Towards Optimized ARMGs’ Low-Carbon Transition Investment Decision Based on Real Options

Abstract

:1. Introduction

2. Literature Review

3. Hydrogen-Powered ARMGs Investment Decision Model

3.1. Scene of the ARMGs Low-Carbon Transition Process

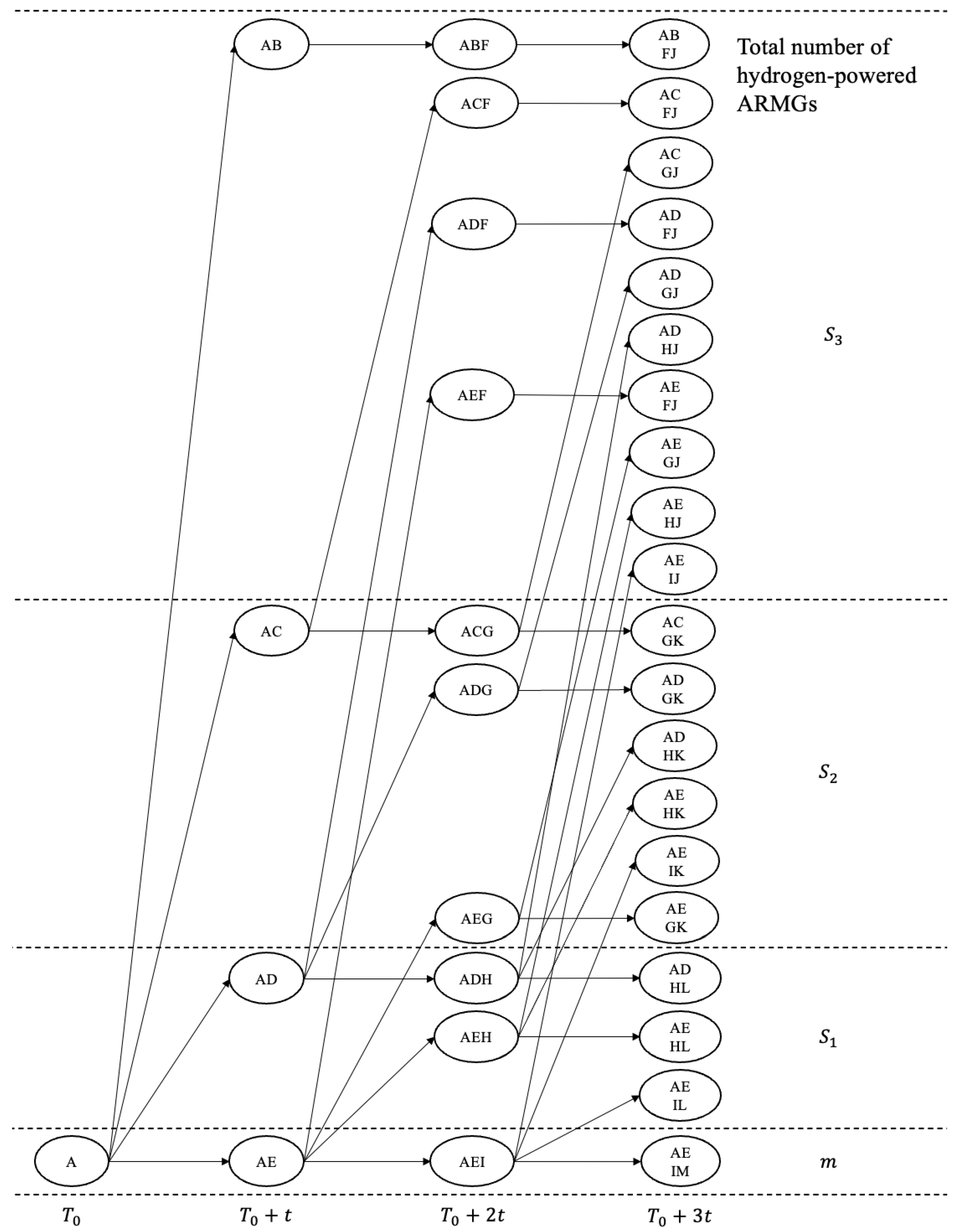

3.2. Establishing a Decision Tree of Hydrogen-Powered ARMGs Investment

3.3. Cost–Benefit Function for Potential Decision

4. Case Study

4.1. Scenario of ARMGs’ Low-Carbon Transition Process at Qingdao Port

4.2. Results of the Case Study

4.3. Sensitivity Analysis

- Impact of technology maturity on port hydrogen-powered ARMGs investment decision

