Emission of Nitric Oxide during the Combustion of Various Forms of Solid Biofuels in a Low-Power Heating Device

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristics of Raw Materials and Fuel

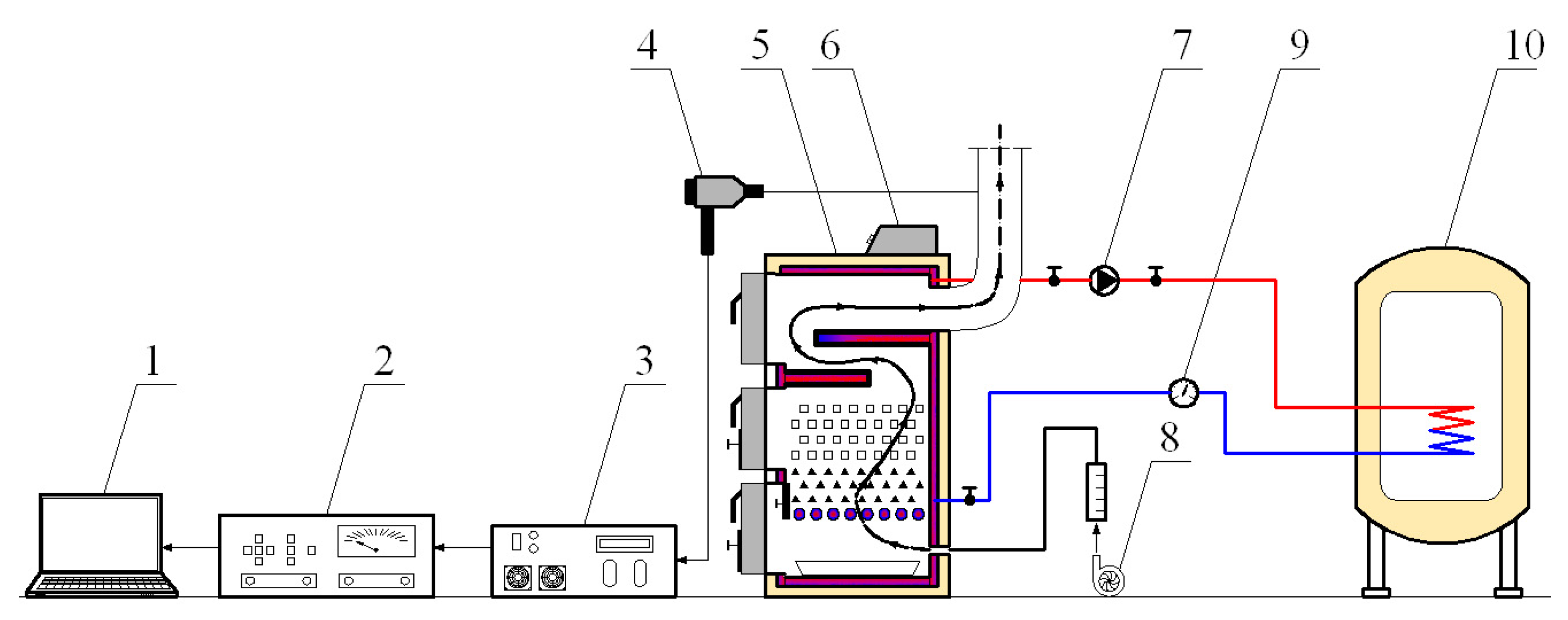

2.2. Biofuel Combustion Experiments

- O2—oxygen content by volume in dry gas (%)

