Cooperative Control Mechanism of Efficient Driving and Support in Deep-Buried Thick Top-Coal Roadway: A Case Study

Abstract

:1. Introduction

2. Analysis of Engineering Geological Conditions

2.1. Engineering Geological Conditions of Roadway

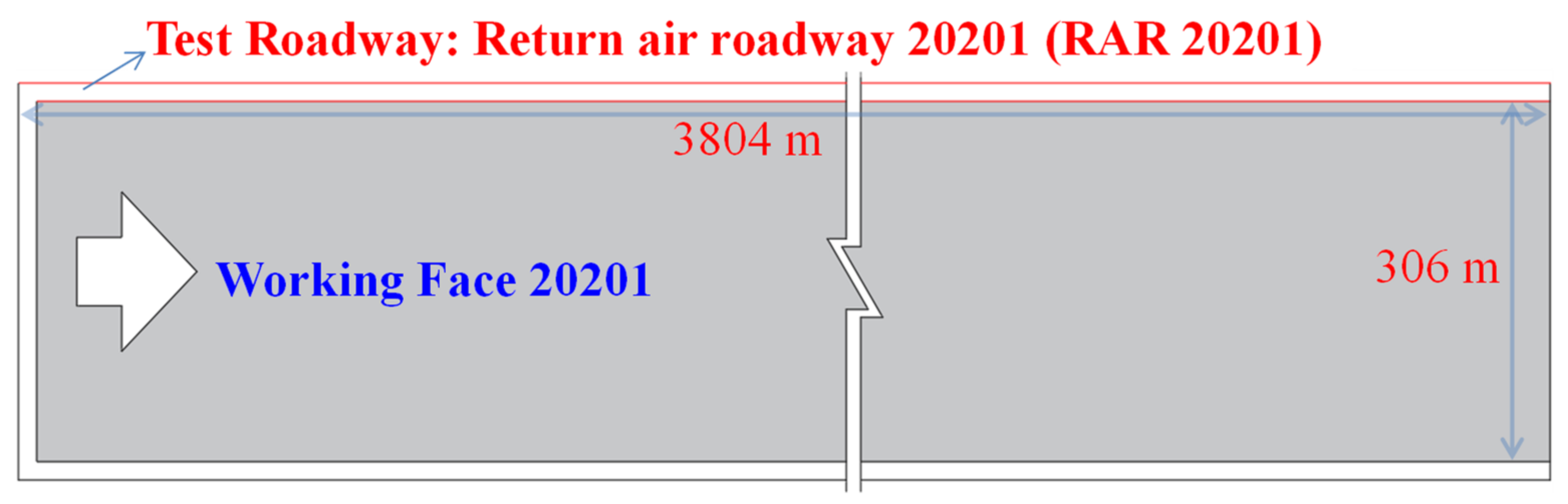

2.1.1. Layout of Working Face and Roadway

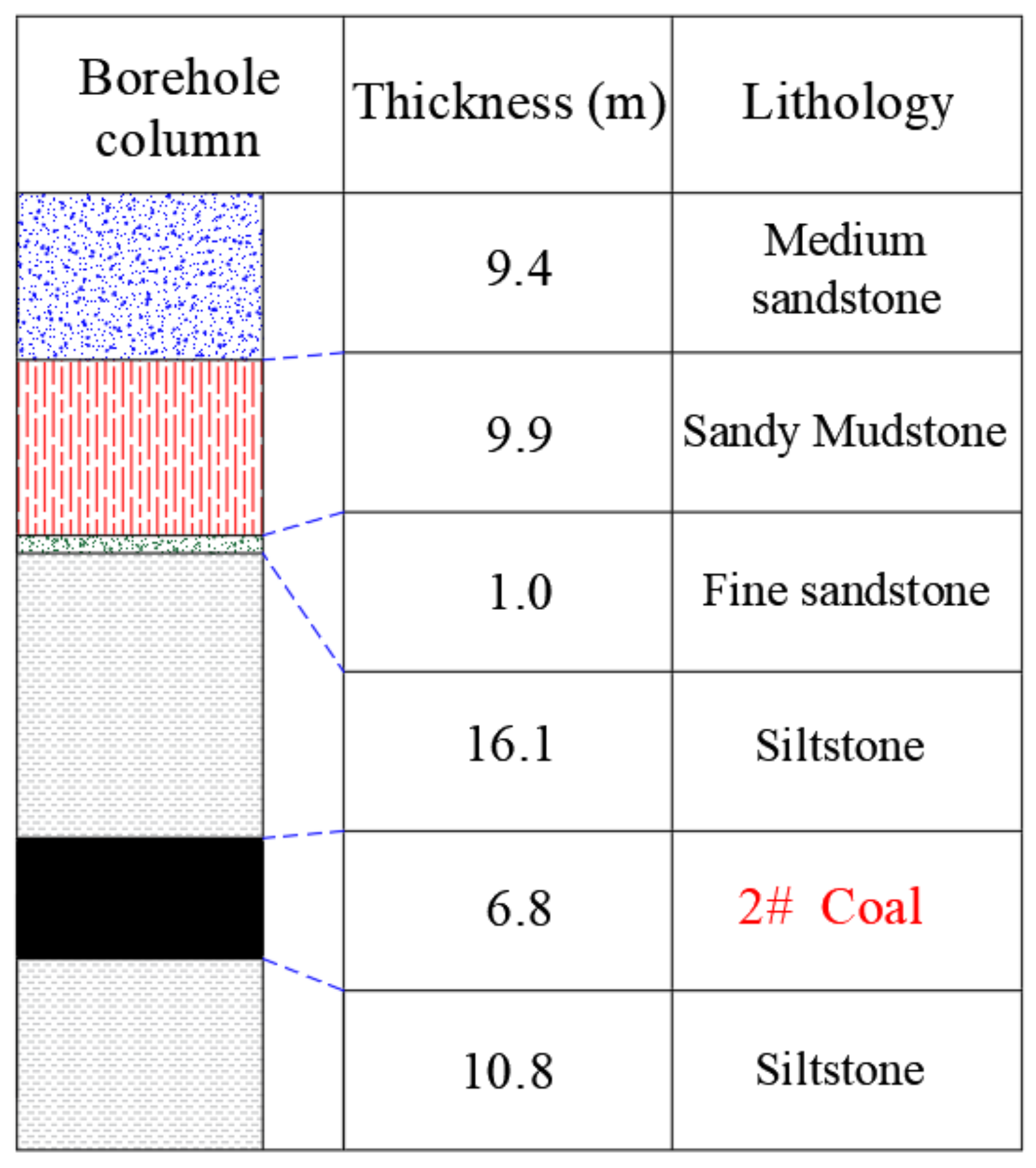

2.1.2. Lithology of the Coal Seam, Roof and Floor

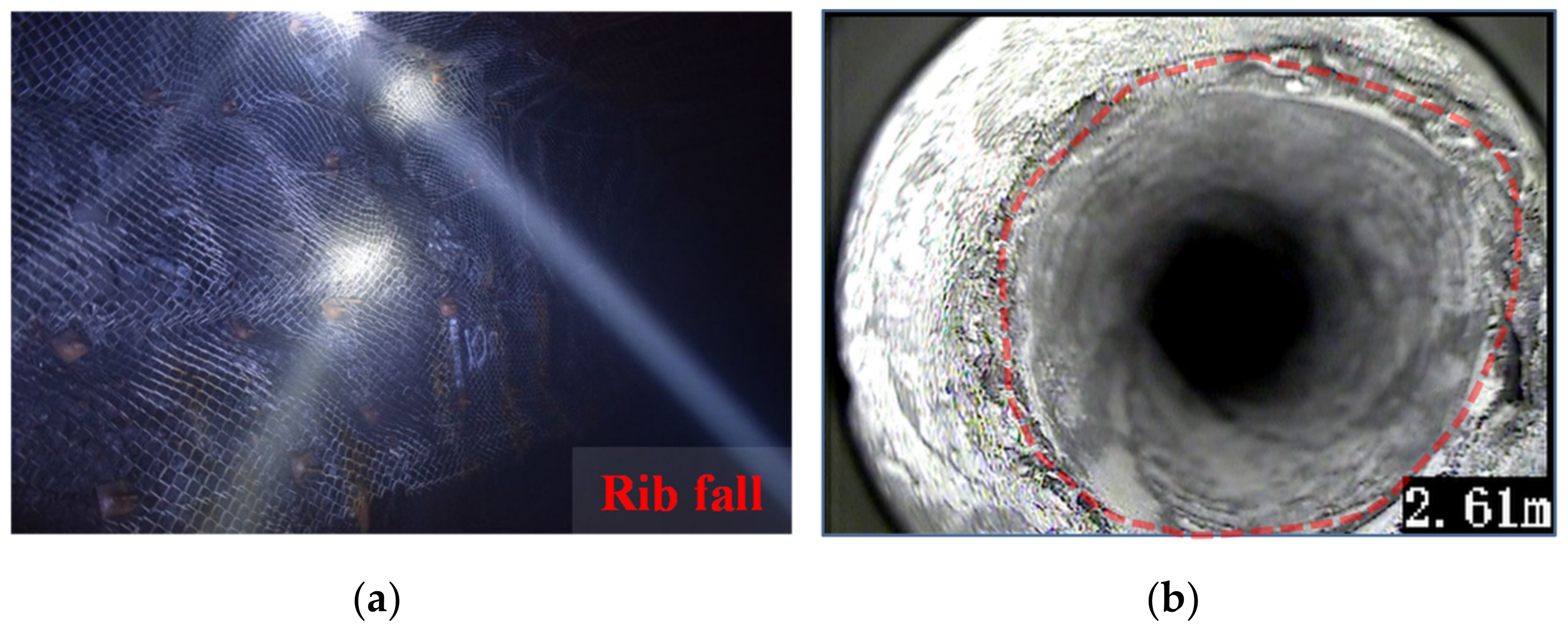

2.2. Analysis of Existing Roadway Support Scheme and Maintenance Effect

2.2.1. Existing Support Scheme

2.2.2. Maintenance Effect

2.3. Issues Proposed and Research Directions

2.3.1. Issues Proposed

- (1)

- Under deep-buried high-stress environments, the roadway surrounding the rock suffers from a larger range of damage.

- (2)

- The support density is large, and the driving speed is difficult to improve. The overall bolt-cable support density of the roadway’s surrounding rock reaches 15.5 pieces/m, with the roof support density reaching 6.4 pieces/m. That is, a large amount of head-on support and a long supporting time in driving-supporting circulation significantly restrict the driving speed of the roadway.

- (3)

- The slow driving speed increases the likelihood of rock stress, which results in more serious damage to the rock mass.

2.3.2. Research Directions

- (1)

- Study of the damage range of the surrounding rock in deep-buried high-stress roadways. From the previous analysis, it can be concluded that the damage range of deep-buried high-stress roadways obviously differs from that of shallow buried roadways. Therefore, taking the shallow buried roadway as a comparison helped in the study of the damage range of the surrounding rock of deep-buried thick top-coal roadways for bolt support design.

- (2)

- Study of the fluctuation patterns of the head-on cutting disturbance stress and speed effect of cutting disturbance. The head-on cutting of roadways will result in unloading disturbance on the adjacent anchorage system. Therefore, it is of great significance to study the fluctuation patterns of the head-on cutting disturbance stress of roadways and the attenuation law of the unloading disturbance stress under different driving speeds, providing guidance for weakening the cutting disturbance by improving the driving speed.

