A Critical Review on the Use of Shallow Geothermal Energy Systems for Heating and Cooling Purposes

Abstract

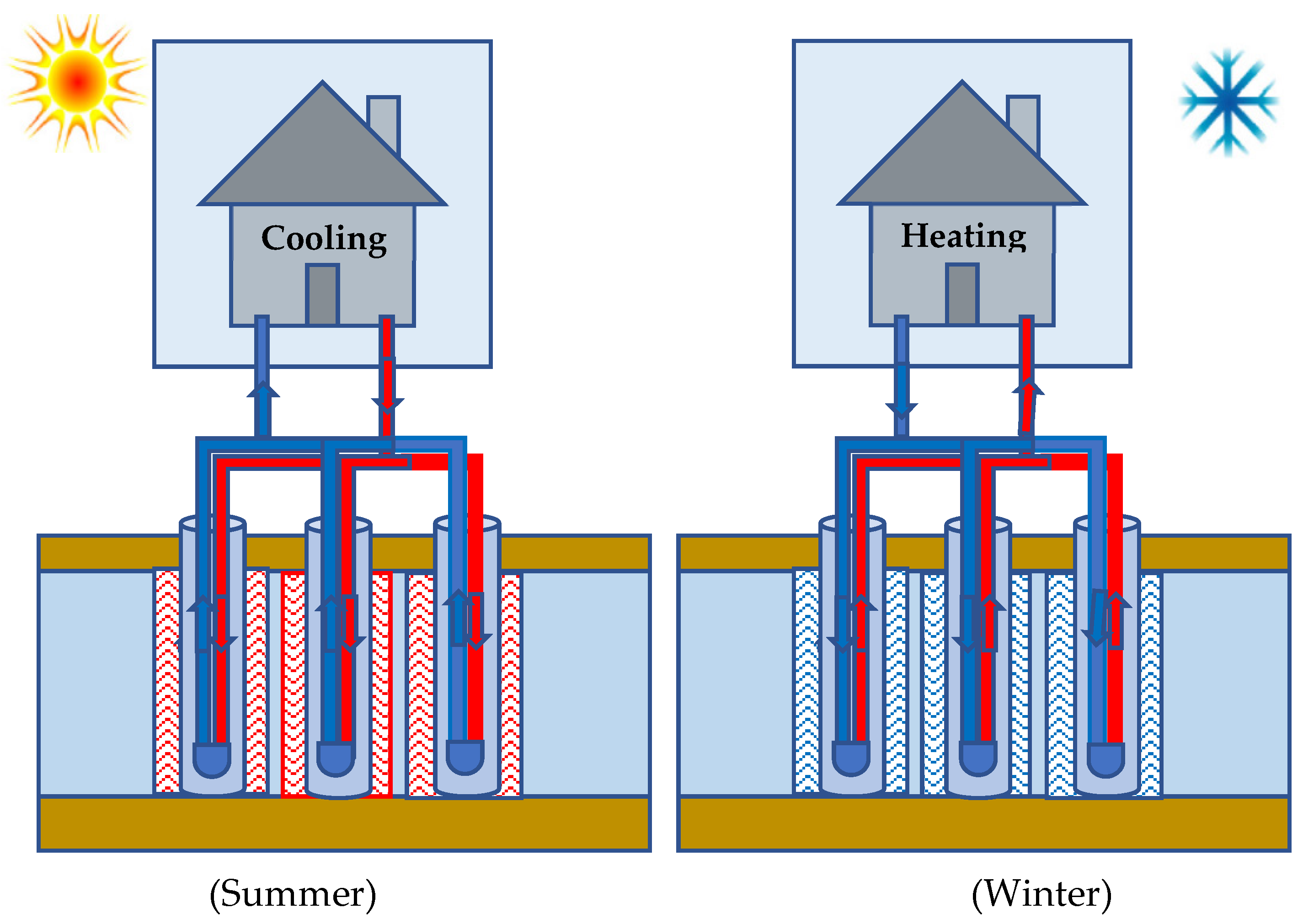

:1. Introduction

2. State of the Art and Technological Advancements

2.1. Rock Thermal Conductivity

2.2. Innovative Borehole Heat Exchanger Structures

2.3. Grouting Materials

2.4. Bore Heat Exchanger Collector

2.5. Heat Carrier Fluids

2.6. Underground Thermal Energy Storages (UTES)

3. Techno-Economic Analysis

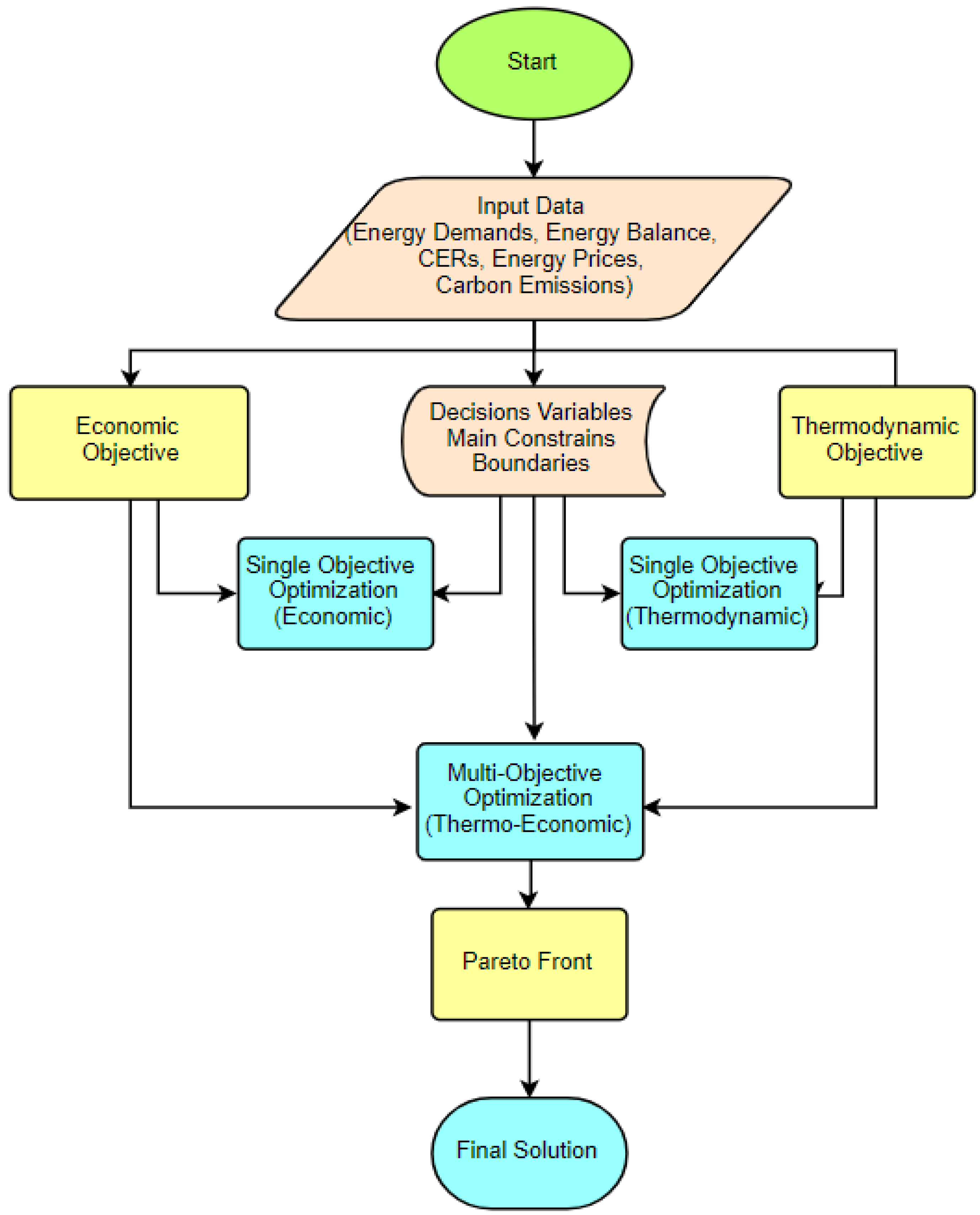

4. Optimization and Modeling

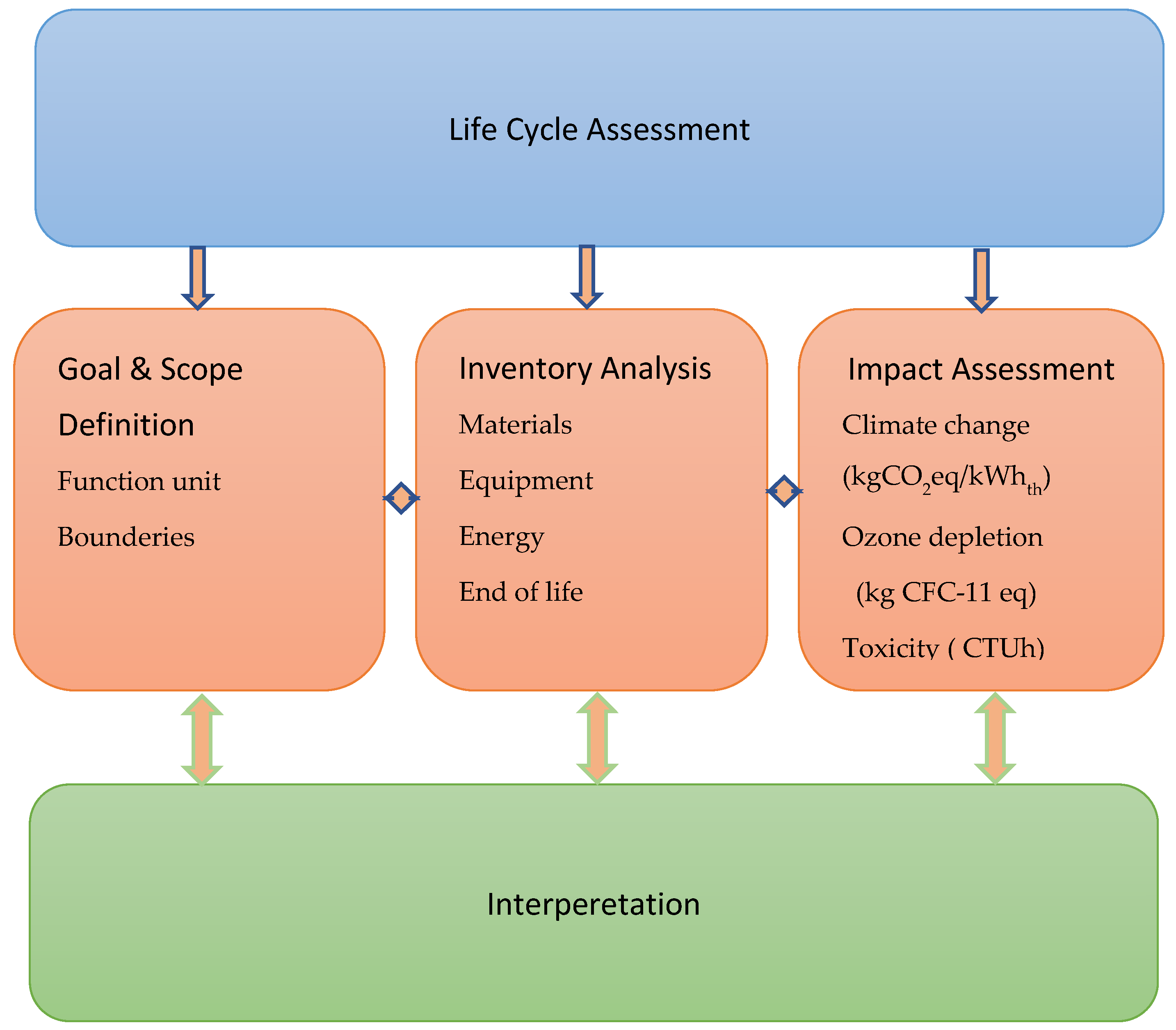

5. Life Cycle Assessment

6. Conclusions

- (1)

- GSHP has one of the highest efficiencies among the other renewable energy systems with efficiency in ranges of 300–500%. By increasing the value of heat transfer in BHE, the efficiency of the GSHP system is increased. GSHPs have been shown to be both profitable and capable of reducing CO2 emissions by numerous researchers, who demonstrated that 26–50% energy reduction and 65–85% emission reduction is achievable when using GSHPs compared to combustion-based fossil fuel systems. In addition, GSHPs have the advantage of being used as a heating or cooling system, depending on the weather, with lower yearly operation and maintenance (O&M) costs compared to other traditional heating systems.

