Framework for Optimized Analysis of Waste Bioenergy Projects

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bibliometric Review

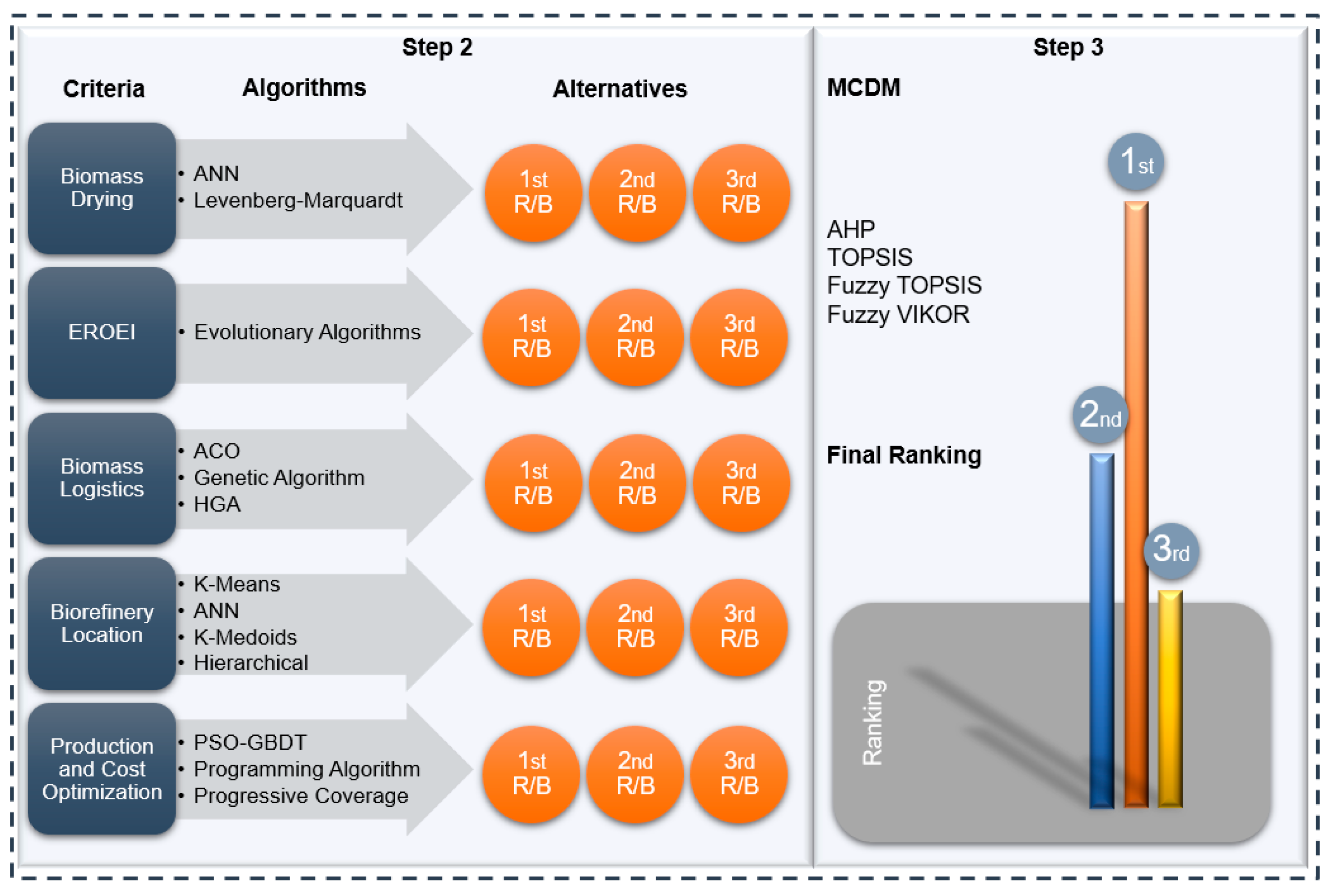

2.2. Composition of the Analysis Framework Review

3. Results and Discussion

- Phase 1: Biomass and Region Assessment.

- Phase 2: Construction or Retrofit of Biorefinery Units.

