Study on Fatigue Life Prediction and Acoustic Emission Characteristics of Sandstone Based on Mesoscopic Crack Propagation Mechanism

Abstract

:1. Introduction

2. Description of the Theoretical Model and AE Methods

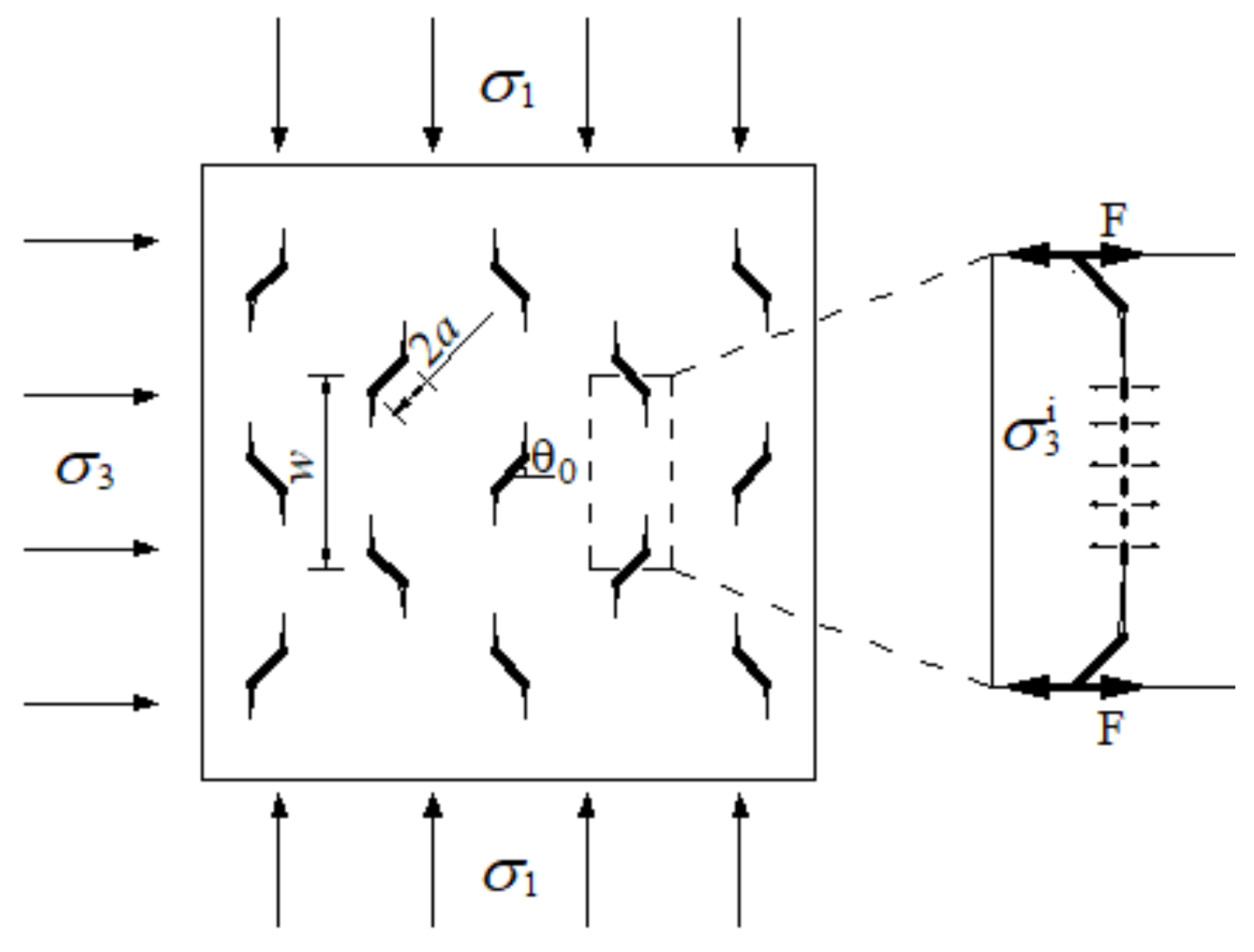

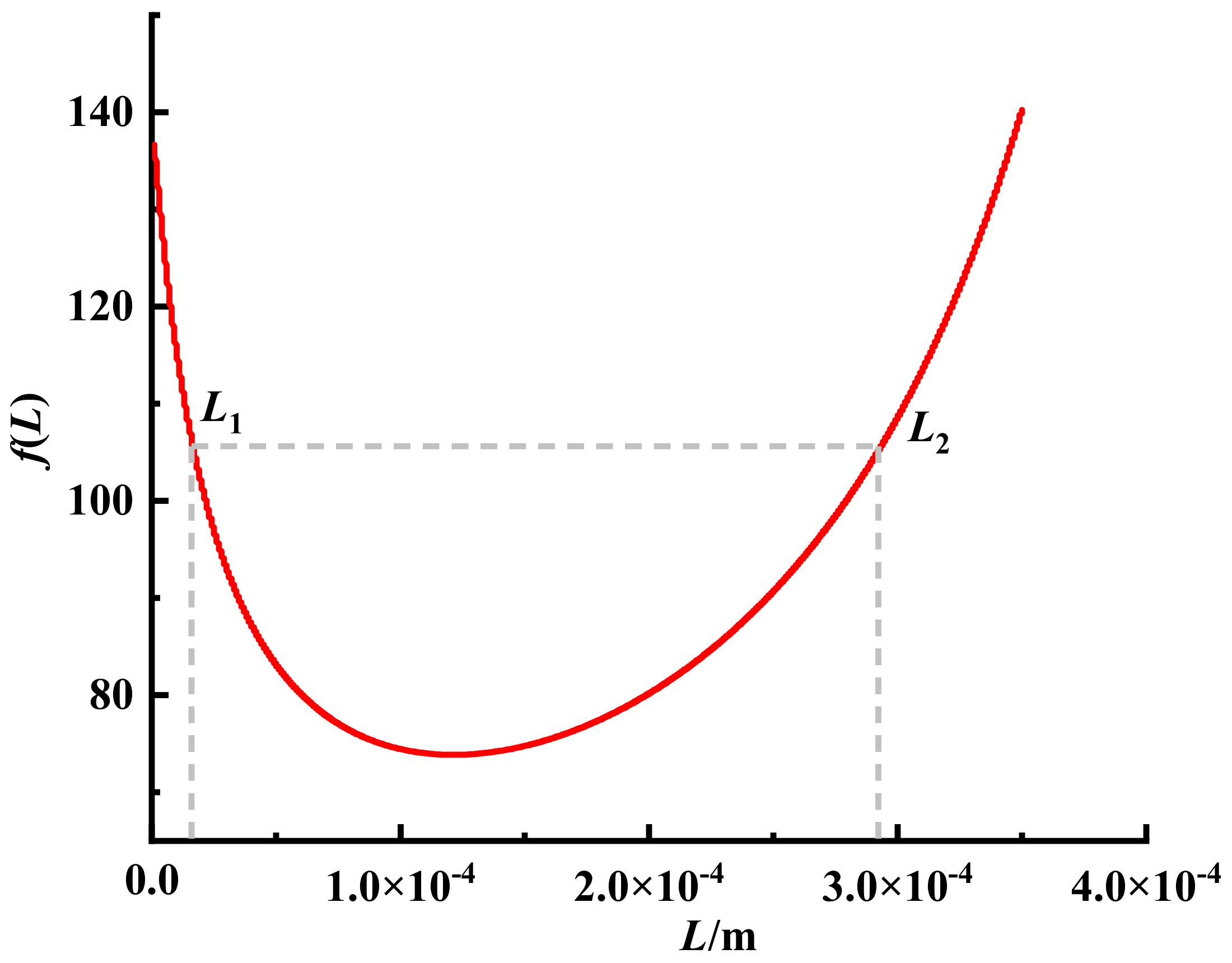

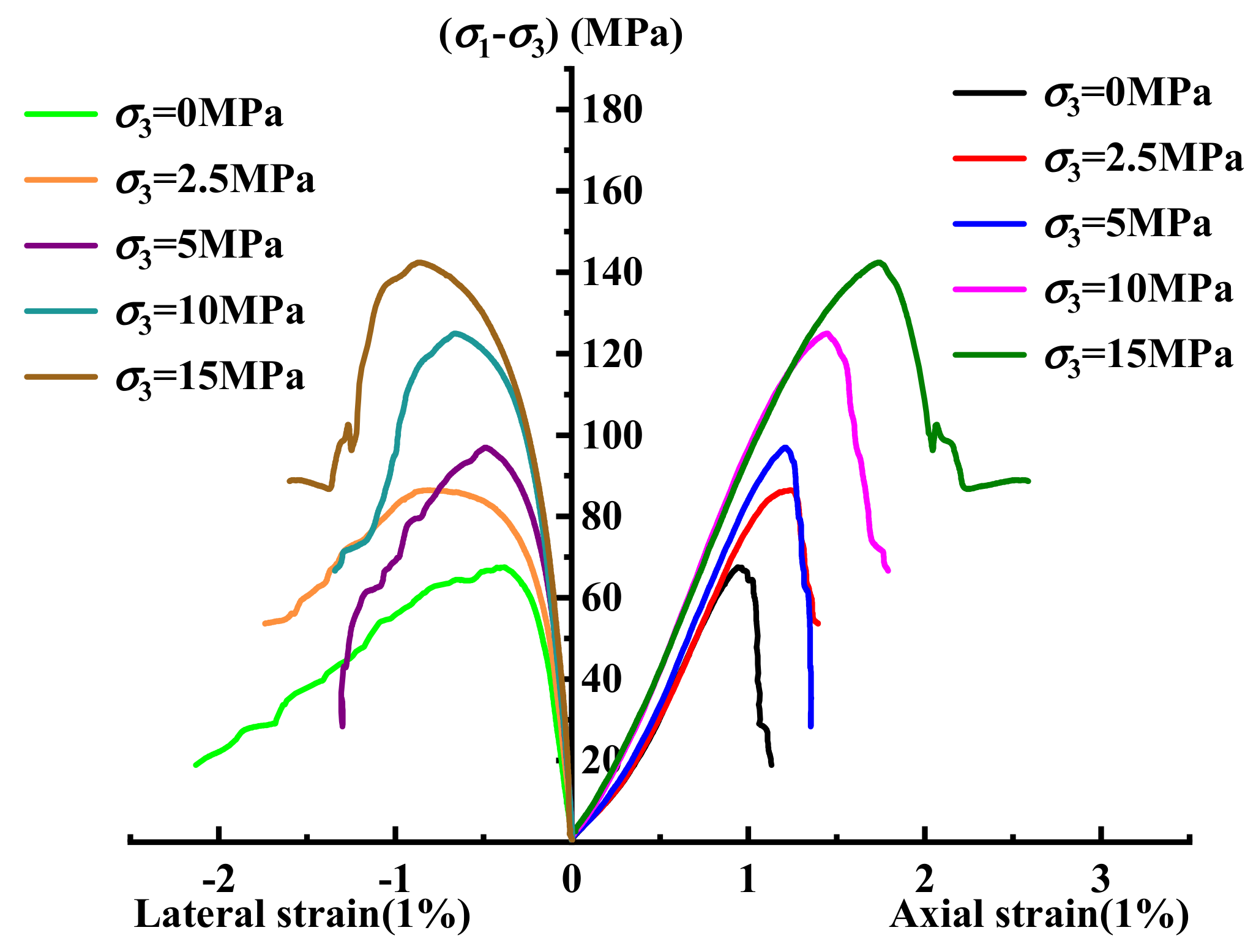

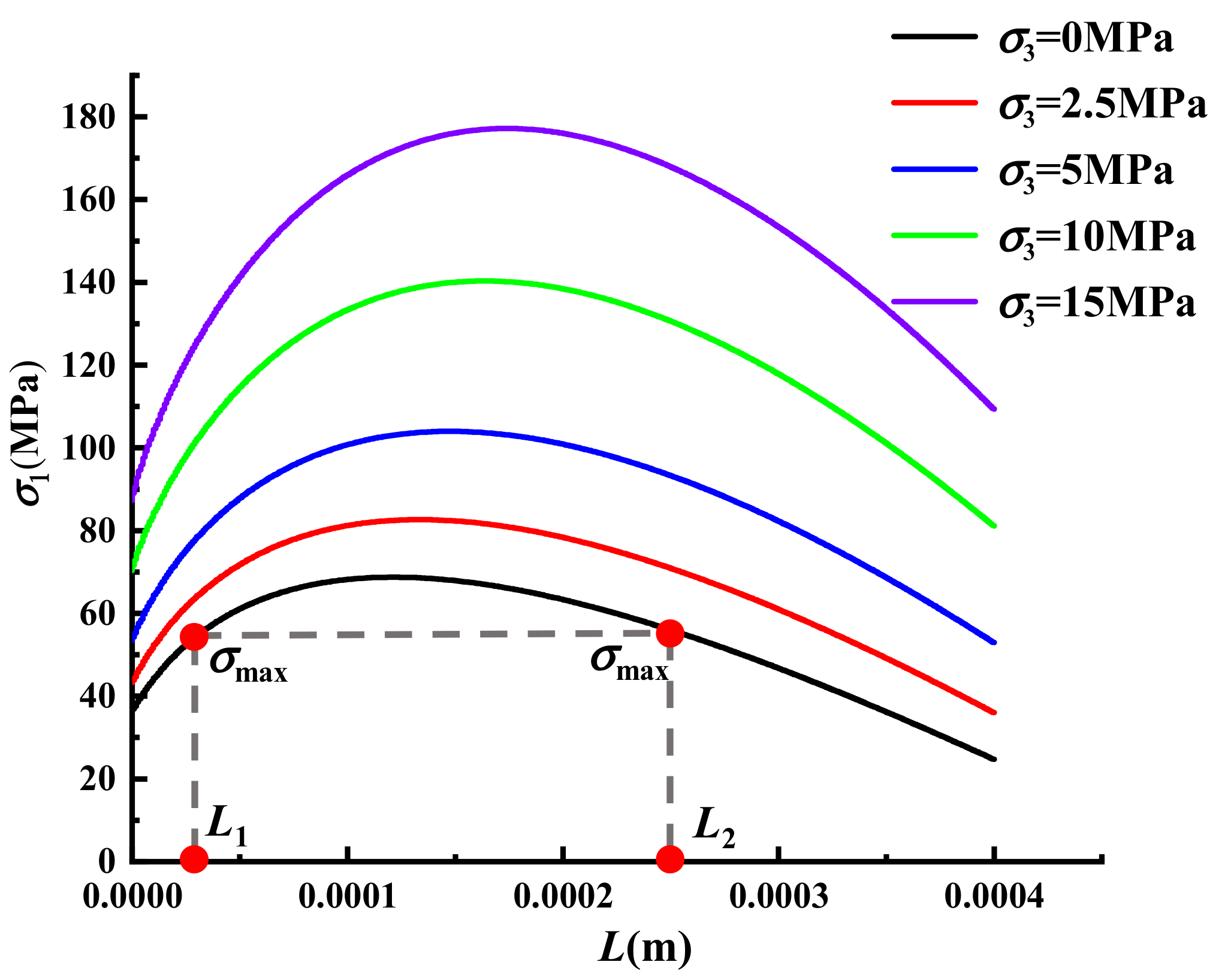

2.1. Fatigue Failure Mechanism from the Perspective of Wing Crack Propagation

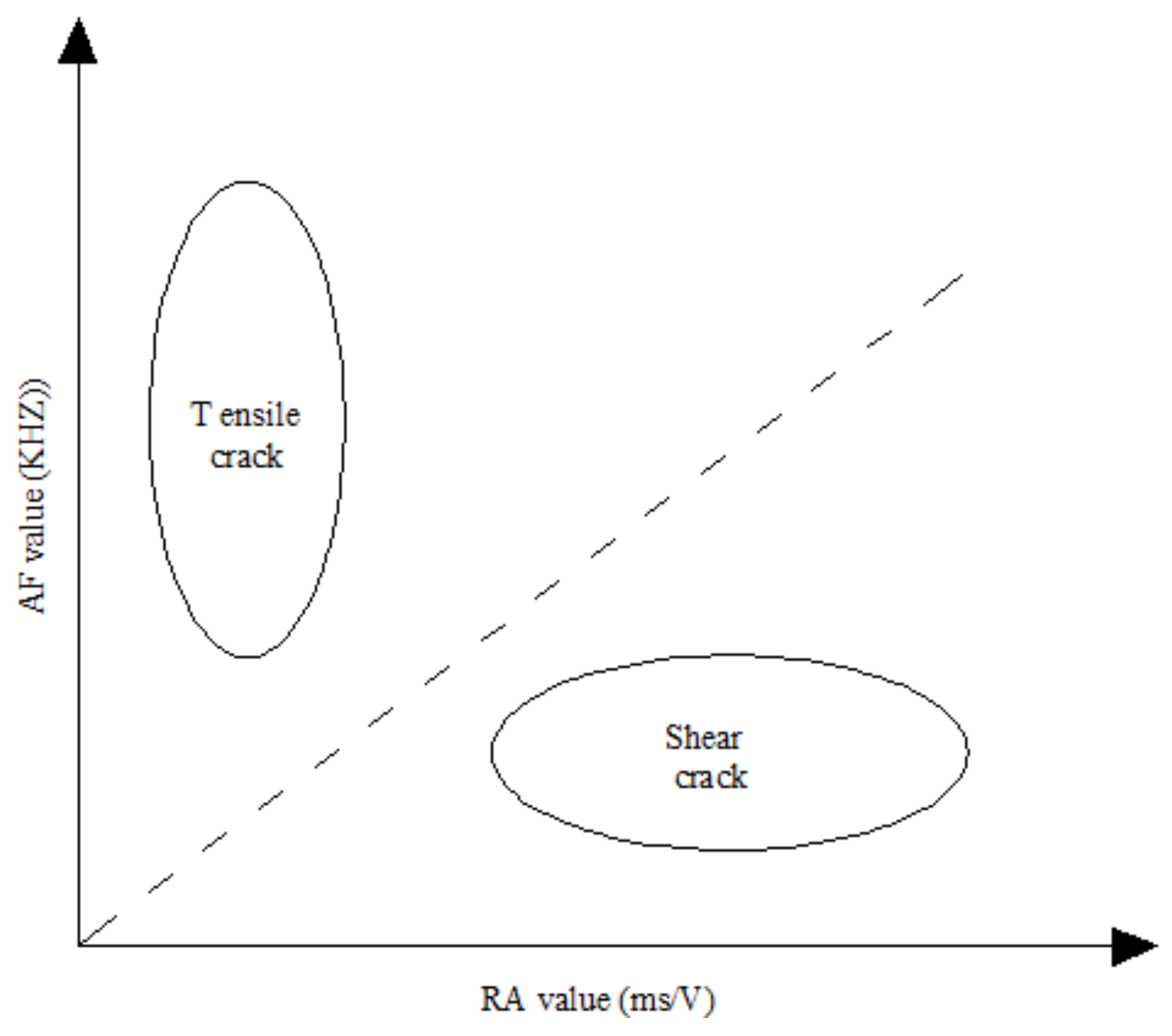

2.2. AE Methods

2.2.1. Crack Classification by RA and AF Values

2.2.2. Crack Classification Using Moment Tensor Method

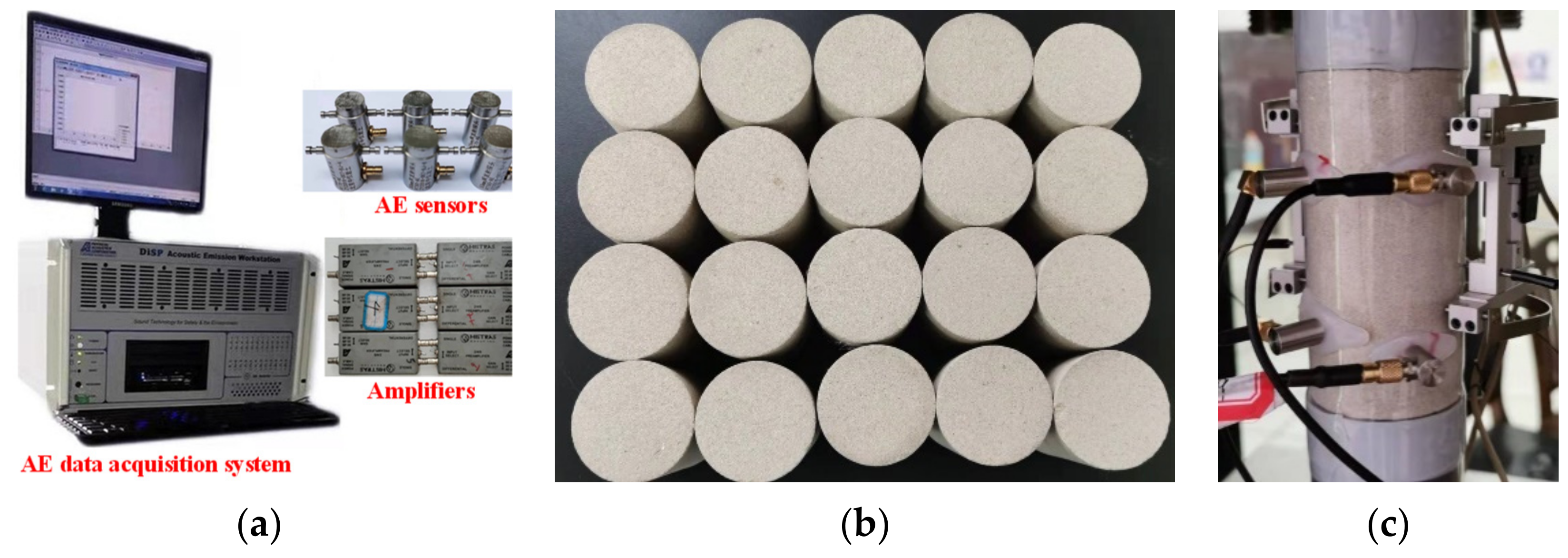

3. Experimental Setup and Sample Description

4. Results and Discussion

