Author Contributions

Conceptualization, R.P., E.G., R.S.R. and D.G.S.; methodology, R.P. and E.G.; investigation, N.G.B., M.S.M., R.P., M.W., P.P., E.G., R.S.R. and D.G.S.; writing—original draft preparation, N.G.B., M.S.M. and E.G.; writing—review and editing, R.P., M.W. and E.G. All authors have read and agreed to the published version of the manuscript.

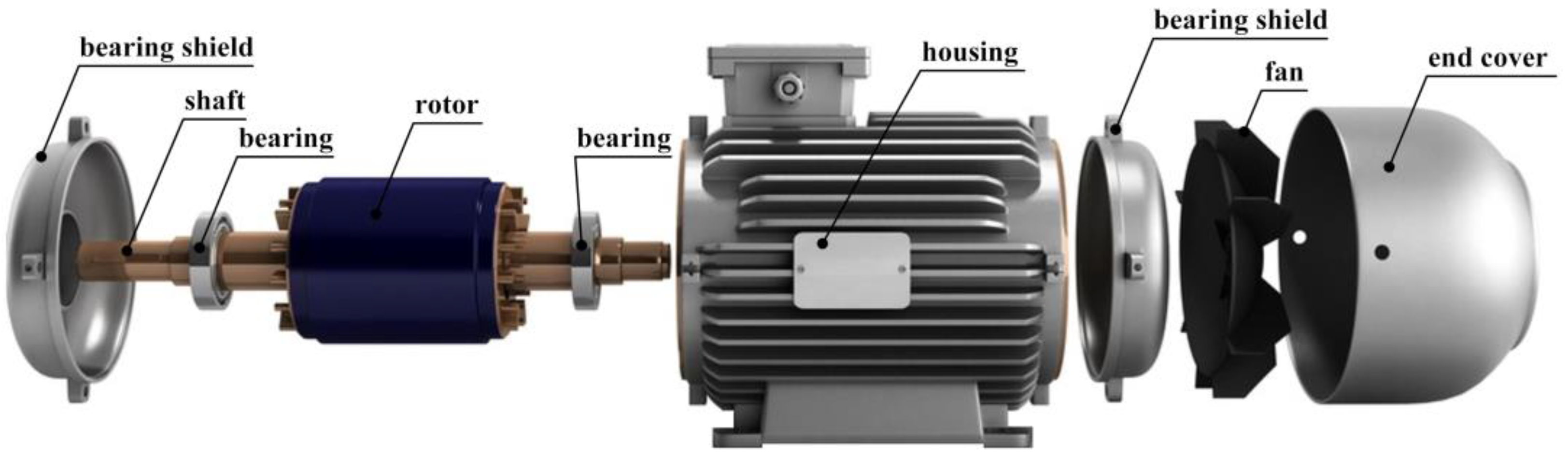

Figure 1.

Typical AC induction motor.

Figure 1.

Typical AC induction motor.

Figure 2.

Weights of various parts of the motor.

Figure 2.

Weights of various parts of the motor.

Figure 3.

Measuring the dimensions of various parts of the motor.

Figure 3.

Measuring the dimensions of various parts of the motor.

Figure 4.

Motor used for research.

Figure 4.

Motor used for research.

Figure 5.

Motor (fan-cooled) drawn using Motor-CAD software (according to specifications of the chosen motor).

Figure 5.

Motor (fan-cooled) drawn using Motor-CAD software (according to specifications of the chosen motor).

Figure 6.

Water-cooled motor drawn using Motor-CAD.

Figure 6.

Water-cooled motor drawn using Motor-CAD.

Figure 7.

Radial view of fan-cooled motor mainly showcasing the housing type-axial fins (the windings, stator, and rotor) (a); axial view of fan-cooled motor depicting air flow coming from fan cooling system through the arrows (b).

Figure 7.

Radial view of fan-cooled motor mainly showcasing the housing type-axial fins (the windings, stator, and rotor) (a); axial view of fan-cooled motor depicting air flow coming from fan cooling system through the arrows (b).

Figure 8.

Radial view of motor (fan-cooled) after FEM analysis.

Figure 8.

Radial view of motor (fan-cooled) after FEM analysis.

Figure 9.

Axial view of motor (fan-cooled) after FEM analysis.

Figure 9.

Axial view of motor (fan-cooled) after FEM analysis.

Figure 10.

Radial view (a) and axial view (b) of water-cooled motor with aluminum casing (Alloy 195 cast) water-cooled motor.

Figure 10.

Radial view (a) and axial view (b) of water-cooled motor with aluminum casing (Alloy 195 cast) water-cooled motor.

Figure 11.

Specific heat capacity of water.

Figure 11.

Specific heat capacity of water.

Figure 12.

