1. Introduction

With the increasing severity of the global energy crisis and the environmental pollution caused by transportation energy consumption, the world’s demand for efficient and clean energy is also increasing year by year. As a type of reusable, rechargeable battery, lithium batteries greatly reduce carbon emissions and chemical fuel consumption. In addition, due to the advantages of high energy density, low self-discharge rate, and long service life, lithium batteries are widely used in electric vehicles [

1,

2]. As one of the most important state quantities of lithium batteries, the SOC is not only an important parameter for measuring the remaining power of batteries but also an important index for ensuring the safety and service life of batteries [

3]. Therefore, accurate lithium battery SOC estimation is currently a key problem to be solved.

The SOC is defined as the ratio of the remaining capacity to the nominal capacity of a battery [

4], which is usually calculated by Equation (1). It should be noted that SOC is a state quantity that cannot be measured directly, and there are highly nonlinear relationships between the SOC and observable variables, such as voltage, current, temperature, and other measured data. Using these observable variables, the SOC value can be obtained indirectly. However, these variables also change with battery aging, ambient temperature, and driving conditions, which makes accurate SOC estimation a challenge [

5].

where

is the current remaining capacity of the battery and

is the nominal capacity of the battery. The SOC value range is between [0,1]. When the SOC is 0, the battery is completely discharged. When the SOC is 1, the battery is fully charged.

At present, there are four main types of SOC estimation methods proposed by scholars: the ampere-hour integration method, the open-circuit voltage method, the model-based estimation method, and the data-driven method [

6]. The ampere-hour integration method mainly involves calculating the amount of electricity released by the battery over a period of time by measuring the discharge current of the battery and integrating the current over time, thus achieving battery SOC estimation [

7]. The open-circuit voltage method is mainly used to find the relationship between the open-circuit voltage (OCV) and the battery SOC, and a corresponding OCV–SOC table is established by using discharge experiments to further estimate the SOC according to the mapping relationship between them. The model-based method characterizes the internal characteristics of the battery by establishing a battery model to establish a time-domain space state equation to estimate the SOC [

8,

9,

10]. However, due to high computational complexity, the model’s requirement for prior knowledge, and the variations of a large number of parameters in the model with operating conditions, it is difficult to accurately estimate the SOC of the battery throughout its life cycle using the model-based method. In recent years, the data-driven approach has received much attention from scholars because it does not require a specific battery model and an accurate formula. The data-driven approach treats the battery as a black box and only requires the lithium battery measurement signal to achieve the estimation of SOC [

11]. Many scholars have used many traditional machine learning methods to simulate the nonlinear characteristics of batteries, which have suitable data integrity, and the relationships between the battery SOC and the observable variables (voltage, charge/discharge current, resistance, etc.) can be learned autonomously from the data. Common learning algorithms include support vector machines, semi-supervised learning, artificial neural networks, etc. [

12,

13]. Reference [

14] uses a multi-hidden layer backpropagation (BP) neural network to learn the nonlinear relationship between battery SOC and Li-ion battery measurable variables (i.e., current, voltage, and temperature). Using a genetic algorithm to denoise the prediction error, this method successfully captures the long-term dependence between the observable variables and the battery SOC. Reference [

15] uses the least-squares support vector machine (LS–SVM) model to train the dynamic characteristics of lithium-ion batteries with a small sample and realize the online application of the modeling method. However, these shallow learning architectures lack comprehensiveness when considering the redundancy of feature information, which ultimately leads to low accuracy.

In particular, with the booming development of artificial neural networks, deep learning is also widely used for battery SOC estimation. Deep learning, as an important branch of machine learning, can easily capture the relationships between the measured signals and the SOC by building multilayer deep neural networks with nonlinear transformations to extract feature information from input samples. RNN is a deep learning method based on neural networks, which has been favored by many scholars in recent years in regard to the prediction problem of sequence data. Reference [

16] proposed an SOC estimation method based on RNN by using the time-series memory capability of RNN. Through the data obtained from the lithium battery performance test experiment, a battery SOC estimation simulation experiment was carried out under high-power discharge conditions. Reference [