- AHP is based on the use of pairwise comparisons, both to estimate criteria weights and to compare alternatives against decision criteria. On the other hand, it has a higher computational cost compared to other methods [44];

- TOPSIS is based on an aggregation function that represents the proximity of reference points. It addresses an MCDM problem considering that the optimal alternative must have the shortest distance from the ideal solution and the longest distance from the anti-ideal [44];

- VIKOR is a multi-criteria decision method based on the commitment to the solution, that is, obtaining a satisfactory solution closer to the ideal solution to the problem [44];

- Fuzzy numbers, or more precisely Fuzzy Sets, are represented by sets whose limits are not precise: an element presents a degree of membership about the set [44].

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Authors | Year/Ref. | Technique | Application |

|---|---|---|---|

| Ayoub et al. | 2009/[31] | Genetic Algorithm (GA) | Integrates the bioenergy supply chain. As a result of the development of the bioeconomy, the extension of the life of natural resources has been allowed, reducing the environmental burden and providing a better human living condition, besides adding value to products thanks to the use of waste. |

| Zhu and Yao | 2011/[23] | Mixed Integer Linear Programming (MILP) | The model, produced as mixed-integer linear programming, determined the storage locations, the number of people for the harvest team, and the quantity and type of biomass harvested for purchase, storage, and processing each month. It has proven that there are advantages to using various kinds of biomass raw materials rather than working with just one type. In addition, it analyzed the relationship between the supply capacity of biomass raw material with the production and the cost of biofuel. |

| Muth Jr. et al. | 2012/[36] | Scheduling Algorithm | Optimization of the biomass collection process. In addition to including geoprocessing tools and integration of different spatial scales of data. |

| Chen and Fan | 2012/[37] | Progressive Coverage Algorithm | Optimizes the ethanol production chain, focusing on cost reduction. Through the proposed model, it was possible to conclude that bio-waste-based is as an alternative solution for the sustainable energy of the future. |

| Ren et al. | 2013/[49] | Design the most sustainable bioethanol supply chain | Design of a more sustainable bioethanol supply chain. The proposed method studied several ethanol raw material systems, thus finding the best solution to obtain an ecological footprint. |

| Kaundinya et al. | 2013/[42] | K-Medoids | This method divides the entire region into clusters and locates the biomass energy generation systems in the medoids. A Geographical Information System (GIS) map has represented the results of the clusters. |

| Velázquez-Martí et al. | 2013/[27] | Dendrometric Algorithm | The model calculates the estimated biomass generation. From the regression equations and the dendrometric characteristics of the trees, it was possible to assume the biomass available per tree and hectare. From the results of these equations, it is possible to implement GIS maps and estimate the amount of biomass generated in each area. |

| Authors | Year/Ref. | Technique | Application |

|---|---|---|---|

| Gracia et al. | 2014/[18] | Hybrid Genetic Algorithm—HGA | Responsible for optimizing logistics to route equipment and collect agricultural waste. A real case study was developed through a hybrid approach based on genetic algorithms and local search methods. With the application of algorithms from the industrial engineering domain, results have been obtained that show a significant improvement in operational efficiency. |

| Velázquez-Martí et al. | 2014/[19] | Dendrometric Algorithm | It estimated the volume of biomass in an olive orchard. Correlated productivity and fruit quality, the quantity of residual pruning biomass with Light Detection and Ranging (LIDAR) data obtained an efficient and accurate method to predict biomass. |

| Muir et al. | 2015/[50] | 14C flue gas analysis by accelerator mass spectrometry (AMS) and liquid scintillation counting (LSC). | Defined the biomass fraction of mixed waste located in an operational energy-from-waste plant. Concluded that 14Ctechniques are advantageous for data acquisition and the accuracy and reliability of the electricity generator and industry regulator. |

| Casanova-Peláez et al. | 2015/[20] | Artificial Neural Network (ANN) and Levenberg-Marquardt Algorithm | It optimized the process of drying and transporting biomass. It was defined that ANN is the most appropriate method to get a mathematical function for CO drying kinetics and to open new perspectives for the use of waste as energy. |