3. Study on Stress Distribution Characteristics and Driving Speed Effect of Surrounding Rock in High-Stress Roadways

3.1. Stress Distribution Characteristics of Surrounding Rock in High-Stress Roadways

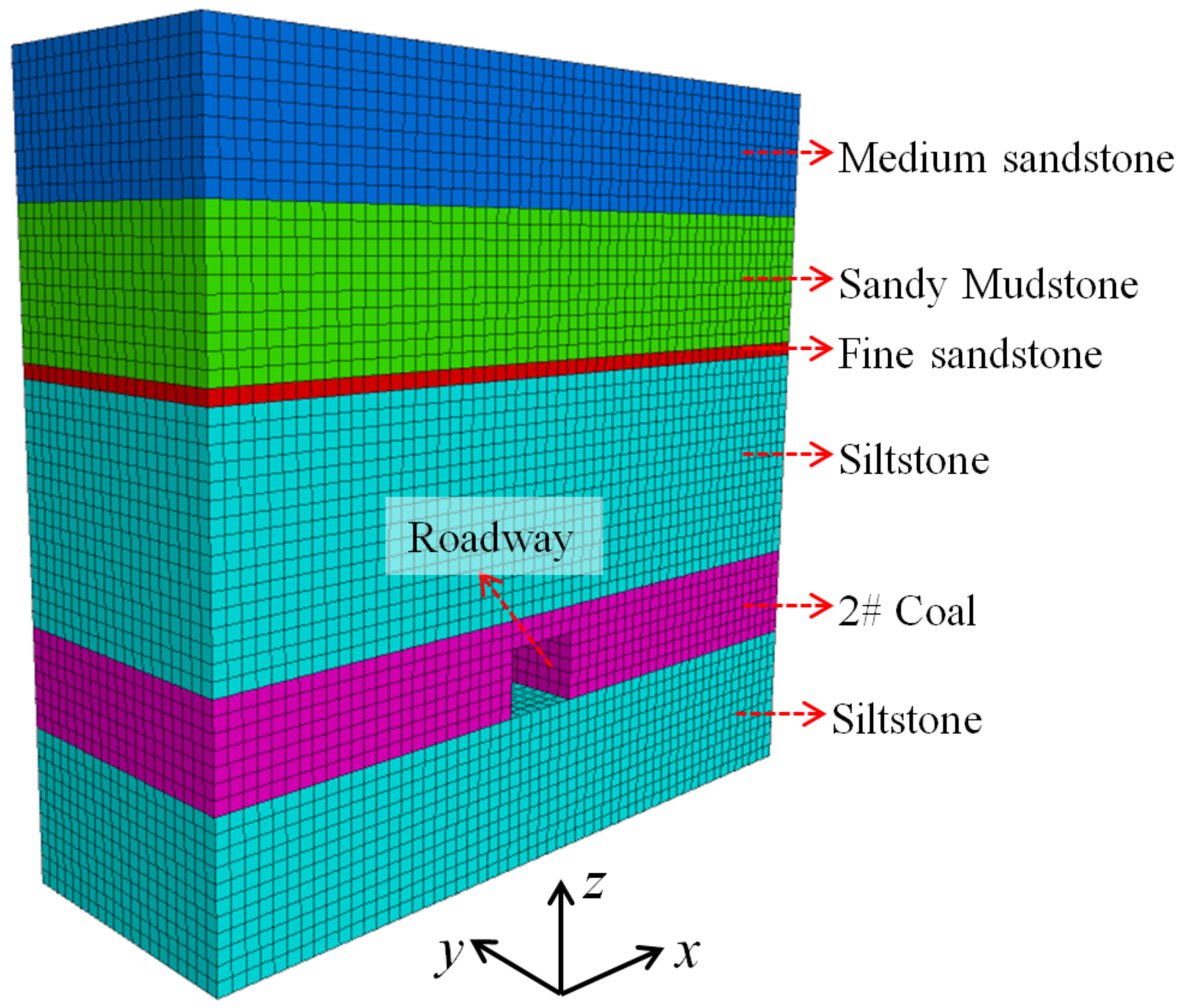

3.1.1. Establishment of Numerical Model

3.1.2. Simulation Methods

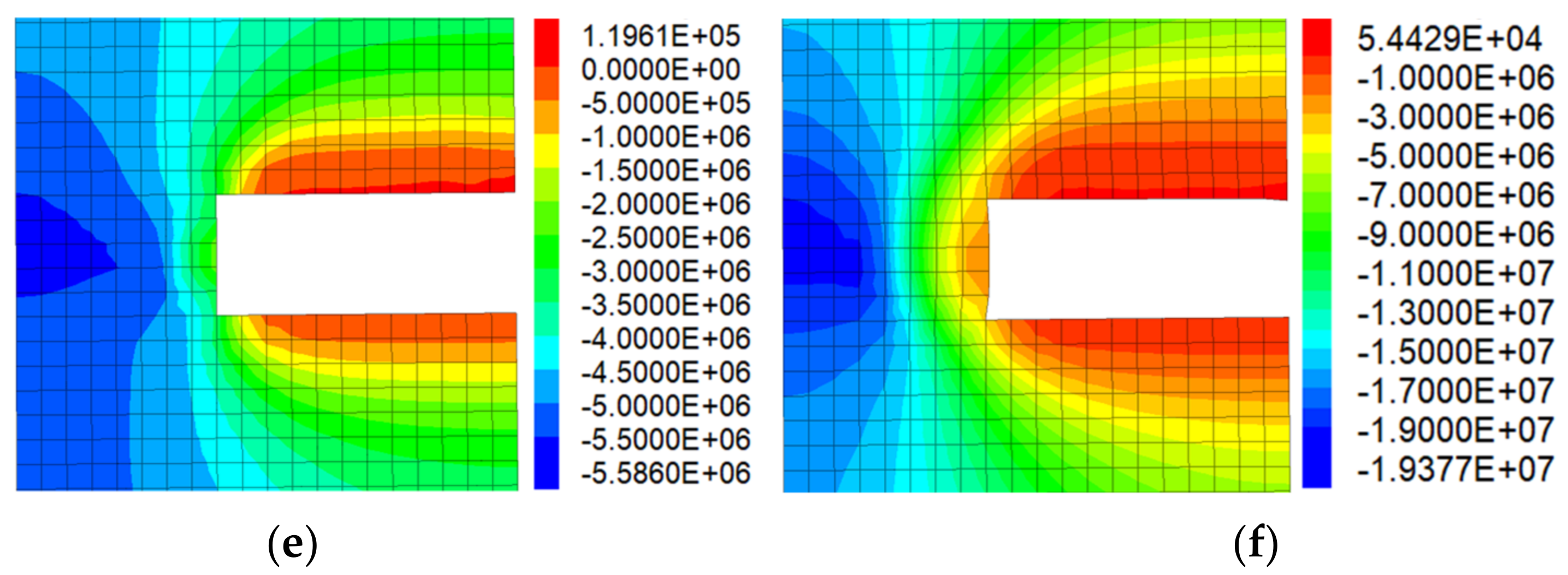

3.1.3. Results Analysis

- (1)

- For low-stress roadways, when lagging 11 m behind the heading face, the low-value stress range of roof strata is 1–2 m, and the low-value stress range of the coal rib is 1 m. After the disturbance of low-stress roadway driving is stable, the stress yield ranges of the roof and coal rib are 1–2 m and 1 m, respectively.

- (2)

- For high-stress roadways, when lagging 11 m behind the heading face, the low-value stress range of the roof strata is 3 m, and the low-value stress range of the coal rib is 2–3 m. Therefore, compared with the shallow buried low-stress roadway, the deep-buried high-stress roadway suffers a larger range of damaged depth and area.