Radial view of water-cooled motor after FEM analysis.

Figure 12.

Radial view of water-cooled motor after FEM analysis.

Figure 13.

Axial view of water-cooled motor (aluminum casing) after the FEM analysis.

Figure 13.

Axial view of water-cooled motor (aluminum casing) after the FEM analysis.

Figure 14.

Radial view of PA6GF30 casing electric motor (water-cooled after FEM analysis).

Figure 14.

Radial view of PA6GF30 casing electric motor (water-cooled after FEM analysis).

Figure 15.

Axial view of water-cooled motor with PA6GF30 casing after FEM analysis.

Figure 15.

Axial view of water-cooled motor with PA6GF30 casing after FEM analysis.

Table 1.

Motor dimensions.

Table 1.

Motor dimensions.

| Section/Part of the Motor | Specific Part | Dimensions (mm) |

|---|

| Radial dimensions | Housing diameter | 140 |

| Stator lamination diameter | 130 |

| Shaft diameter | 50 |

| Shaft height | 95 |

| Axial dimensions | Motor length | 240 |

| Stator lamination length | 50 |

| Rotor lamination length | 90 |

| Base length | 350 |

| Stator parameters | Housing diameter | 140 |

| Tooth width | 71 |

| Fin extension | 12.5 |

| Rotor parameters | Rotor bars | 26 |

| Rotor tooth width | 4 |

| Shaft diameter | 50 |

Table 2.

Specifications of the single-phase induction motor.

Table 2.

Specifications of the single-phase induction motor.

| Parameters | Values |

|---|

| Rated output power | 373 W (0.5 HP) |

| Rated voltage | 230 V |

| Rated speed | 1430 rpm |

| Number of poles | 4 |

| Number of stator slots | 24 |

| Frequency | 50 Hz |

| Type | Permanent split capacitor |

Table 3.

Comparison of properties between cast iron and CFRP.

Table 3.

Comparison of properties between cast iron and CFRP.

| Mechanical Properties | Cast Iron | CFRP |

|---|

| Tensile strength (ultimate) | 1650 MPa | 4000 MPa |

| Compressive stress | 1370 MPa | 890 MPa |

| Young’s modulus | 168 GPa | 500 GPa |

| Damping capacity | 11.5 × 10−3 | 11 × 10−3 |

Table 4.

Lightweight materials comparison.

Table 4.

Lightweight materials comparison.

| No. | Material | Thermal Conductivity (k·m) | Specific Heat

(g·K) | Density

(g/cm) |

|---|

| 1. | PA6GF30 | 0.41 | 1.30 | 1.36 |

| 2. | Mg–Zn (magnesium alloy) | 116 | 1.02 | 1.76 |

| 3. | Ti–6Al–4V (titanium alloy) | 62 | 0.56 | 3.73 |

| 4. | Epoxy carbon fiber | 5 | 2.02 | 1.21 |

Table 5.

Input parameters for thermal analysis on fan-cooled motor (ANSYS Motor-CAD).

Table 5.

Input parameters for thermal analysis on fan-cooled motor (ANSYS Motor-CAD).

| No. | Input Parameter | Input Data |

|---|

| 1. | Housing | Round axial fins |

| 2. | Housing material | Aluminum (alloy 195 cast), thermal conductivity—168 W/m/C, specific heat—833 J/kg/C |

| 3. | Armature winding material | Copper (pure), thermal conductivity—401 W/m/C, specific heat—385 J/kg/C |

| 4. | Calculation type | Steady-state thermal analysis |

| 5. | Input power | 800 W |

| 6. | Shaft speed | 2880 rpm |

| 7. | Cooling type | Blown over (convection) air cooling (TEFC) |

| 8. | Velocity of air | Reference flow velocity proportional to speed at 5 m/s |

Table 6.

Observations after FEM analysis on the air-cooled motor.

Table 6.

Observations after FEM analysis on the air-cooled motor.

| No. | Output Parameter | Value |

|---|

| 1. | Total weight of motor obtained including foot mounted base | 13 kg |

| 2. | Temperature range observed in radial thermal FEM analysis | 160–249 °C |

| 3. | Temperature range observed in axial thermal FEM analysis | 104–250 °C |

Table 7.

Comparison of thermal analyses of two fan-cooled motors from a previous study 28 and this study.

Table 7.

Comparison of thermal analyses of two fan-cooled motors from a previous study 28 and this study.

| No. | Comparison Part | EEC Fan-Cooled Motor [28] (°C) | Fan-Cooled Motor Used in This Study (°C) |

|---|

| 1. | Front cover | 91 | 153.0 |

| 2. | Rear bearing | 89 | 125.2 |

| 3. | Rear case | 84 | 132.0 |

Table 8.

