Study on Chemical Kinetics Mechanism of Ignition Characteristics of Dimethyl Ether Blended with Small Molecular Alkanes

Abstract

:1. Introduction

2. Calculation Method

3. Results and Discussion

3.1. Ignition Delay Characteristic of DME/C1-C4 Alkane Mixtures

3.1.1. Comparison of Ignition Delay Characteristic of DME/C1-C4 Alkane Mixtures at Different Equivalence Ratios

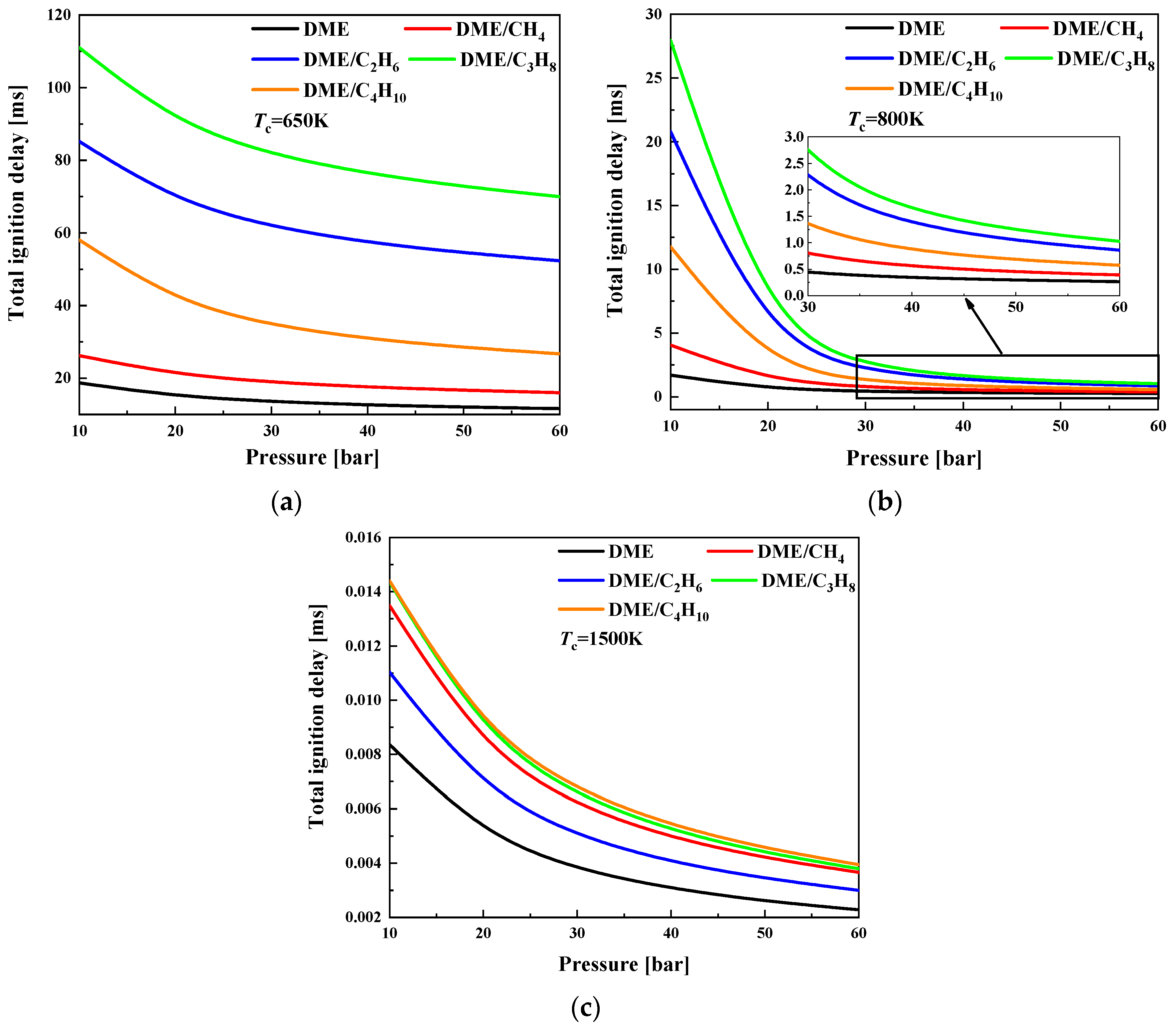

3.1.2. Comparison of Ignition Delay Characteristic of