Anaerobic Digestion of Pig Slurry in Fixed-Bed and Expanded Granular Sludge Bed Reactors

Abstract

:1. Introduction

- Prove the applicability of bioreactors that predominantly utilize granular biomass (EGSB reactor) and biofilm biomass (FB reactor) for the AD of filtered PS;

- Reduce the HRT to less than that of conventional CSTRs to demonstrate more efficient techniques for agricultural waste utilization;

- Compare the performances of FB and EGSB reactors at different operating points;

- Quantify the effect of the OLR on the methane production rate under the constraint of minimizing the HRT.

2. Materials and Methods

2.1. Substrate Properties and Pretreatment

2.2. Reactor Setup

2.3. Execution of Experiments and Analytical Methods

2.4. Calculations

3. Results

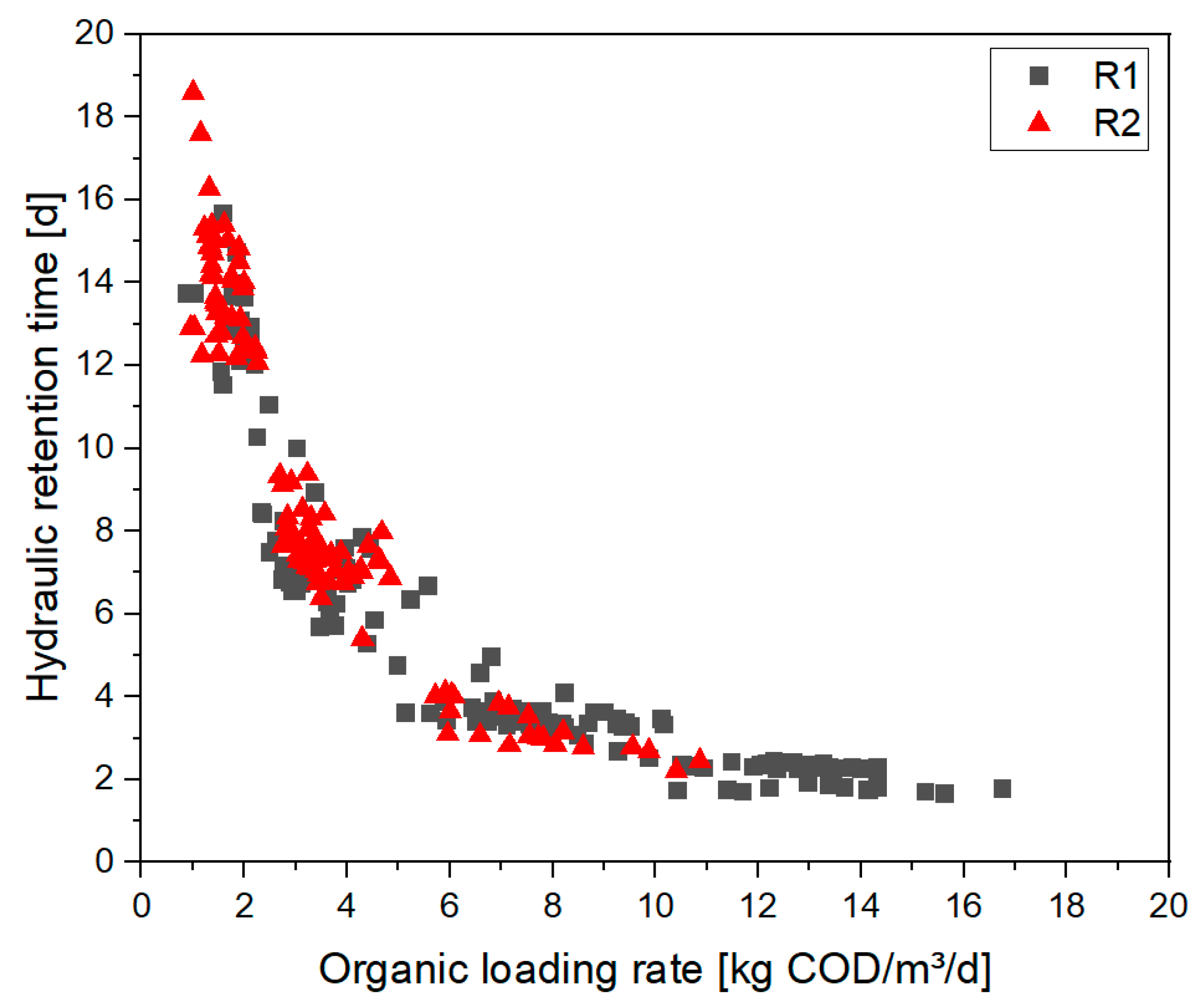

3.1. Description of the Entire Data Basis and the Operating Conditions

3.2. Evaluation of the OPs

3.3. Process Comparison

| Reactor | Volume | Substrate | Temperature | OLR | HRT | MPR | MY | COD Degradation Efficiency | Reference |

|---|---|---|---|---|---|---|---|---|---|

| (−) | (L) | (−) | (°C) | (kgCOD/m3/d) | (d) | (m3/m3/d) | (L/kgCOD) | (%) | (-) |

| CSTR | 9.2 | Filtered pig slurry | 35 | 0.6–2.0 | 10–20 | 0.08–0.47 | - | - | [53] |

| UASB | 1 | Filtered pig slurry | 35 ± 1 | 14.3 | 1.5 | 3.5 | 246 | - | [20] |

| UASB | 2.6 | Liquid fraction of pig manure | 35 | 12.39 | 1.19 | 3.18 | - | 75 | [50] |

| UASB | 0.84 | Potato leachate | 37 | 1.5–7.0 | 13.2–2.9 | 0.1 ± 0–1.4 ± 0.2 | - | 92 ± 4.2–93 ± 5.3 | [51] |

| FB | 0.7 | Potato leachate | 37 | 1.5–7.0 | 13.2–2.9 | 0.1 ± 0.02–0.7 ± 0.1 | - | 91 ± 4.2–98 ± 1.5 | [51] |

| FB | 34 | Filtered pig slurry | 40 | 3.7–13.5 | 6.6–1.8 | 0.87–3.00 | 217–262 | 53–73 | R1 |