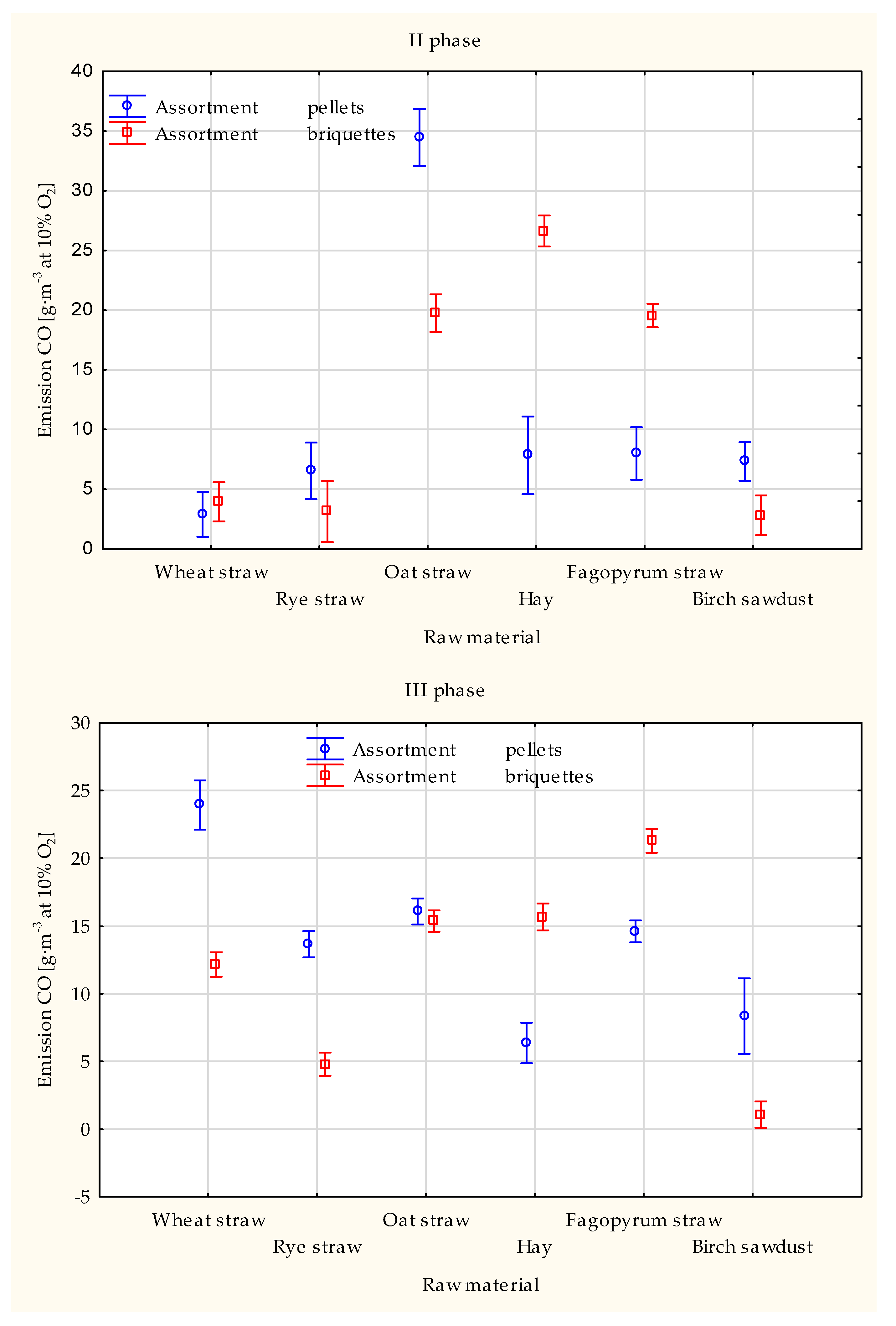

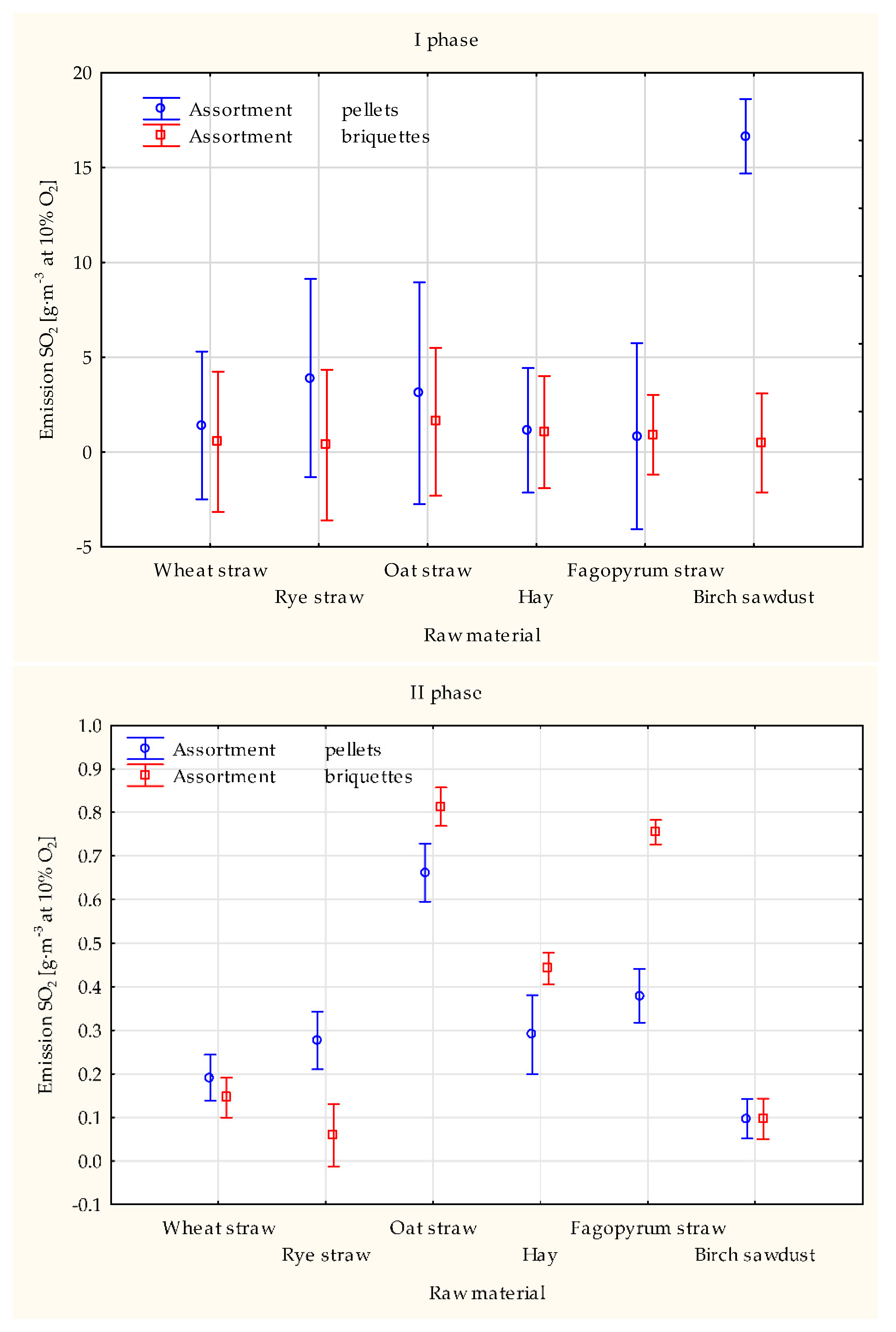

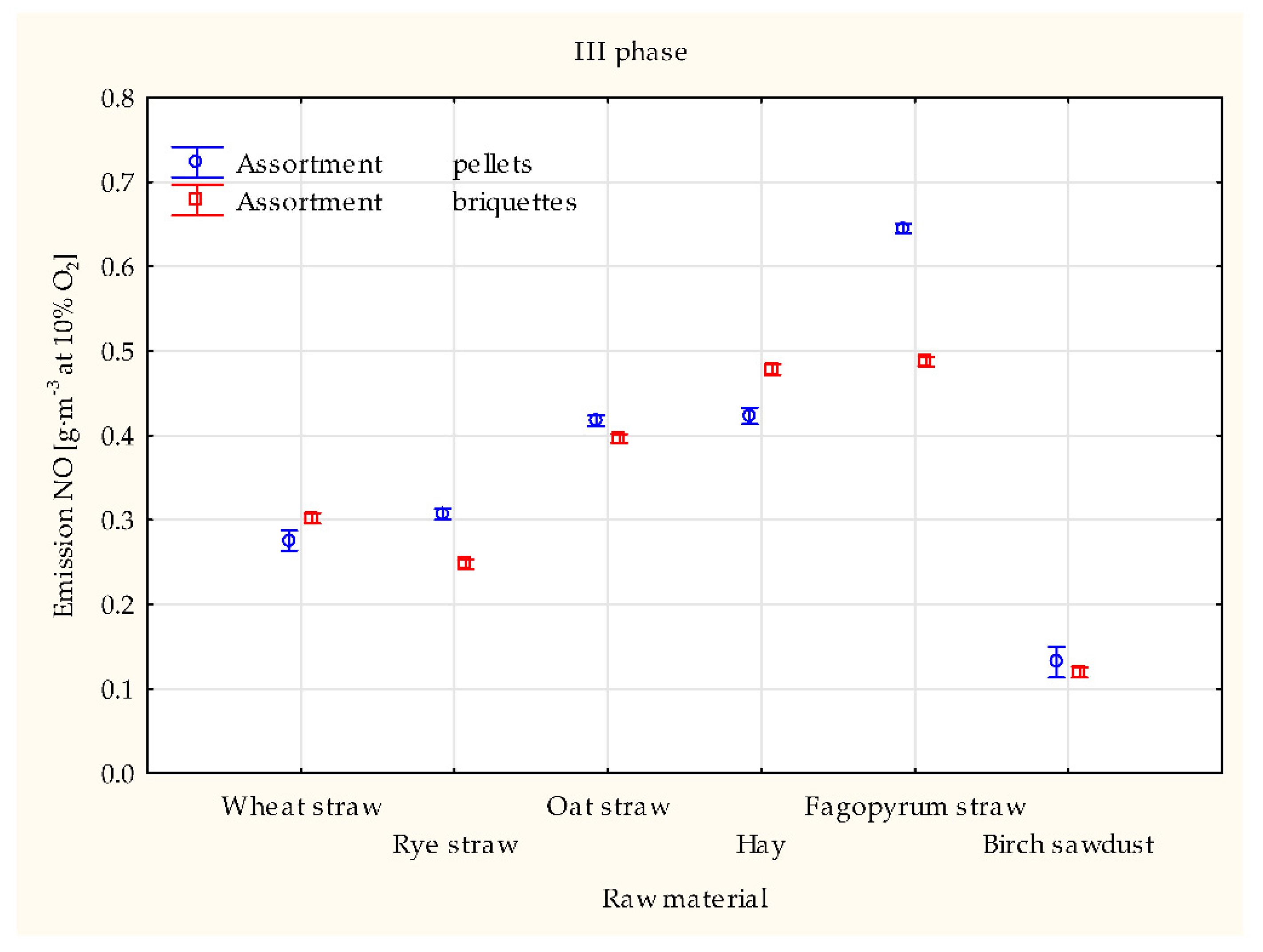

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Malico, I.; Pereira, R.N.; Gonçalves, A.C.; Sousa, A.M.O. Current status and future perspectives for energy production from solid biomass in the European industry. Renew. Sustain. Energy Rev. 2019, 112, 960–977. [Google Scholar] [CrossRef]

- A European Green Deal. Striving to Be the First Climate-Neutral Continent. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 28 March 2022).