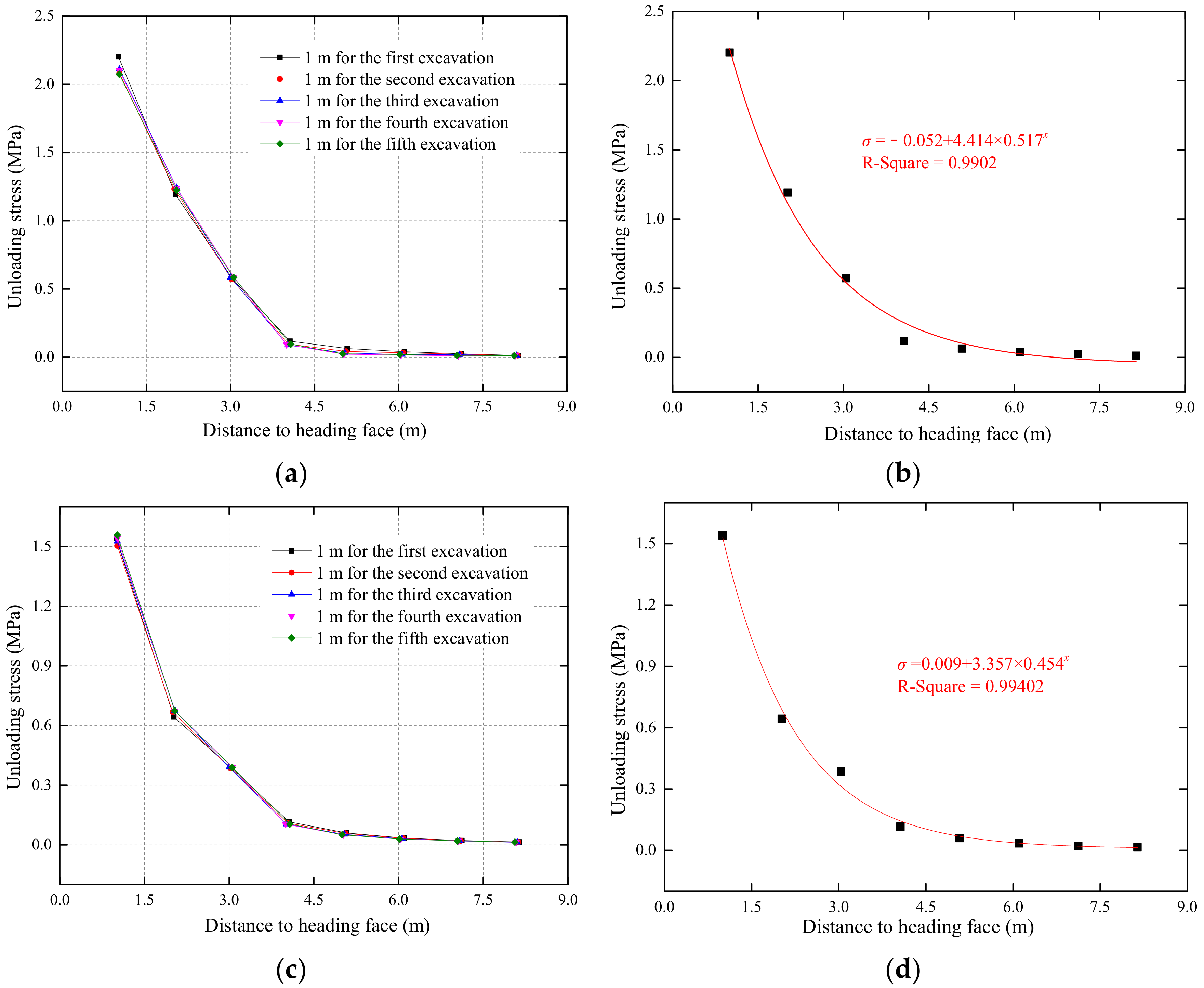

3.2. Disturbance Stress Distribution Characteristics of High-Stress Roadway in Head-On Cutting

3.2.1. Establishment of Numerical Model

3.2.2. Simulation Methods

3.2.3. Results Analysis

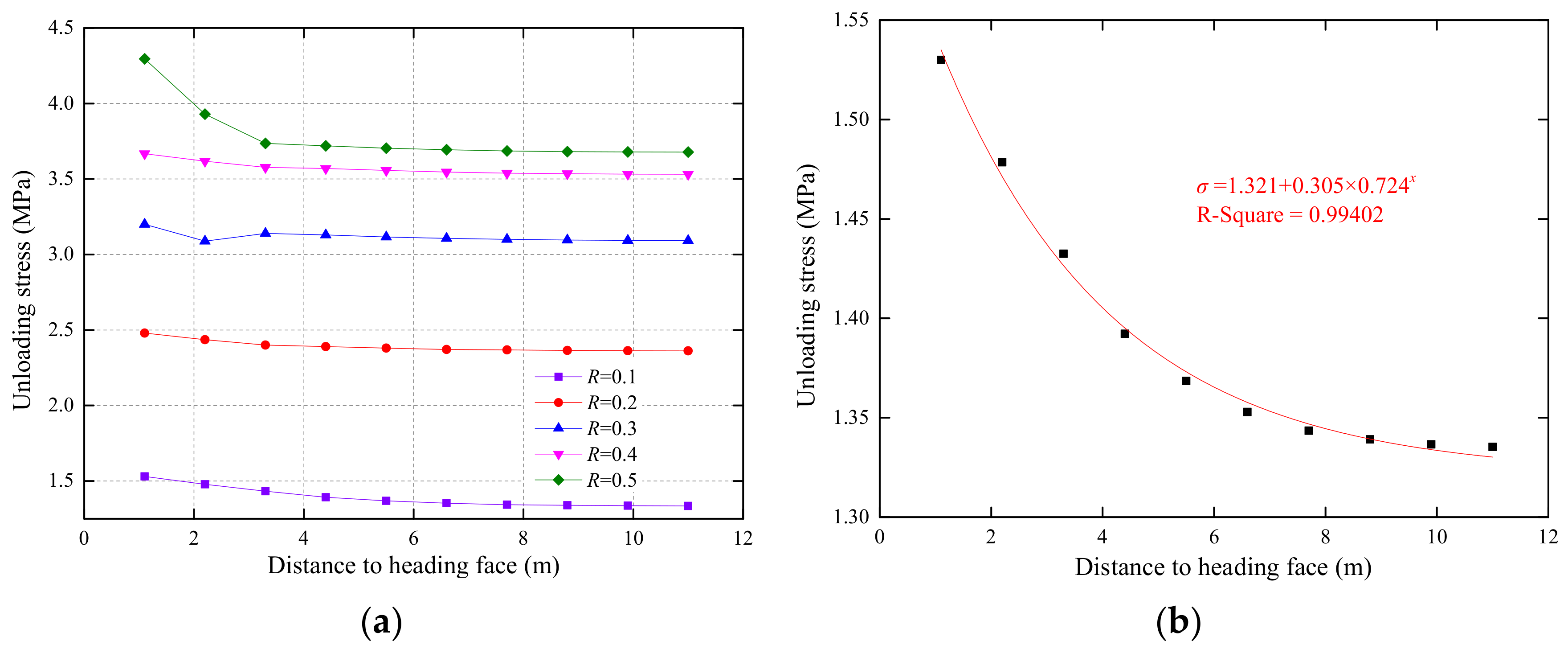

3.3. Speed Effect Analysis of High-Stress Roadway in Head-On Cutting

3.3.1. Establishment of Numerical Model

3.3.2. Simulation Methods

3.3.3. Results Analysis

4. Cooperative Control Countermeasures of Efficient Driving and Support in Deep-Buried Thick Top-Coal Roadways

5. Industrial Testing

5.1. Optimization of Driving and Support

5.1.1. Optimization of Support Scheme

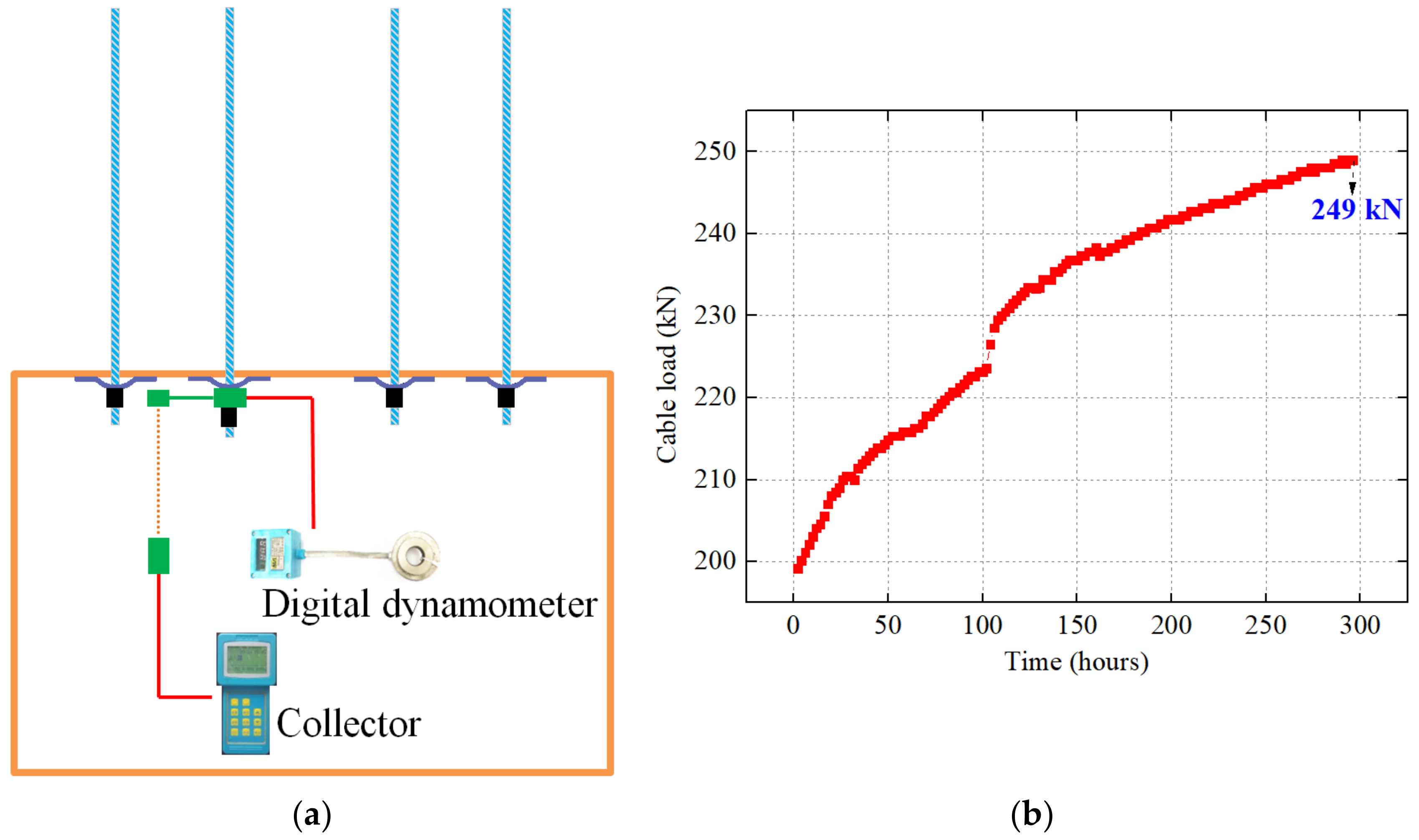

- (1)

- Roof support: As shown in Figure 13, the roof adopts Φ21.8 × 4500 mm anchor cable supports. Each row has four cables with a spacing of 1500 mm and a row spacing of 1500 mm. All the anchor cables are installed perpendicular to the roof. Each cable is anchored with one MSCK 2360 mm and one MSK2360 mm resin cartridge, and the pre-tightening force of the cable is 200 kN. The yield load of the anchor cable is 706 kN

- (2)

- Coal rib support: The support parameters of the two coal sides are consistent, and the foundation supporting adopts a Φ22 × 2600 mm left-handed spiral steel anchor support. Each row adopts five bolts with the spacing of 1500 mm. Among them, the bolts at the shoulder angle are installed at an external inclination of 15°, and all other anchor bolts are installed perpendicular to the coal rib. Each anchor bolt is anchored with one MSCK 2335 mm and one MSK2360 mm resin cartridge, and the pre-tightening force of the bolt is 60 kN.

