Advances in Process Modelling and Simulation of Parabolic Trough Power Plants: A Review

Abstract

:1. Introduction

- Larger variations in load are needed across positive and negative load gradients. In addition, start-up and shut-down dynamics responding to a steep load gradient in the power distribution system also need to be improved;

- The possible range of PTPP operation must be re-evaluated according to the technically required lower load. A complete shut-down is often not desirable, therefore, the number of start-up/shut-down processes and the lifetime consumption of thermally stressed parts can be reduced by decreasing the minimum load;

- The high efficiency of thermal power plants at part load is relevant, because their original operation was at nominal load almost all the time; therefore, they run in load-following operations. Hence, a thermo-economic improvement in various nominal loads and off-design load regimes is fundamental. The parabolic trough power plants that include these new levels of performance characteristics maintain a distinct competitive benefit in the commercial electric markets.

2. Background of Mathematical Modelling

- In the steady-state case, there is no need to consider the time derivatives in the conservation laws;

- In the quasi-steady case, certain parts of the temporal derivative have no relevance and can, therefore, be neglected by the conservation laws, and this leads to significantly simplifying the system of equations;

- In the dynamic case, sufficient consideration must be given to the temporal derivatives.

- Zero-dimensional modelling case: no local discretization is considered in this case. This modelling of PTPP parts, such as pipes, pumps, condensers, heat exchangers, turbines, etc., is implemented by a system of algebraic equations containing the input and output conditions of these parts (such as mass flow rate, pressure, enthalpy, and void fraction);

- One-dimensional modelling case: the components of the PTPP in-between the inflow and the outflow are discretized in finite cells, referred to as a numerical mesh. Consequently, a system of algebraic equations is used to estimate the partial differential equations. Eventually, the case parameters, for example, pressure, temperature, and enthalpy, can be calculated at each discrete location;

- Two- or three-dimensional modelling cases: it is necessary to discretize the extra points locally. This, in turn, leads to the calculation of PTPP components becoming more detailed and having a higher cost.

3. Steady-State Simulation Models

4. Dynamic Simulation Models

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Biencinto, M.; González, L.; Valenzuela, L. A quasi-dynamic simulation model for direct steam generation in parabolic troughs using TRNSYS. Appl. Energy 2016, 1611, 33–42. [Google Scholar] [CrossRef]

- Wahhab, H.A.A.; Al-Maliki, W.A.K. Application of a Solar Chimney Power Plant to Electrical Generation in Covered Agricultural Fields. IOP Conf. Ser. Mater. Sci. Eng. 2020, 671, 012137. [Google Scholar] [CrossRef]

- World Bank. Concentrating Solar Power: Clean Power on Demand 24/7; World Bank: Washington, DC, USA, 2021. [Google Scholar]

