Experimental Optimization with the Emphasis on Techno-Economic Analysis of Production and Purification of High Value-Added Bioethanol from Sustainable Corn Stover

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biomass and Chemicals

2.2. Biomass Elaboration

2.3. Physico-Chemical Pretreatment and Cellulose Fractionation

2.4. Enzymatic Degradation

2.5. Yeast Isolation

2.6. Molecular Identification of the Yeast Isolate

2.7. Fermentation Process

2.8. Characterization of CS and CSM

2.8.1. Hemicellulose, Cellulose, and Lignin Contents

2.8.2. Proximate Analysis, Ultimate Analysis, and HHV

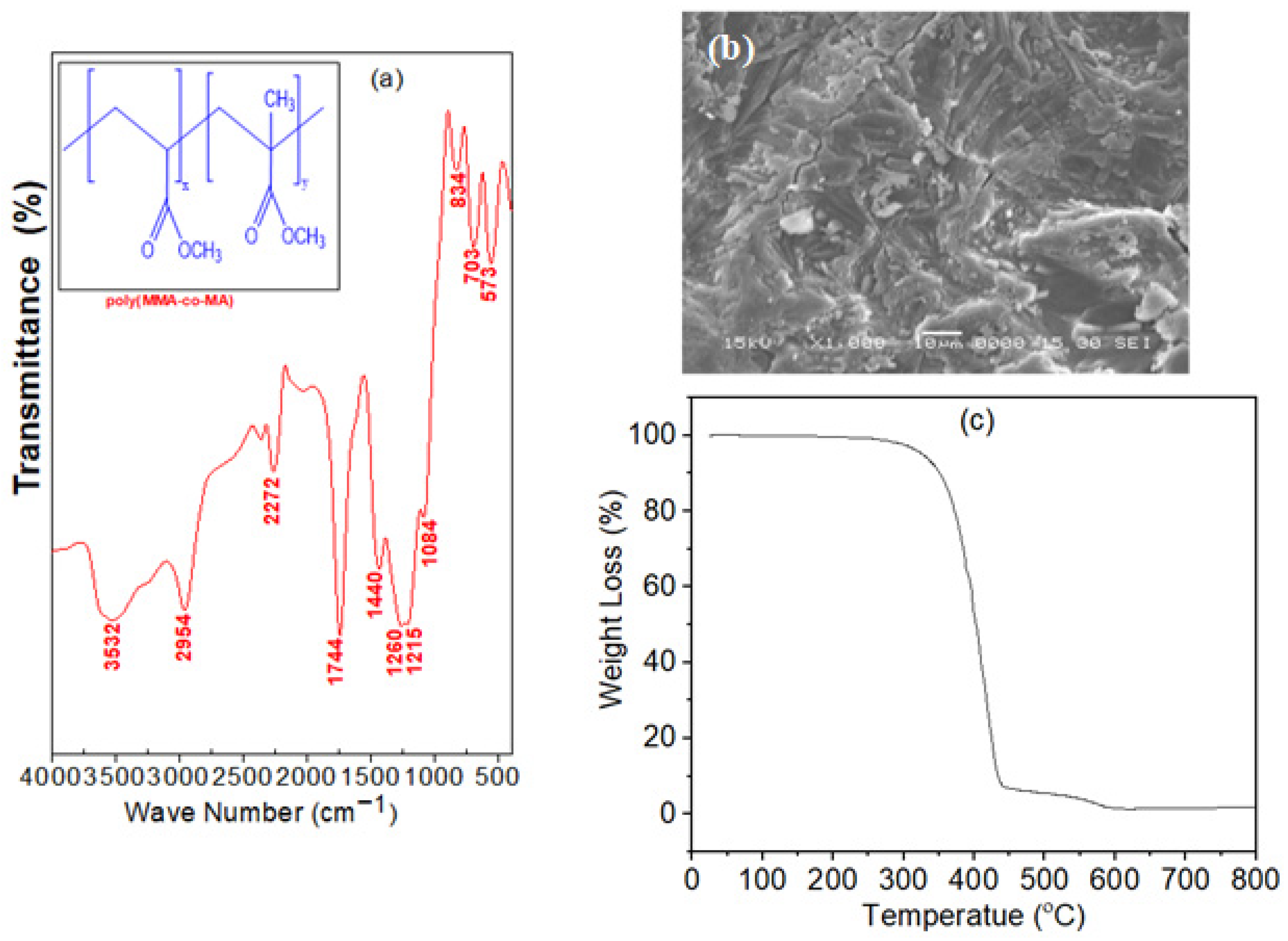

2.8.3. TGA, FTIR, and SEM Analysis

