Experiment and Application of Wax Deposition in Dabei Deep Condensate Gas Wells with High Pressure

Abstract

:1. Introduction

2. Experiment

2.1. Experimental Samples

2.2. Experimental Instruments and Process

- (1)

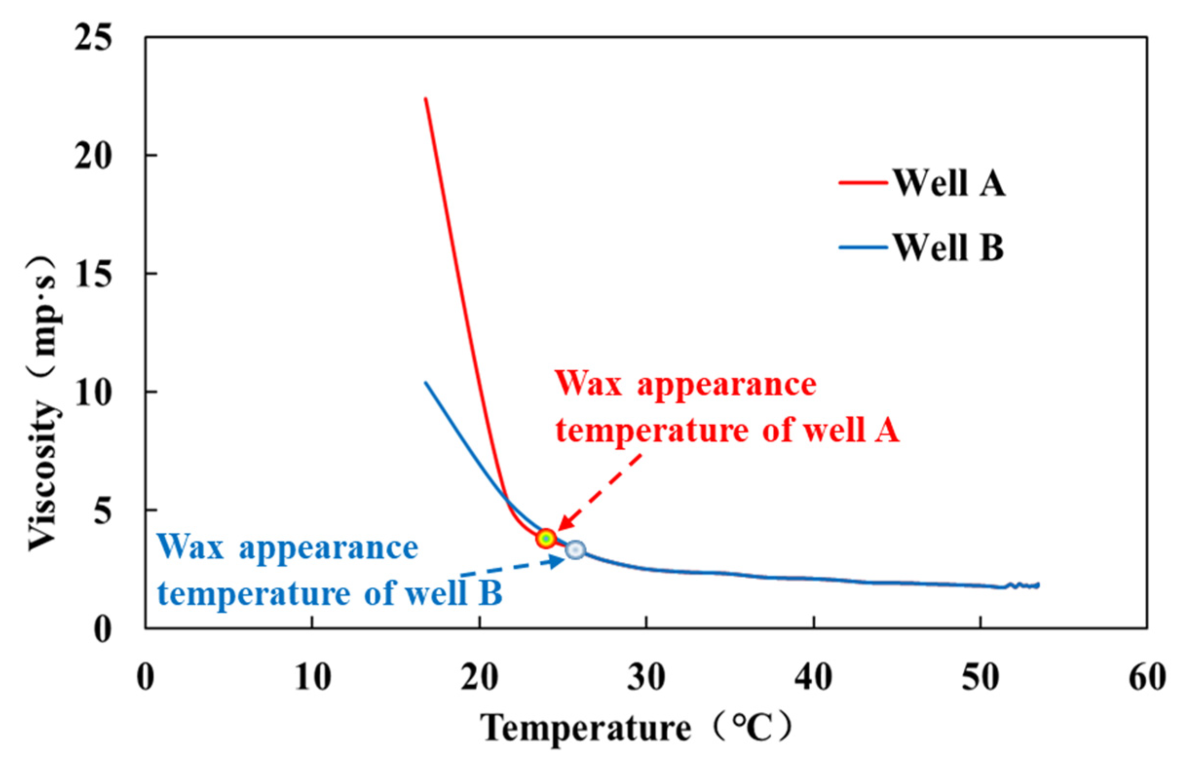

- Capillary viscometer method: The experimental instrument is an Ubbelohde glass capillary viscometer, and the inner diameter of the capillary is 0.63 mm. The capillary viscometer method can determine the wax appearance temperature by measuring the viscosity–temperature curve during the cooling of crude oil. With reference to the method adopted in GB/T 30515-2014 [17], the experiment proceeds as follows: (a) When the liquid flows in an upright capillary at experimental temperature, its viscosity is proportional to the flow time. (b) The viscosity of the condensate can be obtained by measuring the time that the condensate flows out of the viscometer. (c) Changing the experimental temperature to obtain the corresponding viscosity under different temperature conditions. (d) When wax crystals precipitate in the crude oil, the slope of viscosity–temperature curve begins to increase, and this point is identified as the wax appearance temperature.