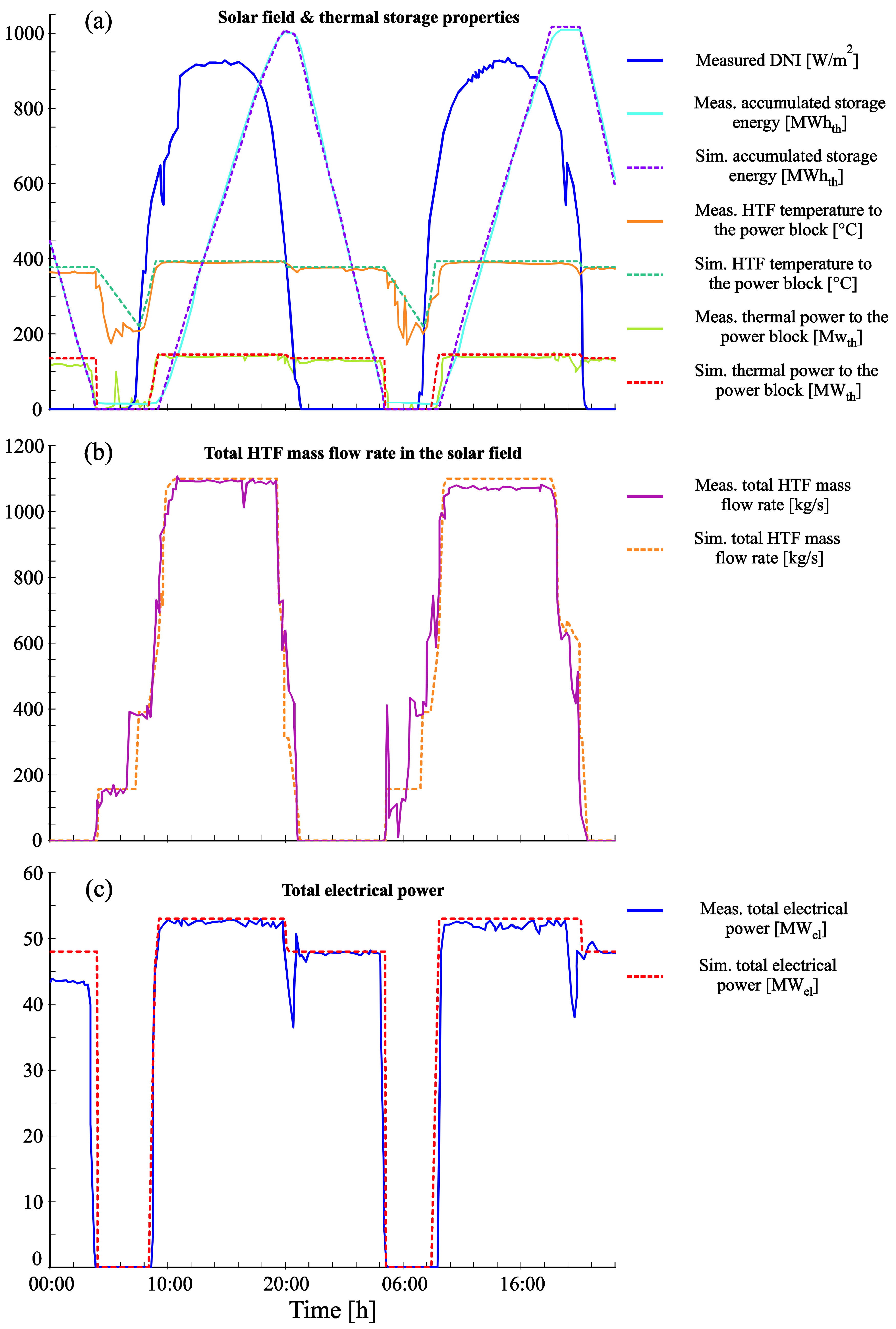

- Al-Maliki, W.A.K.; Alobaid, F.; Starkloff, R.; Kez, V.; Epple, B. Investigation on the dynamic behaviour of a parabolic trough power plant during strongly cloudy days. Appl. Therm. Eng. 2016, 991, 14–32. [Google Scholar] [CrossRef]

- Alobaid, F.; Mertens, N.; Starkloff, R.; Lanz, T.; Heinze, C.; Epple, B. Progress in dynamic simulation of thermal power plants. Prog. Energy Combust. Sci. 2017, 597, 9–162. [Google Scholar] [CrossRef]

- Terdalkar, R.; Doupis, D.; Clark, M.; Joshi, A.; Wang, C. Transient simulation of high temperature high pressure solar tower receiver. Energy Procedia 2015, 691, 451–460. [Google Scholar] [CrossRef] [Green Version]

- Henrion, T.; Ponweiser, K.; Band, D.; Telgen, T. Dynamic simulation of a solar power plant steam generation system. Simul. Model. Pract. Theory 2013, 332, 17. [Google Scholar] [CrossRef]

- Hakkarainen, E.; Tähtinen, M.; Mikkonen, H. Dynamic Model Development of Linear Fresnel Solar Field. In Proceedings of the ASME 2015 9th International Conference on Energy Sustainability collocated with the ASME 2015 Power Conference, the ASME 2015 13th International Conference on Fuel Cell Science, Engineering and Technology, and the ASME 2015 Nuclear Forum: American Society of Mechanical Engineers, San Diego, CA, USA, 28 June–2 July 2015; pp. V001T05A9–VT05A9. [Google Scholar]

