Recent Progress in Electromagnetic Interference Shielding Performance of Porous Polymer Nanocomposites—A Review

Abstract

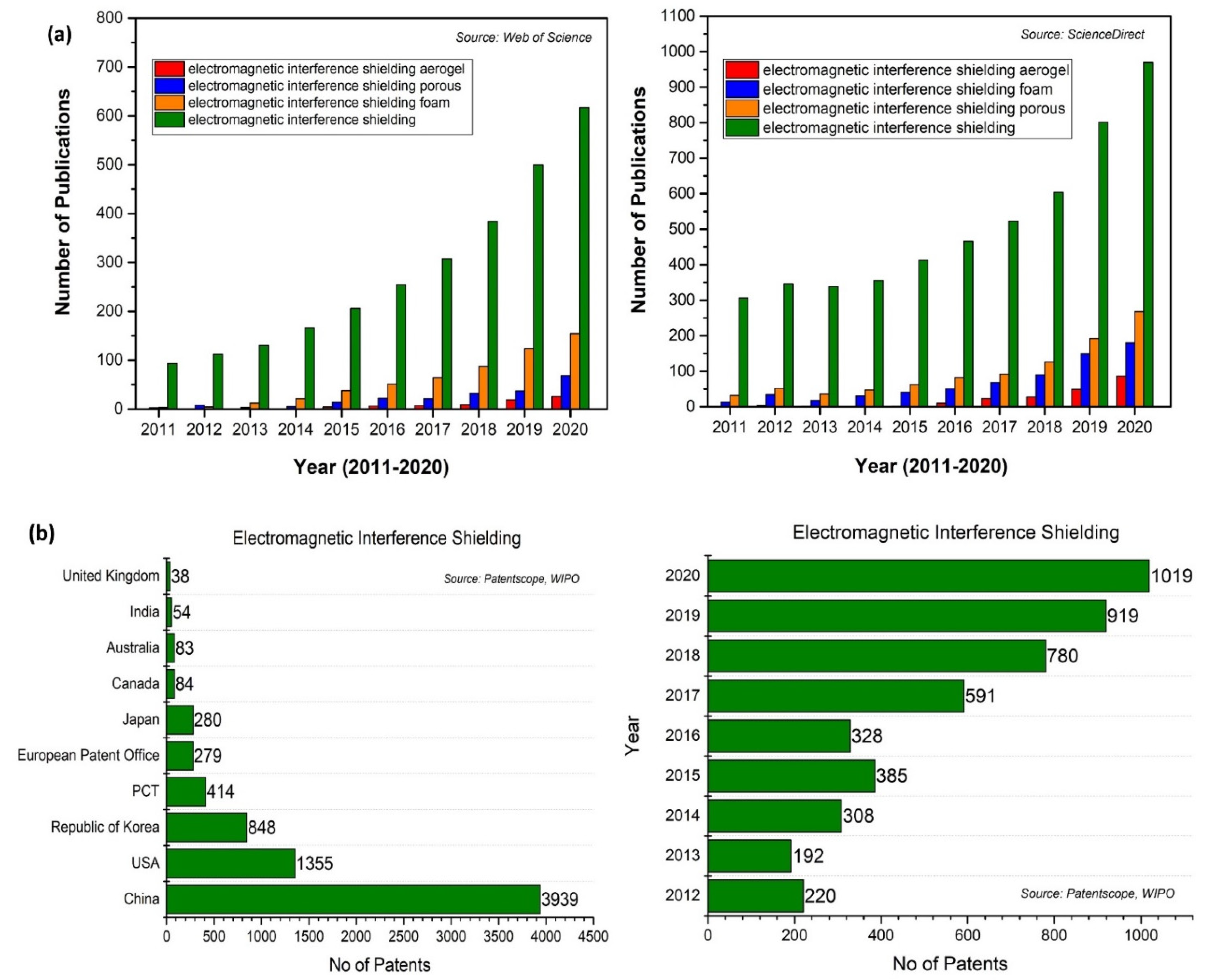

:1. Introduction

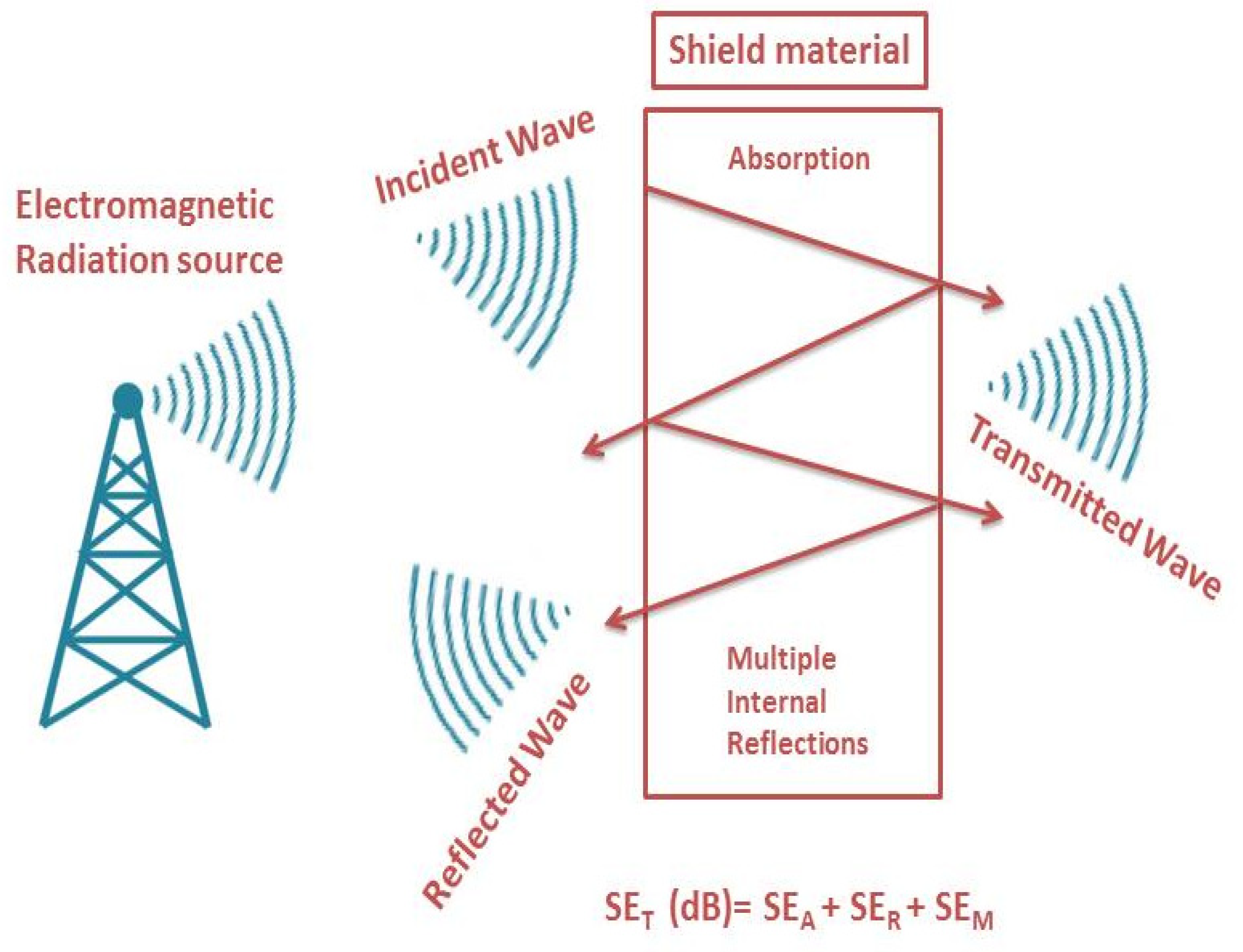

2. Terminologies in EMI Shielding

2.1. Shielding by Absorption (SEA)

2.2. Shielding by Reflection (SER)

2.3. Shielding Due to Multiple Internal Reflections (SEM)

3. Reflection Loss (RL) and Microwave Absorption

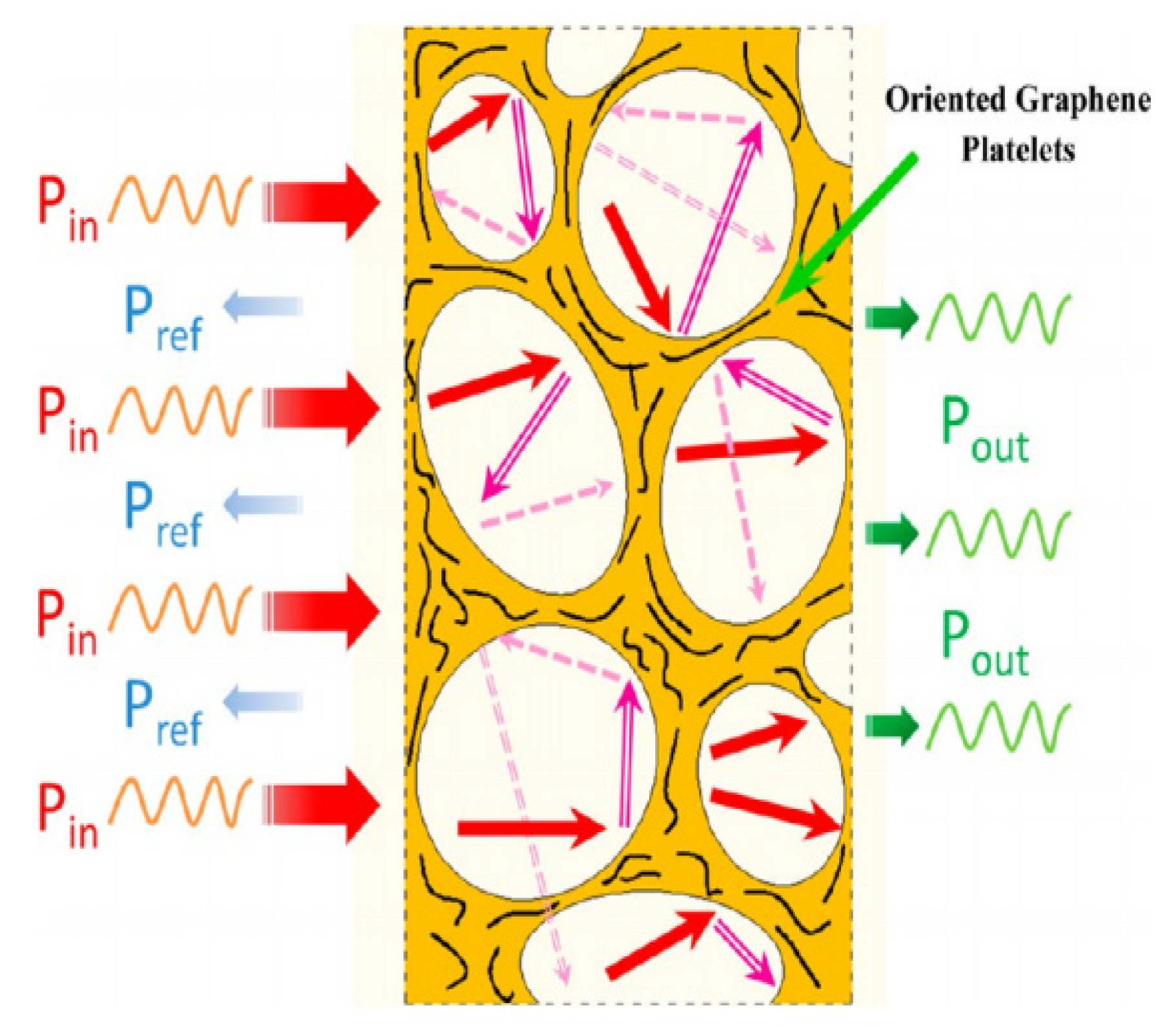

4. Tuning Microwave Absorption for Superior EMI Shielding in Porous Materials

5. Solid vs.Porous EMI Shielding Materials

6. Measuring EMI Shielding Effectiveness (EMI SE) of Porous Polymer Nanocomposites

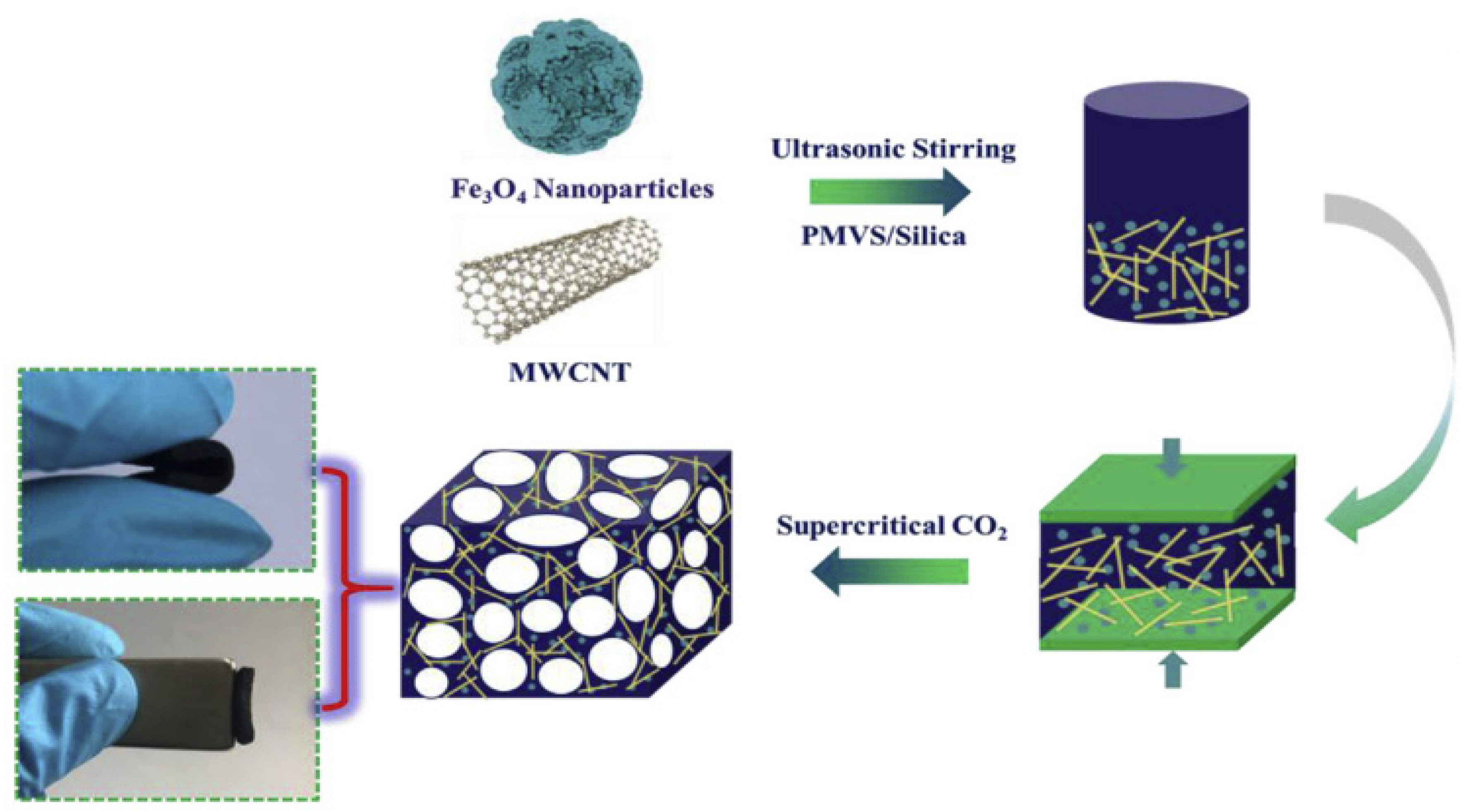

7. Methods to Fabricate Polymer Foams and Aerogels

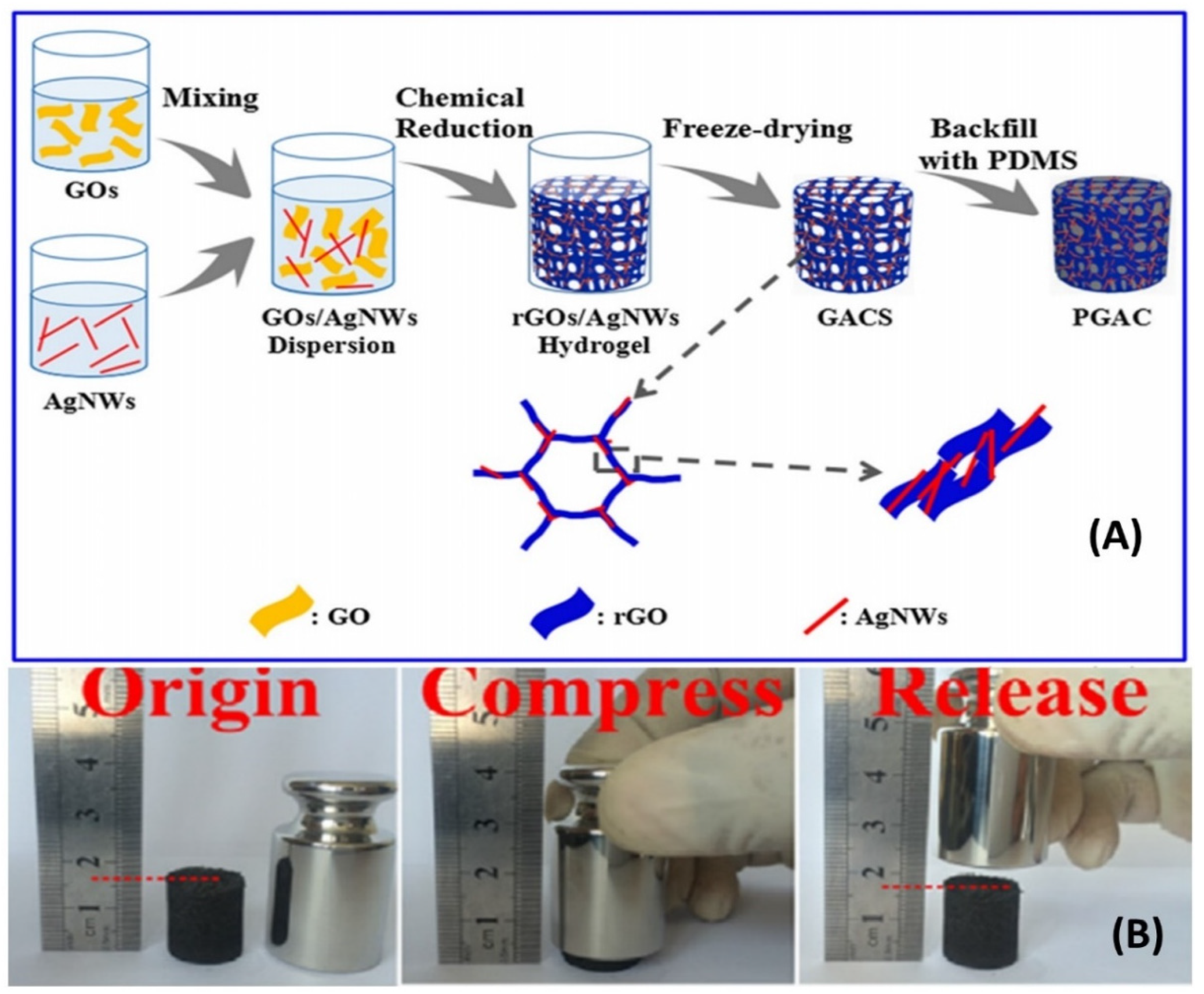

8. Elastomer Nanocomposite Foams for Electromagnetic Interference Shielding

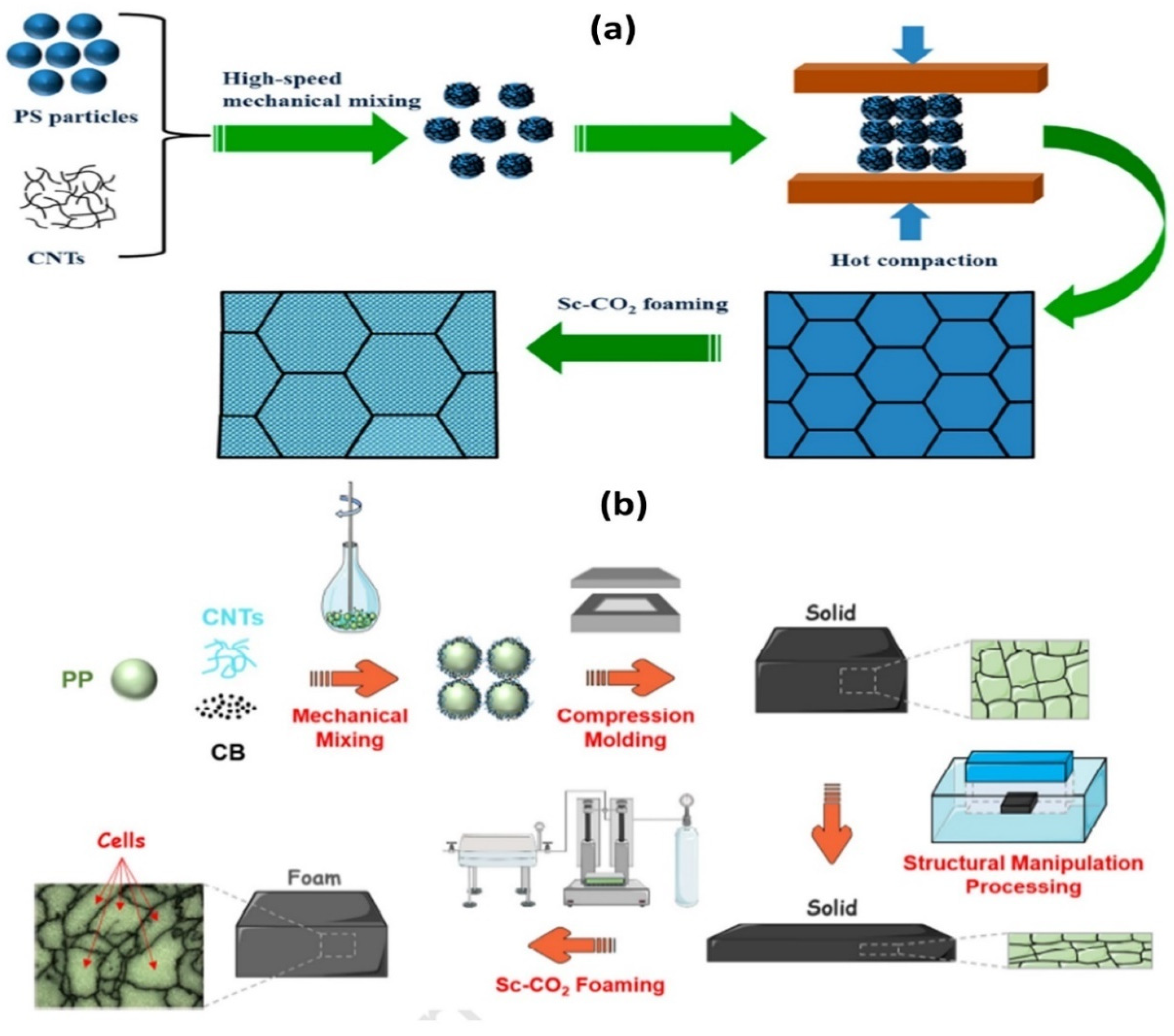

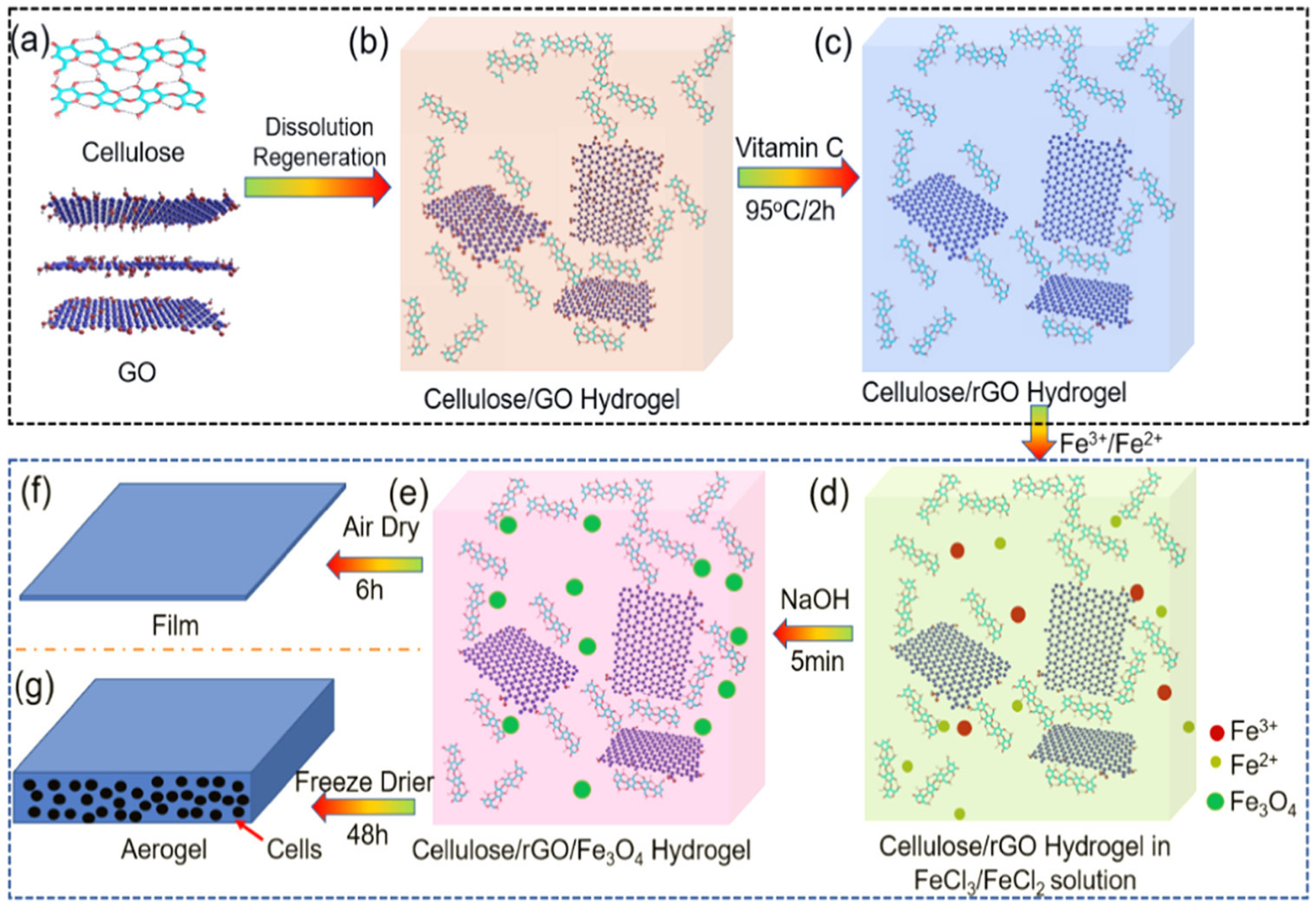

9. Thermoplastic Foams for Electromagnetic Interference Shielding

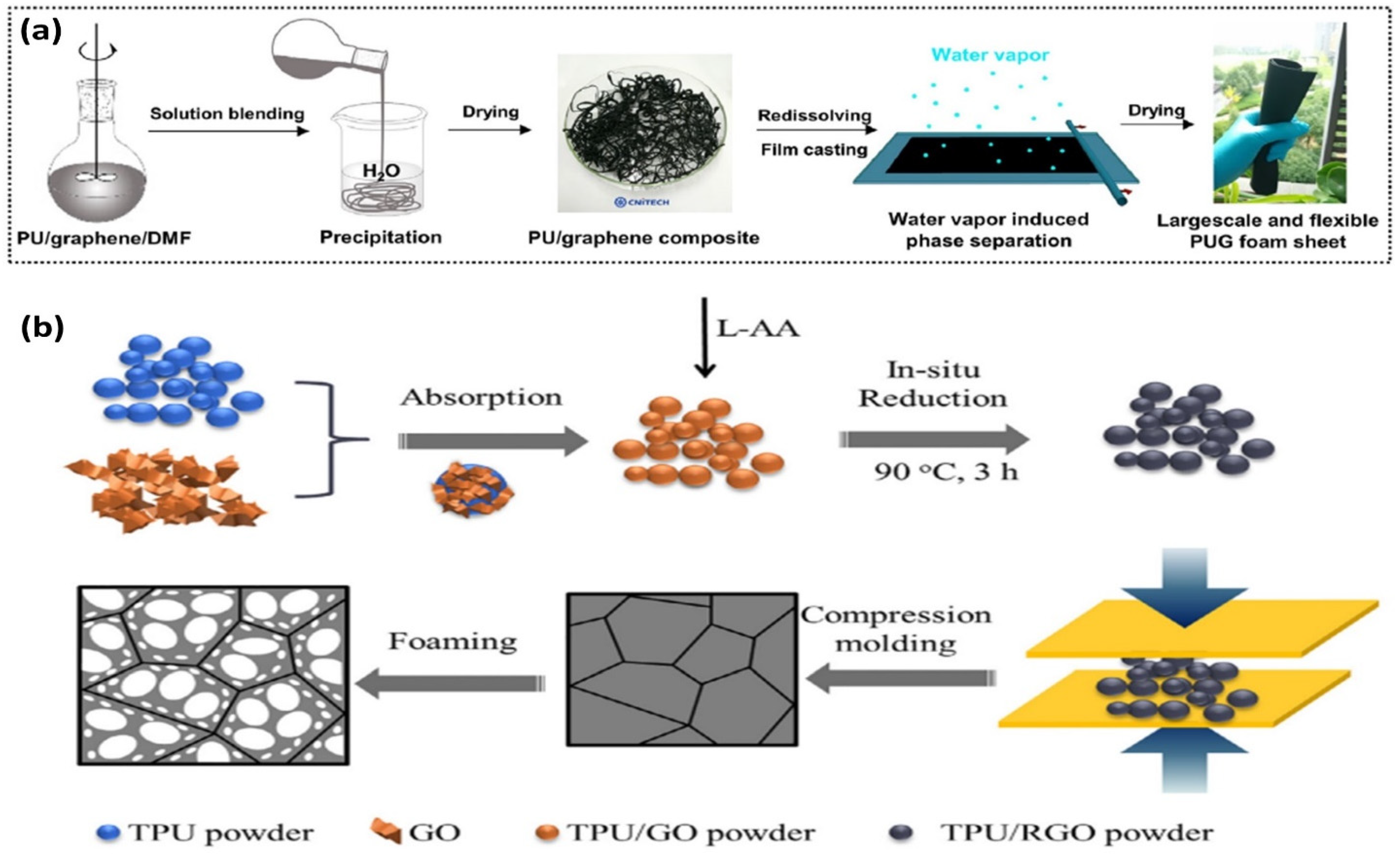