| Enitan et al. | 2017/[30] | Computational Optimization Methods | Distinct approach models to improve the anaerobic digestion processes. Optimization strategies and controls were performed for advanced actor performance and biogas production through evolutionary algorithms. |

| Zamar et al. | 2017/[21] | Evolutionary Algorithm | Responsible for optimizing the biomass transportation logistics. With this, a stochastic vehicle routing problem was solved by a combination of scenario analysis and heuristics. The performance of the proposed model revealed approximately 6 GJ energy savings compared to the reference method. |

| Authors | Year/Ref. | Technique | Application |

|---|---|---|---|

| Matindi et al. | 2018/[22] | Optimization Algorithm LDS | Work developed to optimize the logistics of biomass transportation. In this study, the Bounden Discrepancy Search algorithm was adapted with the integration of other algorithms developed for scalable transport. The algorithms were encoded using the Optimization Programming Language (OPL) to optimize the transportation time of sugarcane and its residues. |

| Cui et al. | 2018/[34] | K-Means | Used to point out potential sites for the installation of biodigestion plants based on the analysis of biomass availability in a given region. The results showed that, by converting 10% of pasture and agricultural land to sorghum, about 37% of the 214 existing corn ethanol biorefineries could be adapted or expanded to work with cellulosic feedstocks and that additional 71 new biorefineries could be built. |

| Babazadeh et al. | 2019/[17] | Benders Decomposition Algorithm (BDA) | Applied to perform the projection of a supply network for second generation biodiesel production. The efficiency of the accelerated decomposition algorithm and the performance of the proposed programming model were validated through a computational analysis using data from a real case in Iran. |

| Zhao and You | 2019/[25] | Global Optimization Algorithm | The use of this algorithm aimed to evaluate the effectiveness of the implementation of incentive policies for the generation of bioenergy. The applicability of the proposed model was validated through a case study that aimed to monitor the rate of adoption of biodigesters in dairy farms in the state of New York. The results obtained showed the effectiveness of public policies in promoting bioelectricity. |

| Sarker et al. | 2019/[32] | Genetic Algorithm—GA | Optimization of the supply chain for biomethane production. The application of this algorithm allowed the resolution of representative problems in an efficient way and with better quality when compared to other solutions found in the market. |

| Khishtandar | 2019/[39] | Hybrid Genetic Algorithm—HGA | Employed to design the formation of a supply network for biogas production. The results indicated that the proposed algorithm effectively contributes to solving the biogas plant location allocation model within an interesting computational time. |

| Chakraborty et al. | 2019/[28] | Random Forest Algorithm | Estimate of bioenergy generation potential from surplus crop residues. The mapping results, which can be used for planning public policies, indicated the type and quantity of surplus waste that can be used as inputs for bioenergy generation in each region of India. |

| Authors | Year/Ref. | Technique | Application |

|---|---|---|---|

| Kokkinos et al. | 2020/[46] | Analysis and Optimization Algorithms | Analysis of all social actors involved to assess the impacts of the use of biowaste for the energy transition. A decision-making tool was presented that uses optimization algorithms to guide the involved actors on aspects related to sustainable energy transition towards decarbonization. |

| Yu et al. | 2020/[35] | Particle Swarm Optimization and Gradient Boosting Decision Tree (PSOGBDT) Algorithm | Optimization of energy production through the combined pyrolysis of agricultural residues and sludge from the pharmaceutical industry. The results contributed to evaluate the behavior of the mixture at different heating rates, to the optimization and to increase the efficiency of the bioenergy production system. |

| Geng et al. | 2020/[51] | Clustering Algorithm | The application of the algorithm in this process aimed to assist the projection and optimization of a biodiesel supply chain and to identify the best location for the installation of a biorefinery to produce this resource. The results indicated that the optimization of the chain can contribute significantly to increase biodiesel production and reduce costs. In relation to the installation site of the plant, the model results showed that the current location is the most appropriate because of the large supply of inputs and low transportation costs. |

| Gorokhova et al. | 2020/[47] | Bioeconomy Support Algorithm | Development and strengthening of bioenergy projects in Ukraine. The research results showed that bioeconomy development can contribute to the diversification of the local economy, to the development of renewable commodities, to the strengthening of territories and regions, and to the extension of the life span of natural resources. |