- Hakkarainen, E.; Kannari, L.; Tähtinen, M. Dynamic Modelling of Concentrated Solar Field for Thermal Energy Storage Integration. In Proceedings of the 9th International Renewable Energy Storage Conference (IRES 2015), Düsseldorf, Germany, 9–11 March 2015. [Google Scholar]

- Al-Maliki, W.A.K.; Al-Hasnawi, A.G.T.; Abdul Wahhab, H.A.; Alobaid, F.; Epple, B. A Comparison Study on the Improved Operation Strategy for a Parabolic trough Solar Power Plant in Spain. Appl. Sci. 2021, 119, 576. [Google Scholar] [CrossRef]

- Al-Maliki, W.A.K.; Hadi, A.S.; Al-Khafaji, H.M.; Alobaid, F.; Epple, B. Dynamic Modelling and Advanced Process Control of Power Block for a Parabolic Trough Solar Power Plant. Energies 2022, 151, 29. [Google Scholar] [CrossRef]

- Al-Maliki, W.A.K.; Mahmoud, N.S.; Al-Khafaji, H.M.; Alobaid, F.; Epple, B. Design and Implementation of the Solar Field and Thermal Storage System Controllers for a Parabolic Trough Solar Power Plant. Appl. Sci. 2021, 116, 155. [Google Scholar] [CrossRef]

- Al-Maliki, W.A.K.; Alobaid, F.; Keil, A.; Epple, B. Dynamic Process Simulation of a Molten-Salt Energy Storage System. Appl. Sci. 2021, 111, 1308. [Google Scholar] [CrossRef]

- Greenhut, A.D.; Tester, J.W.; DiPippo, R.; Field, R.; Love, C.; Nichols, K.; Augustine, C.; Batini, F.; Price, B.; Gigliucci, G.; et al. Solar–Geothermal Hybrid Cycle Analysis for Low Enthalpy Solar and Geothermal Resources. In Proceedings of the World Geothermal Congress 2010, Bali, Indonesia, 25–30 April 2010. [Google Scholar]

- Zhou, C.; Doroodchi, E.; Moghtaderi, B. An in-depth assessment of hybrid solar–geothermal power generation. Energy Convers. Manag. 2013, 748, 8–101. [Google Scholar] [CrossRef]

- Russo, V. CSP Plant Thermal-hydraulic Simulation. Energy Procedia 2014, 491, 533–542. [Google Scholar] [CrossRef] [Green Version]

- García, I.L.; Álvarez, J.L.; Blanco, D. Performance model for parabolic trough solar thermal power plants with thermal storage: Comparison to operating plant data. Sol. Energy 2011, 852, 443–460. [Google Scholar]

- Twomey, B.; Jacobs, P.; Gurgenci, H. Dynamic performance estimation of small-scale solar cogeneration with an organic Rankine cycle using a scroll expander. Appl. Therm. Eng. 2013, 511, 307–316. [Google Scholar] [CrossRef]

- Birnbaum, J.; Feldhoff, J.F.; Fichtner, M.; Hirsch, T.; Jöcker, M.; Pitz-Paal, R.; Zimmermann, G. Steam temperature stability in a direct steam generation solar power plant. Sol. Energy 2011, 856, 60–68. [Google Scholar] [CrossRef] [Green Version]

- Mitterhofer, M.; Orosz, M. Dynamic Simulation and Optimization of an Experimental Micro-CSP Power Plant. ASME 2015 9th International Conference on Energy Sustainability collocated with the ASME 2015 Power Conference, the ASME 2015 13th International Conference on Fuel Cell Science, Engineering and Technology, and the ASME 2015 Nuclear Forum: American Society of Mechanical Engineers, San Diego, CA, USA, 28 June–2 July 2015; pp. V001T05A7–VT05A7. [Google Scholar]

