A Computational Method of Rotating Stall and Surge Transients in Axial Compressor

Abstract

:1. Introduction

2. Methodology

2.1. Governing Equations

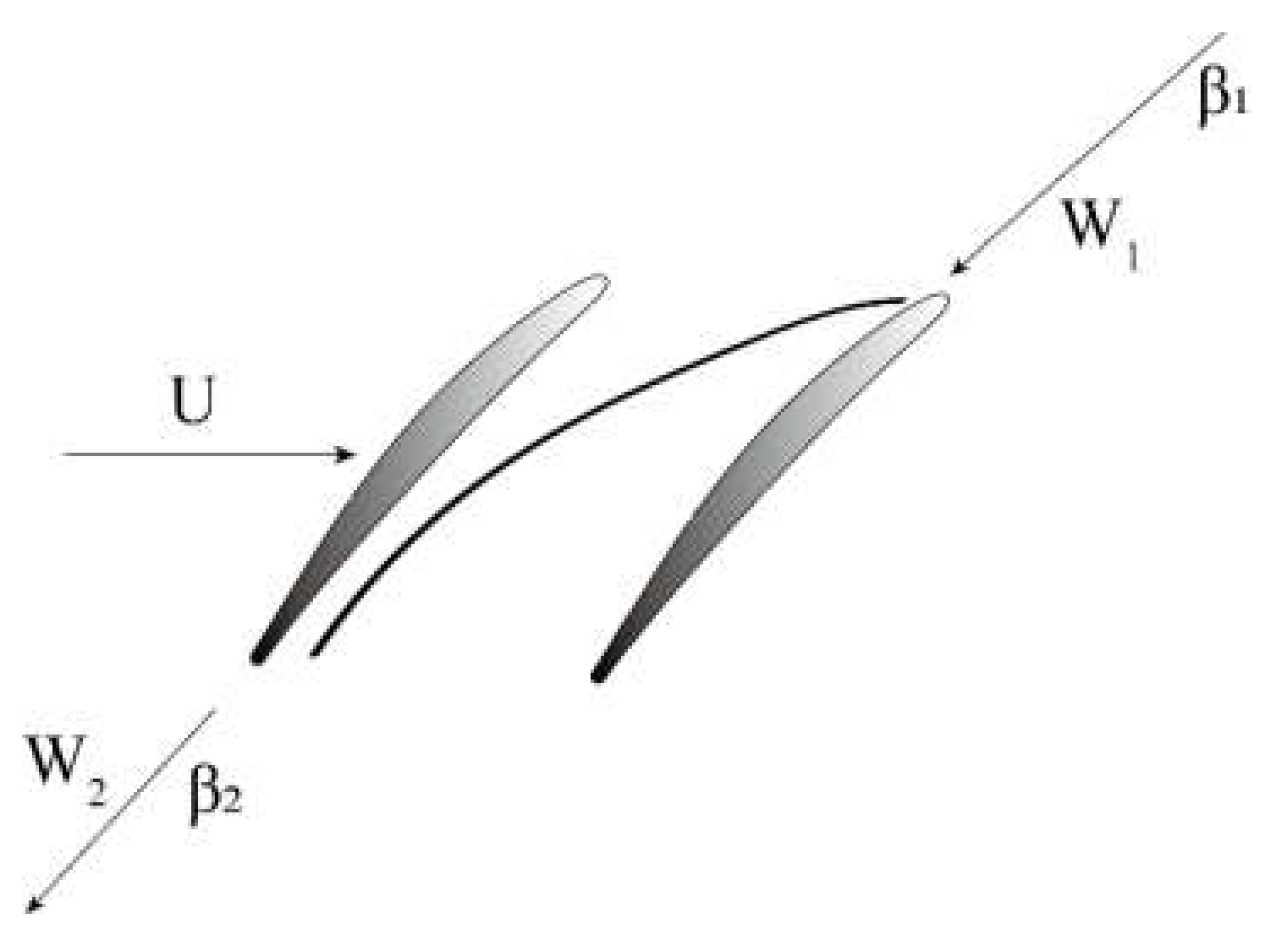

2.2. Blade Force Model

2.3. Elementary Cascade Characteristics

2.4. Unsteady Treatment

2.5. Initial Boundary Conditions

2.6. Numerical Solution Method

3. Model Validation

3.1. Single-Stage Compressor

3.1.1. Steady-State Calculation

3.1.2. Rotating Stall Simulation

3.2. Single Rotor of the Fan

3.2.1. Steady-State Calculation

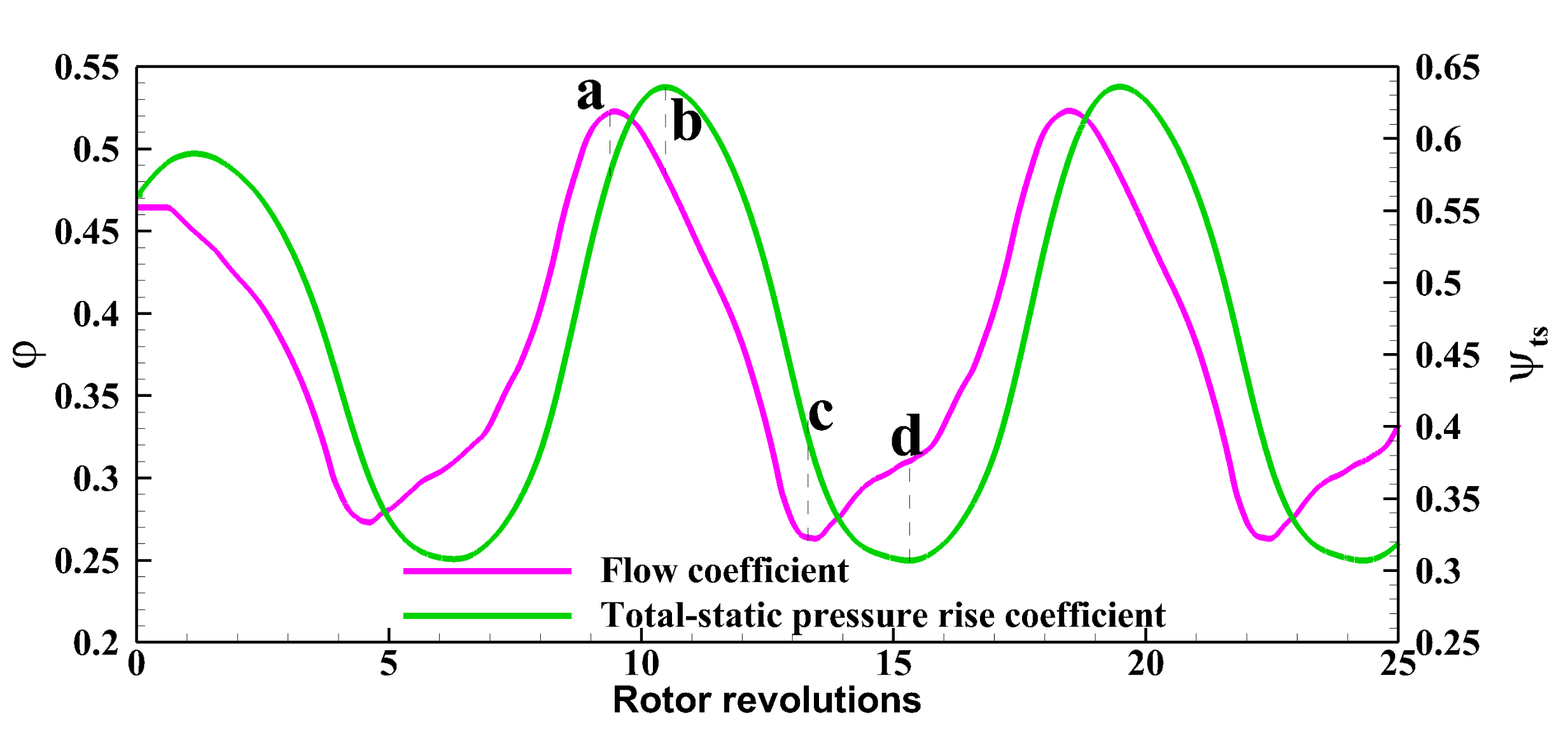

3.2.2. Rotating Stall Simulation

3.2.3. Surge Simulation

4. Conclusions

- The relationship between deviation angle and loss coefficient with attack angle for large attack angle flow regions is proposed for simulating typical three-dimensional flow features that occur during rotating stall and surge. Since the deviation angle and the loss coefficient are calculated in the same way as in the case of small attack angles, there will be no physical discontinuity in the transition from unstalled to stalled flow, which will be more accurate for the judgment of the stability boundary.

- The model is applied to a single-stage axial compressor and compared with the experimental results to verify the accuracy of the steady-state flow field simulation. Further computational analysis shows that the model can simulate rotating stall, and the post-stall stability characteristic and the rotating frequency of the stall cell are predicted with good precision. In addition, due to the three-dimensional nature of the model, it can be used to observe the three-dimensional features of the stall cell.