- Polityka Energetyczna Unii Europejskiej. Available online: https://www.europarl.europa.eu/factsheets/pl/sheet/68/polityka-energetyczna-zasady-ogolne (accessed on 8 March 2022).

- Polityka Energetyczna Polski do 2040 r. Available online: https://www.gov.pl/web/klimat/polityka-energetyczna-polski (accessed on 14 January 2022).

- Bogusz, M.; Matysik-Pejas, R.; Krasnodębski, A.; Dziekański, P. The Concept of Zero Waste in the Context of Supporting Environmental Protection by Consumers. Energies 2021, 14, 5964. [Google Scholar] [CrossRef]

- Ozgen, S.; Cernuschi, S.; Caserini, S. An overview of nitrogen oxides emissions from biomass combustion for domestic heat production. Renew. Sustain. Energy Rev. 2021, 135, 110113. [Google Scholar] [CrossRef]

- Nussbaumer, T. Combustion and Co-combustion of Biomass: Fundamentals, Technologies, and Primary Measures for Emission Reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- Demirbas, A. Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog. Energy Combust. Sci. 2005, 31, 171–192. [Google Scholar] [CrossRef]

- Baran, D.; Kwaśniewski, D.; Mudryk, K. Wybrane właściwości fizyczne trzyletniej wierzby energetycznej. Inżynieria Rol. 2007, 8, 7–12. [Google Scholar]

- Eisenbies, M.H.; Volk, T.A.; Patel, A. Changes in feedstock quality in willow chip piles created in winter from a commercial scale harvest. Biomass Bioenergy 2016, 86, 180–190. [Google Scholar] [CrossRef]

- Krzyżaniak, M.; Stolarski, M.J.; Szczukowski, S.; Tworkowski, J. Thermophysical and chemical properties of biomass obtained from willow coppice cultivated in one- and three-year rotation cycles. J. Elem. 2014, 1, 161–175. [Google Scholar] [CrossRef]

- Graham, S.; Ogunfayo, I.; Hall, M.R.; Snape, C.; Quick, W.; Weatherstone, S.; Eastwick, C. Changes in mechanical properties of wood pellets during artificial degradation in a laboratory environment. Fuel Process. Technol. 2016, 148, 395–402. [Google Scholar] [CrossRef]

- Jenkins, B.M.; Baxter, L.L.; Miles, T.R., Jr.; Miles, T.R. Combustion properties of biomass. Fuel Process. Technol. 1998, 54, 17–46. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 219–230. [Google Scholar] [CrossRef]

- Theerarattananoon, K.; Xua, F.; Wilson, J.; Ballard, R.; Mckinney, L.; Staggenborg, S.; Vadlani, P.; Pei, Z.J.; Wang, D. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw, and big bluestem. Ind. Crops Prod. 2011, 33, 325–332. [Google Scholar] [CrossRef]

- Skonecki, S.; Gawłowski, S.; Potręć, M.; Laskowski, J. Właściwości fizyczne i chemiczne surowców roślinnych stosowanych do produkcji biopaliw. Inżynieria Rol. 2011, 8, 253–260. [Google Scholar]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical properties of solid biofuels–significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Juszczak, M. Concentration of carbon monoxide and nitrogen oxides from a 25 kW boiler supplied periodically. Chem. Process Eng. 2014, 35, 163–172. [Google Scholar] [CrossRef]

- Kjällstrand, J.; Olsson, M. Chimney emissions from small-scale burning of pellets and fuelwood-examples referring to different combustion appliances. Biomass Bioenergy 2004, 27, 557–561. [Google Scholar] [CrossRef]

- Olsson, M.; Kjällstrand, J. Low emission from wood burning in an ecolabelled residential boiler. Atm. Env. 2006, 40, 1148–1158. [Google Scholar] [CrossRef]

- García, R.; Pizarro, C.; Lavín, A.G.; Bueno, J.L. Spanish biofuels heating value estimation. Part II: Proximate analysis data. Fuel 2014, 117, 1139–1147. [Google Scholar] [CrossRef]

- Fenimore, C.P. Formation of nitric oxide in premixed hydrocarbon flames. Symp. (Int.) Combust. 1971, 13, 373–380. [Google Scholar] [CrossRef]

- Miller, J.A.; Bowman, C.T. Mechanism and modelling of nitrogen chemistry in combustion. Prog. Energy Combust. Sci. 1989, 15, 287–338. [Google Scholar] [CrossRef]

- Leckner, B.; Karlsson, M. Gaseous emissions from circulating fluidized bed combustion of wood. Biomass Bioenergy 1993, 4, 379–389. [Google Scholar] [CrossRef]