| EGSB | 27.8 | Filtered pig slurry | 40 | 1.5–7.8 | 14.3–3.2 | 0.43–2.16 | 267–292 | 73–76 | R2 |

3.4. Influence of the Organic Loading Rate on the Methane Production Rate

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- REN21. Renewables 2020 Global Status Report. Available online: https://www.ren21.net/wp-content/uploads/2019/05/GSR2021_Full_Report.pdf (accessed on 16 November 2021).

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Dennehy, C.; Lawlor, P.G.; Jiang, Y.; Gardiner, G.E.; Xie, S.; Nghiem, L.D.; Zhan, X. Greenhouse gas emissions from different pig manure management techniques: A critical analysis. Front. Environ. Sci. Eng. 2017, 11, 11. [Google Scholar] [CrossRef]

- De Oliveira, A.C.L.; Milagres, R.S.; Orlando Junior, W.d.A.; Renato, N.d.S. Evaluation of Brazilian potential for generating electricity through animal manure and sewage. Biomass Bioenergy 2020, 139, 105654. [Google Scholar] [CrossRef]

- Meyer, A.; Ehimen, E.A.; Holm-Nielsen, J.B. Future European biogas: Animal manure, straw and grass potentials for a sustainable European biogas production. Biomass Bioenergy 2018, 111, 154–164. [Google Scholar] [CrossRef]

- Brosowski, A.; Thrän, D.; Mantau, U.; Mahro, B.; Erdmann, G.; Adler, P.; Stinner, W.; Reinhold, G.; Hering, T.; Blanke, C. A review of biomass potential and current utilisation—Status quo for 93 biogenic wastes and residues in Germany. Biomass Bioenergy 2016, 95, 257–272. [Google Scholar] [CrossRef] [Green Version]

- Kougias, P.G.; Angelidaki, I. Biogas and its opportunities—A review. Front. Environ. Sci. Eng. 2018, 12, 14. [Google Scholar] [CrossRef]

- Stinner, W.; Stur, M.; Paul, N.; Riesel, D. Gülle-Kleinanlagen; 1. Auflage; Fachagentur Nachwachsende Rohstoffe e.V. (FNR): Gülzow, Germany, 2015. [Google Scholar]