- The simulation of rotating stall and surge of a single rotor fan is investigated by coupling the developed three-dimensional body-force model with a one-dimensional gas collector model. The calculations show that the model can still simulate the features related to rotating stall and can simulate the “surge ring” during surge. This model can also be used to calculate the blade load during surge, which will be an important reference for the blade design. The relationship between the surge frequency and the volume of the plenum was calculated, and the trend was consistent with the understanding, which further verified the ability of this model to simulate surge.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| b | Blade blockage factor |

| e | Total energy per unit mass of fluid |

| E, F, G | Inviscid fluxes |

| Ev, Fv, Gv | Viscid fluxes |

| f | Magnitude of viscid body force |

| F | Blade body force |

| k | Throttle coefficient |

| m | Meridional coordinate |

| Mass flow rate | |

| p | Pressure |

| q | Turbulent heat transfer term |

| r, θ, z | Cylindrical coordinates |

| R | Universal gas constant |

| s | Entropy |

| S | Centrifugal and Coriolis source terms |

| Sb | Blockage term |

| SF | Blade body force term |

| t | Time |

| T | Temperature |

| U | Rotor rim speed |

| U | Vector of conserved variables |

| v | Velocity |

| V | Volume |

| w | Magnitude of relative velocity |

| β | Flow angle |

| γ | Specific heat ratio |

| δ | Deviation angle |

| ρ | Density |

| τ | Turbulent viscous stress, Convection time |

| φ | Magnitude of inviscid body force, Flow coefficient |

| ψ | Pressure rise coefficient |

| ϖ | Loss coefficient |

| Γ | bound circulation |

| Ω | Rotor rotational speed |

| Subscripts | |

| c | Compressor |

| e | Exit |

| i | i = 1,2,3 |

| m | Meridional direction |

| ns | Near stall |

| pl | Plenum property |

| r, θ, z | Radial, axial, and circumferential direction |

| t | Throttle |

| ts | Total-to-static performance |

| 0 | Total quantity |

| 1,2 | Inlet and outlet |

| Superscripts | |

| ss | Steady-state |

| Abbreviations | |

| CFD | Computational fluid dynamics |

| RANS | Reynolds-averaged Navier–Stokes |

References

- Pan, T.; Li, Q.; Yuan, W.; Lu, H. Effects of axisymmetric arc-shaped slot casing treatment on partial surge initiated instability in a transonic axial flow compressor. Aerosp. Sci. Technol. 2017, 69, 257–268. [Google Scholar] [CrossRef]

- Cravero, C.; Leutcha, P.J.; Marsano, D. Simulation and Modeling of Ported Shroud Effects on Radial Compressor Stage Stability Limits. Energies 2022, 15, 2571. [Google Scholar] [CrossRef]

- Khaleghi, H. Parametric study of injector radial penetration on stalling characteristics of a transonic fan. Aerosp. Sci. Technol. 2017, 66, 112–118. [Google Scholar] [CrossRef]