- Nussbaumer, T. Verbrennung und Vergasung von Energiegras und Feldholz. In Jahresbericht 1994 zum Gleichnamigen Forschungsprojekt; Jahresbericht; Bundesamt für Energiewirtschaft: Bern, Switzerland, 1994. [Google Scholar]

- Boman, C.; Pettersson, E.; Westerholm, R.; Boström, D.; Nordin, A. Stove performance and emission characteristic in residential wood log and pellet combustion. Part 1: Pellet stoves. Energy Fuels 2011, 25, 307–314. [Google Scholar] [CrossRef]

- Liu, H.; Chaney, J.; Li, J.; Sun, C. Control of NOx emissions of a domestic/small-scale biomass pellet boiler by air staging. Fuel 2013, 103, 792–798. [Google Scholar] [CrossRef]

- Van Loo, S.; Koppejan, J. Handbook of Biomass Combustion and Co-Firing, 1st ed.; London Imprint Routledge: London, UK, 2007; pp. 266–272. [Google Scholar]

- Hinckley, J.; Doshi, K. Emission Controls for Small Wood-Fired Boilers; United States Forest Service, Western Forestry Leadership Coalition: Edgewater, CO, USA, May 2010. [Google Scholar]

- Eskilsson, D.; Rönnbäck, M.; Samuelsson, J.; Tullin, C. Optimisation of efficiency and emissions in pellet burners. Biomass Bioenergy 2004, 27, 541–546. [Google Scholar] [CrossRef]

- Obaidullah, M.; Bram, S.; Verma, V.K.; De Ruyck, J. A Review on Particle Emissions from Small Scale Biomass Combustion. Int. J. Renew. Energy Res. 2012, 2, 147–159. [Google Scholar] [CrossRef]

- Niedziółka, I.; Zuchniarz, A. Analiza energetyczna wybranych rodzajów biomasy pochodzenia roślinnego. MOTROL 2006, 8A, 232–237. [Google Scholar]

- Ito, H.; Tokunaga, R.; Nogami, S.; Miura, M. Influence of Biomass Raw Materials on Combustion Behavior of Highly Densified Single Cylindrical Biomass Briquette. Combust. Sci. Technol. 2022, 194, 2072–2086. [Google Scholar] [CrossRef]

- Kraszkiewicz, A. Influence of Geometrical Features of Solid Biofuels on the Implementation of the Combustion Process. Combust. Sci. Technol, 2022; in print. [Google Scholar] [CrossRef]

- Bhattu, D.; Zotter, P.; Zhou, J.; Stefenelli, G.; Klein, F.; Bertrand, A.; Temime-Roussel, B.; Marchand, N.; Slowik, J.G.; Baltensperger, U.; et al. Effect of stove technology and combustion conditions on gas and particulate emissions from residential biomass combustion. Environ. Sci. Technol. 2019, 53, 2209–2219. [Google Scholar] [CrossRef]

- Fachinger, F.; Drewnick, F.; Gieré, R.; Borrmann, S. How the user can influence particulate emissions from residential wood and pellet stoves: Emission factors for different fuels and burning conditions. Atmos. Environ. 2017, 158, 216–226. [Google Scholar] [CrossRef]

- Mitchell, E.J.S.; Lea-Langton, A.R.; Jones, J.M.; Williams, A.; Layden, P.; Johnson, R. The impact of fuel properties on the emissions from the combustion of biomass and other solid fuels in a fixed bed domestic stove. Fuel Process. Technol. 2016, 142, 115–123. [Google Scholar] [CrossRef]

- Houshfar, E.; Skreiberg, Ø.; Løvås, T.; Todorovic, D.; Sorum, L. Effect of excess air ratio and temperature on NOx emission from grate combustion of biomass in the staged air combustion scenario. Energy Fuels 2011, 25, 4643–4654. [Google Scholar] [CrossRef]

- Houshfar, E.; Løvås, T.; Skreiberg, Ø. Experimental Investigation on NOx Reduction by Primary Measures in Biomass Combustion: Straw, Peat, Sewage Sludge, Forest Residues and Wood Pellets. Energies 2012, 5, 270–290. [Google Scholar] [CrossRef]

- Bowman, C.T. Control of combustion-generated nitrogen oxide emissions: Technology driven by regulation. Symp. (Int.) Combust. 1992, 24, 859–878. [Google Scholar] [CrossRef]

- Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products. L285/10–L285/35. 2009. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32009L0125 (accessed on 18 March 2022).

- Decreto del Ministero dell’Ambiente e della Tutela del Territorio e del Mare n. 186. Regolamento Recante la Disciplina dei Requisiti, delle Procedure e delle Competenze per il Rilascio di una Certificazione dei Generatori di Calore Alimentati a Biomasse Combustibili Solide. Available online: https://www.reteambiente.it/normativa/30664/ (accessed on 30 March 2022).