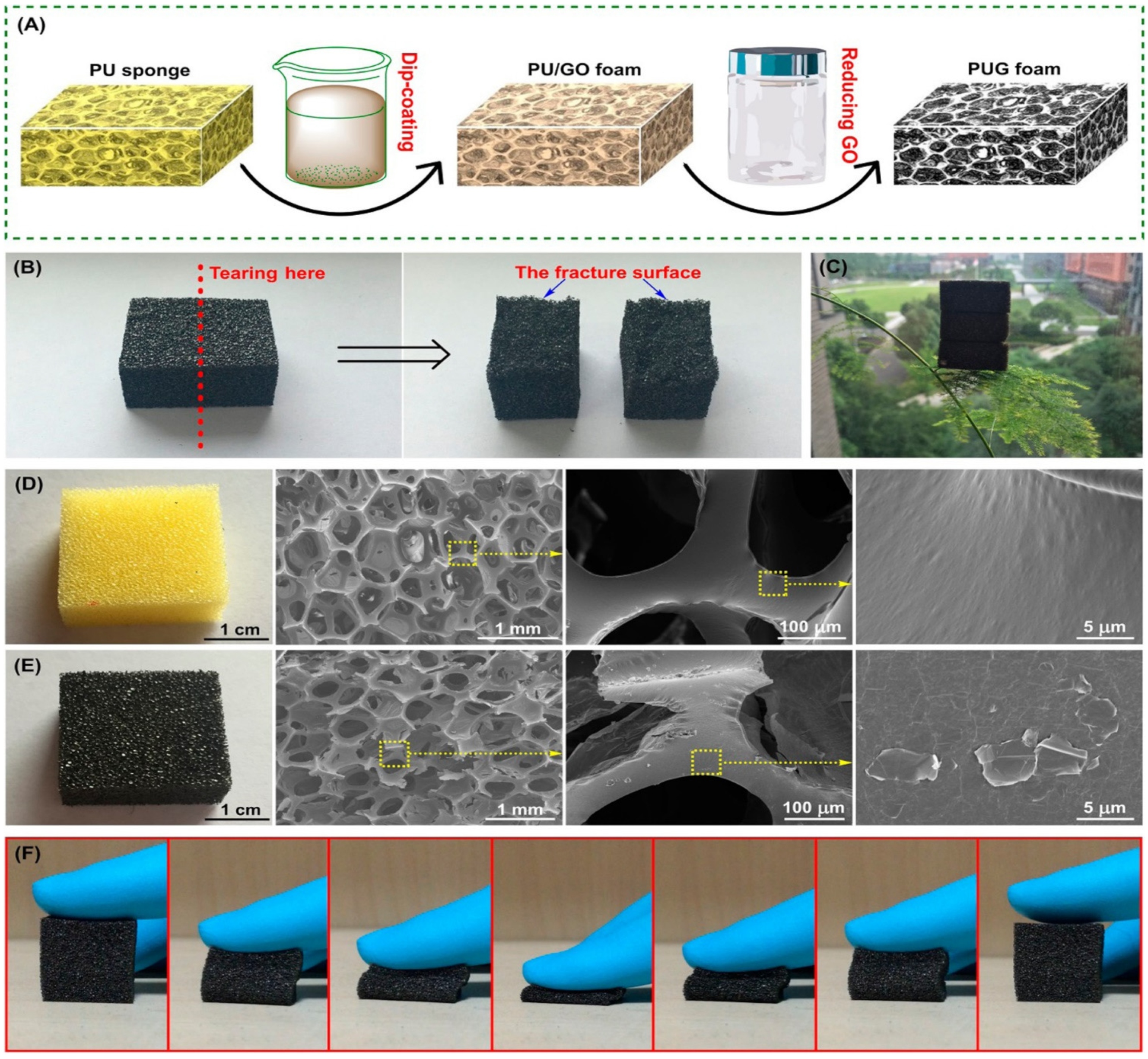

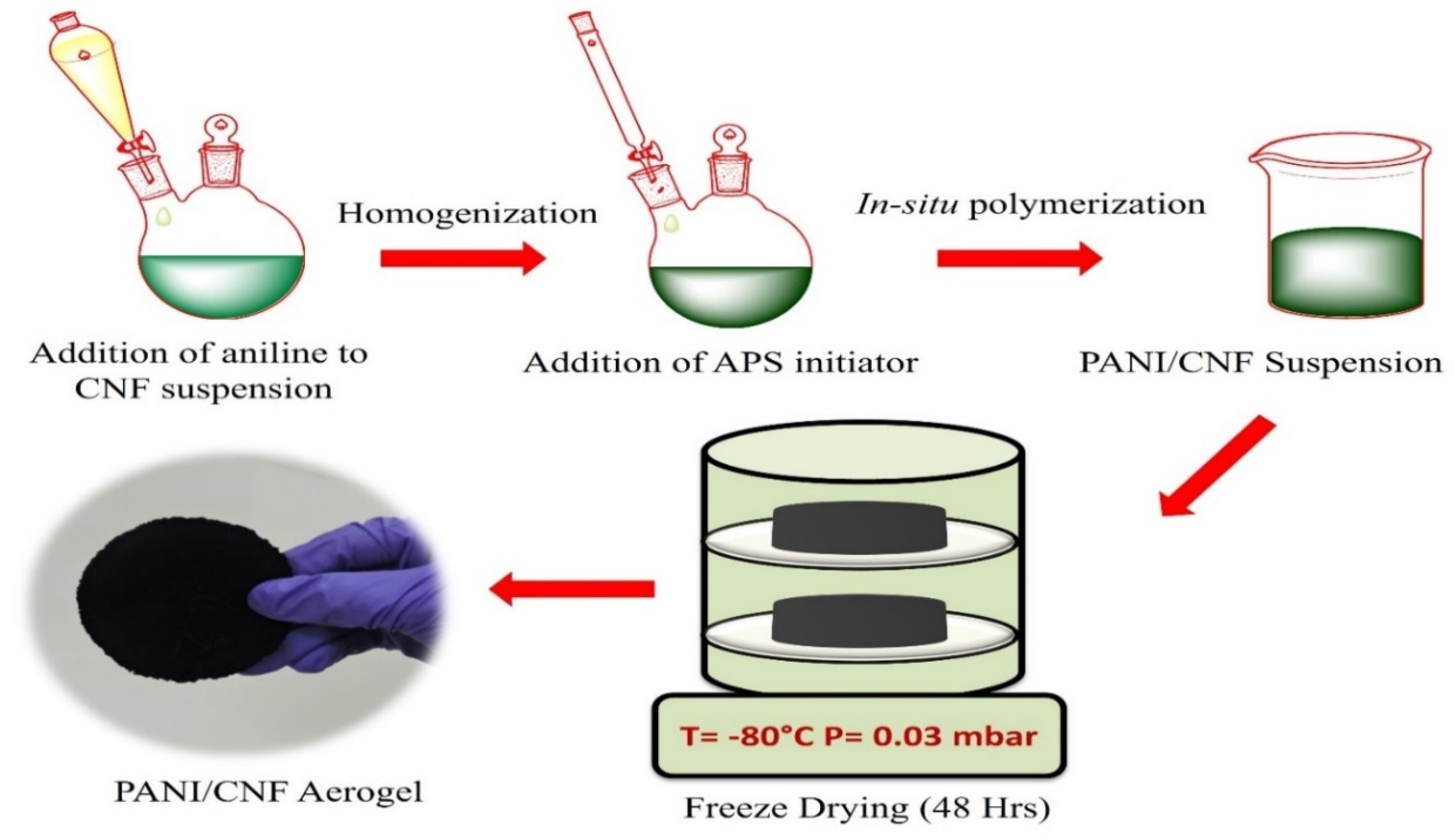

10. Polyurethane Foams for Electromagnetic Interference Shielding

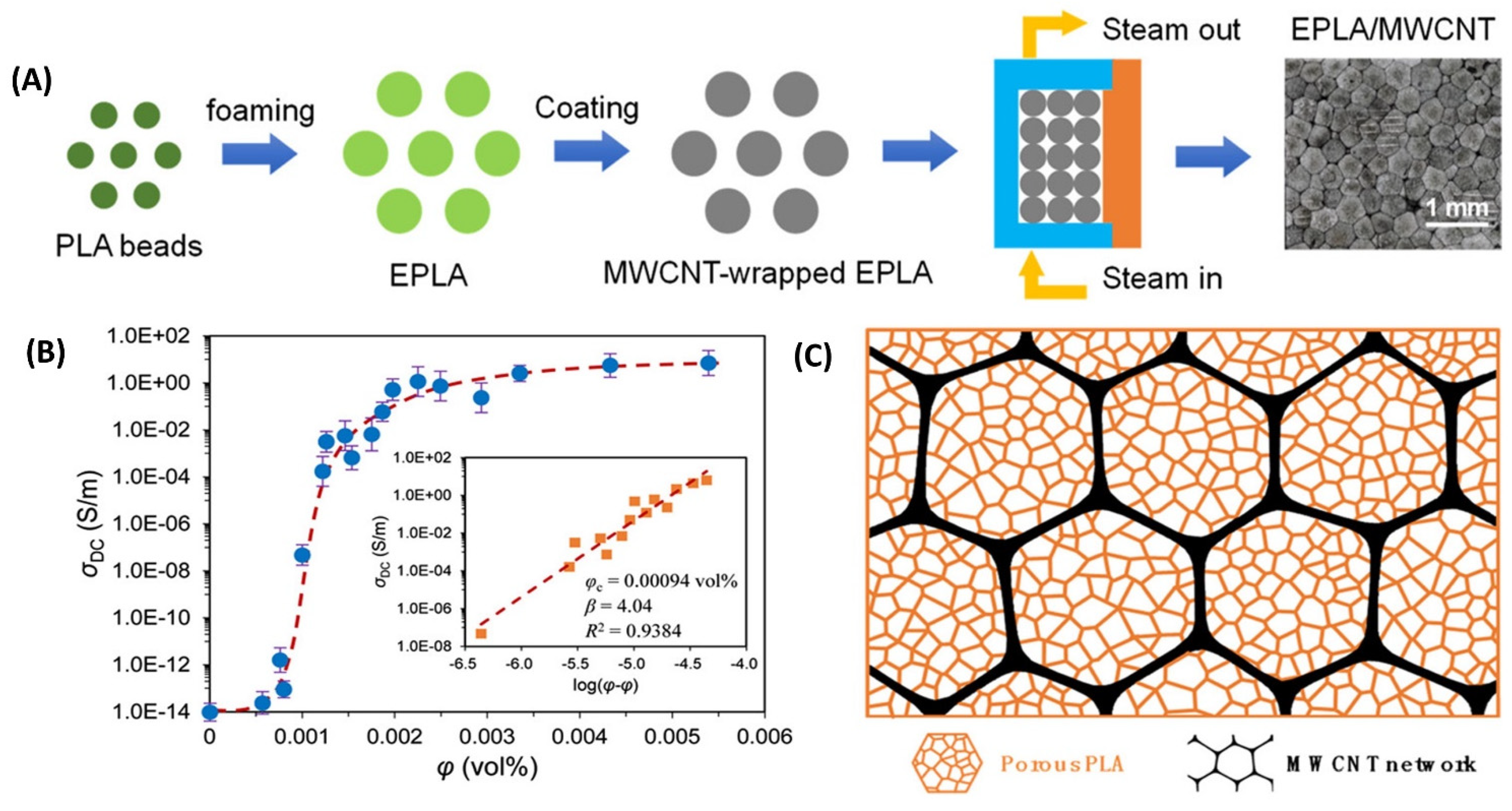

11. Bioplastic Foams for Electromagnetic Interference Shielding

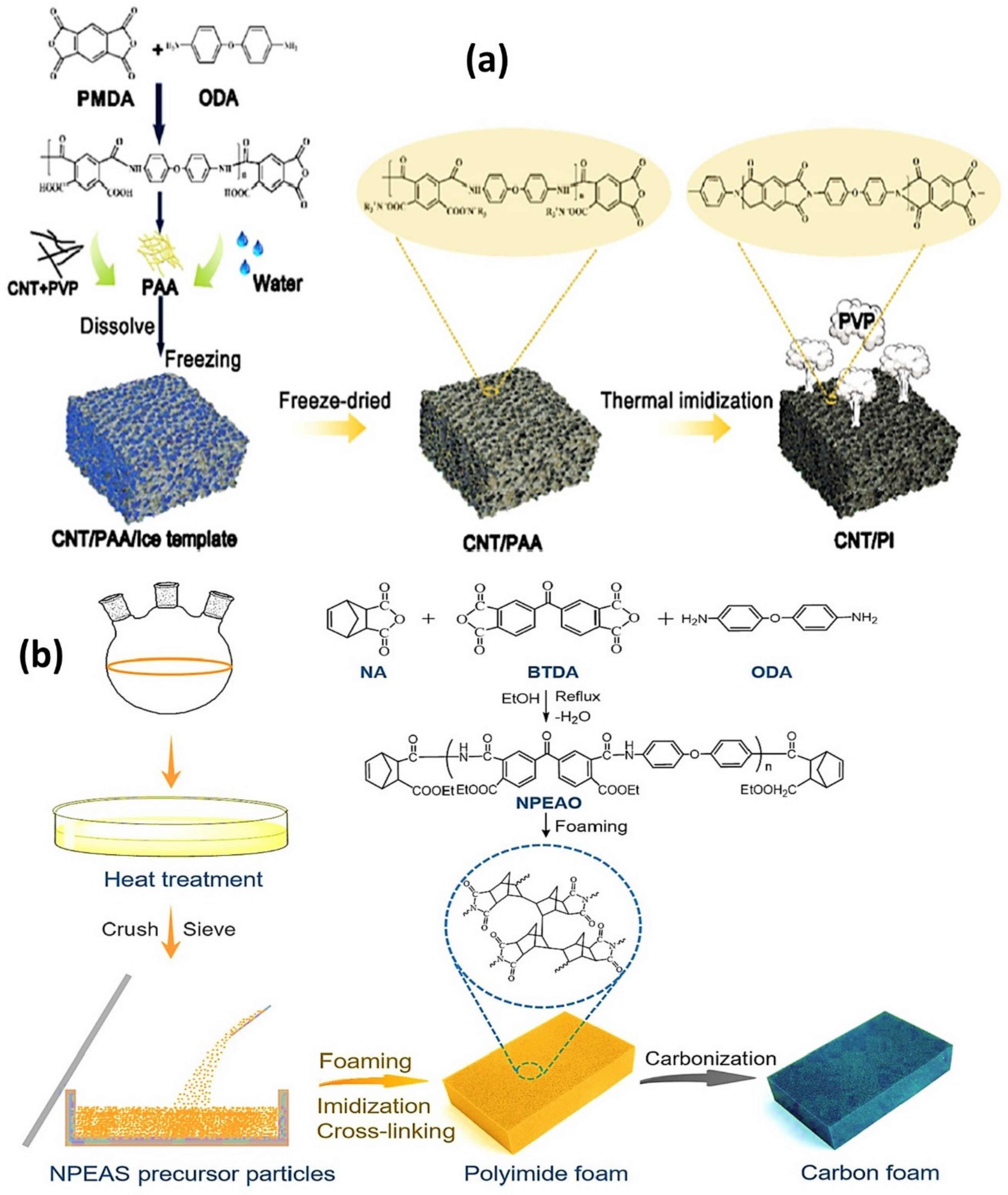

12. Porous Polyimide Nanocomposites for Electromagnetic Interference Shielding

13. Nanocellulose Aerogels for Electromagnetic Interference Shielding

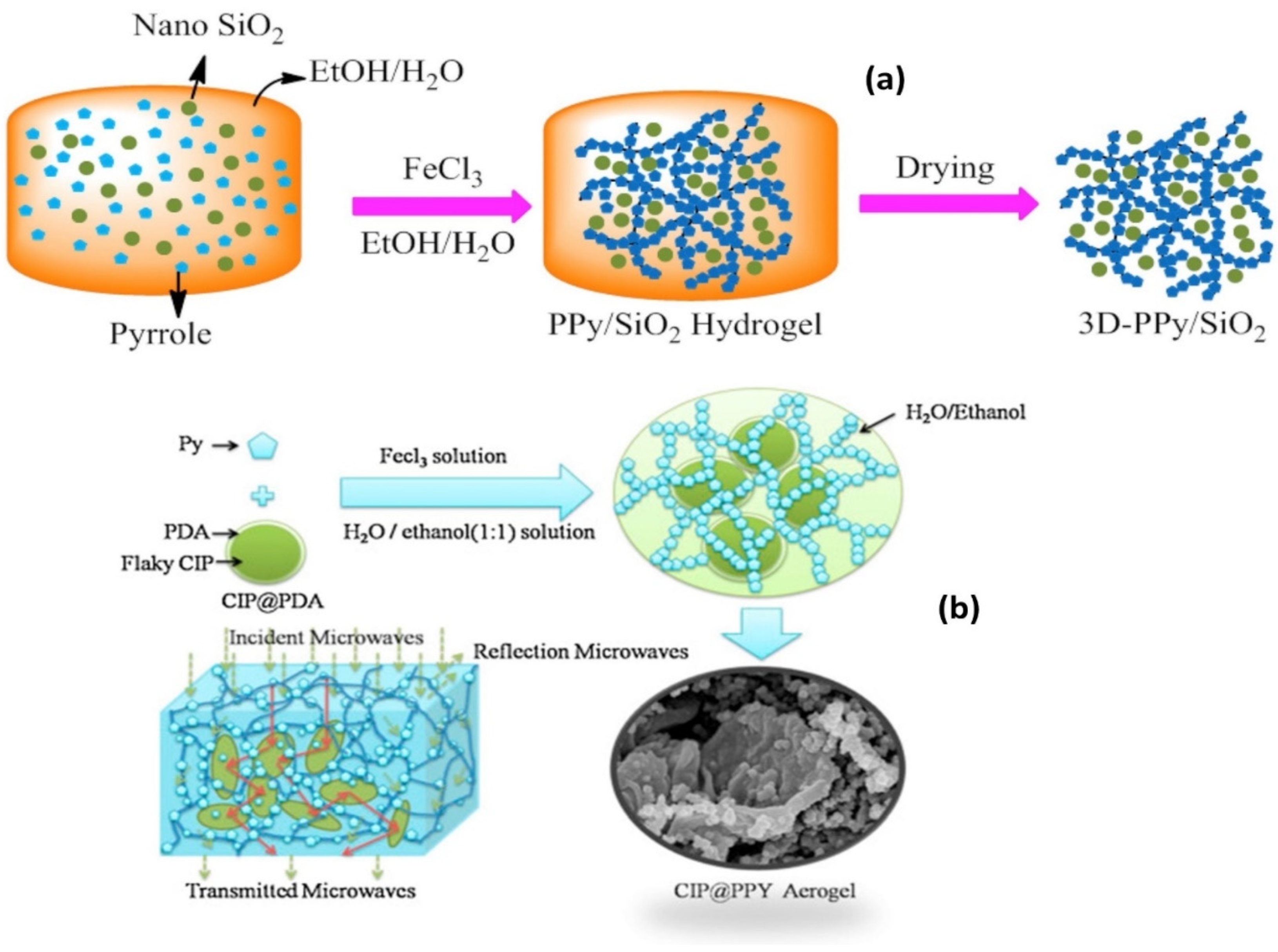

14. Intrinsically Conducting Polymer Aerogels for Electromagnetic Interference Shielding

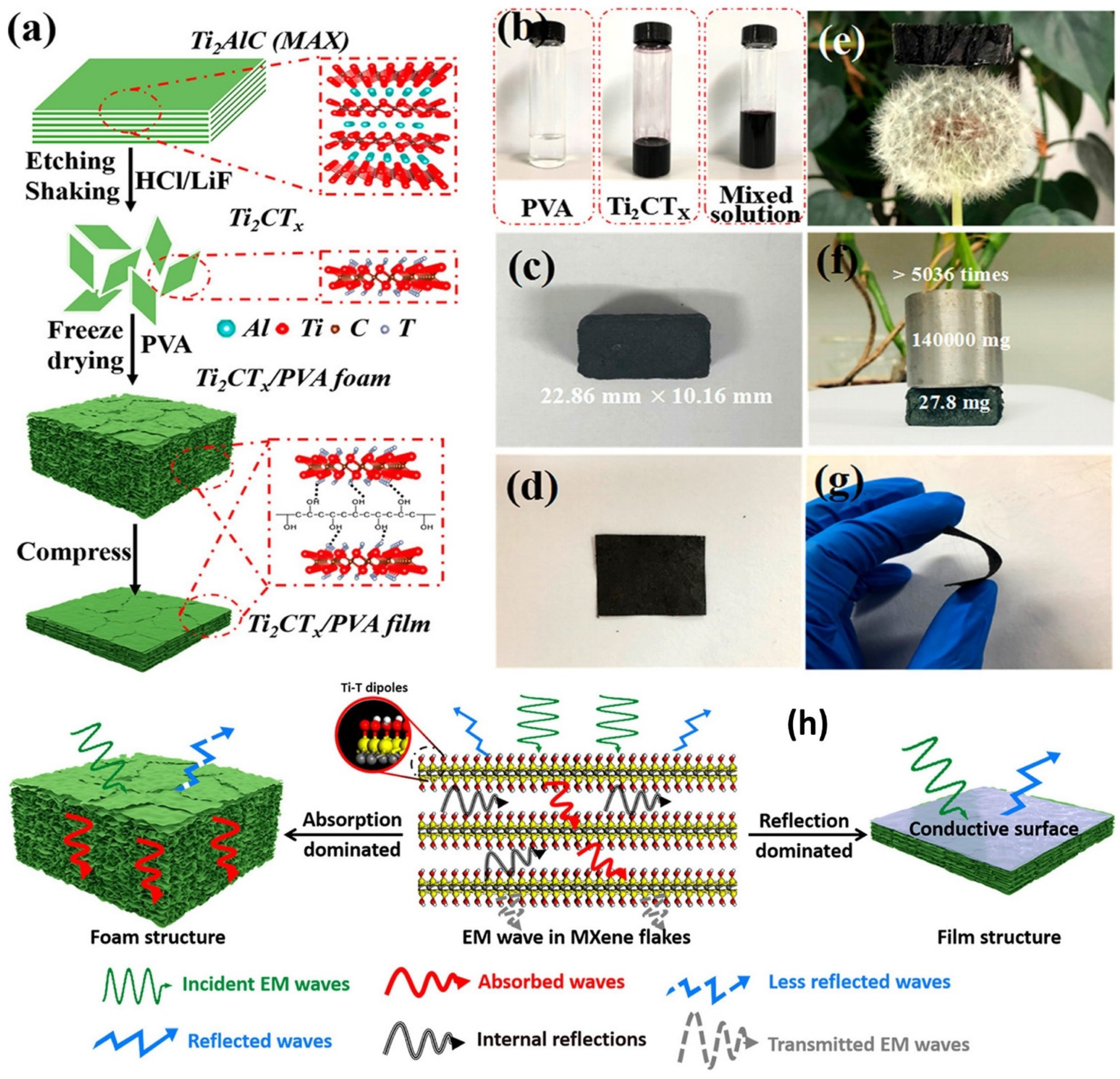

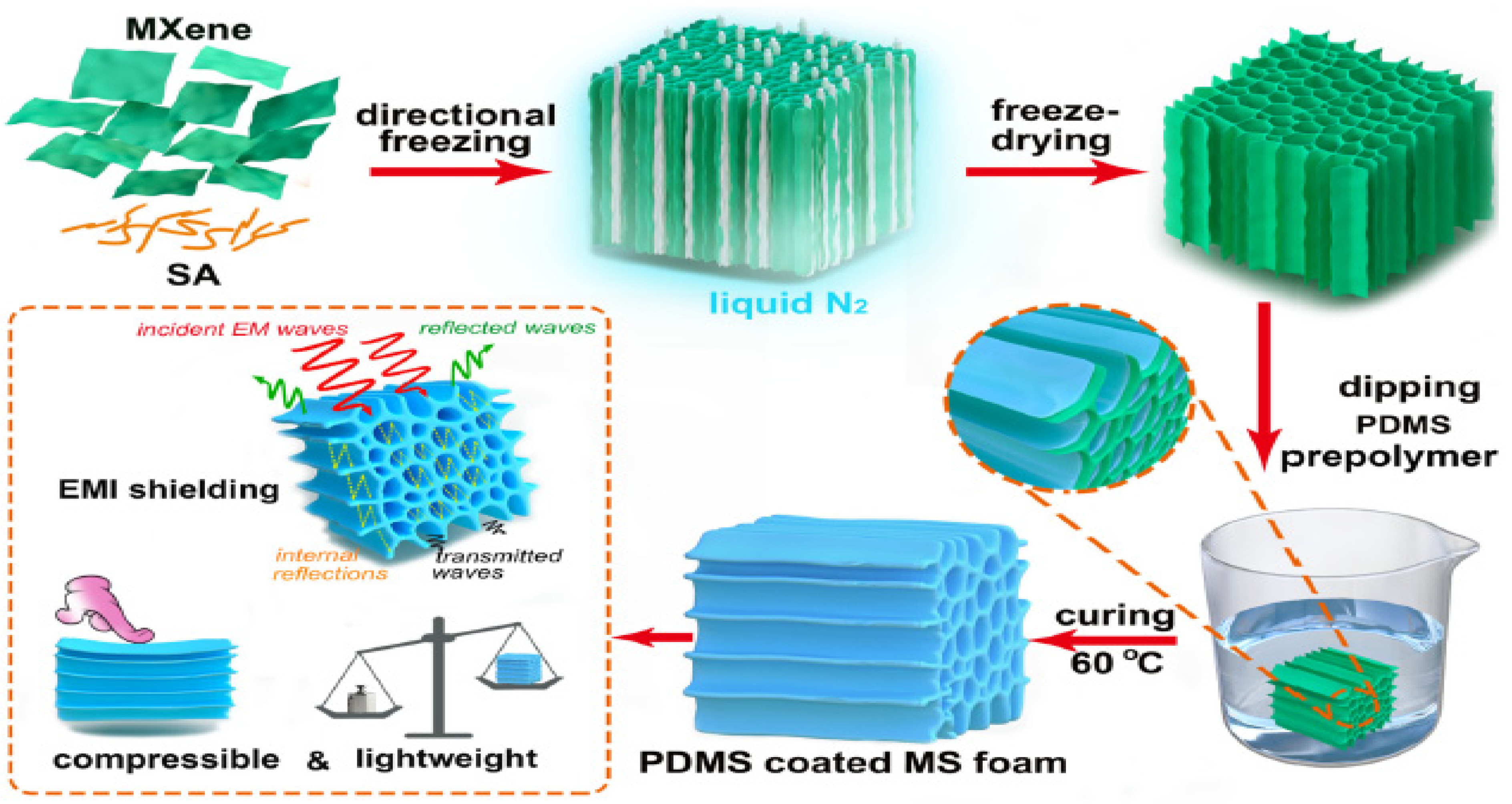

15. Next-Generation 2D Materials for High-Performance Porous EMI Shields

16. Conclusions and Future Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 1D | One-dimensional |

| 2D | Two-dimensional |

| 3D | Three-dimensional |

| AgNWs | Silver nanowires |

| BaTiO3 | Barium titanate |

| CB | Carbon Black |

| CFCs | Chlorofluorocarbons |

| CIP | Carbonyl iron powder |

| CO2 | Carbon dioxide |