| De Jesus et al. | 2021/[29] | Multicriteria—GIS | Development and application of a methodology that enables the identification of suitable locations for the implantation of biodigesters. The results showed that the definition of biodigesters’ location is a fundamental step for the project’s viability, since, in addition to meeting environmental issues and legal requirements, it directly influences issues related to biomass transport costs. |

| De Jesus et al. | 2021/[43] | Agglomerative hierarchical algorithm/multi criteria analysis/(GIS) | Identification of opportunities to create strategic partnerships for the generation of bioenergy. The results, obtained through a case study, showed that it is perfectly viable to build clusters to produce bioenergy using geographic coordinates of raw material suppliers and the volume of biomass residues supplied by each actor. In addition, with the input of environmental, economic, social, and legal criteria and requirements, it is also possible to identify the best location for installing the biodigesters. |

| Geng and Sun | 2021/[33] | Genetic Algorithm—NSGAII | Optimization of the biodiesel supply chain. The efficiency of the method and the optimal solution were verified by a case study. |

| Lomazov et al. | 2021/[45] | Genetic Algorithm—GA | Optimization of construction costs for a biogas plant. The use of evolutionary algorithms in this process aims, together with other classic tools and methods, to optimize the construction steps of a bioenergy generation plant. The research results showed the development of a mathematical model that contributes to increase the efficiency of the system and that provides a reduction in the construction costs of a biogas plant. |

References

- Rodias, E.; Aivazidou, E.; Achillas, C.; Aidonis, D.; Bochtis, D. Waterenergy-nutrients synergies in the agrifood sector: A circular economy framework. Energies 2021, 14, 159. [Google Scholar] [CrossRef]

- Diamantis, V.; Eftaxias, A.; Stamatelatou, K.; Noutsopoulos, C.; Vlachokostas, C.; Aivasidis, A. Bioenergy in the era of circular economy: Anaerobic digestion technological solutions to produce biogas from lipid-rich wastes. Renew. Energy 2020, 168, 438–447. [Google Scholar] [CrossRef]

- Molina-Moreno, V.; Leyva-Díaz, J.C.; Llorens-Montes, F.J.; Cortés-García, F.J. Design of Indicators of Circular Economy as Instruments for the Evaluation of Sustainability and Efficiency in Wastewater from Pig Farming Industry. Water 2017, 9, 653. [Google Scholar] [CrossRef]

- Li, L.; Li, X.; Chong, C.; Wang, C.-H.; Wang, X. A decision support framework for the design and operation of sustainable urban farming systems. J. Clean. Prod. 2020, 268, 121928. [Google Scholar] [CrossRef]

- Fisher, O.J.; Watson, N.J.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Multiple target data-driven models to enable sustainable process manufacturing: An industrial bioprocess case study. J. Clean. Prod. 2021, 296, 126242. [Google Scholar] [CrossRef]

- Mirkouei, A.; Haapala, K.R.; Sessions, J.; Murthy, G.S. A mixed biomass-based energy supply chain for enhancing economic and environmental sustainability benefits: A multi-criteria decision making framework. Appl. Energy 2017, 206, 1088–1101. [Google Scholar] [CrossRef]

- Scott, J.A.; Ho, W.; Dey, P.K. A review of multi-criteria decision-making methods for bioenergy systems. Energy 2012, 42, 146–156. [Google Scholar] [CrossRef] [Green Version]

- Shen, Y.; Zhao, P.; Shao, Q.; Takahashi, F.; Yoshikawa, K. In situ catalytic conversion of tar using rice husk char/ash supported nickel–iron catalysts for biomass pyrolytic gasification combined with the mixing-simulation in fluidized-bed gasifier. Appl. Energy 2015, 160, 808–819. [Google Scholar] [CrossRef]

- World Bioenergy Association. Statistics; World Bioenergy Association: Stockholm, Sweden, 2019. [Google Scholar]

- Hagman, L.; Blumenthal, A.; Eklund, M.; Svensson, N. The role of biogas solutions in sustainable biorefineries. J. Clean. Prod. 2018, 172, 3982–3989. [Google Scholar] [CrossRef] [Green Version]

