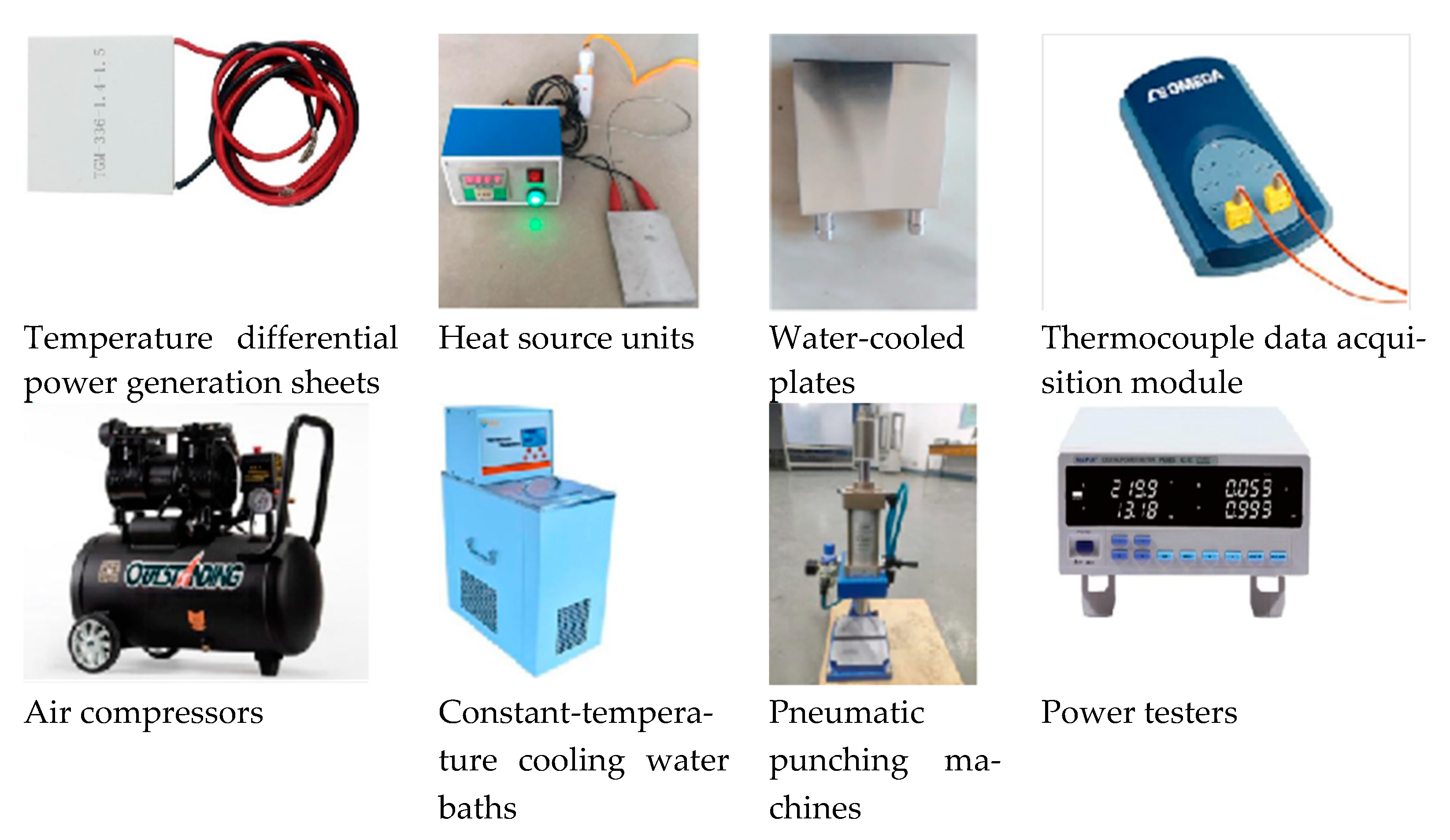

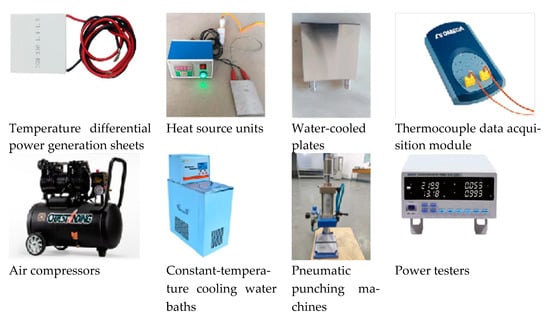

The specific experimental equipment and test equipment used in this paper are shown in Figure 3 below.

Figure 3.

Experimental equipment.

4. Experimental Results and Analysis

According to the theory of the temperature difference generator, the output and the open-circuit voltage of the temperature difference generator are proportional to the temperature difference between its two ends, and the temperature difference is the most important factor affecting the power generation performance of the power generation module.

The experimental parameters were recorded after the device reached the steady state. In order to reduce the experimental measurement error, each parameter was recorded 10 times, and the interval between each recording was 1 min. After this, the average value of the 10 recorded values for each parameter was taken for calculation and analysis.

