Resource Efficiency in the Construction Sector: Material Intensities of Residential Buildings—A German Case Study

Abstract

:1. Introduction

1.1. Literature

1.2. Aim of the Study

2. Method

2.1. Determining Materials via Building Life Cycle Assessments

2.2. Case Study

- Mineral building material;

- Renewable building materials;

- Metal;

- Plastics, fossil;

- Waterproofing, protective coatings, adhesives, roofing, sealants;

- Floor coverings, screeds;

- Insulation materials;

- Plaster, finishing panels, facade, ceiling cladding;

- Coatings;

- Technical finishing;

- Translucent components.

3. Results

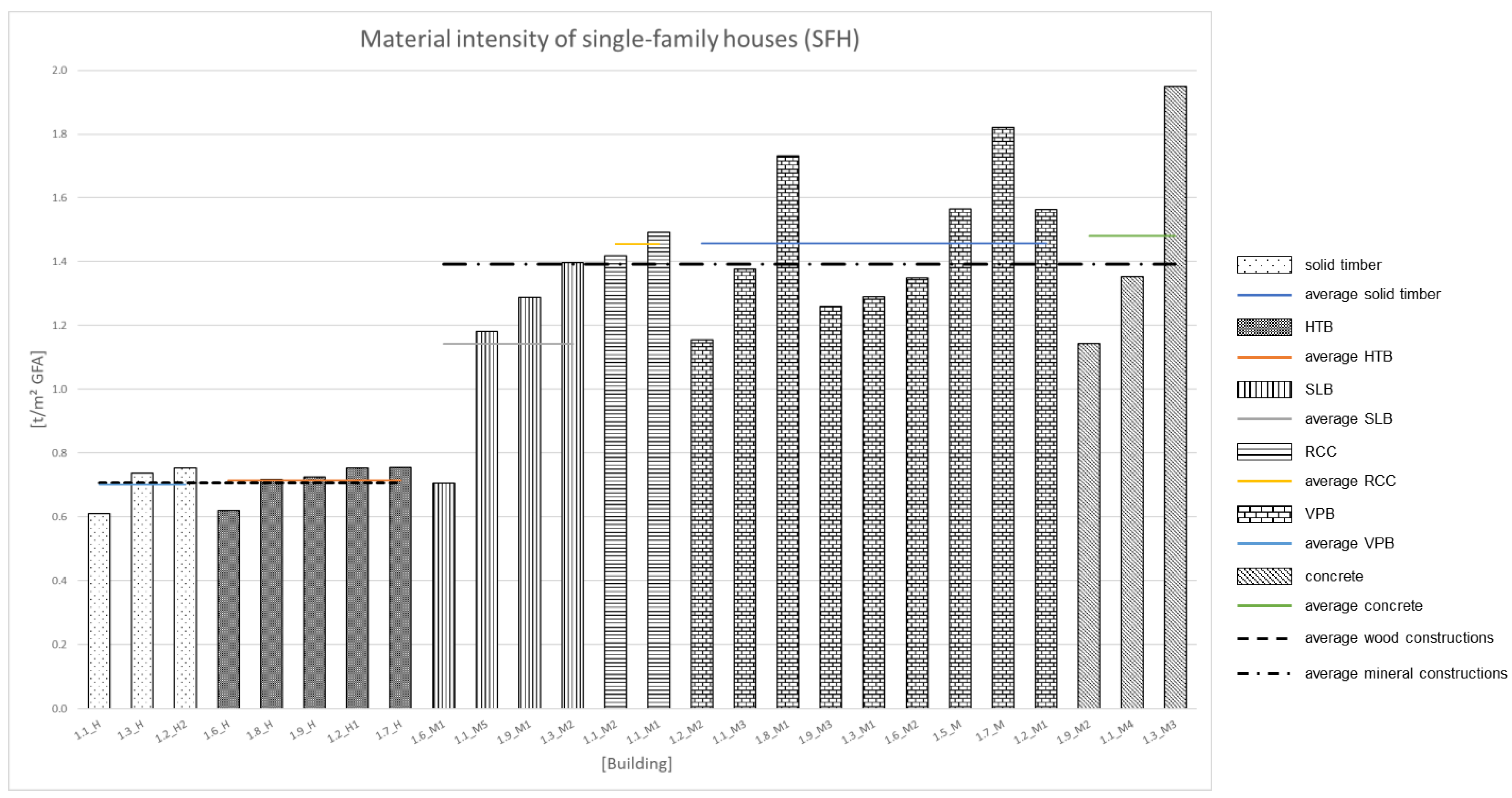