17] proposed an SOC estimation model combining RNN with the Coulomb counting method. The model takes voltage, current, and temperature as inputs and considers the effect of battery degradation during charging and discharging to estimate battery SOC under three different operating conditions. However, the structure of RNN is relatively shallow, and a typical RNN is unable to learn the intrinsic features of the measured data layer by layer upon encountering the extended sequence problem. To improve the capability of RNNs in handling sequential data, an LSTM, gated recurrent unit (GRU) structure can be added to RNN to solve the vanishing gradient phenomenon problem. Reference [

18] proposed a method to accurately estimate lithium battery SOC by using LSTM and formed a single network that correctly estimated the SOC under different ambient temperature conditions by encoding the time-dependent term. Reference [

19] estimated lithium-ion battery SOC based on a gated recurrent neural network (GRU-RNN) and established mapping relationships between the battery observable variables and SOC to achieve battery SOC estimation at different temperatures. In the literature [

2], a gated recurrent neural network model with an activation functional layer (GRU-ATL) was proposed to estimate the battery charge state, and a stable and accurate SOC estimation performance was achieved by estimating the battery SOC online under different operating conditions without relying on the battery model. Reference [

1] proposed a method combining a denoising auto-encoder (DAE) with a GRU to estimate lithium battery SOC. By reducing noise and increasing the dimension of battery measurement data to obtain useful data information and then using GRU-RNN for training, experimental results were obtained that showed that the proposed DAE-GRU had suitable robustness. All of these studies achieved suitable results for battery SOC estimation, but most of these studies only focus on the correlation of forward series data, while the correlation study of reverse series data acquisition is lacking. Reference [

20] proposed an SOC estimation method combining multichannel convolution and bidirectional recurrent neural network (MCNN-BRNN) to sequentially estimate SOC by extracting multi-scale local robust features and using the BRNN to capture effective time-varying signals. This reduced the accumulation of errors and improved the overall estimation accuracy. Reference [

21] proposed a stacked bidirectional long short-term memory (SBLSTM) model for estimating lithium battery SOC. This method captured the forward and reverse battery information through the bidirectional structure and improved the depth of the model by stacking the bidirectional structure, which further improved the estimation performance of the model. It is worth mentioning that the network setting of the model in this document is highly random. Artificially setting the super parameters of the network will not only increase the training cost of the model but also affect the prediction effect of the model. Therefore, the parameter adjustment of the model needs to be further resolved. In this paper, a Bayesian optimization-based bidirectional long short-term memory (Bayes-BiLSTM) neural network model is proposed for lithium battery SOC estimation. Compared with the unidirectional LSTM network, this model uses a bidirectional structure to summarize the temporal dependence of past and future contexts by capturing the forward and reverse battery information. In addition, compared with other methods, the proposed model also introduces a Bayesian optimization algorithm. The introduction of this optimization algorithm assists in finding the optimal network parameters to improve the network performance and compensates for the defect of manually setting the network parameters. In particular, this paper adopts the Bayesian optimization algorithm to optimize the parameters of the BiLSTM model. The optimization parameters include the number of hidden layer neurons

, the maximum number of iterations

MaxEpochs, the initial learning rate

and the learning decline rate factor

. Finally, this paper evaluates the effectiveness and applicability of the proposed method by conducting multiple sets of comparative experiments using two public lithium battery data sets, and the experimental results show that under different constant temperature and variable temperature environments, the proposed method has better accuracy, adaptability, and generalizability for the SOC estimation of different types of lithium batteries.

The rest of the paper is organized as follows: the second part details the LSTM, BiLSTM, and Bayes-BiLSTM models. The third part introduces the lithium battery data set and experimental procedure. The fourth part analyzes and discusses the experimental results. The fifth part comprises the conclusion of this paper.