- Hu, J. Theory of Aviation Impeller; National Defense Industry Press: Beijing, China, 2014. [Google Scholar]

- Day, I.J. Stall, Surge, and 75 Years of Research. J. Turbomach. 2015, 138, 011001. [Google Scholar] [CrossRef]

- Greitzer, E.M. Surge and Rotating Stall in Axial Flow Compressors—Part I: Theoretical Compression System Model. J. Eng. Power 1976, 98, 190–198. [Google Scholar] [CrossRef]

- Greitzer, E.M. Surge and Rotating Stall in Axial Flow Compressors—Part II: Experimental Results and Comparison with Theory. J. Eng. Power 1976, 98, 199–211. [Google Scholar] [CrossRef]

- Longley, J.P. Calculating Stall and Surge Transients. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, QC, Canada, 14–17 May 2007; Volume 6, pp. 125–136. [Google Scholar]

- Moreno, J.; Dodds, J.; Sheaf, C.; Zhao, F.; Vahdati, M. Aerodynamic Loading Considerations of Three-Shaft Engine Compression System During Surge. J. Turbomach. 2021, 143, 121002. [Google Scholar] [CrossRef]

- Zhao, F.; Dodds, J.; Vahdati, M. Flow Physics during Surge and Recovery of a Multi-Stage High-Speed Compressor. J. Turbomach. 2021, 84102, V02ET41A009. [Google Scholar] [CrossRef]

- Huang, Q.; Zhang, M.; Zheng, X. Compressor surge based on a 1D-3D coupled method—Part 1: Method establishment. Aerosp. Sci. Technol. 2019, 90, 342–356. [Google Scholar] [CrossRef]

- Moore, F.K.; Greitzer, E.M. A Theory of Post-Stall Transients in Axial Compression Systems: Part I—Development of Equations. J. Eng. Gas Turbines Power 1986, 108, 68–76. [Google Scholar] [CrossRef]

- Greitzer, E.M.; Moore, F.K. A Theory of Post-Stall Transients in Axial Compression Systems: Part II—Application. J. Eng. Gas Turbines Power 1986, 108, 231–239. [Google Scholar] [CrossRef]

- Bonnaure, L.P. Modelling High Speed Multistage Compressor Stability. Master’s Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1991; pp. 107–111. [Google Scholar]

- Takata, H.; Nagano, S. Nonlinear Analysis of Rotating Stall. J. Eng. Power 1972, 94, 279–293. [Google Scholar] [CrossRef] [Green Version]

- Escuret, J.; Garnier, V. Numerical simulations of surge and rotating-stall in multi-stage axial-flow compressors. In Proceedings of the Joint Propulsion Conference & Exhibit, Indianapolis, IN, USA, 27–29 June 1994. [Google Scholar]

- Gong, Y. A Computational Model for Rotating Stall and Inlet Distortions in Multistage Compressors. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1999; pp. 175–182. [Google Scholar]

- Chima, R.V. A Three-Dimensional Unsteady CFD Model of Compressor Stability. In Proceedings of the ASME Turbo Expo 2006: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May 2006; Volume 6, pp. 1157–1168. [Google Scholar]

- Righi, M.; Pachidis, V.; Könözsy, L.; Pawsey, L. Three-dimensional through-flow modelling of axial flow compressor rotating stall and surge. Aerosp. Sci. Technol. 2018, 78, 271–279. [Google Scholar] [CrossRef]

- Righi, M.; Pachidis, V.; Könözsy, L. On the prediction of the reverse flow and rotating stall characteristics of high-speed axial compressors using a three-dimensional through-flow code. Aerosp. Sci. Technol. 2020, 99, 105578. [Google Scholar] [CrossRef]

- Zeng, H.; Zheng, X.; Vahdati, M. A Method of Stall and Surge Prediction in Axial Compressors Based on Three-Dimensional Body-Force Model. J. Eng. Gas Turbines Power 2022, 144, 031021. [Google Scholar] [CrossRef]