- (2)

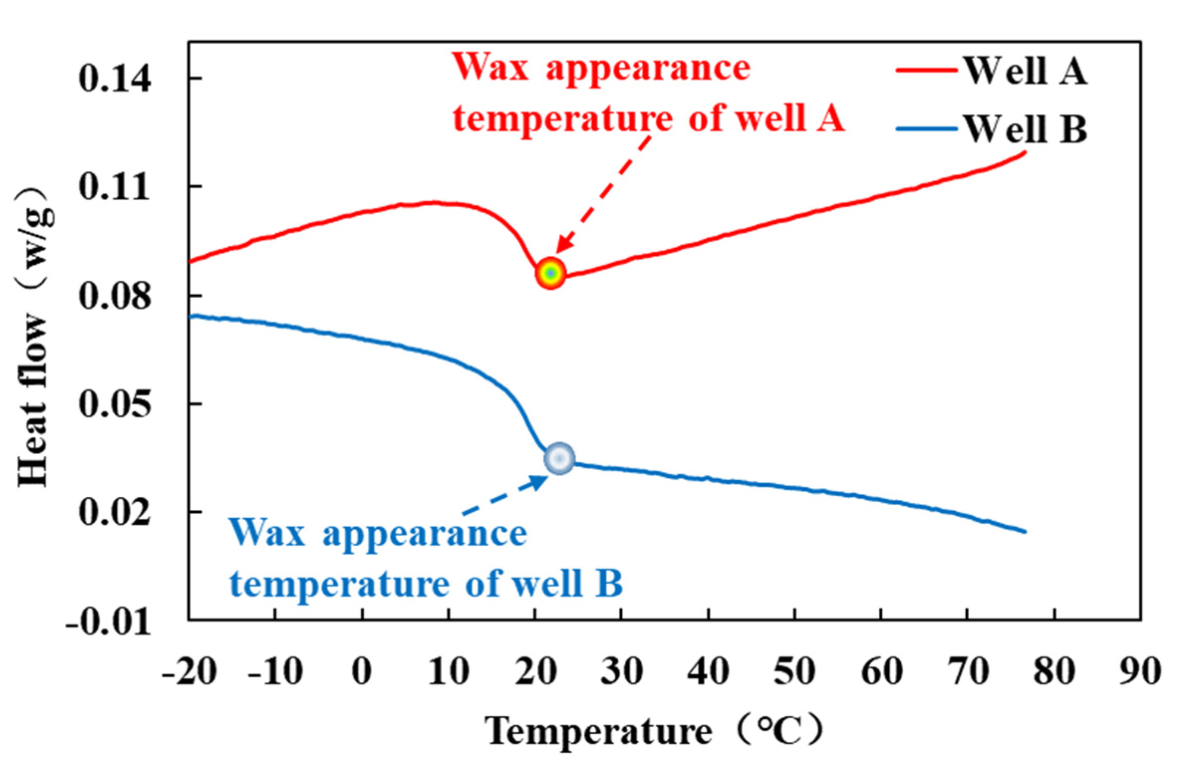

- DSC method: The experimental instrument is a Mettler Toledo DSC823 thermal analyzer with sensitivity of 0.04 μw. The measuring temperature range is −50–700 °C, and the temperature accuracy is ±0.02 °C. In this method, air is selected as the reference material. When no wax precipitation occurs in the waxy condensate oil, the condensate oil and air change according to the programmed temperature, and their difference is ΔT = 0. When the temperature is lower than the wax appearance temperature, the latent heat of crystallization in the condensate oil is released, causing a change in the temperature difference between the condensate oil and air. To maintain the temperature difference ΔT = 0, the instrument automatically supplements the temperature and expresses it in the form of heat flow. With reference to the standard SY/T0545-2012 determination of thermal characteristic parameters of wax precipitation in crude oil using DSC [18], the experiment proceeds as follows: (a) The crude oil sample is heated to above the wax appearance temperature and then cooled at a constant rate. (b) The differential heat flow of the sample and reference material at each temperature are monitored. A relationship curve is drawn between differential heat flow and temperature, which is called the wax precipitation DSC curve. (c) When wax crystals precipitate, the DSC curve deviates from the original baseline to form an exothermic peak. (d) When the temperature drops to −20 °C, all the wax crystals reach a stable solid phase and wax precipitation is completed.