Input parameters for thermal analysis on water-cooled motor with aluminum casing (ANSYS Motor-CAD).

Table 8.

Input parameters for thermal analysis on water-cooled motor with aluminum casing (ANSYS Motor-CAD).

| No. | Comparison Part | Fan-Cooled Induction Motor Used in This Study (°C) |

|---|

| 1. | Housing | Water jacket (axial) |

| 2. | Housing material | Aluminum (Alloy 195 cast), thermal conductivity—168 W/m/C, specific heat—833 J/kg/C |

| 3. | Armature winding material | Copper (pure), thermal conductivity—401 W/m/C, specific heat—385 J/kg/C) |

| 4. | Calculation type | Steady-state thermal analysis |

| 5. | Input power | 800 W |

| 6. | Shaft speed | 2880 rpm |

| 7. | Cooling type | Housing water jacket |

| 8. | Housing water jacket inlet temperature | 15 °C |

| 9. | Fluid properties | 7 L/min |

| 10. | Fluid volume flow rate | Fluid–water |

Table 9.

Fluid (coolant used) properties.

Table 9.

Fluid (coolant used) properties.

| Fluid–Water |

|---|

| Thermal conductivity | 0.6167 W/m·K |

| Density | 994 kg/m3 |

Table 10.

Observations for water-cooled motor with aluminum (Alloy 195 cast) casing.

Table 10.

Observations for water-cooled motor with aluminum (Alloy 195 cast) casing.

| No. | Output Parameter | Value |

|---|

| 1. | Total weight of motor obtained including foot mounted base | 12.1 kg |

| 2. | Temperature range observed in radial thermal FEA | 18–123 °C |

| 3. | Temperature range observed in axial thermal FEA | 17–124 °C |

Table 11.

Comparison of temperature analyses of two water-cooled motors from a previous study and this study.

Table 11.

Comparison of temperature analyses of two water-cooled motors from a previous study and this study.

| No. | Comparison Part | Water-Cooled Motor [5] (°C) | Water-Cooled Motor Used in This Study Set to Same Parameters as Study Motor in [5] (°C) |

|---|

| 1. | Casing temperature | 84 | 65 |

| 2. | Stator core temperature | 98 | 80 |

Table 12.

Axial temperatures for fan-cooled motor.

Table 12.

Axial temperatures for fan-cooled motor.

| Part | Endcap | Front | Overhang | Central | Overhang | Rear | Endcap |

|---|

| Ambient | | | | 40 °C | | | |

| Housing | 153.5 °C | 157.9 °C | 158. 6 °C | 160.2 °C | 145.2 °C | 140.5 °C | 132.2 °C |

| Stator (back iron) | | | | 184.0 °C | | | |

| Stator surface | | | | 202.3 °C | | | |

| Rotor surface | | | | 219.1 °C | | | |

| Rotor tooth | | | | 219.3 °C | | | |

| Rotor lamination | | | | 219.0 °C | | | |

| Shaft | 164.3 °C | 170.1 °C | 193.7 °C | 217.3 °C | 164.7 °C | 104.68 °C | 125.23 °C |

| Rotor bar | | | 218.9 °C | 219.3 °C | 218.3 °C | | |

| Blown over air | | | 83.6 °C | 78.2 °C | 55.8 °C | 40 °C | |

| Winding max. | | | 252.9 °C | 248.3 °C | 252.8 °C | | |

| Winding av. | | | 247.3 °C | 234.1 °C | 246.7 °C | | |

| Winding min. | | | 232.2 °C | 195.7 °C | 233.8 °C | | |

Table 13.

Axial temperatures for water cooled motor (Alloy 195 casing).

Table 13.

Axial temperatures for water cooled motor (Alloy 195 casing).

| Part | Endcap | Front | Overhang | Central | Overhang | Rear | Endcap |

|---|

| Ambient | | | | 40 °C | | | |

| Housing | 32.5 °C | 20.0 °C | 17.5 °C | 18.1 °C | 17.1 °C | 21.8 °C | 26.1 °C |

| Stator (back iron) | | | | 45.7 °C | | | |

| Stator surface | | | | 67.7 °C | | | |

| Rotor surface | | | | 94.9 °C | | | |

| Rotor tooth | | | | 95.2 °C | | | |

| Rotor lamination | | | | 95.1 °C | | | |

| Shaft | 48.0 °C | 60.5 °C | 76.3 °C | 94.2 °C | 74.1 °C | 55.7 °C | 42.9 °C |

| Rotor bar | | | 94.7 °C | 95.2 °C | 94.6 °C | | |

| Winding max. | | | 127.0 °C | 122.2 °C | 127.0 °C | | |

| Winding av. | | | 120.8 °C | 105.2 °C | 120.8 °C | | |

| Winding min. | | | 108.2 °C | 59.6 °C | 108.1 °C | | |

Table 14.