DME/C1-C4 Alkane Mixtures at Different Compressed Pressures

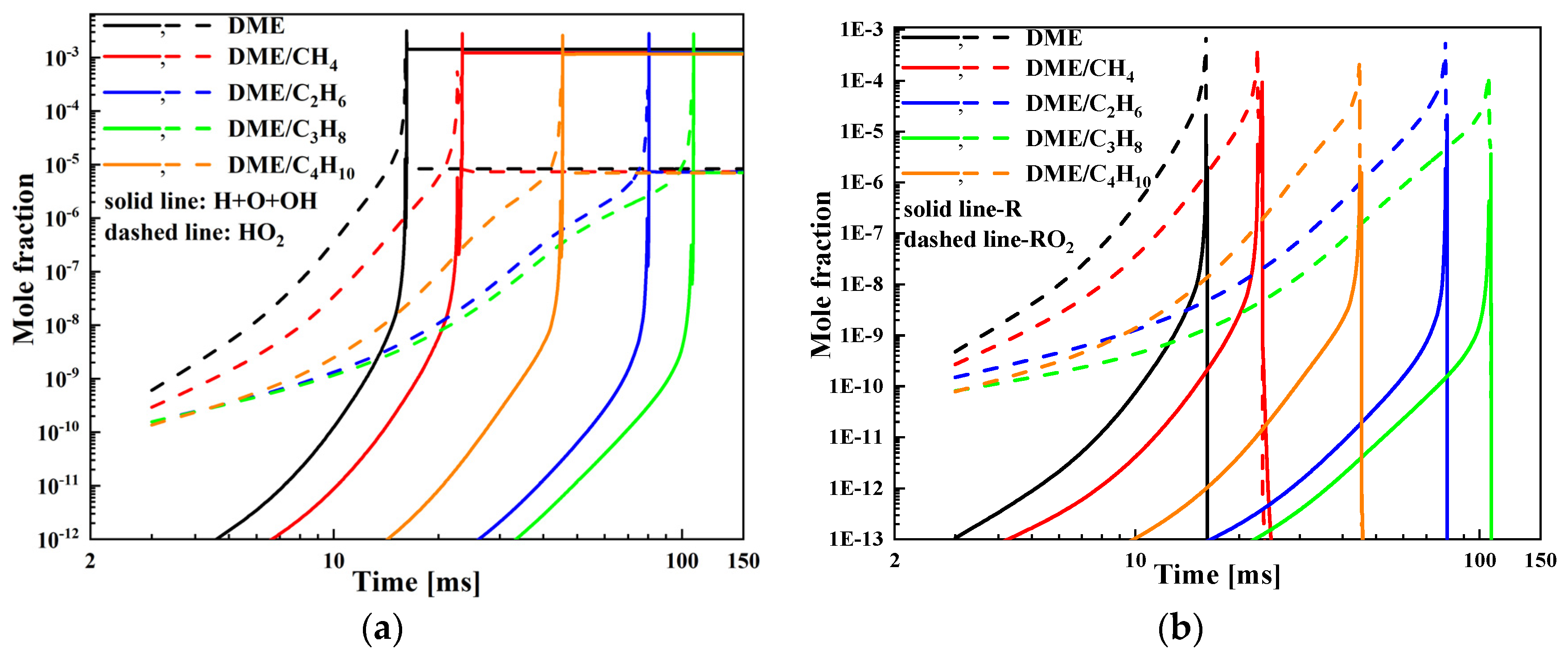

3.1.3. Mole Fraction Analysis

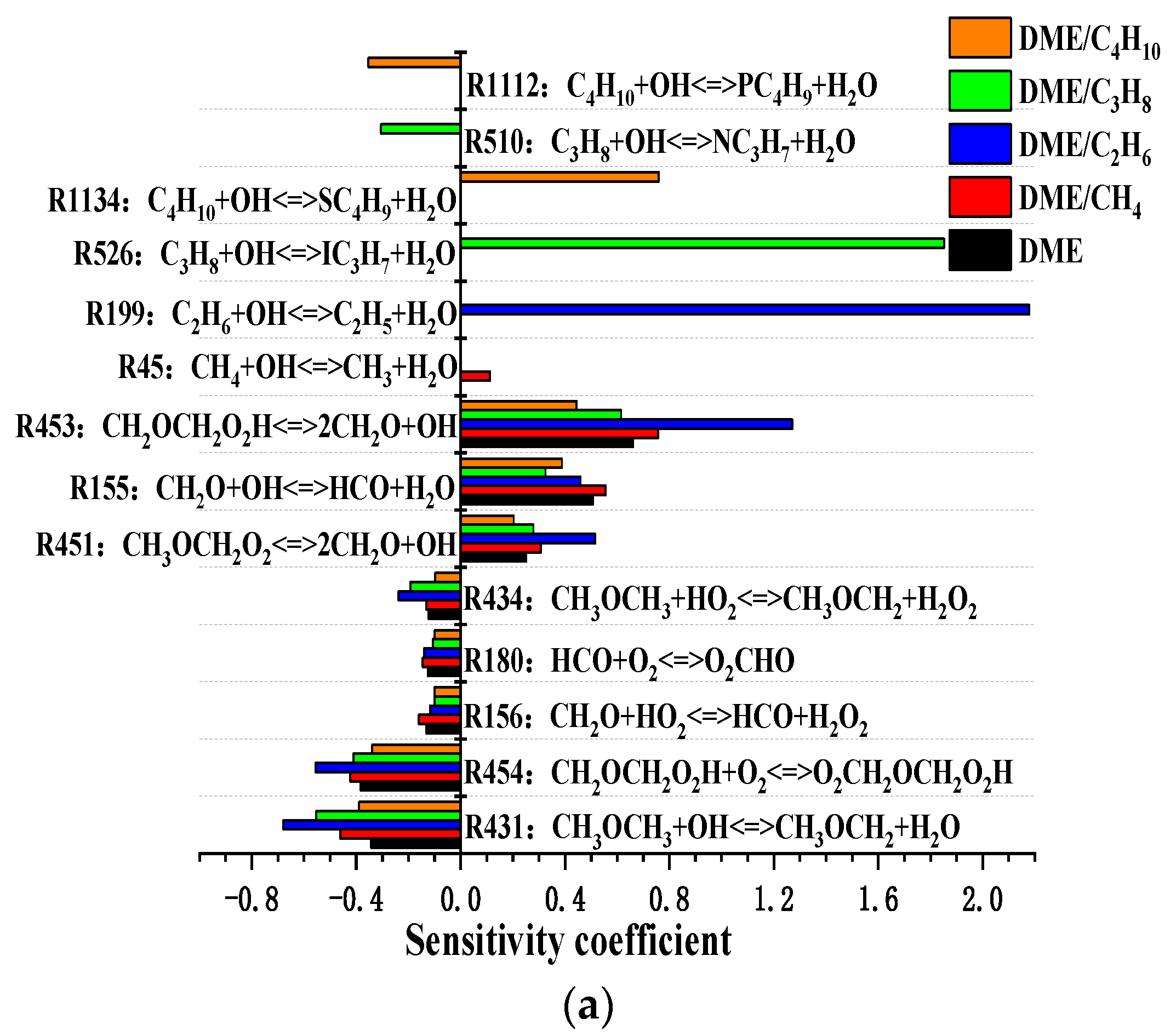

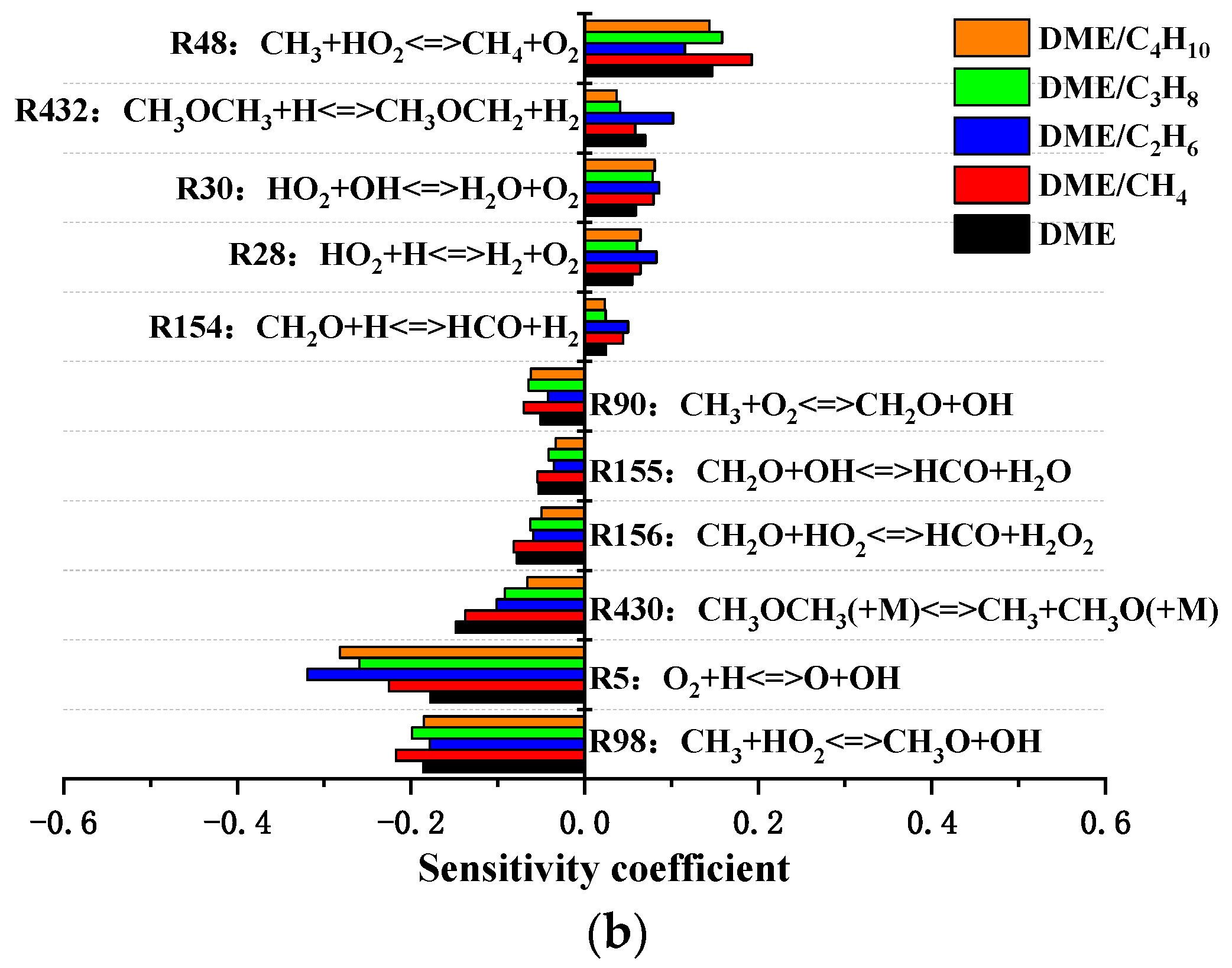

3.1.4. Sensitivity Analysis