- Ciupek, B.; Judt, W.; Gołoś, K.; Urbaniak, R. Analysis of Low-Power Boilers Work on Real Heat Loads: A Case of Poland. Energies 2021, 14, 3101. [Google Scholar] [CrossRef]

- Pełka, G.; Wygoda, M.; Lubo´n, W.; Pachytel, P.; Jachimowski, A.; Paprocki, M.; Wyczesany, P.; Kotyza, J. Analysis of the Efficiency of a Batch Boiler and Emissions of Harmful Substances during Combustion of Various Types of Wood. Energies 2021, 14, 6783. [Google Scholar] [CrossRef]

- Jarosiński, J. Techniki Czystego Spalania; WNT: Warszawa, Polish, 1996; pp. 277–294. [Google Scholar]

- EN ISO 18134-3:2015; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Sample. Polish Committee for Standardization: Warsaw, Poland, 2015.

- Lisowski, A.; Dąbrowska-Salwin, M.; Ostrowska-Ligęza, E.; Nawrocka, A.; Stasiak, M.; Świętochowski, A.; Klonowski, K.; Sypuła, M.; Lisowska, B. Effects of the biomass moisture content and pelleting temperature on the pressure-induced agglomeration process. Biomass Bioenergy 2017, 107, 376–383. [Google Scholar] [CrossRef]

- Zawiślak, K.; Sobczak, P.; Kraszkiewicz, A.; Niedziółka, I.; Parafiniuk, S.; Kuna-Broniowska, I.; Tanaś, W.; Żukiewicz-Sobczak, W.; Obidziński, S. The use of lignocellulosic waste in the pro-duction of pellets for energy purposes. Renew. Energy 2020, 145, 997–1003. [Google Scholar] [CrossRef]

- Niedziółka, I.; Szpryngiel, M.; Kachel-Jakubowska, M.; Kraszkiewicz, A.; Zawiślak, K.; Sobczak, P.; Nadulski, R. Assessment of the energetic and mechanical properties of pellets produced from agricultural biomass. Renew. Energy 2015, 76, 312–317. [Google Scholar] [CrossRef]

- CEN/TS 15104:2006; Solid Biofuels. Determination of Total Content of Carbon, Hydrogen and Nitrogen. Instrumental Methods. British Standards Institute: London, UK, 2011.

- EN PN-G-04584:2001; Solid Fuels—Determination of Total and Ash Sulfur Content by Automatic Analyzers. Polish Committee for Standardization: Warsaw, Poland, 2001.

- PN-G-04516:1998; Solid Fuels-Determination of Volatile Matter Content by Weight Method. Polish Committee for Standardization: Warsaw, Poland, 1998.

- EN ISO 18122:2016; Solid Biofuels—Determination of Ash Content. Polish Committee for Standardization: Warsaw, Poland, 2016.

- EN ISO 18125:2017; Solid Biofuels. Determination of Calorific Value. Polish Committee for Standardization: Warsaw, Poland, 2017.

- EN ISO 16127:2012; Solid Biofuels—Determination of Length and Diameter of Pellets. Polish Committee for Standardization: Warsaw, Poland, 2012.

- PN-EN 303-5:2012; Heating Boilers for Solid Fuels with Manual and Automatic Fuel Hopper of Nominal Power Up to 300 kW. Terminology, Requirements, Testing and Marking. Polish Committee for Standardization: Warsaw, Poland, 2012.

- Speth, K.; Murer, M.; Spliethoff, H. Experimental investigation of nitrogen species distribution in wood combustion and their influence on NOx reduction by combining air staging and ammonia injection. Energy Fuels 2016, 30, 5816–5824. [Google Scholar] [CrossRef]

- Jach-Nocoń, M.; Pełka, G.; Luboń, W.; Mirowski, T.; Nocoń, A.; Pachytel, P. An Assessment of the Efficiency and Emissions of a Pellet Boiler Combusting Multiple Pellet Types. Energies 2021, 14, 4465. [Google Scholar] [CrossRef]

- Khodaei, H.; Guzzomi, F.; Yeoh, G.H.; Regueiro, A.; Pati, D. An experimental study into the effect of air staging distribution and position on emissions in a laboratory scale biomass combustor. Energy 2016, 118, 1243–1255. [Google Scholar] [CrossRef]

- Lamberg, H. Small-Scale Pellet Boiler Emissions–Characterization and Comparison to Other Combustion Units. In Report Series in Aerosol Science n:o 156; Academic Dissertation: Kuopio, Finland, 2014; Volume 156, Available online: https://www.atm.helsinki.fi/faar/reportseries/rs-156.pdf (accessed on 27 April 2022).

