The Research on Characteristics of CI Engine Supplied with Biodiesels from Brown and Yellow Grease

Abstract

:1. Introduction

2. Feedstocks for Biodiesel

3. Technologies for Biodiesel Production

4. Research on Biodiesel from Yellow Grease

5. Research on Biodiesel from Brown Grease

6. Materials and Methods

- pure diesel fuel (as delivered);

- a blend of diesel with 6% of biodiesel obtained from yellow grease, more specifically in the form of methyl ester of rapeseed oil (as delivered);

- a blend of diesel with 6% of biodiesel obtained from a brown grease, more specifically in the form of methyl ester of goose fat obtained via transesterification process described further.

6.1. Goose Fat Transesterification

6.1.1. Reagents and Equipment

- goose lard;

- sodium methoxide solution.

- round bottom flask with a capacity of 100 and 250 mL;

- reflux cooler;

- magnetic stirrer;

- water bath;

- thermometer;

- manifold with a capacity of 250 mL;

- measuring cylinder;

- beakers;

- conical flask with a stopper;

- glass funnel.

6.1.2. Methodology

6.2. Chromatographic Analysis of Fuels Used

6.3. Measurement of Engine Characteristics, Fuel Consumption, and Emissions at Full Engine Load

- —measured sum of the beaker mass and the -th fuel mass,

- —measured mass of beaker,

- —mass of the -th fuel, while: = 1 for pure diesel, = 2 for the blend of diesel and 6% of methyl ester of yellow grease (rapeseed oil), = 3 for the blend of diesel and 6% of methyl ester of brown grease (goose fat),

- —volume of the -th fuel equal to 50 mL.

- —the -th fuel consumption at the engine speed set,

- —the -th fuel density obtained from Equation (1),

- —the -th fuel volume registered at the beginning of the measurement process of the -th fuel consumption at the engine speed set,

- —the -th fuel volume registered at the end of the measurement process of the -th fuel consumption at the engine speed set,

- —time registered for the measurement process of the -th fuel consumption at the engine speed set,

- —measured engine power at the engine speed set under full engine load, as described further.

6.3.1. Measurement under Full Engine Load

- First, the engine operated at idle speed until reaching the temperature value of the balance temperature;

- Then, the additional transparent plastic tank was replaced by the other one with the same dose of the pure diesel;

- Engine characteristics were obtained for the diesel engine supplied with pure diesel (fuel quality and content as delivered);

- Simultaneously for each engine speed value set, the time of engine operation and volume of fuel consumed were determined;

- Additionally, for each engine speed value set, the engine emissions were measured using the Elwico unit [43] comprising an exhaust gas analyzer and an opacimeter;

- Then, the additional tank was replaced with the one filled with diesel with 6% of biodiesel in the form of the methyl ester of rapeseed oil (blend quality and content as delivered);

- Next, the engine characteristics, time of engine operation, volume of fuel consumed, and engine emissions were determined for the same engine speed values as for the case of pure diesel supply;

- Then, the additional tank was replaced with the one filled with pure diesel;

- The engine was operated once again at idle speed until reaching the temperature value of the balance temperature;

- Next, the additional tank was replaced with the one filled with diesel with 6% of biodiesel in the form of methyl ester of goose fat obtained from the transesterification process described earlier;

- Then, the engine characteristics, time of engine operation, volume of fuel consumed, and engine emissions were determined for the engine speed value equal to 1500 rpm;

- Next, the engine was supplied with fuel from the vehicle tank and operated once again at idle speed until reaching the temperature value of the balance temperature.