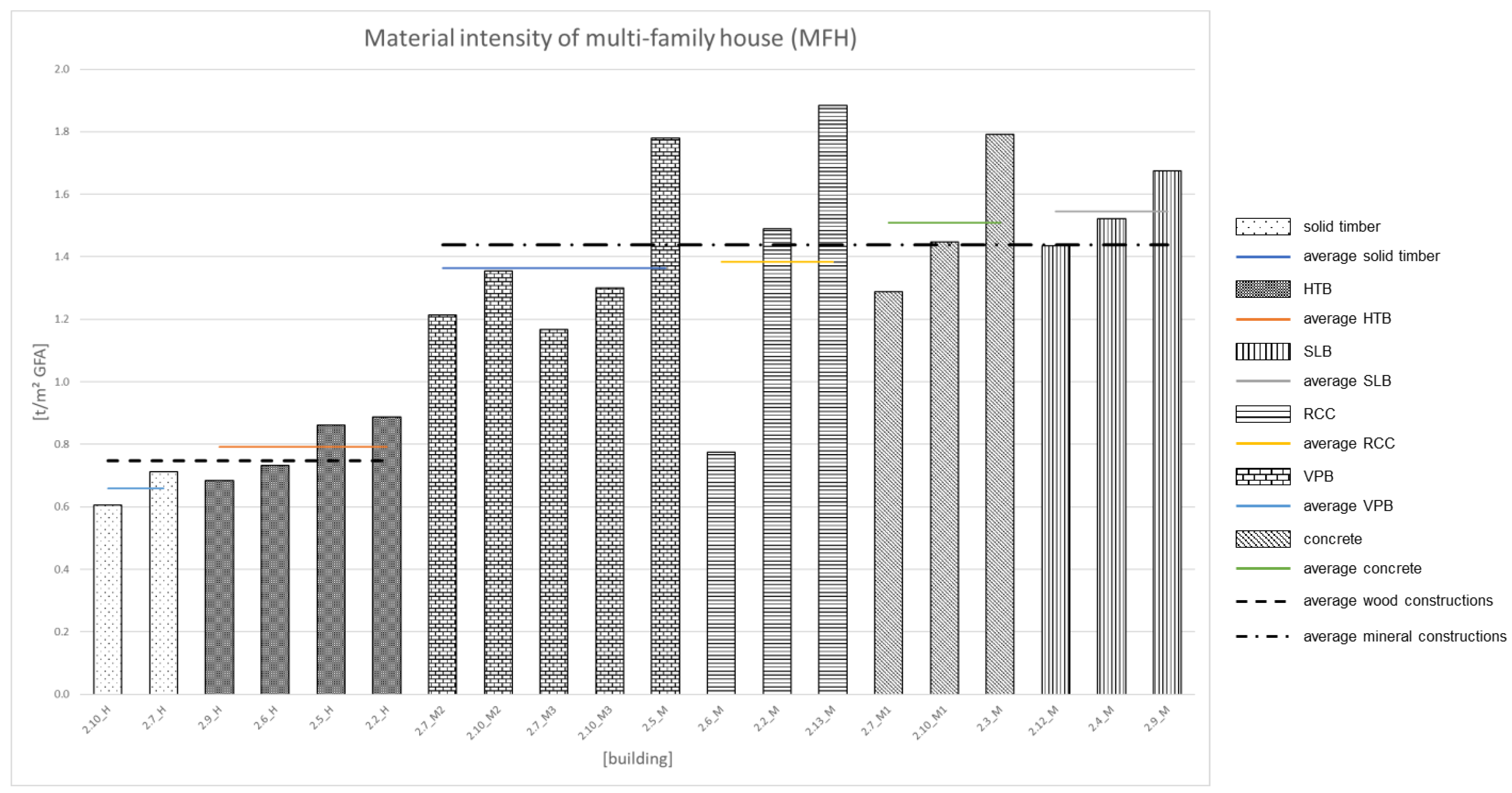

3.1. Results Regarding Area Related Material Intensity

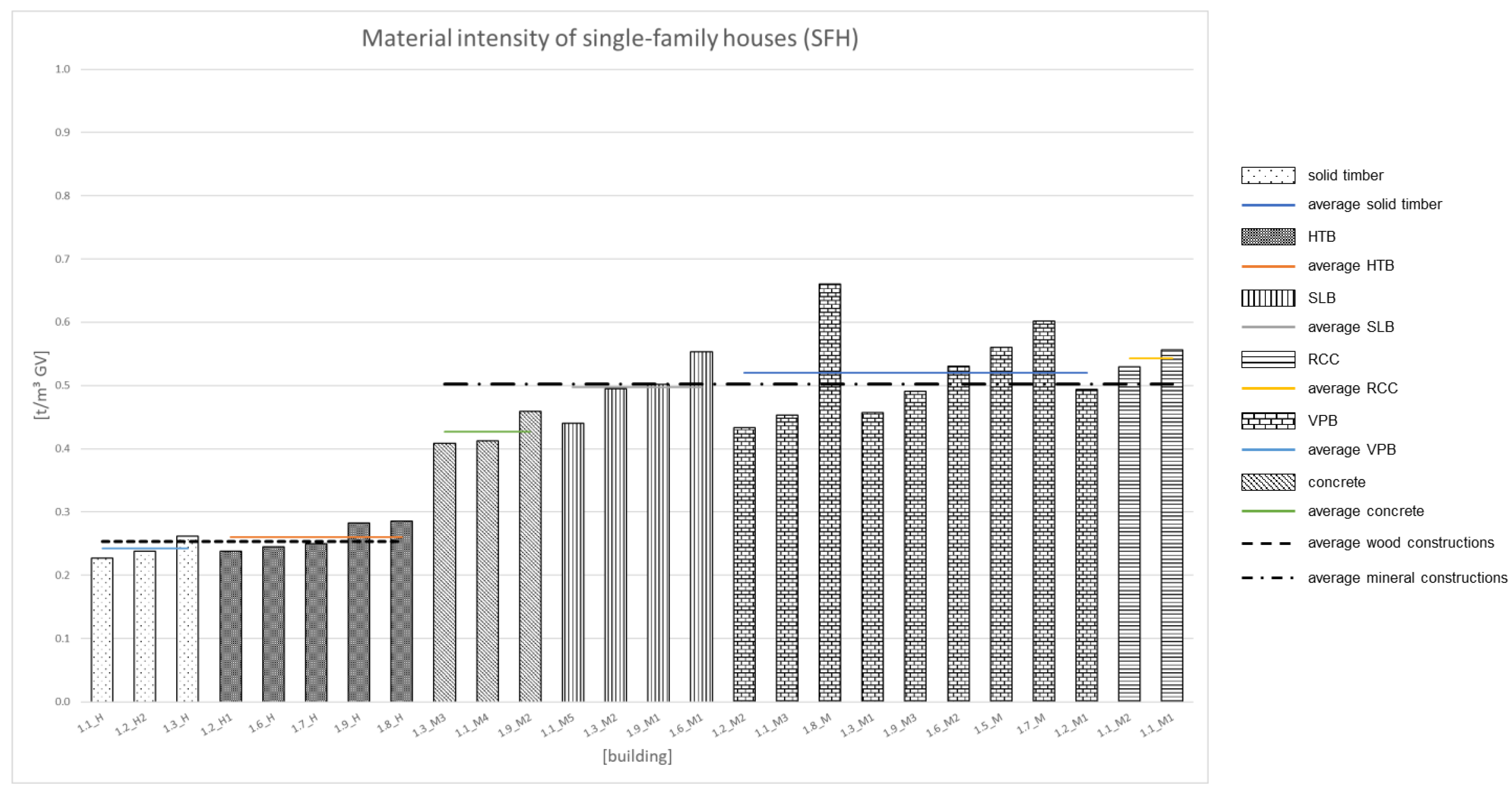

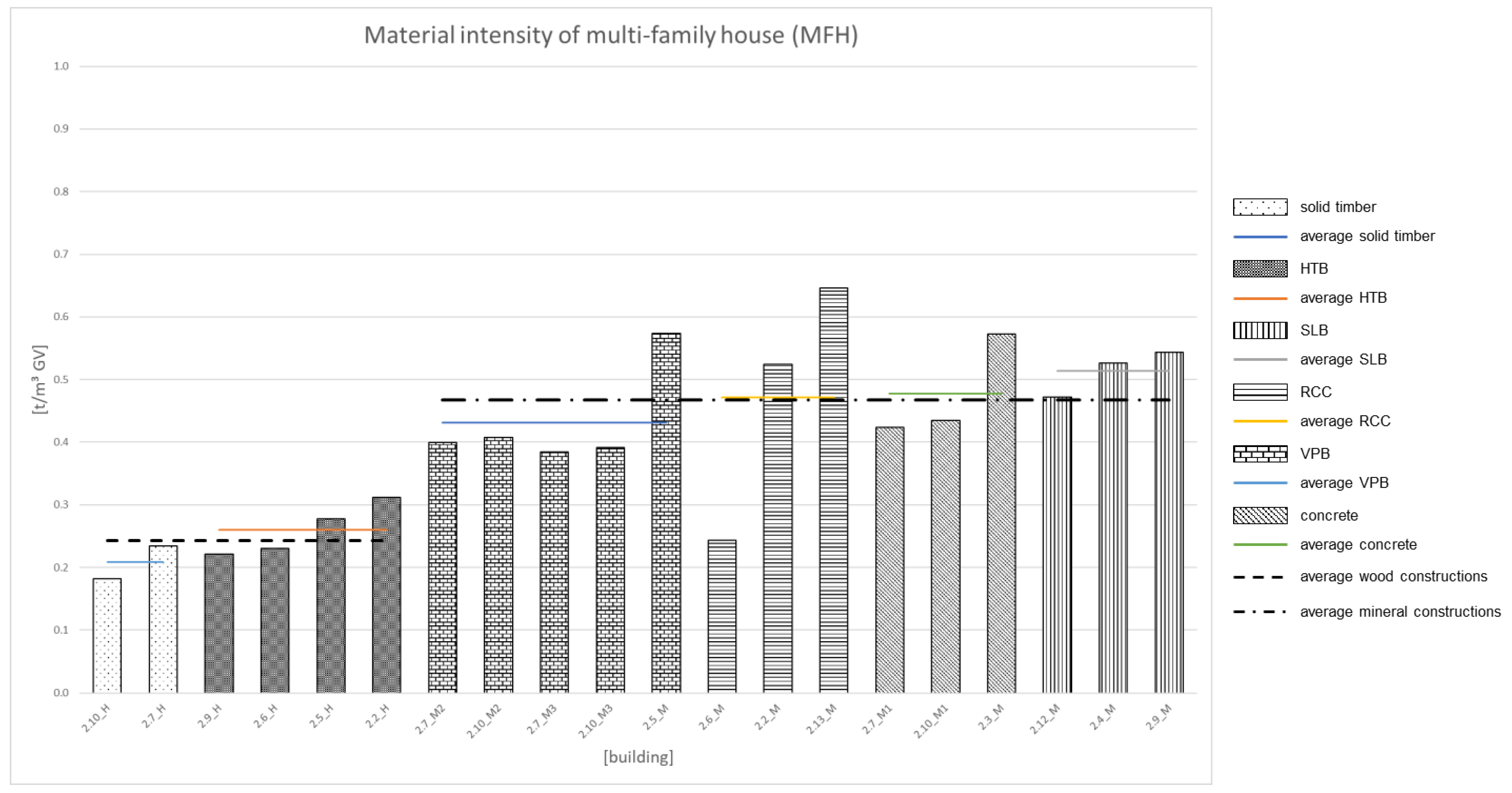

3.2. Results Regarding Volume-Based Material Intensity

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations. Paris Agreement. 2015. Available online: https://treaties.un.org/Pages/ViewDetails.aspx?src=IND&mtdsg_no=XXVII-7-d&chapter=27&clang=_en (accessed on 24 July 2022).

- European Commission. Mitteilung der Kommission an das Europäische Parlament, den Europäischen Rat, den Rat, den Europäischen Wirtschafts- und Sozialausschuss und den Ausschuss der Regionen der Europäische Grüne Deal. 