- Mauky, E.; Jacobi, H.F.; Liebetrau, J.; Nelles, M. Flexible biogas production for demand-driven energy supply--feeding strategies and types of substrates. Bioresour. Technol. 2015, 178, 262–269. [Google Scholar] [CrossRef]

- Theuerl, S.; Klang, J.; Hülsemann, B.; Mächtig, T.; Hassa, J. Microbiome Diversity and Community-Level Change Points within Manure-based small Biogas Plants. Microorganisms 2020, 8, 1169. [Google Scholar] [CrossRef]

- Zhou, L.; Hülsemann, B.; Cui, Z.; Merkle, W.; Sponagel, C.; Zhou, Y.; Guo, J.; Dong, R.; Müller, J.; Oechsner, H. Operating Performance of Full-Scale Agricultural Biogas Plants in Germany and China: Results of a Year-Round Monitoring Program. Appl. Sci. 2021, 11, 1271. [Google Scholar] [CrossRef]

- Schmidt, T.; Ziganshin, A.M.; Nikolausz, M.; Scholwin, F.; Nelles, M.; Kleinsteuber, S.; Pröter, J. Effects of the reduction of the hydraulic retention time to 1.5 days at constant organic loading in CSTR, ASBR, and fixed-bed reactors—Performance and methanogenic community composition. Biomass Bioenergy 2014, 69, 241–248. [Google Scholar] [CrossRef]

- Ruile, S.; Schmitz, S.; Mönch-Tegeder, M.; Oechsner, H. Degradation efficiency of agricultural biogas plants--a full-scale study. Bioresour. Technol. 2015, 178, 341–349. [Google Scholar] [CrossRef] [PubMed]

- Tápparo, D.C.; Cândido, D.; Steinmetz, R.L.R.; Etzkorn, C.; do Amaral, A.C.; Antes, F.G.; Kunz, A. Swine manure biogas production improvement using pre-treatment strategies: Lab-scale studies and full-scale application. Bioresour. Technol. Rep. 2021, 15, 100716. [Google Scholar] [CrossRef]

- Gallert, C.; Winter, J. Mikrobielle Grundlagen der Methangärung. In Anaerobtechnik: Abwasser-, Schlamm- und Reststoffbehandlung, Biogasgewinnung, 3rd ed.; Rosenwinkel, K.-H., Kroiss, H., Dichtl, N., Seyfried, C.F., Weiland, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 34–53. ISBN 978-3-642-24895-5. [Google Scholar]

- Austermann-Haun, U.; Engelhart, M.; Fischer, P.; Jördening, H.-J.; Kroiss, H.; Lange, R.; Meyer, H.; Müller, G.; Pascik, I.; Ríos-Valdovinos, E.; et al. Auswahl und Bewertung von Systemen und Reaktoren zur anaeroben Industrieabwasserbehandlung: Achter Arbeitsbericht der DWA-Arbeitsgruppe IG-5.1. Anaerobe Verfahren zur Behandlung von Industrieabwassern. Korrospondenz Abwasser Abfall 2012, 59, 36–44. [Google Scholar]

- Cruz-Salomón, A.; Ríos-Valdovinos, E.; Pola-Albores, F.; Lagunas-Rivera, S.; Meza-Gordillo, R.; Ruíz-Valdiviezo, V.M.; Cruz-Salomón, K.C. Expanded granular sludge bed bioreactor in wastewater treatment. Glob. J. Environ. Sci. Manag. 2019, 5, 119–138. [Google Scholar] [CrossRef]

- Ülgüdür, N.; Ergüder, T.H.; Uludağ-Demirer, S.; Demirer, G.N. High-rate anaerobic treatment of digestate using fixed film reactors. Environ. Pollut. 2019, 252, 1622–1632. [Google Scholar] [CrossRef]

- Terboven, C.; Ramm, P.; Herrmann, C. Demand-driven biogas production from sugar beet silage in a novel fixed bed disc reactor under mesophilic and thermophilic conditions. Bioresour. Technol. 2017, 241, 582–592. [Google Scholar] [CrossRef]

- Rico, C.; Montes, J.A.; Rico, J.L. Evaluation of different types of anaerobic seed sludge for the high rate anaerobic digestion of pig slurry in UASB reactors. Bioresour. Technol. 2017, 238, 147–156. [Google Scholar] [CrossRef] [Green Version]