6.3.2. Measurement under Zero Engine Load

7. Results and Discussion

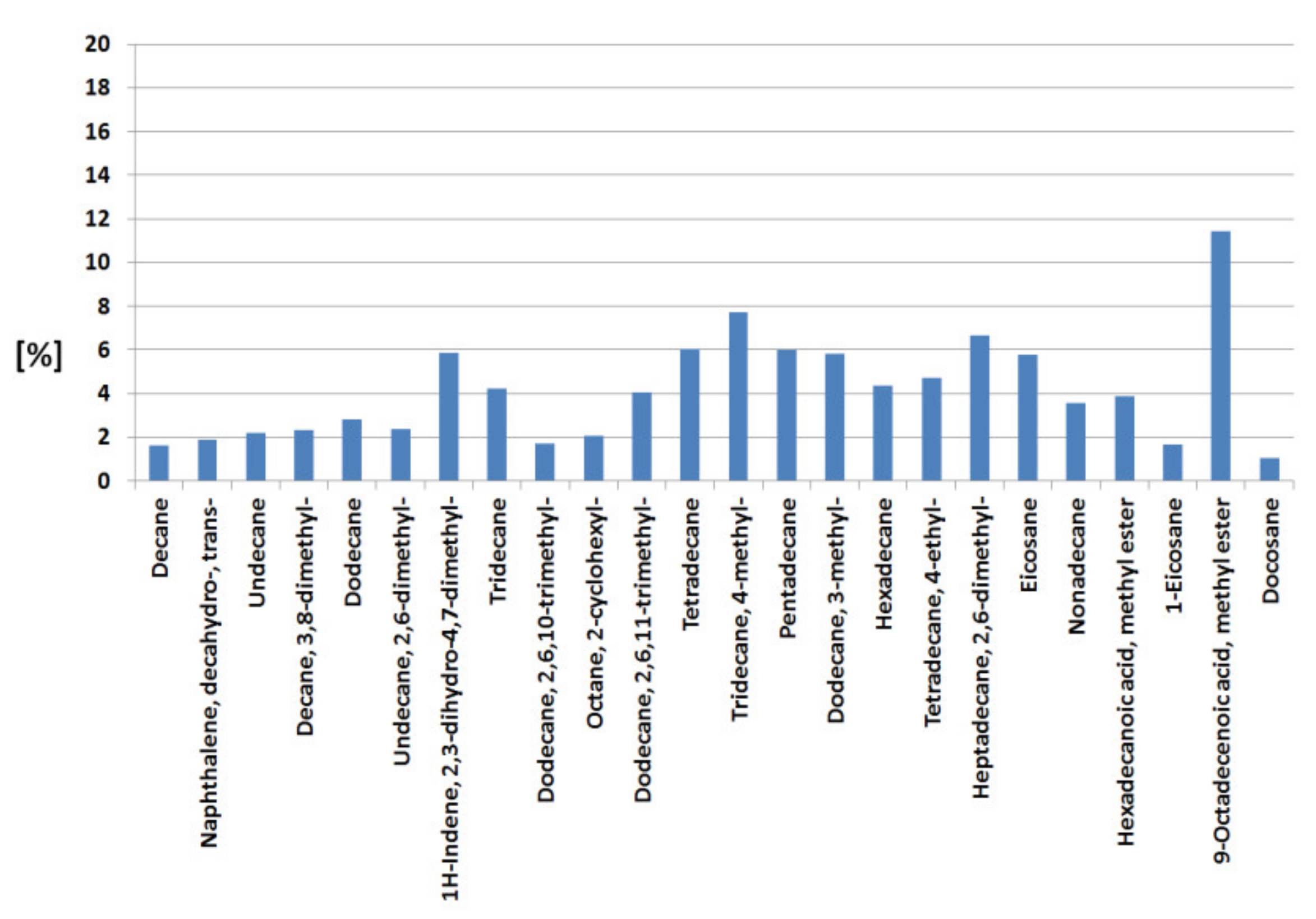

7.1. Results from Chromatographic Analysis of Fuels Supplied to the Combustion Engine

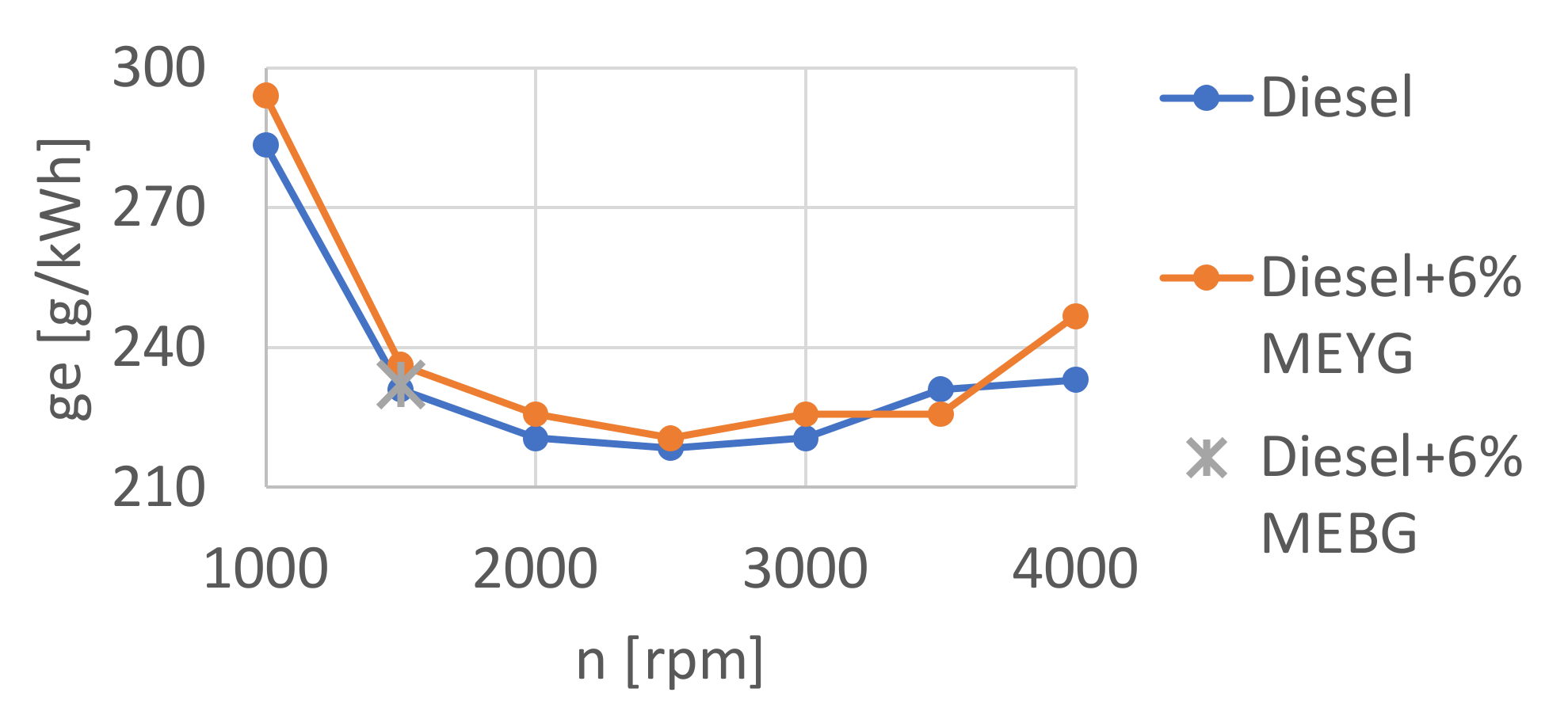

7.2. Resulted Engine Characteristics

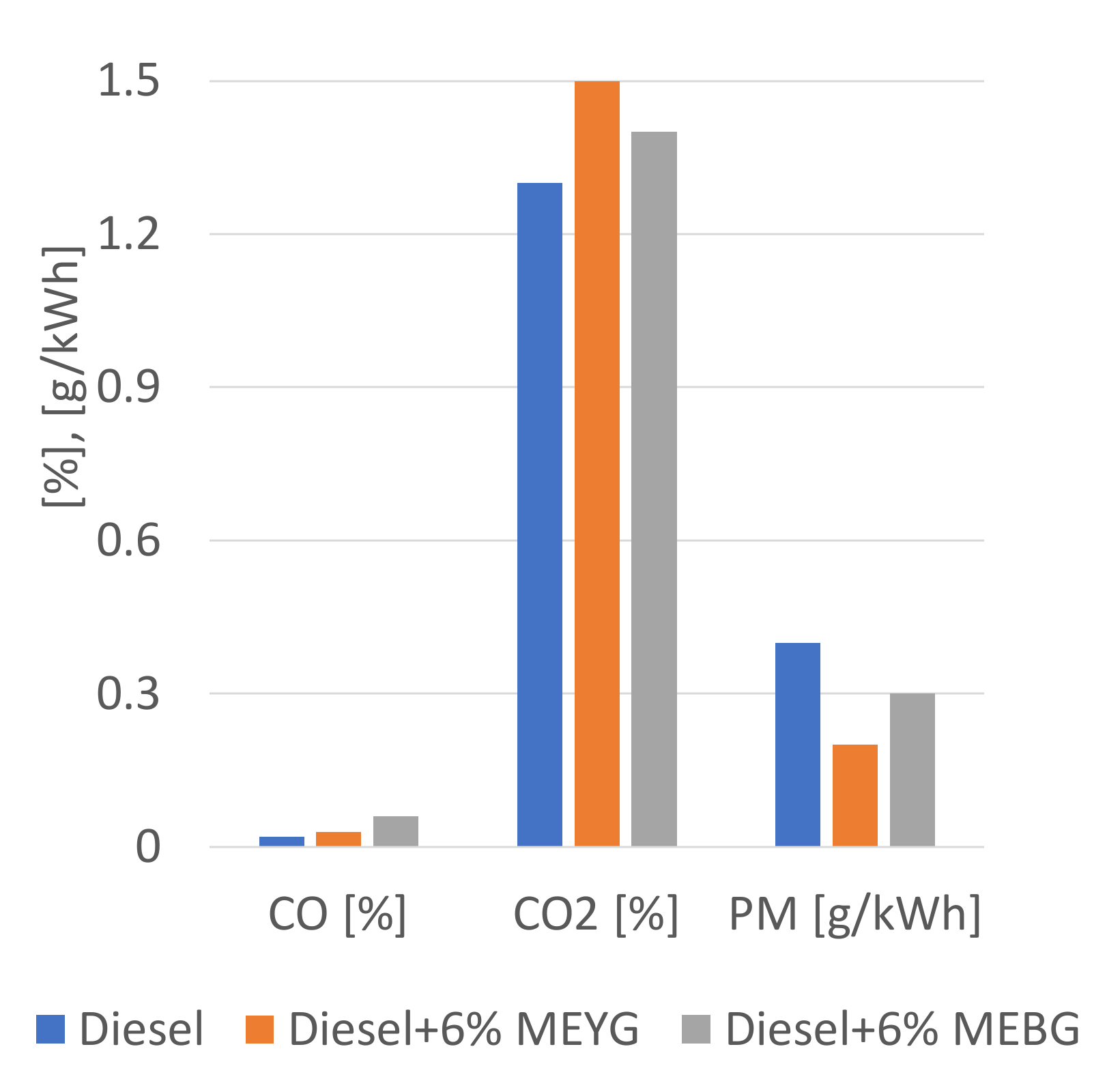

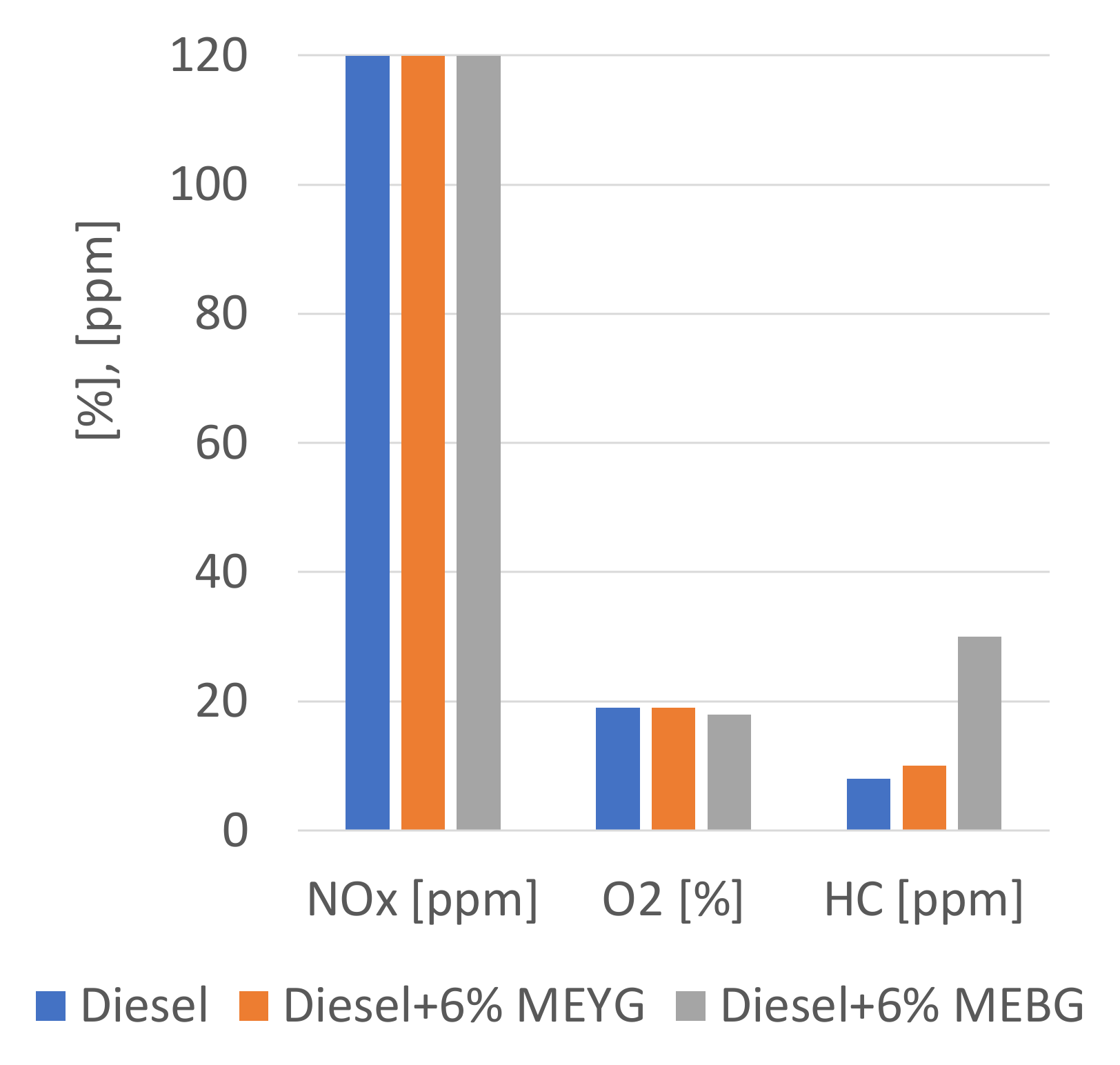

7.3. Resulted Fuel Consumption and Emissions at Zero Engine Load

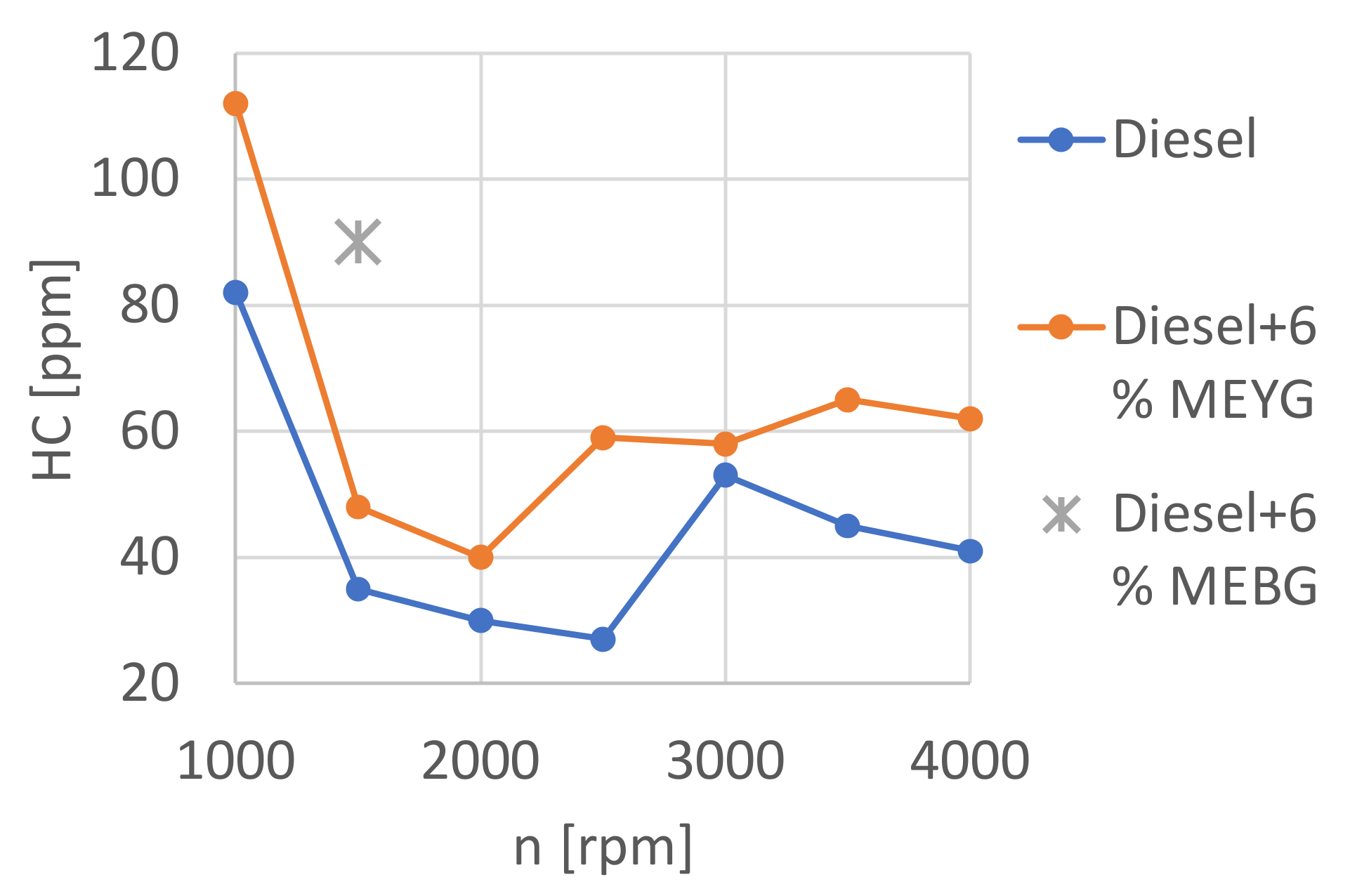

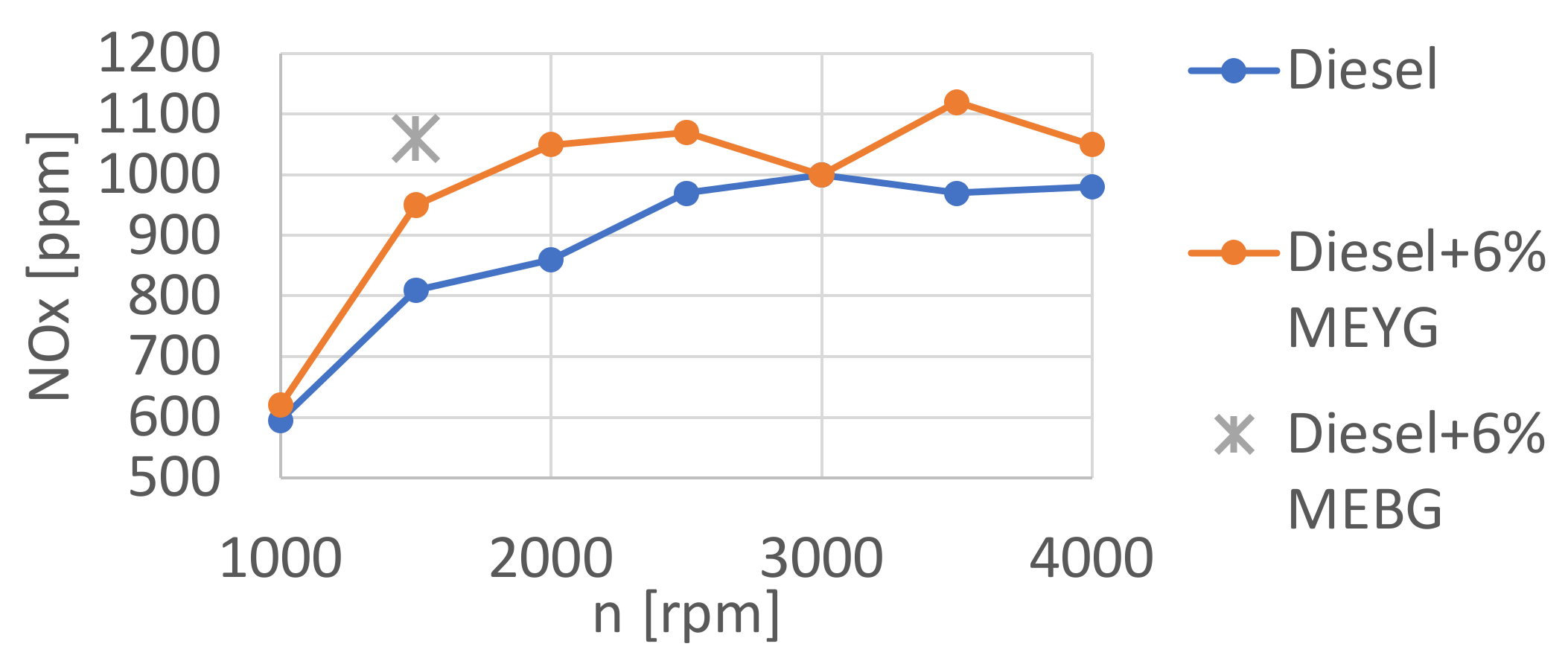

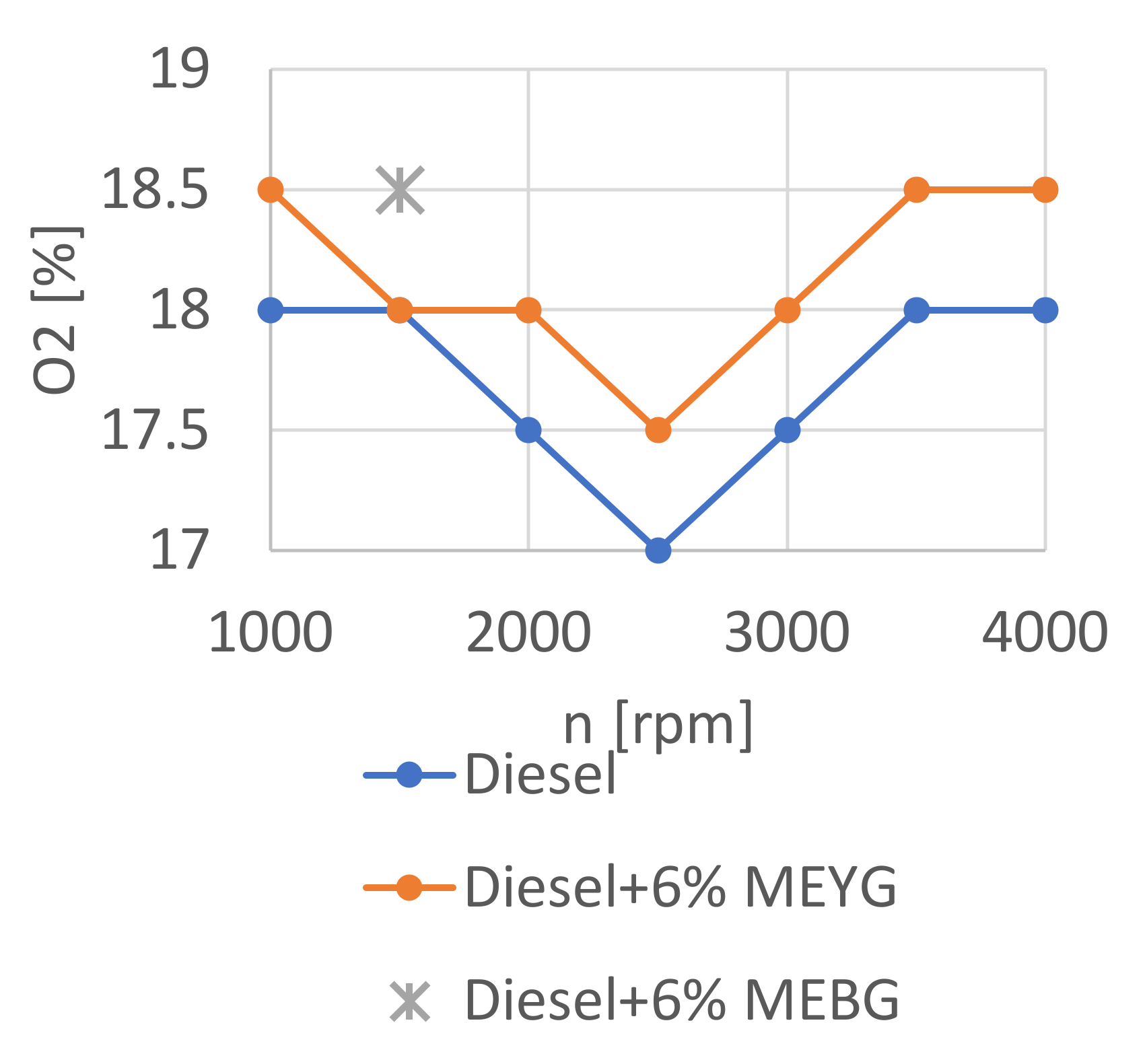

7.4. Resulted Fuel Consumption and Emissions at Full Engine Load

8. Conclusions

- The comparison of the effect of the diesel engine supply with three fuels, including pure diesel, a blend of diesel with 6% of methyl ester of rapeseed oil (yellow grease), and one with 6% of methyl ester of goose fat (brown grease) on the engine characteristics, fuel consumption, and engine emissions was performed.