- Werther, J.; Saenger, M.; Hartge, E.U.; Ogada, T.; Siagi, Z. Combustion of agricultural residues. Prog. Energy Combust. Sci. 2000, 26, 1–27. [Google Scholar] [CrossRef]

- Mentes, D.; Sajti, S.Z.; Koós, T.L.; Póliska, C.S. Optimizing the combustion processes of a small scale solid fuel fired boiler. Int. J. Eng. Manag. Sci. 2019, 4, 358–369. [Google Scholar] [CrossRef]

- Yang, Y.B.; Ryu, C.H.; Khor, A.; Yates, N.E.; Sharifi, V.N.; Swithenbank, J. Effect of fuel properties on biomass combustion. Part II. Modelling approach identification of the controlling factors. Fuel 2005, 84, 2116–2130. [Google Scholar] [CrossRef]

- Czech, H.; Pieber, S.M.; Tiitta, P.; Sippula, O.; Kortelainen, M.; Lamberg, H.; Grigonyte, J.; Streibel, T.; Prévôt, A.S.H.; Jokiniemi, J.; et al. Time-Resolved analysis of primary volatile emissions and secondary aerosol formation potential from a small-scale pellet boiler. Atmos. Environ. 2017, 158, 236–245. [Google Scholar] [CrossRef]

| Raw Material | Sortment | L mm | D mm | MC % | VD kg·m−3 | GPI kg·m−1 | VM % | C % | H % | N % | S % | LHV MJ·kg−1 | AC % |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wheat straw | P | 32.3 | 8 | 10.55 | 1130 | 0.0036 | 70.73 | 47 | 5.79 | 0.78 | 0.06 | 16.29 | 2.3 |

| B | 15.5 | 50 | 10.41 | 946 | 0.0217 | ||||||||

| Rye straw | P | 28.9 | 8 | 10.41 | 1034 | 0.0032 | 72.23 | 47.95 | 5.92 | 0.85 | 0.12 | 16.28 | 3.4 |

| B | 18.7 | 50 | 10.28 | 856 | 0.0245 | ||||||||

| Oat straw | P | 34.1 | 8 | 10.53 | 1016 | 0.0033 | 69.53 | 43.7 | 5.22 | 0.44 | 0.07 | 15.47 | 6.45 |

| B | 25.2 | 50 | 10.40 | 1004 | 0.0295 | ||||||||

| Hay | P | 31.7 | 8 | 9.70 | 1063 | 0.0034 | 68.2 | 46.1 | 5.85 | 1.4 | 0.61 | 16.26 | 6.2 |

| B | 23.4 | 50 | 9.47 | 1132 | 0.0413 | ||||||||

| Fagopyrum straw | P | 29.40 | 8 | 9.90 | 1080 | 0.0033 | 67.9 | 44.4 | 5.56 | 0.88 | 0.13 | 15.48 | 9.2 |

| B | 31 | 50 | 9.80 | 998 | 0.0478 | ||||||||

| Birch sawdust | P | 11.2 | 8 | 9.79 | 926 | 0.0020 | 73.35 | 49.08 | 5.95 | 0.22 | 0.1 | 16.34 | 1.3 |

| B | 48.7 | 50 | 9.80 | 996 | 0.0680 |

| Raw Material | Assortment | Fuel Consumption [kg·h−1] | Content CO2 in Exhaust Gas [%] | Air Excess Coefficient λ [−] | Exhaust Gas Temperature (Tgas) [°C] | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| I Phase | II Phase | III Phase | I Phase | II Phase | III Phase | I Phase | II Phase | III Phase | |||

| Wheat straw | P | 3.96 | 0.76 | 7.71 | 1.13 | 29.36 | 2.92 | 24.62 | 122 | 423 | 184 |

| B | 3.41 | 2.51 | 8.05 | 5.41 | 8.80 | 2.59 | 4.25 | 117 | 292 | 248 | |

| Rye straw | P | 4.64 | 0.60 | 6.88 | 4.48 | 32.90 | 3.91 | 7.78 | 93 | 419 | 322 |

| B | 3.76 | 4.83 | 9.42 | 8.14 | 4.90 | 2.10 | 2.80 | 227 | 329 | 328 | |

| Oat straw | P | 4.44 | 0.76 | 2.64 | 4.21 | 166.43 | 13.94 | 5.37 | 57 | 168 | 294 |

| B | 2.71 | 1.74 | 3.26 | 4.06 | 12.37 | 6.19 | 5.14 | 68 | 134 | 180 | |

| Hay | P | 4.43 | 0.95 | 5.33 | 5.90 | 23.42 | 4.20 | 3.50 | 71 | 280 | 295 |

| B | 3.07 | 2.07 | 4.06 | 2.89 | 10.55 | 4.83 | 7.42 | 92 | 192 | 158 | |

| Fagopyrum straw | P | 3.38 | 0.12 | 0.66 | 1.78 | 205.27 | 30.10 | 13.92 | 20 | 36 | 111 |

| B | 2.07 | 0.80 | 1.44 | 1.58 | 27.52 | 15.10 | 13.49 | 46 | 119 | 138 | |

| Birch sawdust | P | 4.25 | 3.66 | 9.03 | 3.30 | 28.94 | 2.25 | 6.17 | 301 | 576 | 267 |