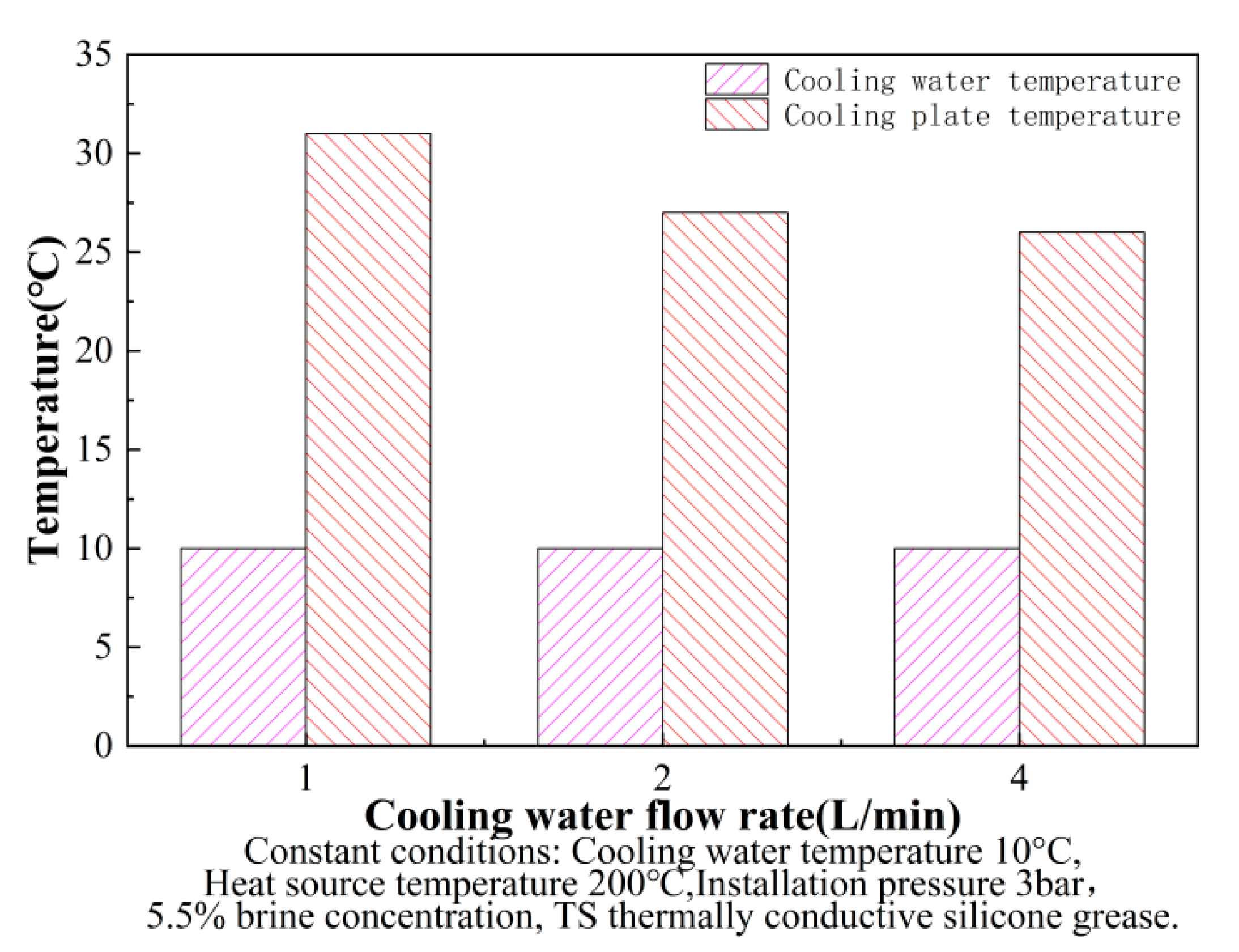

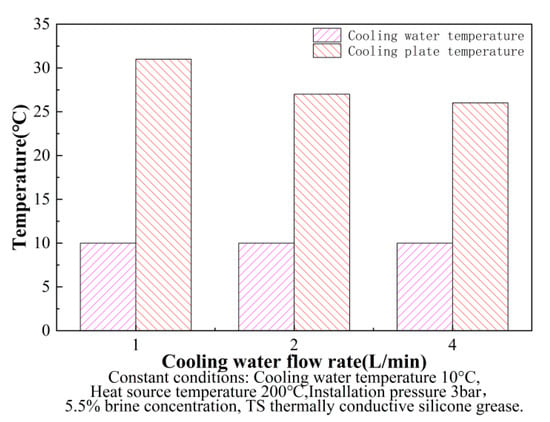

4.1. Effect of Cooling Water Flow Rate

In this experiment, the cooling water flow rate was changed while keeping other parameters constant. Three different cooling flow rates, namely 1 L/min, 2 L/min, and 4 L/min, were used. Moreover, the cooling water temperature, the heat source temperature, the installation pressure, the concentrated brine, and the cooling plate area were 10 °C, 200 °C, 3 bar, 5.5%, and 80 × 80 mm2, respectively. In addition, the TS thermally conductive silicone grease was applied.

Figure 4 shows that the cooling plate temperature experiences a continuous decrease as the cooling water flow rate increases. The cooling plate temperature is 31 °C, 27 °C, and 26 °C when the cooling water flow rate is 1 L/min, 2 L/min, and 4 L/min, respectively. In addition, the growth rate of the cooling plate temperature relative to the cooling water temperature is 210%, 170%, and 160% at 1 L/min, 2 L/min, and 4 L/min cooling water flow rate, respectively.

Figure 4.

Effect of cooling water flow rate on cooling plate temperature.

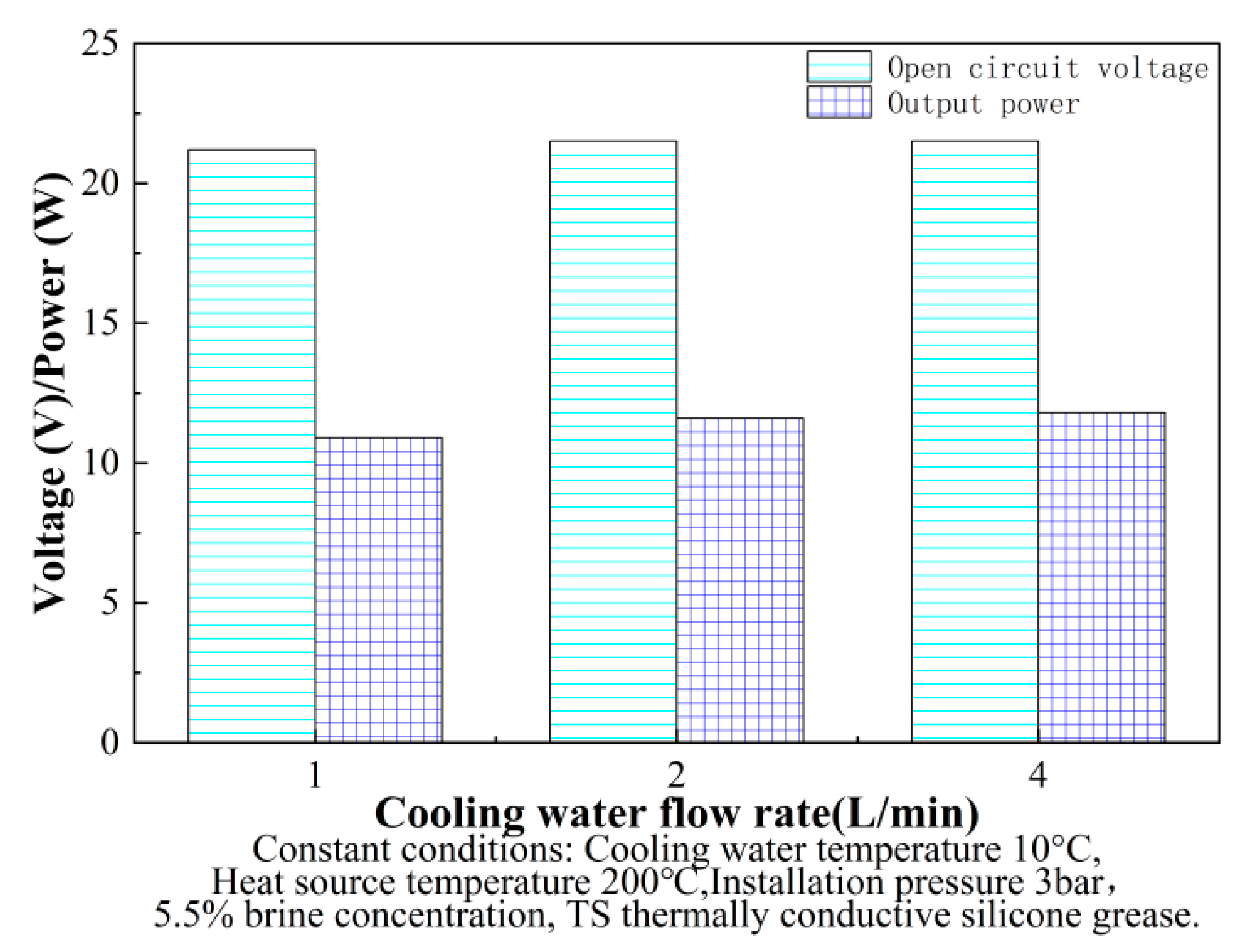

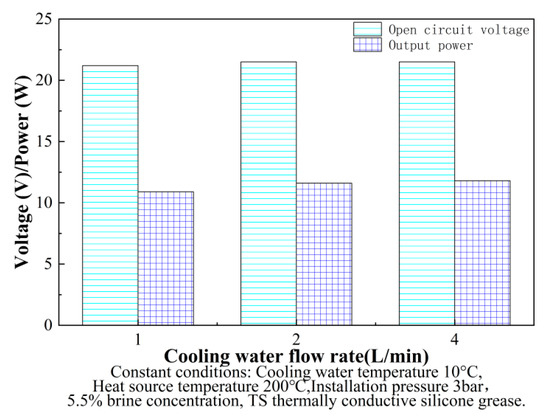

The effect of cooling water flow rate on the open-circuit voltage and the output power is shown in Figure 5. With the increase in the cooling water flow rate, the open-circuit voltage slightly increases from 21.2 V at 1 L/min to 21.5 V at 2 L/min and remains unchanged at 4 L/min. The growth rate of the open-circuit voltage is 1.42% at 2 L/min and 4 L/min cooling water flow rates as compared to the value at 1 L/min.

Figure 5.

Effect of cooling water flow rate on open-circuit voltage and output power.