5.1.2. Improvement of Driving and Support Efficiency

5.2. Effect Analysis

5.2.1. Control Effect of Roadway Surroundings

5.2.2. Roadway Driving Speed

6. Conclusions

- (1)

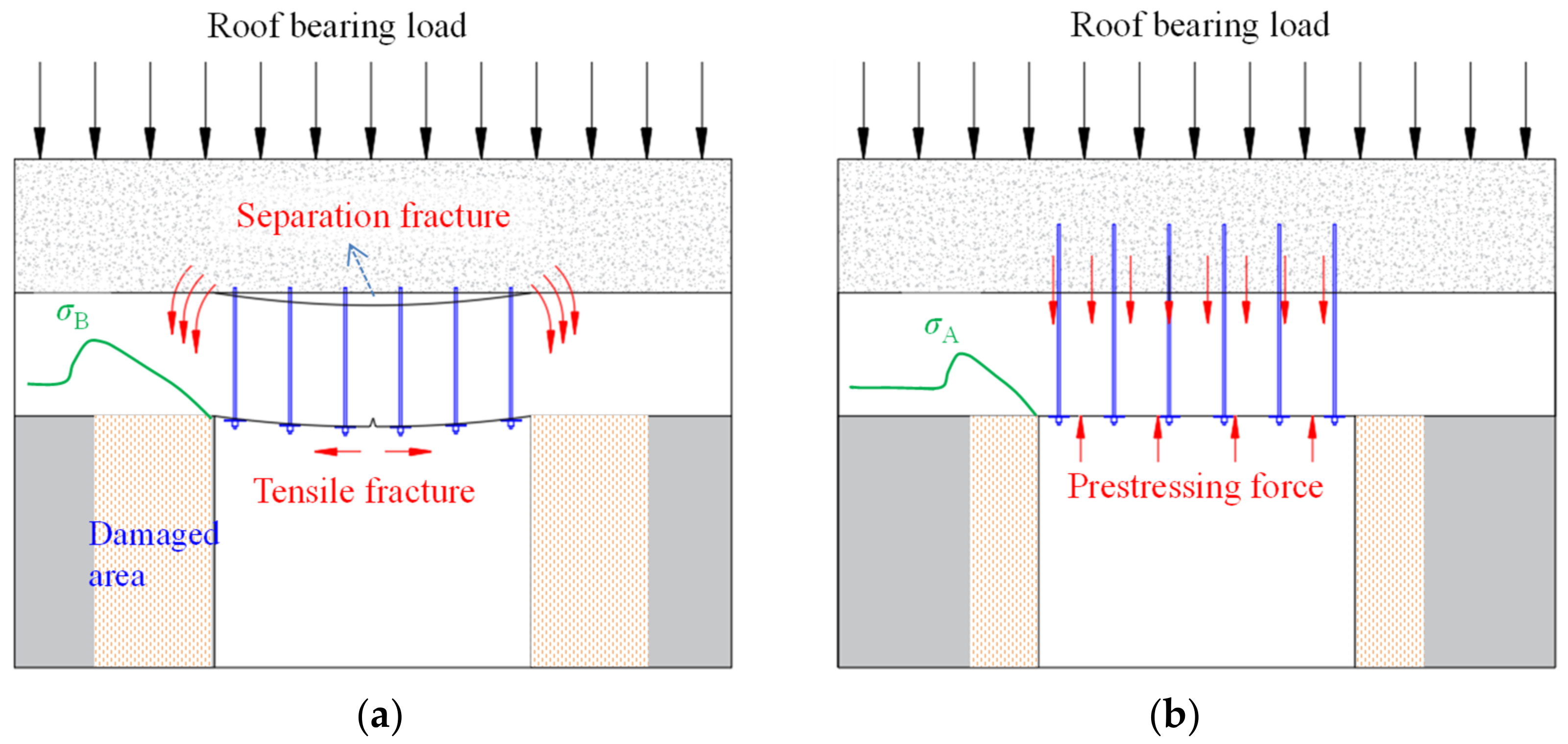

- The maintenance effect and existing problems of deep-buried thick top-coal roadways are analyzed, and the research directions are determined as the damaged zone of the roadway surrounding the rock and the driving speed. During driving on the deep-buried thick top-coal roadway, there exist the problems of separation fracture development outside the roof anchorage zone, coal rib fall and slow driving speed. It is believed that under the condition of deep burial, high stress and thick top-coal, the damage range of the roof may exceed the range of the bolt anchorage. Moreover, the development of separation fracture outside the anchorage zone promotes the roof stress transfer to both sides, thereby affecting the stability of the roadway roof and ribs.

- (2)

- The stress distribution characteristics of the surrounding rock in the deep-buried high-stress roadway are studied; furthermore, the fluctuation form and speed effect of the disturbance stress in head-on cutting are revealed. After roadway driving, for a deep-buried high-stress roadway, the low-value stress range of the roof strata and coal rib is 3 m and 2–3 m, which enlarge the damage range compared with shallow buried roadway. The fluctuation curve of unloading disturbance stress produced by head-on cutting conforms to the “power exponential” composite function. Compared with the shallow buried low-stress roadway, the head-on cutting of the deep-buried high-stress roadway causes stronger unloading disturbance intensity, which will gradually decrease with the increase of the driving speed.

- (3)

- The cooperative control countermeasures of efficient driving and support in deep-buried thick top-coal roadway are proposed. On one hand, we improve the support efficiency of the single bolt to reduce the overall support density; meanwhile, we thicken the bolt anchorage layer to allow it to pass through the fracture layer in the shallow part of the roof into the deep rock layer with good stability. Moreover, we eliminate the separation fracture outside the anchorage end to allow the roof stress to continuously transfer downward rather than towards both sides, which helps to control the stability of the roof and rib. On the other hand, under overall reduced support density, the rapid completion of head-on driving-supporting circulation as well as improved driving speed can lessen the unloading disturbance of head-on cutting on the roof strata.

