Dynamic Characteristics Analysis of a 660 MW Ultra-Supercritical Circulating Fluidized Bed Boiler

Abstract

:1. Introduction

2. System Architecture

2.1. Water-Steam System

2.1.1. Superheated Steam System

2.1.2. Reheated Steam System

2.2. Air-Flue Gas System

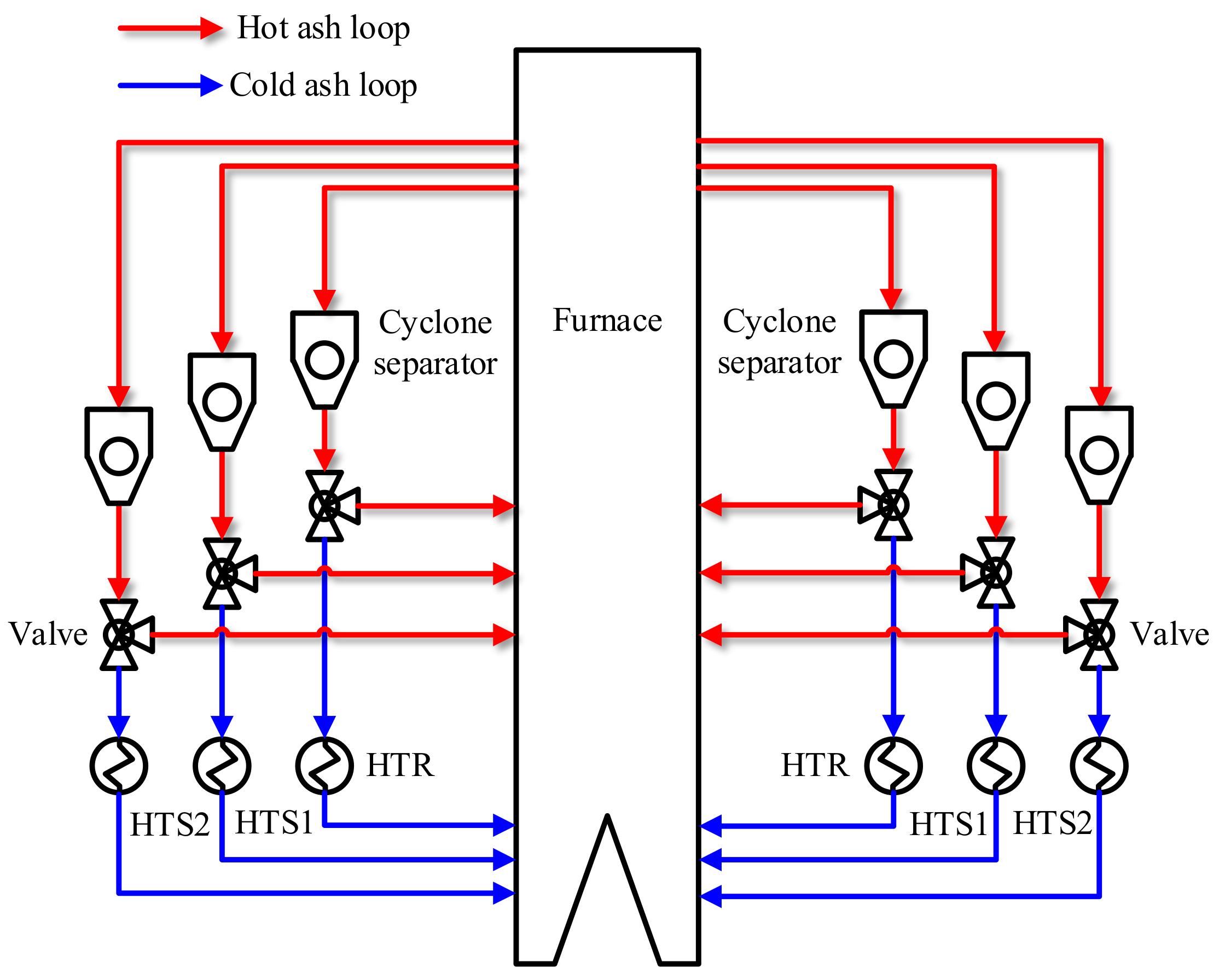

2.3. Ash Circulation System

3. Mathematical Model

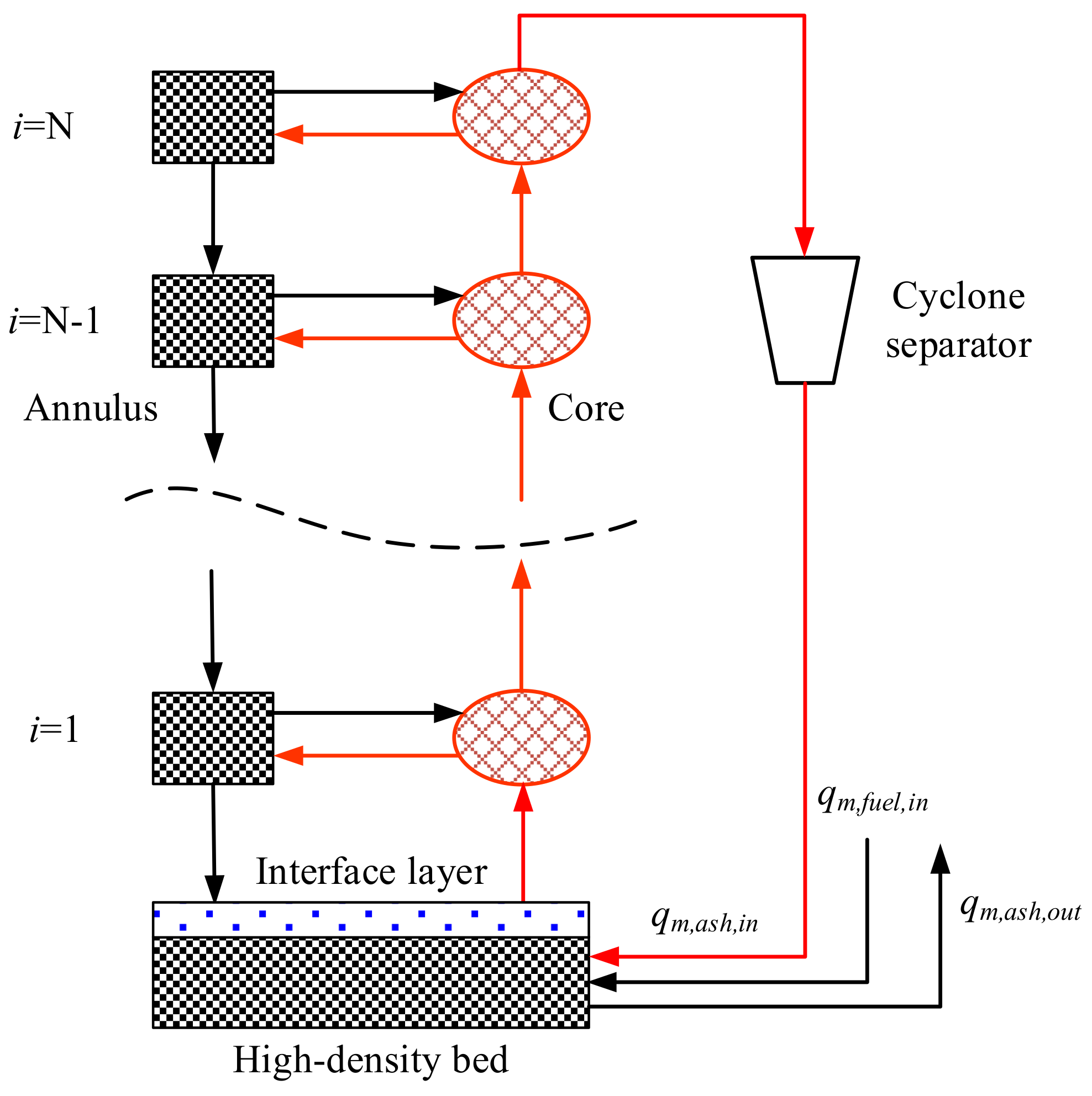

3.1. Gas-Solid Two-Phase Flow and Heat Transfer Model

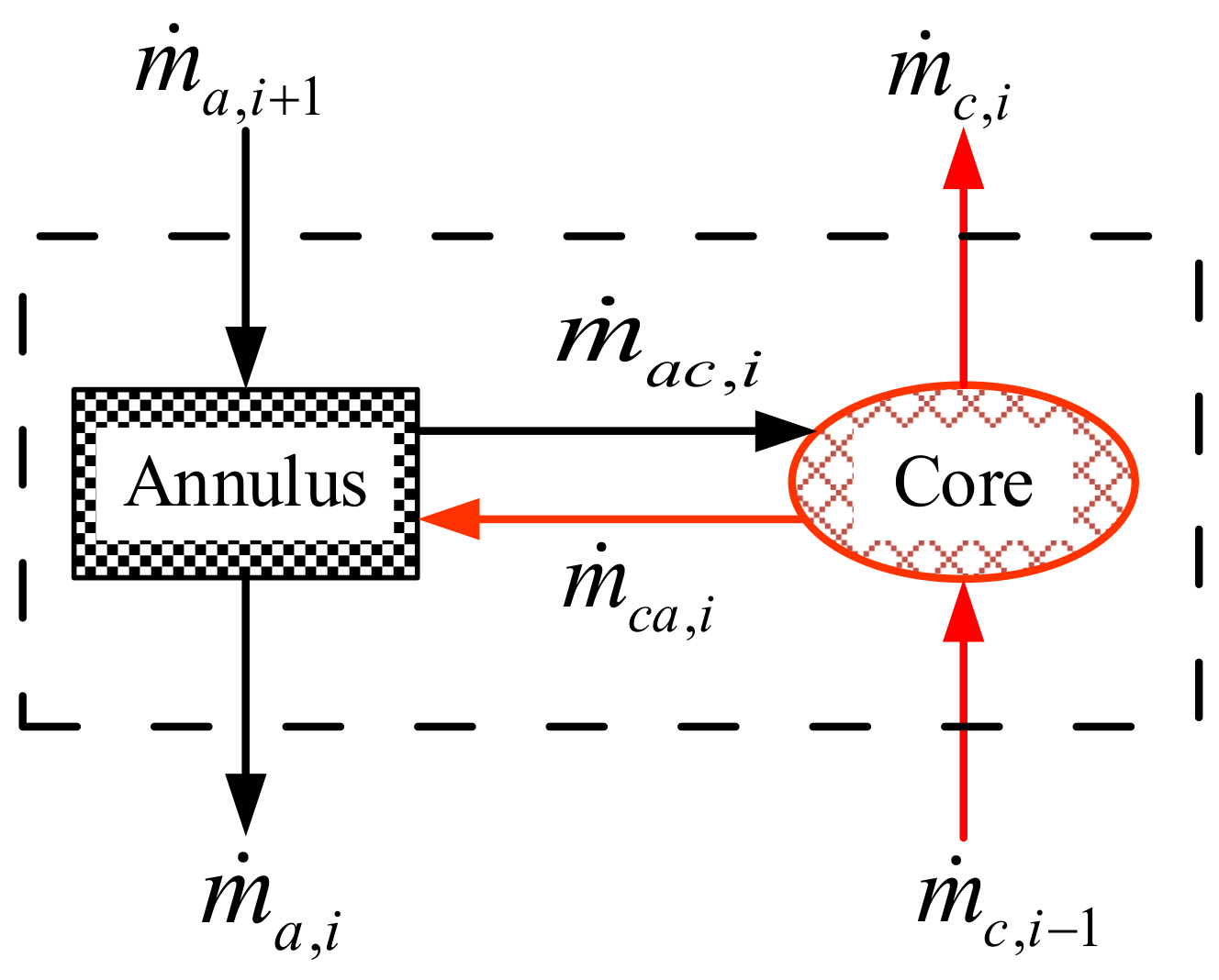