Likewise, the maximum output power of the temperature difference power generator module increases from 10.9 W at 1 L/min to reach 11.6 W and 11.8 W at 2 L/min and 4 L/min, respectively. Moreover, the maximum output power growth rate is 6.42% and 8.26% when the cooling water flow rate is 2 L/min and 4 L/min, compared to the output power growth rate at 1 L/min. The study of the effect of cooling water on the performance of temperature differential generation tablets is a new idea. This phenomenon is to be expected. The flow rate of cooling water is accelerated, thus increasing the heat transfer rate of the cooling plate and increasing the temperature difference of the temperature difference generator. The output power of the temperature difference generator is proportional to the temperature difference between the two ends of the temperature difference generator, thus increasing the power generation performance of the temperature difference generator. However, after the cooling water flow rate reaches a certain speed, the heat transfer rate of the temperature difference power generator sheet will reach the saturation point (influenced by the temperature of the heat source). It is possible to control the relationship between the cooling water flow rate, the temperature difference power generation efficiency, and the control of the flow rate to generate electrical energy, so as to arrive at the best effective power generation efficiency for practical applications (this practical in-depth study is not done in this paper).

4.2. Effect of Different Thermally Conductive Silicone Greases

In order to study the effect of the thermally conductive silicone grease type on the performance of the temperature difference power generation module, four different types of thermally conductive silicone grease, including TS thermally conductive silicone grease, silver silicone grease, HY880 silicone grease, and HY510 silicone grease, were applied, while other conditions remained the same. The cooling water temperature, the heat source temperature, the installation pressure, the concentrated brine, the cooling plate area, and the cooling water flow rate were 10 °C, 200 °C, 3 bar, 5.5%, 80 × 80 mm2, and 4 L/min, respectively.

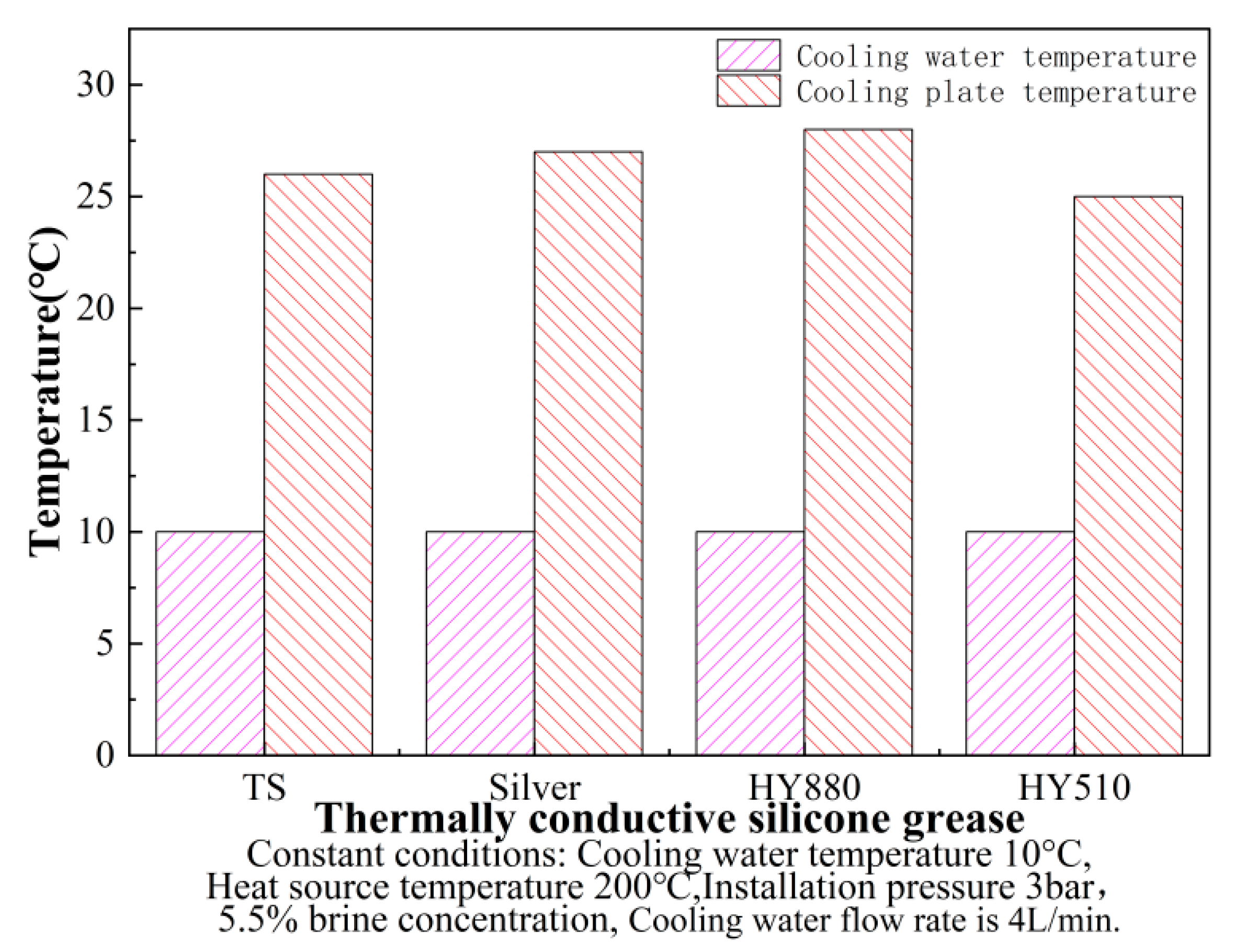

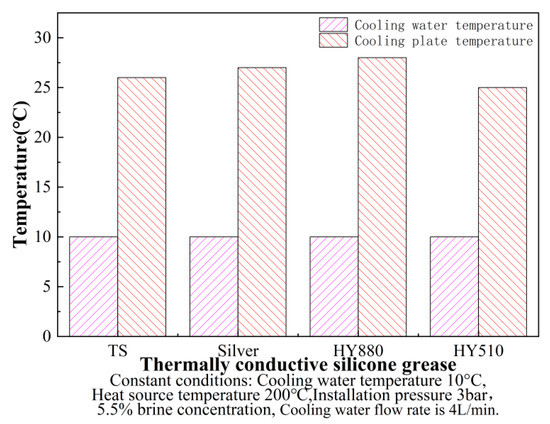

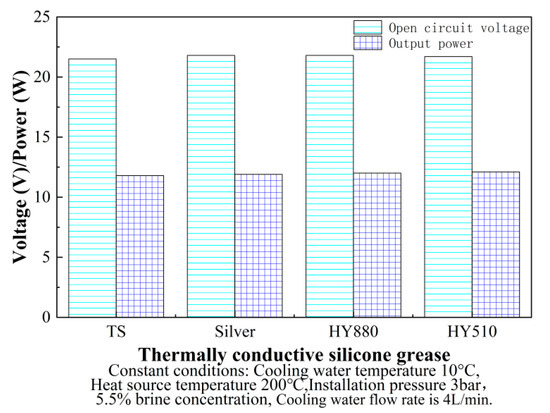

The cooling plate temperature was almost the same, with a slight change under different thermally conductive silicone grease materials, as shown in Figure 6. For the TS thermally conductive silicone grease, silver silicone grease, HY880 silicone grease, and HY510 silicone grease, the cooling plate temperature was 26 °C, 27 °C, 28 °C, and 25 °C, respectively.

Figure 6.

Effect of different thermally conductive silicone greases on cooling plate temperature.

