Performance Evaluation of PVT Air Collector Coupled with a Triangular Block in Actual Climate Conditions in Korea

Abstract

:1. Introduction

2. Experimental Apparatus and Methods

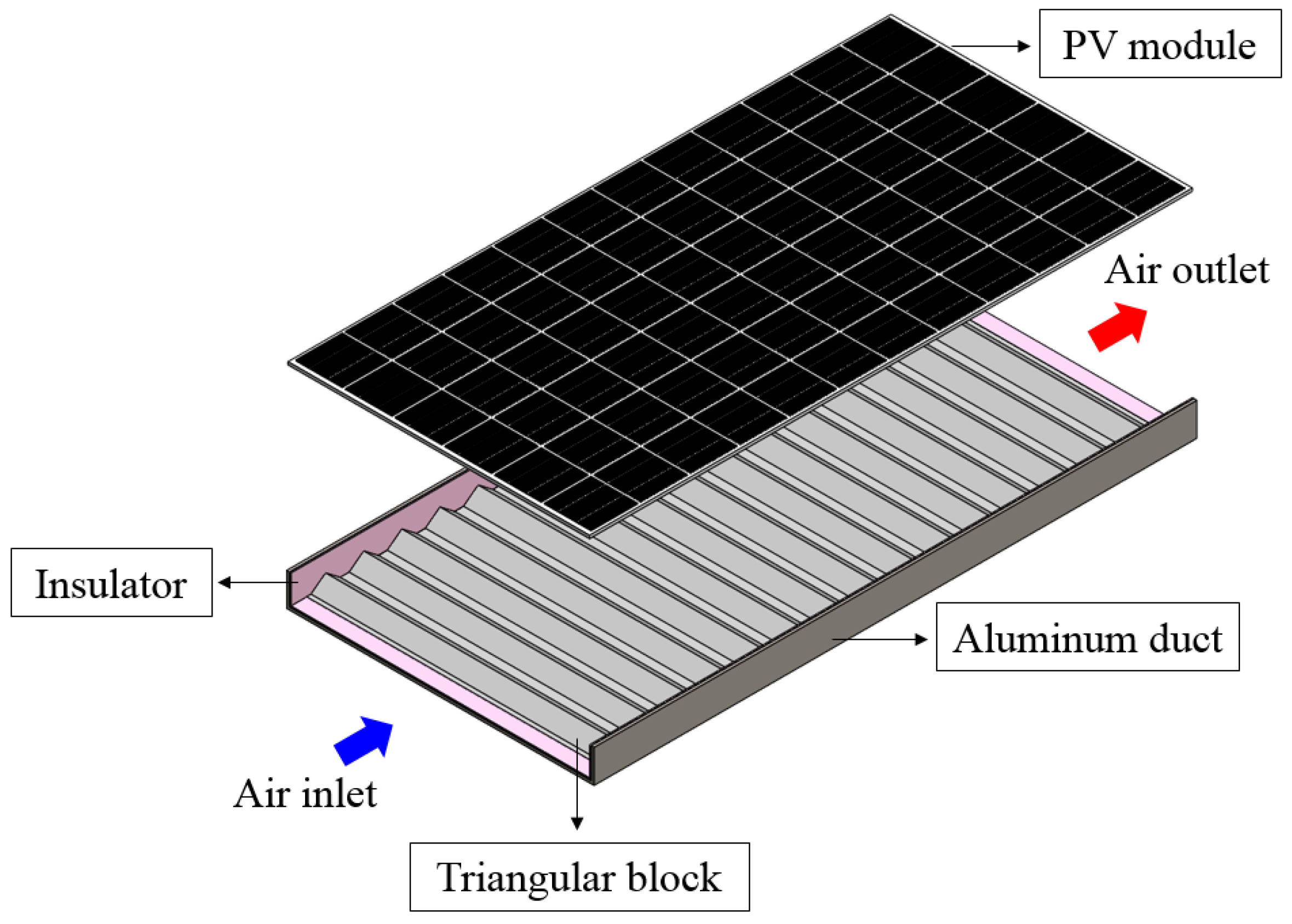

2.1. PVT Air Collector Coupled with a Triangular Block

2.2. Experimental Setup and Methods

3. Results and Discussion

3.1. Weather Conditions

3.2. Electrical Performance

3.3. Thermal Performance

3.4. Total Energy Efficiency

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, S.M.; Kim, J.H.; Kim, J.T. Experimental Study on the Thermal and Electrical Characteristics of an Air-Based Photovoltaic Thermal Collector. Energies 2019, 12, 2661. [Google Scholar] [CrossRef] [Green Version]