2019. Available online: https://ec.europa.eu/info/sites/default/files/european-green-deal-communication_de.pdf (accessed on 24 July 2022).

- European Commission. Renovierungswelle: Verdoppelung der Renovierungsquote zur Senkung von Emissionen, zur Ankurbelung der wirtschaftlichen Erholung und zur Verringerung von Energiearmut. 2020. Available online: https://ec.europa.eu/commission/presscorner/api/files/document/print/de/ip_20_1835/IP_20_1835_DE.pdf (accessed on 24 July 2022).

- European Commission. EU-Taxonomie: Kommission legt ergänzenden delegierten Klima-Rechtsakt vor, um die Dekarbonisierung zu beschleunigen. 2022. Available online: https://ec.europa.eu/commission/presscorner/api/files/document/print/de/ip_22_711/IP_22_711_DE.pdf (accessed on 24 July 2022).

- Federal Constitutional Court. Leitsätze zum Beschluss des Ersten Senats vom 24. März 2021. 2021. Available online: https://www.bundesverfassungsgericht.de/SharedDocs/Downloads/DE/2021/03/rs20210324_1bvr265618.pdf?__blob=publicationFile&v=6 (accessed on 24 July 2022).

- BMUV. Bundesministerium für Umwelt, Naturschutz und nukleare Sicherheit. Klimaschutz in Zahlen–Fakten, Trends und Impulse deutscher Klimapolitik Ausgabe 2021. 2021. Available online: https://www.bmuv.de/fileadmin/Daten_BMU/Pools/Broschueren/klimaschutz_zahlen_2021_bf.pdf (accessed on 24 July 2022).