2.8.4. Glucose Production Yield

2.8.5. Bioethanol Concentration

2.9. Bioethanol Separation and Purification

2.9.1. Membrane Preparation

2.9.2. Membrane Characterization

2.9.3. Water and Ethanol Uptake

3. Results and Discussion

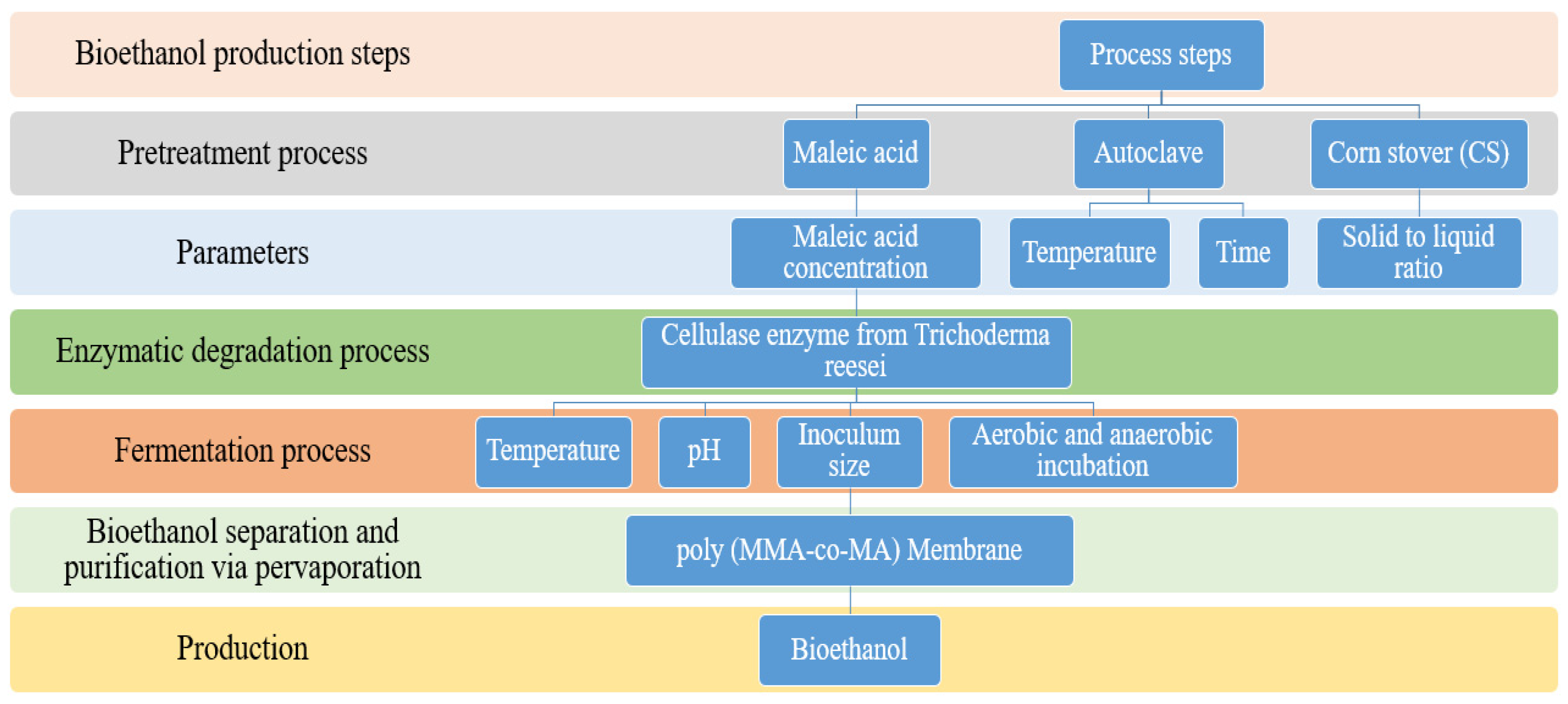

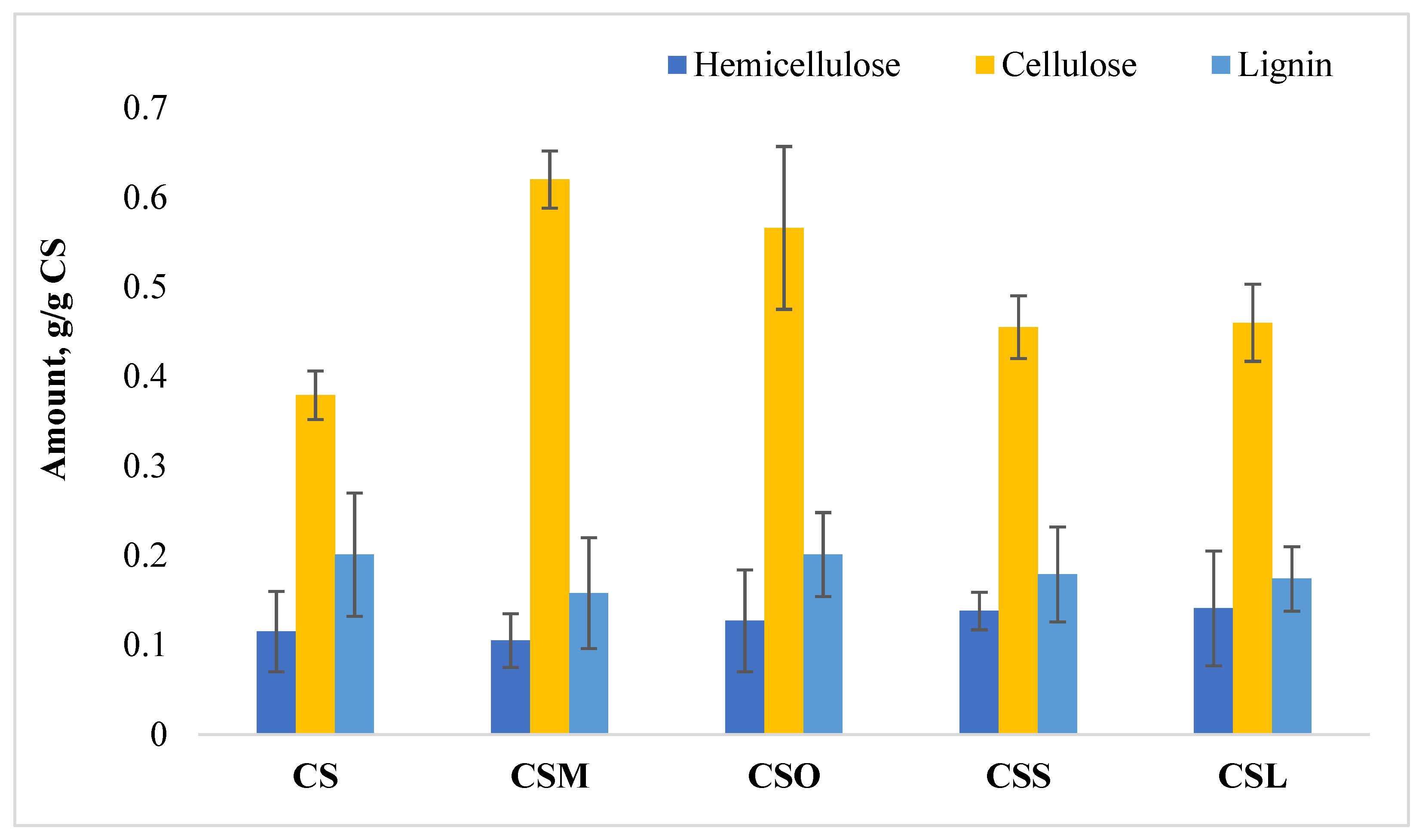

3.1. The Role of Various Organic Acids Pretreatment

3.2. Proximate Analysis

3.3. Ultimate Analysis and HHV

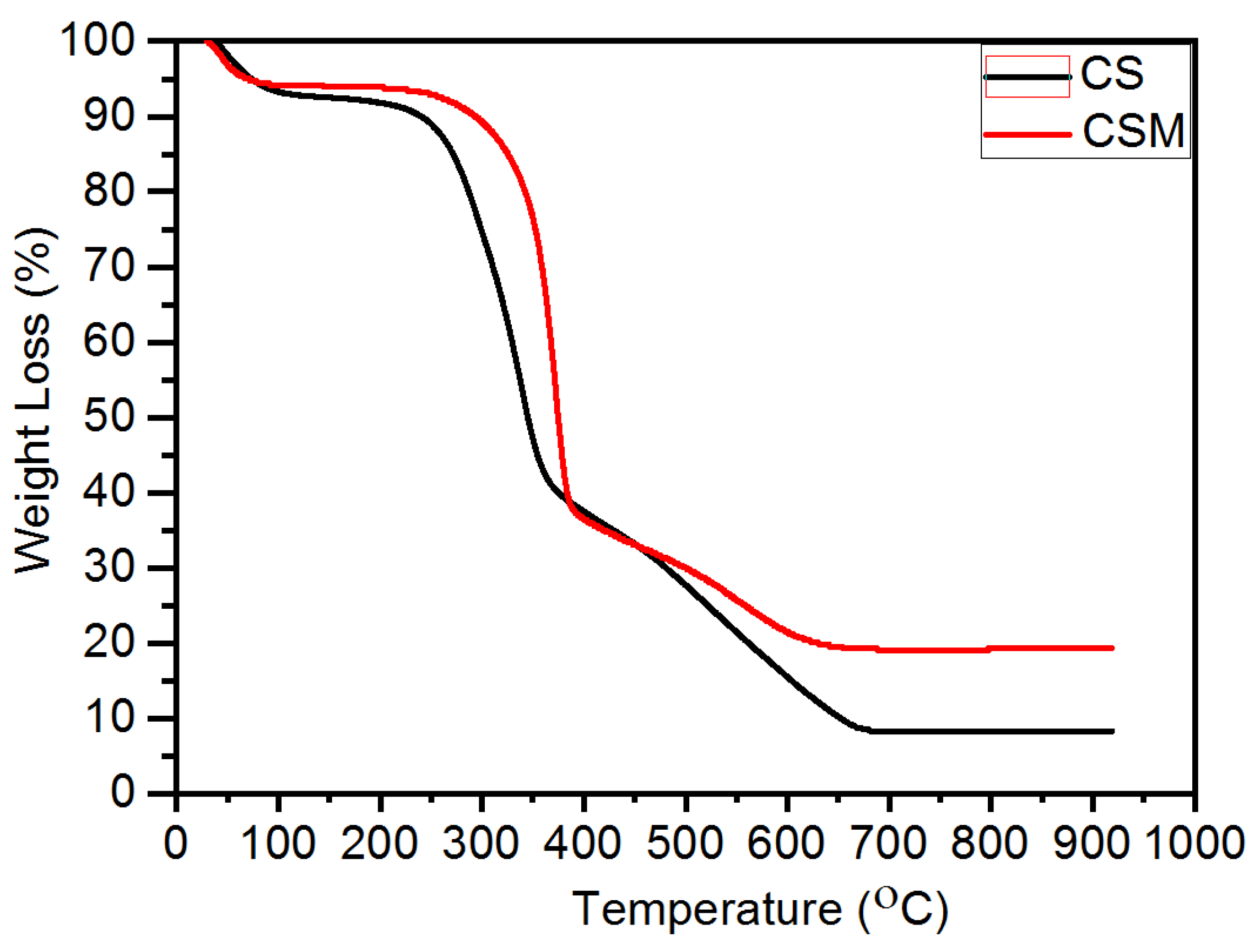

3.4. Thermal Analysis

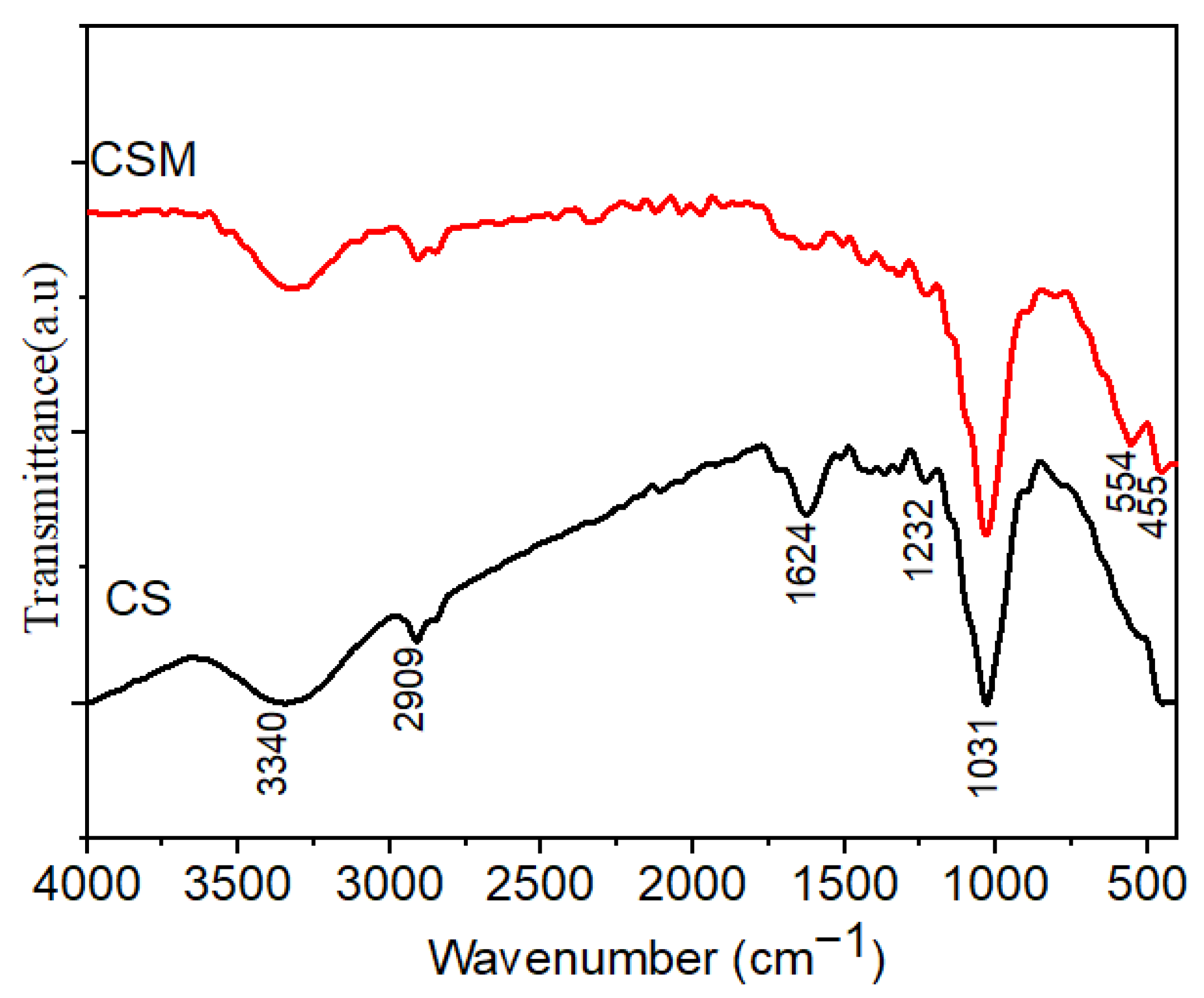

3.5. Functional Analysis

3.6. Morphological Characteristics

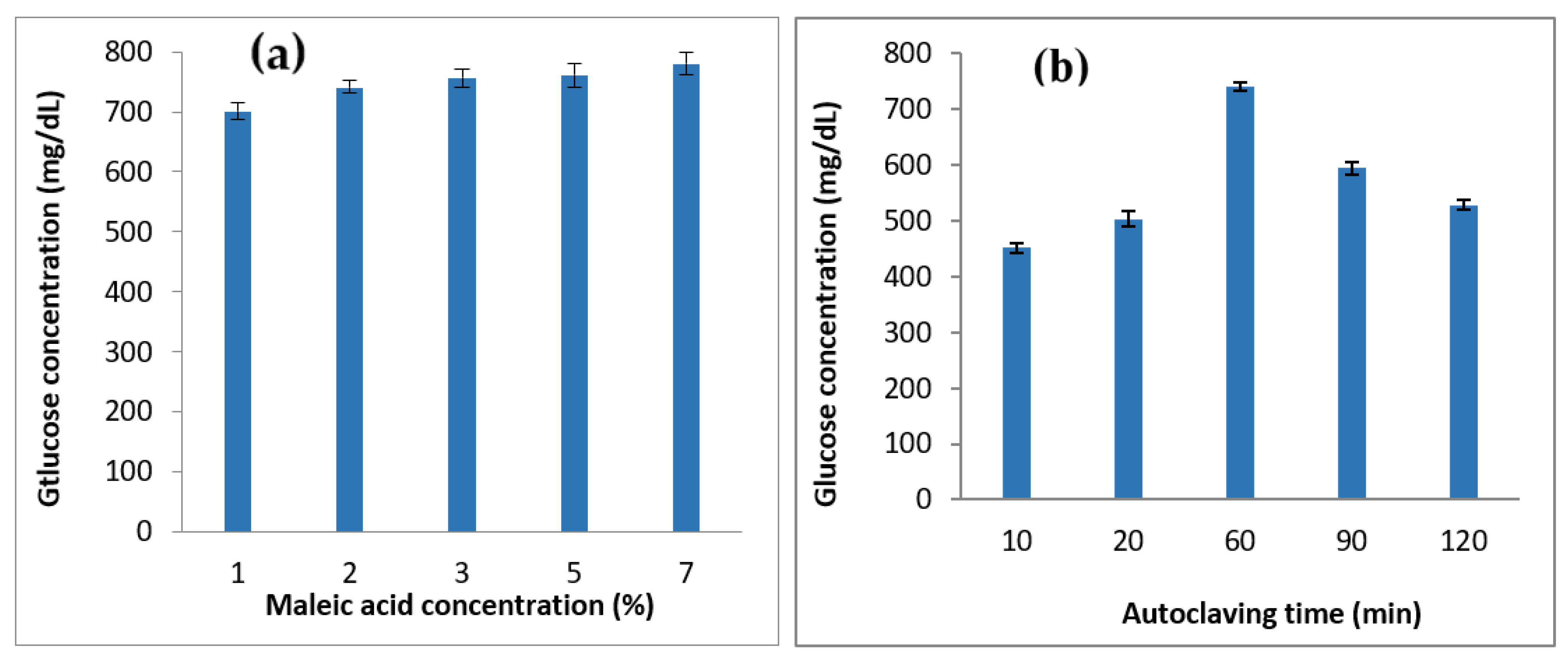

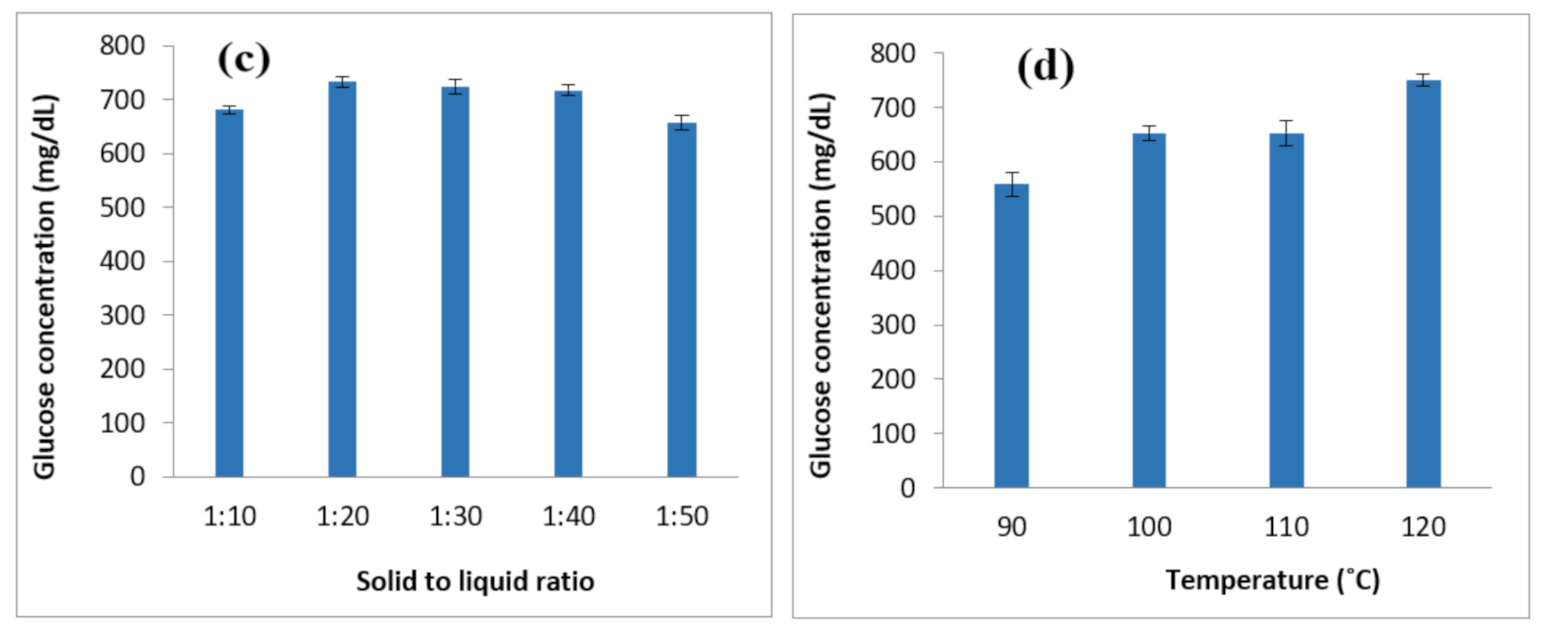