4.1. Theoretical and Experimental Results Analysis of Sandstone Fatigue Life

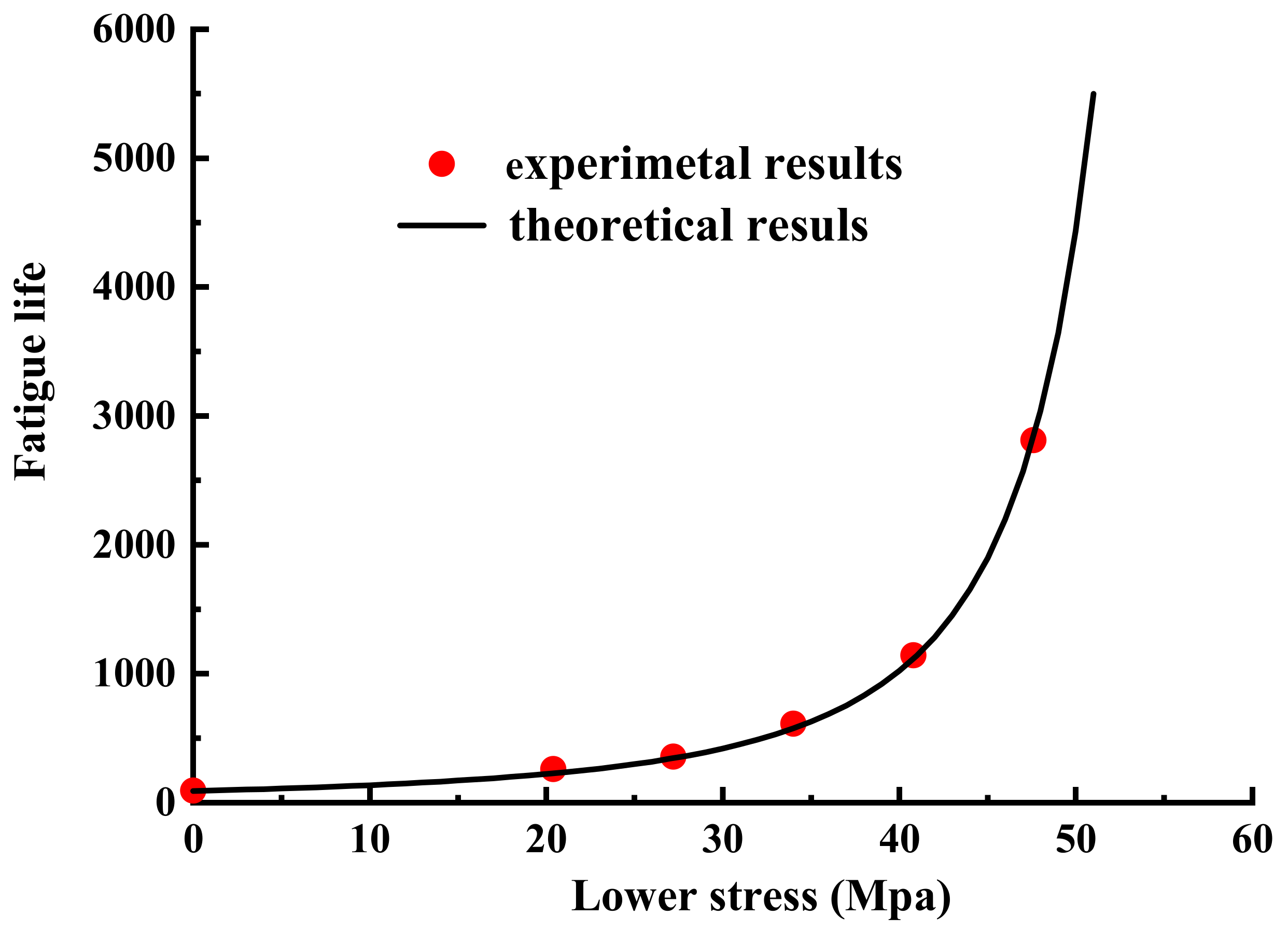

4.1.1. The Effect of Lower Limit Stress on Fatigue Life

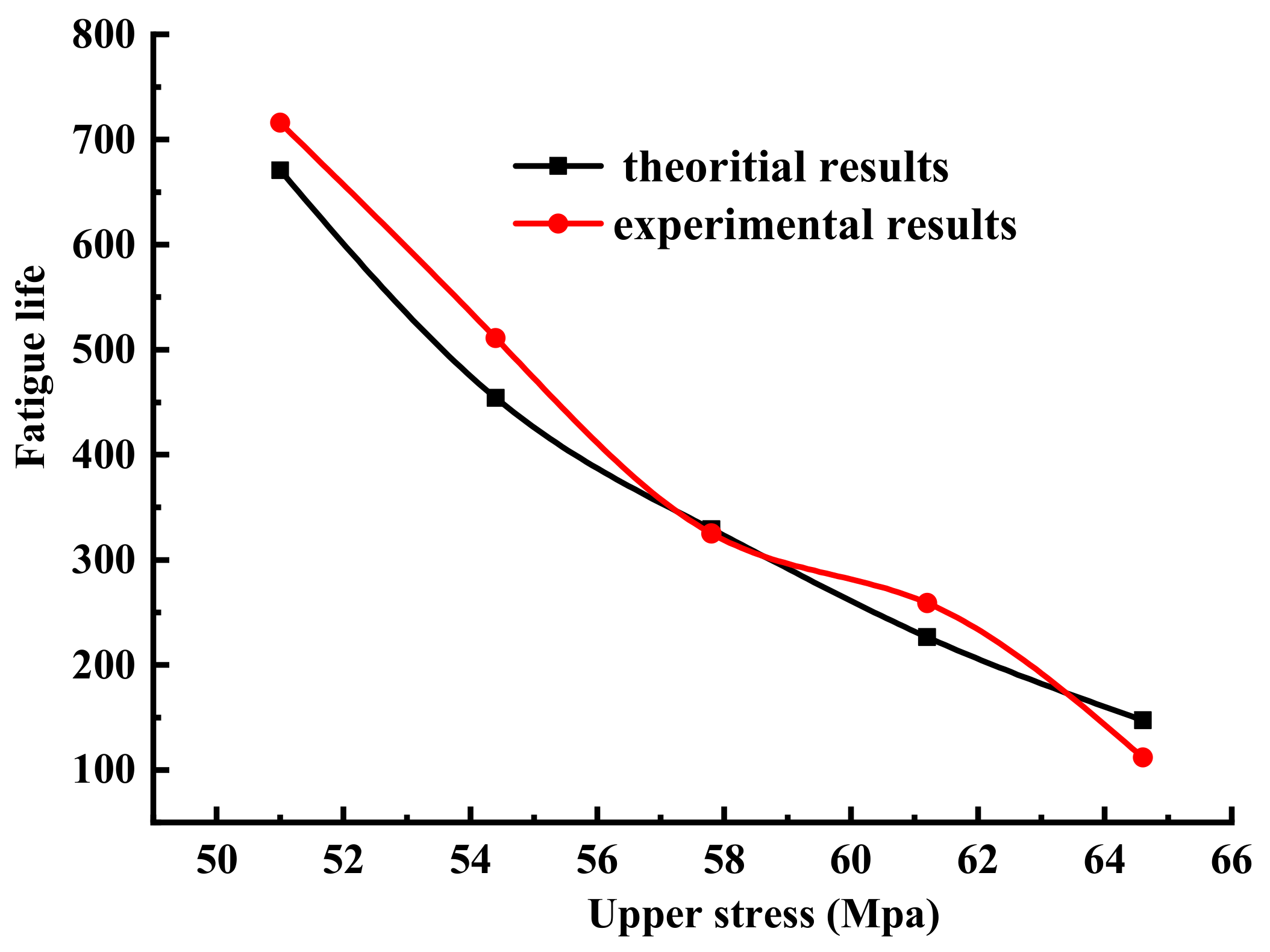

4.1.2. The Effect of Upper Limit Stress on Fatigue Life

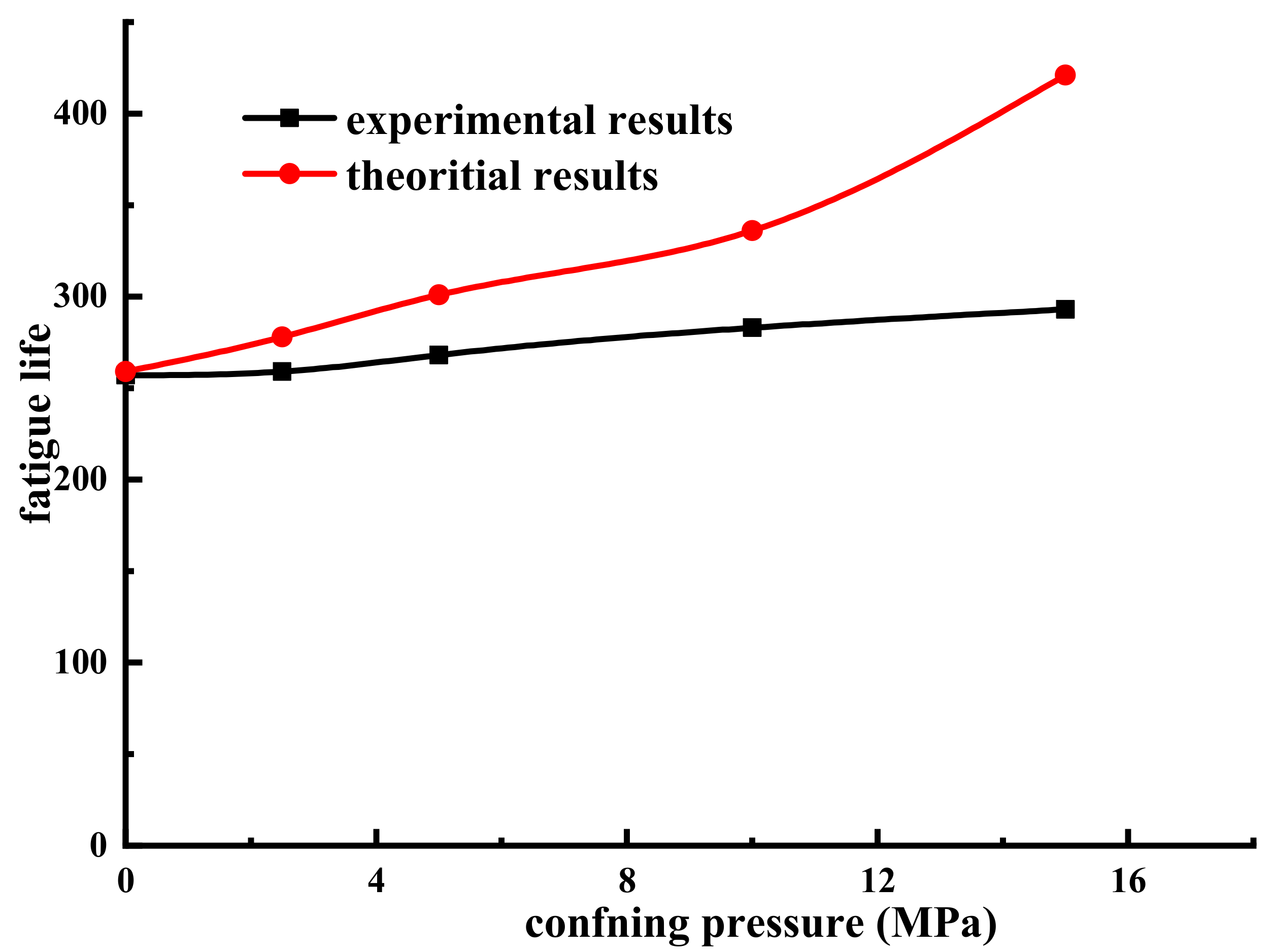

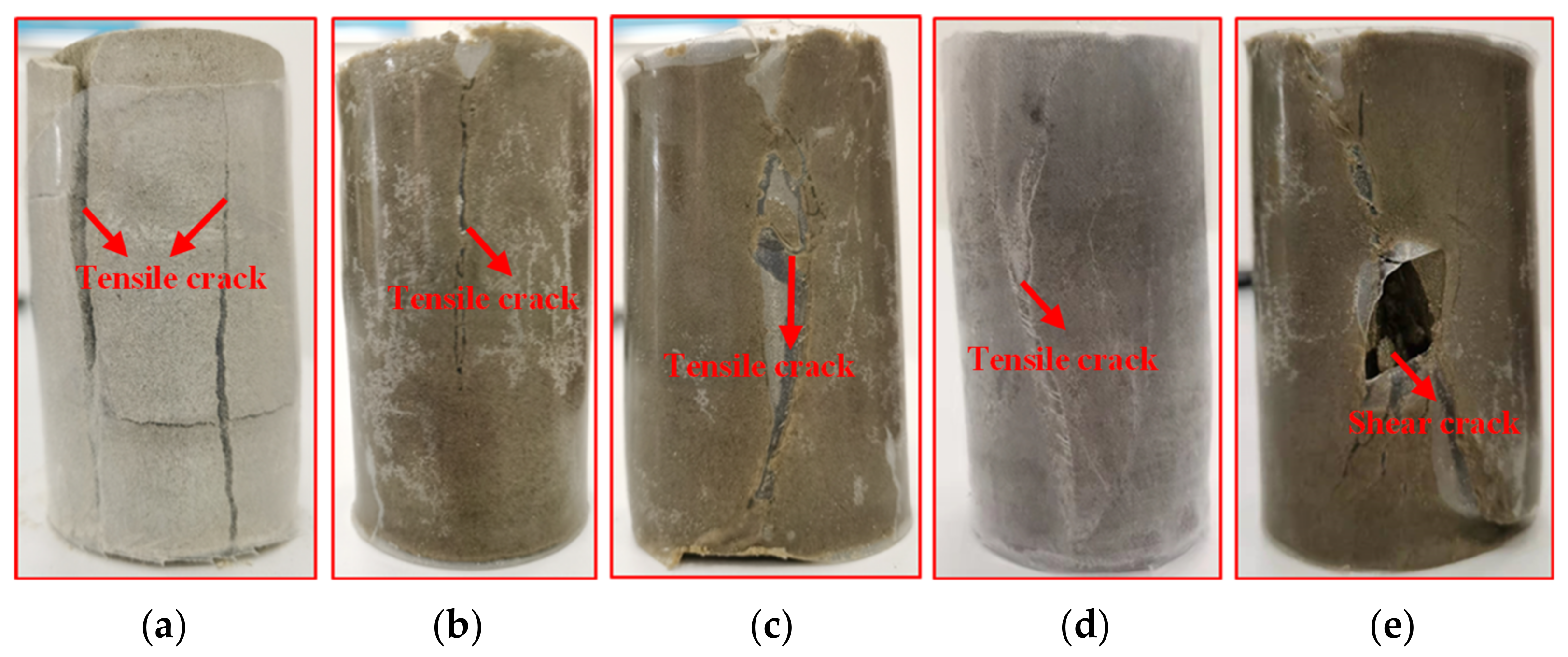

4.1.3. The Effect of Confining Pressure on Fatigue Life

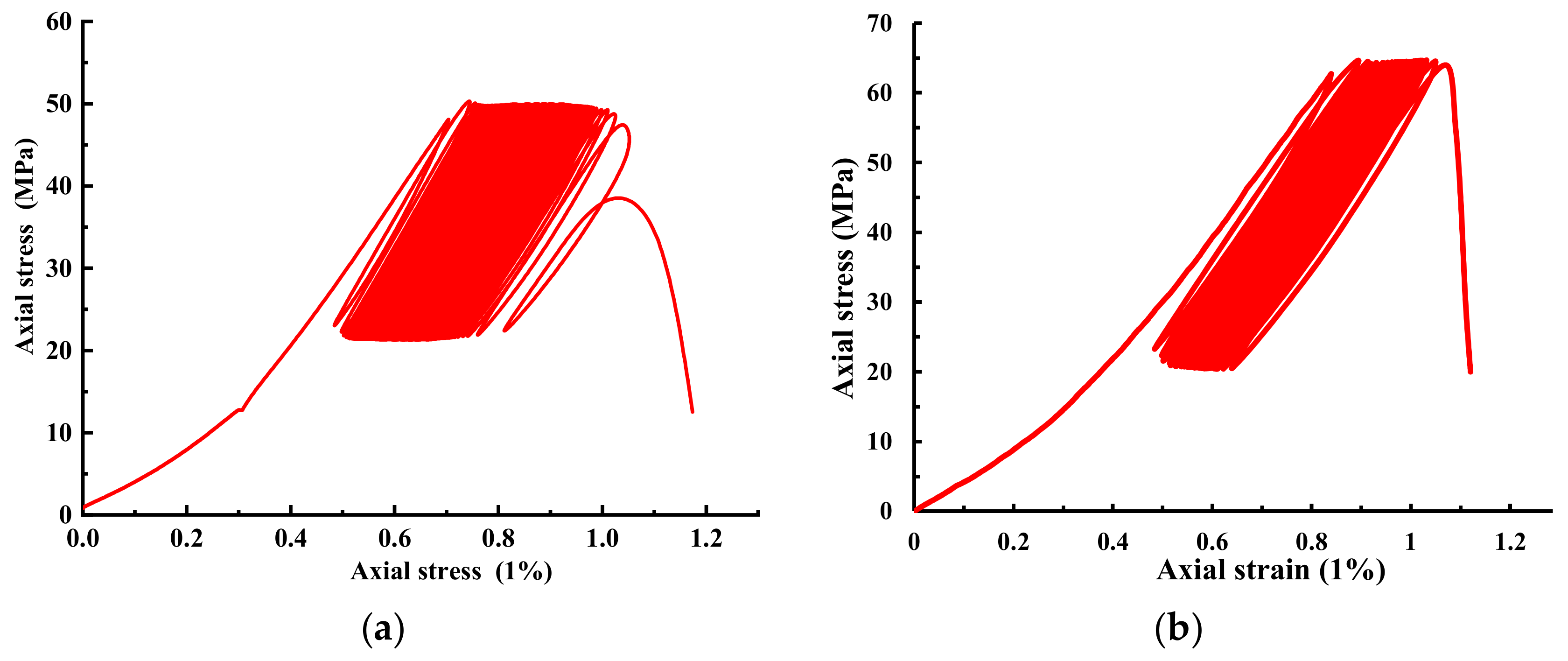

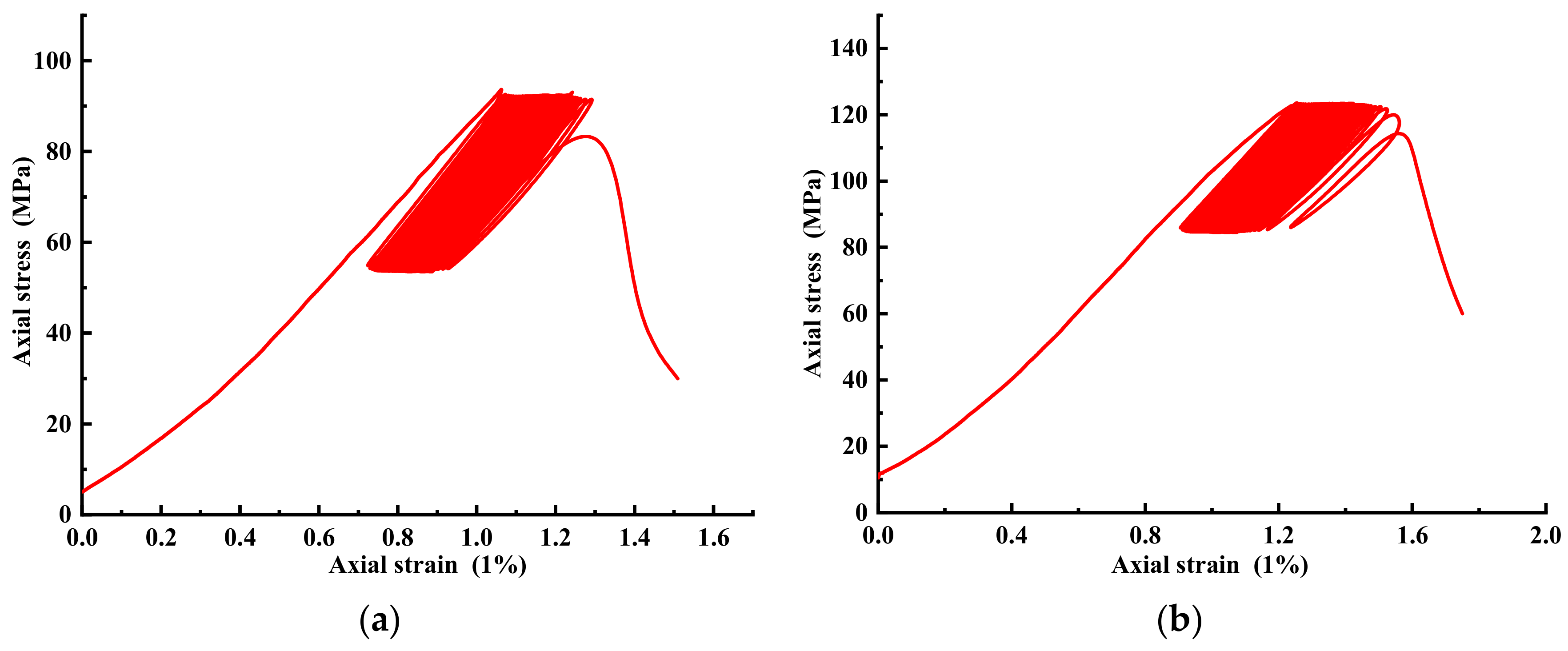

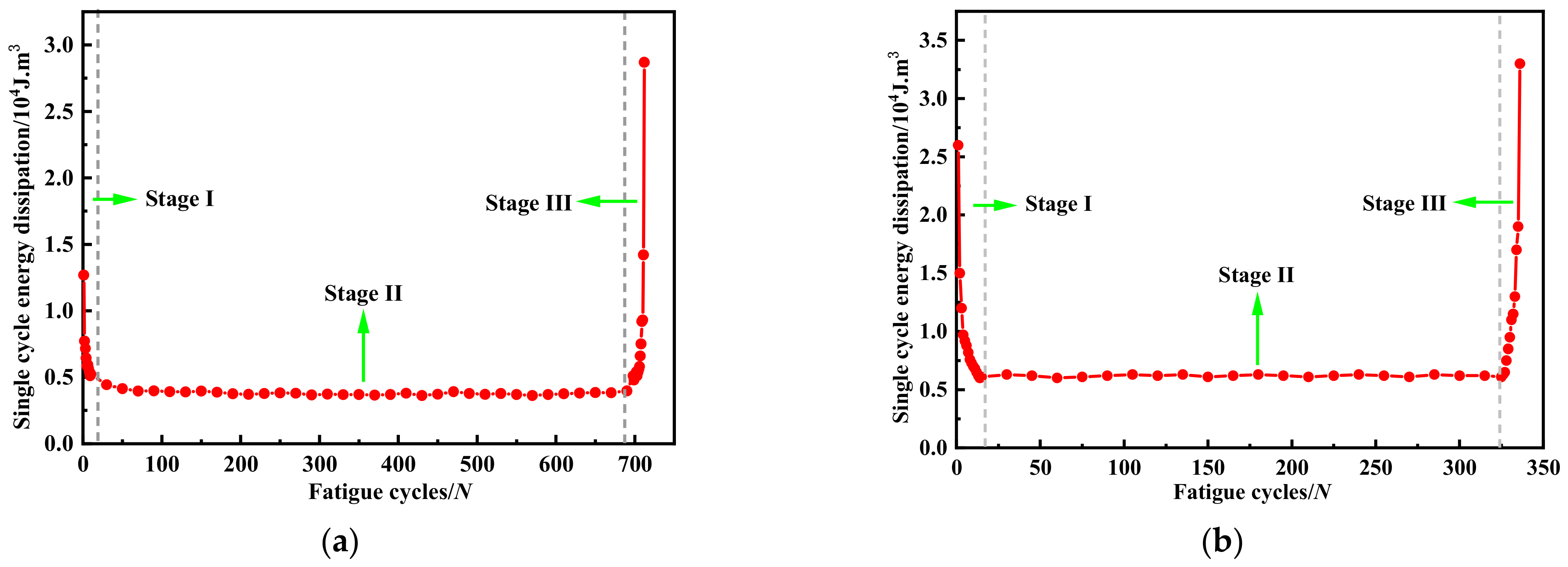

4.1.4. Fatigue Crack Growth Stage Analysis

4.1.5. Limitations and Future Works

4.2. AE Results Analysis

4.2.1. Crack Classification Results by RA and AF Values

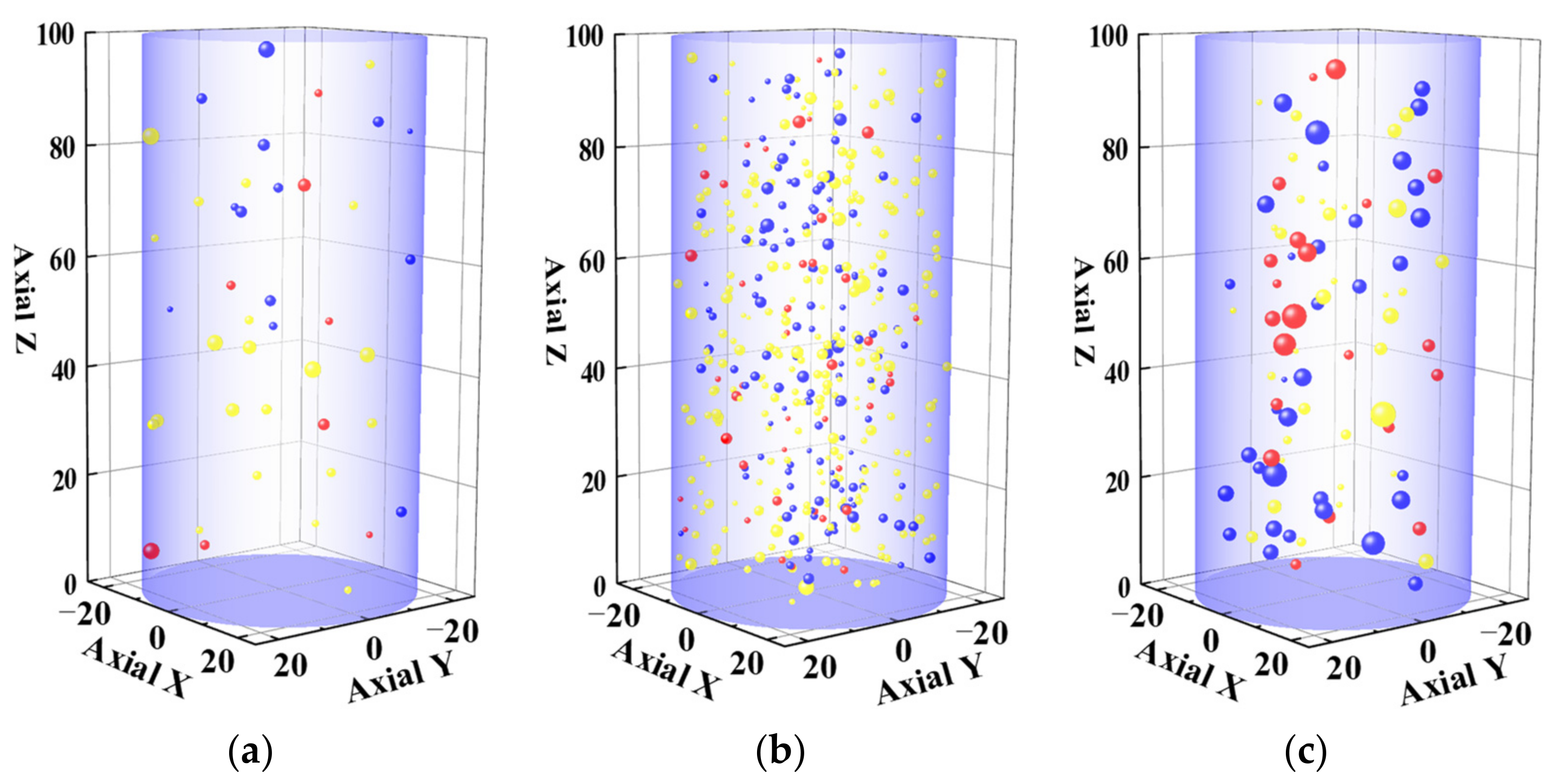

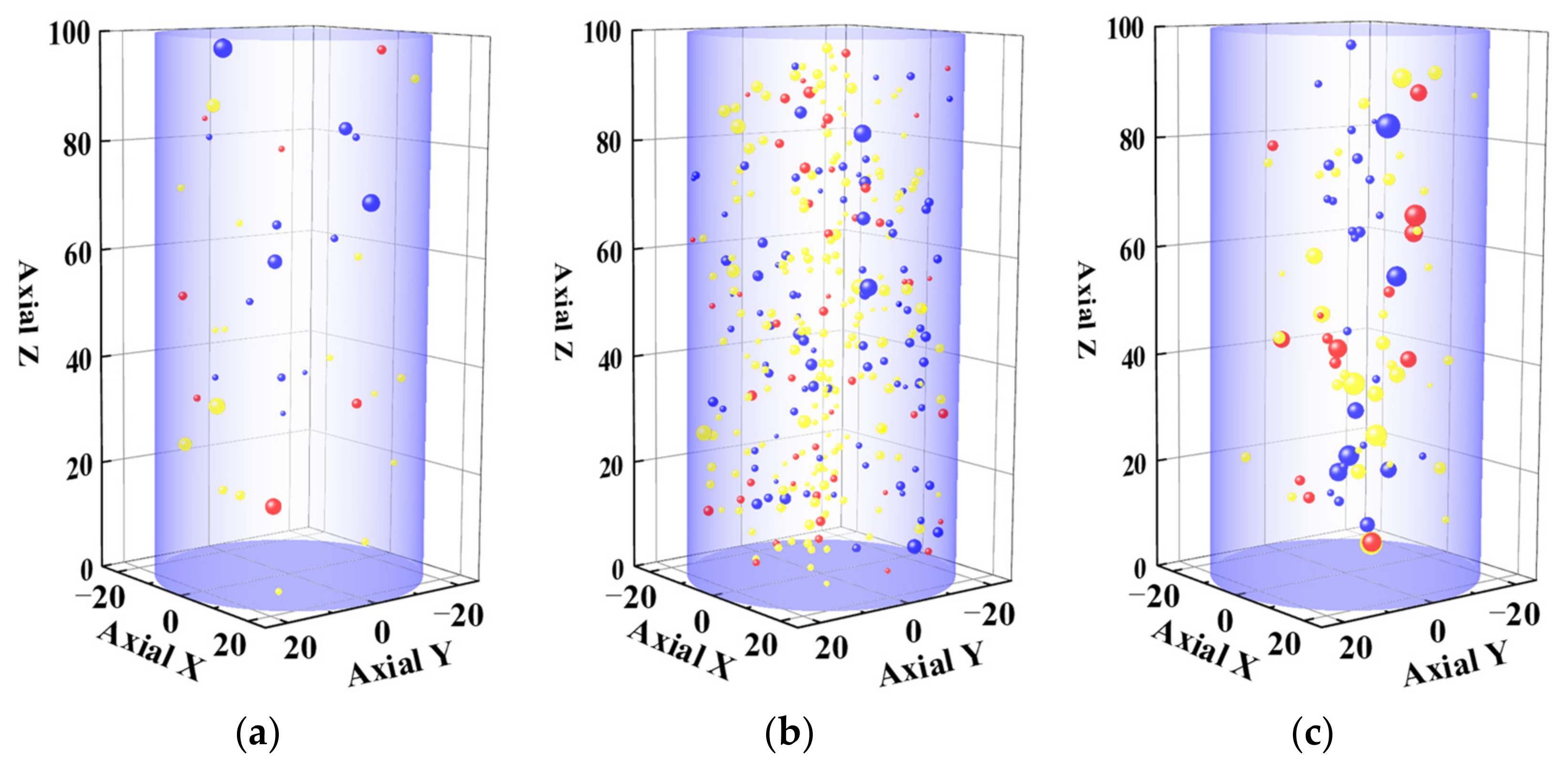