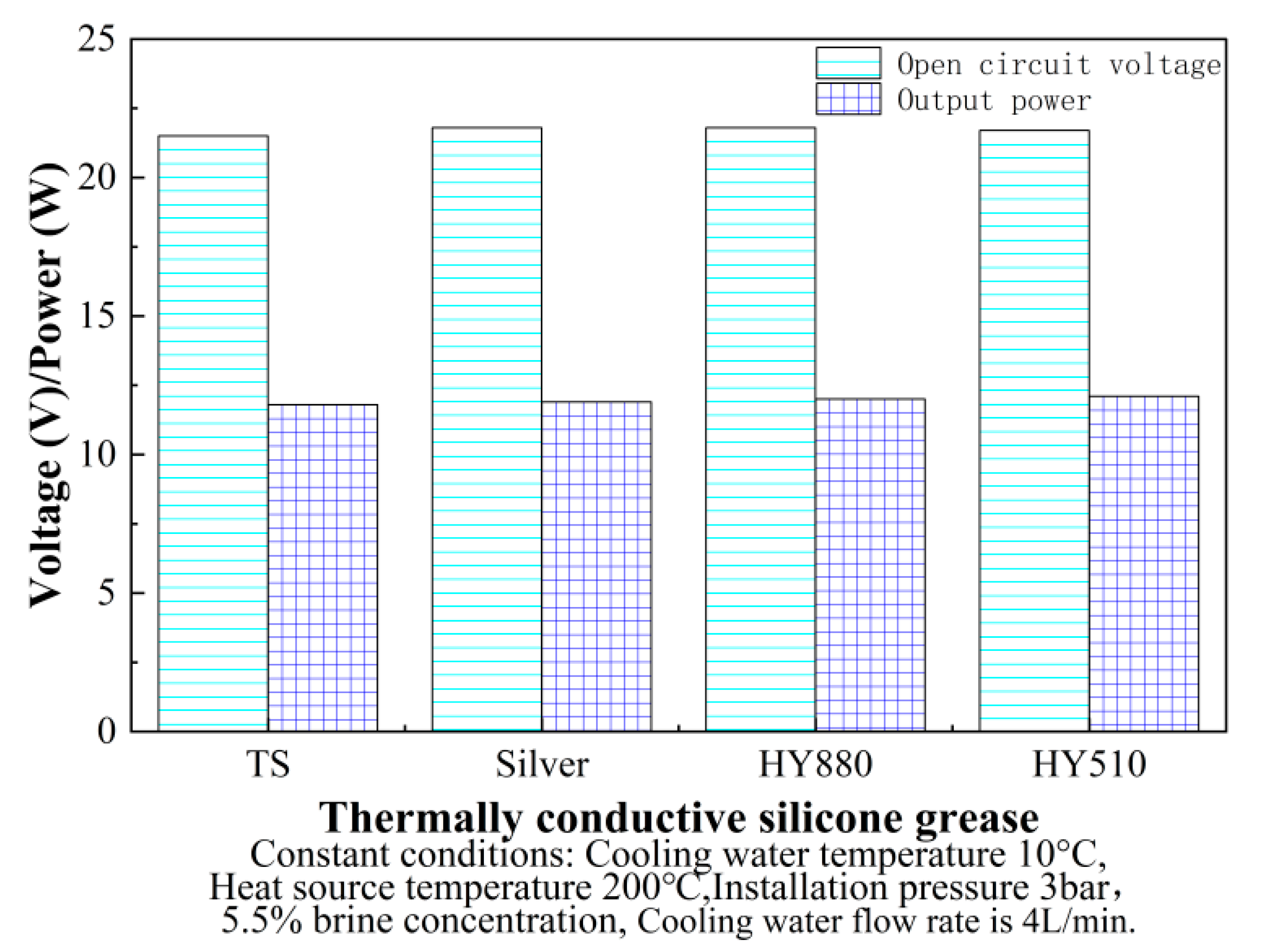

Figure 7 shows that the open-circuit voltage was almost constant under different thermally conductive silicone grease materials. The open-circuit voltage slightly increased from 21.5 V once the TS thermal conductive silicone grease was used to 21.8 V for the silver silicone grease and HY880 silicone grease, and then, it decreased slightly to reach 21.7 V once the HY510 silicone grease was applied. In addition, the open-circuit voltage growth rate was 1.40%, 1.40%, and 0.93% for silver silicone grease, HY880 silicone grease, and HY510 silicone grease, respectively, compared to the TS thermally conductive silicone grease.

Figure 7.

Effect of different thermally conductive silicone greases on open-circuit voltage and output power.

As can be seen from Figure 7, using different thermally conductive silicone grease materials had a minor impact on the maximum output power of the temperature difference power generation device, as it was essentially at the same level. The maximum output power reached 12.1 W with the use of HY510 silicone grease, with a growth rate of 2.54% compared to the case when the TS thermal conductive silicone grease was used. The study of the effect of cooling water on the performance of temperature differential generation tablets is a new idea. As the parameters of each thermally conductive silicone are basically different (e.g., thermal conductivity), they should also produce different results when applied to the two end faces of the temperature difference generators, but this phenomenon is unexpected. It could be that the thickness of the thermal conductive silicone applied, with different weights, resulted in essentially the same performance of the different thermal conductive silicones and almost the same output of the temperature difference generator. It is thought that this experiment will explore a better thermally conductive silicone grease, which can then be applied to actual ship exhaust power generation, which will produce better power generation efficiency.

4.3. Effect of Cooling Plate Area

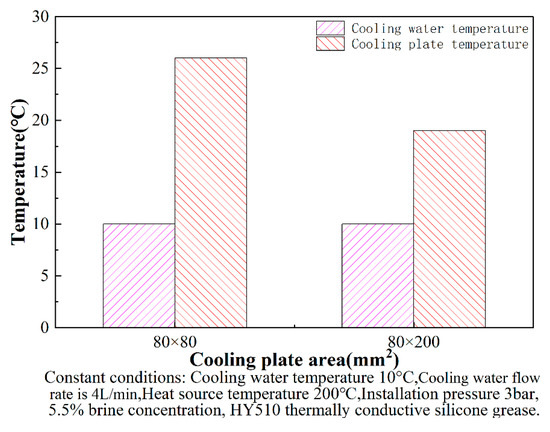

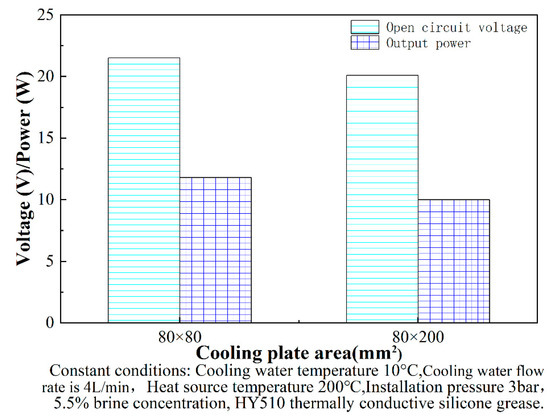

Two different cooling plate areas were used in this experiment, while other conditions remained unchanged. The cooling water temperature, the heat source temperature, the installation pressure, the concentrated brine, and the cooling water flow rate were 10 °C, 200 °C, 3 bar, 5.5%, and 4 L/min, respectively. Moreover, HY510 thermally conductive silicone grease was used.