3.7. The Role of Maleic Acid in the Delignification Process

3.8. Optimization of the Pretreatment Process

3.9. Molecular Identification of the Yeast Isolate

3.10. Optimization of Fermentation Parameters

3.10.1. Incubation under Aerobic and Anaerobic Conditions

3.10.2. Incubation Temperature

3.10.3. pH of the Media

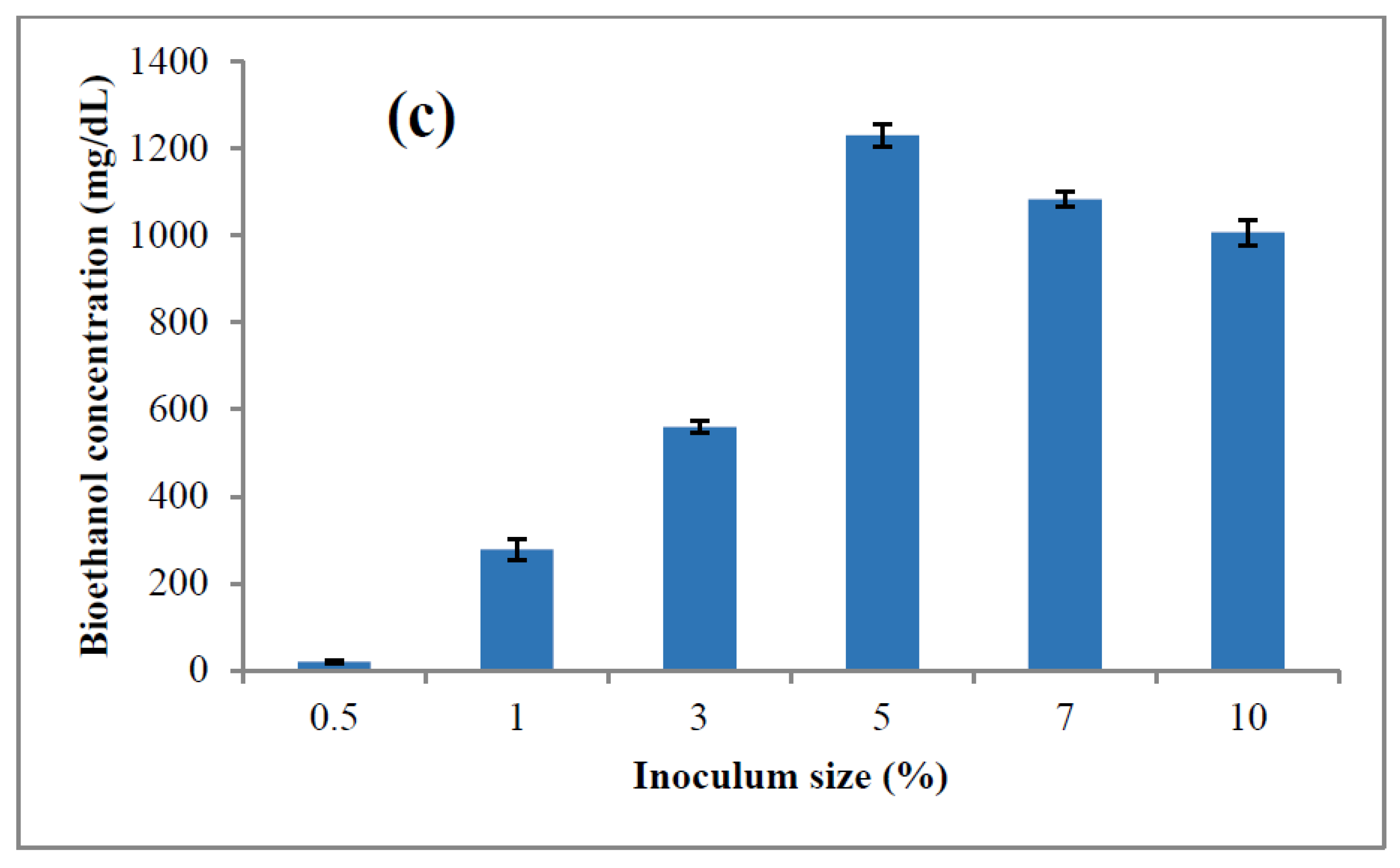

3.10.4. Inoculum Size

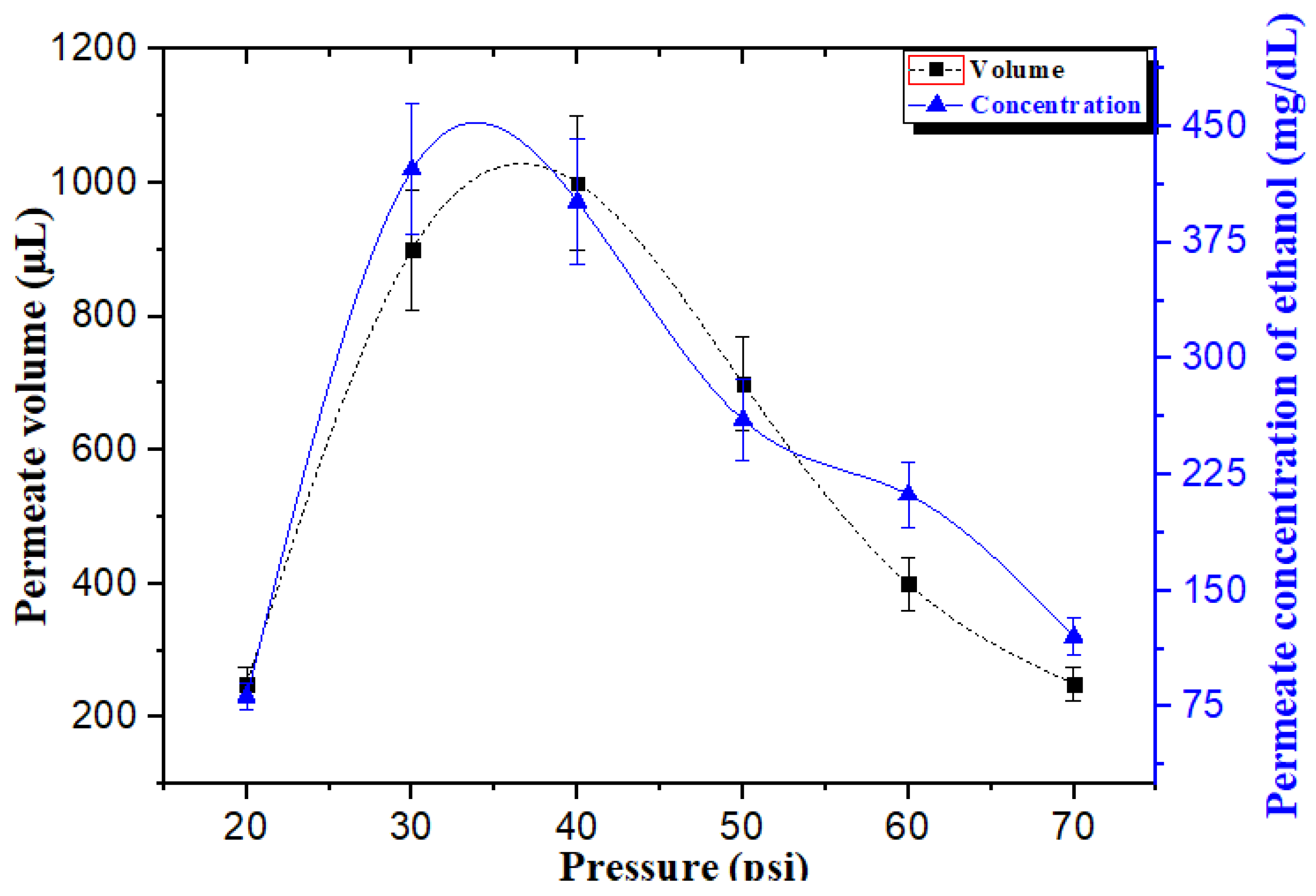

3.11. Bioethanol Separation and Purification

3.11.1. Physico-Chemical Characterization of Polymer Membranes

3.11.2. Water and Ethanol Uptake

3.11.3. Application of the Polymeric Membrane in Ethanol Separation