3.1.1. Bed Material Distribution

3.1.2. Heat Transfer

3.2. Water-Steam Two-Phase Flow Model

3.2.1. Homogeneous Model

3.2.2. Two-Phase Flow Model

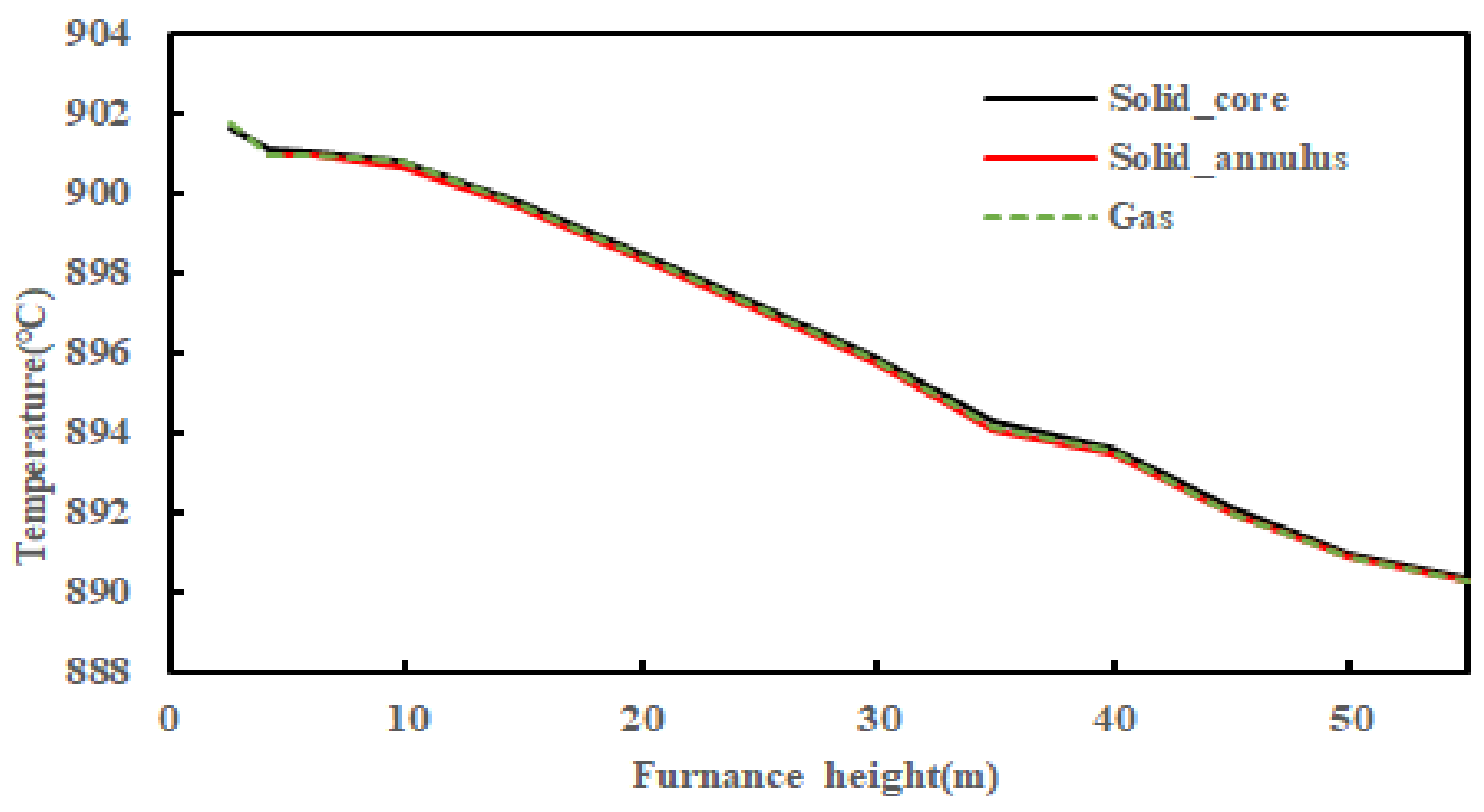

4. Model Calibration and Validation

5. Results and Discussion

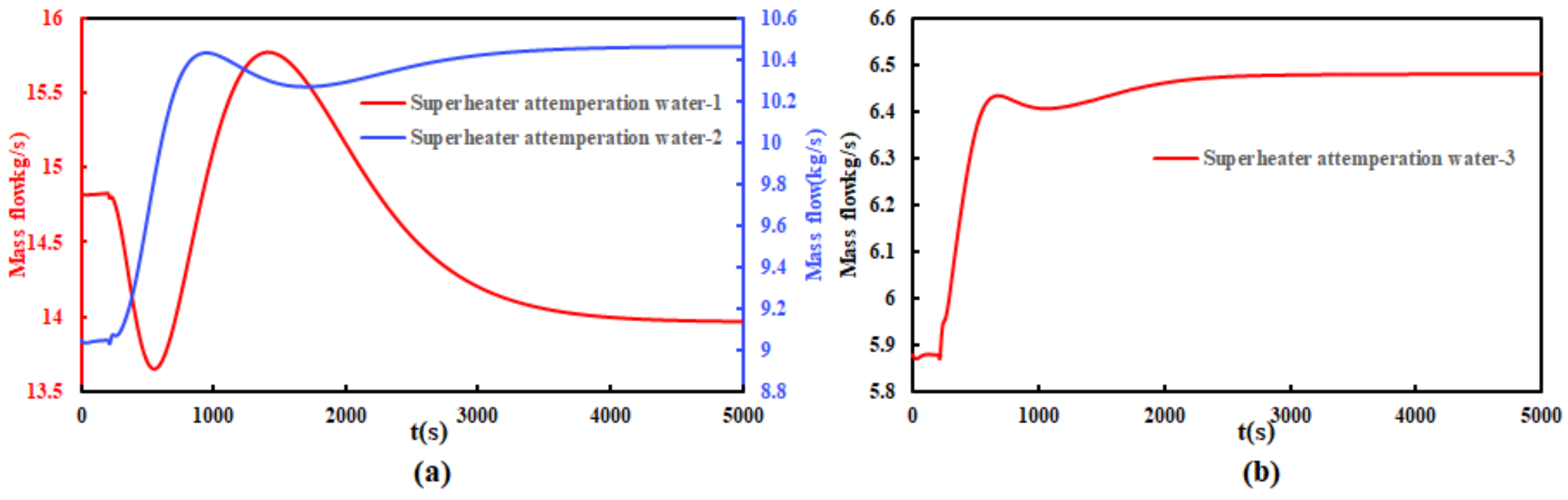

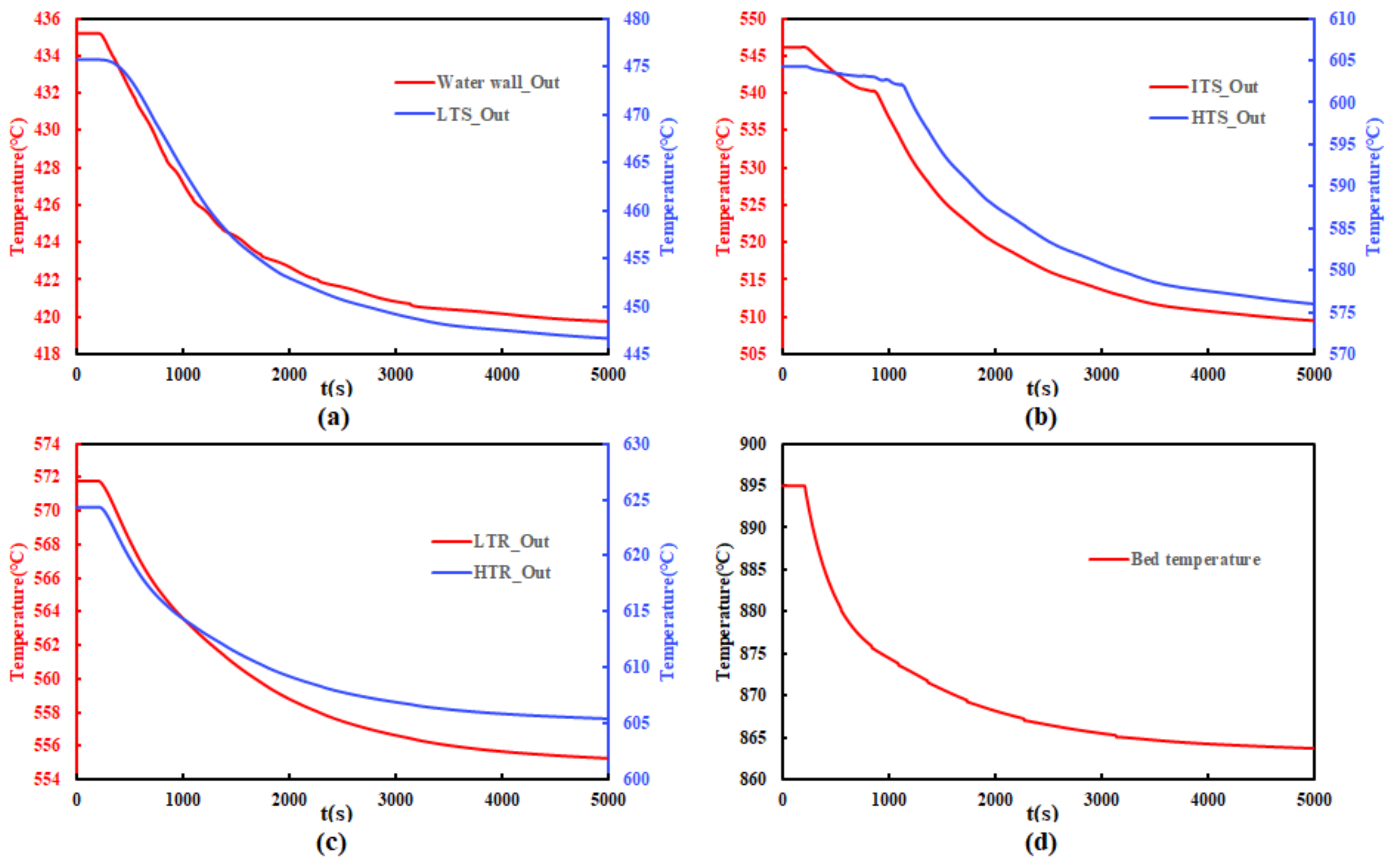

5.1. Feedwater Mass Flow Decreased by 5%

5.2. Total Air Mass Flow Decreased by 5%

5.3. Coal Mass Flow Decreased by 5%