- 2.

- Impact of hydrogen prices on port hydrogen-powered ARMGs investment decision

- 3.

- Impact of accounting for carbon emission reduction income on port hydrogen-powered ARMGs investment decision

5. Conclusions and Prospects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Time Period | From Node | To Node | Cost and Revenue (Million RMB) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Direct Investment | Annual Energy Consumption Cost | Annual Maintenance Cost | Annual Total Saving Cost | Annual Carbon Revenue | |||||

| Annual Electricity Cost | Annual Maintenance Cost | ||||||||

| 2021–2025 | A | AB | 64.1712 | 14.4461 | 40 | 32.8320 | 2.6 | 3.4 | −38.7154 |

| A | AC | 52.0526 | 11.9180 | 33 | 27.0864 | 2.1 | 2.8 | −31.0516 | |

| A | AD | 24.8541 | 6.5007 | 18 | 14.7744 | 1.2 | 1.5 | −13.3990 | |

| A | AE | 0 | 2.1669 | 6 | 4.9248 | 0.4 | 0.5 | 3.2182 | |

| 2026–2030 | AB | ABF | 0 | 78.7968 | 40 | 32.8320 | 2.6 | 6.4 | −43.3190 |

| AC | ACF | 12.1186 | 78.7968 | 40 | 32.8320 | 2.6 | 6.4 | −56.2398 | |

| ACG | 0 | 65.0074 | 33 | 27.0864 | 2.1 | 5.3 | −35.7381 | ||

| AD | ADH | 0 | 35.4586 | 18 | 14.7744 | 1.2 | 2.9 | −19.4935 | |

| ADG | 27.1985 | 65.0074 | 33 | 27.0864 | 2.1 | 5.3 | −62.9367 | ||

| ADF | 39.3171 | 78.7968 | 40 | 32.8320 | 2.6 | 6.4 | −82.6361 | ||

| AE | AEF | 64.1712 | 78.7968 | 40 | 32.8320 | 2.6 | 6.4 | −107.4902 | |

| AEG | 52.0526 | 65.0074 | 33 | 27.0864 | 2.1 | 5.3 | −87.7908 | ||

| AEH | 24.8541 | 35.4586 | 18 | 14.7744 | 1.2 | 2.9 | −44.3476 | ||

| AEI | 0 | 11.8195 | 6 | 4.9248 | 0.4 | 1.0 | −6.4978 | ||

| 2031–2035 | ABF | ABFJ | 0 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | 14.2995 |

| ACF | ACFJ | 12.1186 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | 2.1810 | |

| ACG | ACGJ | 12.1186 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | 2.1810 | |

| ACGK | 0 | 32.5037 | 33 | 27.0864 | 2.1 | 9.5 | 11.7971 | ||

| ADF | ADFJ | 0 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | 14.2995 | |

| 2031–2035 | ADG | ADGJ | 12.1186 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | 2.1810 |

| ADGK | 0 | 32.5037 | 33 | 27.0864 | 2.1 | 9.5 | 11.7971 | ||

| ADH | ADHJ | 39.3171 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | −25.0176 | |

| ADHK | 27.1985 | 32.5037 | 33 | 27.0864 | 2.1 | 9.5 | −15.4014 | ||

| ADHL | 0 | 17.7293 | 18 | 14.7744 | 1.2 | 5.2 | 6.4348 | ||

| AEF | AEFJ | 0 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | 14.2995 | |