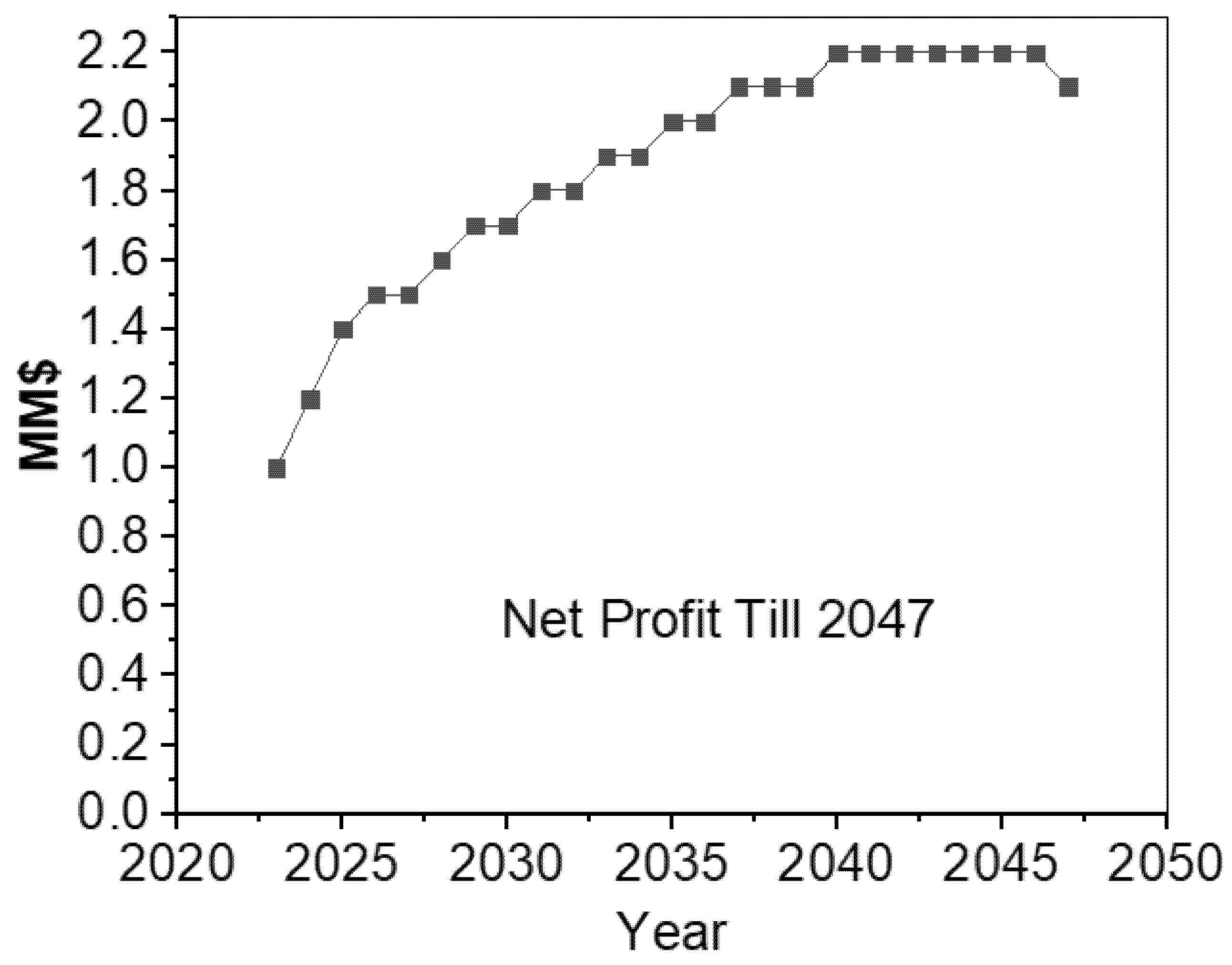

3.12. Techno-Economic Study of Bioethanol Production from Corn Stover

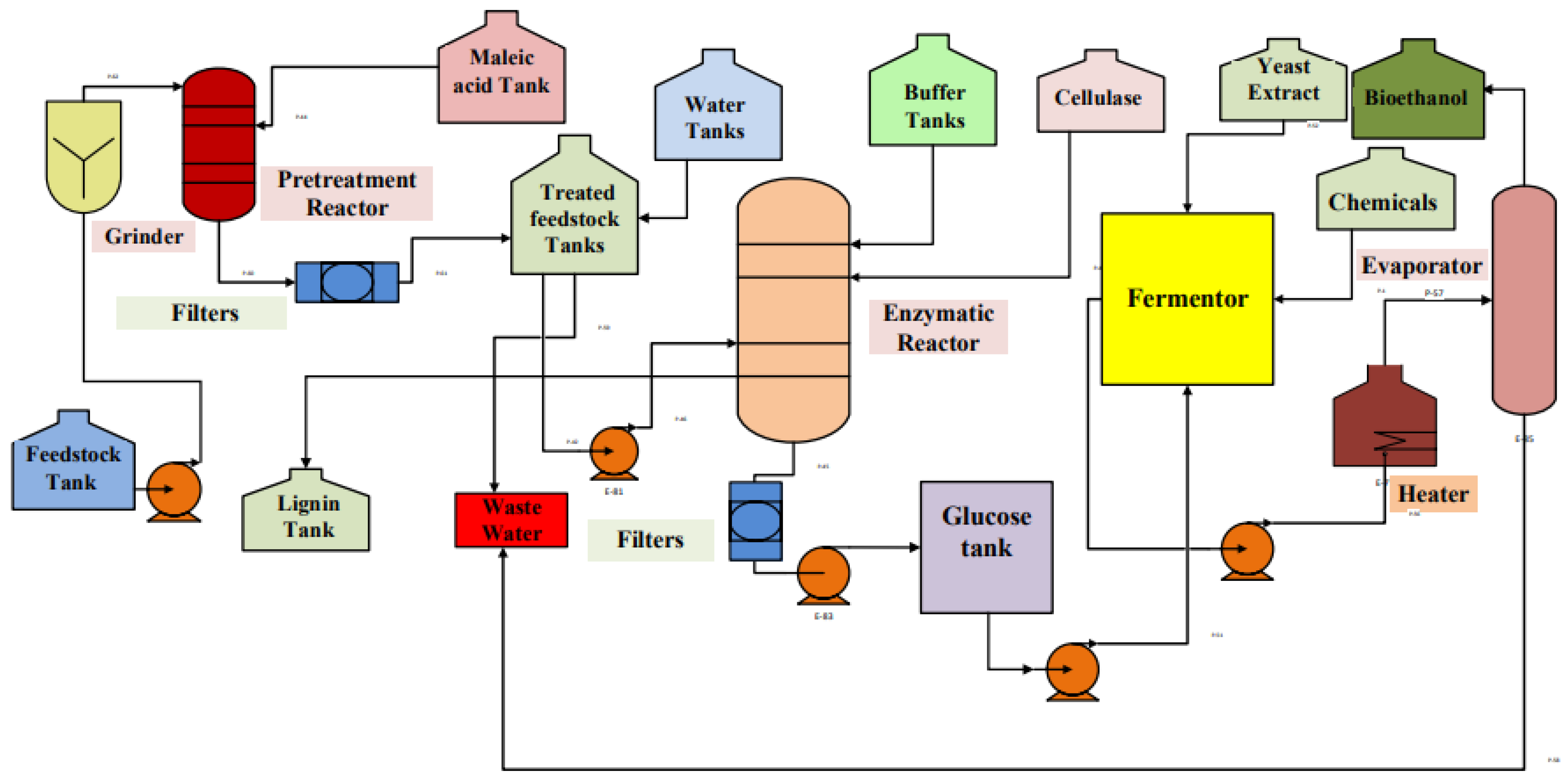

3.12.1. Plant Layout

3.12.2. Equipment LIST

| Treated feedstock processed annually by one reactor | = mass of reactants per batch × number of periods × working days annually = 150 × 330 × 24 = 1,188,000 tons |

| Number of reactors required | = total amount of feedstock/(Treated corn processed annually by one reactor) = 3,120,000/(1,188,000) = 2.6 |

| Treated feedstock processed annually by one reactor | = mass of reactants per batch × number of periods/working days annually = 150 × (330/4) = 12,375 tons |

| Number of reactors required | = total amount of feedstock/(Treated corn processed annually by one reactor) = 3,800,000/(12,375) = 308 |

| Feedstock fermented by one tank annually | = volume of reactants per batch × number of periods/working days annually = 150 × (330/3) = 16,500 tons |

| Number of tanks required | = total amount of feedstock/(Treated corn processed annually by one tank) = 3,800,000/(16,500) = 230 tanks |

3.13. Process Description of the Bioethanol Production

- The feedstock passes through a grinder for milling and sieving. The milled feedstock is pretreated in the reactor in order to react using a solution containing maleic acid (2%) at 120 °C, 45 psi for 1 h.