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BCP | boiler circulation pump |

| BMCR | boiler maximum continuous rating |

| CFB | circulating fluidized bed |

| ECO | economizer |

| HTR | high-temperature reheater |

| HTS | high-temperature superheater |

| ITS | intermediate-temperature superheater |

| LTR | low-temperature reheater |

| LTS | low-temperature superheater |

| THA | turbine heat acceptance |

| Parameters | |

| Ar | Archimedes number |

| D | diameter (m) |

| E | rate of entrainment |

| F | Friction (N/m3) |

| f | friction factor |

| h | enthalpy (J/kg) |

| m | mass (kg) |

| m | mass flow (kg/s) |

| P | pressure (Pa) |

| q | heat transfer (W/m3) |

| Re | Reynolds number |

| T | Temperature (°C) |

| V | volume (m3) |

| u | velocity (m/s) |

| z | spatial coordinate (m) |

| α | volume fraction |

| ρ | density (kg/m3) |

| Γ | mass transfer rate (kg/(m3*s)) |

| ε | fraction |

| μ | dynamic viscosity (N*s/m2) |

| Subscripts | |

| a | annulus, annular flow |

| avg | average |

| b | bubble, bubbly flow |

| c | core |

| d | dense bed, droplet flow |

| g | gas |

| h | height |

| i | node i, interface |

| k | index, liquid (k = l), gas (k = g) |

| l | liquid |

| mf | minimum fluidization |

| p | particle |

| s | solid, stratified flow |

| w | wall |

Appendix A

References

- Li, Q. The view of technological innovation in coal industry under the vision of carbon neutralization. Int. J. Coal Sci. Technol. 2021, 8, 1197–1207. [Google Scholar] [CrossRef]