- Bergland, W.H.; Dinamarca, C.; Toradzadegan, M.; Nordgård, A.S.R.; Bakke, I.; Bakke, R. High rate manure supernatant digestion. Water Res. 2015, 76, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Kato, M.T.; Field, J.A.; Versteeg, P.; Lettinga, G. Feasibility of expanded granular sludge bed reactors for the anaerobic treatment of low-strength soluble wastewaters. Biotechnol. Bioeng. 1994, 44, 469–479. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Han, G.-B. Pig slurry treatment by a hybrid multi-stage unit system consisting of an ATAD and an EGSB followed by a SBR reactor. Biosyst. Eng. 2012, 111, 243–250. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Han, G.-B. Waste treatment with the pilot scale ATAD and EGSB pig slurry management system followed by sequencing batch treatment. Environ. Eng. Res. 2015, 20, 277–284. [Google Scholar] [CrossRef] [Green Version]

- Liebetrau, J.; Pfeiffer, D. Collection of Measurement Methods for Biogas. 2020. Available online: https://www.energetische-biomassenutzung.de/publikationen/schriftenreihe/07-messmethodensammlung-biogas-en (accessed on 16 November 2021).

- EN ISO 11885:2009; Water Quality—Determination of Selected Elements by Inductively Coupled Plasma Optical Emission Spectrometry Deutsche Fassung EN_ISO_11885:2009. Beuth Verlag GmbH: Berlin, Germany, 2009.

- DIN 38406; Deutsche Einheitsverfahren zur Wasser-, Abwasser- und Schlammuntersuchung; Kationen (Gruppe_E). Bestimmung des Ammonium-Stickstoffs_(E_5). Beuth Verlag GmbH: Berlin, Germany, 1983.

- VDLUFA. Bestimmung von Gesamtstickstoff: 3.5.2.7. In Methodenbuch II.1: 125 Jahre VDLUFA im Dienste von Landwirtschaft, Umwelt- und Verbraucherschutz; VDLUFA-Verl.: Darmstadt, Germany, 2014; ISBN 978-3-941273-15-3. [Google Scholar]

- Fachagentur Nachwachsende Rohstoffe e.V. Guide to Biogas: From Production to Use, 5th ed.; Fachagentur Nachwachsende Rohstoffe e.V.: Gülzow, Germany, 2012. [Google Scholar]

- Costa, J.C.; Oliveira, J.V.; Alves, M.M. Response surface design to study the influence of inoculum, particle size and inoculum to substrate ratio on the methane production from Ulex sp. Renew. Energy 2016, 96, 1071–1077. [Google Scholar] [CrossRef] [Green Version]

- Shen, F.; Yuan, H.; Pang, Y.; Chen, S.; Zhu, B.; Zou, D.; Liu, Y.; Ma, J.; Yu, L.; Li, X. Performances of anaerobic co-digestion of fruit & vegetable waste (FVW) and food waste (FW): Single-phase vs. two-phase. Bioresour. Technol. 2013, 144, 80–85. [Google Scholar] [CrossRef] [PubMed]

- Weide, T.; Peitzmeier, J.; Wetter, C.; Wichern, M.; Brügging, E. Comparison of thermophilic and hyperthermophilic dark fermentation with subsequent mesophilic methanogenesis in expanded granular sludge bed reactors. Int. J. Hydrogen Energy 2020, 46, 29142–29159. [Google Scholar] [CrossRef]

- Jafarzadeh, M.T.; Jamshidi, N.; Talebiazar, L.; Aslaniavali, R. Performance evaluation of an anaerobic hybrid reactor treating petrochemical effluent. Int. J. Geol. 2021, 14, 51–57. [Google Scholar] [CrossRef]

- Karim, K.; Thomas Klasson, K.; Hoffmann, R.; Drescher, S.R.; Depaoli, D.W.; Al-Dahhan, M.H. Anaerobic digestion of animal waste: Effect of mixing. Bioresour. Technol. 2005, 96, 1607–1612. [Google Scholar] [CrossRef]

- Duan, N.; Zhang, D.; Lin, C.; Zhang, Y.; Zhao, L.; Liu, H.; Liu, Z. Effect of organic loading rate on anaerobic digestion of pig manure: Methane production, mass flow, reactor scale and heating scenarios. J. Environ. Manag. 2019, 231, 646–652. [Google Scholar] [CrossRef]