- (3)

- Polarizing microscopic observation: The experimental instrument is a self-designed wax crystal high-pressure visual microscope. The test temperature range is −30–300 °C, and the maximum test pressure is 100 MPa. The polarizing microscope can be used to observe roughly 1 micron crystal size. Among all wax appearance temperature testing methods, polarizing microscope observation is the only one that can directly observe the entire process of wax precipitation. The principle is to observe the precipitation using the optical property of double refraction of the wax crystal. With reference to the standard SY/T0521-2008 microscopic observation method for the determination of wax appearance temperature of crude oil [19], the experiment proceeds as follows: (a) The crude oil sample is placed on the microscopic observation platform for heating, and the wax is melted in the crude oil completely and then cooled at a constant cooling rate. (b) When small wax crystals first appear in the image acquisition system, the crude oil temperature at this point is the wax appearance temperature.

3. Experimental Results and Discussion of Wax Precipitation

3.1. Capillary Viscometer Method

3.2. Differential Scanning Calorimetry (DSC) Method

3.3. Polarizing Microscope Observation Method

4. Comparison of Wax Precipitation Test Methods

5. Wax Appearance Temperature Test of Condensate Oil under Different Pressures

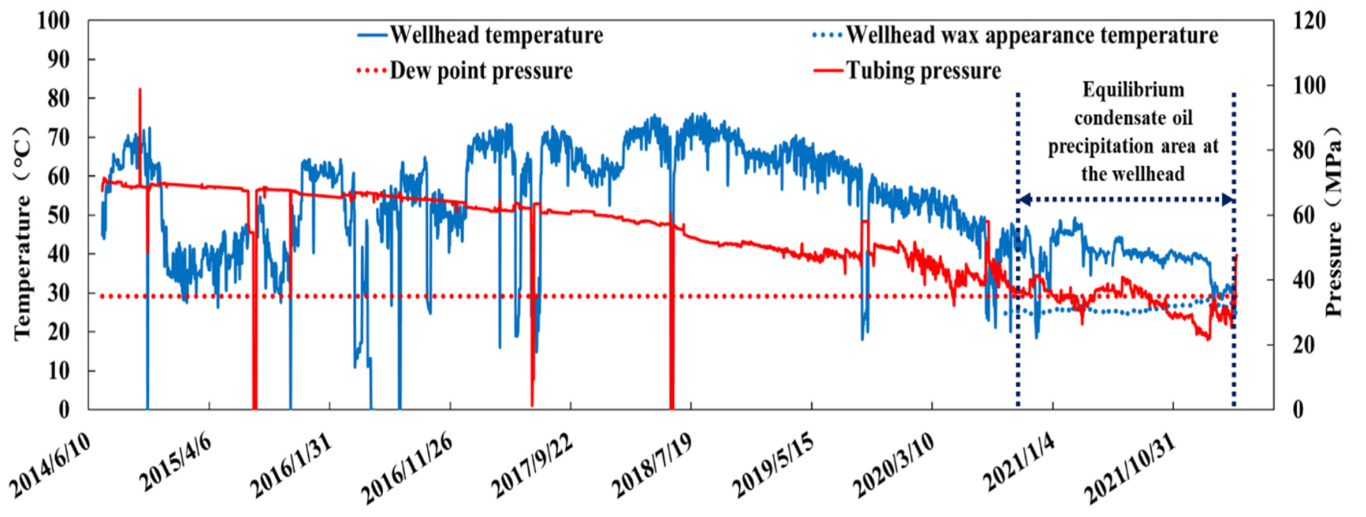

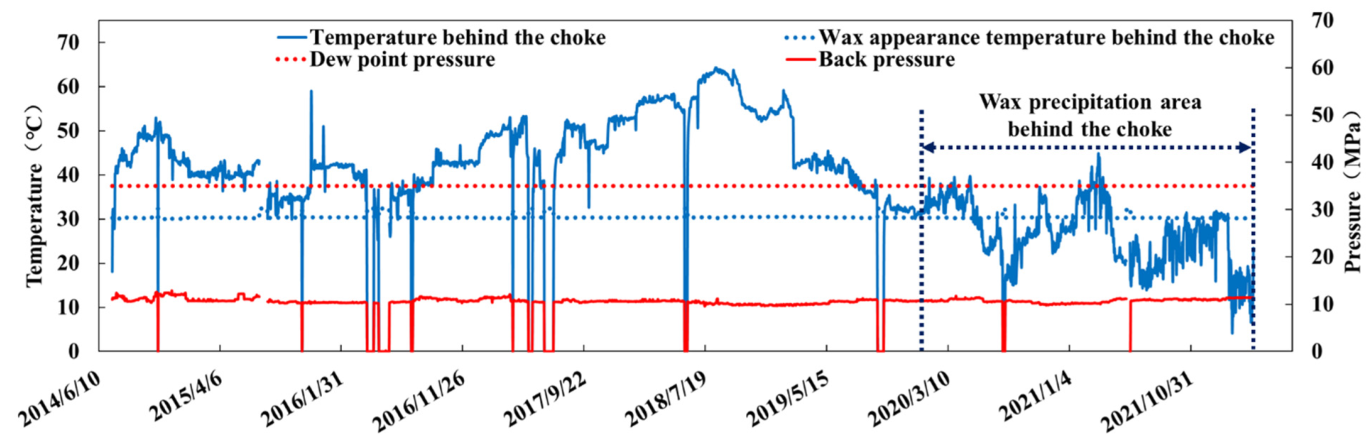

6. Field Application

7. Conclusions and Future Work

7.1. Conclusions

- (1)

- The Dabei condensate oil is rich in heavy components, more than 69% of C11+ components, moderate wax, and resins and less asphaltenes. The wax appearance temperature test can be divided into direct and indirect methods. The polarizing microscope observation can be regarded as the direct method, and the other methods are the indirect methods. The wax appearance temperature measured using the indirect method can be regarded as the cloud point. The wax appearance temperature measured using the polarizing microscope observation method is more accurate, and the polarizing microscope observation can be used to measure the wax appearance temperature of the Dabei condensate oil.

- (2)

- The wax contents of wells A and B measured using the DSC method are 4.48% and 3.96%, respectively, and those measured using the crystallization separation test method are 9.01% and 6.78%, respectively. The DSC adopts continuous cooling, which leads to insufficient wax precipitation of the Dabei condensate oil. This results in the wax content tested using DSC being lower than that of the one using crystallization separation test method.