- Yazdanpanahi, J.; Sarhaddi, F.; Mahdavi Adeli, M. Experimental Investigation of Exergy Efficiency of a Solar Photovoltaic Thermal (PVT) Water Collector Based on Exergy Losses. Sol. Energy 2015, 118, 197–208. [Google Scholar] [CrossRef]

- Tomar, V.; Tiwari, G.N.; Bhatti, T.S. Performance of Different Photovoltaic-Thermal (PVT) Configurations Integrated on Prototype Test Cells: An Experimental Approach. Energy Convers. Manag. 2017, 154, 394–419. [Google Scholar] [CrossRef]

- Ahmed, O.K.; Mohammed, Z.A. Influence of Porous Media on the Performance of Hybrid PV/Thermal Collector. Renew. Energy 2017, 112, 378–387. [Google Scholar] [CrossRef]

- Wolf, M. Performance analyses of combined heating and photovoltaic power systems for residences. Energy Convers. Manag. 1976, 16, 79–90. [Google Scholar] [CrossRef]

- Slimani, M.E.A.; Amirat, M.; Bahria, S.; Kurucz, I.; Aouli, M.; Sellami, R. Study and Modeling of Energy Performance of a Hybrid Photovoltaic/Thermal Solar Collector: Configuration Suitable for an Indirect Solar Dryer. Energy Convers. Manag. 2016, 125, 209–221. [Google Scholar] [CrossRef]

- Tiwari, S.; Tiwari, G.N.; Al-Helal, I.M. Performance Analysis of Photovoltaic-Thermal (PVT) Mixed Mode Greenhouse Solar Dryer. Sol. Energy 2016, 133, 421–428. [Google Scholar] [CrossRef]

- Fine, J.P.; Friedman, J.; Dworkin, S.B. Detailed Modeling of a Novel Photovoltaic Thermal Cascade Heat Pump Domestic Water Heating System. Renew. Energy 2017, 101, 500–513. [Google Scholar] [CrossRef]

- Nualboonrueng, T.; Tuenpusa, P.; Ueda, Y.; Akisawa, A. Field Experiments of PV-Thermal Collectors for Residential Application in Bangkok. Energies 2012, 5, 1229–1244. [Google Scholar] [CrossRef] [Green Version]

- Jahromi, S.N.; Vadiee, A.; Yaghoubi, M. Exergy and Economic Evaluation of a Commercially Available PVT Collector for Different Climates in Iran. Energy Procedia 2015, 75, 444–456. [Google Scholar] [CrossRef] [Green Version]

- Motamedi, M.; Chung, C.Y.; Rafeie, M.; Hjerrild, N.; Jiang, F.; Qu, H.; Taylor, R.A. Experimental Testing of Hydrophobic Microchannels, with and without Nanofluids, for Solar PVT Collectors. Energies 2019, 14, 3036. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.H.; Hwang, S.G.; Lee, G.H. Efficiency Improvement of a Photovoltaic Thermal (PVT) System Using Nanofluids. Energies 2019, 12, 3063. [Google Scholar] [CrossRef] [Green Version]

- Calise, F.; Figaj, R.D.; Vanoli, L. Experimental and Numerical Analyses of a Flat Plate Photovoltaic/Thermal Solar Collector. Energies 2017, 10, 491. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Zhou, Y.; Li, C.Q.; Lin, Y.; Yang, W.; Zhang, G. Optimization of a New Phase Change Material Integrated Photovoltaic/Thermal Panel with the Active Cooling Technique Using Taguchi Method. Energies 2019, 12, 1022. [Google Scholar] [CrossRef] [Green Version]

- Sarafraz, M.M.; Safaei, M.R.; Leon, A.S.; Tlili, I.; Alkanhal, T.A.; Tian, Z.; Goodarzi, M.; Arjomandi, M. Experimental Investigation on Thermal Performance of a PVT-PCM (Photovoltaic/Thermal) System Cooling with a PCM and Nanofluid. Energies 2019, 12, 2572. [Google Scholar] [CrossRef] [Green Version]

- Herrando, M.; Markides, C.N.; Hellgardt, K. A UK-Based Assessment of Hybrid PV and Solar-Thermal Systems for Domestic Heating and Power: System Performance. Appl. Energy 2014, 122, 288–309. [Google Scholar] [CrossRef] [Green Version]

- Hussain, F.; Othman, M.Y.H.; Sopian, K.; Yatim, B.; Ruslan, H.; Othman, H. Design Development and Performance Evaluation of Photovoltaic/Thermal (PV/T) Air Base Solar Collector. Renew. Sustain. Energy Rev. 2013, 25, 431–441. [Google Scholar] [CrossRef]