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- Souza, G.M.; Ballester, M.V.R.; de Brito Cruz, C.H.; Chum, H.; Dale, B.; Dale, V.H.; Fernandes, E.C.; Foust, T.; Karp, A.; Lynd, L.; et al. The role of bioenergy in a climate-changing world. Environ. Dev. 2017, 23, 57–64. [Google Scholar] [CrossRef]

- Castillo-Villar, K.K. Metaheuristic Algorithms Applied to Bioenergy Supply Chain Problems: Theory, Review, Challenges, and Future. Energies 2014, 7, 7640–7672. [Google Scholar] [CrossRef] [Green Version]

- Thran, D.; Bauschmann, M.; Dahmen, N.; Erlach, B.; Heinbach, K.; Hirschl, B.; Hildebrand, J.; Rau, I.; Majer, S.; Oehmichen, K.; et al. Bioenergy beyond the german “energiewende”–assessment framework for integrated bioenergy strategies. Biomass Bioenergy 2020, 142, 105769. [Google Scholar] [CrossRef]

- Wu, Y.; Yan, Y.; Wang, S.; Liu, F.; Xu, C.; Zhang, T. Study on locationdecision framework of agroforestry biomass cogeneration project: A case of china. Biomass Bioenergy 2019, 127, 105289. [Google Scholar] [CrossRef]

- Maccarini, A.; Bessa, M.; Errera, M. Energy valuation of urban pruning residues feasibility assessment. Biomass Bioenergy 2020, 142, 105763. [Google Scholar] [CrossRef]

- Babazadeh, R.; Ghaderi, H.; Pishvaee, M.S. A benders-local branching algorithm for second-generation biodiesel supply chain network design under epistemic uncertainty. Comput. Chem. Eng. 2019, 124, 364–380. [Google Scholar] [CrossRef] [Green Version]

- Gracia, C.; Marti, B.V.; Estornell, J. An application of the vehicle routing problem to biomass transportation. Biosyst. Eng. 2014, 124, 40–52. [Google Scholar] [CrossRef]

- Marti, B.V.; Cortés, I.L.; Salazar-Hernández, D.M. Dendrometric analysis of olive trees for wood biomass quantification in Mediterranean orchards. Agrofor. Syst. 2014, 88, 755–765. [Google Scholar] [CrossRef]

- Casanova-Peláez, P.J.; Palomar-Carnicero, J.M.; Manzano-Agugliaro, F.; Cruz-Peragón, F. Olive cake improvement for bioenergy: The drying kinetics. Int. J. Green Energy 2015, 12, 559–569. [Google Scholar] [CrossRef]

- Zamar, D.S.; Gopaluni, B.; Sokhansanj, S. Optimization of sawmill residues collection for bioenergy production. Appl. Energy 2017, 202, 487–495. [Google Scholar] [CrossRef]

- Matindi, R.; Masoud, M.; Hobson, P.; Kent, G.; Liu, S.Q. Harvesting and transport operations to optimise biomass supply chain and industrial biorefinery processes. Int. J. Ind. Eng. Comput. 2018, 9, 265–288. [Google Scholar] [CrossRef]

- Zhu, X.; Yao, Q. Logistics system design for biomass-to-bioenergy industry with multiple types of feedstocks. Bioresour. Technol. 2011, 102, 10936–10945. [Google Scholar] [CrossRef] [PubMed]

- Plessen, M.G. GPU-accelerated logistics optimisation for biomass production with multiple simultaneous harvesters tours, fields and plants. Biomass Bioenergy 2020, 141, 105650. [Google Scholar] [CrossRef]

- Zhao, N.; You, F. Dairy waste-to-energy incentive policy design using Stackelberg-game-based modeling and optimization. Appl. Energy 2019, 254, 113701. [Google Scholar] [CrossRef]

- Pagani, R.N.; Kovaleski, J.; Resende, L.M. Methodi Ordinatio: A proposed methodology to select and rank relevant scientific papers encompassing the impact factor, number of citation, and year of publication. Scientometrics 2015, 105, 2109–2135. [Google Scholar] [CrossRef]

- Velázquez-Martí, B.; González, E.F.; Cortés, I.L.; Callejón-Ferre, A. Prediction and evaluation of biomass obtained from citrus trees pruning. J. Food Agric. Environ. 2013, 11, 1485–1494. [Google Scholar]