- Hinks, J.; Edwards, S.; Sallis, P.J.; Caldwell, G.S. The steady state anaerobic digestion of Laminaria hyperborea--effect of hydraulic residence on biogas production and bacterial community composition. Bioresour. Technol. 2013, 143, 221–230. [Google Scholar] [CrossRef]

- Rossi, E.; Pecorini, I.; Iannelli, R. Multilinear Regression Model for Biogas Production Prediction from Dry Anaerobic Digestion of OFMSW. Sustainability 2022, 14, 4393. [Google Scholar] [CrossRef]

- Singh, S.P.; Prerna, P. Review of recent advances in anaerobic packed-bed biogas reactors. Renew. Sustain. Energy Rev. 2009, 13, 1569–1575. [Google Scholar] [CrossRef]

- Lim, S.J.; Kim, T.-H. Applicability and trends of anaerobic granular sludge treatment processes. Biomass Bioenergy 2014, 60, 189–202. [Google Scholar] [CrossRef]

- Khanal, S.K. Anaerobic Biotechnology for Bioenergy Production: Principles and Applications; Wiley-Blackwell: Ames, IA, USA, 2008. [Google Scholar]

- Mata-Alvarez, J.; Dosta, J.; Romero-Güiza, M.S.; Fonoll, X.; Peces, M.; Astals, S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Hinken, L.; Austermann-Haun, U.; Meyer, H.; Urban, I. Anaerobe Abwasserbehandlung zur Kohlenstoffelimination. In Anaerobtechnik: Abwasser-, Schlamm- und Reststoffbehandlung, Biogasgewinnung, 3rd ed.; Rosenwinkel, K.-H., Kroiss, H., Dichtl, N., Seyfried, C.F., Weiland, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2015; pp. 283–356. ISBN 978-3-642-24895-5. [Google Scholar]

- Regalado, R.E.H.; Weide, T.; Baumkötter, D.; Wettwer, L.; Häner, J.; Brügging, E.; Tränckner, J. Optimization and Analysis of Liquid Anaerobic Co-Digestion of Agro-Industrial Wastes via Mixture Design. Processes 2021, 9, 877. [Google Scholar] [CrossRef]

- Wresta, A.; Sintawardani, N.; Adisasmito, S.; Kurniawan, T.A.; Setiadi, T. Characteristics of tofu whey degradation during self-sustaining batch anaerobic process for methane production. J. Environ. Chem. Eng. 2021, 9, 106359. [Google Scholar] [CrossRef]

- Van, D.P.; Fujiwara, T.; Leu Tho, B.; Song Toan, P.P.; Hoang Minh, G. A review of anaerobic digestion systems for biodegradable waste: Configurations, operating parameters, and current trends. Environ. Eng. Res. 2020, 25, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Uddin, M.M.; Wright, M.M. Anaerobic digestion fundamentals, challenges, and technological advances. Phys. Sci. Rev. 2022. [Google Scholar] [CrossRef]

- Lossie, U.; Pütz, P. Targeted Control of Biogas Plants with the Help of FOS/TAC. 2008. Available online: https://tr.hach.com/asset-get.download.jsa?id=25593611361 (accessed on 6 June 2022).

- Verein Deutscher Ingenieure. Fermentation of Organic Materials–Characterisation of the Substrate, Sampling, Collection of Material Data, Fermentation Tests; VDI: Düsseldorf, Germany, 2016. [Google Scholar]

- Fang, C.; Boe, K.; Angelidaki, I. Biogas production from potato-juice, a by-product from potato-starch processing, in upflow anaerobic sludge blanket (UASB) and expanded granular sludge bed (EGSB) reactors. Bioresour. Technol. 2011, 102, 5734–5741. [Google Scholar] [CrossRef]

- Kalyuzhnyi, S.; Skylar, V.; Fedorovich, V.; Kovalev, A.; Nozhevnikova, A.; Klapwijk, A. The development of biological methods for utilisation and treatment of diluted manure streams. Water Sci. Technol. 1999, 40, 223–229. [Google Scholar] [CrossRef]