5. Conclusions

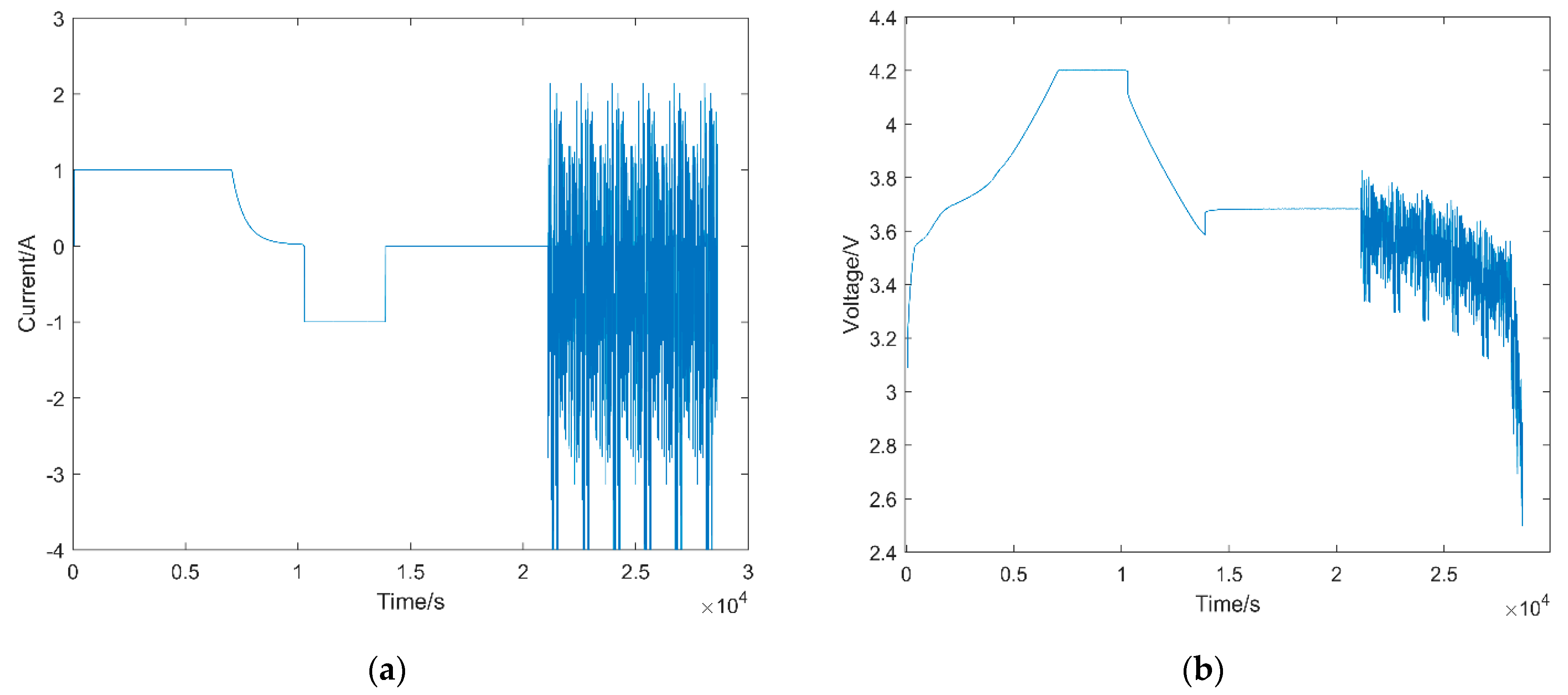

In this paper, we propose a method for lithium battery state-of-charge estimation based on Bayesian optimized bidirectional long- and short-term memory neural networks. The proposed method breaks the mold of traditional RNN studies that have been using only forward dependencies and further summarizes the temporal dependencies in the context of lithium battery sequence data by adding reverse dependencies. This study uses two publicly available lithium battery data sets, the CALCE data set, and the Oxford path-dependent battery degradation data set, and establishes mapping relationships between the observable voltage, current, and temperature variables of the battery and the battery SOC through the data provided by the data sets. The training results of different network models and a combination of previous experiences are used to determine the parameter intervals of the network, and then a Bayesian optimization algorithm is introduced to obtain the optimal parameters of the network. Through a large number of comparative experiments, including battery SOC estimation under different constant temperatures, a variable temperature environment, and different methods, the experimental results show that the proposed Bayes-BiLSTM model has a suitable fitting ability, and the SOC of batteries with different chemical compositions is estimated with higher accuracy and adaptability.

Future work will focus on verifying the applicability of the model for battery SOC estimation based on the collected data by adding a battery testing experimental platform; furthermore, the structure of the proposed model will be further improved to enhance its battery SOC estimation accuracy in low-temperature environments.