| AEG | AEGJ | 12.1186 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | 2.1810 | |

| AEGK | 0 | 32.5037 | 33 | 27.0864 | 2.1 | 9.5 | 11.7971 | ||

| AEH | AEHJ | 39.3171 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | −25.0176 | |

| AEHK | 27.1985 | 32.5037 | 33 | 27.0864 | 2.1 | 9.5 | −15.4014 | ||

| AEHL | 0 | 17.7293 | 18 | 14.7744 | 1.2 | 5.2 | 6.4348 | ||

| AEI | AEIJ | 64.1712 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | −49.8717 | |

| AEIK | 52.0526 | 32.5037 | 33 | 27.0864 | 2.1 | 9.5 | −40.2555 | ||

| AEIL | 24.8541 | 17.7293 | 18 | 14.7744 | 1.2 | 5.2 | −18.4193 | ||

| AEIM | 0 | 5.9098 | 6 | 4.9248 | 0.4 | 1.7 | 2.1449 | ||

| >2035 | J | - | 0 | 39.3984 | 40 | 32.8320 | 2.6 | 11.5 | 88.8700 |

| K | - | 0 | 32.5037 | 33 | 27.0864 | 2.1 | 9.5 | 73.3178 | |

| L | - | 0 | 17.7293 | 18 | 14.7744 | 1.2 | 5.2 | 39.9915 | |

| M | - | 0 | 5.9098 | 6 | 4.9248 | 0.4 | 1.7 | 13.3305 | |

References

- Azarkamand, S.; Ferré, G.; Darbra, R.M. Calculating the Carbon Footprint in ports by using a standardized tool. Sci. Total Environ. 2020, 734, 139407. [Google Scholar] [CrossRef] [PubMed]

- Fan, S.; Lu, Z. Research on the Peak Carbon Dioxide Emission Strategy of Chinese Port Based on Carbon Emission Estimation. Front. Environ. Sci. 2022, 9, 789970. [Google Scholar] [CrossRef]

- Azarkamand, S.; Balbaa, A.; Wooldridge, C.; Darbra, R.M. Climate Change—Challenges and Response Options for the Port Sector. Sustainability 2020, 12, 6941. [Google Scholar] [CrossRef]

- Wang, T.S.; Wang, X.C.; Meng, Q. Joint berth allocation and quay crane assignment under different carbon taxation policies. Transp. Res. Part B Methodol. 2018, 117, 18–36. [Google Scholar] [CrossRef]

- Yun, P.; Xiangda, L.I.; Wenyuan, W.; Ke, L.I.U.; Chuan, L.I. A simulation-based research on carbon emission mitigation strategies for green container terminals. Ocean Eng. 2018, 163, 288–298. [Google Scholar] [CrossRef]

- Hu, H.T.; Mo, J.; Zhen, L. Improved Benders decomposition for stochastic yard template planning in container terminals. Transp. Res. Part C Emerg. Technol. 2021, 132, 103365. [Google Scholar] [CrossRef]

- Kanellos, F.D. Multiagent-System-Based Operation Scheduling of Large Ports’ Power Systems with Emissions Limitation. IEEE Syst. J. 2018, 13, 1831–1840. [Google Scholar] [CrossRef]

- Wang, W.; Huang, L.; Gu, J.; Jiang, L.P. Green port project scheduling with comprehensive efficiency consideration. Marit. Policy Manag. 2019, 46, 967–981. [Google Scholar] [CrossRef]

- Hua, C.Y.; Chen, J.H.; Wan, Z.; Xu, L.; Bai, Y.; Zheng, T.X.; Fei, Y.J. Evaluation and governance of green development practice of port: A sea port case of China. J. Clean. Prod. 2019, 249, 119434. [Google Scholar] [CrossRef]

- Li, C.G.; Dixit, P.; Welch, B.; Nigam, A.; Soriano, B.; Lee, J.; Russell, R.L.; Jiang, Y.; Zhu, H.W.; Karavalakis, G.; et al. Yard tractors: Their path to zero emissions. Transp. Res. Part D Transp. Environ. 2021, 98, 102972. [Google Scholar] [CrossRef]