- (2)

- The thermal conductivity of the grout and collector has a significant impact on the borehole thermal resistance. Adding thermally enhanced materials such as graphite to grout or pipe materials improves their thermal properties and thus reduces the borehole thermal resistance. Laboratory investigations have shown the great potential for graphite, sand, and magnesium powder additives to increase the cement and bentonite conductivity to 1.5 to 5 Wm−1K−1. Despite the development of increasing the thermal conductivity of the grout and collector materials used in borehole completion, there is still a gap between the theoretical optimum and the commercially available products. Modeling has shown a continuous reduction in BHE’s thermal resistance, with the collector’s thermal conductivities up to 4–5 Wm−1K−1, while commercial collectors have thermal conductivities less than 1 Wm−1K−1. This is also the case for grout materials, which have a commercial product with a maximum thermal conductivity of 2.8 Wm−1K−1. Many researchers have shown the significant effect of using enhanced materials to reduce the borehole thermal resistance and increase the thermal exchange rate. However, investigations of BHEs’ design length have reduced and the economic benefits of using enhanced materials remain scarce.

- (3)

- BTES is the ideal alternative for seasonal cooling and heat energy storage due to the high thermal capacity of the ground. BTES can store surplus solar, and waste the thermal energy collected in the summer that can be used in the winter. BTES is a dispatchable renewable energy source, available everywhere, that can reduce the undesired effects of the intermittency of the other renewable energy sources. BTES should be designed so that its internal volume and external surface areas are maximized. Therefore, equidimensional cylindrical or cubic arrays of the BTES will perform best. For BTES systems, geological conditions are not crucial, unlike ATES systems, which depend heavily on the geology of the subsurface layers and the type of aquifer.

- (4)

- The high upfront cost of shallow geothermal energy systems creates financing obstacles for households. GSHPs without subsidy are more expensive heating solutions compared to fuel-based heating systems. To make GSHP compete with gas, it is necessary to create balanced taxation levels between electricity and gas. Increased prices or carbon taxation on fossil fuels will likely have a direct impact on GSHPs’ ability to compete against gas boilers. The cost-effectiveness of GSHP could be improved in the future through several driving factors, including market maturity, increased efficiency, access to cheap electricity, and subsidy programs.

- (5)

- Increasing the thermal properties of materials (grout, collector, and heat-carrier fluid) and implementing innovative configurations could improve BHE performance. The extra costs associated with using such materials must be justified by their reasonable effect on BHE efficiency. The optimal decision should therefore consider efficiency alongside the total costs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation | Full Title |

| ATES | Aquifer Thermal Energy Storage |

| BHE | Borehole Heat Exchanger |

| BTES | Boreholes Thermal Energy Storage |

| Capex | Capital Expenditure |

| CBA | Cost Benefits Analysis |

| COP | Coefficient of Performance |

| DHW | Domestic Hot Water |

| GHG | Greenhouse Gas |

| GSHP | Ground Source Heat Pump |

| IEA | International Energy Agency |

| IRR | Internal Rate of Return |

| LCOE | Levelized Cost of Energy |

| LCOH | Levelized Cost of Heat |

| MOGA | Multi-Objective Genetic Algorithm |

| MRE | Mean Relative Error |

| NPV | Net Present Value |

| Opex | Operating Expenditure |

| O&M | Operation And Maintenance |

| PBP | Payback Period |

| PE | Polyethylene |

| PP | Polypropylene |

| PU | Polyurethane |

| PVC | Polyvinylchloride |

| UTES | Under Ground Thermal Energy Storage |

| RBDO | Reliability-Based Design Optimization |

| RMSE | Root Mean Squared Error |

| TRT | Thermal Response Test |

References

- Secretariat, United Nations Framework Convention on Climate Change. Report of the Conference of the Parties on Its Twenty-First; United Nations Framework Convention on Climate Change: Bonn, Germany, 2015. [Google Scholar]

- International Energy Agency. Renewables. 2019. Available online: www.iea.org/renewables2019 (accessed on 8 January 2022).

- European Union. An EU Strategy on Heating and Cooling; European Union: Brussels, Belgium, 2016. [Google Scholar]

- Osička, J.; Kemmerzell, J.; Zoll, M.; Lehotský, L.; Černoch, F.; Knodt, M. What’s next for the European coal heartland? Exploring the future of coal as presented in German, Polish and Czech press. Energy Res. Soc. Sci. 2020, 61, 101316. [Google Scholar] [CrossRef]

- Toleikyte, A.; Carlsson, J.; European Commission. Joint Research Centre. In Assessment of Heating and Cooling Related Chapters of the National Energy and Climate Plans (NECPs); Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- Institute for Renewable Energy. Implementation of Renewable Energy Sources in District Heating Systems in Poland; Institute for Renewable Energy: Bozen, Italy, 2018. [Google Scholar]

- Hakkaki-Fard, A.; Aidoun, Z.; Ouzzane, M. Applying refrigerant mixtures with thermal glide in cold climate air-source heat pumps. Appl. Therm. Eng. 2014, 62, 714–722. [Google Scholar] [CrossRef]

- Sayyaadi, H.; Amlashi, E.H.; Amidpour, M. Multi-objective optimization of a vertical ground source heat pump using evolutionary algorithm. Energy Convers. Manag. 2009, 50, 2035–2046. [Google Scholar] [CrossRef]

- Javadi, H.; Ajarostaghi, S.S.M.; Rosen, M.A.; Pourfallah, M. Performance of ground heat exchangers: A comprehensive review of recent advances. Energy 2019, 178, 207–233. [Google Scholar] [CrossRef]

- Gamage, K.J. Numerical Methodology for Feasibility Analysis of Ground Source Heat Pumps. Master’s Thesis, Middle East Technical University, Ankara, Türkiye, 2014. Available online: https://www.researchgate.net/publication/265250440 (accessed on 8 January 2022).

- Sliwa, T.; Sapińska-Śliwa, A.; Gonet, A.; Kowalski, T.; Sojczyńska, A. Geothermal Boreholes in Poland—Overview of the Current State of Knowledge. Energies 2021, 14, 3251. [Google Scholar] [CrossRef]

- Badenes, B.; Pla, M.M.; Magraner, T.; Soriano, J.; Urchueguía, J.F. Theoretical and Experimental Cost–Benefit Assessment of Borehole Heat Exchangers (BHEs) According to Working Fluid Flow Rate. Energies 2020, 13, 4925. [Google Scholar] [CrossRef]

- Sliwa, T.; Leśniak, P.; Sapińska-Śliwa, A.; Rosen, M.A. Effective Thermal Conductivity and Borehole Thermal Resistance in Selected Borehole Heat Exchangers for the Same Geology. Energies 2022, 15, 1152. [Google Scholar] [CrossRef]

- Sapińska-Sliwa, A.; Rosen, M.A.; Gonet, A.; Kowalczyk, J.; Sliwa, T. A New Method Based on Thermal Response Tests for Determining Effective Thermal Conductivity and Borehole Resistivity for Borehole Heat Exchangers. Energies 2019, 12, 1072. [Google Scholar] [CrossRef]