- BBSR. Bauwende, Zukunft Bau Kongress 2021. 2021. Available online: https://www.bbsr.bund.de/BBSR/DE/veroeffentlichungen/zukunft-bauen-fp/2022/band-31-dl.pdf?__blob=publicationFile&v=2 (accessed on 27 July 2022).

- Destatis, Federal Statistical Office. Flächennutzung. 2022. Available online: https://www.destatis.de/DE/Themen/Branchen-Unternehmen/Landwirtschaft-Forstwirtschaft-Fischerei/Flaechennutzung/_inhalt.html (accessed on 24 July 2022).

- UBA. Klima- und Ressourcenschutz Stärker Zusammendenken. 2020. Available online: www.umweltbundesamt.de (accessed on 14 May 2021).

- BMU. Bundesministerium für Umwelt, Naturschutz und nukleare Sicherheit; Deutsche Nachhaltigkeitsstrategie: Berlin, Germany, 2020. [Google Scholar]

- BMU. Kurzinfo Ressourceneffizienz. 2020. Available online: https://www.bmu.de/themen/wirtschaft-produkte-ressourcen-tourismus/ressourceneffizienz/ressourceneffizienz-worum-geht-es/ (accessed on 17 June 2020).

- VDI. Ressourceneffizienz im Bauwesen. 2021. Available online: https://www.ressource-deutschland.de/themen/bauwesen/ (accessed on 13 February 2021).

- Schiller, G.; Ortlepp, R.; Krauß, N.; Steger, S.; Schütz, H.; Fernandez, J.A.; Reichenberg, J.; Wagner, J.; Baumann, J. Kartierung des anthropogenen Lagers in Deutschland zur Optimierung der Sekundärrohstoffwirtschaft; UBA-Texte 83/15; Umweltbundesamt: Dessau-Roßlau, Germany, 2015. [Google Scholar]

- Kleeman, F. Buildings as Potenzial Urban Mines: Quantitative, Qualitative and Spatial Analysis for Vienna. Ph.D. Thesis, Vienna, Austria, 2016. Available online: https://publik.tuwien.ac.at/files/PubDat_250939.pdf (accessed on 27 June 2022).

- Kleeman, F.; Lederer, J.; Fellner, J. Combining GIS data sets and material intensities to estimate Vienna’s building stock. In Proceedings of the Expanding boundaries. Systems Thinking in the Built Environment; Sustainable Built Environment (SBE) Regional Conference, Zurich, Switzerland, 15–17 June 2016. [Google Scholar]

- Kleemann, F.; Lederer, J.; Fellner, J.; Rechberger, H. Wien als Rohstofflager: Quantitative, qualitativeund räumliche Analyse. 2016. Available online: https://publik.tuwien.ac.at/files/pub-lik_258954.pdf (accessed on 27 June 2022).

- Hashimoto, S.; Tanikawa, H.; Moriguchi, Y. Where will large amounts of materials accumulated within the economy go? -A material flow analysis of construction minerals for Japan. Waste Manag. 2007, 27, 1725–1738. [Google Scholar] [CrossRef] [PubMed]

- Arora, M.; Raspall, F.; Cheah, L.; Silva, A. Residential building material stocks and component-level circularity. The case of Singapore. J. Clean. Prod. 2019, 216, 239–248. [Google Scholar] [CrossRef]

- Bergsdal, H.; Brattebø, H.; Bohne, R.A.; Müller, D.B. Dynamic material flow analysis for Norway’s dwelling stock. Build. Res. Inf. 2007, 35, 557–570. [Google Scholar] [CrossRef]

- Gontia, P.; Nägeli, C.; Rosado, L.; Kalmykova, Y.; Österbring, M. Material-intensity database of residential buildings. A case-study of Sweden in the international context. Resour. Conserv. Recycl. 2018, 130, 228–239. [Google Scholar] [CrossRef]

- Stephan, A.; Athanassiadis, A. Quantifying and mapping embodied environmental requirements of urban building stocks. Build. Environ. 2017, 114, 187–202. [Google Scholar] [CrossRef]

- Mastrucci, A.; Marvuglia, A.; Popovici, E.; Leopold, U.; Benetto, E. Geospatial characterization of building material stocks for the life cycle assessment of end-of-life scenarios at the urban scale. Resour. Conserv. Recycl. 2017, 123, 54–66. [Google Scholar] [CrossRef]

- De Tudela, A.R.P.; Rose, C.M.; Stegemann, J.A. Quantification of Material Stocks in Existing Buildings Using Secondary Data- A Case Study for Timber in a London Borough. Resour. Conserv. Recycl. X 2019, 5, 100027. [Google Scholar] [CrossRef]