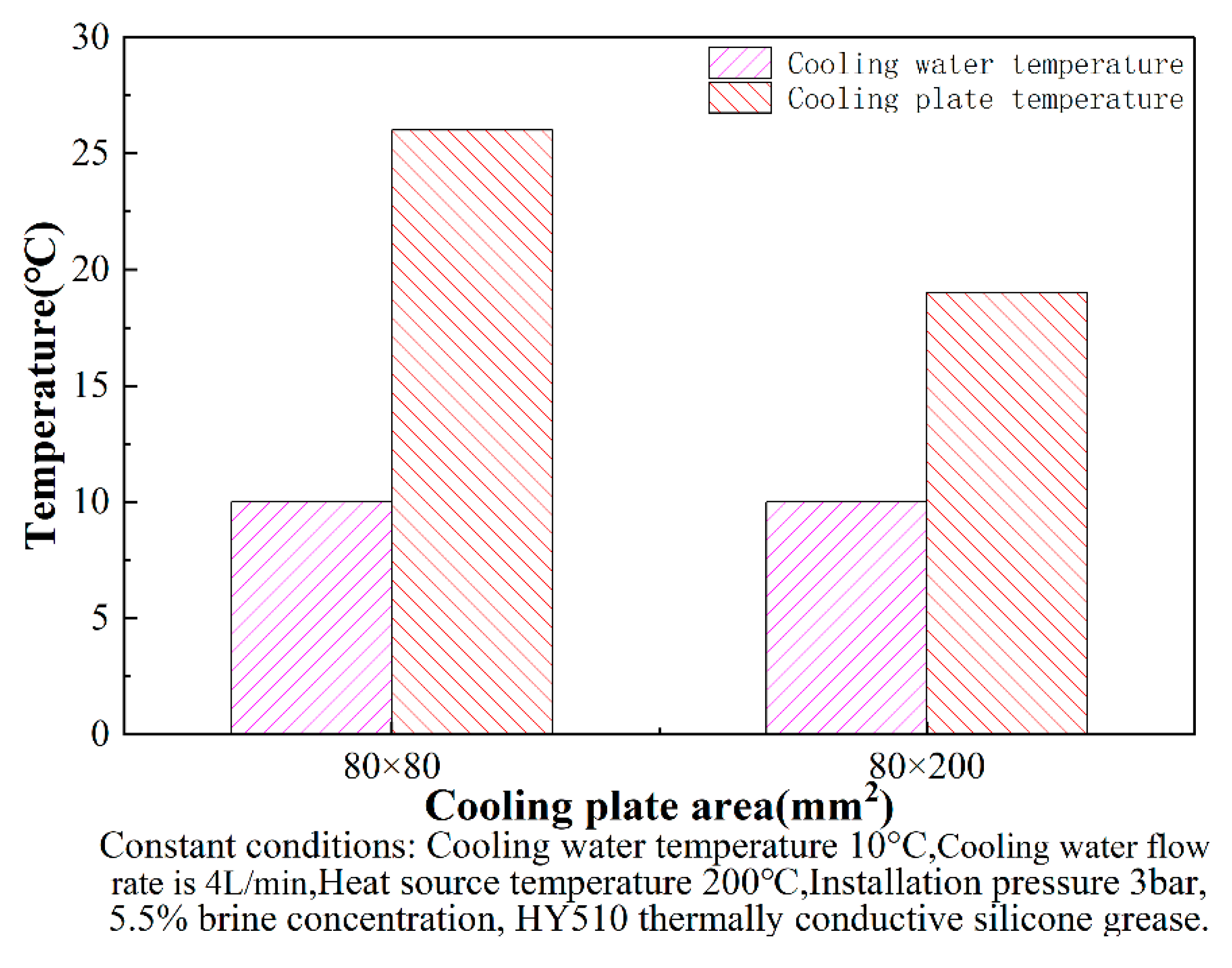

The effect of the cooling plate area on the cooling plate temperature is displayed in Figure 8. As the area of the cooling plate increased from 80 × 80 mm2 to 80 × 200 mm2, the temperature of the cooling plate decreased gradually from 26 to 19 °C, respectively. Furthermore, the cooling plate temperature was reduced by 26.92% when the cooling plate area was 80 × 200 mm2 compared to 80 × 80 mm2.

Figure 8.

Effect of cooling plate area on cooling plate temperature.

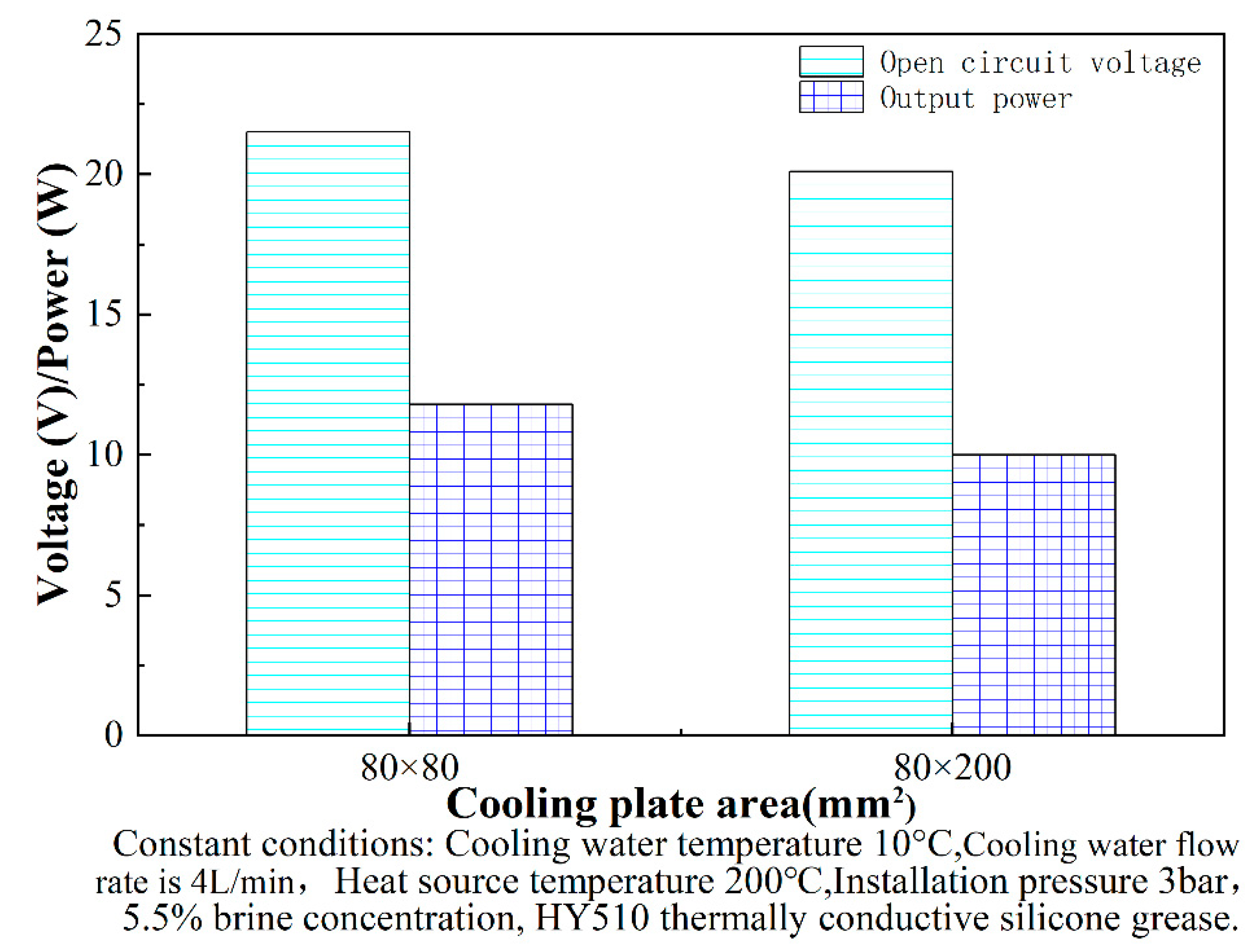

Figure 9 shows that the open-circuit voltage and the maximum output power of the temperature difference power generation device decreased from 21.5 to 20.1 V and from 11.8 to 10 W, respectively, as the cooling plate area increased from 80 × 80 mm2 to 80 × 200 mm2. Moreover, the reduction rate of the open-circuit voltage and the maximum output power when the cooling plate area was 80 × 200 mm2 was equal to 6.51% and 15.25%, respectively, as compared to 80 × 80 mm2. The study of the effect of cooling plate area on the performance of temperature differential power sheets is a new idea. This phenomenon is unexpected due to the increased area of the cooling plate, which increases the heat transfer area of the cold deficient water and thus should increase the power generation performance of the thermoelectric generator (hypothesis). It may be that as the area of the cooling plate increases, the heat around the heat source radiates toward the cooling plate, thus reducing the temperature difference between the heat and cold sources and ultimately reducing the output of the thermoelectric generator. This section will investigate the relationship between the cooling plate and the area of the thermoelectric generators to explore the maximum power generation ratio so that the best economic area ratio can be found for further application to the ship’s tailpipe.

Figure 9.

Effect of cooling plate area on open-circuit voltage and output power.

4.4. Heat Source Temperature Influence

Two different heat source temperatures, namely, 200 °C and 220 °C, were used in this experiment, while other conditions remained unchanged. The cooling water temperature, the cooling plate area, the installation pressure, the concentrated brine, and the cooling water flow rate were 10 °C, 80 × 80 mm2, 3 bar, 5.5%, and 4 L/min, respectively. Moreover, HY510 silicone grease was used.