- Sliwa, T.; Gołas, A.; Wołoszyn, J.; Gonet, A. Numerical model of borehole heat exchanger in ansys CFX software. Arch. Min. Sci. 2012, 57, 375–390. [Google Scholar] [CrossRef]

- Koenig, A. Thermal resistance of borehole heat exchangers composed of multiple loops and custom shapes. Geotherm. Energy 2015, 3, 933. [Google Scholar] [CrossRef]

- Lund, J.W.; Toth, A.N. Direct utilization of geothermal energy 2020 worldwide review. Geothermics 2021, 90, 101915. [Google Scholar] [CrossRef]

- García, L.S.; Paardekooper, S.; Thellufsen, J.Z.; Djørup, S.R. Towards a Decarbonised Heating and Cooling Sector in Europe Unlocking the Potential of Energy Efficiency and District Energy; Aalborg Universitet: Aalborg, Denmark, 2019. [Google Scholar]

- Galindo Fernández, M.; Bacquet, A.; Bensadi, S.; Morisot, P.; Oger, A.; European Commission; Joint Research Centre. Integrating Renewable and Waste Heat and Cold Sources into District Heating and Cooling Systems: Case Studies Analysis, Replicable Key Success Factors and Potential Policy Implications; Institute for Renewable Energy: Bozen, Italy, 2021. [Google Scholar]

- Garabetian, T. EGEC Geothermal Market Report; European Geothermal Energy Council: Bruxelles, Belgium, 2021. [Google Scholar]

- Meek, C. Heat pumps and UK’s decarbonisation: Lessons from an Ofgem dataset of more than 2000 domestic installations. In Context-Methodology-Analysis-Discussion-Recommendations; Spring 2021; RECC: London, UK, 2021. [Google Scholar]

- Longa, F.D.; Nogueira, L.P.; Limberger, J.; van Wees, J.-D.; van der Zwaan, B. Scenarios for geothermal energy deployment in Europe. Energy 2020, 206, 118060. [Google Scholar] [CrossRef]

- Zhang, Y.; Hao, S.; Yu, Z.; Fang, J.; Zhang, J.; Yu, X. Comparison of test methods for shallow layered rock thermal conductivity between in situ distributed thermal response tests and laboratory test based on drilling in northeast China. Energy Build. 2018, 173, 634–648. [Google Scholar] [CrossRef]

- Santa, G.D.; Galgaro, A.; Sassi, R.; Cultrera, M.; Scotton, P.; Mueller, J.; Bertermann, D.; Mendrinos, D.; Pasquali, R.; Perego, R.; et al. An updated ground thermal properties database for GSHP applications. Geothermics 2020, 85, 101758. [Google Scholar] [CrossRef]

- Fujii, H.; Okubo, H.; Nishi, K.; Itoi, R.; Ohyama, K.; Shibata, K. An improved thermal response test for U-tube ground heat exchanger based on optical fiber thermometers. Geothermics 2009, 38, 399–406. [Google Scholar] [CrossRef]

- Jia, G.; Tao, Z.; Meng, X.; Ma, C.; Chai, J.; Jin, L. Review of effective thermal conductivity models of rock-soil for geothermal energy applications. Geothermics 2019, 77, 1–11. [Google Scholar] [CrossRef]

- Horai, K.-I.; Simmons, G. Thermal conductivity of rock-forming minerals. Earth Planet. Sci. Lett. 1969, 6, 359–368. [Google Scholar] [CrossRef]

- Null, J. Performance Investigation of Multiple-Tube Ground Heat Exchangers for Ground-Source Heat Pump. Am. J. Energy Eng. 2014, 2, 103. [Google Scholar] [CrossRef]

- Liu, X.; Xiao, Y.; Inthavong, K.; Tu, J. Experimental and numerical investigation on a new type of heat exchanger in ground source heat pump system. Energy Effic. 2015, 8, 845–857. [Google Scholar] [CrossRef]

- Raymond, J.; Mercier, S.; Nguyen, L. Designing coaxial ground heat exchangers with a thermally enhanced outer pipe. Geotherm. Energy 2015, 3, 7. [Google Scholar] [CrossRef]

- Chang, K.S.; Kim, M.J. Thermal performance evaluation of vertical U-loop ground heat exchanger using in-situ thermal response test. Renew. Energy 2016, 87, 585–591. [Google Scholar] [CrossRef]

- Jahanbin, A. Thermal performance of the vertical ground heat exchanger with a novel elliptical single U-tube. Geothermics 2020, 86, 101804. [Google Scholar] [CrossRef]

- Badenes, B.; Sanner, B.; Pla, M.M.; Cuevas, J.M.; Bartoli, F.; Ciardelli, F.; González, R.M.; Ghafar, A.N.; Fontana, P.; Zuñiga, L.L.; et al. Development of advanced materials guided by numerical simulations to improve performance and cost-efficiency of borehole heat exchangers (BHEs). Energy 2020, 201, 117628. [Google Scholar] [CrossRef]

- Dehkordi, S.E.; Schincariol, R.A. Effect of thermal-hydrogeological and borehole heat exchanger properties on performance and impact of vertical closed-loop geothermal heat pump systems. Appl. Hydrogeol. 2014, 22, 189–203. [Google Scholar] [CrossRef]

- Lee, C.; Lee, K.; Choi, H.; Choi, H.-P. Characteristics of thermally-enhanced bentonite grouts for geothermal heat exchanger in South Korea. Sci. China Technol. Sci. 2010, 53, 123–128. [Google Scholar] [CrossRef]

- Mahmoud, M.; Ramadan, M.; Pullen, K.; Abdelkareem, M.A.; Wilberforce, T.; Olabi, A.-G.; Naher, S. A review of grout materials in geothermal energy applications. Int. J. Thermofluids 2021, 10, 100070. [Google Scholar] [CrossRef]

- Kim, D.; Oh, S. Relationship between the thermal properties and degree of saturation of cementitious grouts used in vertical borehole heat exchangers. Energy Build. 2019, 201, 1–9. [Google Scholar] [CrossRef]

- Jobmann, M.; Buntebarth, G. Influence of graphite and quartz addition on the thermo–physical properties of bentonite for sealing heat-generating radioactive waste. Appl. Clay Sci. 2009, 44, 206–210. [Google Scholar] [CrossRef]