- Condeixa, K.; Haddad, A.; Boer, D. Material flow analysis of the residential building stock at the city of Rio de Janeiro. J. Clean. Prod. 2017, 149, 1249–1267. [Google Scholar] [CrossRef]

- Lichtensteiger, T. (Ed.) Bauwerke als Ressourcennutzer und Ressourcenspender in der langfristigen Entwicklung urbaner Systeme. Ein Beitrag zur Exploration urbaner Lagerstätten. Eidgenössische Anstalt für Wasserversorgung, Abwasserreinigung und Gewässerschutz, 1st ed.; Vdf Hochschulverl: Zürich, Switzerland, 2006. [Google Scholar]

- Destatis. Fachserie 5, Reihe 3: Bauen und Wohnen, Bestand an Wohnungen. 2010. Available online: https://www.destatis.de/DE/Themen/Gesellschaft-Umwelt/Wohnen/Publikationen/Downloads-Wohnen/bestand-wohnungen-2050300217004.pdf;jsessionid=2F2FEEEE4203006EEDC831839C64D344.live732?__blob=publicationFile (accessed on 27 June 2022).

- Destatis. Fachserie 5, Reihe 1: Bauen und Wohnen, Bautätigkeit. 2010. Available online: https://www.destatis.de/DE/Themen/Branchen-Unternehmen/Bauen/Publikationen/Downloads-Bautaetigkeit/bautaetigkeit-2050100217004.pdf;jsessionid=3CA8D2960CE67A1D252D95D5207AD5F4.live731?__blob=publicationFile (accessed on 27 June 2022).

- Schiller, G.; Deilmann, C.; Gruhler, K.; Röhm, P.; Reichenbach, J.; Baumann, J.; Günther, M. Ermittlung von Ressourcenschonungspotenzialen bei der Verwertung von Bauabfällen und Erarbeitung von Empfehlungen zu deren Nutzung; Umweltbundesamt: Dessau-Roßlau, Germany, 2010. [Google Scholar]

- Buchert, M.; Fritsche, U.R.; Gensch, C.-O.; Grießheim, R.; Jenseit, W.; Peter, B.; Rausch, L. Stoffflußbezogene Bausteine für ein nationales Konzept der nachhaltigen Entwicklung; Umweltbundesamt: Berlin, Germany, 1999. [Google Scholar]

- Buchert, M.; Fritsche, U.; Jenseit, W.; Rausch, L.; Deilmann, C.; Schiller, G.; Siedentop, S.; Lipkow, A. Nachhaltiges Bauen und Wohnen in Deutschland. Stoffflussbezogene Bausteine für ein nationales Konzept der nachhaltigen Entwicklung-Verknüpfung des Bereiches Bauen und Wohnen mit dem komplementären Bereich; Umweltbundesamt: Berlin, Germany, 2004. [Google Scholar]

- Gruhler, K.; Böhm, R.; Deilmann, C.; Schiller, G. Stofflich-energetische Gebäudesteckbriefe. Gebäudevergleiche und Hochrechnungen für Bebauungsstrukturen; Inst. für ökologische Raumentwicklung e.V (IÖR-Schriften, 38): Dresden, Germany, 2002. [Google Scholar]

- IÖR. Informationssystem Gebaute Umwelt. 2021. Available online: http://ioer-bdat.de/ (accessed on 14 May 2021).

- Faktor, X.; Faktor, X. Agentur der Entwicklungsgesellschaft indeland GmbH. Available online: https://www.faktor-x.info/ (accessed on 14 May 2021).

- Hafner, A.; Schäfer, S. Comparative LCA study of different timber and mineral buildings and calculation method for substitution factors on building level. J. Clean. Prod. 2017, 167, 630–642. [Google Scholar] [CrossRef]

- Hafner, A.; Rüter, S.; Ebert, S.; Schäfer, S.; König, H.; Cristofaro, L.; Diederichs, S.; Kleinhenz, M.; Krechel, M. Resource Efficient Building, Ruhr-University Bochum: Greenhouse Gas Balances for Timber Buildings-Implementation of New Requirements for Life-Cycle Assessments and Calculation of Empiric Substitution Factors; Forschungsbericht: 28W-B-3-054-01 Waldklimafonds; BMEL/BMUB: Bochum, Germany, 2017; ISBN 978-3-00-055101-7. [Google Scholar]

- BMWSB. ÖKOBAUDAT. Available online: https://www.oekobaudat.de/ (accessed on 27 July 2022).