- In the enzymatic reactor, the biomass incubates with cellulase in the presence of the acetate buffer solution pH 5.0 at 50 °C for 4 days.

- The separated lignin and hemicellulose (a by-product from the enzymatic reactor) are stored in the crude lignin tank and sold for green power generation.

- The produced liquid phase of the glucose is oriented to the fermentation tank to be incubated with the yeast cells and some nutrients, such as potassium di-hydrogen phosphate, magnesium sulfate, and ammonium sulfate. This enhances the fermentation process for 3 days to produce bioethanol broth.

- For bioethanol purification, the produced bioethanol broth passes through heaters to raise the temperature. This enhances the bioethanol separation.

- The final purified bioethanol is withdrawn from the top of the evaporator and stored in the dedicated tanks.

3.14. Design of Cost Estimation Model

3.14.1. Capital Expenditure (CAPEX)

- I.

- Equipment installation cost

- II.

- Instrumentation costs

- III.

- Piping costs

- IV.

- Electrical costs

- V.

- Building and civil costs

- VI.

- Transportation cost

- VII.

- Contingency reserves cost

3.14.2. Operating Expenditure (OPEX)

3.15. Project Indicators

3.16. Practical Implications

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmad, A.; Ismail, S.; Ahmad, I.; Adamu, I.; Jakada, A.; Farouq, I.; Mustapha, U.; Muhammad, U.; Abdullahi, A.; Fagge, A.; et al. Pollutant emissions, renewable energy consumption and economic growth: An empirical review from 2015–2019. J. Environ. Treat. Tech. 2020, 8, 323–335. [Google Scholar]

- Salleh, S.; Gunawan, M.; Bin Zulkarnain, M.; Shamsuddin, A.; Abdullah, T. Modelling and optimization of biomass supply chain for bioenergy production. J. Environ. Treat. Tech. 2019, 7, 689–695. [Google Scholar]

- Bušić, A.; Marđetko, N.; Kundas, S.; Morzak, G.; Belskaya, H.; Šantek, M.; Komes, D.; Novak, S.; Šantek, B. Bioethanol production from renewable raw materials and its separation and purification: A review. Food Technol. Biotechnol. 2018, 56, 289–311. [Google Scholar] [CrossRef]

- Independent Statistics and Analysis, U.S. Energy Information and Administration, Biofuel Explained, Ethanol and Environment. Available online: www.eia.gov/todayinenergy/details.php?id=52380 (accessed on 20 May 2022).

- Jeswani, H.K.; Chilvers, A.; Azapagic, A. Environmental sustainability of biofuels: A review. Proc. R. Soc. A 2020, 476, 20200351. [Google Scholar] [CrossRef]

- Elyamny, S.; Hamdy, A.; Ali, R.; Hamad, H. Role of combined Na2HPO4 and ZnCl2 in the unprecedented catalysis of the sequential pretreatment of sustainable agricultural and agro-industrial wastes in boosting bioethanol production. Int. J. Mol. Sci. 2022, 23, 1777. [Google Scholar] [CrossRef]

- Hassan, M.; Chowdhury, R.; Ghosh, S.; Manna, D.; Pappinen, A.; Kuittinen, S. Energy and environmental impact assessment of Indian rice straw for the production of second-generation bioethanol. Sustain. Energy Technol. Assess. 2021, 47, 101546. [Google Scholar] [CrossRef]

- Behera, S.; Arora, R.; Nandhagopal, N.; Kumar, S. Importance of chemical pretreatment for bioconversion of lignocellulosic biomass. Renew. Sustain. Energy Rev. 2014, 36, 91–106. [Google Scholar] [CrossRef]

- Chen, M.; Zhao, J.; Xia, L. Comparison of four different chemical pretreatments of corn stover for enhancing enzymatic digestibility. Biomass Bioenergy 2009, 33, 1381–1385. [Google Scholar] [CrossRef]

- Tan, H.; Yang, R.; Sun, W.; Wang, S. Peroxide-acetic acid pretreatment to remove bagasse lignin prior to enzymatic hydrolysis. Ind. Eng. Chem. Res. 2010, 49, 1473–1479. [Google Scholar] [CrossRef]

- Hsu, T.-C.; Guo, G.-L.; Chen, W.-H.; Hwang, W.-S. Effect of dilute acid pretreatment of rice straw on structural properties and enzymatic hydrolysis. Bioresour. Technol. 2010, 101, 4907–4913. [Google Scholar] [CrossRef]

- Hamdy, A.; Abd Elhafez, S.; Hamad, H.; Ali, R. The Interplay of Autoclaving with Oxalate as Pretreatment Technique in the View of Bioethanol Production Based on Corn Stover. Polymers 2021, 13, 3762. [Google Scholar] [CrossRef]

- Kootstra, A.M.J.; Beeftink, H.H.; Scott, E.L.; Sanders, J.P.M. Comparison of dilute mineral and organic acid pretreatment for enzymatic hydrolysis of wheat straw. Biochem. Eng. J. 2009, 46, 126–131. [Google Scholar] [CrossRef]

- Qin, L.; Liu, Z.; Li, B.; Dale, B.; Yuan, Y. Bioresource Technology Mass balance and transformation of corn stover by pretreatment with different dilute organic acids. Bioresour. Technol. 2012, 112, 319–326. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, C.; Lin, Q.; Wang, X.; Cheng, B.; Li, H.; Ren, J. Microwave-Assisted Oxalic Acid Pretreatment for the Enhancing of Enzyme Hydrolysis in the Production of Xylose and Arabinose from Bagasse. Molecules 2018, 23, 862. [Google Scholar] [CrossRef] [Green Version]

- Chai, L.; Li, H.; Zheng, X.; Wang, J.; Yang, J.; Lu, J.; Yin, D.; Zhang, Y. Pervaporation separation of ethanol–Water mixtures through B-ZSM-11 zeolite membranes on macroporous supports. J. Membr. Sci. 2015, 491, 168–175. [Google Scholar] [CrossRef]

- Zentou, H.; Abidin, Z.; Yunus, R.; Biak, D.; Issa, M.; Pudza, M. Modelling of mass transfer during pervaporation of ethanol/water mixture using polydimethylsiloxane membrane. Chem. Eng. Res. Des. 2021, 175, 320–329. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Li, Q.; Liu, G.; Liu, G.; Jin, W. Mixed-matrix hollow fiber composite membranes comprising of PEBA and MOF for pervaporation separation of ethanol/water mixtures. Sep. Purif. Technol. 2019, 214, 2–10. [Google Scholar] [CrossRef]

- Ranjithkumar, M.; Uthandi, S.; Kumar, P.; Muniraj, I.; Thanabal, V.; Rajarathinam, R. Highly crystalline cotton spinning wastes utilization: Pretreatment, optimized hydrolysis and fermentation using Pleurotus florida for bioethanol production. Fuel 2022, 308, 122052. [Google Scholar] [CrossRef]

- Singh, Y.; Mahanta, P.; Bora, U. Comprehensive characterization of lignocellulosic biomass through proximate, ultimate and compositional analysis for bioenergy production. Renew. Energy 2017, 103, 490–500. [Google Scholar] [CrossRef]

- Demirbas, A. Combustion characteristics of different biomass fuels. Prog. Energy Combust. Sci. 2004, 30, 216–230. [Google Scholar] [CrossRef]

- Srivastava, H.; Lade, H.; Paul, D.; Arthanareeswaran, G.; Kweon, J. Styrene-based copolymer for polymer membrane modifications. Appl. Sci. 2016, 6, 159. [Google Scholar] [CrossRef]

- Lyu, Q.; Chen, X.; Zhang, Y.; Yu, H.; Han, L.; Xiao, W. One-pot fractionation of corn stover with peracetic acid and maleic acid. Bioresour. Technol. 2021, 320, 124306. [Google Scholar] [CrossRef]

- Prasad, B.; Padhi, R.; Ghosh, G. A review on key pretreatment approaches for lignocellulosic biomass to produce biofuel and value-added products. Int. J. Environ. Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Yusuf, A.; Inambao, F. Characterization of Ugandan biomass wastes as the potential candidates towards bioenergy production. Renew. Sustain. Energy Rev. 2020, 117, 109477. [Google Scholar] [CrossRef]

- Hossain, M.A.; Ganesan, P.B.; Sandaran, S.C.; Rozali, S.B.; Krishnasamy, S. Catalytic microwave pyrolysis of oil palm fiber (OPF) for the biochar production. Environ. Sci. Pollut. Res. 2017, 24, 26521–26533. [Google Scholar] [CrossRef]