- Berktaş, İ. Facile Synthesis of Graphite-and Graphene-Based Hybrid Additives by Silanization and Effects of These Additives on the Thermal Conductivity of Cementitious Grouts Used in Shallow Geothermal Systems. Ph.D. Thesis, Sabanci University, Tuzla, Türkiye, 2020. [Google Scholar]

- Delaleux, F.; Py, X.; Olives, R.; Dominguez, A. Enhancement of geothermal borehole heat exchangers performances by improvement of bentonite grouts conductivity. Appl. Therm. Eng. 2012, 33, 92–99. [Google Scholar] [CrossRef]

- Bae, S.; Nam, Y.; Choi, J.; Lee, K.; Choi, J. Analysis on Thermal Performance of Ground Heat Exchanger According to Design Type Based on Thermal Response Test. Energies 2019, 12, 651. [Google Scholar] [CrossRef]

- Zeng, H.; Diao, N.; Fang, Z. Heat transfer analysis of boreholes in vertical ground heat exchangers. Int. J. Heat Mass Transf. 2003, 46, 4467–4481. [Google Scholar] [CrossRef]

- Śliwa, T.; Rosen, M. Efficiency analysis of borehole heat exchangers as grout varies via thermal response test simulations. Geothermics 2017, 69, 132–138. [Google Scholar] [CrossRef]

- Hellström, G. THERMAL Performance of Borehole Heat Exchangers. In Proceedings of the Stockton International Geothermal Conference, Stockton, NJ, USA, 16–17 March 1998. [Google Scholar]

- Sliwa, T.; Sapińska-Śliwa, A.; Wysogląd, T.; Kowalski, T.; Konopka, I. Strength Tests of Hardened Cement Slurries for Energy Piles, with the Addition of Graphite and Graphene, in Terms of Increasing the Heat Transfer Efficiency. Energies 2021, 14, 1190. [Google Scholar] [CrossRef]

- Sliwa, T.; Kowalski, T.; Cekus, D.; Sapińska-Śliwa, A. Research on Fresh and Hardened Sealing Slurries with the Addition of Magnesium Regarding Thermal Conductivity for Energy Piles and Borehole Heat Exchangers. Energies 2021, 14, 5119. [Google Scholar] [CrossRef]

- Liu, X.; Spitler, J.D.; Qu, M.; Shi, L. Recent Developments in the Design of Vertical Borehole Ground Heat Exchangers for Cost Reduction and Thermal Energy Storage. J. Energy Resour. Technol. 2021, 143, 100803. [Google Scholar] [CrossRef]

- Mehrjerdi, A.K.; Naudin, S.; Skrifvars, M. Development of Polyolefin Compound and Post-Polymerization Treatments for Ground Heat Exchangers; SHAREOK: Norman, OK, USA, 2017. [Google Scholar]

- Kurevija, T.; Kalantar, A.; Macenić, M.; Hranić, J. Investigation of Steady-State Heat Extraction Rates for Different Borehole Heat Exchanger Configurations from the Aspect of Implementation of New TurboCollector™ Pipe System Design. Energies 2019, 12, 1504. [Google Scholar] [CrossRef]

- Mehrjerdi, A.K.; Åkesson, D.; Skrifvars, M. Influence of talc fillers on bimodal polyethylene composites for ground heat exchangers. J. Appl. Polym. Sci. 2020, 137, 49220. [Google Scholar] [CrossRef]

- Mehrjerdi, A.K.; Adl-Zarrabi, B.; Cho, S.-W.; Skrifvars, M. Mechanical and thermo-physical properties of high-density polyethylene modified with talc. J. Appl. Polym. Sci. 2013, 129, 2128–2138. [Google Scholar] [CrossRef]

- Mehrjerdi, A.K. Thesis for the Degree of Doctor of Philosophy Thermally Conductive High-Density Polyethylene Composites for Ground Heat Exchangers. 2020. Available online: http://urn.kb.se/resolve?urn=urn:nbn:se:hb:diva-23698 (accessed on 8 January 2022).

- Mehrjerdi, A.K.; Bashir, T.; Skrifvars, M. Melt rheology and extrudate swell properties of talc filled polyethylene compounds. Heliyon 2020, 6, e04060. [Google Scholar] [CrossRef]

- Emmi, G.; Zarrella, A.; De Carli, M.; Donà, M.; Galgaro, A. Energy performance and cost analysis of some borehole heat exchanger configurations with different heat-carrier fluids in mild climates. Geothermics 2017, 65, 158–169. [Google Scholar] [CrossRef]

- Melinder, Å. Thermophysical Properties of Aqueous Solutions Used as Secondary Working Fluids. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2007. [Google Scholar]

- Klotzbücher, T.; Kappler, A.; Straub, K.L.; Haderlein, S.B. Biodegradability and groundwater pollutant potential of organic anti-freeze liquids used in borehole heat exchangers. Geothermics 2007, 36, 348–361. [Google Scholar] [CrossRef]

- Casasso, A.; Sethi, R. Efficiency of closed loop geothermal heat pumps: A sensitivity analysis. Renew. Energy 2014, 62, 737–746. [Google Scholar] [CrossRef]

- Kavanaugh, S.P.; Rafferty, K.D.; Kavanaugh, S.P. Geothermal Heating and Cooling: Design of Ground-Source Heat Pump Systems; ASHRAE: Peachtree Corners, GA, USA, 2014. [Google Scholar]

- Patel, D.M. Brines–A Large Scale Cooling Solution|Cooling India Monthly Business Magazine on the HVACR Business|Green HVAC Industry|Heating, Ventilation, Air conditioning and Refrigeration News Magazine Updates, Articles, Publications on HVACR Business Industry|HVACR Business Magazine. Cooling India, 15 February 2016. [Google Scholar]

- Sundar, L.S.; Ramana, E.V.; Singh, M.K.; Sousa, A. Thermal conductivity and viscosity of stabilized ethylene glycol and water mixture Al2O3 nanofluids for heat transfer applications: An experimental study. Int. Commun. Heat Mass Transf. 2014, 56, 86–95. [Google Scholar] [CrossRef]

- Wei, X.; Li, N.; Peng, J.; Cheng, J.; Su, L.; Hu, J. Analysis of the Effect of the CaCl2 Mass Fraction on the Efficiency of a Heat Pump Integrated Heat-Source Tower Using an Artificial Neural Network Model. Sustainability 2016, 8, 410. [Google Scholar] [CrossRef]

- Herri, J.M.; Darbouret, M.; Herr, J.-M. Rheological Study of Two-Phase Secondary Fluids for Refrigeration and Air Conditioning. Mines Saint-Etienne. 2013. Available online: https://hal.archives-ouvertes.fr/hal-00841701 (accessed on 8 January 2022).