- Chakraborty, A.; Biswal, A.; Pandey, V.; Murthy, C.S.; Rao, P.V.N.; Chowdhury, S. Spatial disaggregation of the bioenergy potential from crop residues using geospatial technique. ISPRS—Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2019, 42, 369–375. [Google Scholar] [CrossRef] [Green Version]

- De Jesus, R.H.G.; de Souza, J.T.; Puglieri, F.N.; Piekarski, C.M.; de Francisco, A.C. Biodigester location problems, its economic–environmental–social aspects and techniques: Areas yet to be explored. Energy Rep. 2021, 7, 3998–4008. [Google Scholar] [CrossRef]

- Enitan, A.; Adeyemo, J.; Swalaha, F.M.; Kumari, S.; Bux, F. Optimization of biogas generation using anaerobic digestion models and computational intelligence approaches. Rev. Chem. Eng. 2017, 33, 309–335. [Google Scholar] [CrossRef]

- Ayoub, N.; Elmoshi, E.; Seki, H.; Naka, Y. Evolutionary algorithms approach for integrated bioenergy supply chains optimization. Energy Convers. Manag. 2009, 50, 2944–2955. [Google Scholar] [CrossRef]

- Sarker, B.R.; Wu, B.; Paudel, K.P. Modeling and optimization of a supply chain of renewable biomass and biogas: Processing plant location. Appl. Energy 2019, 239, 343–355. [Google Scholar] [CrossRef]

- Geng, N.; Sun, Y. Multiobjective Optimization of Sustainable WCO for Biodiesel Supply Chain Network Design. Discrete Dyn. Nat. Soc. 2021, 2021, 6640358. [Google Scholar] [CrossRef]

- Cui, X.; Kavvada, O.; Huntington, T.; Scown, C.D. Strategies for near-term scale-up of cellulosic biofuel production using sorghum and crop residues in the US. Environ. Res. Lett. 2018, 13, 124002. [Google Scholar] [CrossRef]

- Yu, Z.; Yousaf, K.; Ahmad, M.; Yousaf, M.; Gao, Q.; Chen, K. Efficient pyrolysis of ginkgo biloba leaf residue and pharmaceutical sludge (mixture) with high production of clean energy: Process optimization by particle swarm optimization and gradient boosting decision tree algorithm. Bioresour. Technol. 2020, 304, 123020. [Google Scholar] [CrossRef] [PubMed]

- Muth, D.; Koch, J.; McCorkle, D.; Bryden, K. A Computational Strategy for Design and Implementation of Equipment That Addresses Sustainable Agricultural Residue Removal at the Subfield Scale. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference; American Society of Mechanical Engineers: New York, NY, USA, 2012; Volume 45011, pp. 1287–1294. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.-W.; Fan, Y. Bioethanol supply chain system planning under supply and demand uncertainties. Transp. Res. Part E—Logist. Transp. Rev. 2012, 48, 150–164. [Google Scholar] [CrossRef]

- Andrade, R.O.; Yoo, S.G. A Comprehensive Study of the Use of LoRa in the Development of Smart Cities. Appl. Sci. 2019, 9, 4753. [Google Scholar] [CrossRef] [Green Version]

- Khishtandar, S. Simulation based evolutionary algorithms for fuzzy chance-constrained biogas supply chain design. Appl. Energy 2018, 236, 183–195. [Google Scholar] [CrossRef]

- Naso, D.; Turchiano, B.; Meloni, C. Single and Multi-objective Evolutionary Algorithms for the Coordination of Serial Manufacturing Operations. J. Intell. Manuf. 2006, 17, 251–270. [Google Scholar] [CrossRef]

- Abrishambaf, O.; Faria, P.; Vale, Z.; Corchado, J.M. Energy scheduling using decision trees and emulation: Agriculture irrigation with run-ofthe-river hydroelectricity and a pv case study. Energies 2019, 12, 3987. [Google Scholar] [CrossRef] [Green Version]