- Obtained biodiesel containing 6% yellow grease clearly differed not only from pure diesel but also much more from the biodiesel containing 6% brown grease.

- Under a full load of the engine, the addition of 6% of yellow grease to the diesel allowed a decrease in engine power by 8% and engine torque by about 4%, while the addition of 6% of brown grease to the diesel allowed an increase in engine power about 1% and practically resulted in no change in the engine torque.

- Under 0% load of the engine, the addition of 6% MEYG to diesel resulted in a minor increase in CO and HC emissions and a more clearly visible increase in CO2 and decrease in PM emissions compared to the case of pure diesel.

- Under 0% load of the engine, the addition of 6% MEBG to diesel caused a small enhancement in CO emissions and a more clearly visible increase in HC and CO2 emissions, and a decrease in PM emissions in comparison to the case of pure diesel.

- Under full load of the engine, the addition of 6% MEYG to diesel resulted in a clear decrease in CO and PM emissions for all engine speeds and an enhancement in NOx and HC emissions for all engine speeds, compared to the case of pure diesel. The fuel consumption was a little higher, but rather for the lower engine speed, the CO2 emission varied with engine speed compared to the case of pure diesel.

- Under full load of the engine, the addition of 6% MEBG to diesel resulted in a small enhancement in the fuel consumption, a clear increase in NOx and HC emissions, a small decrease in PM emission and a clear decrease in CO2 emissions, while CO emissions were not changed compared to the case of pure diesel.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Szufa, S.; Wielgosinski, G.; Piersa, P.; Czerwinska, J.; Dzikuc, M.; Adrian, L.; Lewandowska, W.; Marczak-Grzesik, M. Torrefaction of Straw from Oats and Maize for Use as A Fuel and Additive to Organic Fertilizers—TGA Analysis, Kinetics as Products for Agricultural Purposes. Energies 2020, 13, 2064. [Google Scholar] [CrossRef] [Green Version]