4.2.2. Crack Classification Results Using the Moment Tensor Method

5. Conclusions

- Through the combination of the wing crack propagation model and Paris formula, the fatigue failure mechanism of sandstone was expounded. This model can better predict the fatigue life of sandstone, and it reflects the influence of upper limit stress, lower limit stress and confining pressure on sandstone fatigue life. The model also proves that in the process of rock fatigue loading, the upper limit stress has a greater effect on the rock fatigue failure process than the lower limit stress.

- The theoretical model and experimental results both showed that the fatigue life of sandstone increases with the increase in confining pressure. At the same time, the prediction of rock fatigue life using the wing crack model is based on tensile fatigue failure, so when the confining pressure is large and rock fatigue shear failure occurs, the rock fatigue life deduced by the wing crack growth model is no longer applicable.

- The AE method is a reliable method for predicting the fatigue failure process of rock. The AE clustering method can effectively identify the crack propagation stage of sandstone samples in the process of fatigue failure and establish precursor information for sandstone fatigue failure. Through the AE clustering method and moment tensor method, it was verified that the cracks produced by sandstone during the fatigue failure process under the condition of low confining pressure are mainly in the form of tension.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Erarslan, N.; Williams, D. The damage mechanism of rock fatigue and its relationship to the fracture toughness of rocks. Int. J. Rock Mech. Min. Sci. 2012, 56, 15–26. [Google Scholar] [CrossRef]

- Song, R.; Bai, Y.M.; Zhang, J.P.; Jiang, D.Y. Experimental investigation of the fatigue properties of salt rock. Int. J. Rock Mech. Min. Sci. 2013, 64, 68–72. [Google Scholar] [CrossRef]

- Bagde, M.N.; Petroš, V. Fatigue properties of intact sandstone samples subjected to dynamic uniaxial cyclical loading. Int. J. Rock Mech. Min. Sci. 2005, 42, 237–250. [Google Scholar] [CrossRef]

- Xiao, J.Q.; De, X.D.; Jiang, F.L.; Xu, G. Fatigue damage variable and evolution of rock subjected to cyclic loading. Int. J. Rock Mech. Min. Sci. 2010, 47, 461–468. [Google Scholar] [CrossRef]