- Cheng, L.; Ji, J.; Wei, Y.; Wang, Q.; Cen, K. A note on large-size supercritical CFB technology development. Powder Technol. 2019, 363, 398–407. [Google Scholar] [CrossRef]

- Huilin, L.; Rushan, B.; Wenti, L.; Binxi, L.; Lidan, Y. Computations of a Circulating Fluidized-Bed Boiler with Wide Particle Size Distributions. Ind. Eng. Chem. Res. 2000, 39, 3212–3220. [Google Scholar] [CrossRef]

- Golriz, M.R. Temperature distribution at the membrane wall of a 165-MWth CFB boiler. Exp. Heat Transf. 2001, 14, 299–313. [Google Scholar] [CrossRef]

- Hua, Y.; Flamant, G.J.; Gauthier, D. Modelling of axial and radial solid segregation in a CFB boiler. Chem. Eng. Process. Process Intensif. 2004, 43, 971–978. [Google Scholar] [CrossRef]

- Tayebi, T.; Dogonchi, A.S.; Chamkha, A.J.; Ben Hamida, M.B.; El-Sapa, S.; Galal, A.M. Micropolar nanofluid thermal free convection and entropy generation through an inclined I-shaped enclosure with two hot cylinders. Case Stud. Therm. Eng. 2022, 31, 101813. [Google Scholar] [CrossRef]

- Aly, A.M.; El-Sapa, S. Double rotations of cylinders on thermosolutal convection of a wavy porous medium inside a cavity mobilized by a nanofluid and impacted by a magnetic field. Int. J. Numer. Methods Heat Fluid Flow 2022, 32, 2383–2405. [Google Scholar] [CrossRef]

- Pilawska, M. Testing of Heat Transfer Coefficients and Frictional Losses in Internally Ribbed Tubes and Verification of Results through CFD Modelling. Energies 2021, 15, 207. [Google Scholar]

- Liu, Y.; Wang, H.G.; Song, Y.Q.; Qi, H.Y. Numerical study on key issues in the Eulerian-Eulerian simulation of fluidization with wide particle size distributions. Int. J. Chem. React. Eng. 2022, 20, 357–372. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, W.; Li, J. CFD Simulation of Combustion in a 150 MW e CFB Boiler. In Proceedings of the International Symposium on Coal Combustion, Harbin, China, 12–21 July 2011. [Google Scholar]

- Adamczyk, W.P. Modeling of particle transport and combustion phenomena in a large-scale circulating fluidized bed boiler using a hybrid Euler-Lagrange approach. Particuology 2014, 12, 29–40. [Google Scholar] [CrossRef]

- Hong, X.; Bai, J.; Wu, Y.; Wang, J.; Zhang, G. Dynamic simulation of a large scale 260 t/h CFB boiler based on SIMUCAD platform. In Proceedings of the 2009 ISECS International Colloquium on Computing, Communication, Control, and Management, Sanya, China, 8–9 August 2009. [Google Scholar]

- Wu, H.; Yang, C.; He, H.; Huang, S.; Chen, H. A Hybrid Simulation of a 600 MW Supercritical Circulating Fluidized Bed Boiler System. Appl. Therm. Eng. 2018, 143, 977–987. [Google Scholar] [CrossRef]

- Gao, M.; Zhang, B.; Hong, F.; Chen, F. Design and application of the feed water control strategy for a 350 MW circulating fluidized bed boiler. Appl. Therm. Eng. 2017, 125, 1–8. [Google Scholar] [CrossRef]

- Amczyk, W.P.; Kozołub, P.; Kruczek, G.; Pilorz, M.; Klimanek, A.; Czakiert, T.; Węcel, G. Numerical approach for modeling particle transport phenomena in a closed loop of a circulating fluidized bed. Particuology 2016, 29, 69–79. [Google Scholar] [CrossRef]

- Mirek, P. Air Distributor Pressure Drop Analysis in a Circulating Fluidized-Bed Boiler for Non-reference Operating Conditions. Chem. Eng. Technol. 2020, 43, 2233–2246. [Google Scholar] [CrossRef]

- Tang, G.; Zhang, M.; Junping, G.U.; Yuxin, W.U.; Junfu, L. Thermal-hydraulic Calculation and Analysis on Evaporator System of a 660 MWe Ultra-supercritical CFB boiler. Appl. Therm. Eng. 2019, 151, 385–393. [Google Scholar] [CrossRef]

- Zhu, S.; Zhang, M.; Huang, Y.; Wu, Y.; Yang, H.; Lyu, J.; Gao, X.; Wang, F.; Yue, G. Thermodynamic analysis of a 660 MW ultra-supercritical CFB boiler unit. Energy 2019, 173, 352–363. [Google Scholar] [CrossRef]