| CNFs | Carbon nanofibers |

| CNTs | Carbon nanotubes |

| dB | Decibel |

| DC | Direct current |

| DCM | Dichloromethane |

| EAB | Electromagnetic absorption bandwidth |

| EM | Electromagnetic |

| EMI | Electromagnetic interference |

| EPLA | Expanded polylactic acid |

| FeCl3 | Ferric chloride |

| FeCl2 | Ferrous chloride |

| Fe2O3 | Ferric oxide |

| Fe3O4 | Iron oxide |

| GHz | Gigahertz |

| GO | Graphene oxide |

| GnP | Graphene nanoplatelet |

| hBN | Hexagonal boron nitride |

| HCl | Hydrochloric acid |

| HDPE | High-density polyethylene |

| Hz | Hertz |

| ICPs | Intrinsically conducting polymers |

| LiF | Lithium fluoride |

| MoS2 | Molybdenum disulfide |

| MG | Maxwell Garnett |

| MWCNTs | Multi-walled carbon nanotubes |

| NPs | Nanoparticles |

| NW | Nanowire |

| PA | Polyacetlyene |

| PAA | Polyamic acid |

| PANI | Polyaniline |

| PbTiO3 | Lead titanate |

| PDLA | Poly(D-lactide acid) |

| PDMS | Polydimethylsiloxane |

| PEDOT | Poly(3,4-rthylenedioxythiophene) |

| PEI | Polyethylenimine |

| PI | Polyimide |

| PLA | Polylactic acid |