- Simo, J.C.; Ju, J.W. Strain- and stress-based continuum damage models-II. Computational aspects. Int. J. Solids Struct. 1987, 23, 821–840. [Google Scholar] [CrossRef]

- Ju, J.W. On two-dimensional self-consistent micro mechanical damage models for brittle solids. Int. J. Solids Struct. 1991, 27, 227–258. [Google Scholar] [CrossRef]

- Ashby, M.F.; Hallam, S.D. The failure of brittle solids containing small cracks under compressive stress states. Acta Met. 1986, 34, 497–510. [Google Scholar] [CrossRef]

- Basista, M.; Gross, D. The sliding crack model of brittle deformation: An internal variable approach. Int. J. Solids Struct. 1998, 35, 487–509. [Google Scholar] [CrossRef]

- Diederichs, M.S. Instability of Hard Rockmasses, the Role of Tensile Damage and Relaxation. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 1999. [Google Scholar]

- Kim, J.-S.; Lee, K.-S.; Cho, W.-J.; Choi, H.-J.; Cho, G.-C. A Comparative Evaluation of Stress-Strain and Acoustic Emission Methods for Quantitative Damage Assessments of Brittle Rock. Rock Mech. Rock Eng. 2015, 48, 495–508. [Google Scholar] [CrossRef]

- Koerner, R.M.; McCabe, W.M.; Lord, A.E. Overview of acoustic emission monitoring of rocks tructures. Rock Mech. Rock Eng. 1981, 14, 27–35. [Google Scholar] [CrossRef]

- Diederichs, M.S.; Kaiser, P.K.; Eberhardt, E. Damage initiation and propagation in hard rock during tunnelling and the influence of near-face stress rotation. Int. J. Rock Mech. Min. Sci. 2004, 41, 785–812. [Google Scholar] [CrossRef]