- Parawira, W.; Murto, M.; Zvauya, R.; Mattiasson, B. Comparative performance of a UASB reactor and an anaerobic packed-bed reactor when treating potato waste leachate. Renew. Energy 2006, 31, 893–903. [Google Scholar] [CrossRef]

- Nasir, I.M.; Mohd Ghazi, T.I.; Omar, R. Anaerobic digestion technology in livestock manure treatment for biogas production: A review. Eng. Life Sci. 2012, 12, 258–269. [Google Scholar] [CrossRef]

- Regueiro, L.; Carballa, M.; Alvarez, J.A.; Lema, J.M. Enhanced methane production from pig manure anaerobic digestion using fish and biodiesel wastes as co-substrates. Bioresour. Technol. 2012, 123, 507–513. [Google Scholar] [CrossRef]

- Friehe, J.; Weiland, P.; Schattauer, A. Fundamentals of anaerobic digestion. In Guide to Biogas: From Production to Use, 5th ed.; Fachagentur Nachwachsende Rohstoffe e.V.: Gülzow, Germany, 2012; pp. 21–32. [Google Scholar]

- Yu, H.; Wilson, F.; Tay, J.-H. Kinetic analysis of an anaerobic filter treating soybean wastewater. Water Res. 1998, 32, 3341–3352. [Google Scholar] [CrossRef]

- Korres, N.; O’Kiely, P.; Benzie, J.A.; West, J.S. Bioenergy Production by Anaerobic Digestion: Using Agricultural Biomass and Organic wastes; Earthscan from Routledge: Abingdon, UK; New York, NY, USA, 2013; ISBN 9781136489648. [Google Scholar]

- Pereda Reyes, I.; Teixeira Correia, G.; Pérez Pérez, T.; Oliva Merencio, D.; Zaiat, M.; Kwong, W. Mathematical Modeling of the Hydrodynamics of an EGSB Reactor. J. Chem. Chem. Eng. 2014, 8, 602–610. [Google Scholar]

- Hernández Regalado, R.E.; Häner, J.; Baumkötter, D.; Wettwer, L.; Brügging, E.; Tränckner, J. Continuous Co-Digestion of Agro-Industrial Mixtures in Laboratory Scale Expanded Granular Sludge Bed Reactors. Appl. Sci. 2022, 12, 2295. [Google Scholar] [CrossRef]

- Rolf, J.; Weide, T.; Brügging, E.; Wetter, C. The Application of Biodegradable Flocculants derived from Potato Starch for Nutrient Recovery in Pig Manure. Glob. J. Agric. Res. 2021, 9, 1–15. [Google Scholar] [CrossRef]

- Gesetz für den Ausbau erneuerbarer Energien: EEG-2021; The German Federal Ministry of Justice: Berlin, Germany, 2021; Available online: https://www.gesetze-im-internet.de/eeg_2014/BJNR106610014.html (accessed on 6 June 2022).

- United Nations. The Sustainable Development Goals Report 2020. Available online: https://unstats.un.org/sdgs/report/2020/ (accessed on 30 May 2022).

- Thrän, D.; Schindler, H.; Kornatz, P.; Dotzauer, M.; Nelles, M. Die Rolle von Biogas für eine Sichere Gasversorgung in Deutschland: Stand der Biogasnutzung und Empfehlungen für Ihren Verbesserten Beitrag zur Versorgungssicherheit Nach Dem Russischen Überfall auf die Ukraine. 2022. Available online: https://www.dbfz.de/fileadmin//user_upload/Referenzen/Statements/Positionspapier_Biogas_Ukraine.pdf (accessed on 30 May 2022).

- Rodriguez-Verde, I.; Regueiro, L.; Carballa, M.; Hospido, A.; Lema, J.M. Assessing anaerobic co-digestion of pig manure with agroindustrial wastes: The link between environmental impacts and operational parameters. Sci. Total Environ. 2014, 497–498, 475–483. [Google Scholar] [CrossRef]

- Liebetrau, J.; O’Shea, R.; Wellisch, M.; Lyng, K.-A.; Bochmann, G.; McCabe, B.K.; Harris, P.W.; Lukehurst, C.; Kornatz, P.; Murphy, J.D. Potential and Utilization of Manure to Generate Biogas in Seven Countries. IEA Bioenergy: Task 37. June 2021. Available online: https://www.ieabioenergy.com/wp-content/uploads/2021/07/Potential-utilization_WEB_END_NEW.pdf (accessed on 30 May 2022).