- Saldarriaga, J.F.; Aguado, R.; Pablos, A.; Amutio, M.; Olazar, M.; Bilbao, J. Fast characterization of biomass fuels by thermogravimetric analysis (TGA). Fuel 2015, 140, 744–751. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Baloch, H.; Siddiqui, M.; Mubarak, N.; Tunio, M.; Bhutto, A.; Jatoi, A.; Griffin, G.; Srinivasan, M. An overview of microwave hydrothermal carbonization and microwave pyrolysis of biomass. Rev. Environ. Sci. Biotechnol. 2018, 17, 813–837. [Google Scholar] [CrossRef]

- Makul, N.; Fediuk, R.; Amran, M.; Al-Akwaa, M.; Pralat, K.; Nemova, D.; Petropavlovskii, K.; Novichenkova, T.; Petropavlovskaya, V.; Sulman, M. Utilization of Biomass to Ash: An Overview of the Potential Resources for Alternative Energy. Materials 2021, 14, 6482. [Google Scholar] [CrossRef]

- Hassaan, M.A.; Hosny, S.; ElKatory, M.R.; Ali, R.M.; Rangreeze, T.A.; El Nemr, A. Dual action of both green and chemically synthesized zinc oxide nanoparticles: Antibacterial activity and removal of Congo red dye. Desalin. Water Treat. 2021, 218, 423–435. [Google Scholar] [CrossRef]

- Elkatory, M.; Soliman, E.; Hassaan, M.; Ali, R.; Hafez, E.; Ibrahim, H.S.; Hashem, A. Chemical mitigation technology for wax deposition in submarine oil pipeline systems. Egypt. J. Chem. 2021, 64, 5989–5997. [Google Scholar] [CrossRef]

- Bassyouni, D.; Mohamed, M.E.; El-Ashtoukhy, E.; Abd El-Latif, M.; Zaatout, A.; Hamad, H. Fabrication and characterization of electrospun Fe3O4/o-MWCNTs/polyamide 6 hybrid nanofibrous membrane composite as an efficient and recoverable adsorbent for removal of Pb (II). Microchem. J. 2019, 149, 103998. [Google Scholar] [CrossRef]

- Eltarahony, M.; Abu-Serie, M.; Hamad, H.; Zaki, S.; Abd-El-Haleem, D. Unveiling the role of novel biogenic functionalized CuFe hybrid nanocomposites in boosting anticancer, antimicrobial and biosorption activities. Sci. Rep. 2021, 11, 7790. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, W.; Xia, Q.; Guo, B.; Wang, Q.; Liu, S.; Liu, Y.; Li, J.; Yu, H. Efficient cleavage of lignin–carbohydrate complexes and ultrafast extraction of lignin oligomers from wood biomass by microwave-assisted treatment with deep eutectic solvent. Chem. Sus. Chem. 2017, 10, 1692–1700. [Google Scholar] [CrossRef] [Green Version]

- Scelsi, E.; Angelini, A.; Pastore, C. Deep eutectic solvents for the valorisation of lignocellulosic biomasses towards fine chemicals. Biomass 2021, 1, 29–59. [Google Scholar] [CrossRef]

- Banoth, C.; Sunkar, B.; Tondamanati, P.R.; Bhukya, B. Improved physicochemical pretreatment and enzymatic hydrolysis of rice straw for bioethanol production by yeast fermentation. 3 Biotech 2017, 7, 334. [Google Scholar] [CrossRef]

- Singh, R.; Shukla, A.; Tiwari, S.; Monika Srivastava, M. A review on delignification of lignocellulosic biomass for enhancement of ethanol production potential. Renew. Sust. Energ. Rev. 2014, 32, 713–728. [Google Scholar] [CrossRef]

- Kham, L.; Le Bigot, Y.; Delmas, M.; Avignon, G. Delignification of wheat straw using a mixture of carboxylic acids and peroxoacids. Ind. Crop. Prod. 2005, 21, 9–15. [Google Scholar] [CrossRef]

- Saifuddin, N.; Refal, H. Optimization of fermentation parameters for bioethanol production from waste glycerol by microwave induced mutant Escherichia coli. Res. J. Pharm. Biol. Chem. Sci. 2015, 6, 1449–1461. [Google Scholar]

- Periyasamy, S.; Venkatachalam, S.; Ramasamy, S.; Srinivasan, V. Production of bio-ethanol from sugar molasses using Saccharomyces cerevisiae. Mod. Appl. Sci. 2009, 3, 32–37. [Google Scholar] [CrossRef]

- Wong, Y.; Sanggari, V. Bioethanol production from sugarcane bagasse using fermentation process. Orient. J. Chem. 2014, 30, 507–513. [Google Scholar] [CrossRef] [Green Version]

- Hassaan, M.A.; Pantelo, A.; Luigi, T.; Elkatory, M.R.; Ali, R.M.; El Nemr, A. Enhancement of biogas production via green ZnO nanoparticles: Experimental results of selected herbaceous crops. Chem. Eng. Commun. 2021, 208, 242–255. [Google Scholar] [CrossRef]

- Hamadi, A.; Yeddou-Mezenner, N.; Azeddine, L.; Ali, R.M.; Hamd, H. Upgrading of agro-industrial green biomass residues from chocolate industry for adsorption process: Diffusion and mechanistic insights. J. Food Sci. Technol. 2021, 58, 1081–1092. [Google Scholar] [CrossRef]

- Ali, R.M.; Hamad, H.A.; Hussein, M.M.; Malash, G.F. Potential of using green adsorbent of heavy metal removal from aqueous solutions: Adsorption kinetics, isotherm, thermodynamic, mechanism and economic analysis. Ecol. Eng. 2016, 91, 317–332. [Google Scholar] [CrossRef]

- Kamel, D.A.; Farag, H.A.; Amin, N.K.; Zaatout, A.A.; Ali, R.M. Smart utilization of Jatropha (Jatropha curcas Linnaeus) seeds for biodiesel production: Optimization and mechanism. Ind. Crop. Prod. 2018, 111, 407–413. [Google Scholar] [CrossRef]

- Sindhu, K.P.; Abdul Majeed, S.S.M.; Shahitha Parveen, J. PEO/PMMA Solid Nanocomposite Polyelectrolyte with Enhanced Ionic Conductivity and Promising Dielectric Properties. J. Electron. Mater. 2021, 50, 6654–6666. [Google Scholar] [CrossRef]

- Ali, R.M.; Hassaan, M.A.; Elkatory, M.R. Towards potential removal of malachite green from wastewater: Adsorption process optimization and prediction. MSF 2020, 1008, 213–221. [Google Scholar] [CrossRef]

- Eldin, M.M.; Elaassar, M.; Elzatahry, A.; Al-Sabah, M. Poly (acrylonitrile-co-methyl methacrylate) nanoparticles: I. Preparation and characterization. Arab. J. Chem. 2017, 10, 1153–1166. [Google Scholar]

- Rao, M.; Liu, J.; Li, W.; Liang, Y.; Liao, Y.; Zhao, L. Performance improvement of poly (acrylonitrile-vinyl acetate) by activation of poly (methyl methacrylate). J. Power Source 2009, 189, 711–715. [Google Scholar] [CrossRef]

- Rahimalimamaghani, A.; Tanaka, D.; Tanco, M.; D’Angelo, F.; Gallucc, F. New hydrophilic carbon molecular sieve membranes for bioethanol dehydration via pervaporation. Chem. Eng. J. 2022, 435, 134891. [Google Scholar] [CrossRef]

- Abu-Saied, M.; Taha, T.H.; Elnaggar, E.M.; Amer, R.A.; Mansy, A.; Elkady, G.M. Green production of bio-ethanol from cellulosic fiber waste and its separation using polyacrylonitrile-co-poly methyl acrylate membrane. Cellulose 2018, 25, 6621–6644. [Google Scholar] [CrossRef]

- De Paola, M.G.; Mazza, I.; Paletta, R.; Lopresto, C.G.; Calabrò, V. Small-Scale Biodiesel Production Plants—An Overview. Energies 2021, 14, 1901. [Google Scholar] [CrossRef]

- Elgharbawy, A.S.; Sadik, W.A.; Sadek, O.M.; Kasaby, M.A. Glycerolysis treatment to enhance biodiesel production from low-quality feedstocks. Fuel 2021, 284, 118970. [Google Scholar] [CrossRef]

- Elgharbawy, A.S.; Sadik, W.A.; Sadek, O.M.; Kasaby, M.A. Maximizing biodiesel production from high free fatty acids feedstocks through glycerolysis treatment. Biomass Bioenergy 2021, 146, 105997. [Google Scholar] [CrossRef]

- Elgharbawy, A.; Sayed, A. A review on natural gas previous, current and forecasting prices and demand. JPME 2020, 22, 61–64. [Google Scholar] [CrossRef]

- Deo, P. Fixed Asset Management-Revisited. J. Account. Finance 2021, 21, 2158–3625. [Google Scholar]