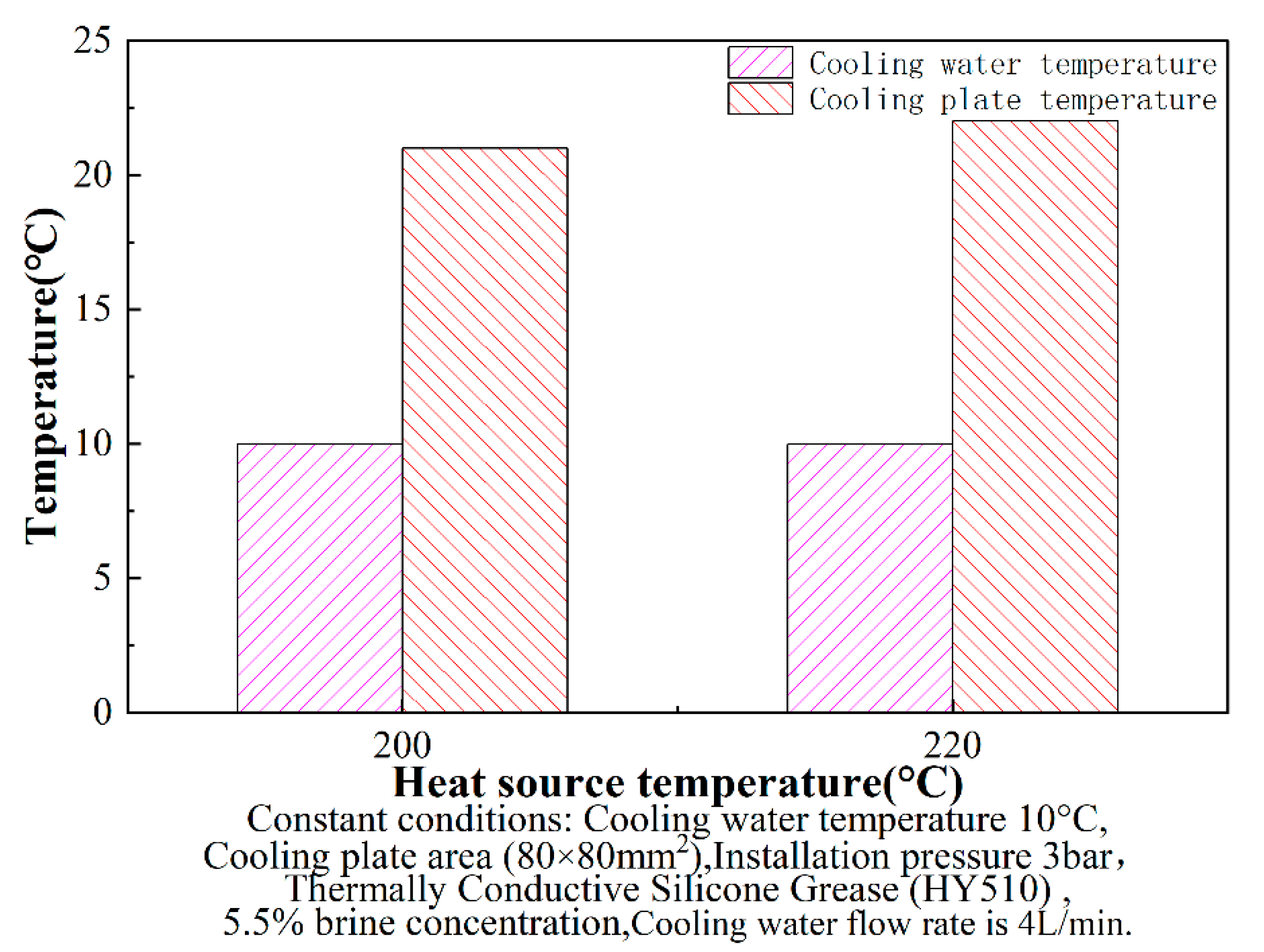

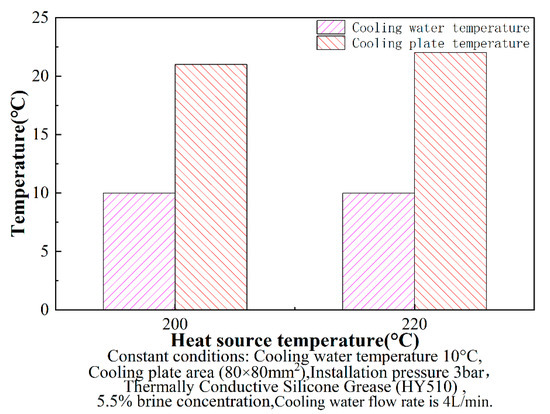

The heat source temperature had a minor influence on the cooling plate temperature, as can be seen from Figure 10. Increasing the heat source temperature from 200 to 220 °C slightly increased the cooling plate temperature, which experienced a continuous increase from 21 to 22 °C, respectively. In addition, the growth rate of the cooling plate temperature relative to the cooling water temperature was 110% and 120% at 200 °C and 220 °C, respectively.

Figure 10.

Effect of heat source temperature on cooling plate temperature.