- Moses, H.L.; Thomason, S.B. An approximation for fully stalled cascades. J. Propuls. Power 1986, 2, 188–189. [Google Scholar] [CrossRef]

- Tauveron, N.; Saez, M.; Ferrand, P.; Leboeuf, F. Axial turbomachine modelling with a 1D axisymmetric approach: Application to gas cooled nuclear reactor. Nucl. Eng. Des. 2007, 237, 1679–1692. [Google Scholar] [CrossRef]

- Gallimore, S.J.; Cumpsty, N.A. Spanwise mixing in multistage axial flow compressors. I—Experimental investigation. In Proceedings of the ASME 31st International Gas Turbine Conference and Exhibit, Duesseldorf, Germany, 8–12 June 1986; p. 9. [Google Scholar]

- Gallimore, S.J. Spanwise mixing in multistage axial flow compressors. II—Throughflow calculations including mixing. J. Turbomach. 1986, 108, 10–16. [Google Scholar] [CrossRef]

- Marble, F.E. Three-dimensional flow in turbomachines. In Aerodynamics of Turbines and Compressors. (HSA-1); Hawthorne, W.R., Ed.; Princeton University Press: Princeton, NJ, USA, 1964; Volume 1, pp. 83–166. [Google Scholar]

- Guo, J.; Hu, J. A three-dimensional computational model for inlet distortion in fan and compressor. Proc. Inst. Mech. Eng. Part A J. Power Energy 2018, 232, 144–156. [Google Scholar] [CrossRef]

- Jameson, A.; Schmidt, W.; Turkel, E. Numerical Solution of the Euler Equations by Finite Volume methods Using Runge-Kutta Time-Stepping Schemes. In Proceedings of the 14th Fluid and Plasma Dynamics Conference, Palo Alto, CA, USA, 23–25 June 1981. [Google Scholar]

- Edwards, J.R. A low-diffusion flux-splitting scheme for Navier-Stokes calculations. Comput. Fluids 1997, 26, 635–659. [Google Scholar] [CrossRef]

- Dumas, M.; Vo, H.D.; Yu, H. Post-Surge Load Prediction for Multi-Stage Compressors via CFD Simulations. In Proceedings of the ASME Turbo Expo 2015: Turbine Technical Conference and Exposition, Montreal, QC, Canada, 15–19 June 2015; Volume 2. [Google Scholar]

- Cumpsty, N.A. Compressor Aerodynamics; Krieger Publishing Company: Malabar, FL, USA, 2004. [Google Scholar]

- Day, I.J. Axial compressor performance during surge. J. Propuls. Power 1971, 10, 329–336. [Google Scholar] [CrossRef]

| Geometric Parameters | Value |

|---|---|

| Blade number of rotor/stator | 34/37 |

| Shroud radius (mm) | 450 |

| Hub radius (mm) | 337.5 |

| Hub-to-tip ratio | 0.75 |

| Tip clearance (mm) | 1 |

| Operating Points | Variations | Experimental | Calculated | Percentual Errors |

|---|---|---|---|---|

| Op1 | Flow coefficient | 0.495 | 0.505 | 2.02% |

| Total-static pressure ratio coefficient | 0.467 | 0.482 | 3.21% | |

| Op2 | Flow coefficient | 0.383 | 0.369 | −3.66% |

| Total-static pressure ratio coefficient | 0.246 | 0.266 | 8.13% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, J.; Hu, J.; Ma, S.; Xu, R. A Computational Method of Rotating Stall and Surge Transients in Axial Compressor. Energies 2022, 15, 5246. https://doi.org/10.3390/en15145246

Ji J, Hu J, Ma S, Xu R. A Computational Method of Rotating Stall and Surge Transients in Axial Compressor. Energies. 2022; 15(14):5246. https://doi.org/10.3390/en15145246

Chicago/Turabian StyleJi, Jiajia, Jun Hu, Shuai Ma, and Rong Xu. 2022. "A Computational Method of Rotating Stall and Surge Transients in Axial Compressor" Energies 15, no. 14: 5246. https://doi.org/10.3390/en15145246