- Song, S.; Peng, C. Viscosities of Binary and Ternary Mixtures of Water, Alcohol, Acetone, and Hexane. J. Dispers. Sci. Technol. 2008, 29, 1367–1372. [Google Scholar] [CrossRef]

- Conde, M. Thermophysical Properties of Brines Models; Conde Engineering: Zurich, Switzerland, 2011. [Google Scholar]

- Available online: https://www.vapcocompany.com/glycol-calculator/ (accessed on 20 March 2022).

- Available online: https://sciencelab.com/ (accessed on 20 March 2022).

- Tarodiya, R.; Verma, V.; Thangavel, S. A study on utilization of ground source energy for space heating using a nanofluid as a heat carrier. Heat Transf. 2021, 50, 3842–3860. [Google Scholar] [CrossRef]

- Pérez-Tavernier, J.; Vallejo, J.; Cabaleiro, D.; Fernández-Seara, J.; Lugo, L. Heat transfer performance of a nano-enhanced propylene glycol:water mixture. Int. J. Therm. Sci. 2019, 139, 413–423. [Google Scholar] [CrossRef]

- Sui, D.; Langåker, V.H.; Yu, Z. Investigation of Thermophysical Properties of Nanofluids for Application in Geothermal Energy. Energy Procedia 2017, 105, 5055–5060. [Google Scholar] [CrossRef]

- Sun, X.-H.; Yan, H.; Massoudi, M.; Chen, Z.-H.; Wu, W.-T. Numerical Simulation of Nanofluid Suspensions in a Geothermal Heat Exchanger. Energies 2018, 11, 919. [Google Scholar] [CrossRef]

- Du, R.; Jiang, D.; Wang, Y. Numerical Investigation of the Effect of Nanoparticle Diameter and Sphericity on the Thermal Performance of Geothermal Heat Exchanger Using Nanofluid as Heat Transfer Fluid. Energies 2020, 13, 1653. [Google Scholar] [CrossRef]

- Du, R.; Jiang, D.; Wang, Y.; Shah, K.W. An experimental investigation of CuO/water nanofluid heat transfer in geothermal heat exchanger. Energy Build. 2020, 227, 110402. [Google Scholar] [CrossRef]

- Doerte, L.; Wolf-Dieter, S.; Rainer, T. Advances in thermal energy storage development at the German Aerospace Center DLR). Energy Storage Sci. Technol. 2012, 1, 13. [Google Scholar]

- Skarphagen, H.; Banks, D.; Frengstad, B.S.; Gether, H. Design Considerations for Borehole Thermal Energy Storage (BTES): A Review with Emphasis on Convective Heat Transfer. Geofluids 2019, 2019, 1–26. [Google Scholar] [CrossRef]

- Hendriks, M.; Snijders, A.; Boid, N. Underground thermal energy storage for efficient heating and cooling of buildings. In Proceedings of the 1st International Conference on Industrialised, Integrated, Intelligent Construction, Loughborough, UK, 14–16 May 2008; p. 358. [Google Scholar]

- Guo, F.; Zhu, X.; Zhang, J.; Yang, X. Large-scale living laboratory of seasonal borehole thermal energy storage system for urban district heating. Appl. Energy 2020, 264, 114763. [Google Scholar] [CrossRef]

- Dahash, A.; Ochs, F.; Janetti, M.B.; Streicher, W. Advances in seasonal thermal energy storage for solar district heating applications: A critical review on large-scale hot-water tank and pit thermal energy storage systems. Appl. Energy 2019, 239, 296–315. [Google Scholar] [CrossRef]

- Sovacool, B. The intermittency of wind, solar, and renewable electricity generators: Technical barrier or rhetorical excuse? Util. Policy 2009, 17, 288–296. [Google Scholar] [CrossRef]

- Schmidt, T.; Pauschinger, T.; Sørensen, P.A.; Snijders, A.; Djebbar, R.; Boulter, R.; Thornton, J. Design Aspects for Large-scale Pit and Aquifer Thermal Energy Storage for District Heating and Cooling. Energy Procedia 2018, 149, 585–594. [Google Scholar] [CrossRef]

- Nordell, B. A Borehole Heat Store in Rock at the University of Luleaa; ETDEWeb: Oak Ridge, TN, USA, 1989. [Google Scholar]

- Chuard, P.; Hadorn, J.C. Central Solar Heating Plants with Seasonal Storage Heat Storage Systems Concepts Engineering Data and Compilation of Projects; ETDEWeb: Oak Ridge, TN, USA, 1983. [Google Scholar]

- Seiwald, H.; Hahne, E.; Reus, M. Underground seasonal heat storage for a solar heating system in Neckarsulm, Germany. Bull. Hydrogeol. 1999, 17, 349–357. [Google Scholar]

- Xu, L.; Torrens, J.I.; Guo, F.; Yang, X.; Hensen, J. Application of large underground seasonal thermal energy storage in district heating system: A model-based energy performance assessment of a pilot system in Chifeng, China. Appl. Therm. Eng. 2018, 137, 319–328. [Google Scholar] [CrossRef]

- Midttømme, K.; Hauge, A.; Grini, R.S.; Stene, J.; Skarphagen, H. Underground Thermal Energy Storage (UTES) with Heat Pumps in Norway. 2009. Available online: https://www.researchgate.net/publication/264846817 (accessed on 20 March 2022).

- Hammock, C.W.; Sullens, J.S. Coupling Geothermal Heat Pumps with Underground Seasonal Thermal Energy Storage; Andrews, Hammock and Powell, Inc.: Macon, GA, USA, 2017. [Google Scholar]

- Burk, C. Techno-Economic Modeling for New Technology Development. Chem. Eng. Prog. 2017, 114, 43–52. [Google Scholar]

- Giacomella, L. Techno-Economic Assessment (TEA) and Life Cycle Costing Analysis (LCCA): Discussing methodological steps and integrability. Insights Reg. Dev. 2021, 3, 176–197. [Google Scholar] [CrossRef]

- Zhou, K.; Mao, J.; Li, Y.; Zhang, H. Performance assessment and techno-economic optimization of ground source heat pump for residential heating and cooling: A case study of Nanjing, China. Sustain. Energy Technol. Assess. 2020, 40, 100782. [Google Scholar] [CrossRef]

- Wang, G.; Wang, H.; Kang, Z.; Feng, G. Data-Driven Optimization for Capacity Control of Multiple Ground Source Heat Pump System in Heating Mode. Energies 2020, 13, 3595. [Google Scholar] [CrossRef]