| PLLA | Poly(L-lactide acid) |

| PP | Polypropylene |

| PPy | Polypyrrole |

| PS | Polystyrene |

| PSS | Polystyrene sulfonate |

| PT | Polythiophene |

| PU | Polyurathane |

| PUG | Polyurathene/graphene |

| PVA | Poly vinyl alcohol |

| R | Reflectivity |

| RL | Reflection loss |

| rGO | Reduced graphene oxide |

| SA | Sodium alginate |

| ScPLA | Stereo complex polylactide |

| Sc-CO2 | Supercritical carbon dioxides |

| SE | Shielding effectiveness |

| SEA | Shielding effectiveness due to absorption |

| SEM | Shielding effectiveness due to multiple reflections |

| SER | Shielding effectiveness due to reflection |

| SEM | Scanning electron microscopy |

| SiO2 | Silicon dioxide |

| SSE | Specific shielding efficiency |

| SWCNTs | Single-walled carbon nanotubes |

| TEM | Transmission electron microscopy |

| TiO2 | Titanium dioxide |

| TPU | Thermoplastic polyurethanes |

| VMQ | Vinyl silicon rubber |

References

- Health Effects of Exposure to EMF; Scientific Committee on Emerging and Newly Identified Health Risks, European Commission: Brussels, Belgium, 2009.