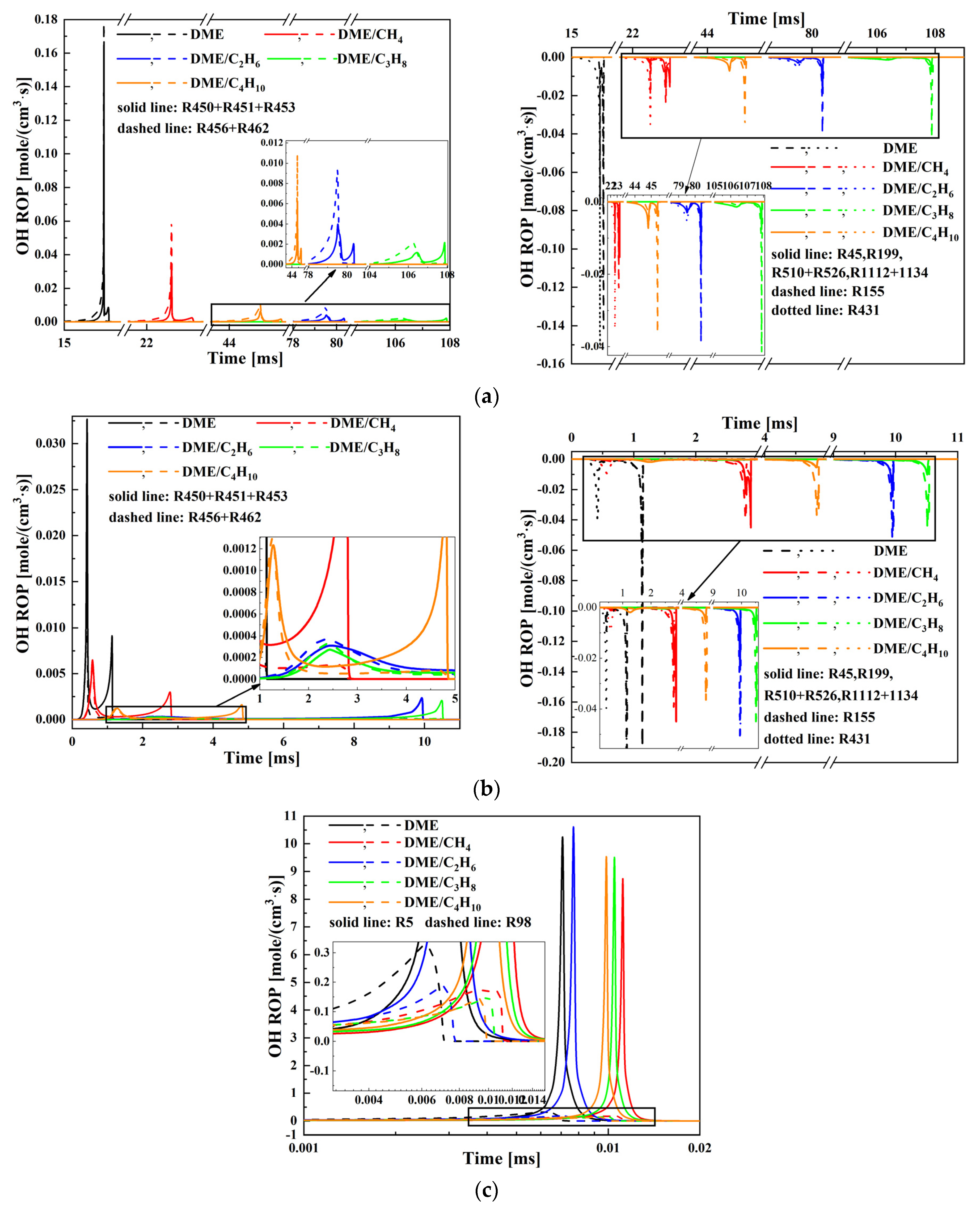

3.1.5. Production Rate Analysis

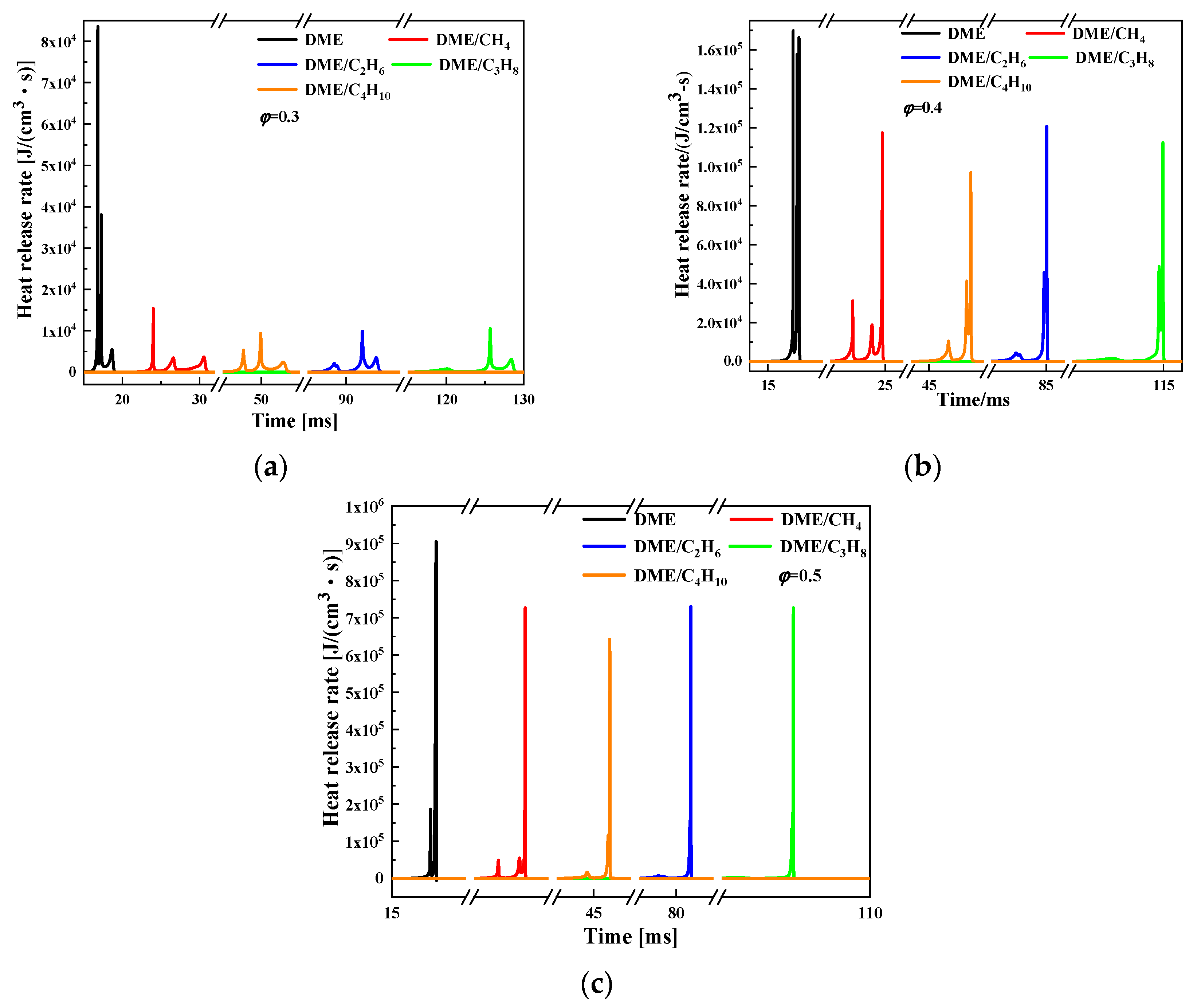

3.2. Multi-Stage Ignition Characteristic of DME/C1-C4 Alkane Mixtures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, D.C.; Zhao, R.N.; Wu, H.; Shi, Z.C.; Li, X.R. Experimental study on combustion and emission characteristics of diesel engine with high supercharged condition. Chemosphere 2022, 304, 135336. [Google Scholar] [CrossRef]