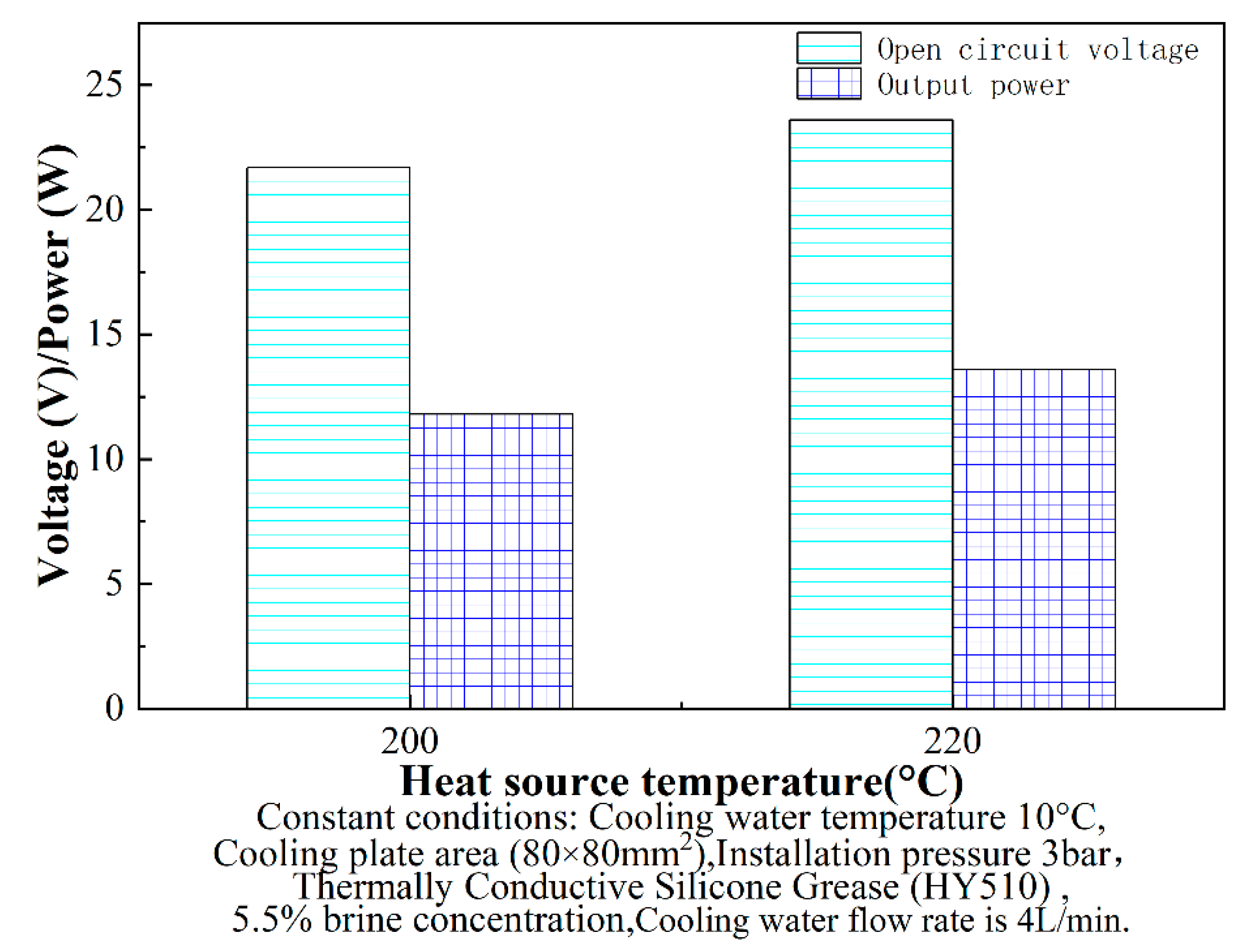

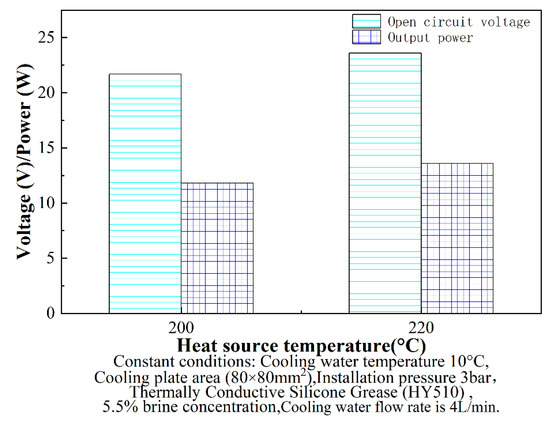

Figure 11 shows the effect of the heat source temperature on the open-circuit voltage and the maximum output power. From Figure 11, increasing the heat source temperature from 200 to 220 °C increased the open-circuit voltage from 21.7 to 23.6 V and increased the maximum output power of the temperature difference power generation device from 11.8 to 13.6 W. As compared to the heat source temperature of 200 °C, the growth rate of the open-circuit voltage and the maximum output power was 8.76% and 15.25%, respectively, when the heat source temperature was 220 °C. This set of experimental phenomena is expected; as the temperature of the heat source increases, the temperature difference between the two ends of the temperature differential generators increases, thus increasing the power generation performance of the temperature differential generators.

Figure 11.

Effect of heat source temperature on open-circuit voltage and output power.

Through analyzing the results of this series of experiments, the optimal conditions that can provide the maximum benefit during the operation of the temperature difference power generation device are an installation pressure of 3 bar, a heat-conductive silicone grease of type HY510, a cooling water flow rate of 4 L/min, a cooling plate area of 80 × 80 mm2, a cooling water temperature of 10 °C, and a heat source temperature of 220 °C. The maximum output power of the temperature differential power generation device under these optimal conditions is 13.6 W. The increased temperature of the heat source raises the temperature difference between the hot and cold ends, which in turn improves the power generation performance of the temperature differential power generation sheet.

4.5. Theoretical Calculation of Energy Savings and Emission Reduction

The thermal efficiency of marine diesel engines is currently over 49%, with little room for further improvement. More than 50% of the heat converted from fuel oil is released into the environment by various means, causing energy waste and a global temperature rise. The heat of the exhaust gas in the ship’s waste heat is approximately 25.4%. Making full use of ship waste heat can not only reduce fuel consumption and costs but also reduce the emission of carbon dioxide and other pollutants, which is an important strategy for ship companies to achieve the goal of “carbon neutrality and carbon peaking”.

In this section, the 6260ZCD marine supercharged diesel engine is used as the research object. The experimentally derived temperature differential power generation piece is distributed evenly over four measurement surfaces (the tailpipe is replaced by a rectangular tube), and the corresponding optimum experimental conditions are also theoretically applied to the tailpipe so that the temperature differential power generation efficiency of the whole tailpipe, as well as the recovered electrical energy and carbon emissions, can be found for the purpose of energy saving and emission reduction. The specific parameters of the engine are shown in Table 3.

Table 3.

Parameters of 6260ZCD-type marine supercharged diesel engine.

According to the formula for converting horsepower and kilowatts: 1 PS = 0.735 kW.

Let the fuel consumption of the diesel engine in normal operation for 1 h be M; then, M = Ne × 0.2.

The unit of M is kg.

The equation for the combustion of diesel fuel in air is as follows:

2C12H26 + 37O2 = 24CO2 + 26H2O

Combining Equation (10) with some calculations, it is estimated that 5.44 kW·h of electricity can be saved per hour of temperature difference power generation, which can reduce CO2 emissions by 0.3435 kg.

5. Conclusions

In this study, the effects of cooling water flow rate, different thermal conductive silicone grease, cooling plate area, and heat source temperature on the open-circuit voltage and output power performance of a single temperature differential power generation module were investigated experimentally. The single control variable method was used to analyze the results. The main conclusions are as follows:

- The open-circuit voltage slightly increased with the increase in the cooling water flow rate. The growth rate of open-circuit voltage was 1.42% at 2 and 4 L/min as compared to the case at 1 L/min cooling water flow rate. In addition, the maximum output power of the temperature difference power generator module increased from 10.9 W at 1 L/min to reach 11.6 and 11.8 W at 2 and 4 L/min, respectively. The maximum output power growth rate was 6.42% and 8.26% when the cooling water flow rate was 2 and 4 L/min compared to the output power growth rate at 1 L/min.

- The use of different thermally conductive silicone grease materials had little effect on the open-circuit voltage and the maximum output power of the temperature differential power generator. The maximum output power reached 12.1 W when using HY510 silicone grease, with a growth rate of 2.54% compared to the case when TS thermally conductive silicone grease was used.

- The open-circuit voltage and the maximum output power of the temperature difference power generation device decreased as the cooling plate area increased from 80 × 80 mm2 to 80 × 200 mm2. The open-circuit voltage reduction rate was 6.51% and the maximum output power reduction rate was 15.25% when the cooling plate area was 80 × 200 mm2 relative to 80 × 80 mm2. Furthermore, the open-circuit voltage growth rate and the maximum output power growth rate reached 8.76% and 15.25% when the heat source temperature was 220 °C compared to the case when a 200 °C heat source temperature was used.

- Throughout the experiments, the installation pressure of 3 bar, the heat-conductive silicone grease of type HY510, the cooling water flow rate of 4 L/min, the cooling plate area of 80 × 80 mm2, the cooling water temperature of 10 °C, and the heat source temperature of 220 °C were the optimal conditions for the operation of the temperature difference power generation device. The maximum output power of the temperature differential power generation device under these optimal conditions reached 13.6 W.

- Finally, assuming that the temperature difference power generation plate was evenly distributed on the tailpipe of the 6260ZCD marine booster diesel engine, it could save approximately 5.44 kW·h electric power per hour and achieve a reduction of 0.3435 kg in CO2 emissions per hour.

Author Contributions

Funding acquisition, Z.W.; Investigation, H.G. and Z.W.; Resources, X.L.; Software, X.L.; Writing—original draft, C.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Science & Technology Commission of Shanghai Municipality and Shanghai Engineering Research Center of Ship Intelligent Maintenance and Energy Efficiency under Grant 20DZ2252300.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares that there is no conflict of interest regarding the publication of this paper.