- Wang, L.; Liang, C.; Shi, J.; Molavi, A.; Lim, G.; Zhang, Y. A bilevel hybrid economic approach for optimal deployment of onshore power supply in maritime ports. Appl. Energy 2021, 292, 116892. [Google Scholar] [CrossRef]

- Wang, W.Y.; Peng, Y.; Li, X.D.; Qi, Q.; Feng, P.; Zhang, Y. A two-stage framework for the optimal design of a hybrid renewable energy system for port application. Ocean Eng. 2019, 191, 106555. [Google Scholar] [CrossRef]

- Elnajjar, H.M.; Shehata, A.S.; Elbatran, A.H.A.; Shehadeh, M.F. Experimental and techno-economic feasibility analysis of renewable energy technologies for Jabel Ali Port in UAE. Energy Rep. 2021, 7, 116–136. [Google Scholar] [CrossRef]

- Li, L.; Zhu, J.D.; Ye, G.Q.; Feng, X.H. Development of Green Ports with the Consideration of Coastal Wave Energy. Sustainability 2018, 10, 4270. [Google Scholar] [CrossRef] [Green Version]

- Macía, Y.M.; Machuca, P.R.; Soto, A.A.R.; Campos, R.C. Green Hydrogen Value Chain in the Sustainability for Port Operations: Case Study in the Region of Valparaiso, Chile. Sustainability 2021, 13, 13681. [Google Scholar] [CrossRef]

- Vichos, E.; Sifakis, N.; Tsoutsos, T. Challenges of integrating hydrogen energy storage systems into nearly zero-energy ports. Energy 2022, 241, 122878. [Google Scholar] [CrossRef]

- Wang, X.B.; Huang, W.T.; Wei, W.; Tai, N.L.; Li, R.; Huang, Y.W. Day-Ahead Optimal Economic Dispatching of Integrated Port Energy Systems Considering Hydrogen. IEEE Trans. Ind. Appl. 2021, 58, 2619–2629. [Google Scholar] [CrossRef]

- Tan, Z.Y.; Zhang, Q.; Yuan, Y.Y.; Jin, Y. A decision method on yard cranes transformation and deployment in green ports. Int. Trans. Oper. Res. 2021, 29, 323–346. [Google Scholar] [CrossRef]

- Martínez-Moya, J.; Vazquez-Paja, B.; Maldonado, J.A.G. Energy efficiency and CO2 emissions of port container terminal equipment: Evidence from the Port of Valencia. Energy Policy 2019, 131, 312–319. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, W.Y.; Liu, K.; Li, X.D.; Tian, Q. The Impact of the Allocation of Facilities on Reducing Carbon Emissions from a Green Container Terminal Perspective. Sustainability 2018, 10, 1813. [Google Scholar] [CrossRef] [Green Version]

- Schmid, U.; Prakash, N.; van der Vleugel, M.; Claunch, J. Bringing the Power of Enterprise Technology to Decarbonization; Bain & Company: Boston, MA, USA, 2021. [Google Scholar]

- Kovacic, D.; Bogataj, M. Net Present Value Evaluation of Energy Production and Consumption in Repeated Reverse Logistics. Technol. Econ. Dev. Econ. 2017, 23, 877–894. [Google Scholar] [CrossRef]

- Kawabata, Y.; Kato, E.; Yokota, H.; Iwanami, M. Net present value as an effective indicator leading to preventive maintenance of port mooring facilities. Struct. Infrastruct. Eng. 2020, 16, 714–725. [Google Scholar] [CrossRef]

- Zhu, M.; Li, K.X.; Shi, W.M.; Lam, J.S.L. Incentive policy for reduction of emission from ships: A case study of China. Mar. Policy 2017, 86, 253–258. [Google Scholar] [CrossRef]