- Rodat, S.; Souza, J.; Thebault, S.; Vuillerme, V.; Dupassieux, N. Dynamic simulations of Fresnel solar power plants. Energy Procedia 2014, 491, 501–510. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Valle-Marcos, J.; El-Hefni, B.; Wang, Z.; Chen, G.; Ma, G.; Li, X.; Soler, R. Dynamic Simulation of a 1MWe Concentrated Solar Power Tower Plant System with Dymola®. Energy Procedia 2014, 491, 592–602. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.J.; Faille, D.; Fouquet, M.; El-Hefni, B.; Wang, Y.; Zhang, J.B.; Wang, Z.F.; Chen, G.F.; Soler, R. Dynamic Simulation of a 1MWe CSP Tower Plant with Two-level Thermal Storage Implemented with Control System. Energy Procedia 2015, 691, 335–343. [Google Scholar] [CrossRef] [Green Version]

- Jones, S.A.; Blair, N.; Pitz-Paal, R.; Schwarzboezl, P.; Cable, R. TRNSYS Modeling of the SEGS VI Parabolic Trough Solar Electric Generating System. In Solar Forum 2001: Solar Energy: The Power to Choose; ASME: Washington, DC, USA, 2001. [Google Scholar]

- Fernández-García, A.; Valenzuela, L.; Zarza, E.; Rojas, E.; Pérez, M.; Hernández-Escobedo, Q.; Manzano-Agugliaro, F. SMALL-SIZED parabolic-trough solar collectors: Development of a test loop and evaluation of testing conditions. Energy 2018, 152, 401–415. [Google Scholar] [CrossRef]

- Kearney, D. Utility-scale parabolic trough solar systems: Performance acceptance test guidelines. Contract 2011, 3032, 75–3000. [Google Scholar]

- Sallaberry, F.; Valenzuela, L.; de Jalón, A.G.; Leon, J.; Bernad, I.D. Towards Standardization of In-Site Parabolic Trough Collector Testing in Solar Thermal Power Plants. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2016; p. 130019. [Google Scholar]

- Valenzuela, L.; López-Martín, R.; Zarza, E. Optical and thermal performance of large-size parabolic-trough solar collectors from outdoor experiments: A test method and a case study. Energy 2014, 704, 56–64. [Google Scholar] [CrossRef]

- Sallaberry, F.; Valenzuela, L.; Palacin, L.G.; Leon, J.; Fischer, S.; Bohren, A. Harmonization of Standards for Parabolic trough Collector Testing in Solar Thermal Power Plants. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2017; p. 020014. [Google Scholar]

- Nation, D.D.; Heggs, P.J.; Dixon-Hardy, D.W. Modelling and simulation of a novel Electrical Energy Storage (EES) Receiver for Solar Parabolic Trough Collector (PTC) power plants. Appl. Energy 2017, 1959, 50–73. [Google Scholar] [CrossRef]

- Salazar, G.A.; Fraidenraich, N.; de Oliveira, C.A.A.; de Castro Vilela, O.; Hongn, M.; Gordon, J.M. Analytic modeling of parabolic trough solar thermal power plants. Energy 2017, 138, 1148–1156. [Google Scholar] [CrossRef]

- Murtuza, S.A.; Byregowda, H.; Imran, M. Experimental and simulation studies of parabolic trough collector design for obtaining solar energy. Resour. Effic. Technol. 2017, 3, 414–421. [Google Scholar] [CrossRef]

- Janotte, N.; Lüpfert, E.; Pitz-Paal, R. Acceptance Testing and Advanced Evaluation Strategies for Commercial Parabolic Trough Solar Fields. Editorship of Proceedings. 2012. Available online: https://elib.dlr.de/78605/ (accessed on 27 July 2022).

- Silva, R.; Pérez, M.; Fernández-Garcia, A. Modeling and co-simulation of a parabolic trough solar plant for industrial process heat. Appl. Energy 2013, 1062, 87–300. [Google Scholar] [CrossRef]

- Ehrhart, B.; Gill, D. Evaluation of annual efficiencies of high temperature central receiver concentrated solar power plants with thermal energy storage. Energy Procedia 2014, 497, 52–61. [Google Scholar] [CrossRef] [Green Version]

- El Hefni, B.; Soler, R. Dynamic Multi-configuration Model of a 145 MWe Concentrated Solar Power Plant with the ThermoSysPro Library (Tower Receiver, Molten Salt Storage and Steam Generator). Energy Procedia 2015, 691, 249–258. [Google Scholar] [CrossRef] [Green Version]