- Guidelines for Limiting Exposure to Electromagnetic Fields (100 kHz to 300 GHz), International Commission on Non-Ionizing Radiation Protection (ICNIRP). Health Phys. 2020, 118, 483–524. [CrossRef] [PubMed]

- IEEE Standard for Safety Levels with Respect to Human Exposure to Electric, Magnetic, and Electromagnetic Fields, 0 Hz to 300 GHz. In IEEE Std C95.1-2019 (Revision of IEEE Std C95.1-2005/Incorporates IEEE Std C95.1-2019/Cor 1-2019); IEEE Standard Association: Piscataway, NJ, USA, 2019; pp. 1–312. [CrossRef]

- Tiikkaja, M.; Aro, A.L.; Alanko, T.; Lindholm, H.; Sistonen, H.; Hartikainen, J.E.; Toivonen, L.; Juutilainen, J.; Hietanen, M. Electromagnetic Interference with Cardiac Pacemakers and Implantable Cardioverter-Defibrillators from Low-Frequency Electromagnetic Fields in Vivo. Europace 2013, 15, 388–394. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Qin, S.; Jiang, Y.; Song, P.; Wang, H. Lightweight high-performance carbon-polymer nanocomposites for electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2021, 145, 106376. [Google Scholar] [CrossRef]

- Li, Y.; Sun, N.; Liu, J.; Hao, X.; Du, J.; Yang, H.; Li, X.; Cao, M. Multifunctional BiFeO3 Composites: Absorption Attenuation Dominated Effective Electromagnetic Interference Shielding and Electromagnetic Absorption Induced by Multiple Dielectric and Magnetic Relaxations. Compos. Sci. Technol. 2018, 159, 240–250. [Google Scholar] [CrossRef]

- Li, X.-H.; Li, X.; Liao, K.-N.; Min, P.; Liu, T.; Dasari, A.; Yu, Z.-Z. Thermally Annealed Anisotropic Graphene Aerogels and Their Electrically Conductive Epoxy Composites with Excellent Electromagnetic Interference Shielding Efficiencies. ACS Appl. Mater. Interfaces 2016, 8, 33230–33239. [Google Scholar] [CrossRef]

- Zeng, Z.; Jin, H.; Chen, M.; Li, W.; Zhou, L.; Zhang, Z. Lightweight and Anisotropic Porous MWCNT/WPU Composites for Ultrahigh Performance Electromagnetic Interference Shielding. Adv. Funct. Mater. 2016, 26, 303–310. [Google Scholar] [CrossRef]

- Wan, C.; Li, J. Synthesis and Electromagnetic Interference Shielding of Cellulose-Derived Carbon Aerogels Functionalized with α-Fe2O3 and Polypyrrole. Carbohydr. Polym. 2017, 161, 158–165. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Zhu, P.-L.; Yu, S.-H.; Sun, R.; Wong, C.-P.; Liao, W.-H. Ultralight, Super-Elastic and Volume-Preserving Cellulose Fiber/Graphene Aerogel for High-Performance Electromagnetic Interference Shielding. Carbon 2017, 115, 629–639. [Google Scholar] [CrossRef]

- Huang, H.-D.; Liu, C.-Y.; Zhou, D.; Jiang, X.; Zhong, G.-J.; Yan, D.-X.; Li, Z.-M. Cellulose Composite Aerogel for Highly Efficient Electromagnetic Interference Shielding. J. Mater. Chem. A 2015, 3, 4983–4991. [Google Scholar] [CrossRef]

- Guo, J.; Song, H.; Liu, H.; Luo, C.; Ren, Y.; Ding, T.; Khan, M.A.; Young, D.P.; Liu, X.; Zhang, X.; et al. Polypyrrole-Interface-Functionalized Nano-Magnetite Epoxy Nanocomposites as Electromagnetic Wave Absorbers with Enhanced Flame Retardancy. J. Mater. Chem. C 2017, 5, 5334–5344. [Google Scholar] [CrossRef]

- Madani, M. Conducting Carbon Black Filled NR/ IIR Blend Vulcanizates: Assessment of the Dependence of Physical and Mechanical Properties and Electromagnetic Interference Shielding on Variation of Filler Loading. J. Polym. Res. 2010, 17, 53–62. [Google Scholar] [CrossRef]

- Yang, W.; Shao, B.; Liu, T.; Zhang, Y.; Huang, R.; Chen, F.; Fu, Q. Robust and Mechanically and Electrically Self-Healing Hydrogel for Efficient Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2018, 10, 8245–8257. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; Zhao, C.; Hamidinejad, M.; Wang, C.; Li, R.; Wang, S.; Yasamin, K.; Park, C.B. Incorporating a Microcellular Structure into PVDF/Graphene-Nanoplatelet Composites to Tune Their Electrical Conductivity and Electromagnetic Interference Shielding Properties. J. Mater. Chem. C 2018, 6, 10292–10300. [Google Scholar] [CrossRef]

- Zachariah, S.M.; Grohens, Y.; Kalarikkal, N.; Thomas, S. Hybrid Materials for Electromagnetic Shielding: A Review. Polym. Compos. 2022, 43, 2507–2544. [Google Scholar] [CrossRef]

- Pawar, S.P.; Gandi, M.; Arief, I.; Krause, B.; Pötschke, P.; Bose, S. Graphene Derivatives Doped with Nickel Ferrite Nanoparticles as Excellent Microwave Absorbers in Soft Nanocomposites. ChemistrySelect 2017, 2, 5984–5999. [Google Scholar] [CrossRef]

- Bora, P.J.; Mallik, N.; Ramamurthy, P.C.; Kishore, S.; Madras, G. Poly(Vinyl Butyral)-Polyaniline-Magnetically Functionalized Fly Ash Cenosphere Composite Film for Electromagnetic Interference Shielding. Compos. Part B Eng. 2016, 106, 224–233. [Google Scholar] [CrossRef]

- Dalal, J.; Lather, S.; Gupta, A.; Tripathi, R.; Maan, A.S.; Singh, K.; Ohlan, A. Reduced Graphene Oxide Functionalized Strontium Ferrite in Poly(3,4-Ethylenedioxythiophene) Conducting Network: A High-Performance EMI Shielding Material. Adv. Mater. Technol. 2019, 4, 1900023. [Google Scholar] [CrossRef]

- Hong, X.; Chung, D. Carbon Nanofiber Mats for Electromagnetic Interference Shielding. Carbon 2017, 111, 529–537. [Google Scholar] [CrossRef]

- Yang, S.; Lozano, K.; Lomeli, A.; Foltz, H.D.; Jones, R. Electromagnetic Interference Shielding Effectiveness of Carbon Nanofiber/LCP Composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 691–697. [Google Scholar] [CrossRef]

- Deeraj, B.; George, G.; Dhineshbabu, N.; Bose, S.; Joseph, K. Electrospun ZrO2@carbon Nanofiber Mats and Their Epoxy Composites as Effective EMI Shields in Ku Band. Mater. Res. Bull. 2021, 144, 111477. [Google Scholar] [CrossRef]

- Abraham, J.; Mohammed Arif, P.; Kailas, L.; Kalarikkal, N.; George, S.C.; Thomas, S. Developing Highly Conducting and Mechanically Durable Styrene Butadiene Rubber Composites with Tailored Microstructural Properties by a Green Approach Using Ionic Liquid Modified MWCNTs. RSC Adv. 2016, 6, 32493–32504. [Google Scholar] [CrossRef] [Green Version]

- Kunjappan, A.M.; Poothanari, M.A.; Ramachandran, A.A.; Padmanabhan, M.; Mathew, L.; Thomas, S. High-Performance Electromagnetic Interference Shielding Material Based on an Effective Mixing Protocol. Polym. Int. 2019, 68, 637–647. [Google Scholar] [CrossRef]

- Abraham, J.; Arif, P.M.; Xavier, P.; Bose, S.; George, S.C.; Kalarikkal, N.; Thomas, S. Investigation into Dielectric Behaviour and Electromagnetic Interference Shielding Effectiveness of Conducting Styrene Butadiene Rubber Composites Containing Ionic Liquid Modified MWCNT. Polymer 2017, 112, 102–115. [Google Scholar] [CrossRef]

- Ajitha, A.A.; Mohammed Arif, M.P.; Aswathi, M.K.; Mathew, L.P.; Geethamma, G.; Kalarikkal, N.; Thomas, S.; Volova, T. An Effective EMI Shielding Material Based on Poly(Trimethylene Terephthalate) Blend Nanocomposites with Multiwalled Carbon Nanotubes. New J. Chem. 2018, 42, 13915–13926. [Google Scholar]

- Poothanari, M.A.; Abraham, J.; Kalarikkal, N.; Thomas, S. Excellent Electromagnetic Interference Shielding and High Electrical Conductivity of Compatibilized Polycarbonate/Polypropylene Carbon Nanotube Blend Nanocomposites. Ind. Eng. Chem. Res. 2018, 57, 4287–4297. [Google Scholar] [CrossRef]

- Sharika, T.; Abraham, J.; Arif, P.M.; George, S.C.; Kalarikkal, N.; Thomas, S. Excellent Electromagnetic Shield Derived from MWCNT Reinforced NR/PP Blend Nanocomposites with Tailored Microstructural Properties. Compos. Part B Eng. 2019, 173, 106798. [Google Scholar] [CrossRef]

- Shin, B.; Mondal, S.; Lee, M.; Kim, S.; Huh, Y., II; Nah, C. Flexible Thermoplastic Polyurethane-Carbon Nanotube Composites for Electromagnetic Interference Shielding and Thermal Management. Chem. Eng. J. 2021, 418, 129282. [Google Scholar] [CrossRef]

- Zhu, G.; Isaza, L.G.; Huang, B.; Dufresne, A. Multifunctional Nanocellulose/Carbon Nanotube Composite Aerogels for High-Efficiency Electromagnetic Interference Shielding. ACS Sustain. Chem. Eng. 2022, 10, 2397–2408. [Google Scholar] [CrossRef]

- Sushmita, K.; Formanek, P.; Krause, B.; Pötschke, P.; Bose, S. Distribution of Carbon Nanotubes in Polycarbonate-Based Blends for Electromagnetic Interference Shielding. ACS Appl. Nano Mater. 2022, 5, 662–677. [Google Scholar] [CrossRef]

- Lee, T.W.; Lee, S.E.; Jeong, Y.G. Highly Effective Electromagnetic Interference Shielding Materials Based on Silver Nanowire/Cellulose Papers. ACS Appl. Mater. Interfaces 2016, 8, 13123–13132. [Google Scholar] [CrossRef]

- Ravindren, R.; Mondal, S.; Nath, K.; Das, N.C. Prediction of Electrical Conductivity, Double Percolation Limit and Electromagnetic Interference Shielding Effectiveness of Copper Nanowire Filled Flexible Polymer Blend Nanocomposites. Compos. Part B Eng. 2019, 164, 559–569. [Google Scholar] [CrossRef]

- Ma, Z.; Xiang, X.; Shao, L.; Zhang, Y.; Gu, J. Multifunctional Wearable Silver Nanowire Decorated Leather Nanocomposites for Joule Heating, Electromagnetic Interference Shielding and Piezoresistive Sensing. Angew. Chem. Int. Ed. 2022, 61, e202200705. [Google Scholar] [CrossRef] [PubMed]

- Xie, Q.; Yan, Z.; Wang, S.; Wang, Y.; Mei, L.; Qin, F.; Jiang, R. Transparent, Flexible, and Stable Polyethersulfone/Copper-Nanowires/Polyethylene Terephthalate Sandwich-Structured Films for High-Performance Electromagnetic Interference Shielding. Adv. Eng. Mater. 2021, 23, 2100283. [Google Scholar] [CrossRef]

- Joshi, A.; Bajaj, A.; Singh, R.; Anand, A.; Alegaonkar, P.; Datar, S. Processing of Graphene Nanoribbon Based Hybrid Composite for Electromagnetic Shielding. Compos. Part B Eng. 2015, 69, 472–477. [Google Scholar] [CrossRef]

- Zhang, H.-B.; Yan, Q.; Zheng, W.-G.; He, Z.; Yu, Z.-Z. Tough Graphene-Polymer Microcellular Foams for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2011, 3, 918–924. [Google Scholar] [CrossRef]

- Xu, J.; Li, R.; Ji, S.; Zhao, B.; Cui, T.; Tan, X.; Gou, G.; Jian, J.; Xu, H.; Qiao, Y.; et al. Multifunctional Graphene Microstructures Inspired by Honeycomb for Ultrahigh Performance Electromagnetic Interference Shielding and Wearable Applications. ACS Nano 2021, 15, 8907–8918. [Google Scholar] [CrossRef] [PubMed]

- Tan, X.; Yuan, Q.; Qiu, M.; Yu, J.; Jiang, N.; Lin, C.-T.; Dai, W. Rational Design of Graphene/Polymer Composites with Excellent Electromagnetic Interference Shielding Effectiveness and High Thermal Conductivity: A Mini Review. J. Mater. Sci. Technol. 2022, 117, 238–250. [Google Scholar] [CrossRef]

- Yan, D.-X.; Pang, H.; Li, B.; Vajtai, R.; Xu, L.; Ren, P.-G.; Wang, J.-H.; Li, Z.-M. Structured Reduced Graphene Oxide/Polymer Composites for Ultra-Efficient Electromagnetic Interference Shielding. Adv. Funct. Mater. 2015, 25, 559–566. [Google Scholar] [CrossRef]

- Song, P.; Liang, C.; Wang, L.; Qiu, H.; Gu, H.; Kong, J.; Gu, J. Obviously Improved Electromagnetic Interference Shielding Performances for Epoxy Composites via Constructing Honeycomb Structural Reduced Graphene Oxide. Compos. Sci. Technol. 2019, 181, 107698. [Google Scholar] [CrossRef]

- Li, J.; Zhao, X.; Wu, W.; Ji, X.; Lu, Y.; Zhang, L. Bubble-Templated RGO-Graphene Nanoplatelet Foams Encapsulated in Silicon Rubber for Electromagnetic Interference Shielding and High Thermal Conductivity. Chem. Eng. J. 2021, 415, 129054. [Google Scholar] [CrossRef]

- Shen, Y.; Lin, Z.; Wei, J.; Xu, Y.; Wan, Y.; Zhao, T.; Zeng, X.; Hu, Y.; Sun, R. Facile Synthesis of Ultra-Lightweight Silver/Reduced Graphene Oxide (RGO) Coated Carbonized-Melamine Foams with High Electromagnetic Interference Shielding Effectiveness and High Absorption Coefficient. Carbon 2022, 186, 9–18. [Google Scholar] [CrossRef]

- Sankaran, S.; Deshmukh, K.; Ahamed, M.B.; Sadasivuni, K.K.; Faisal, M.; Pasha, S.K. Electrical and Electromagnetic Interference (EMI) Shielding Properties of Hexagonal Boron Nitride Nanoparticles Reinforced Polyvinylidene Fluoride Nanocomposite Films. Polym. Plast. Technol. Mater. 2019, 58, 1191–1209. [Google Scholar] [CrossRef]

- Zhan, Y.; Lago, E.; Santillo, C.; Del Río Castillo, A.E.; Hao, S.; Buonocore, G.G.; Chen, Z.; Xia, H.; Lavorgna, M.; Bonaccorso, F. An Anisotropic Layer-by-Layer Carbon Nanotube/Boron Nitride/Rubber Composite and Its Application in Electromagnetic Shielding. Nanoscale 2020, 12, 7782–7791. [Google Scholar] [CrossRef] [PubMed]

- Habibi, N.; Pourjavadi, A. Superhydrophobic and Thermally Conductive Carbon Black/Hexagonal Boron Nitride@Fe3O4/Cellulose Composite Paper for Electromagnetic Interference Shielding. Synth. Met. 2022, 285, 117008. [Google Scholar] [CrossRef]

- Shang, Y.; Ji, Y.; Dong, J.; Yang, G.; Zhang, X.; Su, F.; Feng, Y.; Liu, C. Sandwiched Cellulose Nanofiber/Boron Nitride Nanosheet/Ti3C2Tx MXene Composite Film with High Electromagnetic Shielding and Thermal Conductivity yet Insulation Performance. Compos. Sci. Technol. 2021, 214, 108974. [Google Scholar] [CrossRef]

- Ding, X.; Huang, Y.; Li, S.; Zhang, N.; Wang, J. 3D Architecture Reduced Graphene Oxide-MoS2 Composite: Preparation and Excellent Electromagnetic Wave Absorption Performance. Compos. Part A Appl. Sci. Manuf. 2016, 90, 424–432. [Google Scholar] [CrossRef]

- Saboor, A.; Khalid, S.M.; Jan, R.; Khan, A.N.; Zia, T.; Farooq, M.U.; Afridi, S.; Sadiq, M.; Arif, M. PS/PANI/MoS2 Hybrid Polymer Composites with High Dielectric Behavior and Electrical Conductivity for EMI Shielding Effectiveness. Materials 2019, 12, 2690. [Google Scholar] [CrossRef] [Green Version]

- Prasad, J.; Singh, A.K.; Tomar, M.; Gupta, V.; Singh, K. Hydrothermal Synthesis of Micro-Flower like Morphology Aluminum-Doped MoS2/RGO Nanohybrids for High Efficient Electromagnetic Wave Shielding Materials. Ceram. Int. 2021, 47, 15648–15660. [Google Scholar] [CrossRef]

- Prasad, J.; Singh, A.K.; Singh Gahlot, A.P.; Tomar, M.; Gupta, V.; Singh, K. Electromagnetic Interference Shielding Properties of Hierarchical Core-Shell Palladium-Doped MoS2/CNT Nanohybrid Materials. Ceram. Int. 2021, 47, 27586–27597. [Google Scholar] [CrossRef]