- Szufa, S.; Piersa, P.; Adrian, L.; Czerwinska, J.; Lewandowski, A.; Lewandowska, W.; Sielski, J.; Dzikuc, M.; Wrobel, M.; Jewiarz, M.; et al. Sustainable Drying and Torrefaction Processes of Miscanthus for Use as a Pelletized Solid Biofuel and Biocar-bon-Carrier for Fertilizers. Molecules 2021, 26, 1014. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.H.; Bonifacio, S.; Clowes, J.; Foulds, A.; Holland, R.; Matthews, J.C.; Percival, C.J.; Shallcross, D.E. Investigation of Biofuel as a Potential Renewable Energy Source. Atmosphere 2021, 12, 1289. [Google Scholar] [CrossRef]

- Afshin, G.; Rahimpour, M.R.; Ghasemi, Y.; Raeissi, S. The Biodiesel of Microalgae as a Solution for Diesel Demand in Iran. Energies 2018, 11, 950. [Google Scholar] [CrossRef] [Green Version]

- Tito, I.F.; Sales, E.A.; Nascimento, A.N.; Padula, A.D. Optimizing the Cooperated “Multi-Countries” Biodiesel Production and Consumption in Sub-Saharan Africa. Energies 2020, 13, 4717. [Google Scholar] [CrossRef]

- Alternative Fuels Data Center. Biodiesel Fuel Basics. Available online: https://afdc.energy.gov/fuels/biodiesel_basics.html (accessed on 14 March 2022).

- Hanson, S.; Agarwal, N. Biodiesels Produced from Certain Feedstocks Have Distinct Properties from Petroleum Diesel. Today in Energy, 3 May 2018. Available online: https://www.eia.gov/todayinenergy/detail.php?id=36052 (accessed on 14 March 2022).

- U.S. Energy Information Administration. Biofuels Explained. Biodiesel, Renewable Diesel, and Other Biofuels. Available online: https://www.eia.gov/energyexplained/biofuels/biodiesel.php (accessed on 14 March 2022).

- Alternative Fuels Data Center. Renewable Hydrocarbon Biofuels. Available online: https://afdc.energy.gov/fuels/emerging_hydrocarbon.html (accessed on 14 March 2022).

- Biofuel Feedstock Overview. Oil & Energy Online. 2022. Available online: https://oilandenergyonline.com/articles/all/biofuel-feedstock-overview/ (accessed on 14 March 2022).