- Cano, P.I.; Colon, J.; Ramirez, M.; Lafuente, J.; Gabriel, D.; Cantero, D. Life cycle assessment of different physical-chemical and biological technologies for biogas desulfurization in sewage treatment plants. J. Clean Prod. 2018, 181, 663–674. [Google Scholar] [CrossRef]

- Santana, G.; Martins, P.; Da Silva, N.D.L.; Batistella, C.; Maciel Filho, R.; Maciel, M.W. Simulation and cost estimate for biodiesel production using castor oil. Chem. Eng. Res. Des. 2010, 88, 626–632. [Google Scholar] [CrossRef]

- Yuan, T.; Xiang, P.; Li, H.; Zhang, L. Identification of the main risks for international rail construction projects based on the effects of cost-estimating risks. J. Clean Prod. 2020, 274, 122904. [Google Scholar] [CrossRef]

- Streimikiene, D.; Baležentis, T.; Baležentienė, L. Comparative assessment of road transport technologies. Renew. Sustain. Energy Rev. 2013, 20, 611–618. [Google Scholar] [CrossRef]

- Ioannou, A.; Angus, A.; Brennan, F. Stochastic prediction of offshore wind farm LCOE through an integrated cost model. Energy Procedia 2017, 107, 383–389. [Google Scholar] [CrossRef]

- Gnanaprakasam, A.; Sivakumar, V.M.; Surendhar, A.; Thirumarimurugan, M.; Kannadasan, T. Recent strategy of biodiesel production from waste cooking oil and process influencing parameters: A review. J. Energy 2013, 2013, 926392. [Google Scholar] [CrossRef] [Green Version]

- Campbell, R.M.; Anderson, N.M.; Daugaard, D.E.; Naughton, H.T. Financial viability of biofuel and biochar production from forest biomass in the face of market price volatility and uncertainty. Appl. Energy 2018, 230, 330–343. [Google Scholar] [CrossRef]

- Available online: https://www.trade.gov/country-commercial-guides/egypt-renewable-energy (accessed on 15 May 2022).

- Available online: https://knoema.com/atlas/Egypt/topics/Energy/Oil/Exports-of-crude-oil (accessed on 15 May 2022).

- Yusuf, A.A.; Inambao, F.L. Progress in alcohol-gasoline blends and their effects on the performance and emissions in SI engines under different operating conditions. Int. J. Ambient Energy 2018, 42, 465–481. [Google Scholar] [CrossRef]

| Sample Code | Solid Recovery, % | Hemicellulose Removal, % | Cellulose Recovery, % | Lignin Removal, % |

|---|---|---|---|---|

| CS | - | - | - | - |

| CSM | 60 | 45.22 | 98.15 | 52.84 |

| CSO | 60 | 33.74 | 89.6 | 40 |

| CSS | 83 | 0.04 | 99.64 | 26.08 |

| CSL | 81.5 | 0.07 | 98.92 | 17.49 |

| Samples | Proximate Analysis | Ultimate Analysis | HHV (MJ·kg−1) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MC | VM | Ash | FC | C | H | N | O | S | ||

| (wt%) | (wt%) | |||||||||

| CS | 10.09 | 70.63 | 2.2 | 17.08 | 35.36 | 5.32 | 0.26 | 58.44 | 0.62 | 13.11 |

| CSM | 8.05 | 83.63 | 2.0 | 6.32 | 37.42 | 5.39 | 0.26 | 56.86 | 0.07 | 13.38 |

| No. | Equipment | Uses |

|---|---|---|

| 1 | Plastic Tanks | Plastic tanks will be used for the enzymatic process, fermentation process, and the storage of feedstocks, methanol, distilled water, chemicals, and bioethanol. |

| 2 | Reactor | The reactors are usually cylindrical and with a vertical axis. The top of the reactor is closed to prevent air from entering the reaction. |

| 3 | Heat exchanger | The heat exchanger is used for heat recovery. Therefore, there will be two heat exchangers in service. |

| 4 | Pumps | The pump will be used to transfer the streams to the required destination. |

| 5 | Filters | The filters remove the solid biomass from the liquid after the enzymatic process. There will be 10 filters in the whole process. |

| 6 | Grinder | The grinder will be used to grind the feedstock to small particles. |

| 7 | Heaters | The heaters are used to heat the liquid to the required temperature. A thermal oil heater type is used in the study. There will be three heaters in the whole process, two in service, and one standby. |

| No. | Equipment | No. | Price/Unit | Price (USD) |

|---|---|---|---|---|

| 1 | Tanks (including storage and separator tanks) | 300 | 1500 | 450,000 |

| 2 | Evaporator | 2 | 20,000 | 40,000 |

| 3 | Heat exchanger | 2 | 15,000 | 30,000 |

| 4 | Pumps | 5 | 5000 | 25,000 |

| 5 | Filters | 10 | 2000 | 20,000 |

| 7 | Batched stirred reactor (150 tons) | 311 | 10,000 | 3,110,000 |

| 8 | Miller/grinder | 3 | 8000 | 24,000 |

| 9 | Heaters | 3 | 20,000 | 60,000 |

| Total PEC: 3,609,000 | ||||

| Item | Percentage | Price (USD) |

|---|---|---|

| Piping | 0.66 | 897,250 |

| Building | 0.25 | 358,900 |

| Civil | 0.1 | 717,800 |

| Instrumentation | 0.2 | 394,790 |

| Electrical | 0.11 | 897,250 |

| Installation | 0.35 | 1,256,150 |

| Soft cost (license fees, financing fees) | 0.2 | 717,800 |

| Transportation | 0.15 | 538,350 |

| Contingency | 0.1 | 358,900 |

| Total related PEC | 7,651,080 |

| Item | Value (USD Million) |

|---|---|

| PEC | 3.6 |

| Related PEC | 7.6 |

| Total CAPEX | 11.2 |

| Item | Percentage of PIC |

|---|---|

| Maintenance | 10 |

| Insurance | 3 |

| Administration | 15 |

| Depreciation | 10 |

| Item | KTA |

|---|---|

| Input products | |

| Corn feedstock | 312.5 |

| Remaining Solid Mass | 190 |

| Malic acid | 31.3 |

| Cellulase | 50.7 |

| S. Cerevisiae cells | 22.1 |

| Acetic Acid | 28.4 |

| Sodium Acetate | 9.5 |

| Potassium dihydrogen phosphate (KH2PO4) | 1.9 |

| Ammonium sulfate | 9.5 |

| Magnesium sulfate | 0.9 |

| Yeast extract | 1.9 |

| Output products | |

| Lignin | 79 |

| Bioethanol Yield | 37.5 |

| NPV (USD million) | 3.35 |

| Payback (years) | 8 |

| IRR | 13% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

AbdElhafez, S.E.; Taha, T.; Mansy, A.E.; El-Desouky, E.; Abu-Saied, M.A.; Eltaher, K.; Hamdy, A.; El Fawal, G.; Gamal, A.; Hashim, A.M.; et al. Experimental Optimization with the Emphasis on Techno-Economic Analysis of Production and Purification of High Value-Added Bioethanol from Sustainable Corn Stover. Energies 2022, 15, 6131. https://doi.org/10.3390/en15176131

AbdElhafez SE, Taha T, Mansy AE, El-Desouky E, Abu-Saied MA, Eltaher K, Hamdy A, El Fawal G, Gamal A, Hashim AM, et al. Experimental Optimization with the Emphasis on Techno-Economic Analysis of Production and Purification of High Value-Added Bioethanol from Sustainable Corn Stover. Energies. 2022; 15(17):6131. https://doi.org/10.3390/en15176131

Chicago/Turabian StyleAbdElhafez, Sara E., Tarek Taha, Ahmed E. Mansy, Eman El-Desouky, Mohamed A. Abu-Saied, Khloud Eltaher, Ali Hamdy, Gomaa El Fawal, Amr Gamal, Aly M. Hashim, and et al. 2022. "Experimental Optimization with the Emphasis on Techno-Economic Analysis of Production and Purification of High Value-Added Bioethanol from Sustainable Corn Stover" Energies 15, no. 17: 6131. https://doi.org/10.3390/en15176131

APA StyleAbdElhafez, S. E., Taha, T., Mansy, A. E., El-Desouky, E., Abu-Saied, M. A., Eltaher, K., Hamdy, A., El Fawal, G., Gamal, A., Hashim, A. M., Elgharbawy, A. S., El-Latif, M. M. A., Hamad, H., & Ali, R. M. (2022). Experimental Optimization with the Emphasis on Techno-Economic Analysis of Production and Purification of High Value-Added Bioethanol from Sustainable Corn Stover. Energies, 15(17), 6131. https://doi.org/10.3390/en15176131