- Xu, L.; Wang, Z.; Li, X.; Yuan, G.; Sun, F.; Lei, D. Dynamic test model for the transient thermal performance of parabolic trough solar collectors. Sol. Energy 2013, 956, 5–78. [Google Scholar] [CrossRef]

- Janotte, N.; Feckler, G.; Kötter, J.; Decker, S.; Herrmann, U.; Schmitz, M.; Lüpfert, E. Dynamic performance evaluation of the HelioTrough® collector demonstration loop–towards a new benchmark in parabolic trough qualification. Energy Procedia 2014, 491, 9–17. [Google Scholar] [CrossRef] [Green Version]

- Xu, L.; Wang, Z.; Li, X.; Yuan, G.; Sun, F.; Lei, D.; Li, S. A comparison of three test methods for determining the thermal performance of parabolic trough solar collectors. Sol. Energy 2014, 991, 1–27. [Google Scholar] [CrossRef]

- Xu, L.; Wang, Z.; Yuan, G.; Sun, F.; Zhang, X. Thermal performance of parabolic trough solar collectors under the condition of dramatically varying DNI. Energy Procedia 2015, 692, 18–25. [Google Scholar] [CrossRef] [Green Version]

- Mosleh, H.J.; Ahmadi, R. Linear parabolic trough solar power plant assisted with latent thermal energy storage system: A dynamic simulation. Appl. Therm. Eng. 2019, 1611, 14204. [Google Scholar]

- Boukelia, T.; Mecibah, M.; Kumar, B.; Reddy, K. Optimization, selection and feasibility study of solar parabolic trough power plants for Algerian conditions. Energy Convers. Manag. 2015, 1014, 50–59. [Google Scholar] [CrossRef]

- Al-Maliki, W.A.K.; Alobaid, F.; Kez, V.; Epple, B. Modelling and dynamic simulation of a parabolic trough power plant. J. Process Control. 2016, 391, 23–38. [Google Scholar] [CrossRef]

- Guo, S.; Liu, D.; Chen, X.; Chu, Y.; Xu, C.; Liu, Q.; Zhou, L. Model and control scheme for recirculation mode direct steam generation parabolic trough solar power plants. Appl. Energy 2017, 2027, 700–714. [Google Scholar] [CrossRef]

- El Ghazzani, B.; Plaza, D.M.; El Cadi, R.A.; Ihlal, A.; Abnay, B.; Bouabid, K. Thermal plant based on parabolic trough collectors for industrial process heat generation in Morocco. Renew. Energy 2017, 1131, 261–275. [Google Scholar] [CrossRef]

- Zhang, R.; Aziz, S.; Farooq, M.U.; Hasan, K.N.; Mohammed, N.; Ahmad, S.; Ibadah, N. A wind energy supplier bidding strategy using combined ega-inspired hpsoifa optimizer and deep learning predictor. Energies 2021, 143, 059. [Google Scholar] [CrossRef]

- Wang, H.; Cai, R.; Zhou, B.; Aziz, S.; Qin, B.; Voropai, N.; Voropai, N.; Gan, L.; Barakhtenko, E. Solar irradiance forecasting based on direct explainable neural network. Energy Convers. Manag. 2020, 2261, 13487. [Google Scholar] [CrossRef]

- Mobeen, F.; Ahmad, S.; Shoukat, A.; Batool, S. A Generalized Modeling and Analysis for Transformer Parameterization. In Proceedings of the 2021 16th International Conference on Emerging Technologies (ICET), Islamabad, Pakistan, 22–23 December 2021; pp. 1–7. [Google Scholar]

- Behram, B.; Ahmad, S.; Shoukat, A.; Khan, S.S. Fabrication of Three-phase Automatic Transfer Switching System with Reduced Switching Time. In Proceedings of the 2021 16th International Conference on Emerging Technologies (ICET), Islamabad, Pakistan, 22–23 December 2021; pp. 1–4. [Google Scholar]