- Al-Waeli, A.H.A.; Sopian, K.; Kazem, H.A.; Chaichan, M.T. Photovoltaic/Thermal (PV/T) Systems: Status and Future Prospects. Renew. Sustain. Energy Rev. 2017, 77, 109–130. [Google Scholar] [CrossRef]

- Sopian, K.; Yigit, K.S.; Liu, H.T.; Kakaç, S.; Veziroglu, T.N. Performance Analysis of Photovoltaic Thermal Air Heaters. Energy Convers. Manag. 1996, 37, 1657–1670. [Google Scholar] [CrossRef]

- Othman, M.Y.; Yatim, B.; Sopian, K.; Abu Bakar, M.N. Performance Studies on a Finned Double-Pass Photovoltaic-Thermal (PVT) Solar Collector. Desalination 2007, 209, 43–49. [Google Scholar] [CrossRef]

- Jin, G.L.; Ibrahim, A.; Chean, Y.K.; Daghigh, R.; Ruslan, H.; Mat, S.; Othman, M.Y.; Sopian, K. Evaluation of Single-Pass Photovoltaic-Thermal Air Collector with Rectangle Tunnel Absorber. Am. J. Appl. Sci. 2010, 7, 277–282. [Google Scholar] [CrossRef] [Green Version]

- Teo, H.G.; Lee, P.S.; Hawlader, M.N.A. An Active Cooling System for Photovoltaic Modules. Appl. Energy 2012, 90, 309–315. [Google Scholar] [CrossRef]

- Hussain, F.; Othman, M.Y.H.; Yatim, B.; Ruslan, H.; Sopian, K.; Anuar, Z.; Khairuddin, S. An Improved Design of Photovoltaic/Thermal Solar Collector. Sol. Energy 2015, 122, 885–891. [Google Scholar] [CrossRef]

- Fan, W.; Kokogiannakis, G.; Ma, Z. A Multi-Objective Design Optimisation Strategy for Hybrid Photovoltaic Thermal Collector (PVT)-Solar Air Heater (SAH) Systems with Fins. Sol. Energy 2018, 163, 315–328. [Google Scholar] [CrossRef]

- Choi, H.U.; Choi, K.H. Performance Evaluation of PVT Air Collector Having a Single-Pass Double-Flow Air Channel and Non-Uniform Cross-Section Transverse Rib. Energies 2020, 13, 2203. [Google Scholar] [CrossRef]

- Kim, J.H.; Ahn, J.G.; Kim, J.T. Demonstration of the Performance of an Air-Type Photovoltaic Thermal (PVT) System Coupled with a Heat-Recovery Ventilator. Energies 2016, 9, 728. [Google Scholar] [CrossRef] [Green Version]

- Yu, J.S.; Kim, J.H.; Kim, J.T. A Study on the Thermal Performance of Air-Type BIPVT Collectors Applied to Demonstration Building. Energies 2019, 12, 3120. [Google Scholar] [CrossRef] [Green Version]

- Das, D.; Kalita, P.; Roy, O. Flat Plate Hybrid Photovoltaic- Thermal (PVT) System: A Review on Design and Development. Renew. Sustain. Energy Rev. 2018, 84, 111–130. [Google Scholar] [CrossRef]

- Emmanuel, B.; Yuan, Y.; Maxime, B.; Gaudence, N.; Zhou, J. A Review on the Influence of the Components on the Performance of PVT Modules. Sol. Energy 2021, 226, 365–388. [Google Scholar] [CrossRef]

- Hamzat, A.K.; Sahin, A.Z.; Omisanya, M.I.; Alhems, L.M. Advances in PV and PVT Cooling Technologies: A Review. Sustain. Energy Technol. Assess. 2021, 47, 101360. [Google Scholar] [CrossRef]

- Ramos, A. Photovoltaic-Thermal (PV-T) Systems for Combined Cooling, Heating and Power in Buildings: A Review. Energies 2022, 15, 3021. [Google Scholar] [CrossRef]

- Choi, H.U.; Choi, K.H. CFD Analysis on the Heat Transfer and Fluid Flow of Solar Air Heater Having Transverse Triangular Block at the Bottom of Air Duct. Energies 2020, 13, 1099. [Google Scholar] [CrossRef] [Green Version]

- Choi, H.U.; Kim, Y.B.; Son, C.H.; Yoon, J.I.; Choi, K.H. Experimental Study on the Performance of Heat Pump Water Heating System Coupled with Air Type PV/T Collector. Appl. Therm. Eng. 2020, 178, 115427. [Google Scholar] [CrossRef]