- Zhao, X.G.; Cai, M.; Wang, J.; Ma, L.K. Damage stress and acoustic emission characteristics of the Beishan granite. Int. J. Rock Mech. Min. Sci. 2013, 64, 258–269. [Google Scholar] [CrossRef]

- Khazaei, C.; Hazzard, J.; Chalaturnyk, R. Damage quantification of intact rocks using acoustic emission energies recorded during uniaxial compression test and discrete element modeling. Comput. Geotech. 2015, 67, 94–102. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G. Damage evaluation of three masonry towers by acoustic emission. Eng. Struct. 2007, 29, 1569–1579. [Google Scholar] [CrossRef]

- Farhidzadeh, A.; Salamone, S.; Luna, B.; Whittaker, A. Acoustic emission monitoring of a reinforced concrete shear wall by b-value based outlier analysis. Struct. Health Monit. 2013, 12, 3–13. [Google Scholar] [CrossRef]

- Chai, M.Y.; Zhang, Z.X.; Quan, D. A new qualitative acoustic emission parameter based on Shannon’s entropy for damage monitoring. Mech. Syst. Signal Processing 2018, 100, 617–629. [Google Scholar] [CrossRef]

- Eberhardt, E.; Stead, D.; Stimpson, B. Quantifying progressive pre-peak brittle fracture damage in rock during uniaxial compression. Int. J. Rock Mech. Min. Sci. 1999, 36, 361–380. [Google Scholar] [CrossRef]

- Chang, S.-H.; Lee, C.-I. Estimation of cracking and damage mechanisms in rock under triaxial compression by moment tensor analysis of acoustic emission. Int. J. Rock Mech. Min. Sci. 2004, 41, 1069–1086. [Google Scholar] [CrossRef]

- Su, G.; Shi, Y.; Feng, X.; Jiang, J.; Zhang, J.; Jiang, Q. True-Triaxial Experimental Study of the Evolutionary Features of the Acoustic Emissions and Sounds of Rockburst Processes. Rock Mech. Rock Eng. 2018, 51, 375–389. [Google Scholar] [CrossRef]

- Ashby, M.F.; Sammis, C.G. The damage mechanics of brittle solids in compression. Pure Appl. Geophys. 1990, 133, 489–521. [Google Scholar] [CrossRef]

- Paris, P.; Erdogan, F. A Critical Analysis of Crack Propagation Laws. J. Basic Eng. 1963, 85, 528. [Google Scholar] [CrossRef]

- Horii, H.; Nemat-Nasser, S. Compression-induced microcrack growth in brittle solids: Axial splitting and shear failure. J. Geophys. Res. 1985, 90, 3105. [Google Scholar] [CrossRef]

- Shigeishi, M.; Ohtsu, M. Acoustic emission moment tensor analysis: Development for crack identification in concrete materials. Constr. Build. Mater. 2001, 15, 311–319. [Google Scholar] [CrossRef]

- Aggelis, D.G. Classification of cracking mode in concrete by acoustic emission parameters. Mech. Res. Commun. 2011, 38, 153–157. [Google Scholar] [CrossRef]

- Ohtsu, M. Simplified moment tensor analysis and unified decomposition of acoustic emission source: Application to in situ hydrofracturing test. J. Geophys. Res. 1991, 96, 6211–6221. [Google Scholar] [CrossRef]

- Haghgouei, H.; Baghbanan, A.; Hashemolhosseini, H.; Jamali, S. Variable Amplitude Fatigue Life Prediction of Rock Samples Under Completely Reversed Loading. Geotech. Geol. Eng. 2021, 39, 1951–1962. [Google Scholar] [CrossRef]

- Li, R.; Wang, Y.; Fu, F. Research on Fatigue Damage and Affecting Factors of Defected Rock Mass Based on Ultrasonic Wave Velocity. Teh. Vjesn. Tech. Gaz. 2019, 26, 1061–1067. [Google Scholar]

- Liu, E.L.; He, S.M.; Xue, X.H.; Xu, J. Dynamic Properties of Intact Rock Samples Subjected to Cyclic Loading under Confining Pressure Conditions. Rock Mech. Rock Eng. 2011, 44, 629–634. [Google Scholar] [CrossRef]

- Bagde, M.N.; Petros, V. Waveform effect on fatigue properties of intact sandstone in uniaxial cyclical loading. Rock Mech. Rock Eng. 2005, 38, 169–196. [Google Scholar] [CrossRef]

- Attewell, P.B.; Farmer, I.W. Fatigue behaviour of rock. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1973, 10, 101–109. [Google Scholar] [CrossRef]

- Ishizuka, Y.; Abe, T. Fatigue behaviour of granite under cyclic loading. In Static and Dynamic Considerations in Rock Engineering; CRC Press: Boca Raton, FL, USA, 1990; pp. 139–147. [Google Scholar]

| Sample No. | F1-1 | F1-2 | F1-3 | F1-4 | F1-5 | F1-6 |

|---|---|---|---|---|---|---|

| Upper stress/Mpa | 61.2 | 61.2 | 61.2 | 61.2 | 61.2 | 61.2 |

| Upper stress ratio | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 | 0.90 |

| Lower stress/Mpa | 0 | 20.4 | 27.2 | 34.0 | 40.8 | 47.6 |

| Lower stress ratio/Mpa | 0 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 |

| Stress difference/Mpa | 61.2 | 40.8 | 34.0 | 27.2 | 20.4 | 13.6 |

| Stress difference ratio | 0.90 | 0.60 | 0.50 | 0.40 | 0.30 | 0.20 |

| Fatigue life | 91 | 259 | 356 | 612 | 1141 | 2812 |

| Sample No. | F2-1 | F2-2 | F2-3 | F2-4 | F2-5 |

|---|---|---|---|---|---|

| Upper stress/Mpa | 51.0 | 54.4 | 57.8 | 61.2 | 61.2 |

| Upper stress ratio | 0.75 | 0.80 | 0.85 | 0.90 | 0.95 |

| Lower stress/Mpa | 20.4 | 20.4 | 20.4 | 20.4 | 20.4 |

| Lower stress ratio/Mpa | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Stress difference/Mpa | 29.6 | 34.0 | 37.4 | 40.8 | 44.2 |

| Stress difference ratio | 0.45 | 0.50 | 0.55 | 0.60 | 0.65 |

| Fatigue life | 716 | 511 | 325 | 259 | 112 |

| Sample No. | F1-2 | F3-1 | F3-2 | F3-3 | F3-4 |

|---|---|---|---|---|---|

| Upper stress/Mpa | 61.2 | 74.3 | 93.6 | 125.1 | 159.5 |

| Upper stress ratio | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 |

| Lower stress/Mpa | 20.4 | 33.5 | 52.8 | 84.3 | 118.7 |

| Lower stress ratio/Mpa | 0.30 | 0.41 | 0.51 | 0.61 | 0.68 |

| Stress difference/Mpa | 40.8 | 40.8 | 40.8 | 40.8 | 40.8 |

| Confining pressure/Mpa | 0 | 2.5 | 5 | 10 | 15 |

| Fatigue life | 259 | 278 | 301 | 336 | 421 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Si, K.; Cui, Z.; Peng, R.; Zhao, L. Study on Fatigue Life Prediction and Acoustic Emission Characteristics of Sandstone Based on Mesoscopic Crack Propagation Mechanism. Energies 2022, 15, 4807. https://doi.org/10.3390/en15134807

Si K, Cui Z, Peng R, Zhao L. Study on Fatigue Life Prediction and Acoustic Emission Characteristics of Sandstone Based on Mesoscopic Crack Propagation Mechanism. Energies. 2022; 15(13):4807. https://doi.org/10.3390/en15134807

Chicago/Turabian StyleSi, Kai, Zhendong Cui, Ruidong Peng, and Leilei Zhao. 2022. "Study on Fatigue Life Prediction and Acoustic Emission Characteristics of Sandstone Based on Mesoscopic Crack Propagation Mechanism" Energies 15, no. 13: 4807. https://doi.org/10.3390/en15134807

APA StyleSi, K., Cui, Z., Peng, R., & Zhao, L. (2022). Study on Fatigue Life Prediction and Acoustic Emission Characteristics of Sandstone Based on Mesoscopic Crack Propagation Mechanism. Energies, 15(13), 4807. https://doi.org/10.3390/en15134807