References

- Ye, W.; Liu, C.; Liu, J.; Wang, H.; Yang, S.; Pan, X. Research on TEG–ORC Combined Bottom Cycle for Cascade Recovery from Various Vessel Waste Heat Sources. Arab. J. Sci. Eng. 2021, 47, 3151–3161. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, K.; Deng, K. A review of waste heat recovery from the marine engine with highly efficient bottoming power cycles. Renew. Sustain. Energy Rev. 2020, 120, 109611. [Google Scholar] [CrossRef]

- Di Battista, D.; Fatigati, F.; Carapellucci, R.; Cipollone, R. An improvement to waste heat recovery in internal combustion engines via combined technologies. Energy Convers. Manag. 2021, 232, 113880. [Google Scholar] [CrossRef]

- Mariani, A.; Mastellone, M.L.; Morrone, B.; Prati, M.V.; Unich, A. An organic Rankine cycle bottoming a diesel engine powered passenger car. Energies 2020, 13, 314. [Google Scholar] [CrossRef] [Green Version]

- Pacheco, N.; Brito, F.; Vieira, R.; Martins, J.; Barbosa, H.; Goncalves, L. Compact automotive thermoelectric generator with embedded heat pipes for thermal control. Energy 2020, 197, 117154. [Google Scholar] [CrossRef]

- Zoui, M.A.; Bentouba, S.; Stocholm, J.G.; Bourouis, M. A review on thermoelectric generators: Progress and applications. Energies 2020, 13, 3606. [Google Scholar] [CrossRef]

- Esrafilian, M.; Ahmadi, R. Energy, environmental and economic assessment of a polygeneration system of local desalination and CCHP. Desalination 2019, 454, 20–37. [Google Scholar] [CrossRef]

- Khalil, H.; Hassan, H. Enhancement of waste heat recovery from vertical chimney via thermoelectric generators by heat spreader. Process Saf. Environ. Prot. 2020, 140, 314–329. [Google Scholar] [CrossRef]

- Omam, S.H. Exhaust waste energy recovery using Otto-ATEG-Stirling engine combined cycle. Appl. Therm. Eng. 2021, 183, 116210. [Google Scholar] [CrossRef]

- Huang, Y.; Ng, E.C.; Yam, Y.-S.; Lee, C.K.; Surawski, N.; Mok, W.-C.; Organ, B.; Zhou, J.L.; Chan, E.F. Impact of potential engine malfunctions on fuel consumption and gaseous emissions of a Euro VI diesel truck. Energy Convers. Manag. 2019, 184, 521–529. [Google Scholar] [CrossRef]

- Di Battista, D.; Fatigati, F.; Carapellucci, R.; Cipollone, R. Inverted Brayton Cycle for waste heat recovery in reciprocating internal combustion engines. Appl. Energy 2019, 253, 113565. [Google Scholar] [CrossRef]

- Liu, C.; Li, F.; Zhao, C.; Ye, W.; Wang, K.; Dong, Y.; Gao, W. Experimental research of thermal electric power generation from ship incinerator exhaust heat. Earth Environ. Sci. 2019, 227, 022031. [Google Scholar] [CrossRef]

- Ye, W.X.; Liu, C.X.; Liu, J.H. Experimental research of ship waste heat utilization by TEG-ORC combined cycle. J. Xi’an Jiaotong Univ. 2020, 54, 50. [Google Scholar]

- Liu, C.; Ye, W.; Li, H.; Liu, J.; Zhao, C.; Mao, Z.; Pan, X. Experimental study on cascade utilization of ship’s waste heat based on TEG-ORC combined cycle. Int. J. Energy Res. 2021, 45, 4184–4196. [Google Scholar] [CrossRef]

- Parikhani, T.; Azariyan, H.; Behrad, R.; Ghaebi, H.; Jannatkhah, J. Thermodynamic and thermoeconomic analysis of a novel ammonia-water mixture combined cooling, heating, and power (CCHP) cycle. Renew Energy 2020, 145, 1158–1175. [Google Scholar] [CrossRef]

- Jamali, D.H.; Noorpoor, A. Optimization of a novel solar-based multi-generation system for waste heat recovery in a cement plant. J. Clean. Prod. 2019, 240, 117825. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, T.; Liang, Y.; Sun, H.; Zhu, Y. A novel cooling and power cycle based on the absorption power cycle and booster-assisted ejector refrigeration cycle driven by a low-grade heat source: Energy, exergy and exergoeconomic analysis. Energy Convers. Manag. 2020, 204, 112321. [Google Scholar] [CrossRef]

- Lim, T.-W.; Choi, Y.-S. Thermal design and performance evaluation of a shell-and-tube heat exchanger using LNG cold energy in LNG fuelled ship. Appl. Therm. Eng. 2020, 171, 115120. [Google Scholar] [CrossRef]

- Tian, Z.; Zeng, W.; Gu, B.; Zhang, Y.; Yuan, X. Energy, exergy, and economic (3E) analysis of an organic Rankine cycle using zeotropic mixtures based on marine engine waste heat and LNG cold energy. Energy Convers. Manag. 2021, 228, 113657. [Google Scholar] [CrossRef]

- Yuan, T.; Song, C.; Zhang, R.; Zhang, X.; Zhang, N.; Bao, J. Energy and Economic Optimization of the Multistage Condensation Rankine Cycle That Utilizes LNG Cold Energy: Considerations on Working Fluids and Cycle Configurations. ACS Sustain. Chem. Eng. 2019, 7, 13505–13516. [Google Scholar] [CrossRef]

- Yu, H.; Kim, D.; Gundersen, T. A study of working fluids for Organic Rankine Cycles (ORCs) operating across and below ambient temperature to utilize Liquefied Natural Gas (LNG) cold energy. Energy 2019, 167, 730–739. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Zhang, G.; Yang, Y. Thermodynamic analysis of a novel combined cooling and power system utilizing liquefied natural gas (LNG) cryogenic energy and low-temperature waste heat. Energy 2020, 199, 117479. [Google Scholar] [CrossRef]

- Emadi, M.A.; Mahmoudimehr, J. Modeling and thermo-economic optimization of a new multi-generation system with geothermal heat source and LNG heat sink. Energy Convers. Manag. 2019, 189, 153–166. [Google Scholar] [CrossRef]

- Emadi, M.A.; Chitgar, N.; Oyewunmi, O.A.; Markides, C. Working-fluid selection and thermoeconomic optimisation of a combined cycle cogeneration dual-loop organic Rankine cycle (ORC) system for solid oxide fuel cell (SOFC) waste-heat recovery. Appl. Energy 2020, 261, 114384. [Google Scholar] [CrossRef]

- Wu, Z.; Feng, H.; Chen, L.; Tang, W.; Shi, J.; Ge, Y. Constructal thermodynamic optimization for ocean thermal energy conversion system with dual-pressure organic Rankine cycle. Energy Convers. Manag. 2020, 210, 112727. [Google Scholar] [CrossRef]

- Chen, W.-H.; Wang, C.-M.; Saw, L.H.; Hoang, A.T.; Bandala, A.A. Performance evaluation and improvement of thermoelectric generators (TEG): Fin installation and compromise optimization. Energy Convers. Manag. 2021, 250, 114858. [Google Scholar] [CrossRef]

- Luo, D.; Wang, R.; Yan, Y.; Yu, W.; Zhou, W. Transient numerical modelling of a thermoelectric generator system used for automotive exhaust waste heat recovery. Appl. Energy 2021, 297, 117151. [Google Scholar] [CrossRef]

- Kober, M.; Knobelspies, T.; Rossello, A.; Heber, L. Thermoelectric Generators for Automotive Applications: Holistic Optimization and Validation by a Functional Prototype. J. Electron. Mater. 2020, 49, 2902–2909. [Google Scholar] [CrossRef] [Green Version]

- Kober, M. The High Potential for Waste Heat Recovery in Hybrid Vehicles: A Comparison Between the Potential in Conventional and Hybrid Powertrains. J. Electron. Mater. 2020, 49, 2928–2936. [Google Scholar] [CrossRef] [Green Version]

- Ezzitouni, S.; Fernández-Yáñez, P.; Rodríguez, L.S.; Armas, O.; de las Morenas, J.; Massaguer, E.; Massaguer, A. Electrical Modelling and Mismatch Effects of Thermoelectric Modules on Performance of a Thermoelectric Generator for Energy Recovery in Diesel Exhaust Systems. Energies 2021, 14, 3189. [Google Scholar] [CrossRef]

- Heber, L.; Schwab, J. Modelling of a thermoelectric generator for heavy-duty natural gas vehicles: Techno-economic approach and experimental investigation. Appl. Therm. Eng. 2020, 174, 115156. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).