- (3)

- The wax precipitation temperature of the equilibrium condensate oil increases with pressure drop. The lower the pressure, the faster the wax precipitation temperature rises. The wax precipitation law of the equilibrium condensate oil is opposite to that of the degassed condensate oil. The reason can be that more gas would dissolve in the equilibrium condensate oil under a higher pressure, which could prevent wax precipitation.

- (4)

- Although wax precipitates in the wellbore and gathering pipeline, wax deposition does not necessarily occur. Even if wax deposits occur, pipeline plugging does not necessarily occur completely. Whether it is the wellbore or gathering and transmission pipelines, long-term production under the condition of wax precipitation could lead to wax deposition and plugging, and thus, wax prevention measures and regular wax removal are necessary.

7.2. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dan, V.N.; Goual, L.; Firoozabadi, A. Wax precipitation in gas condensate mixtures. SPE Prod. Facil. 2001, 16, 250–259. [Google Scholar]

- Carnahan, N.F. Paraffin deposition in petroleum production. J. Pet. Technol. 1989, 41, 1024–1025. [Google Scholar] [CrossRef]

- Karan, K.; Ratulowski, J.; German, P. Measurement of waxy crude properties using novel laboratory techniques. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 1–4 October 2000; p. 62945. [Google Scholar]

- Vieira, L.C.; Buchuid, M.B.; Lucas, E.F. Effect of pressure on the crystallization of crude oil waxes II. Evaluation of crude oil and condensate. Energy Fuels 2009, 24, 2213–2220. [Google Scholar]

- Barker, K.M.; Bigler, J.M.; Hake, K.; Sallee, D.C. Paraffin problems in gas systems. In Proceedings of the SPE Eastern Regional Meeting, Pittsburgh, PA, USA, 6–10 September 2003. [Google Scholar]

- Mark, M.B.; Laura, B.R.Z. Optimizing paraffin and naphthene wax-treatment options using cross-polarized microscopy. In Proceedings of the SPE International Symposium on Oil Field Chemistry, Woodlands, TX, USA, 9–11 April 2011. [Google Scholar]

- Japper-Jaafar, A.; Bhaskoro, P.T.; Mior, Z.S. A new perspective on the measurements of wax appearance temperature: Comparison between DSC, thermomicroscopy and rheometry and the cooling rate effects. J. Pet. Sci. Eng. 2016, 147, 672–681. [Google Scholar] [CrossRef]