| B | 3.54 | 2.81 | 7.37 | 7.66 | 6.96 | 2.81 | 2.58 | 124 | 278 | 310 | |

| Variables | Combustion Phase | |||||

|---|---|---|---|---|---|---|

| I | II | III | ||||

| P | B | P | B | P | B | |

| CO vs. C | 0.830 | 0.105 | 0.336 | −0.121 | −0.371 | −0.541 |

| CO vs. H | 0.604 | 0.236 | 0.120 | 0.030 | −0.512 | −0.529 |

| CO vs. N | −0.772 | 0.438 | −0.573 | 0.525 | −0.372 | 0.126 |

| CO vs. S | −0.378 | 0.663 | −0.060 | 0.704 | −0.076 | 0.040 |

| CO vs. VM | 0.834 | −0.070 | 0.474 | −0.308 | −0.054 | −0.375 |

| CO vs. VD | −0.869 | 0.448 | −0.625 | 0.670 | −0.398 | 0.175 |

| CO vs. GPI | −0.913 | −0.203 | −0.594 | −0.147 | −0.056 | −0.387 |

| SO2 vs. C | 0.717 | 0.019 | 0.141 | −0.473 | 0.295 | −0.617 |

| SO2 vs. H | 0.522 | −0.097 | 0.065 | −0.515 | 0.235 | −0.640 |

| SO2 vs. N | −0.678 | 0.048 | −0.064 | 0.137 | 0.064 | 0.073 |

| SO2 vs. S | −0.347 | 0.328 | 0.006 | 0.264 | 0.068 | 0.158 |

| SO2 vs. VM | 0.723 | 0.093 | 0.174 | −0.322 | 0.333 | −0.356 |

| SO2 vs. VD | −0.754 | 0.284 | 0.032 | 0.413 | −0.322 | 0.381 |

| SO2 vs. GPI | −0.797 | −0.185 | 0.023 | −0.209 | −0.208 | −0.264 |

| NO vs. C | 0.685 | −0.162 | 0.097 | 0.278 | −0.105 | 0.119 |

| NO vs. H | 0.495 | −0.212 | 0.183 | 0.210 | −0.096 | 0.061 |

| NO vs. N | −0.652 | 0.237 | 0.424 | 0.150 | 0.176 | 0.074 |

| NO vs. S | −0.327 | 0.125 | 0.151 | 0.051 | 0.397 | −0.071 |

| NO vs. VM | 0.691 | −0.058 | 0.004 | 0.269 | −0.092 | 0.062 |

| NO vs. VD | −0.725 | −0.126 | 0.481 | −0.215 | −0.213 | −0.325 |

| NO vs. GPI | −0.766 | −0.670 | 0.458 | −0.813 | 0.052 | −0.510 |

| Variables | Combustion Phase | |||||

|---|---|---|---|---|---|---|

| I | II | III | ||||

| P | B | P | B | P | B | |

| CO vs. Tgas | 0.612 | 0.323 | 0.444 | −0.237 | 0.163 | −0.634 |

| CO vs. CO2 | 0.561 | 0.376 | 0.328 | −0.178 | 0.110 | −0.542 |

| CO vs. λ | −0.330 | −0.387 | −0.335 | −0.170 | −0.402 | 0.177 |

| SO2 vs. Tgas | 0.485 | 0.244 | 0.304 | −0.436 | 0.580 | −0.407 |

| SO2 vs. CO2 | 0.388 | 0.336 | 0.246 | −0.321 | 0.578 | −0.304 |

| SO2 vs. λ | −0.265 | −0.470 | −0.361 | −0.078 | −0.563 | −0.407 |

| NO vs. CO | 0.851 | 0.596 | −0.166 | 0.093 | 0.170 | −0.245 |

| NO vs. SO2 | 0.992 | 0.725 | 0.330 | 0.079 | 0.453 | 0.200 |

| NO vs. Tgas | 0.396 | 0.429 | 0.354 | 0.662 | 0.763 | 0.648 |

| NO vs. CO2 | 0.294 | 0.521 | 0.501 | 0.713 | 0.921 | 0.682 |

| NO vs. λ | −0.248 | −0.322 | −0.531 | −0.638 | −0.679 | −0.563 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kraszkiewicz, A.; Przywara, A.; Parafiniuk, S. Emission of Nitric Oxide during the Combustion of Various Forms of Solid Biofuels in a Low-Power Heating Device. Energies 2022, 15, 5960. https://doi.org/10.3390/en15165960

Kraszkiewicz A, Przywara A, Parafiniuk S. Emission of Nitric Oxide during the Combustion of Various Forms of Solid Biofuels in a Low-Power Heating Device. Energies. 2022; 15(16):5960. https://doi.org/10.3390/en15165960

Chicago/Turabian StyleKraszkiewicz, Artur, Artur Przywara, and Stanisław Parafiniuk. 2022. "Emission of Nitric Oxide during the Combustion of Various Forms of Solid Biofuels in a Low-Power Heating Device" Energies 15, no. 16: 5960. https://doi.org/10.3390/en15165960

APA StyleKraszkiewicz, A., Przywara, A., & Parafiniuk, S. (2022). Emission of Nitric Oxide during the Combustion of Various Forms of Solid Biofuels in a Low-Power Heating Device. Energies, 15(16), 5960. https://doi.org/10.3390/en15165960