- Bartha-Vári, J.-H.; Moisă, M.E.; Bencze, L.C.; Irimie, F.; Paizs, C.; Tosa, M.I. Efficient Biodiesel Production Catalyzed by Nanobioconjugate of Lipase from Pseudomonas fluorescens. Molecules 2020, 25, 651. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chua, S.Y.; Periasamy, L.A.; Goh, C.M.H.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Khalid, M.; Walvekar, R.; Abdullah, E.C. Biodiesel synthesis using natural solid catalyst derived from biomass waste—A review. J. Ind. Eng. Chem. 2020, 81, 41–60. [Google Scholar] [CrossRef]

- Kolet, M.; Zerbib, D.; Molina, K.; Nakonechny, F.; Nisnevitch, M. Biodiesel Production using Lewis Catalysts under Ultrasonic Activation. Isr. J. Chem. 2020, 60, 644–651. [Google Scholar] [CrossRef]

- Gebremariam, S.N.; Marchetti, J.M. Economics of biodiesel production: Review. Energy Convers. Manag. 2018, 168, 74–84. [Google Scholar] [CrossRef]

- Mansir, N.; Teo, S.H.; Rashid, U.; Saiman, M.I.; Tan, Y.P.; Alsultan, G.A.; Taufiq-Yap, Y.H. Modified waste egg shell derived bifunctional catalyst for biodiesel production from high FFA waste cooking oil. A review. Renew. Sustain. Energy Rev. 2018, 82, 3645–3655. [Google Scholar] [CrossRef]

- Abdurakhman, Y.B.; Putra, Z.A.; Bilad, M.R.; Nordin, N.A.H.M.; Wirzal, M.D.H. Techno-economic analysis of biodiesel production process from waste cooking oil using catalytic membrane reactor and realistic feed composition. Chem. Eng. Res. Des. 2018, 134, 564–574. [Google Scholar] [CrossRef]

- Tran, N.N.; Tisma, M.; Budzaki, S.; McMurchie, E.J.; Gonzalez, O.M.M.; Hessel, V.; Yung, N. Scale-up and economic analysis of biodiesel production from recycled grease trap waste. Appl. Energy 2018, 229, 142–150. [Google Scholar] [CrossRef]

- Da Silva, C.A.; dos Santos, R.N.; Oliveira, G.G.; de Souza Ferreira, T.P.; de Souza, N.L.G.D.; Soares, A.S.; de Melo, J.F.; Colares, C.J.G.; de Souza, U.J.B.; de Araújo-Filho, R.N.; et al. Biodiesel and Bioplastic Production from Waste-Cooking-Oil Transesterification: An Environmentally Friendly Approach. Energies 2022, 15, 1073. [Google Scholar] [CrossRef]

- Mushtaq, A.; Hanif, M.A.; Zahid, M.; Rashid, U.; Mushtaq, Z.; Zubair, M.; Moser, B.R.; Alharthi, F.A. Production and Evaluation of Fractionated Tamarind Seed Oil Methyl Esters as a New Source of Biodiesel. Energies 2021, 14, 7148. [Google Scholar] [CrossRef]

- Elgharbawy, A.S.; Sadik, W.A.; Sadek, O.M.; Kasaby, M.A. A Review on Biodiesel Feedstocks and Production Technologies. J. Chil. Chem. Soc. 2021, 66, 5098–5109. [Google Scholar] [CrossRef]

- Grzelak, P.; Zoltowski, A. Environmental assessment of the exploitation of diesel engines powered by biofuels. Combust. Engines 2020, 180, 31–35. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Sharma, P.K.; Jhalani, A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Karmakar, B.; Sucharita, S.; Halder, G. Delonix regia heterogeneous catalyzed two-step biodiesel production from Pongamia pinnata oil using methanol and 2-propanol. J. Clean. Prod. 2020, 255, 120313. [Google Scholar] [CrossRef]

- Pascoal, C.V.P.; Oliveira, A.L.L.; Figueiredo, D.D.; Assunção, J.C.C. Optimization and kinetic study of ultrasonic-mediated in situ transesterification for biodiesel production from the almonds of Syagrus cearensis. Renew. Energy 2020, 147, 1815–1824. [Google Scholar] [CrossRef]

- Raman, L.A.; Deepanraj, B.; Rajakumar, S.; Sivasubramanian, V. Experimental investigation on performance, combustion and emission analysis of a direct injection diesel engine fuelled with rapeseed oil biodiesel. Fuel 2019, 246, 69–74. [Google Scholar] [CrossRef]

- Anguebes-Franseschi, F.; Abatal, M.; Bassam, A.; Soberanis, M.A.E.; Tzuc, O.M.; Bucio-Galindo, L.; Quiroz, A.V.C.; Ucan, C.A.A.; Ramirez-Elias, M.A. Esterification Optimization of Crude African Palm Olein Using Response Surface Methodology and Heterogeneous Acid Catalysis. Energies 2018, 11, 157. [Google Scholar] [CrossRef] [Green Version]

- Panchal, B.L.; Deshmukh, S.A.; Sharma, M.R. Production and kinetic transesterifi-cation of biodiesel from yellow grease with dimethyl carbonate using methanesulfonic acid as a catalyst. Environ. Prog. Sustain. Energy 2017, 36, 802–807. [Google Scholar] [CrossRef]

- Ortiz-Martínez, V.M.; Salar-García, M.J.; Palacios-Nereo, F.J.; Olivares Carrillo, P.; Quesada-Medina, J.; De los Ríos, A.; Hernández-Fernández, F. In-depth study of the transesterification reaction of Pongamia pinnata oil for biodiesel production using cata-lyst-free supercritical methanol process. J. Supercrit. Fluids 2016, 113, 23–30. [Google Scholar] [CrossRef]

- Goembira, F.; Saka, S. Advanced supercritical Methyl acetate method for biodiesel production from Pongamia pinnata oil. Renew. Energy 2015, 83, 1245–1249. [Google Scholar] [CrossRef]

- Özçelik, E.; Aydogan, H.; Acaroglu, M. The Effects of Safflower Biodiesel and its Blends with Diesel Fuel on Engine Performance in a Common-Rail Diesel Engine. In Proceedings of the 20th International Academic Conference, Madrid, Spain, 6 October 2015; Volume 1. [Google Scholar]

- Syamsuddin, Y.; Hameed, B.H. Synthesis of glycerol free-fatty acid methyl esters from Jatropha oil over Ca–La mixed-oxide catalyst. J. Taiwan Inst. Chem. Eng. 2015, 58, 181–188. [Google Scholar] [CrossRef]

- Gaurav, A.; Ng, F.T.T.; Rempel, G.L. A new green process for biodiesel production from waste oils via catalytic distillation using a solid acid catalyst—Modeling, economic and environmental analysis. Green Energy Environ. 2016, 1, 62–74. [Google Scholar] [CrossRef] [Green Version]

- Duda, K.; Wierzbicki, S.; Mikulski, M. An experimental analysis of performance and exhaust emissions of a CRDI diesel engine operating on mixtures containing mineral and renewable components. Combust. Engines 2019, 179, 27–31. [Google Scholar] [CrossRef]

- Moffitt, L. ISCC Redefines Brown Grease: Correction. 2021. Available online: https://www.argusmedia.com/en/news/2280379-iscc-redefines-brown-grease-correction (accessed on 15 March 2022).