- Ong, K.S. Thermal Performance of Solar Air Heaters: Mathematical Model and Solution Procedure. Sol. Energy 1995, 55, 93–109. [Google Scholar] [CrossRef]

- Fudholi, A.; Sopian, K.; Othman, M.Y.; Ruslan, M.H.; Bakhtyar, B. Energy Analysis and Improvement Potential of Finned Double-Pass Solar Collector. Energy Convers. Manag. 2013, 75, 234–240. [Google Scholar] [CrossRef]

- Fudholi, A.; Zohri, M.; Jin, G.L.; Ibrahim, A.; Yen, C.H.; Othman, M.Y.; Ruslan, M.H.; Sopian, K. Energy and Exergy Analyses of Photovoltaic Thermal Collector with ∇-Groove. Sol. Energy 2018, 159, 742–750. [Google Scholar] [CrossRef]

- Slimani, M.E.A.; Amirat, M.; Kurucz, I.; Bahria, S.; Hamidat, A.; Chaouch, W.B. A Detailed Thermal-Electrical Model of Three Photovoltaic/Thermal (PV/T) Hybrid Air Collectors and Photovoltaic (PV) Module: Comparative Study under Algiers Climatic Conditions. Energy Convers. Manag. 2017, 133, 458–476. [Google Scholar] [CrossRef]

- Sarhaddi, F.; Farahat, S.; Ajam, H.; Behzadmehr, A.; Mahdavi Adeli, M. An Improved Thermal and Electrical Model for a Solar Photovoltaic Thermal (PVT) Air Collector. Appl. Energy 2010, 87, 2328–2339. [Google Scholar] [CrossRef]

- Sarhaddi, F.; Farahat, S.; Ajam, H.; Behzadmehr, A. Exergetic Performance Assessment of a Solar Photovoltaic Thermal (PVT) Air Collector. Energy Build. 2010, 42, 2184–2199. [Google Scholar] [CrossRef]

- Amori, K.E.; Taqi Al-Najjar, H.M. Analysis of Thermal and Electrical Performance of a Hybrid (PVT) Air Based Solar Collector for Iraq. Appl. Energy 2012, 98, 384–395. [Google Scholar] [CrossRef]

- Senthilraja, S.; Gangadevi, R.; Marimuthu, R.; Baskaran, M. Performance Evaluation of Water and Air Based PVT Solar Collector for Hydrogen Production Application. Int. J. Hydrogen Energy 2020, 45, 7498–7507. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Electrical efficiency under standard conditions (%) | 17.37 |

| Voltage at maximum power point (V) | 37.7 |

| Current at maximum power point (A) | 9.56 |

| Maximum power output (W) | 360 |

| Temperature coefficient (%/K) | −0.41 |

| Cell size (mm) | 161.7 × 161.7 |

| Number of the cell (ea) | 6 × 12 |

| Parameters | Value | |

|---|---|---|

| Aluminum duct | Length (mm) | 2027 |

| Width (mm) | 1030 | |

| Height (mm) | 100 | |

| Triangular block | Length (mm) | 97 |

| Width (mm) | 1000 | |

| Height (mm) | 37 | |

| Pitch (mm) | 126.5 | |

| Equipment | Model | Accuracy |

|---|---|---|

| Thermocouple | T-type | ±1 °C |

| Voltage meter | MT4Y-DV-43 | ±0.56% |

| Ampere meter | MT4Y-DA-43 | ±0.56% |

| Anemometer | Kanomax 6531-2G | ±0.015 m/s |

| Pyranometer | MS-802 | ±2% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, H.-U.; Choi, K.-H. Performance Evaluation of PVT Air Collector Coupled with a Triangular Block in Actual Climate Conditions in Korea. Energies 2022, 15, 4150. https://doi.org/10.3390/en15114150

Choi H-U, Choi K-H. Performance Evaluation of PVT Air Collector Coupled with a Triangular Block in Actual Climate Conditions in Korea. Energies. 2022; 15(11):4150. https://doi.org/10.3390/en15114150

Chicago/Turabian StyleChoi, Hwi-Ung, and Kwang-Hwan Choi. 2022. "Performance Evaluation of PVT Air Collector Coupled with a Triangular Block in Actual Climate Conditions in Korea" Energies 15, no. 11: 4150. https://doi.org/10.3390/en15114150

APA StyleChoi, H.-U., & Choi, K.-H. (2022). Performance Evaluation of PVT Air Collector Coupled with a Triangular Block in Actual Climate Conditions in Korea. Energies, 15(11), 4150. https://doi.org/10.3390/en15114150