- Hans, P.R.; Brit, B.; Asger, B.H.; Walther, B.P. Wax precipitation from North Sea crude oils: 1. Crystallization and dissolution temperatures, and Newtonian and non-Newtonian flow properties. Energy Fuels 1991, 5, 895–908. [Google Scholar]

- Mustafa, V.K.; Létoffé, J.M.; Pierre, C. Comparison of wax appearance temperatures of crude oils by differential scanning calorimetry, thermomicroscopy and viscometry. Fuel 1996, 75, 787–790. [Google Scholar]

- Meray, V.R.; Volle, J.L.; Schranz, C.J.P. Influence of light ends on the onset crystallization temperature of waxy crudes within the frame of multiphase transport. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–6 October 1993. [Google Scholar]

- Hammami, A.; Raines, M.A. Paraffin deposition from crude oils: Comparison of laboratory results with field data. SPE J. 1999, 4, 9–18. [Google Scholar] [CrossRef]

- Jiang, B.; Xue, L.I.; Yang, S.; Ke, L.I.; Chen, H. Measurement of the wax appearance temperature of waxy oil under the reservoir condition with ultrasonic method. Pet. Explor. Dev. 2014, 41, 509–512. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, F.; Zhang, L.; Huang, Y.; Yao, E.; Zhang, L. Experimental study of wax deposition pattern concerning deep condensate gas in Bozi block of Tarim Oilfield and its application. Thermochim. Acta 2019, 671, 1–9. [Google Scholar] [CrossRef]

- Juyal, P.; Cao, T.; Yen, A.; Venkatesan, R. Study of live oil wax precipitation with high-pressure micro-differential scanning calorimetry. Energy Fuels 2011, 25, 568–572. [Google Scholar] [CrossRef]

- State Energy Administration. SY/T 7550-2012; Determination of Wax, Resins and Asphaltenes in Crude Oil. Petroleum Industry Press: Beijing, China, 2012.

- Su, Z.; Zhang, H.F.; Han, J.F.; Liu, Y. Origin and controlling factors of Mesozoic-Cenozoic gas condensates with high wax content and high-gravity oil in Kuqa Depression. Oil Gas Geol. 2018, 39, 1255–1269. [Google Scholar]

- Standardization Administration of the People’s Republic of China. GB/T 30515-2014; Petroleum Products–Transparent and Opaque Liquids–Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity. Standards Press of China: Beijing, China, 2014.

- State Energy Administration. SY/T 0545-2012; Determination of Thermal Property Parameters of the Wax Precipitation in Crude Oil. Test Method by Differential Scanning Calorimetry. Petroleum Industry Press: Beijing, China, 2012.

- National Development and Reform Commission. SY/T 0521-2008; Determination of Wax Appearance Temperature in Crude Petroleum. Test Method by Microscopic Observation. Petroleum Industry Press: Beijing, China, 2008.

- Letoffe, J.M.; Claudy, P.; Garcin, M.; Volle, J.L. Evaluation of crystallized fractions of crude oils by differential scanning calorimetry Correlation with gas chromatography. Fuel 1995, 74, 92–95. [Google Scholar] [CrossRef]

- Claudy, P.; Létofféc, J.M.; Chaguéa, B.; Orritb, J. Crude oils and their distillates: Characterization by differential scanning calorimetry. Fuel 1988, 67, 58–61. [Google Scholar] [CrossRef]

- Standardization Administration of the People’s Republic of China. GB/T 6986-2014; Standard Test Method for Cloud Point of Petroleum Products. Standards Press of China: Beijing, China, 2014.

| Dabei Well A | Dabei Well B | ||

|---|---|---|---|

| Components | Molar Composition (mol%) | Components | Molar Composition (mol%) |

| C2 | 0.160 | C2 | / |

| C3 | 0.034 | C3 | 0.070 |

| IC4 | 0.044 | IC4 | 0.060 |

| NC4 | 0.089 | NC4 | 0.136 |

| IC5 | 0.170 | IC5 | 0.204 |

| NC5 | 0.177 | NC5 | 0.219 |

| C6 | 0.842 | C6 | 1.076 |

| C7 | 4.317 | C7 | 4.790 |

| C8 | 5.977 | C8 | 9.910 |

| C9 | 6.27 | C9 | 6.954 |

| C10 | 6.325 | C10 | 7.457 |

| C11+ | 75.595 | C11+ | 69.124 |

| Experimental Sample | Wax Content (w%) | Resins Content (w%) | Asphaltenes Contents (w%) |