- Liu, R.; Miao, M.; Li, Y.; Zhang, J.; Cao, S.; Feng, X. Ultrathin Biomimetic Polymeric Ti3C2Tx MXene Composite Films for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2018, 10, 44787–44795. [Google Scholar] [CrossRef]

- Wan, Y.-J.; Li, X.-M.; Zhu, P.-L.; Sun, R.; Wong, C.-P.; Liao, W.-H. Lightweight, Flexible MXene/Polymer Film with Simultaneously Excellent Mechanical Property and High-Performance Electromagnetic Interference Shielding. Compos. Part A Appl. Sci. Manuf. 2020, 130, 105764. [Google Scholar] [CrossRef]

- Zeng, Z.H.; Wu, N.; Wei, J.J.; Yang, Y.F.; Wu, T.T.; Li, B.; Hauser, S.B.; Yang, W.D.; Liu, J.R.; Zhao, S.Y. Porous and Ultra-Flexible Crosslinked MXene/Polyimide Composites for Multifunctional Electromagnetic Interference Shielding. Nano Micro Lett. 2022, 14, 59. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Mckeon, L.; Garcia, J.; Pinilla, S.; Barwich, S.; Möbius, M.; Stamenov, P.; Coleman, J.N.; Nicolosi, V. Additive Manufacturing of Ti3C2-MXene-Functionalized Conductive Polymer Hydrogels for Electromagnetic-Interference Shielding. Adv. Mater. 2022, 34, 2106253. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Liu, J.; Guo, T.; Wang, J.J.; Tang, X.; Nicolosi, V. Multifunctional Ti3C2Tx MXene Composite Hydrogels with Strain Sensitivity toward Absorption-Dominated Electromagnetic-Interference Shielding. ACS Nano 2021, 15, 1465–1474. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.Y.; Kim, Y.C.; Wang, M.; Nam, J.D.; Suhr, J. Anisotropic Electromagnetic Interference Shielding Properties of Polymer-Based Composites with Magnetically-Responsive Aligned Fe3O4 Decorated Reduced Graphene Oxide. Eur. Polym. J. 2020, 127, 109595. [Google Scholar] [CrossRef]

- Li, Y.; Xue, B.; Yang, S.; Cheng, Z.; Xie, L.; Zheng, Q. Flexible Multilayered Films Consisting of Alternating Nanofibrillated Cellulose/Fe3O4 and Carbon Nanotube/Polyethylene Oxide Layers for Electromagnetic Interference Shielding. Chem. Eng. J. 2021, 410, 128356. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Z.; Ruan, K.; Gu, J. Multifunctional Ti3C2Tx-(Fe3O4/Polyimide) Composite Films with Janus Structure for Outstanding Electromagnetic Interference Shielding and Superior Visual Thermal Management. Nano Res. 2022, 1–9. [Google Scholar] [CrossRef]

- Singh, A.P.; Garg, P.; Alam, F.; Singh, K.; Mathur, R.B.; Tandon, R.P.; Chandra, A.; Dhawan, S.K. Phenolic Resin-Based Composite Sheets Filled with Mixtures of Reduced Graphene Oxide, γ-Fe2O3 and Carbon Fibers for Excellent Electromagnetic Interference Shielding in the X-Band. Carbon 2012, 50, 3868–3875. [Google Scholar] [CrossRef]

- Chen, K.Y.; Gupta, S.; Tai, N.H. Reduced Graphene Oxide/Fe2O3 Hollow Microspheres Coated Sponges for Flexible Electromagnetic Interference Shielding Composites. Compos. Commun. 2021, 23, 100572. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Qi, Q.; Xu, N.; Yu, D. Layer-by-Layer Assembly of PDMS-Coated Nickel Ferrite/Multiwalled Carbon Nanotubes/Cotton Fabrics for Robust and Durable Electromagnetic Interference Shielding. Cellulose 2020, 27, 2829–2845. [Google Scholar] [CrossRef]

- Wang, Y.; Qi, Q.; Yin, G.; Wang, W.; Yu, D. Flexible, Ultralight, and Mechanically Robust Waterborne Polyurethane/Ti3C2TX MXene/Nickel Ferrite Hybrid Aerogels for High-Performance Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2021, 13, 21831–21843. [Google Scholar] [CrossRef] [PubMed]

- Saini, P.; Arora, M.; Gupta, G.; Gupta, B.K.; Singh, V.N.; Choudhary, V. High Permittivity Polyaniline–Barium Titanate Nanocomposites with Excellent Electromagnetic Interference Shielding Response. Nanoscale 2013, 5, 4330–4336. [Google Scholar] [CrossRef] [PubMed]

- Sambyal, P.; Singh, A.P.; Verma, M.; Farukh, M.; Singh, B.P.; Dhawan, S.K. Tailored Polyaniline/Barium Strontium Titanate/Expanded Graphite Multiphase Composite for Efficient Radar Absorption. RSC Adv. 2014, 4, 12614–12624. [Google Scholar] [CrossRef] [Green Version]

- Joseph, J.; Deshmukh, K.; Raj, A.N.; Pasha, S.K.K. Electromagnetic Interference Shielding Characteristics of SrTiO3 Nanoparticles Induced Polyvinyl Chloride and Polyvinylidene Fluoride Blend Nanocomposites. J. Inorg. Organomet. Polym. Mater. 2021, 31, 3481–3495. [Google Scholar] [CrossRef]

- Mohanapriya, M.K.; Deshmukh, K.; Kadlec, J.; Sadasivuni, K.K.; Faisal, M.; Nambi Raj, N.A.; Pasha, S.K.K. Dynamic Mechanical Analysis and Broadband Electromagnetic Interference Shielding Characteristics of Poly (Vinyl Alcohol)-Poly (4-Styrenesulfonic Acid)-Titanium Dioxide Nanoparticles Based Tertiary Nanocomposites. Polym. Technol. Mater. 2020, 59, 847–863. [Google Scholar] [CrossRef]

- Tong, X.; Li, W.; Li, J.; Lu, S.; Wang, B.; Ma, K.; Yang, C.; Li, Q. In Situ Generation of TiO2 in Graphene Aerogel and Its Epoxy Composite for Electromagnetic Interference Shielding Performance. J. Mater. Sci. Mater. Electron. 2022, 33, 5886–5898. [Google Scholar] [CrossRef]

- Gopakumar, D.A.; Pai, A.R.; Pottathara, Y.B.; Pasquini, D.; De Morais, L.C.; Luke, M.; Kalarikkal, N.; Grohens, Y.; Thomas, S. Cellulose Nanofiber-Based Polyaniline Flexible Papers as Sustainable Microwave Absorbers in the X-Band. ACS Appl. Mater. Interfaces 2018, 10, 20032–20043. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, T.; Yang, Z. Flexible Polyethylene Terephthalate/Polyaniline Composite Paper with Bending Durability and Effective Electromagnetic Shielding Performance. Chem. Eng. J. 2020, 389, 124433. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Yang, L.; Yin, S. Ti3C2Tx/PANI/Liquid Metal Composite Microspheres with 3D Nanoflower Structure: Preparation, Characterization, and Applications in EMI Shielding. Adv. Mater. Interfaces 2022, 9, 2102266. [Google Scholar] [CrossRef]

- Maruthi, N.; Faisal, M.; Raghavendra, N.; Prasanna, B.; Manohara, S.; Revanasiddappa, M. Promising EMI Shielding Effectiveness and Anticorrosive Properties of PANI-Nb2O5 Nanocomposites: Multifunctional Approach. Synth. Met. 2021, 275, 116744. [Google Scholar] [CrossRef]

- Gopakumar, D.A.; Pai, A.R.; Pottathara, Y.B.; Pasquini, D.; de Morais, L.C.; Khalil, H.P.S.A.; Nzihou, A.; Thomas, S. Flexible Papers Derived from Polypyrrole Deposited Cellulose Nanofibers for Enhanced Electromagnetic Interference Shielding in Gigahertz Frequencies. J. Appl. Polym. Sci. 2021, 138, 50262. [Google Scholar] [CrossRef]

- Parit, M.; Du, H.; Zhang, X.; Prather, C.; Adams, M.; Jiang, Z. Polypyrrole and Cellulose Nanofiber Based Composite Films with Improved Physical and Electrical Properties for Electromagnetic Shielding Applications. Carbohydr. Polym. 2020, 240, 116304. [Google Scholar] [CrossRef] [PubMed]

- Pasha, A.; Khasim, S.; Darwish, A.; Hamdalla, T.A.; Al-Ghamdi, S.; Alfadhli, S. Flexible, Stretchable and Electrically Conductive PDMS Decorated with Polypyrrole/Manganese-Iron Oxide Nanocomposite as a Multifunctional Material for High Performance EMI Shielding Applications. Synth. Met. 2022, 283, 116984. [Google Scholar] [CrossRef]

- Dai, Y.-L.; Zhang, X.-J.; Wen, B.-Y.; Du, Q.-Y. Facile Synthesis of Polypyrrole Nanoparticles with Tunable Conductivity for Efficient Electromagnetic Wave Absorption and Shielding Performance. CrystEngComm 2022, 24, 3287–3296. [Google Scholar] [CrossRef]

- Bora, P.J.; Anil, A.G.; Vinoy, K.J.; Ramamurthy, P.C. Outstanding Absolute Electromagnetic Interference Shielding Effectiveness of Cross-Linked PEDOT:PSS Film. Adv. Mater. Interfaces 2019, 6, 1901353. [Google Scholar] [CrossRef]

- Al-Asbahi, B.A.; Qaid, S.M.; El-Shamy, A.G. Flexible Conductive Nanocomposite PEDOT:PSS/Te Nanorod Films for Superior Electromagnetic Interference (EMI) Shielding: A New Exploration. J. Ind. Eng. Chem. 2021, 100, 233–247. [Google Scholar] [CrossRef]

- Das, P.; Ganguly, S.; Perelshtein, I.; Margel, S.; Gedanken, A. Acoustic Green Synthesis of Graphene-Gallium Nanoparticles and PEDOT:PSS Hybrid Coating for Textile To Mitigate Electromagnetic Radiation Pollution. ACS Appl. Nano Mater. 2022, 5, 1644–1655. [Google Scholar] [CrossRef]

- Iqbal, S.; Shah, J.; Kotnala, R.K.; Ahmad, S. Highly Efficient Low Cost EMI Shielding by Barium Ferrite Encapsulated Polythiophene Nanocomposite. J. Alloys Compd. 2019, 779, 487–496. [Google Scholar] [CrossRef]

- Iqbal, S.; Khatoon, H.; Kotnala, R.K.; Ahmad, S. Electromagnetic Interference Shielding Performance by Thermally Stable Magnesium Ferrite Encapsulated Polythiophene Composite. J. Mater. Sci. Mater. Electron. 2021, 32, 19191–19202. [Google Scholar] [CrossRef]

- Alamri, S.; Rajhi, A.A.; Anqi, A.E.; Tran, N. Enhanced Microwave Dissipation Features of BiFe0.8Co0.1Mn0.1O3/MWCNTs Composite Decorate of Polythiophene. J. Magn. Magn. Mater. 2022, 545, 168724. [Google Scholar] [CrossRef]

- Chung, D.D.L. Materials for Electromagnetic Interference Shielding. J. Mater. Eng. Perform. 2000, 9, 350–354. [Google Scholar] [CrossRef]

- Li, R.; Ding, L.; Gao, Q.; Zhang, H.; Zeng, D.; Zhao, B.; Fan, B.; Zhang, R. Tuning of anisotropic electrical conductivity and enhancement of EMI shielding of polymer composite foam via CO2-assisted delamination and orientation of MXene. Chem. Eng. J. 2021, 415, 128930. [Google Scholar] [CrossRef]

- Gupta, P.; Singh, B.; Agrawal, A.; Maji, P.K. Low Density and High Strength Nanofibrillated Cellulose Aerogel for Thermal Insulation Application. Mater. Des. 2018, 158, 224–236. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, J.; Gu, W.; Zhao, H.; Zheng, J.; Zhang, B.; Ji, G. Cellulose-Chitosan Framework/Polyailine Hybrid Aerogel toward Thermal Insulation and Microwave Absorbing Application. Chem. Eng. J. 2020, 395, 125190. [Google Scholar] [CrossRef]

- Mi, H.Y.; Jing, X.; Politowicz, A.L.; Chen, E.; Huang, H.X.; Turng, L.S. Highly Compressible Ultra-Light Anisotropic Cellulose/Graphene Aerogel Fabricated by Bidirectional Freeze Drying for Selective Oil Absorption. Carbon 2018, 132, 199–209. [Google Scholar] [CrossRef]

- Yao, Y.; Jin, S.; Zou, H.; Li, L.; Ma, X.; Lv, G.; Gao, F.; Lv, X.; Shu, Q. Polymer-Based Lightweight Materials for Electromagnetic Interference Shielding: A Review. J. Mater. Sci. 2021, 56, 6549–6580. [Google Scholar] [CrossRef]

- Saini, P.; Choudhary, V.; Singh, B.P.; Mathur, R.B.; Dhawan, S.K. Enhanced Microwave Absorption Behavior of Polyaniline-CNT/Polystyrene Blend in 12.4–18.0 GHz Range. Synth. Met. 2011, 161, 1522–1526. [Google Scholar] [CrossRef]

- Shahzad, F.; Alhabeb, M.; Hatter, C.B.; Anasori, B.; Hong, S.M.; Koo, C.M.; Gogotsi, Y. Electromagnetic Interference Shielding with 2D Transition Metal Carbides (MXenes). Science 2016, 353, 1137–1140. [Google Scholar] [CrossRef] [Green Version]

- Weng, L.; Lei, X.; Liu, J.; Hu, H.; Wang, J.; Zhang, Z. Three-dimensional network FeNi/C composites with excellent microwave-absorbing properties. J. Alloys Compd. 2022, 906, 164301. [Google Scholar] [CrossRef]

- Mohammed, J.; Tchouank Tekou Carol, T.; Hafeez, H.Y.; Basandrai, D.; Bhadu, G.R.; Godara, S.K.; Narang, S.B.; Srivastava, A.K. Electromagnetic Interference (EMI)Shielding, Microwave Absorption, and Optical Sensing Properties of BaM/CCTO Composites in Ku-Band. Results Phys. 2019, 13, 102307. [Google Scholar] [CrossRef]

- Dhakate, S.R.; Subhedar, K.M.; Singh, B.P. Polymer Nanocomposite Foam Filled with Carbon Nanomaterials as an Efficient Electromagnetic Interference Shielding Material. RSC Adv. 2015, 5, 43036–43057. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, R.; Wang, D.; Li, K.; Sun, Q.; Xiao, Y.; Teng, H.; Huang, X.; Sun, T.; Liu, Z.; et al. Lightweight, Low-Cost Co2SiO4@diatomite Core-Shell Composite Material for High-Efficiency Microwave Absorption. Molecules 2022, 27, 1055. [Google Scholar] [CrossRef] [PubMed]

- Ling, J.; Zhai, W.; Feng, W.; Shen, B.; Zhang, J.; Zheng, W.G. Facile Preparation of Lightweight Microcellular Polyetherimide/Graphene Composite Foams for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2013, 5, 2677–2684. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Cao, J.; Li, Y.; Li, Z.; Zhao, H.; Ji, G.; Du, Y. The Outside-In Approach to Construct Fe3O4 Nanocrystals/Mesoporous Carbon Hollow Spheres Core–Shell Hybrids toward Microwave Absorption. ACS Sustain. Chem. Eng. 2018, 6, 1427–1435. [Google Scholar] [CrossRef]

- Yan, J.; Huang, Y.; Liu, X.; Zhao, X.; Li, T.; Zhao, Y.; Liu, P. Polypyrrole-Based Composite Materials for Electromagnetic Wave Absorption. Polym. Rev. 2021, 61, 646–687. [Google Scholar] [CrossRef]

- Shukla, V. Review of Electromagnetic Interference Shielding Materials Fabricated by Iron Ingredients. Nanoscale Adv. 2019, 1, 1640–1671. [Google Scholar] [CrossRef]