| Parameter | Unit | Value |

|---|---|---|

| pH | (-) | 7.93 |

| Dry matter | (wt%) | 1.9 ± 0.3 |

| Organic dry matter | (wt%) | 61.1 ± 2.8 |

| Chemical oxygen demand | (gCOD/L) | 25.48 ± 7.72 |

| Biochemical oxygen demand after 5 days | (g/L) | 13.43 ± 4.25 |

| Total nitrogen | (wt%) | 0.28 |

| Ammonium–nitrogen | (wt%) | 0.22 |

| Phosphorus pentoxide | (wt%) | 0.061 |

| Potassium oxide | (wt%) | 0.22 |

| Magnesium oxide | (wt%) | <0.05 |

| Calcium oxide | (wt%) | <0.1 |

| Sulfur | (wt%) | 0.04 |

| Parameter | Interval | Sampling Point |

|---|---|---|

| pH | Every second | Recirculation flow |

| Temperature | Every second | Recirculation flow |

| Effluent mass | Every day | SP1.3/SP2.3 |

| Gas volume | Every day | TG 0.5.1/TG 0.5.2 |

| Gas quality | Every day | GB1/GB2 |

| Chemical oxygen demand | Twice a week | SP1.1/SP2.1; SP1.3/SP2.3 |

| VOA/TIC | Twice a week | SP1.2/SP2.2 |

| Dry matter and organic dry matter | Every two weeks | SP1.1/SP2.1; SP1.3/SP2.3 |

| Reactor | Operation Point | Operating Conditions | |

|---|---|---|---|

| Hydraulic Retention Time | Organic Loading Rate | ||

| (d) | (kgCOD/m3/d) | ||

| R1 | OP1 | 13.3 ± 1.5 | 1.70 ± 0.43 |

| OP2 | - | - | |

| OP3 | 7.2 ± 1.6 | 3.32 ± 0.96 | |

| OP4 | 3.5 ± 0.3 | 7.13 ± 0.88 | |

| OP5 | 2.4 ± 0.2 | 12.26 ± 1.52 | |

| OP6 | 1.8 ± 0.1 | 13.52 ± 1.73 | |

| R2 | OP1 | 13.9 ± 1.4 | 1.55 ± 0.33 |

| OP2 | 9.7 ± 1.4 | 3.03 ± 0.51 | |

| OP3 | 7.4 ± 0.6 | 3.57 ± 0.56 | |

| OP4.1 | 3.2 ± 0.6 | 7.60 ± 1.54 | |

| OP4.2 | 3.1 ± 0.4 | 7.83 ± 0.16 | |

| Reactor | Relationship | OLRmin | OLRmax | R2 | Datasplit | R2 Validation |

|---|---|---|---|---|---|---|

| R1 | MPR = 0.188·OLR + 0.32515 | 2.5 | 16.8 | 90.78% | 90/10 | 92.66% |

| R2 | MPR = 0.245·OLR + 0.07853 | 1.0 | 10.9 | 90.20% | 80/20 | 94.34% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Häner, J.; Weide, T.; Naßmacher, A.; Hernández Regalado, R.E.; Wetter, C.; Brügging, E. Anaerobic Digestion of Pig Slurry in Fixed-Bed and Expanded Granular Sludge Bed Reactors. Energies 2022, 15, 4414. https://doi.org/10.3390/en15124414

Häner J, Weide T, Naßmacher A, Hernández Regalado RE, Wetter C, Brügging E. Anaerobic Digestion of Pig Slurry in Fixed-Bed and Expanded Granular Sludge Bed Reactors. Energies. 2022; 15(12):4414. https://doi.org/10.3390/en15124414

Chicago/Turabian StyleHäner, Jurek, Tobias Weide, Alexander Naßmacher, Roberto Eloy Hernández Regalado, Christof Wetter, and Elmar Brügging. 2022. "Anaerobic Digestion of Pig Slurry in Fixed-Bed and Expanded Granular Sludge Bed Reactors" Energies 15, no. 12: 4414. https://doi.org/10.3390/en15124414