- Ji, J.; Cheng, L.; Wei, Y.; Wang, J.; Gao, X.; Fang, M.; Wang, Q. Predictions of NOx/N2O emissions from an ultra-supercritical CFB boiler using a 2-D comprehensive CFD combustion model. Particuology 2020, 49, 77–87. [Google Scholar] [CrossRef]

- Zhou, X.; Niu, T.; Xin, Y.; Li, Y.; Yang, D. Experimental and numerical investigation on heat transfer in the vertical upward flow water wall of a 660 MW ultra-supercritical CFB boiler. Appl. Therm. Eng. 2021, 188, 116664. [Google Scholar] [CrossRef]

- Xin, Y.F.; Niu, T.T.; Li, Y.L.; Yang, D. Experimental investigation on gas-liquid flow distribution in downward parallel pipes of a 660 MW ultrasupercritical CFB boiler. Int. J. Energy Res. 2021, 45, 6303–6319. [Google Scholar] [CrossRef]

- Juslin, K. A Companion Model Approach to Modelling and Simulation of Industrial Processes; VTT Publishing: Espoo, Finland, 2008. [Google Scholar]

- Zhang, Z.; Yang, C.; Wu, H.; Deng, K. Modeling and simulation of the start-up process of a 660 MW ultra-supercritical circulating fluidized bed boiler. Comput. Chem. Eng. 2022; in press. [Google Scholar]

- Myöhänen, K. Modelling of Combustion and Sorbent Reactions in Three-Dimensional Flow Environment of a Circulating Fluidized Bed Furnace. Doctor’s Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2011. [Google Scholar]

- Hiidenkari, H.; Tuuri, S.; Lappalainen, J.; Ritvanen, J. Dynamic Core-Annulus Model for Circulating Fluidized Bed Boilers. In Proceedings of the Nordic Flame Days 2019, Turku, Finland, 28–29 August 2019. [Google Scholar]

- Heimo, H. Dynamic Core-Annulus Model of Circulating Fluidized Bed Boilers. Master’s Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2018. [Google Scholar]

- Wen, C.Y.; Chen, L.H. Fluidized bed freeboard phenomena: Entrainment and elutriation. AIChE J. 1982, 28, 117–128. [Google Scholar] [CrossRef]

- Apros. User Manual: Apros 6 Feature Tutorial; Version 6.09; VTT & Fortum: Espoo, Finland, 2019. [Google Scholar]

- Kunii, D. Flow modeling of fast fluidized beds. In Circulating Fluidized Beds; Springer: Dordrecht, The Netherlands, 1991. [Google Scholar]

- Johnsson, F. Fluid Dynamics and Heat Transfer in Fluidized Beds—With Applications to Boilers. Doctor’s Thesis, Chalmers University, Gothenburg, Sweden, 1991. [Google Scholar]

- Broadhurst, T.E.; Becker, H.A. Onset of fluidization and slugging in beds of uniform particles. AIChE J. 1975, 21, 238–247. [Google Scholar] [CrossRef]

- Mostoufi, N.; Chaouki, J. Prediction of effective drag coefficient in fluidized beds. Chem. Eng. Sci. 1999, 54, 851–858. [Google Scholar] [CrossRef]

- Dukhan, N.; Patel, P. Equivalent particle diameter and length scale for pressure drop in porous metals. Exp. Therm. Fluid Sci. 2008, 32, 1059–1067. [Google Scholar] [CrossRef]

- Ergun, S. Fluid flow through packed columns. Chem. Eng. Prog. 1952, 48, 89–94. [Google Scholar]

- Dutta, A.; Basu, P. Overall heat transfer to water walls and wing walls of commercial circulating fluidized-bed boilers. J. Inst. Energy 2002, 75, 85–90. [Google Scholar]

- Deng, K.; Yang, C.; Chen, H.; Zhou, N.; Huang, S. Start-Up and dynamic processes simulation of supercritical once-through boiler. Appl. Therm. Eng. 2017, 115, 937–946. [Google Scholar] [CrossRef]

- Hänninen, M. Phenomenological Extensions to APROS Six-Equation Model. Non-condensable Gas, Supercritical Pressure, Improved CCFL and Reduced Numerical Diffusion for Scalar Transport Calculation. Doctor’s Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2009. [Google Scholar]