- Krause, K. Strategische Erfassung der Sekundärressourcen basierend auf Ökobilanzen und einem Geoinformationssystem am Beispiel von drei Wohngebieten. Ph.D. Thesis, Ruhr-University Bochum, Bochum, Germany, 2020. [Google Scholar]

- DBU; Hafner, A.; Krause, K.; Ebert, S.; Ott, S.; Krechel, M. Ressourcennutzung Gebäude-Entwicklung eines Nachweisverfahrens zur Bewertung der Nachhaltigen Nutzung Natürlicher Ressourcen in Bauwerken; gefördert unter dem AZ: 34301/01-25 von der; Deutschen Bundesstiftung Umwelt (DBU): Bochum, Germany, 2020. [Google Scholar]

| Abbreviations | Year of Construction | GFA | GV | Number of Floors | Building Design | ||||

|---|---|---|---|---|---|---|---|---|---|

| Exterior Wall | Interior Wall | Ceiling | Roof | Foundation | |||||

| 1.1_H | 2012 | 215 | 577 | SFH (GF + 1) | Solid timber with cellulose insulation | Cross-laminated timber | Wooden beam ceiling | Cross-laminated timber with cellulose insulation | Reinforced concrete |

| 1.1_M1 | RCC and mineral wool insulation, facing bricks | Reinforced concrete | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.1_M2 | RCC and ETICS | Reinforced concrete | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.1_M3 | Timber, single-shell | Reinforced concrete | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.1_M4 | Aerated concrete | Reinforced concrete | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.1_M5 | Sand-lime brick and ETICS | Reinforced concrete | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.2_H1 | 2009 | 176 | 557 | SFH (GF + 1) | HTB with mineral wool insulation | Wooden stud wall | Wooden beam ceiling | Wooden beam with mineral wool insulation | Reinforced concrete |

| 1.2_H2 | Solid timber with mineral wool insulation | Wooden stud wall | Board stack | Solid timber | |||||

| 1.2_M1 | Timber and ETICS | Sand-lime brick | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.2_M2 | Timber, single-shell | Vertically perforated brick | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.3_H | 2012 | 379 | 1069 | Duplex (GF + 1) | Solid timber with cellulose insulation | Cross-laminated timber | Cross laminated timber | Cross-laminated timber with cellulose insulation | Reinforced concrete |

| 1.3_M1 | Timber and insulating plaster | Vertically perforated brick | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.3_M2 | Sand-lime brick and ETICS | Sand-lime brick | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.3_M3 | Aerated concrete | Aerated concrete | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.5_M | 2011 | 245 | 685 | SFH (GF + Attic) | Timber and insulating plaster | Vertically perforated brick | Hollowcore ceiling | Wooden beam with mineral wool insulation | Reinforced concrete |

| 1.6_H | 2011 | 190 | 483 | SFH (GF + 2) | HTB with mineral wool insulation | Metal stud wall | Wooden beam ceiling | Wooden beam with mineral wool insulation | Reinforced concrete |

| 1.6_M1 | Sand-lime brick and ETICS | Sand-lime brick | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.6_M2 | Timber and insulating plaster | Vertically perforated brick | Hollowcore ceiling | Wooden beam with mineral wool insulation | |||||

| 1.7_H | 2011 | 127 | 384 | SFH (GF + 1) | HTB with mineral wool insulation | Metal stud wall | Wooden beam ceiling | Wooden beam with mineral wool insulation | Reinforced concrete |

| 1.7_M | Timber and insulating plaster | Vertically perforated brick | Vertical perforated brick | Brick solid roof | |||||

| 1.8_H | 2011 | 224 | 564 | Duplex (GF + 2) | HTB with mineral wool insulation | Metal stud wall | Wooden beam ceiling | Purlin roof | Reinforced concrete |

| 1.8_M | Timber, single-shell | Vertically perforated brick | Hollowcore ceiling | Purlin roof | |||||

| 1.9_H | 2009 | 209 | 536 | SFH (GF + 1) | HTB with mineral wool insulation | Wooden stud wall | Wooden beam ceiling | Wooden beam with mineral wool insulation | Reinforced concrete |

| 1.9_M1 | Sand-lime brick and ETICS | Sand-lime brick | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.9_M2 | Aerated concrete | Aerated concrete | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| 1.9_M3 | Timber and insulating plaster | Vertically perforated brick | Reinforced concrete | Wooden beam with mineral wool insulation | |||||

| Abbreviations | Year of Construction | GFA | GV | Number of Floors | Building Design | ||||

|---|---|---|---|---|---|---|---|---|---|

| Exterior Wall | Interior Wall | Ceiling | Roof | Foundation | |||||

| 2.2_H | 2013 | 1.394 | 3.965 | MFH (GF + 5) | HTB and ETICS | Wood and metal stud wall, reinforced concrete | Wood-concrete composite | Cross-laminated timber | Reinforced concrete |