- Kaundinya, D.P.; Balachandra, P.; Ravindranath, N.; Ashok, V. A GIS (geographical information system)-based spatial data mining approach for optimal location and capacity planning of distributed biomass power generation facilities: A case study of Tumkur district, India. Energy 2013, 52, 77–88. [Google Scholar] [CrossRef]

- De Jesus, R.H.G.; Barros, M.V.; Salvador, R.; de Souza, J.T.; Piekarski, C.M.; de Francisco, A.C. Forming clusters based on strategic partnerships and circular economy for biogas production: A gis analysis for optimal location. Biomass Bioenergy 2021, 150, 106097. [Google Scholar] [CrossRef]

- Mulliner, E.; Malys, N.; Maliene, V. Comparative analysis of MCDM methods for the assessment of sustainable housing affordability. Omega 2016, 59, 146–156. [Google Scholar] [CrossRef]

- Lomazov, V.A.; Lomazova, V.I.; Miroshnichenko, I.V.; Petrosov, D.A.; Mironov, A.L. Optimum planning of experimental research at the biogas plant. IOP Conf. Ser.—Earth Environ. Sci. 2021, 659, 012111. [Google Scholar] [CrossRef]

- Kokkinos, K.; Karayannis, V.; Moustakas, K. Circular bio-economy via energy transition supported by Fuzzy Cognitive Map modeling towards sustainable low-carbon environment. Sci. Total Environ. 2020, 721, 137754. [Google Scholar] [CrossRef] [PubMed]

- Gorokhova, T.; Mamatova, L.; Muterko, H. The development of bioeconomics in Ukraine as an element of transformation government strategy of sustainable development. Manag. Theory Stud. Rural Bus. Infrastruct. Dev. 2020, 42, 279–288. [Google Scholar] [CrossRef]

- Scott, J.; Ho, W.; Dey, P.K.; Talluri, S. A decision support system for supplier selection and order allocation in stochastic, multi-stakeholder and multi-criteria environments. Int. J. Prod. Econ. 2014, 166, 226–237. [Google Scholar] [CrossRef] [Green Version]

- Ren, J.; Manzardo, A.; Toniolo, S.; Scipioni, A.; Tan, S.; Dong, L.; Gao, S. Design and modeling of sustainable bioethanol supply chain by minimizing the total ecological footprint in life cycle perspective. Bioresour. Technol. 2013, 146, 771–774. [Google Scholar] [CrossRef]

- Muir, G.; Hayward, S.; Tripney, B.; Cook, G.; Naysmith, P.; Herbert, B.; Garnett, M.; Wilkinson, M. Determining the biomass fraction of mixed waste fuels: A comparison of existing industry and 14C-based methodologies. Waste Manag. 2014, 35, 293–300. [Google Scholar] [CrossRef] [Green Version]

- Geng, N.; Zhang, Y.; Sun, Y. Location optimization of biodiesel processing plant based on rough set and clustering algorithm - a case study in China. Eng. Rev. 2020, 40, 105–115. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guerreiro, E.M.A.; Silva, M.; Guerreiro, M.; Carvalho, T.; Converti, A.; Siqueira, H.V.; Piekarski, C.M. Framework for Optimized Analysis of Waste Bioenergy Projects. Energies 2022, 15, 6136. https://doi.org/10.3390/en15176136

Guerreiro EMA, Silva M, Guerreiro M, Carvalho T, Converti A, Siqueira HV, Piekarski CM. Framework for Optimized Analysis of Waste Bioenergy Projects. Energies. 2022; 15(17):6136. https://doi.org/10.3390/en15176136

Chicago/Turabian StyleGuerreiro, Eliana M. A., Maicon Silva, Marcio Guerreiro, Taís Carvalho, Attilio Converti, Hugo Valadares Siqueira, and Cassiano Moro Piekarski. 2022. "Framework for Optimized Analysis of Waste Bioenergy Projects" Energies 15, no. 17: 6136. https://doi.org/10.3390/en15176136

APA StyleGuerreiro, E. M. A., Silva, M., Guerreiro, M., Carvalho, T., Converti, A., Siqueira, H. V., & Piekarski, C. M. (2022). Framework for Optimized Analysis of Waste Bioenergy Projects. Energies, 15(17), 6136. https://doi.org/10.3390/en15176136