| Proximate Analysis | Unit | Value | Ultimate Analysis | Unit | Value |

|---|---|---|---|---|---|

| Moisture | % | 1.00 | Carbon | % | 47.66 |

| Ash | % | 37.77 | Hydrogen | % | 2.14 |

| Volatile matter | % | 10.32 | Oxygen | % | 1.12 |

| Lower heating value | kJ/kg | 18,370 | Nitrogen | % | 0.83 |

| Sulfur | % | 2.98 |

| Parameters | Unit | Value |

|---|---|---|

| Boiler height | m | 55 |

| Cross-section of boiler | m2 | 31.41 × 16.47 |

| Parameter | Unit | Designed Value | Simulated Value | Relative Error (%) |

|---|---|---|---|---|

| Main steam mass flow | t/h | 1902 | 1902 | 0.00% |

| Main steam pressure | MPa | 29.3 | 29.3 | 0.00% |

| Main steam temperature | °C | 605 | 604.3 | −0.12% |

| Reheated steam mass flow | t/h | 1611.9 | 1611.9 | 0.00% |

| Reheated steam inlet temperature | °C | 366.8 | 366.8 | 0.00% |

| Reheated steam outlet temperature | °C | 623 | 624.4 | 0.22% |

| Coal mass flow | t/h | 294.1 | 295.6 | 0.51% |

| Limestone mass flow | t/h | 42.03 | 42.03 | 0.00% |

| ECO inlet water temperature | °C | 303 | 305.5 | 0.83% |

| ECO outlet water temperature | °C | 350 | 348.1 | −0.54% |

| Water wall outlet steam temperature | °C | 435 | 435.4 | 0.09% |

| Cyclone separator outlet steam temperature | °C | 445 | 446 | 0.22% |

| LTS inlet steam temperature | °C | 454 | 455.7 | 0.37% |

| LTS outlet steam temperature | °C | 473 | 476.2 | 0.68% |

| ITS1 inlet steam temperature | °C | 468 | 468 | 0.00% |

| ITS1 outlet steam temperature | °C | 507 | 507.1 | 0.02% |

| ITS2 outlet steam temperature | °C | 547 | 546.2 | −0.15% |

| HTS1 inlet steam temperature | °C | 538 | 538 | 0.00% |

| HTS1 outlet steam temperature | °C | 578 | 579.2 | 0.21% |

| HTS2 inlet steam temperature | °C | 573 | 573 | 0.00% |

| HTS2 outlet steam temperature | °C | 605 | 604.3 | −0.12% |

| Attemperation water temperature | °C | 350 | 348.1 | −0.54% |

| LTR1 inlet steam temperature | °C | 367 | 367.3 | 0.08% |

| LTR2 inlet steam temperature | °C | 446 | 446.1 | 0.02% |

| HTR inlet steam temperature | °C | 572 | 572 | 0.00% |

| HTR outlet steam temperature | °C | 623 | 624.4 | 0.22% |

| Primary air mass flow | kg/s | 300.3 | 300.3 | 0.00% |

| Secondary air mass flow | kg/s | 312.6 | 312.6 | 0.00% |

| Primary air inlet temperature | °C | 65 | 65 | 0.00% |

| Primary air outlet temperature | °C | 284 | 284.4 | 0.14% |

| Secondary air inlet temperature | °C | 65 | 65 | 0.00% |

| Secondary air outlet temperature | °C | 284 | 284.4 | 0.14% |

| Bed temperature | °C | 895 | 895.2 | 0.02% |

| Cyclone separator outlet flue gas temperature | °C | 889 | 890.3 | 0.15% |

| LTR2 inlet flue gas temperature | °C | 852 | 854.8 | 0.33% |

| LTS inlet flue gas temperature | °C | 692 | 694.4 | 0.35% |

| LTR1 inlet flue gas temperature | °C | 618 | 626.8 | 1.42% |

| ECO inlet flue gas temperature | °C | 502 | 511.8 | 1.95% |

| Air pre-heater inlet flue gas temperature | °C | 307 | 325.6 | 6.06% |

| Air pre-heater outlet flue gas temperature | °C | 127 | 122.8 | −3.31% |

| Furnace outlet excess air coefficient | 1.2 | 1.2 | 0.00% | |

| THS1 ash mass flow | kg/s | 315.2 | 315.2 | 0.00% |

| HTS2 ash mass flow | kg/s | 315 | 315 | 0.00% |

| HTR ash mass flow | kg/s | 333.2 | 333.2 | 0.00% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Zhang, Z.; Wu, H.; Deng, K. Dynamic Characteristics Analysis of a 660 MW Ultra-Supercritical Circulating Fluidized Bed Boiler. Energies 2022, 15, 4049. https://doi.org/10.3390/en15114049

Yang C, Zhang Z, Wu H, Deng K. Dynamic Characteristics Analysis of a 660 MW Ultra-Supercritical Circulating Fluidized Bed Boiler. Energies. 2022; 15(11):4049. https://doi.org/10.3390/en15114049

Chicago/Turabian StyleYang, Chen, Zonglong Zhang, Haochuang Wu, and Kangjie Deng. 2022. "Dynamic Characteristics Analysis of a 660 MW Ultra-Supercritical Circulating Fluidized Bed Boiler" Energies 15, no. 11: 4049. https://doi.org/10.3390/en15114049

APA StyleYang, C., Zhang, Z., Wu, H., & Deng, K. (2022). Dynamic Characteristics Analysis of a 660 MW Ultra-Supercritical Circulating Fluidized Bed Boiler. Energies, 15(11), 4049. https://doi.org/10.3390/en15114049