- Aziz, S.; Wang, H.-Z.; Peng, J.-C.; Ruan, J.-Q. Power Sharing of Transformer. In Proceedings of the 2018 International Conference on Power System Technology (POWERCON), Guangzhou, China, 6–9 November 2018; pp. 4438–4442. [Google Scholar]

| Parabolic Trough Power Plant | |

|---|---|

| Advantages | 1. Working temperature up to 500 °C (400 °C proven commercially) 2. Configurability 3. Favorable land-use factor 4. Minimal material requirements 5. Successful hybrid approach 6. High storability |

| Disadvantages | Nowadays, using oil as HTF limits working temperatures to 400 °C, which results in only medium steam properties. |

| Investigation Type | Software | Comment |

|---|---|---|

| PTPP | APROS | APROS is considered one of the most comprehensive programs in modelling power plants in general, and, in particular, a PTPP. This program can accurately model the plants because it contains all the parts of the modelling, such as pipes, pumps, heat exchangers, and other parts of the power plants. In APROS, real external data can also be added, which is considered as an input to the plant, such as adding the DNI measured at the plant’s site or using the solar data present in the APROS library, which is an average and not the real data measured on that day, but rather the measured data of that date over several years and their average. In addition, it can create advanced control circuits. Multi-day dynamic simulation can be carried out continuously. APROS is considered the best program for modelling various power stations, especially in dynamic machining, due to its high flowability in performance, as well as the accuracy and rapid response to sudden changes during load changes. Most of the previous research dealt with dynamic modelling and simulation of PTPP. |

| TRNSYS | At present, the majority of dynamic research papers published in the relevant studies focus on PTPP, while a limited number of studies are related to the solar tower and linear Fresnel systems, and none of the research papers refer to parabolic trough systems. | |

| ASPEN HYSYS ASPEN PLUS DYNAMIC DYMOLA MATLAB SIMULINK | To date, most investigations concentrate on providing facility dynamics at the in-system level, taking into account unsteady solar irradiance, and other studies examine the dynamic response of sub-systems, such as thermal storage systems. |

| Steady-State Simulation | Dynamic Simulation |

|---|---|

| Steady-state simulation is a basis for evaluation, but with limited specifications, which leads to an error rate in evaluating the work of the plant. | Dynamic simulation becomes a powerful means for evaluating regulation approaches, potentialities, and boundaries. |

| The control circuits are not required. | The control circuits are required. |

| In the literature, many investigations in regard to the improvement of the PTPP use steady-state simulations. | Few studies deal with a dynamic simulation of power plants. |

| The solution to the unsteady equation is not required. | Dynamic flow models demand the transient equation solution. |

| There is no need to consider the time derivatives in the conservation laws. | Sufficient consideration must be given to the temporal derivatives. |

| It is suitable for applications with stable loads only. | It is considered the best for modelling and evaluating the operation of power stations, which includes changes in loads. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Maliki, W.A.K.; Khafaji, H.Q.A.; Abdul Wahhab, H.A.; Al-Khafaji, H.M.H.; Alobaid, F.; Epple, B. Advances in Process Modelling and Simulation of Parabolic Trough Power Plants: A Review. Energies 2022, 15, 5512. https://doi.org/10.3390/en15155512

Al-Maliki WAK, Khafaji HQA, Abdul Wahhab HA, Al-Khafaji HMH, Alobaid F, Epple B. Advances in Process Modelling and Simulation of Parabolic Trough Power Plants: A Review. Energies. 2022; 15(15):5512. https://doi.org/10.3390/en15155512

Chicago/Turabian StyleAl-Maliki, Wisam Abed Kattea, Hayder Q. A. Khafaji, Hasanain A. Abdul Wahhab, Hussein M. H. Al-Khafaji, Falah Alobaid, and Bernd Epple. 2022. "Advances in Process Modelling and Simulation of Parabolic Trough Power Plants: A Review" Energies 15, no. 15: 5512. https://doi.org/10.3390/en15155512

APA StyleAl-Maliki, W. A. K., Khafaji, H. Q. A., Abdul Wahhab, H. A., Al-Khafaji, H. M. H., Alobaid, F., & Epple, B. (2022). Advances in Process Modelling and Simulation of Parabolic Trough Power Plants: A Review. Energies, 15(15), 5512. https://doi.org/10.3390/en15155512