- Zhang, M.M.; Tang, Y.M.; Liu, L.Y.; Zhou, D.Q. Optimal investment portfolio strategies for power enterprises under multi-policy scenarios of renewable energy. Renew. Sustain. Energy Rev. 2022, 154, 111879. [Google Scholar] [CrossRef]

- Van den Boomen, M.; Van der Meulen, S.; Van Ekris, J.; Spanjers, R.; Voorde, O.T.; Mulder, J.; Blommaart, P. Optimized Expansion Strategy for a Hydrogen Pipe Network in the Port of Rotterdam with Compound Real Options Analysis. Sustainability 2021, 13, 9153. [Google Scholar] [CrossRef]

- Duan, F.; Ji, Q.; Liu, B.-Y.; Fan, Y. Energy investment risk assessment for nations along China’s Belt & Road Initiative. J. Clean. Prod. 2018, 170, 535–547. [Google Scholar] [CrossRef]

- Jia, Z.J.; Lin, B.Q. How to achieve the first step of the carbon-neutrality 2060 target in China: The coal substitution perspective. Energy 2021, 233, 121179. [Google Scholar] [CrossRef]

- Deeney, P.; Cummins, M.; Heintz, K.; Pryce, M.T. A real options based decision support tool for R&D investment: Application to CO2 recycling technology. Eur. J. Oper. Res. 2020, 289, 696–711. [Google Scholar] [CrossRef]

- Bangjun, W.; Feng, Z.L.; Feng, J.; Yu, P.; Cui, L.Y. Decision making on investments in photovoltaic power generation projects based on renewable portfolio standard: Perspective of real option. Renew. Energy 2022, 189, 1033–1045. [Google Scholar] [CrossRef]

- Zhang, M.M.; Wang, Q.W.; Zhou, D.Q.; Ding, H. Evaluating uncertain investment decisions in low-carbon transition toward renewable energy. Appl. Energy 2019, 240, 1049–1060. [Google Scholar] [CrossRef]

- Ponomarenko, T.; Marin, E.; Galevskiy, S. Economic Evaluation of Oil and Gas Projects: Justification of Engineering Solutions in the Implementation of Field Development Projects. Energies 2022, 15, 3103. [Google Scholar] [CrossRef]

- Balliauw, M. From theoretical real options models to pragmatic decision making: Required steps, opportunities and threats. Res. Transp. Econ. 2021, 90, 101063. [Google Scholar] [CrossRef]

- Pimentel, P.; Couto, G.; Tavares, A.; Oliveira, A. The impacts of real options analysis on EU co-financing policy: The case of Ponta Delgada Port in the Azores. Res. Transp. Econ. 2021, 90, 100977. [Google Scholar] [CrossRef]

- Li, L.; Liu, J.Q.; Zhu, L.; Zhang, X.-B. How to design a dynamic feed-in tariffs mechanism for renewables—A real options approach. Int. J. Prod. Res. 2020, 58, 4352–4366. [Google Scholar] [CrossRef]

- Zhang, M.M.; Liu, L.Y.; Wang, Q.W.; Zhou, D.Q. Valuing investment decisions of renewable energy projects considering changing volatility. Energy Econ. 2020, 92, 104954. [Google Scholar] [CrossRef]

- Fan, J.-L.; Xu, M.; Yang, L.; Zhang, X. Benefit evaluation of investment in CCS retrofitting of coal-fired power plants and PV power plants in China based on real options. Renew. Sustain. Energy Rev. 2019, 115, 109350. [Google Scholar] [CrossRef]

- Yue, Y.; Ying, Y.R. Real option analysis for emission reduction investment under the sulfur emission control. Sustain. Energy Technol. Assess. 2021, 45, 101055. [Google Scholar] [CrossRef]

- Fan, J.-L.; Wei, S.J.; Zhang, X.; Yang, L. A comparison of the regional investment benefits of CCS retrofitting of coal-fired power plants and renewable power generation projects in China. Int. J. Greenh. Gas Control 2020, 92, 102858. [Google Scholar] [CrossRef]