- Hamidinejad, M.; Zhao, B.; Zandieh, A.; Moghimian, N.; Filleter, T.; Park, C.B. Enhanced Electrical and Electromagnetic Interference Shielding Properties of Polymer-Graphene Nanoplatelet Composites Fabricated via Supercritical-Fluid Treatment and Physical Foaming. ACS Appl. Mater. Interfaces 2018, 10, 30752–30761. [Google Scholar] [CrossRef]

- Peng, M.; Qin, F. Clarification of basic concepts for electromagnetic interference shielding effectiveness. J. Appl. Phys. 2021, 130, 225108. [Google Scholar] [CrossRef]

- Jia, L.-C.; Yan, D.-X.; Cui, C.-H.; Jiang, X.; Ji, X.; Li, Z.-M. Electrically Conductive and Electromagnetic Interference Shielding of Polyethylene Composites with Devisable Carbon Nanotube Networks. J. Mater. Chem. C 2015, 3, 9369–9378. [Google Scholar] [CrossRef]

- Jin, F.-L.; Zhao, M.; Park, M.; Park, S.-J. Recent Trends of Foaming in Polymer Processing: A Review. Polymers 2019, 11, 953. [Google Scholar] [CrossRef] [Green Version]

- Sauceau, M.; Fages, J.; Common, A.; Nikitine, C.; Rodier, E. New Challenges in Polymer Foaming: A Review of Extrusion Processes Assisted by Supercritical Carbon Dioxide. Prog. Polym. Sci. 2011, 36, 749–766. [Google Scholar] [CrossRef] [Green Version]

- Lavoine, N.; Bergström, L. Nanocellulose-Based Foams and Aerogels: Processing, Properties, and Applications. J. Mater. Chem. A 2017, 5, 16105–16117. [Google Scholar] [CrossRef] [Green Version]

- Budtova, T. Cellulose II Aerogels: A Review. Cellulose 2019, 26, 81–121. [Google Scholar] [CrossRef]

- Yang, J.; Liao, X.; Li, J.; He, G.; Zhang, Y.; Tang, W.; Wang, G.; Li, G. Light-Weight and Flexible Silicone Rubber/MWCNTs/Fe3O4 Nanocomposite Foams for Efficient Electromagnetic Interference Shielding and Microwave Absorption. Compos. Sci. Technol. 2019, 181, 107670. [Google Scholar] [CrossRef]

- Li, Y.; Li, C.; Zhao, S.; Cui, J.; Zhang, G.; Gao, A.; Yan, Y. Facile Fabrication of Highly Conductive and Robust Three-Dimensional Graphene/Silver Nanowires Bicontinuous Skeletons for Electromagnetic Interference Shielding Silicone Rubber Nanocomposites. Compos. Part A Appl. Sci. Manuf. 2019, 119, 101–110. [Google Scholar] [CrossRef]

- Zhao, S.; Yan, Y.; Gao, A.; Zhao, S.; Cui, J.; Zhang, G. Flexible Polydimethylsilane Nanocomposites Enhanced with a Three-Dimensional Graphene/Carbon Nanotube Bicontinuous Framework for High-Performance Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2018, 10, 26723–26732. [Google Scholar] [CrossRef]

- Chen, J.; Liao, X.; Xiao, W.; Yang, J.; Jiang, Q.; Li, G. Facile and Green Method to Structure Ultralow-Threshold and Lightweight Polystyrene/MWCNT Composites with Segregated Conductive Networks for Efficient Electromagnetic Interference Shielding. ACS Sustain. Chem. Eng. 2019, 7, 9904–9915. [Google Scholar] [CrossRef]

- Ju, J.; Kuang, T.; Ke, X.; Zeng, M.; Chen, Z.; Zhang, S.; Peng, X. Lightweight Multifunctional Polypropylene/Carbon Nanotubes/Carbon Black Nanocomposite Foams with Segregated Structure, Ultralow Percolation Threshold and Enhanced Electromagnetic Interference Shielding Performance. Compos. Sci. Technol. 2020, 193, 108116. [Google Scholar] [CrossRef]

- Li, Y.; Shen, B.; Yi, D.; Zhang, L.; Zhai, W.; Wei, X.; Zheng, W. The Influence of Gradient and Sandwich Configurations on the Electromagnetic Interference Shielding Performance of Multilayered Thermoplastic Polyurethane/Graphene Composite Foams. Compos. Sci. Technol. 2017, 138, 209–216. [Google Scholar] [CrossRef]

- Jiang, Q.; Liao, X.; Li, J.; Chen, J.; Wang, G.; Yi, J.; Yang, Q.; Li, G. Flexible Thermoplastic Polyurethane/Reduced Graphene Oxide Composite Foams for Electromagnetic Interference Shielding with High Absorption Characteristic. Compos. Part A Appl. Sci. Manuf. 2019, 123, 310–319. [Google Scholar] [CrossRef]

- Shen, B.; Li, Y.; Zhai, W.; Zheng, W. Compressible Graphene-Coated Polymer Foams with Ultralow Density for Adjustable Electromagnetic Interference (EMI) Shielding. ACS Appl. Mater. Interfaces 2016, 8, 8050–8057. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Wang, L.; Mark, L.H.; Shaayegan, V.; Wang, G.; Li, H.; Zhao, G.; Park, C.B. Ultralow-Threshold and Lightweight Biodegradable Porous PLA/MWCNT with Segregated Conductive Networks for High-Performance Thermal Insulation and Electromagnetic Interference Shielding Applications. ACS Appl. Mater. Interfaces 2018, 10, 1195–1203. [Google Scholar] [CrossRef] [PubMed]

- Cui, C.-H.; Yan, D.-X.; Pang, H.; Jia, L.-C.; Xu, X.; Yang, S.; Xu, J.-Z.; Li, Z.-M. A High Heat-Resistance Bioplastic Foam with Efficient Electromagnetic Interference Shielding. Chem. Eng. J. 2017, 323, 29–36. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Zhou, Z.H.; Zhou, C.G.; Sun, W.J.; Gao, J.F.; Dai, K.; Yan, D.X.; Li, Z.M. Lightweight and Robust Carbon Nanotube/Polyimide Foam for Efficient and Heat-Resistant Electromagnetic Interference Shielding and Microwave Absorption. ACS Appl. Mater. Interfaces 2020, 12, 8704–8712. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Ding, Y.; Yu, N.; Gao, Q.; Fan, X.; Wei, X.; Zhang, G.; Ma, Z.; He, X. Lightweight and Stiff Carbon Foams Derived from Rigid Thermosetting Polyimide Foam with Superior Electromagnetic Interference Shielding Performance. Carbon 2020, 158, 45–54. [Google Scholar] [CrossRef]

- Lu, D.; Mo, Z.; Liang, B.; Yang, L.; He, Z.; Zhu, H.; Tang, Z.; Gui, X. Flexible, lightweight carbon nanotube sponges and composites for high-performance electromagnetic interference shielding. Carbon 2018, 133, 457–463. [Google Scholar] [CrossRef]

- Yousefi, N.; Sun, X.; Lin, X.; Shen, X.; Jia, J.; Zhang, B.; Tang, B.; Chan, M.; Kim, J.-K. Highly Aligned Graphene/Polymer Nanocomposites with Excellent Dielectric Properties for High-Performance Electromagnetic Interference Shielding. Adv. Mater. 2014, 26, 5480–5487. [Google Scholar] [CrossRef]

- Shen, B.; Zhai, W.; Tao, M.; Ling, J.; Zheng, W. Lightweight, Multifunctional Polyetherimide/Graphene@Fe3O4 Composite Foams for Shielding of Electromagnetic Pollution. ACS Appl. Mater. Interfaces 2013, 5, 11383–11391. [Google Scholar] [CrossRef]

- Xi, J.; Li, Y.; Zhou, E.; Liu, Y.; Gao, W.; Guo, Y.; Ying, J.; Chen, Z.; Chen, G.; Gao, C. Graphene aerogel films with expansion enhancement effect of high-performance electromagnetic interference shielding. Carbon 2018, 135, 44–51. [Google Scholar] [CrossRef]

- Bi, S.; Zhang, L.; Mu, C.; Liu, M.; Hu, X. Applied Surface Science Electromagnetic Interference Shielding Properties and Mechanisms of Chemically Reduced Graphene Aerogels. Appl. Surf. Sci. 2017, 412, 529–536. [Google Scholar] [CrossRef]

- Wang, L.; Liu, M.; Wang, G.; Dai, B.; Yu, F.; Zhang, J. An ultralight nitrogen-doped carbon aerogel anchored by Ni-NiO nanoparticles for enhanced microwave adsorption performance. J. Alloys Compd. 2018, 776, 43–51. [Google Scholar] [CrossRef]

- Wang, H.; Meng, F.; Li, J.; Li, T.; Chen, Z.; Luo, H.; Zhou, Z. Carbonized Design of Hierarchical Porous Carbon/Fe3O4@Fe Derived from Loofah Sponge to Achieve Tunable High-Performance Microwave Absorption. ACS Sustain. Chem. Eng. 2018, 6, 11801–11810. [Google Scholar] [CrossRef]

- Crespo, M.; González, M.; Elías, A.L.; Rajukumar, L.P.; Baselga, J.; Terrones, M.; Pozuelo, J. Ultra-Light Carbon Nanotube Sponge as an Efficient Electromagnetic Shielding Material in the GHz Range. Phys. Status Solidi Rapid Res. Lett. 2014, 8, 698–704. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhang, H.-B.; Yang, Y.; Wang, M.; Cao, A.; Yu, Z.-Z. High-Performance Epoxy Nanocomposites Reinforced with Three-Dimensional Carbon Nanotube Sponge for Electromagnetic Interference Shielding. Adv. Funct. Mater. 2016, 26, 447–455. [Google Scholar] [CrossRef]

- Zeng, Z.; Wang, C.; Zhang, Y.; Wang, P.; Shahabadi, S.I.S.; Pei, Y.; Chen, M.; Lu, X. Ultralight and Highly Elastic Graphene/Lignin-Derived Carbon Nanocomposite Aerogels with Ultrahigh Electromagnetic Interference Shielding Performance. ACS Appl. Mater. Interfaces 2018, 10, 8205–8213. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Ding, Y.; Yuan, Y.; He, X.; Wu, S.; Hu, S.; Zou, M.; Zhao, W.; Yang, L.; Cao, A.; et al. Graphene aerogel composites derived from recycled cigarette filters for electromagnetic wave absorption. J. Mater. Chem. C 2015, 3, 11893–11901. [Google Scholar] [CrossRef]

- Song, W.; Guan, X.-T.; Fan, L.-Z.; Cao, W.-Q.; Wang, C.-Y.; Cao, M.-S. Tuning Three-Dimensional Textures with Graphene Aerogels for Ultra-Light Flexible Graphene/Texture Composites of Effective Electromagnetic Shielding. Carbon 2015, 93, 151–160. [Google Scholar] [CrossRef]

- Ren, F.; Guo, Z.; Shi, Y.; Jia, L.; Qing, Y.; Ren, P.; Yan, D. Lightweight and Highly Efficient Electromagnetic Wave-Absorbing of 3D CNTs/GNS@CoFe2O4 Ternary Composite Aerogels. J. Alloys Compd. 2018, 768, 6–14. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, H.-B.; Wang, M.; Qian, X.; Dasari, A.; Yu, Z.-Z. Phenolic Resin-Enhanced Three-Dimensional Graphene Aerogels and Their Epoxy Nanocomposites with High Mechanical and Electromagnetic Interference Shielding Performances. Compos. Sci. Technol. 2017, 152, 254–262. [Google Scholar] [CrossRef]

- Li, X.; Yin, X.; Song, C.; Han, M.; Xu, H.; Duan, W.; Cheng, L.; Zhang, L. Self-Assembly Core–Shell Graphene-Bridged Hollow MXenes Spheres 3D Foam with Ultrahigh Specific EM Absorption Performance. Adv. Funct. Mater. 2018, 28, 1803938. [Google Scholar] [CrossRef]

- Bian, R.; He, G.; Zhi, W.; Xiang, S.; Wang, T.; Cai, D. Ultralight MXene-Based Aerogels with High Electromagnetic Interference Shielding Performance. J. Mater. Chem. C 2019, 7, 474–478. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.-B.; Sun, R.; Liu, Y.; Liu, Z.; Zhou, A.; Yu, Z.-Z. Hydrophobic, Flexible, and Lightweight MXene Foams for High-Performance Electromagnetic-Interference Shielding. Adv. Mater. 2017, 29, 1702367. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Xu, C.; Ma, C.; Ren, W.; Cheng, H.-M. Lightweight and Flexible Graphene Foam Composites for High-Performance Electromagnetic Interference Shielding. Adv. Mater. 2013, 25, 1296–1300. [Google Scholar] [CrossRef] [PubMed]

- Wan, C.; Li, J. Graphene Oxide/Cellulose Aerogels Nanocomposite: Preparation, Pyrolysis, and Application for Electromagnetic Interference Shielding. Carbohydr. Polym. 2016, 150, 172–179. [Google Scholar] [CrossRef]

- Ameli, A.; Jung, P.U.; Park, C.B. Electrical Properties and Electromagnetic Interference Shielding Effectiveness of Polypropylene/Carbon Fiber Composite Foams. Carbon 2013, 60, 379–391. [Google Scholar] [CrossRef]

- Yan, D.-X.; Ren, P.-G.; Pang, H.; Fu, Q.; Yang, M.-B.; Li, Z.-M. Efficient Electromagnetic Interference Shielding of Lightweight Graphene/Polystyrene Composite. J. Mater. Chem. 2012, 22, 18772–18774. [Google Scholar] [CrossRef]

- Ameli, A.; Nofar, M.; Wang, S.; Park, C.B. Lightweight Polypropylene/Stainless-Steel Fiber Composite Foams with Low Percolation for Efficient Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2014, 6, 11091–11100. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Zhan, M.; Wang, K. Ultralightweight Silver Nanowires Hybrid Polyimide Composite Foams for High-Performance Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2015, 7, 563–576. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Pei, X.; Shen, B.; Zhai, W.; Zhang, L.; Zheng, W. Polyimide/Graphene Composite Foam Sheets with Ultrahigh Thermostability for Electromagnetic Interference Shielding. RSC Adv. 2015, 5, 24342–24351. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, Z.; Liu, X.; Shen, X.; Zheng, Q.; Xue, Q.; Kim, J.-K. Ultralight Graphene Foam/Conductive Polymer Composites for Exceptional Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2017, 9, 9059–9069. [Google Scholar] [CrossRef]

- Hsiao, S.T.; Ma, C.C.M.; Liao, W.H.; Wang, Y.S.; Li, S.M.; Huang, Y.C.; Yang, R.B.; Liang, W.F. Lightweight and Flexible Reduced Graphene Oxide/Water-Borne Polyurethane Composites with High Electrical Conductivity and Excellent Electromagnetic Interference Shielding Performance. ACS Appl. Mater. Interfaces 2014, 6, 10667–10678. [Google Scholar] [CrossRef] [PubMed]

- Gavgani, J.N.; Adelnia, H.; Zaarei, D.; Moazzami Gudarzi, M. Lightweight Flexible Polyurethane/Reduced Ultralarge Graphene Oxide Composite Foams for Electromagnetic Interference Shielding. RSC Adv. 2016, 6, 27517–27527. [Google Scholar] [CrossRef]

- Fletcher, A.; Gupta, M.C.; Dudley, K.L.; Vedeler, E. Elastomer Foam Nanocomposites for Electromagnetic Dissipation and Shielding Applications. Compos. Sci. Technol. 2010, 70, 953–958. [Google Scholar] [CrossRef]

- Wu, F.; Xie, A.; Sun, M.; Wang, Y.; Wang, M. Reduced Graphene Oxide (RGO) Modified Spongelike Polypyrrole (PPy) Aerogel for Excellent Electromagnetic Absorption. J. Mater. Chem. A 2015, 3, 14358–14369. [Google Scholar] [CrossRef]