- Kolet, M.; Zerbib, D.; Nakonechny, F.; Nisnevitch, M. Production of Biodiesel from Brown Grease. Catalysts 2020, 10, 1189. [Google Scholar] [CrossRef]

- Tran, N.N.; Tišma, M.; Budžaki, S.; McMurchie, E.J.; Yung, N.; Morales-Gonzalez, O.M.; Hessel, V. Production of Biodiesel from Recycled Grease Trap Waste: A Review. Ind. Eng. Chem. Res. 2021, 60, 16547–16560. [Google Scholar] [CrossRef]

- Hums, M.E.; Amin, H.; Tsao, T.C.; Olson, M.S.; Spatari, S.; Cairncross, R.A. Longitudinal Study of Wastewater Greases and Their Potential for the Production of Biofuels. Energy Fuels 2018, 32, 1831–1842. [Google Scholar] [CrossRef]

- Zheng, L.; Hou, Y.; Li, W.; Yang, S.; Li, Q.; Yu, Z. Exploring the potential of grease from yellow mealworm beetle (Tenebrio molitor) as a novel biodiesel feedstock. Appl. Energy 2013, 101, 618–621. [Google Scholar] [CrossRef]

- Spiller, R.; Knoshaug, E.P.; Nagle, N.; Dong, T.; Milbrandt, A.; Clippinger, J.; Peterson, D.; Van Wychen, S.; Panczak, B.; Pienkos, P.T. Upgrading brown grease for the production of biofuel intermediates. Bioresour. Technol. Rep. 2020, 9, 100344. [Google Scholar] [CrossRef]

- Fan, X.; Burton, R.; Austic, G. The Enzymatic Conversion of Brown Grease to Biodiesel in a Solvent-free Medium. Energy Sources Part A Recovery Util. Environ. Eff. 2013, 35, 1779–1786. [Google Scholar] [CrossRef]

- AutoCentrum. Citroen C5 II 1.6 HDi Hatchback 2004–2008. Available online: https://www.autocentrum.pl/dane-techniczne/citroen/c5/ii/hatchback/silnik-diesla-1.6-hdi-109km-2004-2008/ (accessed on 15 March 2022).

- Dynomet Roller Dynamometer. Available online: http://www.dynomet.dk/en_rollersetdynoforcars.htm (accessed on 1 March 2022).

- Elwico Unit. Exhaust Gas Analyzer and Opacimeter. Available online: https://elwico.com/ (accessed on 15 March 2022).

- VitesseAuto. Citroen C5 II 1.6 HDi. Available online: https://vitesse.auto.pl/chiptuning_lodz.php?auto=Citroen_C5_II_1.6%C2%A0HDi%C2%A080kW (accessed on 15 March 2022).

- Labeckas, G.; Slavinskas, S. The effect of rapeseed oil methyl ester on direct injection Diesel engine performance and exhaust emissions. Energy Convers. Manag. 2006, 47, 1954–1967. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S. The effect of diesel fuel blending with rapeseed oil and rme on engine performance and exhaust emissions. J. KONES 2005, 12, 187–194. [Google Scholar]

- Peterson, C.; Reece, D. Emissions Characteristics of Ethyl and Methyl Esters of Rapeseed Oil Compared with Low Sulfur Diesel Control Fuel in a Chassis Dynamometer Test of a Pickup Truck. Trans. ASAE 1996, 39, 805–816. [Google Scholar] [CrossRef] [Green Version]

| [g/kWh] | ||

|---|---|---|

| Pure Diesel | Diesel + 6% MEYG | Diesel + 6% MEBG |

| 580 | 630 | 600 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciesielski, R.; Zakrzewski, M.; Shtyka, O.; Maniecki, T.; Rylski, A.; Wozniak, M.; Kubiak, P.; Siczek, K. The Research on Characteristics of CI Engine Supplied with Biodiesels from Brown and Yellow Grease. Energies 2022, 15, 4083. https://doi.org/10.3390/en15114083

Ciesielski R, Zakrzewski M, Shtyka O, Maniecki T, Rylski A, Wozniak M, Kubiak P, Siczek K. The Research on Characteristics of CI Engine Supplied with Biodiesels from Brown and Yellow Grease. Energies. 2022; 15(11):4083. https://doi.org/10.3390/en15114083

Chicago/Turabian StyleCiesielski, Radosław, Mateusz Zakrzewski, Oleksandr Shtyka, Tomasz Maniecki, Adam Rylski, Marek Wozniak, Przemyslaw Kubiak, and Krzysztof Siczek. 2022. "The Research on Characteristics of CI Engine Supplied with Biodiesels from Brown and Yellow Grease" Energies 15, no. 11: 4083. https://doi.org/10.3390/en15114083

APA StyleCiesielski, R., Zakrzewski, M., Shtyka, O., Maniecki, T., Rylski, A., Wozniak, M., Kubiak, P., & Siczek, K. (2022). The Research on Characteristics of CI Engine Supplied with Biodiesels from Brown and Yellow Grease. Energies, 15(11), 4083. https://doi.org/10.3390/en15114083