- (4)

- The industrial tests of the cooperative control countermeasures of efficient driving and support in deep-buried thick top-coal roadways are carried out. The results show that the subsidence of the roadway roof and the convergence of the coal ribs are controlled within 30 mm, showing effective deformation control. The working load of the roof anchor cable is 249 kN after stability, with good bearing performance. There is no obvious separation fracture development found in the depth of 2.75–5.63 m of the roof, or for the zone outside the anchorage, which creates a favorable chance for the continuous transmission of roof stress. In addition, the driving speed increases from 390 m/month to 660 m/month, which speeds up the roadway formation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RAR 20201 | return air roadway 20201 |

References

- Qi, Q.Q.; Pan, Y.S.; Li, H.T.; Jiang, D.Y.; Shu, L.Y.; Zhao, S.K.; Zhang, Y.J.; Pan, J.F.; Li, H.Y.; Pan, P.P. Theoretical basis and key technology of prevention and control of coal-rock dynamic disasters in deep coal mining. J. China Coal Soc. 2020, 45, 1567–1584. [Google Scholar]

- Chen, X.J.; Li, L.Y.; Wang, L.; Qi, L.L. The current situation and prevention and control countermeasures for typical dynamic disasters in kilometer-deep mines in China. Safety Sci. 2019, 115, 229–236. [Google Scholar] [CrossRef]

- Xie, H.P.; Ju, Y.; Ren, S.H.; Gao, F.; Liu, J.Z.; Zhu, Y. Theoretical and technological exploration of deep in situ fluidized coal mining. Front. Energy 2019, 13, 603–611. [Google Scholar] [CrossRef]

- Pan, D.J.; Hong, K.R.; Fu, H.L.; Zhou, J.J.; Zhang, N.; Lu, G.M. Influence Characteristics and Mechanism of Fragmental Size of Broken Coal Mass on the Injection Regularity of Silica Sol Grouting. Constr. Build. Mater. 2021, 269, 121251. [Google Scholar] [CrossRef]

- Pan, D.J.; Hong, K.R.; Fu, H.L.; Zhou, J.J.; Zhang, N. Experimental Study of the Mechanism of Grouting Colloidal Nano-Silica in Over-Broken Coal Mass. Q. J. Eng. Geol. Hydrogeol. 2021, 54, qjegh2020-161. [Google Scholar] [CrossRef]

- Pan, D.J.; Hong, K.R.; Fu, H.L.; Li, Z.G.; Zhang, L.M.; Lu, G.M.; Sun, F.X.; Wen, S.Y. Numerical Simulation of Nanosilica Sol Grouting for Deep Tunnels Based on the Multifield Coupling Mechanism. Geofluids 2021, 2021, 3963291. [Google Scholar] [CrossRef]

- Coggan, J.; Gao, F.; Stead, D.; Elmo, D. Numerical modelling of the effects of weak immediate roof lithology on coal mine roadway stability. Int. J. Coal Geol. 2012, 90, 100–109. [Google Scholar] [CrossRef]

- Colwell, M.; Frith, R. Utilising the scientific method to demonstrate that slender beam/column behaviour is the dominant behavioural mechanism leading to roof/rib failure. Int. J. Min. Sci. Technol. 2021, 31, 867–887. [Google Scholar] [CrossRef]

- Frith, R.; Reed, G.; McKinnon, M. Fundamental principles of an effective reinforcing roof bolting strategy in horizontally layered roof strata and areas of potential improvement. Int. J. Min. Sci. Technol. 2018, 28, 67–77. [Google Scholar] [CrossRef]

- Zhan, Q.J.; Zheng, X.G.; Du, J.P.; Xiao, T. Coupling Instability Mechanism and Joint Control Technology of Soft-Rock Roadway with a Buried Depth of 1336 m. Rock Mech. Rock Eng. 2020, 53, 2233–2248. [Google Scholar] [CrossRef]

- Xie, H.P.; Gao, M.Z.; Zhang, R.; Peng, G.Y.; Wang, W.Y.; Li, A.Q. Study on the Mechanical Properties and Mechanical Response of Coal Mining at 1000m or Deeper. Rock Mech. Rock Eng. 2019, 52, 1475–1490. [Google Scholar] [CrossRef]

- Li, Z.; Liu, J.C.; Xu, R.C.; Liu, H.X.; Shi, W.H. Study of grouting effectiveness based on shear strength evaluation with experimental and numerical approaches. Acta Geotech. 2021, 16, 3991–4005. [Google Scholar] [CrossRef]

- Ren, J.L.; Zhao, H.B.; Zhang, L.; Zhao, Z.D.; Xu, Y.S.; Cheng, Y.Y.; Wang, M.; Chen, J.C.; Wang, J. Design optimization of cement grouting material based on adaptive Boosting algorithm and simplicial homology global optimization. J. Build. Eng. 2022, 49, 104049. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, M.; Zhao, H.B.; Chang, X. Uncertainty quantification for the mechanical behavior of fully grouted rockbolts subjected to pull-out tests. Comput. Geotech. 2022, 145, 104665. [Google Scholar] [CrossRef]

- Ren, J.L.; Zhang, L.; Zhao, H.B.; Zhao, Z.D.; Wang, S.Y. Determination of the fatigue equation for the cement-stabilized cold recycled mixtures with road construction waste materials based on data-driven. Int. J. Fatigue 2022, 158, 106765. [Google Scholar] [CrossRef]

- Zhang, N.; Han, C.L.; Xie, Z.Z. Theory of continuous beam control and high efficiency supporting technology in coal roadway. J. Min. Strat. Control. Eng. 2019, 1, 48–55. [Google Scholar]

- Yang, H.Q.; Han, C.L.; Zhang, N.; Pan, D.J.; Xie, Z.Z. Research and Application of Low Density Roof Support Technology of Rapid Excavation for Coal Roadway. Geotech. Geol. Eng. Int. J. 2020, 38, 389–401. [Google Scholar] [CrossRef]

- Li, S.C.; Wang, D.C.; Wang, Q.; Wang, F.Q.; Peng, P.; Li, W.T.; Jiang, B.; Wang, H.T. Development and application of large-scale geomechanical model test system for deep thick top coal roadway. J. China Coal Soc. 2013, 38, 1522–1530. [Google Scholar]

- Li, S.C.; Wang, Q.; Wang, H.T.; Jiang, B.; Wang, D.C.; Zhang, B.; Li, Y.; Ruan, G.Q. Model test study on surrounding rock deformation and failure mechanisms of deep roadways with thick top coal. Tunn. Undergr. Sp. Tech. 2015, 47, 52–63. [Google Scholar] [CrossRef]

- Li, W.T.; Li, S.C.; Wang, Q.; Ruan, G.Q.; Zuo, J.Z.; Liu, W.J.; Wang, D.C.; Wang, H.T. Model test study of surrounding rock deformation and failure mechanism of deep roadway with thick top coal. Rock Soil Mech. 2013, 34, 2847–2856. [Google Scholar] [CrossRef]

- Shan, R.L.; Bao, Y.S.; Yuan, H.H. Research and application of whole anchorage support system in roof and two sides of thick top coal roadway. Coal Sci. Technol. 2018, 46, 93–99. [Google Scholar]