- Mahmud, R.; Moni, S.M.; High, K.; Carbajales-Dale, M. Integration of techno-economic analysis and life cycle assessment for sustainable process design—A review. J. Clean. Prod. 2021, 317, 128247. [Google Scholar] [CrossRef]

- Turhan, C.; Kazanasmaz, T.; Uygun, I.E.; Ekmen, K.E.; Akkurt, G.G. Comparative study of a building energy performance software (KEP-IYTE-ESS) and ANN-based building heat load estimation. Energy Build. 2014, 85, 115–125. [Google Scholar] [CrossRef]

- Farzanehkhameneh, P.; Soltani, M.; Kashkooli, F.M.; Ziabasharhagh, M. Optimization and energy-economic assessment of a geothermal heat pump system. Renew. Sustain. Energy Rev. 2020, 133, 110282. [Google Scholar] [CrossRef]

- Ilisei, G.; Catalina, T.; Gavriliuc, R. Sensitivity analysis using simulations for a ground source heat pump—Implementation on a solar passive house. E3S Web Conf. 2019, 111, 01070. [Google Scholar] [CrossRef]

- Pawel, I. The Cost of Storage—How to Calculate the Levelized Cost of Stored Energy (LCOE) and Applications to Renewable Energy Generation. Energy Procedia 2014, 46, 68–77. [Google Scholar] [CrossRef]

- Habibi, M.; Aligolzadeh, F.; Hakkaki-Fard, A. A techno-economic analysis of geothermal ejector cooling system. Energy 2020, 193, 116760. [Google Scholar] [CrossRef]

- Perego, R.; Pera, S.; Galgaro, A. Techno-Economic Mapping for the Improvement of Shallow Geothermal Management in Southern Switzerland. Energies 2019, 12, 279. [Google Scholar] [CrossRef]

- Wang, Y.; He, W. Temporospatial techno-economic analysis of heat pumps for decarbonising heating in Great Britain. Energy Build. 2021, 250, 111198. [Google Scholar] [CrossRef]

- Neves, R.; Cho, H.; Zhang, J. Techno-economic analysis of geothermal system in residential building in Memphis, Tennessee. J. Build. Eng. 2020, 27, 100993. [Google Scholar] [CrossRef]

- Hakkaki-Fard, A.; Eslami-Nejad, P.; Aidoun, Z.; Ouzzane, M. A techno-economic comparison of a direct expansion ground-source and an air-source heat pump system in Canadian cold climates. Energy 2015, 87, 49–59. [Google Scholar] [CrossRef]

- Perković, L.; Leko, D.; Brettschneider, A.; Mikulčić, H.; Varbanov, P. Integration of Photovoltaic Electricity with Shallow Geothermal Systems for Residential Microgrids: Proof of Concept and Techno-Economic Analysis with RES2GEO Model. Energies 2021, 14, 1923. [Google Scholar] [CrossRef]

- Schreurs, T.; Madani, H.; Zottl, A.; Sommerfeldt, N.; Zucker, G. Techno-economic analysis of combined heat pump and solar PV system for multi-family houses: An Austrian case study. Energy Strategy Rev. 2021, 36, 100666. [Google Scholar] [CrossRef]

- Durga, S.; Beckers, K.F.; Taam, M.; Horowitz, F.; Cathles, L.M.; Tester, J.W. Techno-economic analysis of decarbonizing building heating in Upstate New York using seasonal borehole thermal energy storage. Energy Build. 2021, 241, 110890. [Google Scholar] [CrossRef]

- Zhao, Z.; Xu, Y.; Lin, Y.-F.; Wang, X.; Wang, P. Probabilistic modeling and reliability-based design optimization of a ground source heat pump system. Appl. Therm. Eng. 2021, 197, 117341. [Google Scholar] [CrossRef]

- Pu, L.; Qi, D.; Xu, L.; Li, Y. Optimization on the performance of ground heat exchangers for GSHP using Kriging model based on MOGA. Appl. Therm. Eng. 2017, 118, 480–489. [Google Scholar] [CrossRef]

- Sivasakthivel, T.; Murugesan, K.; Thomas, H. Optimization of operating parameters of ground source heat pump system for space heating and cooling by Taguchi method and utility concept. Appl. Energy 2014, 116, 76–85. [Google Scholar] [CrossRef]

- Xia, L.; Ma, Z.; McLauchlan, C.; Wang, S. Experimental investigation and control optimization of a ground source heat pump system. Appl. Therm. Eng. 2017, 127, 70–80. [Google Scholar] [CrossRef]

- Ma, Z.; Xia, L.; Gong, X.; Kokogiannakis, G.; Wang, S.; Zhou, X. Recent advances and development in optimal design and control of ground source heat pump systems. Renew. Sustain. Energy Rev. 2020, 131, 11001. [Google Scholar] [CrossRef]

- Gamage, K.; Yousefzadeh, M.; Merzifonluoglu, Y.; Uzgören, E.; Uzgören, Y.M. Optimization of a ground source heat pump system using Monte-Carlo simulation Organic Rankine cycles View project Concentrated solar power View project Optimization of a Ground Source Heat Pump System Using Monte-Carlo Simulation. In Proceedings of the 7th International Ege Energy Symposium & Exhibition, Usak, Turkey, 18–20 June 2014. [Google Scholar] [CrossRef]

- Ma, Z.; Xia, L. Model-based Optimization of Ground Source Heat Pump Systems. Energy Procedia 2017, 111, 12–20. [Google Scholar] [CrossRef]

- Soleimani, T.; Gilbert, H. An approach to achieve overall farm feed efficiency in pig production: Environmental evaluation through individual life cycle assessment. Int. J. Life Cycle Assess. 2021, 26, 455–469. [Google Scholar] [CrossRef]

- Sutman, M.; Speranza, G.; Ferrari, A.; Larrey-Lassalle, P.; Laloui, L. Long-term performance and life cycle assessment of energy piles in three different climatic conditions. Renew. Energy 2020, 146, 1177–1191. [Google Scholar] [CrossRef]

- Saner, D.; Juraske, R.; Kübert, M.; Blum, P.; Hellweg, S.; Bayer, P. Is it only CO2 that matters? A life cycle perspective on shallow geothermal systems. Renew. Sustain. Energy Rev. 2010, 14, 1798–1813. [Google Scholar] [CrossRef]