|---|---|---|---|

| Dabei well A | 9.01 | 2.24 | 0.74 |

| Dabei well B | 6.78 | 3.14 | 0.07 |

| Well Name | Temperature Corresponding to Maximum Wax Precipitation Rate (°C) | Maximum Wax Precipitation Amount per Unit Temperature Drop (%/°C) | Wax Content (%) |

|---|---|---|---|

| A | 7.55 | 0.18 | 4.48 |

| B | 8.65 | 0.16 | 3.96 |

| Well Name | Wax Appearance Temperature by DSC (°C) | Wax Appearance Temperature by Capillary Viscometer (°C) | Wax Appearance Temperature by Polarizing Microscope (°C) |

|---|---|---|---|

| A | 22.55 | 24.8 | 32.4 |

| B | 23.65 | 25.6 | 34.1 |

| Test Method for Wax Appearance Temperature | Characteristics | |

|---|---|---|

| Direct testing method | Polarizing microscope observation | The initial precipitation temperature of wax crystal can be observed directly. |

| Indirect testing method | Capillary viscometer | Sufficient wax crystals must be precipitated, such that the viscosity can obviously deviate from the normal change trend with the decrease of temperature, and the viscosity–temperature curve can have an obvious turning point. |

| DSC | When a certain amount of wax crystals are precipitated, the thermal effect changes, and the differential heat flow of crude oil sample and reference material can be formed. At this point, the DSC curve deviates from the original baseline and forms an exothermic peak. | |

| Well Name | Wax Content Tested by DSC (%) | Wax Content Tested by Crystallization Separation Test Method (%) |

|---|---|---|

| Well A | 4.48 | 9.01 |

| Well B | 3.96 | 6.78 |

| Condensate Oil Type | Well A | Well B | ||||

|---|---|---|---|---|---|---|

| Pressure (MPa) | Solution Gas-Oil Ratio (S m3/m3) | Wax Precipitation Temperature (°C) | Pressure (MPa) | Solution Gas-Oil Ratio (S m3/m3) | Wax Precipitation Temperature (°C) | |

| Degassed condensate oil | 0.1 | 0 | 32.4 | 0.1 | 0 | 34.1 |

| 10 | 0 | 34 | 10 | 0 | 35.9 | |

| 20 | 0 | 36.3 | 20 | 0 | 37.8 | |

| 30 | 0 | 37.6 | 30 | 0 | 39.6 | |

| 40 | 0 | 39.4 | 40 | 0 | 41.3 | |

| 50 | 0 | 41.3 | 50 | 0 | 43.1 | |

| 60 | 0 | 43.3 | 60 | 0 | 44.8 | |

| 70 | 0 | 45.7 | 70 | 0 | 46.6 | |

| Equilibrium condensate oil | 0.1 | 0 | 32.4 | 0.1 | 0 | 34.1 |

| 5 | 25.8 | 31.6 | 5 | 38.3 | 33.4 | |

| 10 | 59.4 | 30.3 | 10 | 75.8 | 32.2 | |

| 20 | 120.6 | 28.4 | 20 | 133.2 | 30.3 | |

| 30 | 219.1 | 26.5 | 30 | 240.4 | 28.5 | |

| 35 | 264.2 | 25.8 | 40 | 322.5 | 26.2 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, L.; Sun, J.; Liu, J.; Liu, J. Experiment and Application of Wax Deposition in Dabei Deep Condensate Gas Wells with High Pressure. Energies 2022, 15, 6200. https://doi.org/10.3390/en15176200

Cao L, Sun J, Liu J, Liu J. Experiment and Application of Wax Deposition in Dabei Deep Condensate Gas Wells with High Pressure. Energies. 2022; 15(17):6200. https://doi.org/10.3390/en15176200

Chicago/Turabian StyleCao, Lihu, Jinsheng Sun, Jianyi Liu, and Jiquan Liu. 2022. "Experiment and Application of Wax Deposition in Dabei Deep Condensate Gas Wells with High Pressure" Energies 15, no. 17: 6200. https://doi.org/10.3390/en15176200

APA StyleCao, L., Sun, J., Liu, J., & Liu, J. (2022). Experiment and Application of Wax Deposition in Dabei Deep Condensate Gas Wells with High Pressure. Energies, 15(17), 6200. https://doi.org/10.3390/en15176200