Input parameters for thermal analysis of water-cooled motor with PA6GF30 casing.

Table 14.

Input parameters for thermal analysis of water-cooled motor with PA6GF30 casing.

| No. | Input Parameter | Input Data |

|---|

| 1. | Housing | Water jacket (axial) |

| 2. | Housing material | PA6GF30, thermal conductivity—0.41 W/(K·m), specific heat—1.3 J/(g·K) |

| 3. | Armature winding material | Copper (pure), thermal conductivity—401 W/m/C, specific heat—385 J/kg/C) |

| 4. | Calculation type | steady-state thermal analysis |

| 5. | Input power | 800 W |

| 6. | Shaft speed | 2880 rpm |

| 7. | Cooling type | Housing water jacket |

| 8. | Housing water jacket inlet temperature | 15 °C |

| 9. | Fluid properties | 7 L/min |

| 10. | Fluid volume flow rate | Fluid–water |

Table 15.

Results of thermal analysis of water-cooled electric motor of lightweight PA6GF30 casing.

Table 15.

Results of thermal analysis of water-cooled electric motor of lightweight PA6GF30 casing.

| No. | Output Parameter | Value |

|---|

| 1. | Total weight of motor obtained including foot mounted base | 9.647 kg |

| 2. | Temperature range observed in radial thermal FEA | 18–126 °C |

| 3. | Temperature range observed in axial thermal FEA | 17–129 °C |

Table 16.

Axial temperature graph for water-cooled motor with PA6GF30 casing.

Table 16.

Axial temperature graph for water-cooled motor with PA6GF30 casing.

| Part | Endcap | Front | Overhang | Central | Overhang | Rear | Endcap |

|---|

| Ambient | | | | 20 °C | | | |

| Housing | 67.2 °C | 28.0 °C | 17.1 °C | 18.0 °C | 17.1 °C | 53.7 °C | 66.3 °C |

| Stator (back iron) | | | | 46.5 °C | | | |

| Stator surface | | | | 69.4 °C | | | |

| Rotor surface | | | | 104.8 °C | | | |

| Rotor tooth | | | | 105.2 °C | | | |

| Rotor lamination | | | | 105.1 °C | | | |

| Shaft | 84.8 °C | 84.9 °C | 93.7 °C | 104.5 °C | 88.9 °C | 75.5 °C | 76.4 °C |

| Rotor bar | | | 105.1 °C | 105.2 °C | 104.6 °C | | |

| Winding max. | | | 131.0 °C | 125.2 °C | 130.3 °C | | |

| Winding av. | | | 124.1 °C | 107.5 °C | 123.6 °C | | |

| Winding min. | | | 113.6 °C | 60.6 °C | 112.3 °C | | |

Table 17.

Winding temperature graph for water-cooled motor with PA6GF30 casing.

Table 17.

Winding temperature graph for water-cooled motor with PA6GF30 casing.

| Part | Cuboid 1 | Cuboid 2 |

|---|

| End winding max. | 127.8 °C | 131.0 °C |

| End winding av. | 121.0 °C | 127.3 °C |

| End winding min. | 133.6 °C | 117.8 °C |

| Winding max. | 120.9 °C | 125.2 °C |

| Winding av. | 102.7 °C | 112.3 °C |

| Winding min. | 60.6 °C | 86.5 °C |

| End winding max. | 127.8 °C | 130.3 °C |

| End winding av. | 120.5 °C | 126.6 °C |

| End winding min. | 112.3 °C | 116.9 °C |

| Tooth | 58.5 °C | 68.7 °C |

Table 18.

Temperature reduction for Case-2 and Case-3 when compared to air-cooled motor (Case-1).

Table 18.

Temperature reduction for Case-2 and Case-3 when compared to air-cooled motor (Case-1).

| Cases | Lowest Temperature(along Axial Direction) (°C) | Highest Temperature(along Axial Direction) (°C) | Temperature Reduction of Highest Temperature When Compared to Air-Cooled Motor (%) |

|---|

| Case-1 | 104 | 250 | - |

| Case-2 | 17 | 124 | 50.4 |

| Case-3 | 17 | 129 | 48.4 |

Table 19.

Weight reduction for Case-2 and Case-3 when compared to air-cooled motor (Case-1).

Table 19.

Weight reduction for Case-2 and Case-3 when compared to air-cooled motor (Case-1).

| Models | Weight of the Motor (kg) | Weight Reduction When Compared with Air-cooled Motor Model-1 (%) |

|---|

| Model-1 (air-cooled motor) | 13 | - |

| Model-2 (water-cooled withAlloy 195 casing) | 12.1 | - |

| Model-3 (water-cooled with PA6GF30) | 9.647 | 20.27 |