- Pratiwi, A.S.; Trutnevyte, E. Life cycle assessment of shallow to medium-depth geothermal heating and cooling networks in the State of Geneva. Geothermics 2021, 90, 101988. [Google Scholar] [CrossRef]

| Pipe Materials | Thermal Conductivity, Wm−1K−1 | Temperature for Continued Operation, °C |

|---|---|---|

| HDPE-Nano HDPE-Talc | 0.55 0.72 | NA |

| PE100/ PE100-RC | 0.42 | 40 |

| PE-RT | 0.42 | 70 |

| PE-X | 0.41 | 70 |

| PA | 0.24 | 40 |

| PB | 0.22 | 70 |

| PU | 0.29 | 40 |

| PVC | 0.12–0.25 | 27 |

| PP | 0.1–0.22 | 63 |

| Steel | 45 | 399 |

| Copper | 395 | 205 |

| Heat-Carrier Fluids | Thermal Conductivity, Wm−1K−1 | Freezing Point, C | Viscosity, cP | Toxicity, LD50 g/kg |

|---|---|---|---|---|

| Water | 0.598 | 0 | 1 | |

| CaCl2 20% | 0.572 | −17.2 | 4.8 | 1.94 |

| CaCl2 12% | 0.588 | −7.2 | 2.4 | |

| Ethyl alcohol 20 wt.% | 0.46 | −11 | 1.4 | 7.06 |

| Ethyl alcohol 30 wt.% | 0.41 | −20 | 1.6 | |

| Propylene glycol 25 wt.% | 0.48 | −10 | 3.7 | 20 |

| Propylene glycol 33 wt.% | 0.44 | −17 | 6.8 | |

| Ethylene glycol 25 wt.% | 0.49 | −12.2 | 1.4 | 4.7 |

| Ethylene glycol 33 wt.% | 0.4 | −18 | 2.84 |

| Source | Description | Economic Indicators | Remarks |

|---|---|---|---|

| Neves et al., 2020 (USA) [98] | Analyzed the energy savings by replacing an old electric air conditioning/gas furnace system by vertical BHE. | The operation and maintenance costs cannot be assumed due to a neutral component for the payback period calculation that may cause a deviation from the real value. CO2 emissions credits should be considered. Uncertainty analysis should be considered to minimize risks. | |

| Hakkaki-Fard et al., 2015 [99] | Studied efficiency and life cycle cost analysis (LCC) for initial & 10-year operating costs and relative payback period of ASHP (air-source heat pump) and DX-GSHP (direct expansion ground-source heat pump). | IC: initial cost, PVectricity: energy consumed | CO2 emission credits should be considered. The results show that energy consumption of the DX-GSHP system could be reduced by 50%. |

| Perkovi’c et al., 2021 (Croatia) [100] | Investigated the integration of a carbon-free photovoltaic electricity source and a shallow geothermal reservoir as a heat source and heat sink during the heating and cooling season. | Cd is total capital and operating cost | Reduction in CO2 emission has been estimated but it was not considered in financial analysis. The payback period calculation should be considered to identify system feasibility. |

| Schreurs et al., 2021 (Austria) [101] | Identified the critical economic parameters on profitability and make policy recommendations. | NPV, BCR and IRR | Reduction in CO2 emissions has been estimated but was not included in financial analysis. Only used for ‘what-if scenario’ and comparison. Optimization for selected system should be considered. ASHP and GSHP combined with PV were profitable under current subsidy schemes. |

| Durga et al., 2021(USA) [102] | Investigated the technical and economic feasibility of BTES. | NPV, IRR, PBP and LCOH | Annual emission saving was estimated but not considered in financial analysis. |

| Perego et al., 2019 (Switzerland) [96] | Developed techno-economic maps for potential of shallow and closed-loop geothermal system. | Payback Period for BHE when replacing oil and natural gas heating systems. | More accurate mathematical modelling should be considered to minimize the error (23%) for generating m/kW map and to improve PBP. Emission savings against fossils fuel have been estimated but not considered in financial analysis. |

| Source | Objective Function | Decision Variables | Tools Used | Remarks |

|---|---|---|---|---|

| Pu et al., 2017 [104] | Objective Function: Multi-objective.

|

| ANYSIS, Central composite design, Kriging and multi-objective genetic algorithm (MOGA). | Cost-based optimization was not included in the study. CO2 emissions credits should be considered. |

| Farzanehkhameneh et al., (2020) [92] | Objective Function: Single objective.

|

| TRNSYS software and Genetic Algorithm. | Cost-based optimization was not included. CO2 emissions credits should be considered. |

| Wang et al., (2020) [89] | Objective Function: Single objective.

|

| Data driven optimization used ANN, Detailed and DOE-2 techniques, which relates variables, energy consumption, and heating demand. | Cost-based optimization was not included. ANN and DOE-2 were in good agreement with the data. |

| Sivasakthi--vel et al., 2014 [105] | Objective Function: Multi-objective.

|

| Taguchi optimization analysis and utility concept. | Utility concept combined with Taguchi are useful to predict COPs with high confidence level (95%). |

| Zhao et al., 2021 (USA) [103] | Objective Function: Single objective.

|

| An analytical borehole and probabilistic uncertainties using reliability-based design optimization (RBDO). | CO2 emissions credits should be considered. |

| GAMAGE et al., 2014 [108] | Objective Function: Number of boreholes. |

| EnergyPlus, cylindrical heat source solution and Monte Carlo simulation. | CO2 emissions credits should be considered. |

| Ma and Xia (2017) [109] | Objective Function: Single objective.

|

| EnergyPlus and G-function was used for BHE. | Cost-based optimization was not included in the study. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, A.A.; Assadi, M.; Kalantar, A.; Sliwa, T.; Sapińska-Śliwa, A. A Critical Review on the Use of Shallow Geothermal Energy Systems for Heating and Cooling Purposes. Energies 2022, 15, 4281. https://doi.org/10.3390/en15124281

Ahmed AA, Assadi M, Kalantar A, Sliwa T, Sapińska-Śliwa A. A Critical Review on the Use of Shallow Geothermal Energy Systems for Heating and Cooling Purposes. Energies. 2022; 15(12):4281. https://doi.org/10.3390/en15124281

Chicago/Turabian StyleAhmed, Abdelazim Abbas, Mohsen Assadi, Adib Kalantar, Tomasz Sliwa, and Aneta Sapińska-Śliwa. 2022. "A Critical Review on the Use of Shallow Geothermal Energy Systems for Heating and Cooling Purposes" Energies 15, no. 12: 4281. https://doi.org/10.3390/en15124281

APA StyleAhmed, A. A., Assadi, M., Kalantar, A., Sliwa, T., & Sapińska-Śliwa, A. (2022). A Critical Review on the Use of Shallow Geothermal Energy Systems for Heating and Cooling Purposes. Energies, 15(12), 4281. https://doi.org/10.3390/en15124281