| 2.2_M | RCC and ETICS | Reinforced concrete, metal stud wall | Reinforced concrete | Reinforced concrete | |||||

| 2.3_M | 2007 | 7.016 | 21.943 | Residential complex (GF + 3) | Aerated concrete resp. RCC and ETICS | Reinforced concrete, sand-lime brick | Reinforced concrete | Reinforced concrete | Reinforced concrete |

| 2.4_M | 2010 | 1.478 | 4.277 | MFH (GF + 3) | Sand-lime brick and ETICS | Reinforced concrete, Metal stud wall | Reinforced concrete | Reinforced concrete | Reinforced concrete |

| 2.5_H | 2006 | 6.152 | 19.072 | MFH (GF + 2) | HTB with cellulose and mineral wool insulation | Wood and metal stud wall, reinforced concrete | Cross-laminated timber | Cross-laminated timber | Reinforced concrete |

| 2.5_M | Timber and ETICS | Wood and metal stud wall, sand-lime brick | Reinforced concrete | Reinforced concrete | |||||

| 2.6_H | 2013 | 2.717 | 8.646 | MFH (GF + 3) | HTB with mineral wool insulation | HTB, metal stud wall | Structural solid wood | Wooden beam ceiling | Reinforced concrete |

| 2.6_M | Aerated concrete resp. RCC and mineral wool insulation | Reinforced concrete, metal stud wall | Reinforced concrete | Wooden beam ceiling | |||||

| 2.7_H | 2011 | 2.033 | 6.172 | MFH (GF + 7) | Solid timber with mineral wool insulation | Solid wood, Wooden stud wall | Cross-laminated timber | Cross-laminated timber | Reinforced concrete |

| 2.7_M1 | Aerated concrete | Reinforced concrete., metal stud wall | Reinforced concrete | Reinforced concrete | |||||

| 2.7_M2 | Timber and insulating plaster | Reinforced concrete, metal stud wall | Reinforced concrete | Reinforced concrete | |||||

| 2.7_M3 | Timber and mineral wool insulation, facing bricks in facade cladding | Reinforced concrete, metal stud wall | Reinforced concrete | Reinforced concrete | |||||

| 2.9_H | 2011 | 1.257 | 3.876 | MFH (GF + 3) | HTB with cellulose and mineral wool insulation | Solid wood, wooden stud wall | Cross-laminated timber | Cross-laminated timber | Reinforced concrete |

| 2.9_M | Sand-lime brick and ETICS | Reinforced concrete, Sand-lime brick | Reinforced concrete | Reinforced concrete | |||||

| 2.10_H | 2010 | 723 | 2.404 | MFH (GF + 3) | Solid timber with mineral wool insulation | Wooden stud wall | Solid timber | Wooden beam ceiling | Reinforced concrete |

| 2.10_M1 | Aerated concrete | Reinforced concrete | Reinforced concrete | Reinforced concrete | |||||

| 2.10_M2 | Timber and insulating plaster | reinforced concrete | reinforced concrete | Reinforced concrete | |||||

| 2.10_M3 | Timber and mineral wool insulation, facing bricks in facade cladding | Reinforced concrete | Reinforced concrete | Reinforced concrete | |||||

| 2.12_M | 2014 | 1765 | 5363 | MFH (GF + 4) | Sand-lime brick and mineral wool insulation, facing bricks in facade cladding | Reinforced concrete, metal stud wall | Reinforced concrete | Reinforced concrete, wooden beam | Reinforced concrete |

| 2.13_M | 2010 | 1348 | 3933 | MFH (GF + 5) | RCC and ETICS | Reinforced concrete, metal stud wall | Reinforced concrete | Reinforced concrete | Reinforced concrete |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krause, K.; Hafner, A. Resource Efficiency in the Construction Sector: Material Intensities of Residential Buildings—A German Case Study. Energies 2022, 15, 5825. https://doi.org/10.3390/en15165825

Krause K, Hafner A. Resource Efficiency in the Construction Sector: Material Intensities of Residential Buildings—A German Case Study. Energies. 2022; 15(16):5825. https://doi.org/10.3390/en15165825

Chicago/Turabian StyleKrause, Karina, and Annette Hafner. 2022. "Resource Efficiency in the Construction Sector: Material Intensities of Residential Buildings—A German Case Study" Energies 15, no. 16: 5825. https://doi.org/10.3390/en15165825

APA StyleKrause, K., & Hafner, A. (2022). Resource Efficiency in the Construction Sector: Material Intensities of Residential Buildings—A German Case Study. Energies, 15(16), 5825. https://doi.org/10.3390/en15165825