- Zhan, Y.; Wang, J.; Zhang, K.; Li, Y.; Meng, Y.; Yan, N.; Wei, W.; Peng, F.; Xia, H. Fabrication of a Flexible Electromagnetic Interference Shielding Fe3O4@reduced Graphene Oxide/Natural Rubber Composite with Segregated Network. Chem. Eng. J. 2018, 344, 184–193. [Google Scholar] [CrossRef]

- Zhao, W.; Shao, G.; Jiang, M.; Zhao, B.; Wang, H.; Chen, D.; Xu, H.; Li, X.; Zhang, R.; An, L. Ultralight Polymer-Derived Ceramic Aerogels with Wide Bandwidth and Effective Electromagnetic Absorption Properties. J. Eur. Ceram. Soc. 2017, 37, 3973–3980. [Google Scholar] [CrossRef]

- Li, C.; Yang, G.; Deng, H.; Wang, K.; Zhang, Q.; Chen, F.; Fu, Q. The Preparation and Properties of Polystyrene/Functionalized Graphene Nanocomposite Foams Using Supercritical Carbon Dioxide. Polym. Int. 2013, 62, 1077–1084. [Google Scholar] [CrossRef]

- Gedler, G.; Antunes, M.; Velasco, J.I.; Ozisik, R. Electromagnetic Shielding Effectiveness of Polycarbonate/Graphene Nanocomposite Foams Processed in 2-Steps with Supercritical Carbon Dioxide. Mater. Lett. 2015, 160, 41–44. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhang, G.; Zhang, H.; Fan, X.; Zhou, L.; Shang, Z.; Shi, X. Electrical Conductivity and Electromagnetic Interference Shielding of Epoxy Nanocomposite Foams Containing Functionalized Multi-Wall Carbon Nanotubes. Appl. Surf. Sci. 2018, 428, 7–16. [Google Scholar] [CrossRef]

- Tran, M.-P.; Thomassin, J.-M.; Alexandre, M.; Jérôme, C.; Huynen, I.; Detrembleur, C. Nanocomposite Foams of Polypropylene and Carbon Nanotubes: Preparation, Characterization, and Evaluation of Their Performance as EMI Absorbers. Macromol. Chem. Phys. 2015, 216, 1302–1312. [Google Scholar] [CrossRef]

- Verma, M.; Chauhan, S.S.; Dhawan, S.K.; Choudhary, V. Graphene Nanoplatelets/Carbon Nanotubes/Polyurethane Composites as Efficient Shield against Electromagnetic Polluting Radiations. Compos. Part B Eng. 2017, 120, 118–127. [Google Scholar] [CrossRef]

- Pai, A.R.; Paoloni, C.; Thomas, S. Nanocellulose-Based Sustainable Microwave Absorbers to Stifle Electromagnetic Pollution. In Nanocellulose Based Composites for Electronics; Elsevier: Amsterdam, The Netherlands, 2021; pp. 237–258. ISBN 9780128223505. [Google Scholar]

- Zeng, Z.; Wu, T.; Han, D.; Ren, Q.; Siqueira, G.; Nyström, G. Ultralight, Flexible, and Biomimetic Nanocellulose/Silver Nanowire Aerogels for Electromagnetic Interference Shielding. ACS Nano 2020, 14, 2927–2938. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Pötschke, P.; Pionteck, J.; Voit, B.; Qi, H. Multifunctional Cellulose/RGO/Fe3O4 Composite Aerogels for Electromagnetic Interference Shielding. ACS Appl. Mater. Interfaces 2020, 12, 22088–22098. [Google Scholar] [CrossRef]

- Pai, A.R.; Binumol, T.; Gopakumar, D.A.; Pasquini, D.; Seantier, B.; Kalarikkal, N.; Thomas, S. Ultra-Fast Heat Dissipating Aerogels Derived from Polyaniline Anchored Cellulose Nanofibers as Sustainable Microwave Absorbers. Carbohydr. Polym. 2020, 246, 116663. [Google Scholar] [CrossRef] [PubMed]

- Pai, A.R.; Nair, G.G.; Thomas, P.C.; Thomas, S. High-Performance Conducting Polymer Nanocomposites for EMI Shielding Applications. In Conducting Polymers for Advanced Energy Applications; CRC Press: Boca Raton, FL, USA, 2021; pp. 383–398. [Google Scholar]

- Pai, A.R.; Thomas, S.; Kalarikkal, N. Electromagnetic Interference Shielding Composition, Article and Methods Thereof 2021. Available online: https://patentimages.storage.googleapis.com/4b/11/5b/7c0d91c5f85814/WO2021094836A1.pdf (accessed on 27 March 2022).

- Xie, A.; Wu, F.; Xu, Z.; Wang, M. In Situ Preparation of Ultralight Three-Dimensional Polypyrrole/Nano SiO2 Composite Aerogels with Enhanced Electromagnetic Absorption. Compos. Sci. Technol. 2015, 117, 32–38. [Google Scholar] [CrossRef]

- Sui, M.; Lü, X.; Xie, A.; Xu, W.; Rong, X.; Wu, G. The Synthesis of Three-Dimensional (3D) Polydopamine-Functioned Carbonyl Iron Powder@polypyrrole (CIP@PPy) Aerogel Composites for Excellent Microwave Absorption. Synth. Met. 2015, 210, 156–164. [Google Scholar] [CrossRef]

- Naguib, M.; Kurtoglu, M.; Presser, V.; Lu, J.; Niu, J.; Heon, M.; Hultman, L.; Gogotsi, Y.; Barsoum, M.W. Two-Dimensional Nanocrystals: Two-Dimensional Nanocrystals Produced by Exfoliation of Ti3AlC2 (Adv. Mater. 37/2011). Adv. Mater. 2011, 23, 4207. [Google Scholar] [CrossRef]

- Xu, H.; Yin, X.; Li, X.; Li, M.; Liang, S.; Zhang, L.; Cheng, L. Lightweight Ti2CTx MXene/Poly(Vinyl Alcohol) Composite Foams for Electromagnetic Wave Shielding with Absorption-Dominated Feature. ACS Appl. Mater. Interfaces 2019, 11, 10198–10207. [Google Scholar] [CrossRef]

- Wu, X.; Han, B.; Zhang, H.-B.; Xie, X.; Tu, T.; Zhang, Y.; Dai, Y.; Yang, R.; Yu, Z.-Z. Compressible, Durable and Conductive Polydimethylsiloxane-Coated MXene Foams for High-Performance Electromagnetic Interference Shielding. Chem. Eng. J. 2020, 381, 122622. [Google Scholar] [CrossRef]

| EMI Shielding Effectiveness (dB) | Shielding Efficiency (%) | Reflection Loss (RL) (dB) | Microwave Absorption (%) |

|---|---|---|---|

| 0 | 0 | 0 | 0 |

| −10 | 90 | −10 | 90 |

| −20 | 99 | −20 | 99 |

| −30 | 99.9 | −30 | 99.9 |

| −40 | 99.99 | −40 | 99.99 |

| −50 | 99.999 | −50 | 99.999 |

| −60 | 99.9999 | −60 | 99.9999 |

| −70 | 99.99999 | −70 | 99.99999 |

| −80 | 99.999999 | −80 | 99.999999 |

| −90 | 99.9999999 | −90 | 99.9999999 |

| −92 | 99.99999994 | −92 | 99.99999994 |

| Sr No. | Aerogel/Foam Composition | Measurement Technique | Thickness (mm) | Density (g/cm3) | Frequency (GHz) | Electrical Conductivity (S/m) | SETotal (dB) | Specific EMI SE (dB.g−1.cm3) | Ref |

|---|---|---|---|---|---|---|---|---|---|

| 1 | CNT sponge | waveguide | 1.8 | 10.0 | 8–12 | 150–300 | 54.8 | 5480 | [118] |

| 2 | CNT/PDMS | waveguide | 2.0 | 8–12 | 150–300 | 46.3 | - | [118] | |

| 3 | rGO/epoxy composite | - | >0.1 | ~0.01 | 38 | 35.3 | [119] | ||

| 4 | PEI/G@Fe3O4 foam | - | 0.28−0.4 | 8−12 | ~41.5 | - | [120] | ||

| 5 | GAF | coaxial | 1.4 | 0.06 | 0.1–3 | 2.5 × 105 | ~135 | - | [121] |

| 6 | GAF | coaxial | 0.12 | 0.41 | 2–18 | 6600 | 70–105 | - | [121] |

| 7 | GAs | waveguide | 4 | 0.43 | 8–12 | 4.32 | 30 | - | [122] |

| 8 | Ni-NiO/NCA | - | 1.5 | 0.42 | 15.2 | −41.9 | - | [123] | |

| 9 | carbon/Fe3O4@Fe | - | 2 | 13–18 | −49.6 | - | [124] | ||

| 10 | CNT sponge | coaxial | 2–3.5 | 0.02 | 1–18 | 278 | 20 | 1100 | [125] |

| 11 | CNT/Epoxy composite | - | 5–10 | 5 | 8–12 | 516 | 33 | - | [126] |

| 12 | RGO/LDC Aerogel | waveguide | 2 | 8.0 | 8.2–12.4 | - | 49.2 | 53,250 | [127] |

| 13 | RGO/LDC Aerogel | waveguide | 2 | 2.0 | 8.2–12.4 | - | 21.3 | 10,650 | [127] |

| 14 | Graphene Aerogel | - | 3 | 7.6 | 14.6 | - | 30.53 | - | [128] |

| 15 | CF@G@PPy aerogels | - | 3 | 8.8 | 9–12.6 | - | 40.59 | - | [128] |

| 16 | GA-CT | - | 2 | 0.07 | - | - | 27 | 371–385 | [129] |

| 17 | GA-CT | - | 3 | 0.07 | - | - | 37 | 514–528 | [129] |

| 18 | CNTs/GNS@CoFe2O4 | waveguide | 3.0 | 0.095 | 8.2–12.4 | - | 29.1 | - | [130] |

| 19 | epoxy/TGA | - | 4 | 8–12 | - | 27 | - | [7] | |

| 20 | epoxy/TAGA (axial) | - | 4 | 8–12 | 980 | 25 | - | [7] | |

| 21 | epoxy/TAGA (radial | - | 4 | 8–12 | 96 | 32 | - | [7] | |

| 22 | Epoxy/pGAs | Coaxial | 4 | 4.0 | 8–12 | 73 | 35 | [131] | |

| 23 | RGO/Ti3C2TX foam | waveguide | 3.22 | 0.0033 | 8.2–12.4 | - | 14, 299.2 | [132] | |

| 24 | MXene aerogels | Waveguide | 4 | 0.004 | 8.2–12.4 | 22 | 75 | 990 | [133] |

| 25 | Ti3C2Tx MXene/cellulose aerogel | Coaxial | 2 | 0.31 | 11.2 | - | −43.4 | - | [121] |

| 26 | MXene Foams | - | 3.2 | 58 00 | ≈70 | - | [134] | ||

| 27 | Graphene/PDMS foam | coaxial | ~1 | 0.06 | 1.5–30 | 200 | ~30 | 500 | [135] |

| 28 | GN/CNA | coaxial | 2 | 52.1 | 8.2–12.4 | 19.1 | 58.4 | [136] | |

| 29 | Polypropylene/carbon fiber composite foams | Coaxial | - | - | 8.0–12.4 | - | 24.9 | - | [137] |

| 30 | Porous graphene/polystyrene foam composite | - | 2.5 | 0.45 | 8.2–12.4 | 1.25 | 29 | 64.4 | [138] |

| 31 | Polypropylene/stainless-steel fiber composite foams | Coaxial | - | - | 8.2–12.4 | - | 47.6 | 75 | [139] |

| 32 | Silver Nanowire Hybrid Polyimide Composite Foams | Waveguide | 5.0 | 0.014–0.022 | 30 MHz–1.5 GHz | - | 17 | 772 | [140] |

| 33 | Polyimide/reduced graphene oxide | Waveguide | 0.8 | 0.28 | 8.2–12.4 | 0.8 | 17-21 | 75 | [141] |

| 34 | Graphene foam/poly (3,4-ethylenedioxythiophene): poly(styrenesulfonate) Composite | Waveguide | - | 0.0182 | 8.2–12.4 | 43.2 | 91.9 | 3124 | [142] |

| 35 | Polyetherimide/graphene@Fe3O4 composite foams | Waveguide | 2.5 | 0.28–0.4 | 8.2–12.4 | - | 14.3–18.2 | 41.5 | [120] |

| 36 | Reduced graphene oxide/waterborne polyurethane composites | coaxial | 1 | - | 8.2–12.4 | 16.8 | 34 | - | [143] |

| 37 | PU/(rUL-GO) foam | Waveguide | - | 0.053–0.092 | 8.2–12.4 | 4.04 | 20 | 253 | [144] |

| 38 | Fluorocarbon/MWCNT foam | Waveguide | 3.8 | 1.2 | 8.2–12.4 | - | 50 | - | [145] |

| 39 | Polypyrrole and reduced graphene oxide | Coaxial | 1.5–5 | - | 2–18 | - | −54.4 | - | [146] |

| 40 | Natural rubber/magnetic iron oxide (Fe3O4) and reduced graphene oxide | - | 1.6 | - | 8.2–12.4 | 6.1 | 42.4 | 26.4 | [147] |

| 41 | Multilayered thermoplastic polyurethane/graphene composite foams | Waveguide | 6.5 | 0.42 | 12–18 | 3 | 24 | - | [111] |

| 42 | Polymer-derived ceramic aerogels (PDCA) | Coaxial | 2-4.5 | 0.19 | 2–18 | - | −43.37 | - | [148] |

| 43 | Polystyrene/functionalized graphene nanocomposite foams | - | - | - | 8.2–12.4 | 0.1 | 18 | - | [149] |

| 44 | polycarbonate/graphene nanocomposite foams | Waveguide | - | - | 8.2–12.4 | - | - | 39 | [150] |

| 45 | Epoxy/functionalized multi-walled carbon nanotube microcellular foam | Waveguide | 2.5 | - | 12–18 | 1.04 × 10−5 | 20.5 | - | [151] |

| 46 | PP/CNT Foam | Waveguide | 8 | 0.87 | 25–40 | 3.93 | 30–35 | - | [152] |

| 47 | PVDF/graphene nanoplatelet composites | Waveguide | 2.5 | - | 26.5–40 | 0.52 | 27 | - | [15] |

| 48 | Graphene nanoplatelets/carbon nanotubes/polyurethane composites | Waveguide | 3 | - | 12.4–18 | ~10−2 | −47 | - | [153] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pai, A.R.; Puthiyaveettil Azeez, N.; Thankan, B.; Gopakumar, N.; Jaroszewski, M.; Paoloni, C.; Kalarikkal, N.; Thomas, S. Recent Progress in Electromagnetic Interference Shielding Performance of Porous Polymer Nanocomposites—A Review. Energies 2022, 15, 3901. https://doi.org/10.3390/en15113901

Pai AR, Puthiyaveettil Azeez N, Thankan B, Gopakumar N, Jaroszewski M, Paoloni C, Kalarikkal N, Thomas S. Recent Progress in Electromagnetic Interference Shielding Performance of Porous Polymer Nanocomposites—A Review. Energies. 2022; 15(11):3901. https://doi.org/10.3390/en15113901

Chicago/Turabian StylePai, Avinash R., Nizam Puthiyaveettil Azeez, Binumol Thankan, Nandakumar Gopakumar, Maciej Jaroszewski, Claudio Paoloni, Nandakumar Kalarikkal, and Sabu Thomas. 2022. "Recent Progress in Electromagnetic Interference Shielding Performance of Porous Polymer Nanocomposites—A Review" Energies 15, no. 11: 3901. https://doi.org/10.3390/en15113901