- Arcoumains, C.; Bae, C.; Crookes, R.; Kinoshita, E. The potential of dimethyl ether (DME) as an alternative fuel for compression-ignition engines: A review. Fuel 2008, 87, 1014–1030. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, C.S. Applicability of dimethyl ether (DME) in a compression ignition engine as an alternative fuel. Energy Conv. Manag. 2014, 86, 848–863. [Google Scholar] [CrossRef]

- Yao, M.F.; Zheng, Z.L.; Liu, H.F. Progress and recent trends in homogeneous charge compression ignition (HCCI) engines. Prog. Energy Combust. Sci. 2009, 35, 398–437. [Google Scholar] [CrossRef]

- Hasan, M.M.; Rahman, M.M. Homogeneous charge compression ignition combustion: Advantages over compression ignition combustion, challenges and solutions. Renew. Sustain. Energy Rev. 2016, 57, 282–291. [Google Scholar] [CrossRef] [Green Version]

- Bendu, H.; Murugan, S. Homogeneous charge compression ignition (HCCI) combustion: Mixture preparation and control strategies in diesel engines. Renew. Sustain. Energy Rev. 2014, 38, 732–746. [Google Scholar] [CrossRef]

- Jung, D.; Kwon, O.; Lim, O.T. Comparison of DME HCCI operating ranges for the thermal stratification and fuel stratification based on a multi-zone model. J. Mech. Sci. Technol. 2011, 25, 1383–1390. [Google Scholar] [CrossRef]

- Lu, X.C.; Han, D.; Huang, Z. Fuel design and management for the control of advanced compression-ignition combustion modes. Prog. Energy Combust. Sci. 2011, 37, 741–783. [Google Scholar] [CrossRef]

- Duan, X.B.; Lai, M.C.; Jansons, M.; Guo, G.M.; Liu, J.P. A review of controlling strategies of the ignition timing and combustion phase in homogeneous charge compression ignition (HCCI) engine. Fuel 2021, 285, 119142. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, H.; Lu, H.; Liu, H.; Yunsheng, A.; Meng, F. Autoignition of DME/H2 mixtures in a rapid compression machine under low-to-medium temperature ranges. Fuel 2017, 194, 50–62. [Google Scholar] [CrossRef]

- Mittal, G.; Chaos, M.; Sung, C.J.; Dryer, F.L. Dimethyl ether autoignition in a rapid compression machine: Experiments and chemical kinetic modeling. Fuel Process. Technol. 2008, 89, 1244–1254. [Google Scholar] [CrossRef]

- Cook, R.D.; Davidson, D.F.; Hanson, R.K. Shock tube measurements of ignition delay times and OH time-histories in dimethyl ether oxidation. Proc. Combust. Inst. 2009, 32, 189–196. [Google Scholar] [CrossRef]

- Li, Z.H.; Wang, W.J.; Huang, Z.; Oehlschlaeger, M.A. Dimethyl ether autoignition at Engine-Relevant conditions. Energy Fuels 2013, 27, 2811–2817. [Google Scholar] [CrossRef]

- Pan, L.; Hu, E.J.; Tian, Z.M.; Yang, F.Y.; Huang, Z.H. Experimental and kinetic study on ignition delay times of dimethyl ether at high temperatures. Energy Fuels 2015, 29, 3495–3506. [Google Scholar] [CrossRef]

- Schonborn, A.; Sayad, P.; Konnov, A.A.; Klingmann, J. Autoignition of dimethyl ether and air in an optical flow-reactor. Energy Fuels 2014, 28, 4130–4138. [Google Scholar] [CrossRef]

- Fischer, S.L.; Dryer, F.L.; Curran, H.J. The reaction kinetics of dimethyl ether. I: High-temperature pyrolysis and oxidation in flow reactors. Int. J. Chem. Kinet. 2000, 32, 713–740. [Google Scholar] [CrossRef]

- Curran, H.J.; Fischer, S.L.; Dryer, F.L. The reaction kinetics of dimethyl ether. II: Low-temperature oxidation in flow reactors. Int. J. Chem. Kinet. 2000, 32, 741–759. [Google Scholar] [CrossRef]

- Dagaut, P.; Daly, C.; Simmie, J.M.; Cathonnet, M. The oxidation and ignition of dimethyl ether from low to high temperature (500–1600 K): Experiments and kinetic modeling. Symp. Int. Combust. 1998, 27, 361–369. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, H.G.; Shi, Z.C.; Lu, H.T.; Zhao, G.Y.; Yao, B.F. Performance characterization and auto-ignition performance of a rapid compression machine. Energies 2014, 7, 6083–6104. [Google Scholar] [CrossRef] [Green Version]