- Oliveira, A.; Couto, G.; Pimentel, P. Uncertainty and flexibility in infrastructure investments: Application of real options analysis to the Ponta Delgada airport expansion. Res. Transp. Econ. 2020, 90, 100845. [Google Scholar] [CrossRef]

- Li, Y.; Kool, C.; Engelen, P.-J. Analyzing the Business Case for Hydrogen-Fuel Infrastructure Investments with Endogenous Demand in The Netherlands: A Real Options Approach. Sustainability 2021, 12, 5422. [Google Scholar] [CrossRef]

- Rogner, H.-H. Hydrogen technologies and the technology learning curve. Int. J. Hydrogen Energy 1998, 23, 833–840. [Google Scholar] [CrossRef]

- Ferioli, F.; Schoots, K.; van der Zwaan, B.C. Use and limitations of learning curves for energy technology policy: A com-ponent-learning hypothesis. Energy Policy 2009, 37, 2525–2535. [Google Scholar] [CrossRef]

- Luo, Z.; Hu, Y.; Xu, H.; Gao, D.; Li, W. Cost-Economic Analysis of Hydrogen for China’s Fuel Cell Transportation Field. Energies 2020, 13, 6522. [Google Scholar] [CrossRef]

- Slater, H.; De Boer, D.; Qian, G.; Wang, Z. 2020 China Carbon Price Survey; China Carbon Forum: Beijing, China, 2020. (In Chinese) [Google Scholar]

| Transition Process | |||

|---|---|---|---|

| Expectations of the transition process |

| Transition Process | 2021–2025 | 2026–2030 | 2031–2035 |

|---|---|---|---|

| 6 | 15% | 5% | 1% |

| 19 | 80% | 40% | 10% |

| 38 | 4% | 55% | 80% |

| 76 | 1% | 5% | 9% |

| Expectations of the transition process | 18 | 33 | 40 |

| Parameter | Value 1 | Unit | |

|---|---|---|---|

| Beginning time of equipment transition investment decision | 2021 | Year | |

| Investment stage time period | 5 | Year | |

| Initial situation of hydrogen-powered ARMGs completed at the port at time | 6 | Unit | |

| Total number of ARMGs in the port | 76 | Unit | |

| Discount rate | 0.8 | - | |

| Direct investment cost of the first piece of equipment in the port | 2.4 | Million RMB | |

| Learning rate parameter | 0.1 | - | |

| Number of standard containers (TEU) every year of each ARMG’s task | 13.7 | TEU | |

| Hydrogen consumption of handling each container | 0.3 | Kg/TEU | |

| Hydrogen price from 2021 to 2025 | 11 | Kg/RMB | |

| Hydrogen price from 2026 to 2030 | 60 | Kg/RMB | |

| Hydrogen price from 2031 to 2035 | 30 | Kg/RMB | |

| Annual maintenance cost of each hydrogen-powered ARMG | 1000 | RMB | |

| Electric cost of handling each container | 60,000 | RMB | |

| Annual maintenance cost of each traditional ARMG | 64,000 | RMB/Unit | |

| Carbon emissions from handling each container | 12.6 | Kg/TEU/Year | |

| Carbon price from 2021 to 2025 | 49 | RMB/Ton | |

| Carbon price from 2026 to 2030 | 93 | RMB/Ton | |

| Carbon price from 2031 to 2035 | 167 | RMB/Ton | |

| Decision Schemes | Time Period | Decision Path | Number of Hydrogen-Powered ARMGS | (Million RMB) |

|---|---|---|---|---|

| Optimal decision path | 2021–2025 | A–B | 40 | −38.7154 |

| 2026–2030 | B–F | 40 | −43.3190 | |

| 2031–2035 | F–J | 40 | 14.2995 | |

| >2035 | J– | 40 | 88.8700 | |

| Expectations of the decision path | 2021–2025 | A–D | 18 | −13.39.90 |

| 2026–2030 | D–G | 33 | −62.93.67 | |

| 2031–2035 | G–J | 40 | 2.1810 | |

| >2035 | J– | 40 | 88.8700 |

| Decision Schemes | Optimal Decision Path | Expected Decision Path | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Time Period | 2021–2025 | 2026–2030 | 2031–2035 | >2035 | 2021–2025 | 2026–2030 | 2031–2035 | >2035 | |