- Xu, Y.; Zhou, X.K.; Gong, W.M.; Zhang, Z.Z. Mechanism and Control of Cable Breakage in a Roadway with Thick Top Coal in a Rockburst Mine. Adv. Civ. Eng. 2021, 2021, 2275820. [Google Scholar] [CrossRef]

- Yang, Y.L.; Li, X.B.; Li, P.F. Study on Surrounding Rock Deformation Mechanism and Control of Roadway with Large Section and Extra-Thick Top Coal. Shock Vib. 2021, 2021, 6618424. [Google Scholar] [CrossRef]

- Liu, W.J.; Qian, D.Y.; Yang, X.G.; Wang, S.J.; Deng, J.P.; Cui, Q.; Li, Z.X. Stress Relief and Support for Stability of Deep Mining Roadway with Thick Top Coal in Hujiahe Coal Mine with the Risk of Rock Burst. Shock Vib. 2021, 2021, 3822336. [Google Scholar] [CrossRef]

- Ma, P.; Qian, D.Y.; Zhang, N.; Shimada, H.; Pan, D.J.; Huang, K.J. Application of Bolter Miner Rapid Excavation Technology in Deep Underground Roadway in Inner Mongolia: A Case Study. Sustainability 2020, 12, 2588. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Hua, X.Z.; Liu, X.; Wang, E.Q.; Li, C. Deformation and Failure Characteristics of the Roof in an Unsupported Area during Rapid Driving of Coal Roadway. Shock Vib. 2021, 2021, 7275334. [Google Scholar] [CrossRef]

- Liu, Y.D.; Lin, J.; Yang, J.W.; Jiang, P.F. Rapid excavation and supporting technology of ultra-thick top coal roadway based on excavation and bolting integration. Coal Sci. Technol. 2017, 45, 60–65. [Google Scholar]

- Liu, S.G.; Li, Z. Unloading behaviors of shale under the effects of water through experimental and numerical approaches. Int. J. Geomech. 2022, 22, 4022071. [Google Scholar] [CrossRef]

- Kang, H.P.; Jiang, P.F.; Gao, F.Q.; Wang, Z.Y.; Li, C.; Yang, J.W. Analysis on stability of rock surrounding heading faces and technical approaches for rapid heading. J. China Coal Soc. 2021, 46, 2023–2045. [Google Scholar]

- Yang, H.Q.; Han, C.L.; Zhang, N.; Sun, Y.T.; Pan, D.J.; Sun, C.L. Long High-Performance Sustainable Bolt Technology for the Deep Coal Roadway Roof: A Case Study. Sustainability 2020, 12, 1375. [Google Scholar] [CrossRef] [Green Version]

- Xie, Z.Z.; Zhang, N.; Feng, X.W.; Liang, D.X.; Wei, Q.; Weng, M.Y. Investigation on the evolution and control of surrounding rock fracture under different supporting conditions in deep roadway during excavation period. Int. J. Rock Mech. Min. 2019, 123, 104122. [Google Scholar] [CrossRef]

- Xie, Z.Z.; Zhang, N.; Han, C.L.; An, Y.P. Research on principle and application of roof thick layer cross-boundary anchorage in coal roadways. Chin. J. Rock Mech. Eng. 2021, 40, 1195–1208. [Google Scholar]

| Number | Lithology | Thickness (m) | Compressive Strength (MPa) | Elastic Modulus (GPa) | Poisson Ratio | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| 4 | Medium Sandstone | 9.4 | 52.4 | 22.9 | 0.3 | 8.8 |

| 3 | Sandy Mudstone | 9.9 | 32.1 | 11.5 | 0.2 | 4.0 |

| 2 | Fine Sandstone | 1.0 | 43.5 | 17.1 | 0.2 | 6.7 |

| 1 | Siltstone | 16.1 | 40.6 | 15.8 | 0.2 | 6.2 |

| 0 | 2# Coal | 6.8 | 10.4 | 1.8 | 0.2 | 1.2 |

| −1 | Siltstone | 10.8 | 40.6 | 15.8 | 0.2 | 6.2 |

| Number | Lithology | Thickness (m) | Density (kg·m−3) | Bulk Modulus (GPa) | Shear Modulus (GPa) | Internal Friction Angle (°) | Cohesion (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|---|

| 4 | Medium Sandstone | 9.4 | 2630 | 8.6 | 4.5 | 27 | 5.4 | 3.6 |

| 3 | Sandy Mudstone | 9.9 | 2380 | 2.5 | 2.0 | 25 | 1.35 | 2.1 |

| 2 | Fine Sandstone | 1.0 | 2750 | 6.6 | 3.2 | 28 | 5.1 | 3.2 |

| 1 | Siltstone | 16.1 | 2510 | 6.0 | 3.8 | 26 | 8.1 | 3.1 |

| 0 | 2# Coal | 6.8 | 1260 | 1.5 | 0.3 | 20 | 0.9 | 0.5 |

| −1 | Siltstone | 10.8 | 2510 | 6.0 | 3.8 | 26 | 8.1 | 3.1 |

| Driving Speed | Fitting Function | R-Square |

|---|---|---|

| R = 0.1 | 0.9935 | |

| R = 0.2 | 0.9956 | |

| R = 0.3 | 0.9971 | |

| R = 0.4 | 0.9921 | |

| R = 0.5 | 0.9944 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, C.; Han, C.; Wang, L.; Zhao, B.; Yang, H. Cooperative Control Mechanism of Efficient Driving and Support in Deep-Buried Thick Top-Coal Roadway: A Case Study. Energies 2022, 15, 4349. https://doi.org/10.3390/en15124349

Hu C, Han C, Wang L, Zhao B, Yang H. Cooperative Control Mechanism of Efficient Driving and Support in Deep-Buried Thick Top-Coal Roadway: A Case Study. Energies. 2022; 15(12):4349. https://doi.org/10.3390/en15124349

Chicago/Turabian StyleHu, Chengjun, Changliang Han, Lixin Wang, Baofu Zhao, and Houqiang Yang. 2022. "Cooperative Control Mechanism of Efficient Driving and Support in Deep-Buried Thick Top-Coal Roadway: A Case Study" Energies 15, no. 12: 4349. https://doi.org/10.3390/en15124349

APA StyleHu, C., Han, C., Wang, L., Zhao, B., & Yang, H. (2022). Cooperative Control Mechanism of Efficient Driving and Support in Deep-Buried Thick Top-Coal Roadway: A Case Study. Energies, 15(12), 4349. https://doi.org/10.3390/en15124349