- Shi, Z.C.; Zhang, H.G.; Liu, H.; Lu, H.T.; Lia, J.Z.; Gao, X. Effects of buffer gas composition on autoignition of dimethyl ether. Energies 2015, 8, 10198–10218. [Google Scholar] [CrossRef] [Green Version]

- Burke, U.; Somers, K.P.; O’Toole, P.; Zinner, C.M.; Marquet, N.; Bourque, G.; Petersen, E.L.; Metcalfe, W.K.; Serinyel, Z.; Curran, H.J. An ignition delay and kinetic modeling study of methane, dimethyl ether, and their mixtures at high pressures. Combust. Flame 2015, 162, 315–330. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.L.; Wei, L.J.; Zhang, J.X.; Man, X.J.; Huang, Z.H. Shock tube measurements and kinetic investigation on the ignition delay times of methane/dimethyl ether mixtures. Energy Fuels 2012, 26, 6720–6728. [Google Scholar] [CrossRef]

- Shi, Z.C.; Wu, H.; Zhang, H.G.; Wang, Z.M.; Lee, C.F.; Xu, Y.H. Autoignition of DME/C2H6 mixtures under high-pressure and low-temperature conditions. Combust. Sci. Technol. 2018, 191, 1201–1218. [Google Scholar] [CrossRef]

- Zhang, J.X.; Hu, E.J.; Pan, L.; Zhang, Z.H.; Huang, Z.H. Shock-tube measurements of ignition delay times for the ethane/dimethyl ether blends. Energy Fuels 2013, 27, 6247–6254. [Google Scholar] [CrossRef]

- Lu, L.X.; Zou, C.; Xia, W.X.; Lin, Q.J.; Shi, H.Y. Experimental and numerical study on the ignition delay times of dimethyl ether/ethane/oxygen/carbon dioxide mixtures. Fuel 2020, 280, 118675. [Google Scholar] [CrossRef]

- Dames, E.E.; Rosen, A.S.; Weber, B.W.; Gao, C.W.; Sung, C.J.; Green, W.H. A detailed combined experimental and theoretical study on dimethyl ether/propane blended oxidation. Combust. Flame 2016, 168, 310–330. [Google Scholar] [CrossRef]

- Hu, E.J.; Zhang, Z.H.; Pan, L.; Zhang, J.X.; Huang, Z.H. Experimental and modeling study on ignition delay times of dimethyl ether/propane/oxygen/argon mixtures at 20 bar. Energy Fuels 2013, 27, 4007–4013. [Google Scholar] [CrossRef]

- Wu, H.; Shi, Z.C.; Lee, C.F.; Zhang, H.G.; Xu, Y.H. Experimental and kinetic study on ignition of DME/n-butane mixtures under high pressures on a rapid compression machine. Fuel 2018, 225, 35–46. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, Y.J.; Man, X.J.; Pan, L.; Huang, Z.H. Shock tube measurements and kinetic study on ignition delay times of lean DME/n-butane blends at elevated pressures. Energy Fuels 2013, 27, 6238–6246. [Google Scholar] [CrossRef]

- Jiang, X.; Tian, Z.M.; Zhang, Y.J.; Huang, Z.H. Shock tube measurement and simulation of DME/n-butane/air mixtures: Effect of blending in the NTC region. Fuel 2017, 203, 316–329. [Google Scholar] [CrossRef]

- Hu, E.J.; Huang, Z.H.; Jiang, X.; Zhang, J.X. Study on Ignition Delay Times of DME and n-Butane Blends; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Hu, E.J.; Jiang, X.; Huang, Z.H.; Zhang, J.X.; Zhang, Z.H.; Man, X.J. Experimental and kinetic studies on ignition delay times of dimethyl ether/n-butane/O2/Ar mixtures. Energy Fuels 2013, 27, 530–536. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, Y.J.; Man, X.J.; Pan, L.; Huang, Z.H. Experimental and modeling study on ignition delay times of dimethyl ether/n-butane blends at a pressure of 2.0 MPa. Energy Fuels 2014, 28, 2189–2198. [Google Scholar] [CrossRef]

- Jiang, X.; Zhang, Y.J.; Pan, L.; Man, X.J.; Huang, Z.H. Experimental and Modeling Study on Auto-Ignition of DME/n-Butane Blends under Engine Relevant Pressure; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2014. [Google Scholar] [CrossRef]

- Oshibe, H.; Nakamura, H.; Tezuka, T.; Hasegawa, S.; Maruta, K. Stabilized three-stage oxidation of DME/air mixture in a micro flow reactor with a controlled temperature profile. Combust. Flame 2010, 157, 1572–1580. [Google Scholar] [CrossRef]