| A–B | B–F | F–J | J– | A–D | D–G | G–J | J– | ||

| 0.1 | −38.7154 | −43.3190 | 14.2995 | 88.8700 | −13.3990 | −62.9367 | 2.1810 | 88.8700 | |

| 0.2 | −24.5806 | −43.3190 | 14.2995 | 88.8700 | −9.7604 | −55.9603 | 5.7008 | 88.8700 | |

| 0.3 | −13.9060 | −43.3190 | 14.2995 | 88.8700 | −6.7623 | −50.7810 | 8.1981 | 88.8700 | |

| 0.4 | −5.8010 | −43.3190 | 14.2995 | 88.8700 | −4.2862 | −46.9339 | 9.9699 | 88.8700 | |

| Scenario | Decision Schemes | Time Period | Decision Path | Number of Hydrogen-Powered ARMGs | (Million RMB) |

|---|---|---|---|---|---|

| Case study scenario | Optimal decision path | 2021–2025 | A–B | 40 | −38.7154 |

| 2026–2030 | B–F | 40 | −43.3190 | ||

| 2031–2035 | F–J | 40 | 14.2995 | ||

| >2035 | J– | 40 | 88.8700 | ||

| Positive scenario | Optimal decision path | 2021–2025 | A–B | 40 | −35.6279 |

| 2026–2030 | B–F | 40 | 3.3209 | ||

| 2031–2035 | F–J | 40 | 14.2995 | ||

| >2035 | J– | 40 | 88.8700 | ||

| Negative scenario | Optimal decision path | 2021–2025 | A–E | 6 | 3.1661 |

| 2026–2030 | E–I | 6 | −7.2847 | ||

| 2031–2035 | I–M | 6 | −9.7414 | ||

| >2035 | M– | 6 | −60.5415 |

| Scenario | Decision Schemes | Time Period | Decision Path | Number of Hydrogen-Powered ARMGs | (Million RMB) |

|---|---|---|---|---|---|

| Accounting for carbon emission reduction income | Optimal decision path | 2021–2025 | A–B | 40 | −38.71.54 |

| 2026–2030 | B–F | 40 | −43.31.90 | ||

| 2031–2035 | F–J | 40 | 14.29.95 | ||

| >2035 | J– | 40 | 88.87.00 | ||

| Not accounting for carbon emission reduction income | Optimal decision path | 2021–2025 | A–E | 6 | 3.1276 |

| 2026–2030 | E–I | 6 | −7.8664 | ||

| 2031–2035 | I–M | 6 | −1.3294 | ||

| >2035 | M– | 6 | −8.2620 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, A.; Meng, X.; He, H.; Wang, L.; Gao, J. Towards Optimized ARMGs’ Low-Carbon Transition Investment Decision Based on Real Options. Energies 2022, 15, 5153. https://doi.org/10.3390/en15145153

Yang A, Meng X, He H, Wang L, Gao J. Towards Optimized ARMGs’ Low-Carbon Transition Investment Decision Based on Real Options. Energies. 2022; 15(14):5153. https://doi.org/10.3390/en15145153

Chicago/Turabian StyleYang, Ang, Xiangyu Meng, He He, Liang Wang, and Jing Gao. 2022. "Towards Optimized ARMGs’ Low-Carbon Transition Investment Decision Based on Real Options" Energies 15, no. 14: 5153. https://doi.org/10.3390/en15145153

APA StyleYang, A., Meng, X., He, H., Wang, L., & Gao, J. (2022). Towards Optimized ARMGs’ Low-Carbon Transition Investment Decision Based on Real Options. Energies, 15(14), 5153. https://doi.org/10.3390/en15145153