- Lim, O.T. Numerical analysis of the effect of inhomogeneous pre-mixture on the pressure rise rate in an HCCI engine using multi-zone chemical kinetics. Int. J. Automot. Technol. 2014, 15, 535–541. [Google Scholar] [CrossRef] [Green Version]

- Iijima, A.; Tsutsumi, Y.; Yoshida, K.; Shoji, H. Spectroscopic Study of Two-Stage High Temperature Heat Release Behavior in a Supercharged HCCI Engine Using Blended Fuels; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Shimizu, R.; Iijima, A.; Yoshida, K.; Shoji, H. Analysis of Supercharged HCCI Combustion Using a Blended Fuel; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Komatsu, K.; Asanuma, M.; Iijima, A.; Yoshida, K.; Shoji, H. A Study of an HCCI Engine Operating on a Blended Fuel of DME and Methane; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Zhou, C.W.; Li, Y.; Burke, U.; Banyon, C.; Somers, K.P.; Ding, S.T.; Khan, S.; Hargis, J.W.; Sikes, T.; Mathieu, O. An experimental and chemical kinetic modeling study of 1,3-butadiene combustion: Ignition delay time and laminar flame speed measurements. Combust. Flame 2018, 197, 423–438. [Google Scholar] [CrossRef]

| Type | Fuel | XDME (%) | Tc (T) | Pc (bar) | φ (-) |

|---|---|---|---|---|---|

| Ignition delay | DME/CH4 | 50% | 600–2000 | 10–50 | 0.5–2.0 |

| DME/C2H6 | |||||

| DME/C3H8 | |||||

| DME/C4H10 | |||||

| Multi-stage ignition | DME/CH4 | 50% | 650 | 20 | 0.3–0.5 |

| DME/C2H6 | |||||

| DME/C3H8 | |||||

| DME/C4H10 |

| Reaction Number | Reaction Equation |

|---|---|

| R5 | O2 + H <=> O + OH |

| R45 | CH4 + OH <=> CH3 + H2O |

| R98 | CH3 + HO2 <=> CH3O + OH |

| R155 | CH2O + OH <=> HCO + H2O |

| R199 | C2H6 + OH <=> C2H5 + H2O |

| R431 | CH3OCH3 + OH <=> CH3OCH2 + H2O |

| R450 | CH3OCH2 + O2 <=> 2CH2O + OH |

| R451 | CH3OCH2O2 <=> 2CH2O + OH |

| R453 | CH2OCH2O2H <=> 2CH2O + OH |

| R456 | O2CH2OCH2O2H <=> HO2CH2OCHO + OH |

| R462 | HO2CH2OCHO <=> OCH2OCHO + OH |

| R510 | C3H8 + OH <=> NC3H7 + H2O |

| R526 | C3H8 + OH <=> IC3H7 + H2O |

| R1112 | C4H10 + OH <=> PC4H9 + H2O |

| R1134 | C4H10 + OH <=> SC4H9 + H2O |

| Reaction Number | Reaction Equation |

|---|---|

| R2 | H + O2 + M <=> HO2 + M |

| R3 | HCHO + OH <=> HCO + H2O |

| R4 | HCO + O2 <=> CO + HO2 |

| R5 | HO2 + HO2 <=> H2O2 + O2 |

| R6 | H2O2 + M <=> OH + OH + M |

| R7 | CO + OH <=> CO2 + H |

| R8 | HO2 + OH <=> H2O + O2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, K.; Yao, B.; Xu, Y.; Zhang, H.; Shi, Z.; Wang, Y. Study on Chemical Kinetics Mechanism of Ignition Characteristics of Dimethyl Ether Blended with Small Molecular Alkanes. Energies 2022, 15, 4652. https://doi.org/10.3390/en15134652

Niu K, Yao B, Xu Y, Zhang H, Shi Z, Wang Y. Study on Chemical Kinetics Mechanism of Ignition Characteristics of Dimethyl Ether Blended with Small Molecular Alkanes. Energies. 2022; 15(13):4652. https://doi.org/10.3390/en15134652

Chicago/Turabian StyleNiu, Kai, Baofeng Yao, Yonghong Xu, Hongguang Zhang, Zhicheng Shi, and Yan Wang. 2022. "Study on Chemical Kinetics Mechanism of Ignition Characteristics of Dimethyl Ether Blended with Small Molecular Alkanes" Energies 15, no. 13: 4652. https://doi.org/10.3390/en15134652

APA StyleNiu, K., Yao, B., Xu, Y., Zhang, H., Shi, Z., & Wang, Y. (2022). Study on Chemical Kinetics Mechanism of Ignition Characteristics of Dimethyl Ether Blended with Small Molecular Alkanes. Energies, 15(13), 4652. https://doi.org/10.3390/en15134652